light NISSAN PATROL 2000 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 4 of 1033

Diagnostic Procedure....................................... 1088

TROUBLE DIAGNOSIS FOR CONTROL UNIT

(EFP ROM)........................................................... 1089

Description ....................................................... 1089

Diagnostic Procedure....................................... 1090

TROUBLE DIAGNOSIS FOR

NON-DETECTABLE ITEMS................................ 1091

PNP, Overdrive Control, A/T Mode or

Accelerator Position Switches ......................... 1091

DIAGNOSTIC PROCEDURES FOR

SYMPTOMS......................................................... 1097

1. SPORT Indicator Lamp Does Not

Come On.......................................................... 1097

2. SPORT Indicator Lamp Does Not

Come On.......................................................... 1098

3. O/D OFF Indicator Lamp Does Not Come

On .................................................................... 1098

4. SPORT Indicator Lamp Does Not

Come On.......................................................... 1099

5. Engine Cannot Be Started In ªPº and ªNº

Position ............................................................ 1100

6. In ªPº Position, Vehicle Moves Forward Or

Backward When Pushed ................................. 1100

7. In ªNº Position, Vehicle Moves .................... 1101

8. Large Shock. ªNº®ªRº Position ................ 1102

9. Vehicle Does Not Creep Backward In ªRº

Position ............................................................ 1103

10. Vehicle Does Not Creep Forward In ªDº,

ª2º Or ª1º Position ............................................ 1104

11. Vehicle Cannot Be Started From D

1......... 1105

12. A/T Does Not Shift: D

1®D2Or Does Not

Kickdown: D

4®D2......................................... 1106

13. A/T Does Not Shift: D

2®D3.................... 1107

14. A/T Does Not Shift: D

3®D4.................... 1108

15. A/T Does Not Perform Lock-up ................. 1109

16. A/T Does Not Hold Lock-up Condition ...... 1110

17. Lock-up Is Not Released ........................... 1110

18. Engine Speed Does Not Return To Idle

(Light Braking D

4®D3) .................................. 1111

19. Vehicle Does Not Start From D

1............... 1112

20. A/T Does Not Shift: D

2®D1When

Depressing Accelerator Pedal ......................... 1113

21. A/T Does Not Shift: D

4®D3, When

Overdrive Control Switch ªONº®ªOFFº ........ 1114

22. A/T Does Not Shift: D

3®22, When

Selector Lever ªDº®ª2º Position ................... 1114

23. A/T Does Not Shift: 2

2®11, WhenSelector Lever ª2º®ª1º Position .................... 1115

24. Vehicle Does Not Decelerate By Engine

Brake ................................................................ 1115

TROUBLE DIAGNOSES Ð A/T Shift Lock

System................................................................. 1116

Description ....................................................... 1116

Wiring Diagram Ð SHIFT Ð ........................... 1117

Diagnostic Procedure....................................... 1118

Key Interlock Cable.......................................... 1121

Component Check ........................................... 1122

ON-VEHICLE SERVICE...................................... 1124

Control Valve Assembly and Accumulators .... 1124

Revolution Sensor Replacement ..................... 1125

Rear Oil Seal Replacement ............................. 1125

Parking Pawl Components Inspection ............. 1125

PNP Switch Adjustment ................................... 1125

Manual Control Linkage Adjustment................ 1126

REMOVAL AND INSTALLATION....................... 1127

Removal ........................................................... 1127

Installation ........................................................ 1128

MAJOR OVERHAUL........................................... 1129

Oil Channel ...................................................... 1131

Locations of Needle Bearings, Thrust Washers

and Snap Rings ............................................... 1132

DISASSEMBLY.................................................... 1133

REPAIR FOR COMPONENT PARTS................. 1144

Oil Pump .......................................................... 1144

Control Valve Assembly................................... 1148

Control Valve Upper Body ............................... 1154

Control Valve Lower Body ............................... 1159

Reverse Clutch ................................................ 1161

High Clutch ...................................................... 1165

Forward and Overrun Clutches ....................... 1167

Low & Reverse Brake ...................................... 1171

Forward Clutch Drum Assembly ...................... 1175

Rear Internal Gear and Forward Clutch Hub .. 1177

Band Servo Piston Assembly .......................... 1180

Parking Pawl Components .............................. 1184

ASSEMBLY.......................................................... 1186

Assembly (1) .................................................... 1186

Adjustment ....................................................... 1190

Assembly (2) .................................................... 1195

A/T FLUID COOLER SYSTEM........................... 1205

A/T Fluid Cooler ............................................... 1205

SERVICE DATA AND SPECIFICATIONS (SDS)1206

General Specifications ..................................... 1206

Specifications and Adjustment......................... 1206

When you read wiring diagrams:

+Read GI section, ªHOW TO READ WIRING DIAGRAMSº.

+See EL section, ªPOWER SUPPLY ROUTINGº for power distribution circuit.

When you perform trouble diagnoses, read GI section, ªHOW TO FOLLOW FLOW

CHART IN TROUBLE DIAGNOSESº.

AT-1002

Page 36 of 1033

Diagnosis by CONSULT-II

NOTICE

1.The CONSULT-II electrically displays shift timing and lock-up timing (that is, operation timing of each

solenoid).

Check for time difference between actual shift timing and the CONSULT-II display. If the difference is

noticeable, mechanical parts (except solenoids, sensors, etc.) may be malfunctioning. Check mechanical

parts using applicable diagnostic procedures.

2. Shift schedule (which implies gear position) displayed on CONSULT-II and that indicated in Service

Manual may differ slightly. This occurs because of the following reasons:

+Actual shift schedule has more or less tolerance or allowance,

+Shift schedule indicated in Service Manual refers to the point where shifts start. Gear position dis-

played on CONSULT-II indicates the point where shifts are completed.

3. Shift solenoid valve ªAº or ªBº is displayed on CONSULT-II at the start of shifting. Gear position is dis-

played upon completion of shifting (which is computed by TCM).

4. Additional CONSULT-II information can be found in the Operation Manual supplied with the CONSULT-II

unit.

SELF-DIAGNOSTIC RESULT TEST MODE

Refer to AT-1028.

