NISSAN PATROL 2001 Electronic Workshop Manual

PATROL 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57366/w960_57366-0.png

NISSAN PATROL 2001 Electronic Workshop Manual

Trending: wipers, ECU, fog light, wheel, display, air suspension, oil level

Page 51 of 273

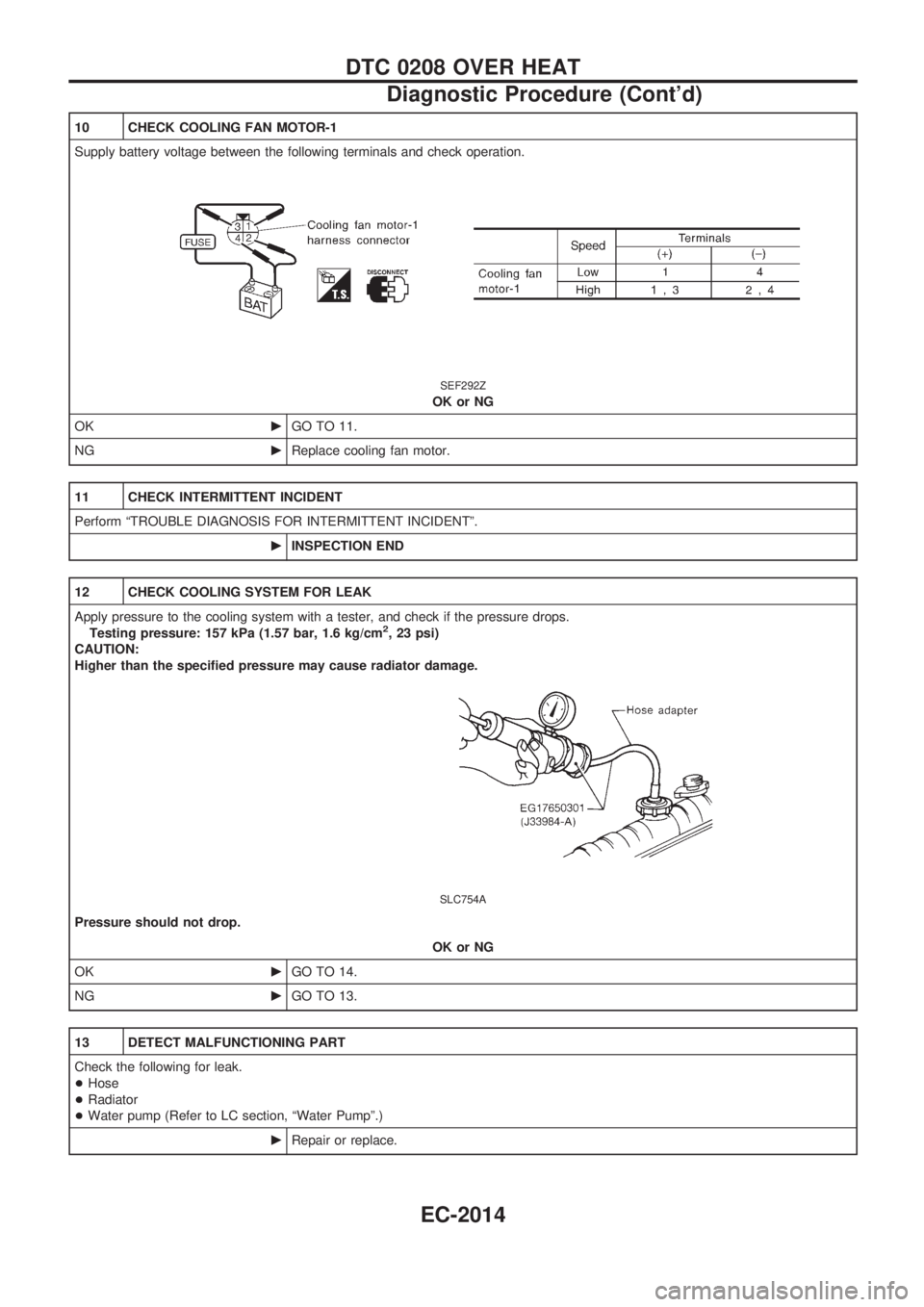

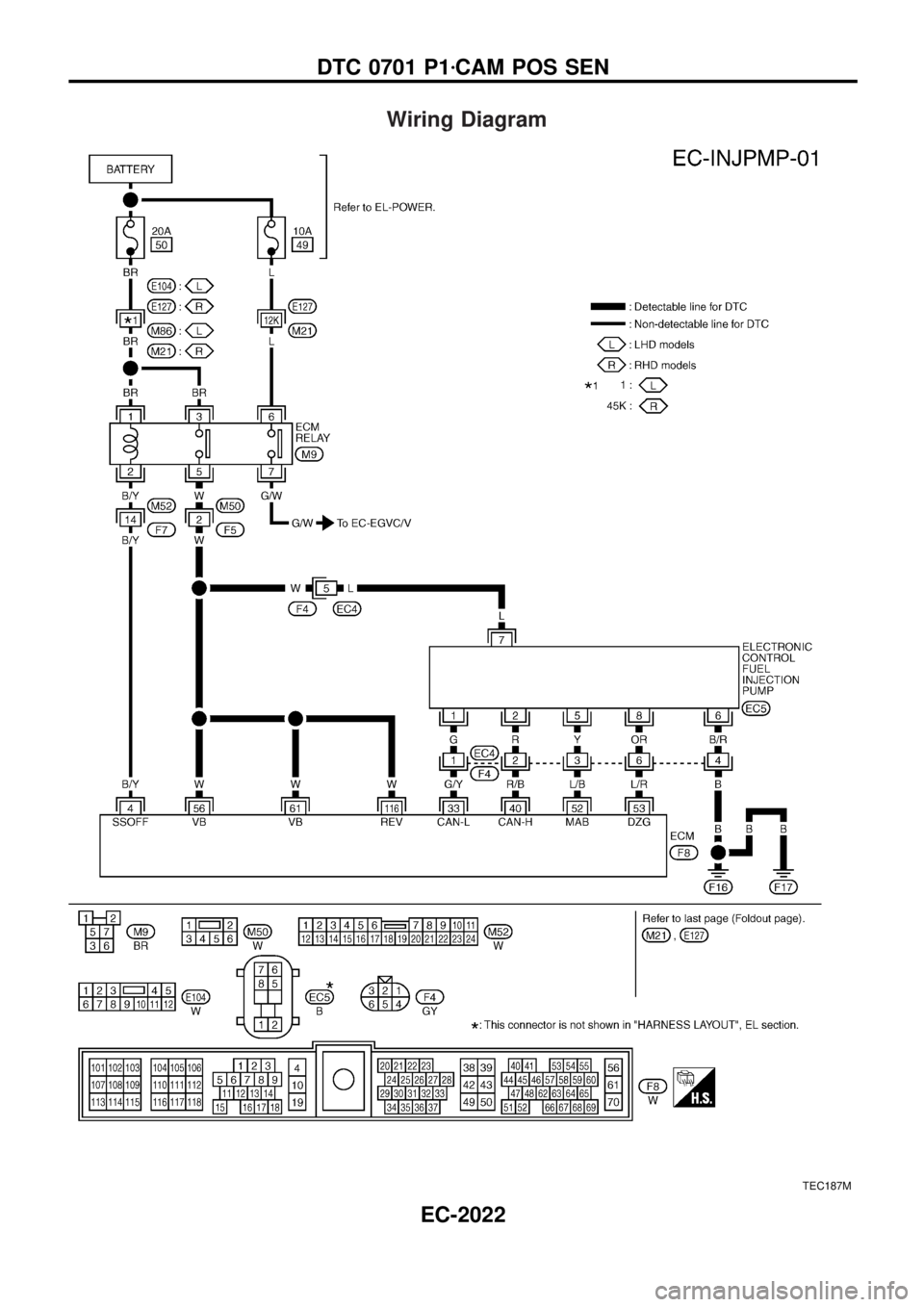

10 CHECK COOLING FAN MOTOR-1

Supply battery voltage between the following terminals and check operation.

SEF292Z

OK or NG

OKcGO TO 11.

NGcReplace cooling fan motor.

11 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº.

cINSPECTION END

12 CHECK COOLING SYSTEM FOR LEAK

Apply pressure to the cooling system with a tester, and check if the pressure drops.

Testing pressure: 157 kPa (1.57 bar, 1.6 kg/cm

2, 23 psi)

CAUTION:

Higher than the specified pressure may cause radiator damage.

SLC754A

Pressure should not drop.

OK or NG

OKcGO TO 14.

NGcGO TO 13.

13 DETECT MALFUNCTIONING PART

Check the following for leak.

+Hose

+Radiator

+Water pump (Refer to LC section, ªWater Pumpº.)

cRepair or replace.

DTC 0208 OVER HEAT

Diagnostic Procedure (Cont'd)

EC-2014

Page 52 of 273

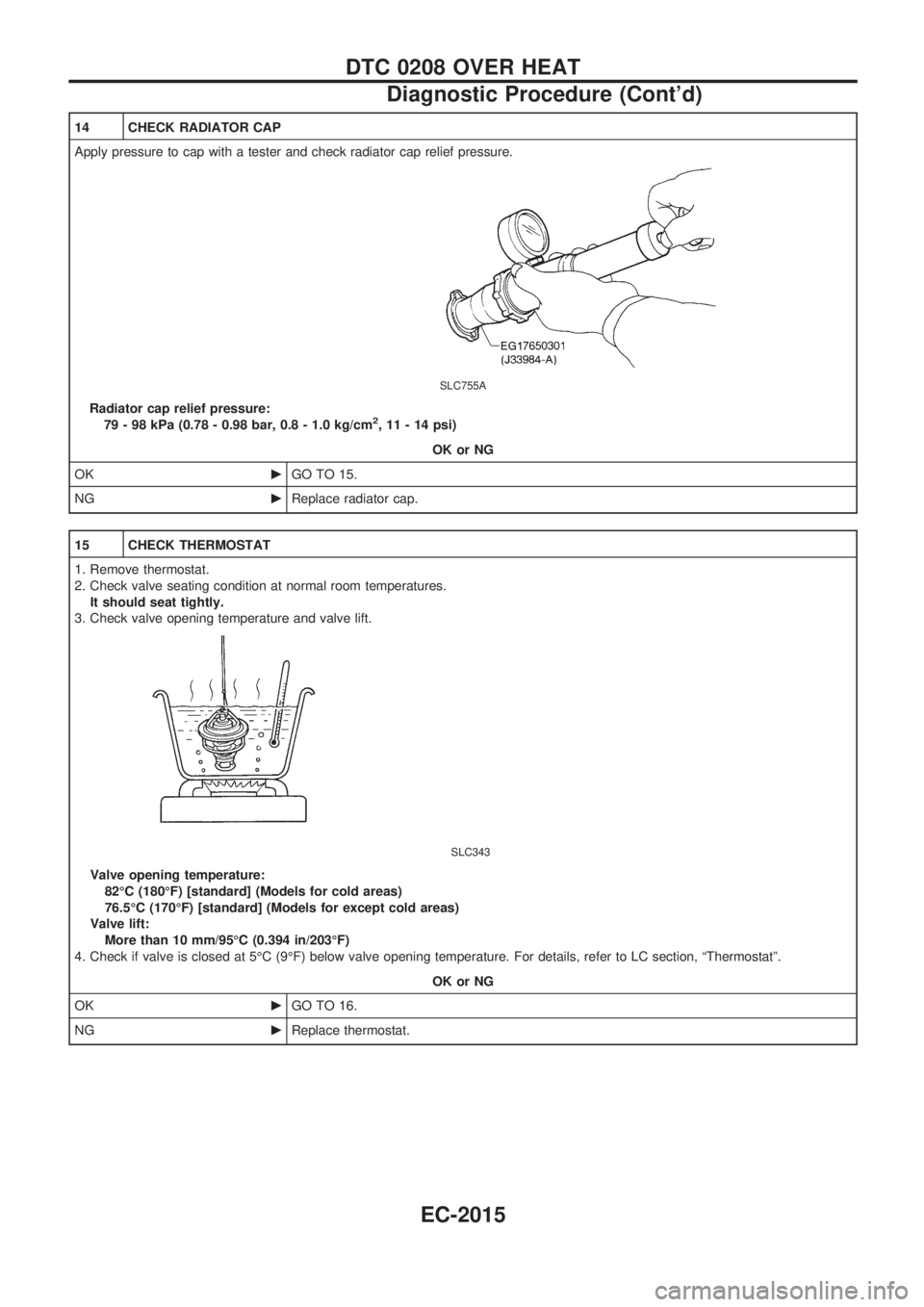

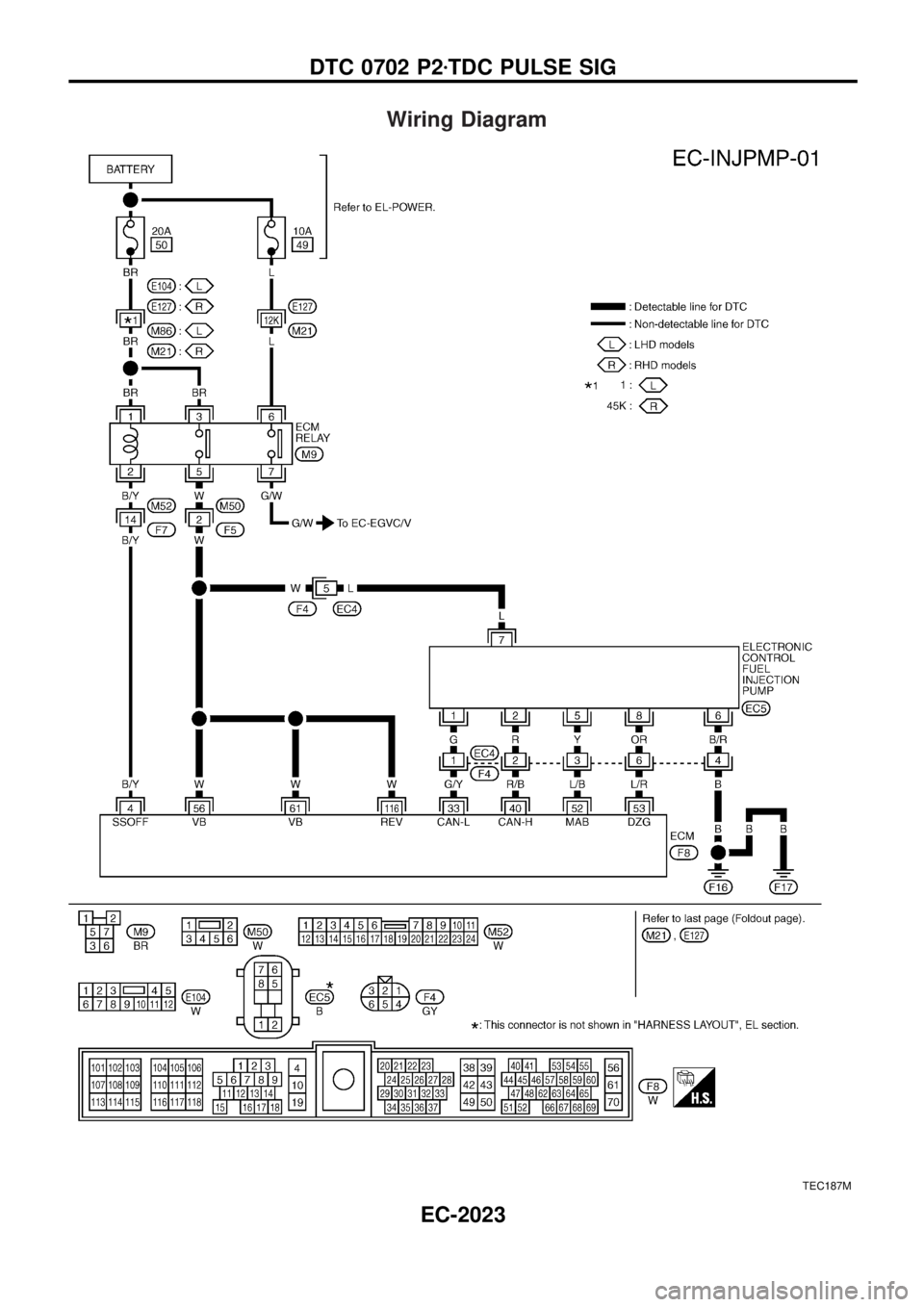

14 CHECK RADIATOR CAP

Apply pressure to cap with a tester and check radiator cap relief pressure.

SLC755A

Radiator cap relief pressure:

79 - 98 kPa (0.78 - 0.98 bar, 0.8 - 1.0 kg/cm2, 11 - 14 psi)

OK or NG

OKcGO TO 15.

NGcReplace radiator cap.

15 CHECK THERMOSTAT

1. Remove thermostat.

2. Check valve seating condition at normal room temperatures.

It should seat tightly.

3. Check valve opening temperature and valve lift.

SLC343

Valve opening temperature:

82ÉC (180ÉF) [standard] (Models for cold areas)

76.5ÉC (170ÉF) [standard] (Models for except cold areas)

Valve lift:

More than 10 mm/95ÉC (0.394 in/203ÉF)

4. Check if valve is closed at 5ÉC (9ÉF) below valve opening temperature. For details, refer to LC section, ªThermostatº.

OK or NG

OKcGO TO 16.

NGcReplace thermostat.

DTC 0208 OVER HEAT

Diagnostic Procedure (Cont'd)