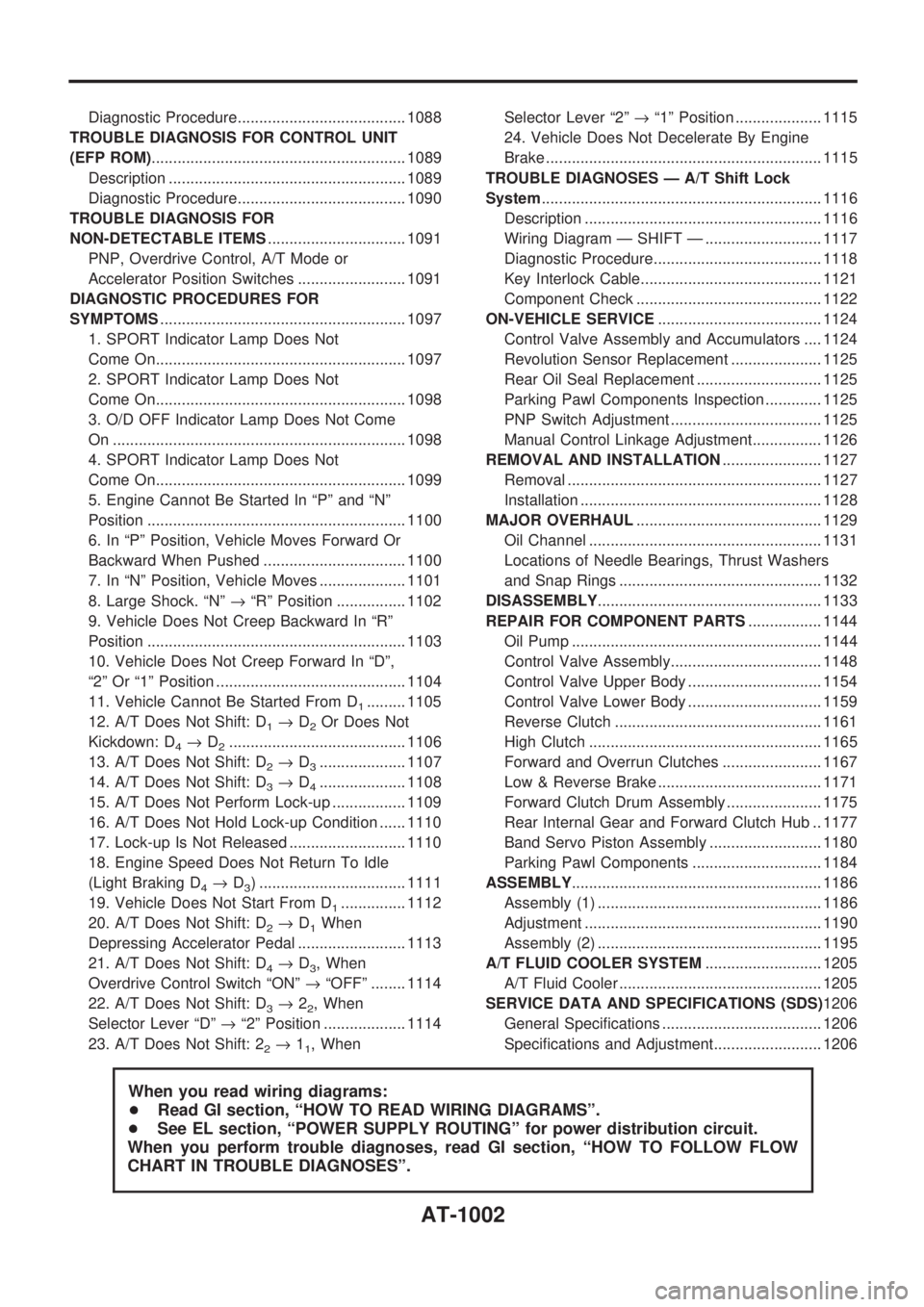

DATA MONITOR DIAGNOSTIC TEST MODE

Item DisplayMonitor item

Description Remarks TCM

input

signalsMain

signals

Vehicle speed sensor 1 (A/T)

(Revolution sensor)VHCL/S SEzA/T

[km/h] or [mph]

XÐ+Vehicle speed computed from

signal of revolution sensor is

displayed.When racing engine in ªNº or ªPº

position with vehicle stationary,

CONSULT data may not indicate

0 km/h (0 MPH).

Vehicle speed sensor 2

(Meter)VHCL/S SEzMTR

[km/h] or [mph]

XÐ+Vehicle speed computed from

signal of vehicle speed sensor

is displayed.Vehicle speed display may not be

accurate under approx. 10 km/h

(6 MPH). It may not indicate 0

km/h (0 MPH) when vehicle is

stationary.

Accelerator position sensor THRTL POS SEN

[V]XÐ+Accelerator position sensor sig-

nal voltage is displayed.

A/T fluid temperature sensor FLUID TEMP SE

[V]

XÐ+A/T fluid temperature sensor

signal voltage is displayed.

+Signal voltage lowers as fluid

temperature rises.

Battery voltage BATTERY VOLT

[V]XÐ+Source voltage of TCM is dis-

played.

Engine speed ENGINE SPEED

[rpm]

XX+Engine speed, computed from

engine speed signal, is dis-

played.Engine speed display may not be

accurate under approx. 800 rpm.

It may not indicate 0 rpm even

when engine is not running.

Overdrive control switch OVERDRIVE SW

[ON/OFF] X Ð+ON/OFF state computed from

signal of overdrive control SW

is displayed.

P/N position switch PN POSI SW

[ON/OFF] X Ð+ON/OFF state computed from

signal of PN position SW is dis-

played.

R position switch R POSITION SW

[ON/OFF] X Ð+ON/OFF state computed from

signal of R position SW is dis-

played.

D position switch D POSITION SW

[ON/OFF] X Ð+ON/OFF state computed from

signal of D position SW is dis-

played.

2 position switch 2 POSITION SW

[ON/OFF] X Ð+ON/OFF status, computed from

signal of 2 position SW, is dis-

played.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

AT-1034

Page 40 of 1033

DIAGNOSTIC WORKSHEET

1.NRead the Fail-safe and listen to customer complaints. AT-1006

2.NA/T FLUID CHECK AT-1041

NLeakage (Follow specified procedure)

NFluid condition

NFluid level

3.NPerform STALL TEST and LINE PRESSURE TEST. AT-1041,

AT-1044

NStall test Ð Mark possible damaged components/others.