EC-2015

Page 53 of 273

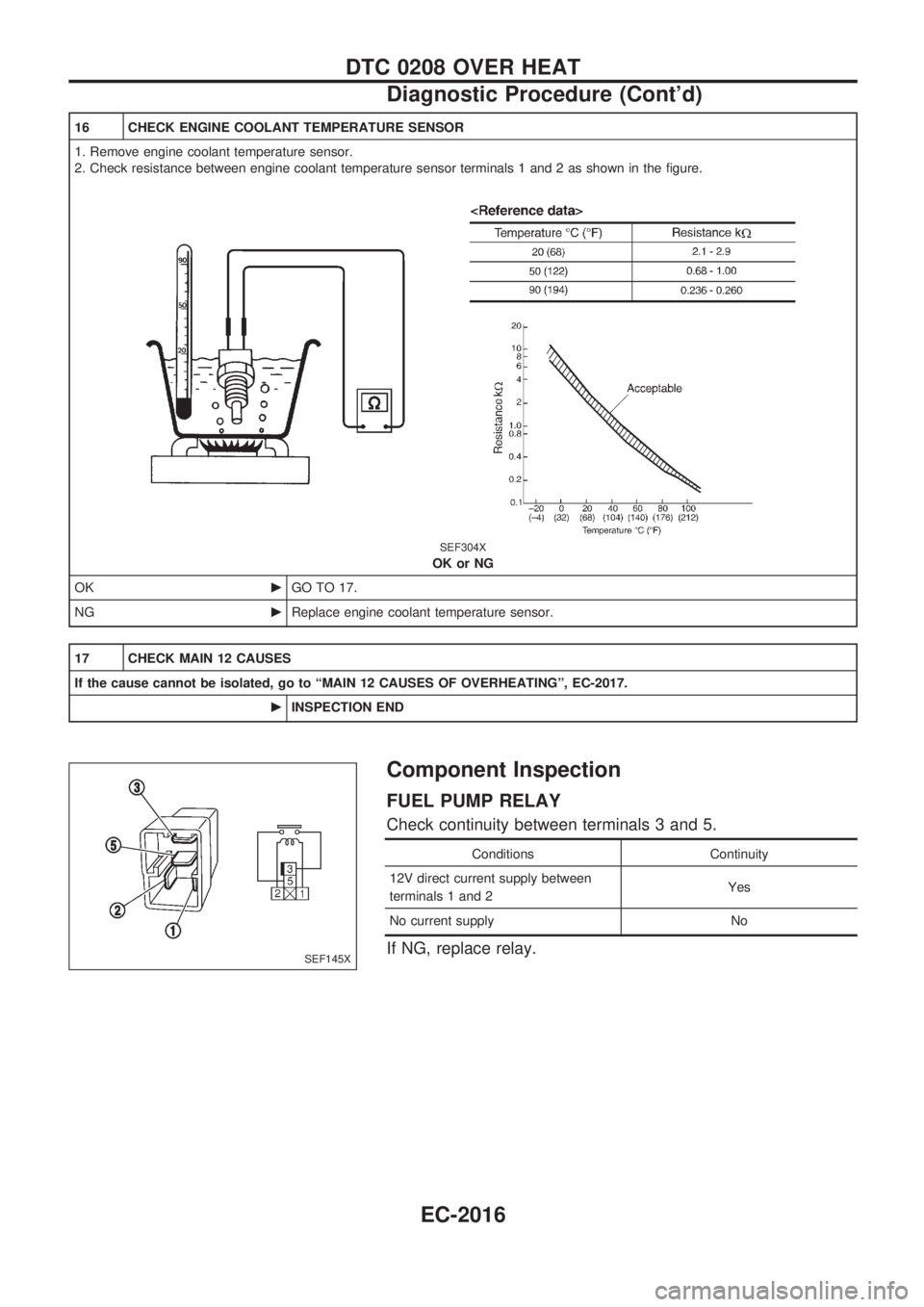

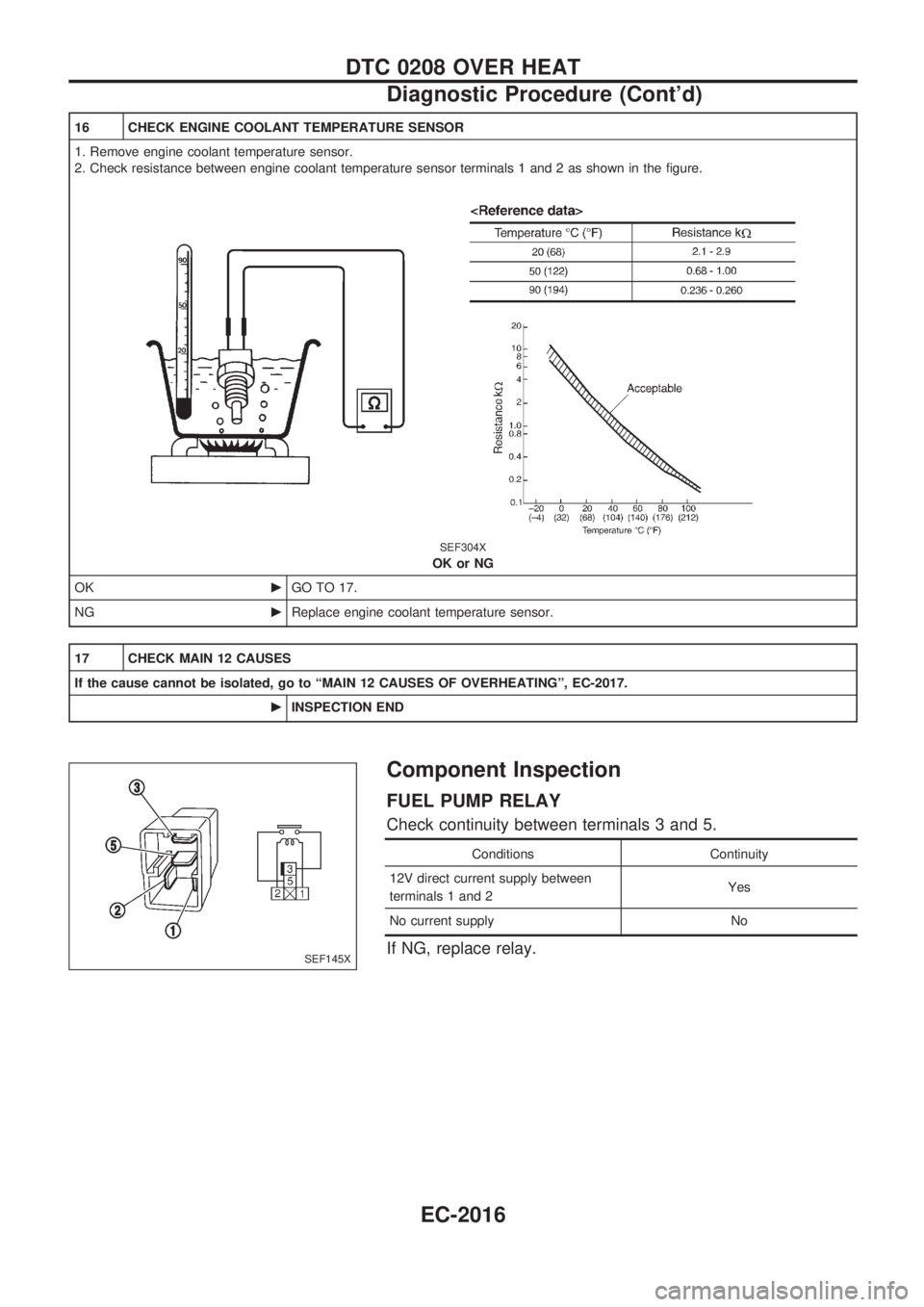

16 CHECK ENGINE COOLANT TEMPERATURE SENSOR

1. Remove engine coolant temperature sensor.

2. Check resistance between engine coolant temperature sensor terminals 1 and 2 as shown in the figure.

SEF304X

OK or NG

OKcGO TO 17.

NGcReplace engine coolant temperature sensor.

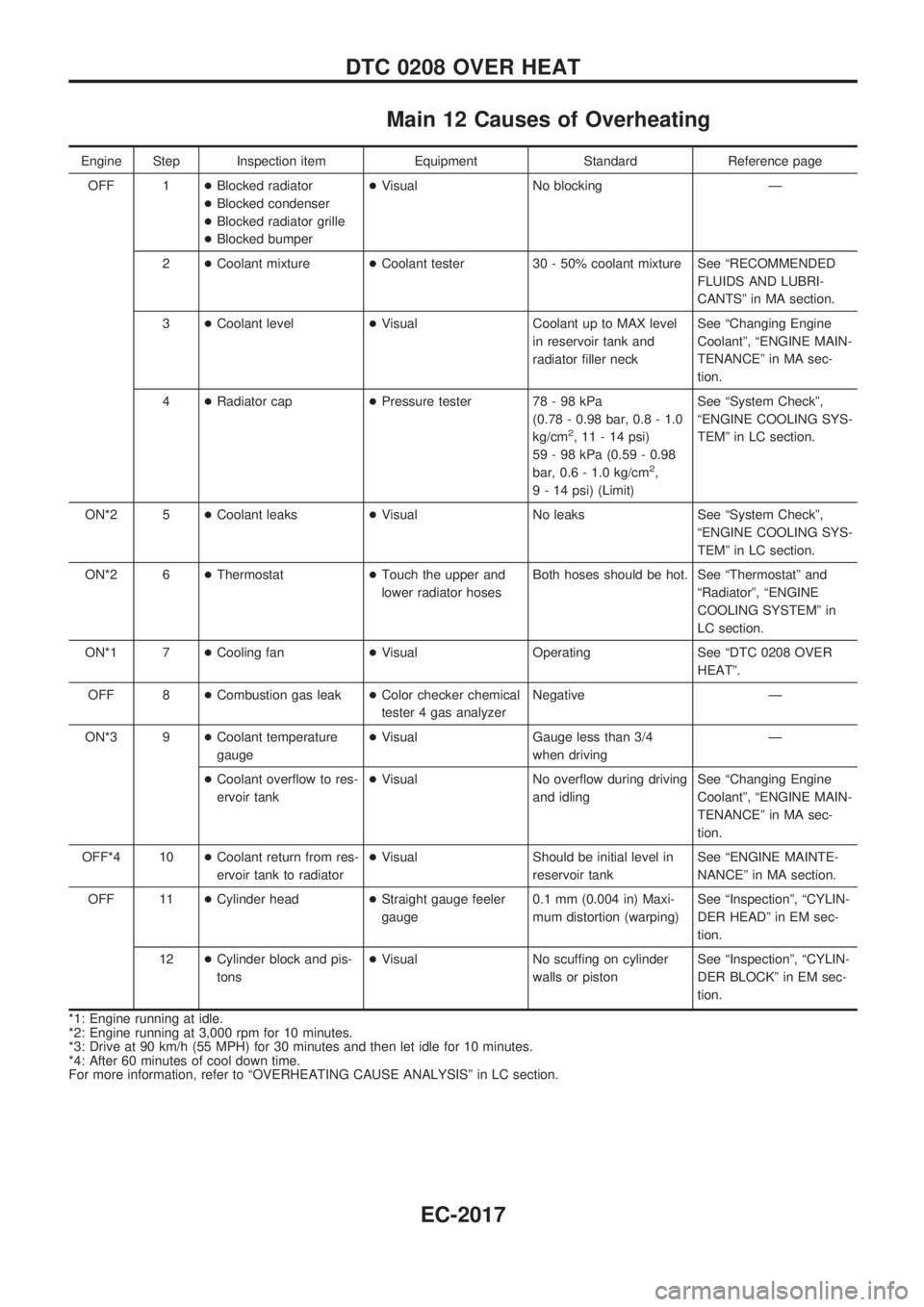

17 CHECK MAIN 12 CAUSES

If the cause cannot be isolated, go to ªMAIN 12 CAUSES OF OVERHEATINGº, EC-2017.

cINSPECTION END

Component Inspection

FUEL PUMP RELAY

Check continuity between terminals 3 and 5.

Conditions Continuity

12V direct current supply between

terminals 1 and 2Yes

No current supply No

If NG, replace relay.SEF145X

DTC 0208 OVER HEAT

Diagnostic Procedure (Cont'd)