NTorque converter one-way clutch

NReverse clutch

NForward clutch

NOverrun clutch

NForward one-way clutchNLow & reverse brake

NLow one-way clutch

NEngine

NLine pressure is low

NClutches and brakes except high

clutch and brake band are OK

NLine pressure test Ð Suspected parts:

4.NPerform all ROAD TEST and mark required procedures. AT-1046

4-1. Check before engine is started. AT-1047

NSELF-DIAGNOSTIC PROCEDURE Ð Mark detected items.

NVehicle speed sensorzA/T (Revolution sensor), AT-1064.

NVehicle speed sensorzMTR, AT-1066.

NAccelerator position sensor, AT-1068.

NShift solenoid valve A, AT-1070.

NShift solenoid valve B, AT-1072.

NOverrun clutch solenoid valve, AT-1074.

NTorque converter clutch solenoid valve, AT-1076.

NA/T fluid temperature sensor and TCM power source, AT-1079.

NEngine speed signal, AT-1082.

NLine pressure solenoid valve, AT-1084.

NPNP, overdrive control, A/T mode and accelerator position switches,

AT-1091.

NBattery

NOthers

4-2. Check at idle AT-1049

N1. SPORT Indicator Lamp Does Not Come On, AT-1097.

N2. SPORT Indicator Lamp Does Not Come On, AT-1098.

N3. O/D OFF Indicator Lamp Does Not Come On, AT-1098.

N4. SPORT Indicator Lamp Does Not Come On AT-1099.

N5. Engine Cannot Be Started In ªPº And ªNº Position, AT-1100.

N6. In ªPº Position, Vehicle Moves Forward Or Backward When Pushed,

AT-1100.

N7. In ªNº Position, Vehicle Moves, AT-1101.

N8. Large Shock. ªNº®ªRº Position, AT-1102.

N9. Vehicle Does Not Creep Backward In ªRº Position, AT-1103.

N10. Vehicle Does Not Creep Forward In ªDº, ª2º Or ª1º Position, AT-1104.

4-3. Cruise test AT-1050,

AT-1053

Part-1

N11. Vehicle Cannot Be Started From D

1, AT-1105.

N12. A/T Does Not Shift: D

1®D2Or Does Not Kickdown: D4®D2, AT-1106.

N13. A/T Does Not Shift: D

2®D3, AT-1107.

N14. A/T Does Not Shift: D

3®D4, AT-1108.

N15. A/T Does Not Perform Lock-up, AT-1109.

N16. A/T Does Not Hold Lock-up Condition, AT-1110.

N17. Lock-up Is Not Released, AT-1110.

N18. Engine Speed Does Not Return To Idle (Light Braking D

4®D3), AT-1111.

TROUBLE DIAGNOSIS Ð Introduction

Diagnostic Worksheet (Cont'd)

AT-1038

Page 43 of 1033

A/T Fluid Check

FLUID LEAKAGE CHECK

1. Clean area suspected of leaking. Ð for example, mating

surface of converter housing and transmission case.

2. Start engine, apply foot brake, place selector lever in ªDº

position and wait a few minutes.

3. Stop engine.

4. Check for fresh leakage.

FLUID CONDITION CHECK

Fluid color Suspected problem

Dark or black with burned odor Wear of frictional material

Milky pinkWater contamination Ð Road water

entering through filler tube or breather

Varnished fluid, light to dark brown

and tackyOxidation Ð Over or under filling, Ð

Overheating

FLUID LEVEL CHECK

Refer to MA section (ªChecking A/T Fluidº, ªCHASSIS AND

BODY MAINTENANCEº).

Stall Test

STALL TEST PROCEDURE

1. Check A/T and engine fluid levels. If necessary, add.

2. Drive vehicle for approx. 10 minutes or until engine oil and

ATF reach operating temperature.

ATF operating temperature:

50 - 80ÉC (122 - 176ÉF)

3. Set parking brake and block wheels.

4. Install a tachometer where it can be seen by driver during

test.

+It is good practice to put a mark on point of specified

engine rpm on indicator.

5. Start engine, apply foot brake, and place selector lever in ªDº

position.

6. Accelerate to wide open throttle gradually while applying foot

brake.

7. Quickly note the engine stall revolution and immediately

release throttle.

+During test, never hold throttle wide open for more than

5 seconds.

Stall revolution:

2,480 - 2,680 rpm

SAT801A

SAT638A

SAT647B

SAT513G

SAT514G

TROUBLE DIAGNOSIS Ð Basic Inspection

AT-1041

Page 56 of 1033

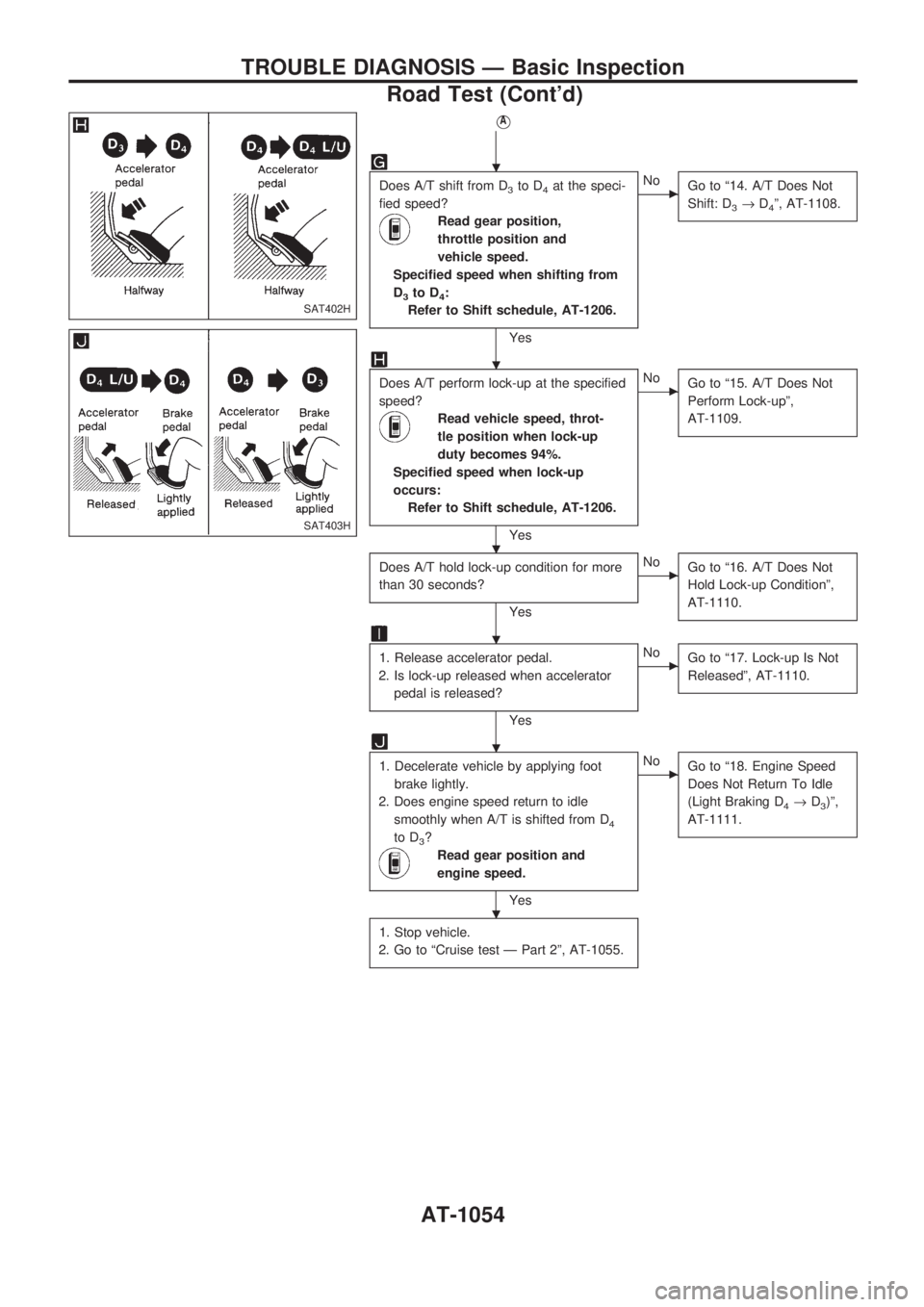

VA

Does A/T shift from D3to D4at the speci-

fied speed?

Read gear position,

throttle position and

vehicle speed.

Specified speed when shifting from

D

3to D4:

Refer to Shift schedule, AT-1206.

Yes

cNo

Go to ª14. A/T Does Not

Shift: D

3®D4º, AT-1108.

Does A/T perform lock-up at the specified

speed?

Read vehicle speed, throt-

tle position when lock-up

duty becomes 94%.

Specified speed when lock-up

occurs:

Refer to Shift schedule, AT-1206.

Yes

cNo

Go to ª15. A/T Does Not

Perform Lock-upº,

AT-1109.

Does A/T hold lock-up condition for more

than 30 seconds?

Yes

cNo

Go to ª16. A/T Does Not

Hold Lock-up Conditionº,

AT-1110.

1. Release accelerator pedal.

2. Is lock-up released when accelerator

pedal is released?

Yes

cNo

Go to ª17. Lock-up Is Not

Releasedº, AT-1110.

1. Decelerate vehicle by applying foot

brake lightly.

2. Does engine speed return to idle

smoothly when A/T is shifted from D

4to D3?

Read gear position and

engine speed.

Yes

cNo

Go to ª18. Engine Speed

Does Not Return To Idle

(Light Braking D

4®D3)º,

AT-1111.

1. Stop vehicle.

2. Go to ªCruise test Ð Part 2º, AT-1055.

SAT402H

SAT403H

.

.

.

.

.

.

TROUBLE DIAGNOSIS Ð Basic Inspection

Road Test (Cont'd)