EC-2016

Page 54 of 273

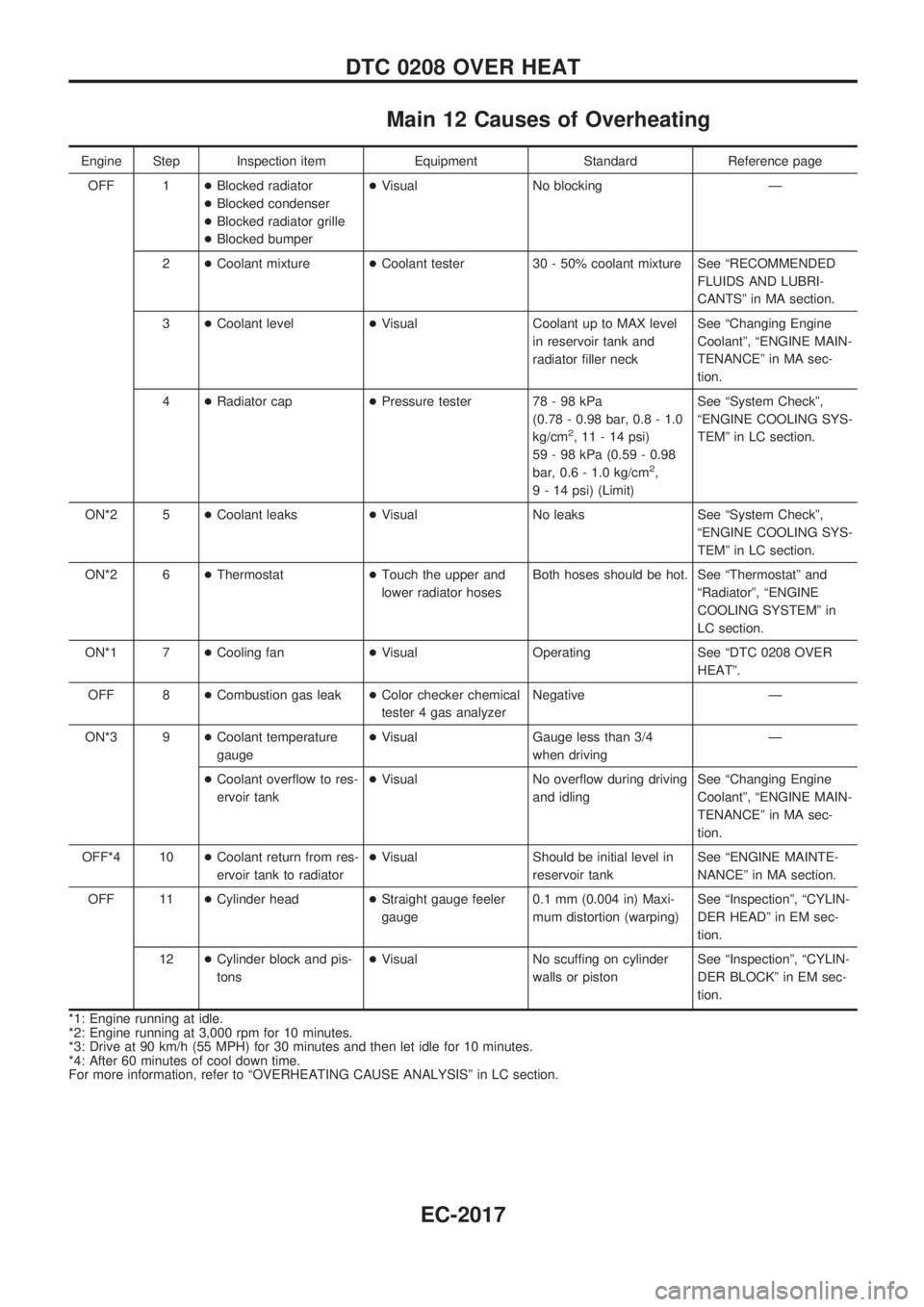

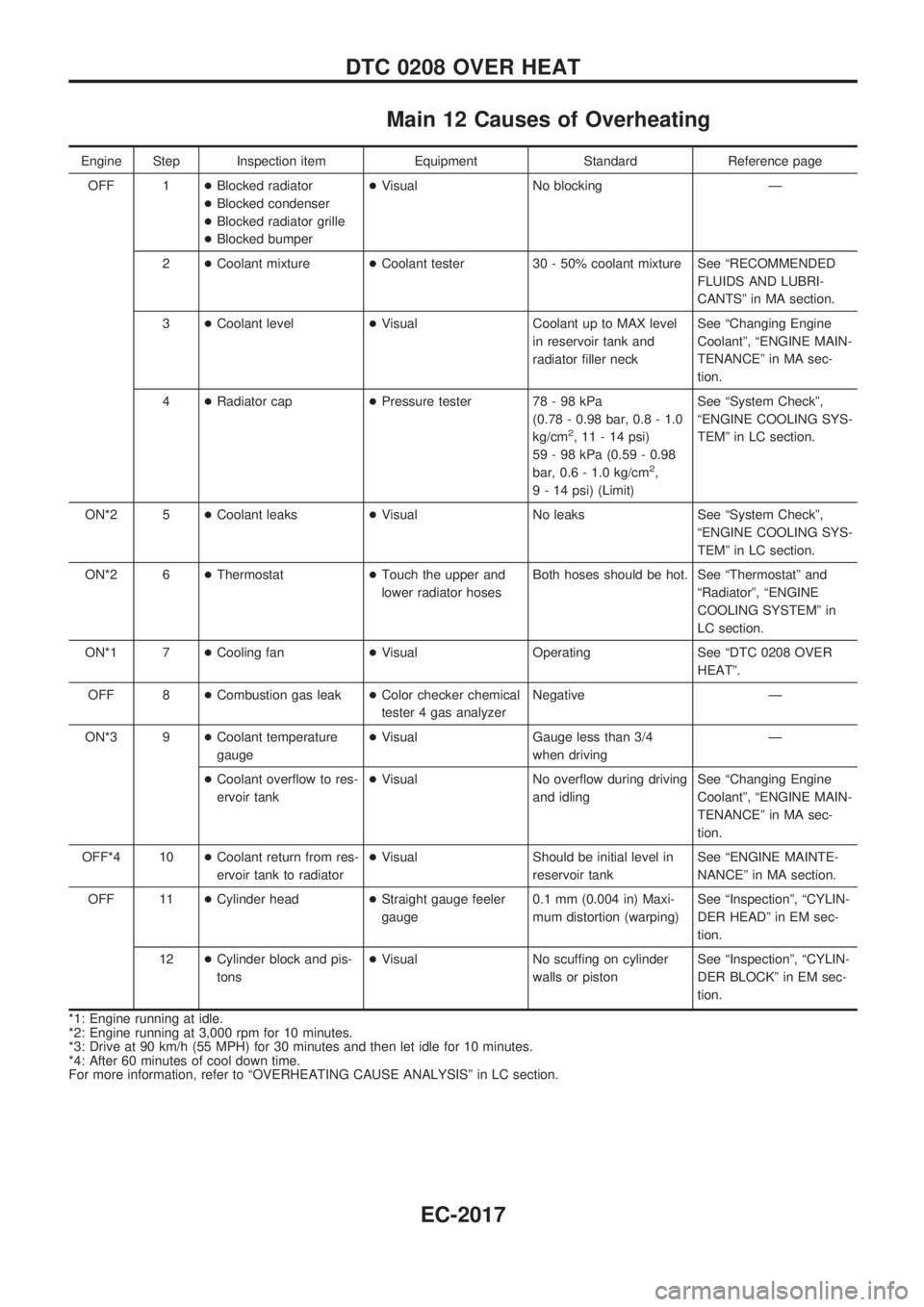

Main 12 Causes of Overheating

Engine Step Inspection item Equipment Standard Reference page

OFF 1+Blocked radiator

+Blocked condenser

+Blocked radiator grille

+Blocked bumper+Visual No blocking Ð

2+Coolant mixture+Coolant tester 30 - 50% coolant mixture See ªRECOMMENDED

FLUIDS AND LUBRI-

CANTSº in MA section.

3+Coolant level+Visual Coolant up to MAX level

in reservoir tank and

radiator filler neckSee ªChanging Engine

Coolantº, ªENGINE MAIN-

TENANCEº in MA sec-

tion.

4+Radiator cap+Pressure tester 78 - 98 kPa

(0.78 - 0.98 bar, 0.8 - 1.0

kg/cm

2, 11 - 14 psi)

59 - 98 kPa (0.59 - 0.98

bar, 0.6 - 1.0 kg/cm

2,

9 - 14 psi) (Limit)See ªSystem Checkº,

ªENGINE COOLING SYS-

TEMº in LC section.

ON*2 5+Coolant leaks+Visual No leaks See ªSystem Checkº,

ªENGINE COOLING SYS-

TEMº in LC section.

ON*2 6+Thermostat+Touch the upper and

lower radiator hosesBoth hoses should be hot. See ªThermostatº and

ªRadiatorº, ªENGINE

COOLING SYSTEMº in

LC section.

ON*1 7+Cooling fan+Visual Operating See ªDTC 0208 OVER

HEATº.

OFF 8+Combustion gas leak+Color checker chemical

tester 4 gas analyzerNegative Ð

ON*3 9+Coolant temperature

gauge+Visual Gauge less than 3/4

when drivingÐ

+Coolant overflow to res-

ervoir tank+Visual No overflow during driving

and idlingSee ªChanging Engine

Coolantº, ªENGINE MAIN-

TENANCEº in MA sec-

tion.

OFF*4 10+Coolant return from res-

ervoir tank to radiator+Visual Should be initial level in

reservoir tankSee ªENGINE MAINTE-

NANCEº in MA section.

OFF 11+Cylinder head+Straight gauge feeler

gauge0.1 mm (0.004 in) Maxi-

mum distortion (warping)See ªInspectionº, ªCYLIN-

DER HEADº in EM sec-

tion.

12+Cylinder block and pis-

tons+Visual No scuffing on cylinder

walls or pistonSee ªInspectionº, ªCYLIN-

DER BLOCKº in EM sec-

tion.

*1: Engine running at idle.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

For more information, refer to ªOVERHEATING CAUSE ANALYSISº in LC section.