AT-1054

Page 58 of 1033

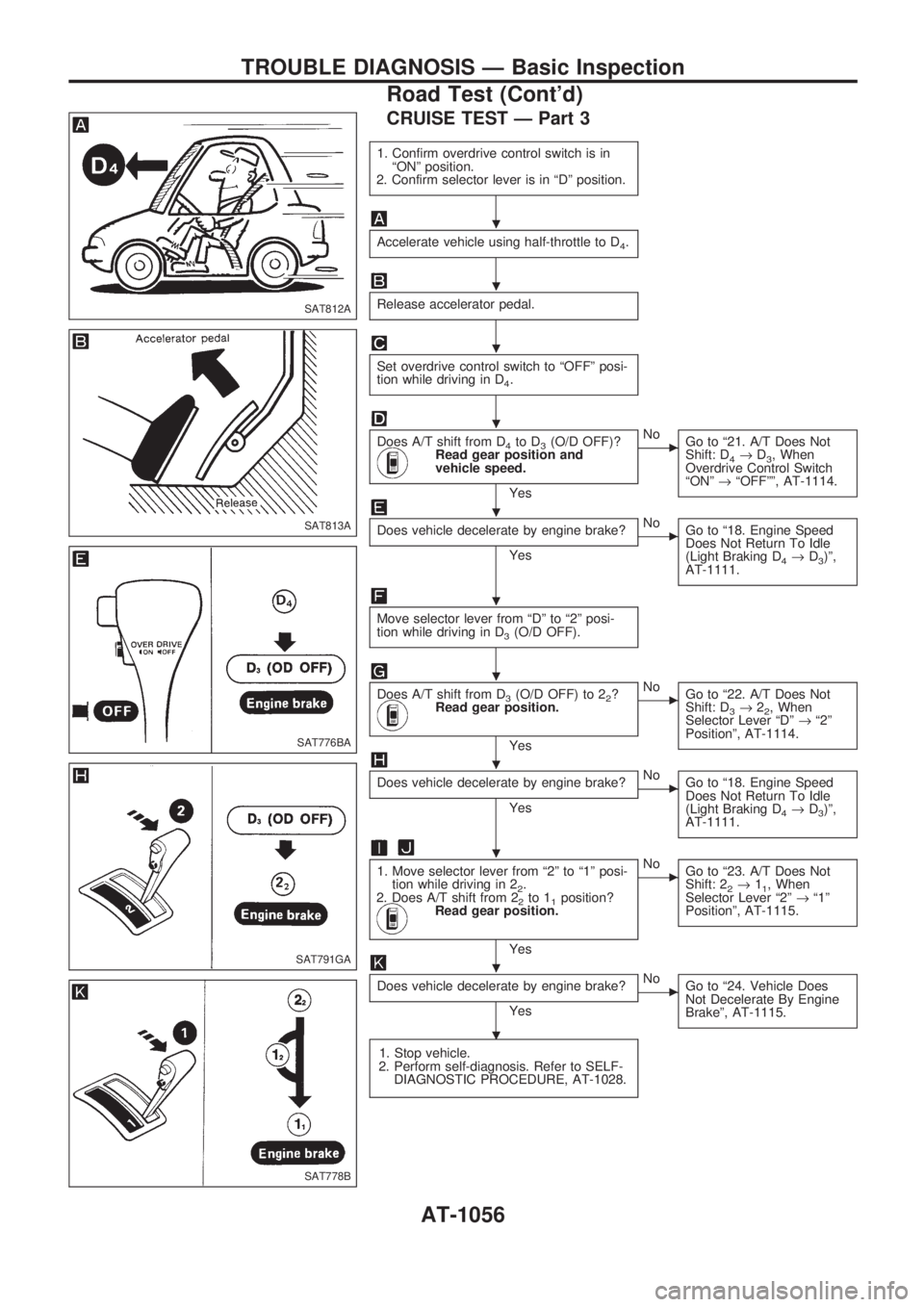

CRUISE TEST Ð Part 3

1. Confirm overdrive control switch is in

ªONº position.

2. Confirm selector lever is in ªDº position.

Accelerate vehicle using half-throttle to D4.

Release accelerator pedal.

Set overdrive control switch to ªOFFº posi-

tion while driving in D

4.

Does A/T shift from D4to D3(O/D OFF)?Read gear position and

vehicle speed.

Yes

cNo

Go to ª21. A/T Does Not

Shift: D

4®D3, When

Overdrive Control Switch

ªONº®ªOFFºº, AT-1114.

Does vehicle decelerate by engine brake?

Yes

cNo

Go to ª18. Engine Speed

Does Not Return To Idle

(Light Braking D

4®D3)º,

AT-1111.

Move selector lever from ªDº to ª2º posi-

tion while driving in D

3(O/D OFF).

Does A/T shift from D3(O/D OFF) to 22?Read gear position.

Yes

cNo

Go to ª22. A/T Does Not

Shift: D

3®22, When

Selector Lever ªDº®ª2º

Positionº, AT-1114.

Does vehicle decelerate by engine brake?

Yes

cNo

Go to ª18. Engine Speed

Does Not Return To Idle

(Light Braking D

4®D3)º,

AT-1111.

1. Move selector lever from ª2º to ª1º posi-

tion while driving in 2

2.

2. Does A/T shift from 2

2to 11position?Read gear position.

Yes

cNo

Go to ª23. A/T Does Not

Shift: 2

2®11, When

Selector Lever ª2º®ª1º

Positionº, AT-1115.

Does vehicle decelerate by engine brake?

Yes

cNo

Go to ª24. Vehicle Does

Not Decelerate By Engine

Brakeº, AT-1115.

1. Stop vehicle.

2. Perform self-diagnosis. Refer to SELF-

DIAGNOSTIC PROCEDURE, AT-1028.

SAT812A

SAT813A

SAT776BA

SAT791GA

SAT778B

.

.

.

.

.

.

.

.

.

.

.

TROUBLE DIAGNOSIS Ð Basic Inspection

Road Test (Cont'd)