DTC 0208 OVER HEAT

EC-2017

Page 55 of 273

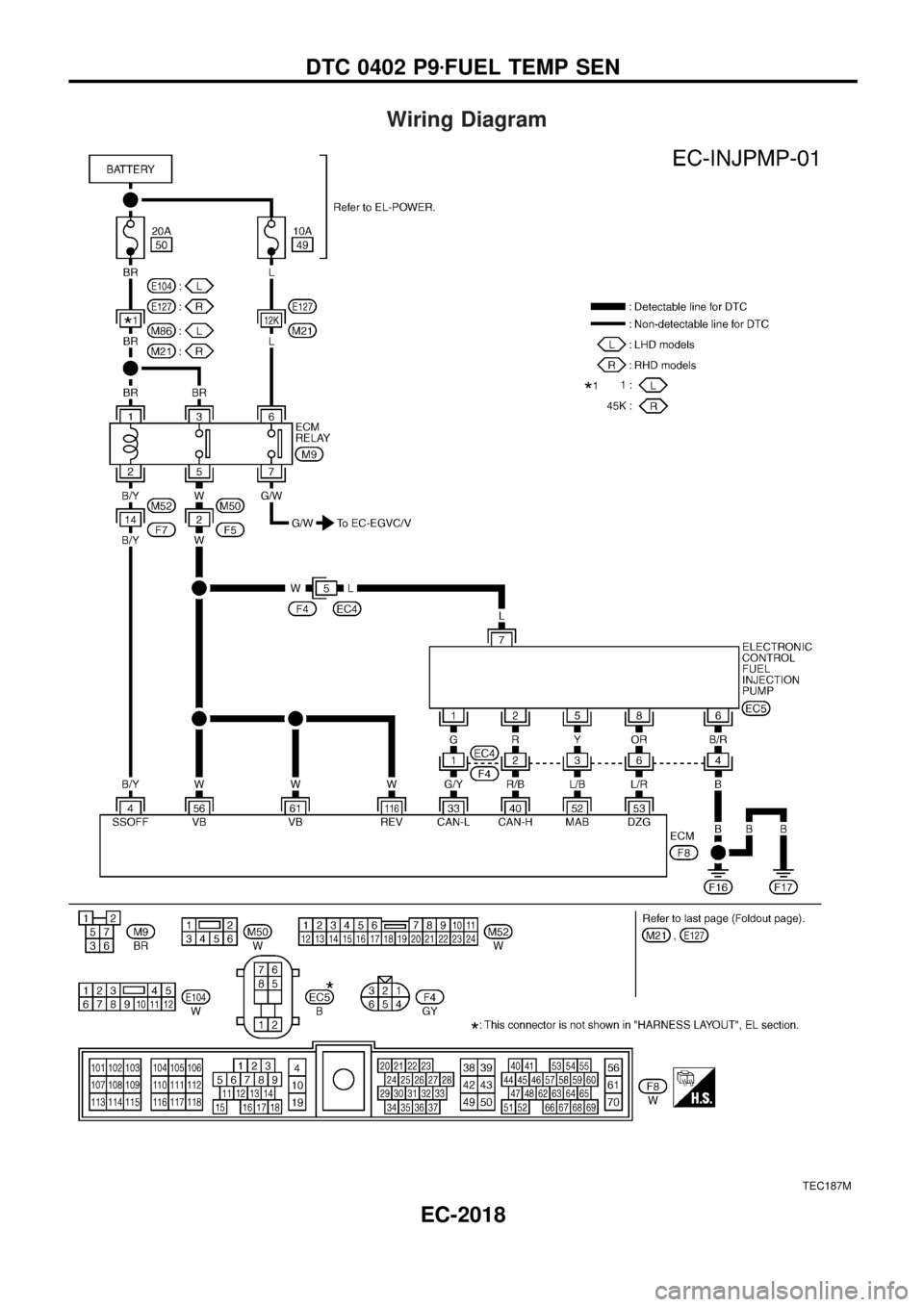

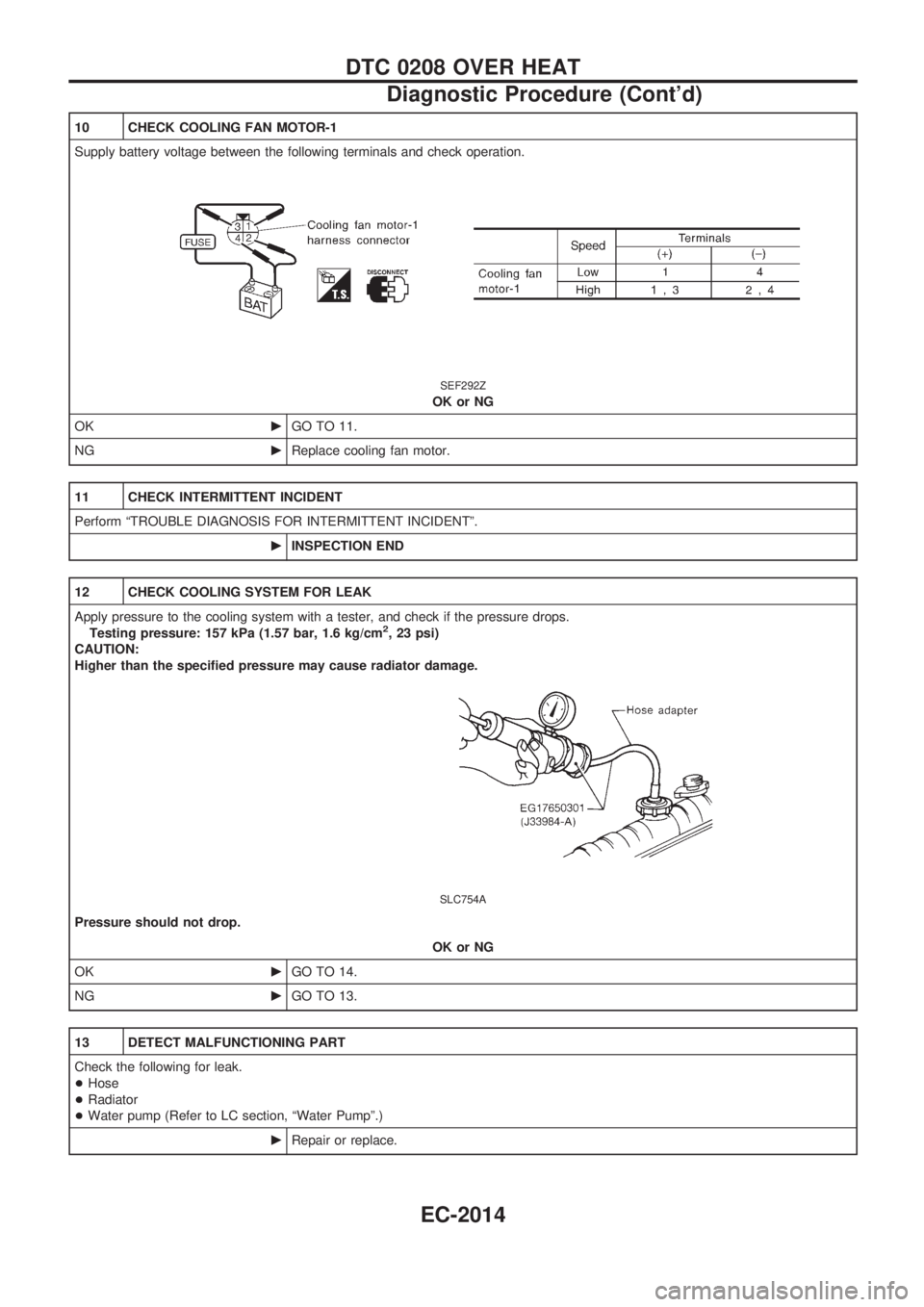