AT-1056

Page 98 of 1033

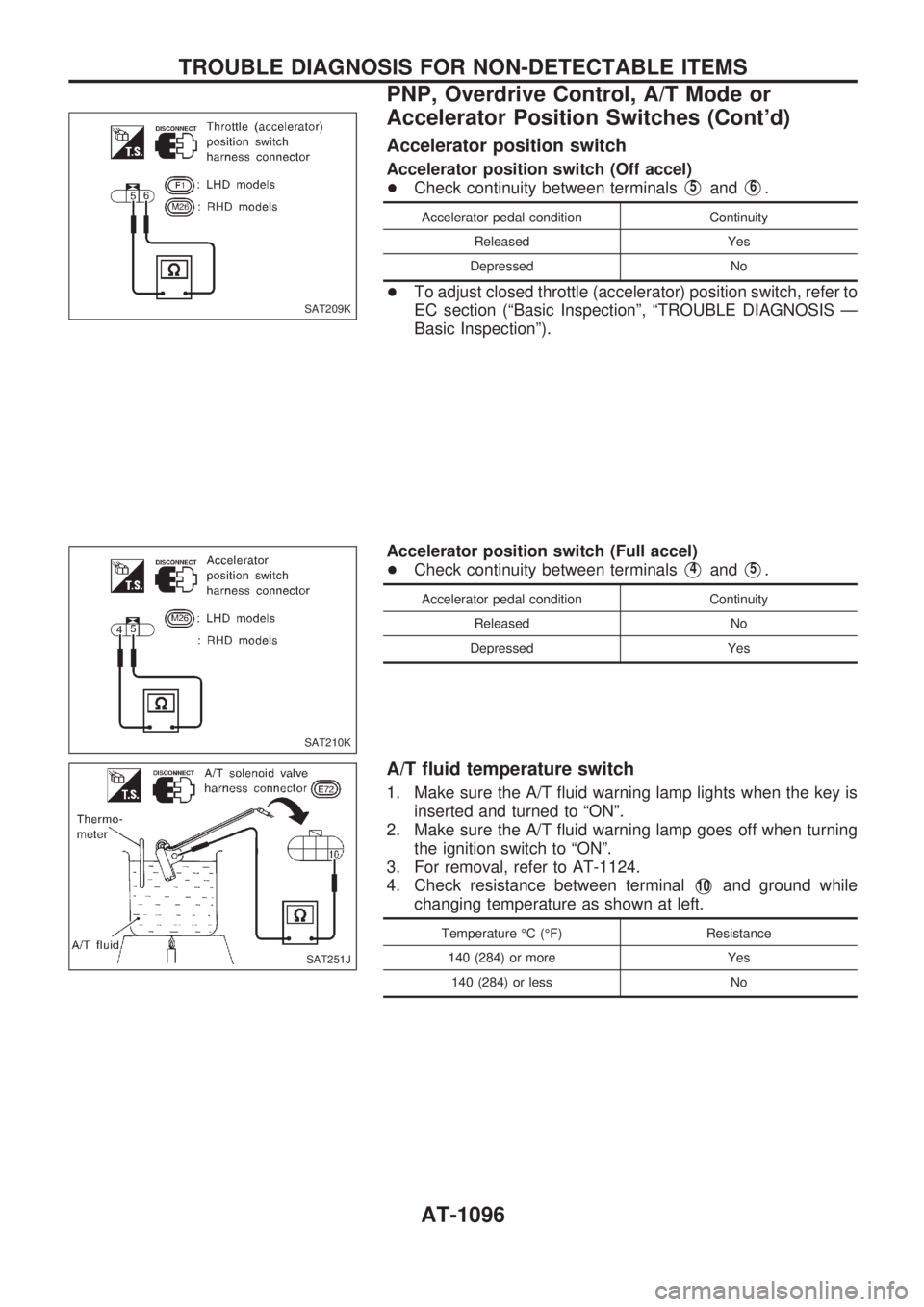

Accelerator position switch

Accelerator position switch (Off accel)

+Check continuity between terminals

V5andV6.

Accelerator pedal condition Continuity

Released Yes

Depressed No

+To adjust closed throttle (accelerator) position switch, refer to

EC section (ªBasic Inspectionº, ªTROUBLE DIAGNOSIS Ð

Basic Inspectionº).

Accelerator position switch (Full accel)

+Check continuity between terminals

V4andV5.

Accelerator pedal condition Continuity

Released No

Depressed Yes

A/T fluid temperature switch

1. Make sure the A/T fluid warning lamp lights when the key is

inserted and turned to ªONº.

2. Make sure the A/T fluid warning lamp goes off when turning

the ignition switch to ªONº.

3. For removal, refer to AT-1124.

4. Check resistance between terminal

V10and ground while

changing temperature as shown at left.

Temperature ÉC (ÉF) Resistance

140 (284) or more Yes

140 (284) or less No

SAT209K

SAT210K

SAT251J

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMS

PNP, Overdrive Control, A/T Mode or

Accelerator Position Switches (Cont'd)

AT-1096

Page 113 of 1033

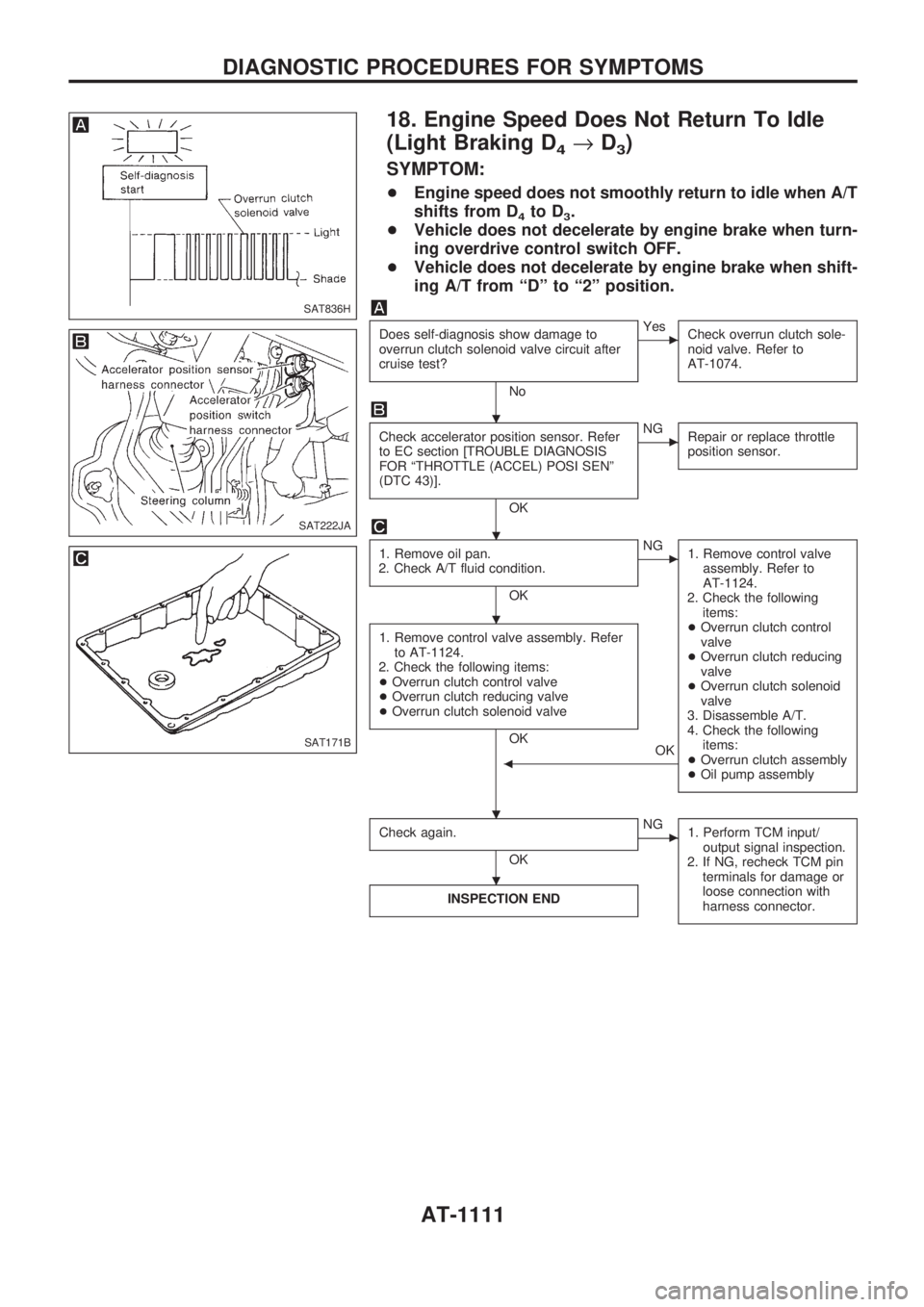

18. Engine Speed Does Not Return To Idle

(Light Braking D

4®D3)

SYMPTOM:

+Engine speed does not smoothly return to idle when A/T

shifts from D

4to D3.

+Vehicle does not decelerate by engine brake when turn-

ing overdrive control switch OFF.

+Vehicle does not decelerate by engine brake when shift-

ing A/T from ªDº to ª2º position.

Does self-diagnosis show damage to

overrun clutch solenoid valve circuit after

cruise test?

No

cYes

Check overrun clutch sole-

noid valve. Refer to

AT-1074.

Check accelerator position sensor. Refer

to EC section [TROUBLE DIAGNOSIS

FOR ªTHROTTLE (ACCEL) POSI SENº

(DTC 43)].

OK

cNG

Repair or replace throttle

position sensor.

1. Remove oil pan.

2. Check A/T fluid condition.

OK

cNG

1. Remove control valve

assembly. Refer to

AT-1124.

2. Check the following

items:

+Overrun clutch control

valve

+Overrun clutch reducing

valve

+Overrun clutch solenoid

valve

3. Disassemble A/T.

4. Check the following

items:

+Overrun clutch assembly

+Oil pump assembly

1. Remove control valve assembly. Refer

to AT-1124.

2. Check the following items:

+Overrun clutch control valve

+Overrun clutch reducing valve

+Overrun clutch solenoid valve

OK

OK

b

Check again.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT836H

SAT222JA

SAT171B

.

.

.

. .

.

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-1111

Page 117 of 1033

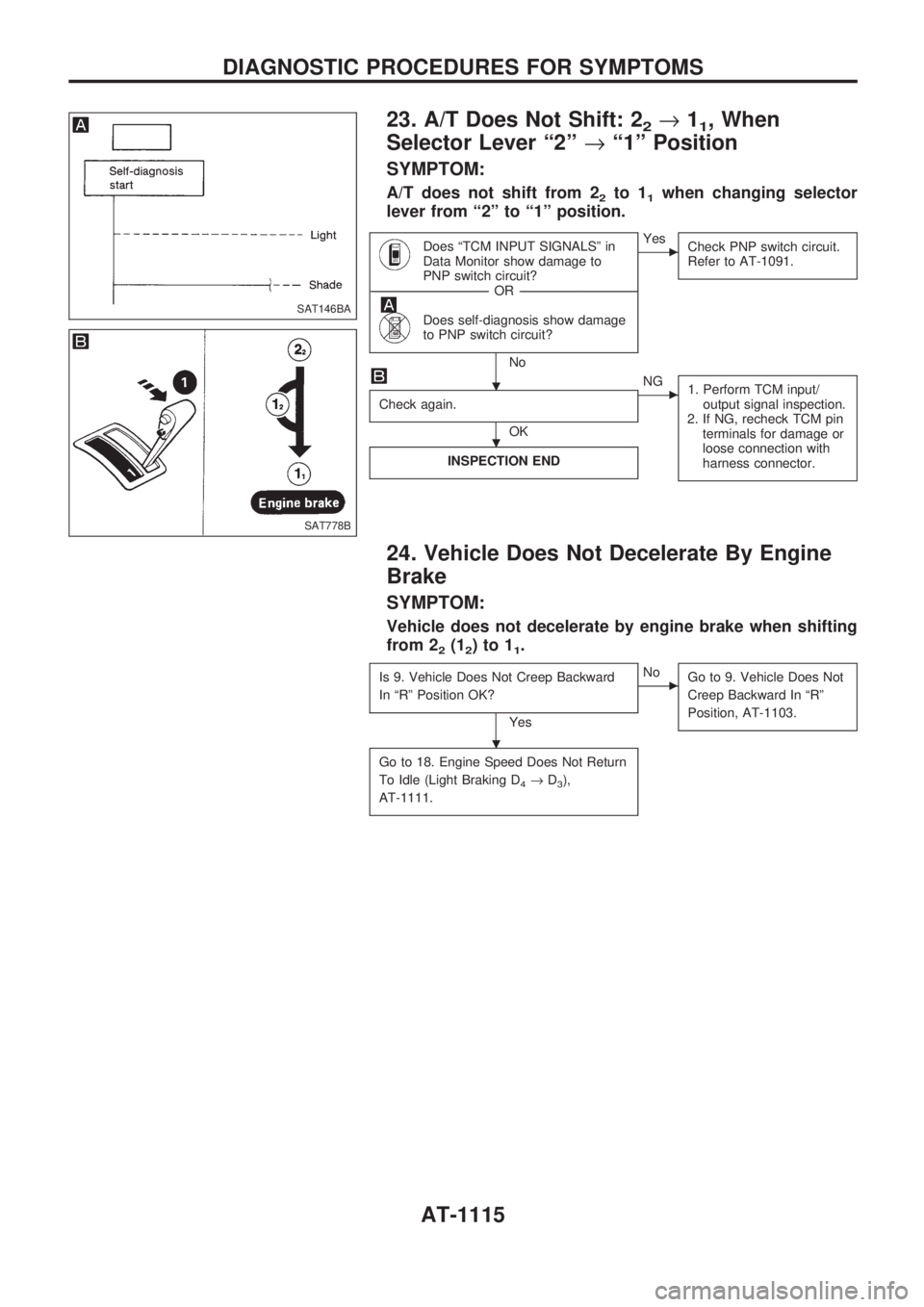

23. A/T Does Not Shift: 22®11, When

Selector Lever ª2º®ª1º Position

SYMPTOM:

A/T does not shift from 22to 11when changing selector

lever from ª2º to ª1º position.

Does ªTCM INPUT SIGNALSº in

Data Monitor show damage to

PNP switch circuit?

------------------------------------------------------------------------------------------------------------------------------------OR------------------------------------------------------------------------------------------------------------------------------------

Does self-diagnosis show damage

to PNP switch circuit?

No

cYes

Check PNP switch circuit.

Refer to AT-1091.

Check again.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

24. Vehicle Does Not Decelerate By Engine

Brake

SYMPTOM:

Vehicle does not decelerate by engine brake when shifting

from 2

2(12)to11.

Is 9. Vehicle Does Not Creep Backward

In ªRº Position OK?

Yes

cNo

Go to 9. Vehicle Does Not

Creep Backward In ªRº

Position, AT-1103.

Go to 18. Engine Speed Does Not Return

To Idle (Light Braking D

4®D3),

AT-1111.

SAT146BA

SAT778B

.

.

.

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-1115

Page 130 of 1033

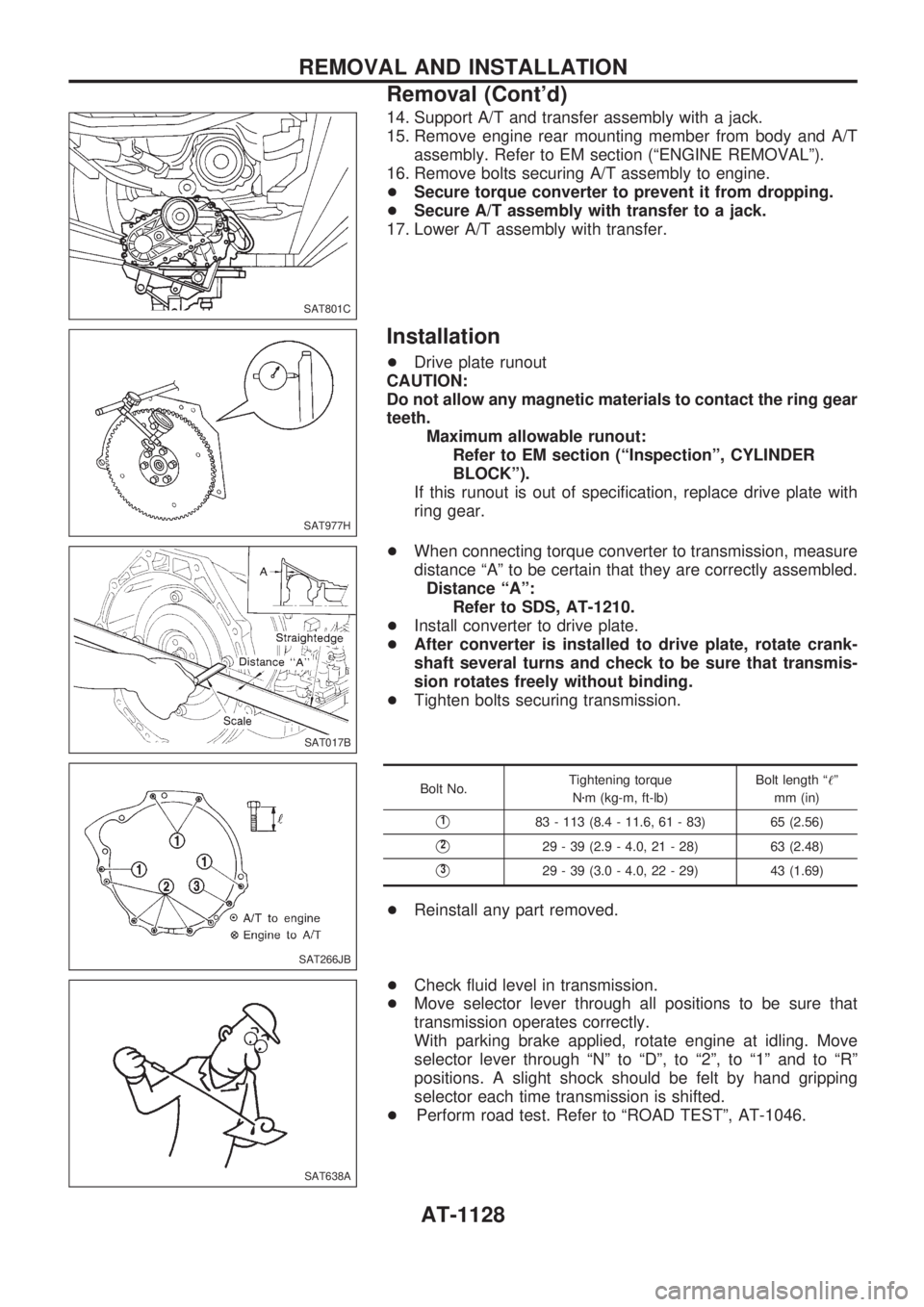

14. Support A/T and transfer assembly with a jack.

15. Remove engine rear mounting member from body and A/T

assembly. Refer to EM section (ªENGINE REMOVALº).

16. Remove bolts securing A/T assembly to engine.

+Secure torque converter to prevent it from dropping.

+Secure A/T assembly with transfer to a jack.

17. Lower A/T assembly with transfer.

Installation

+Drive plate runout

CAUTION:

Do not allow any magnetic materials to contact the ring gear

teeth.

Maximum allowable runout:

Refer to EM section (ªInspectionº, CYLINDER

BLOCKº).

If this runout is out of specification, replace drive plate with

ring gear.

+When connecting torque converter to transmission, measure

distance ªAº to be certain that they are correctly assembled.

Distance ªAº:

Refer to SDS, AT-1210.

+Install converter to drive plate.

+After converter is installed to drive plate, rotate crank-

shaft several turns and check to be sure that transmis-

sion rotates freely without binding.

+Tighten bolts securing transmission.

Bolt No.Tightening torque

Nzm (kg-m, ft-lb)Bolt length ª!º

mm (in)

V183 - 113 (8.4 - 11.6, 61 - 83) 65 (2.56)

V229 - 39 (2.9 - 4.0, 21 - 28) 63 (2.48)

V329 - 39 (3.0 - 4.0, 22 - 29) 43 (1.69)

+Reinstall any part removed.

+Check fluid level in transmission.

+Move selector lever through all positions to be sure that

transmission operates correctly.

With parking brake applied, rotate engine at idling. Move

selector lever through ªNº to ªDº, to ª2º, to ª1º and to ªRº

positions. A slight shock should be felt by hand gripping

selector each time transmission is shifted.

+Perform road test. Refer to ªROAD TESTº, AT-1046.

SAT801C

SAT977H

SAT017B

SAT266JB

SAT638A

REMOVAL AND INSTALLATION

Removal (Cont'd)

AT-1128