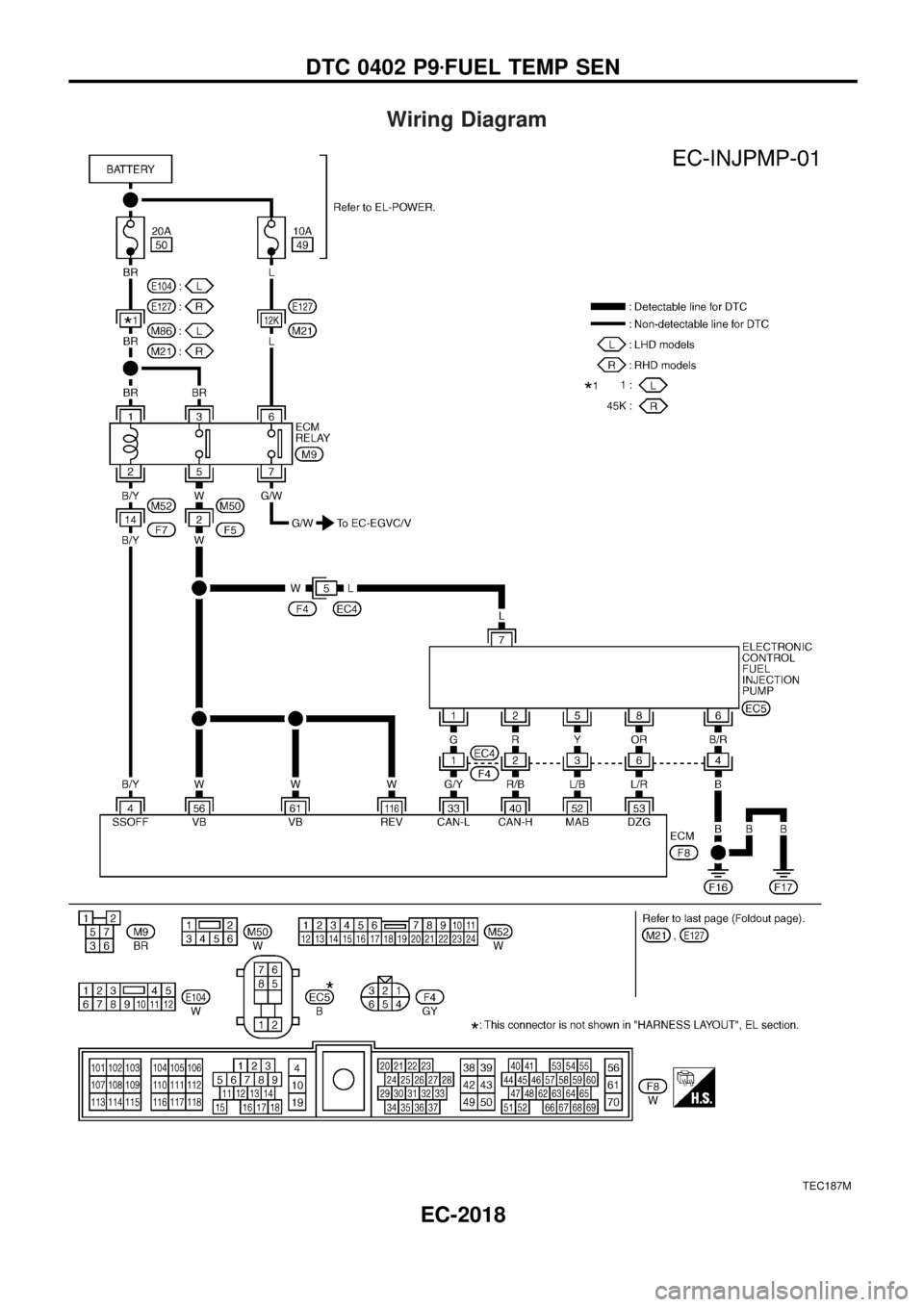

Wiring Diagram

TEC187M

DTC 0402 P9zFUEL TEMP SEN

EC-2018

Page 56 of 273

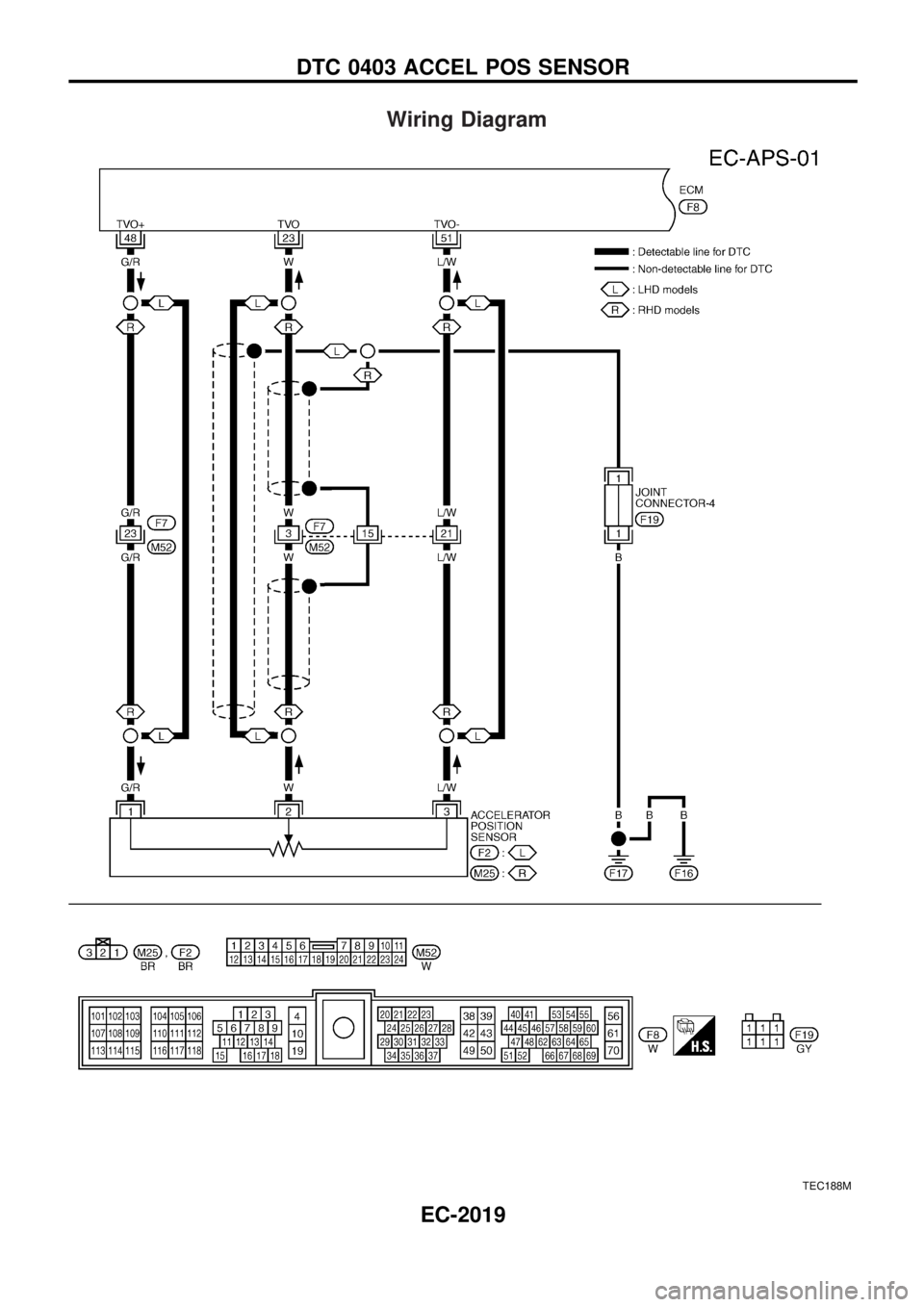

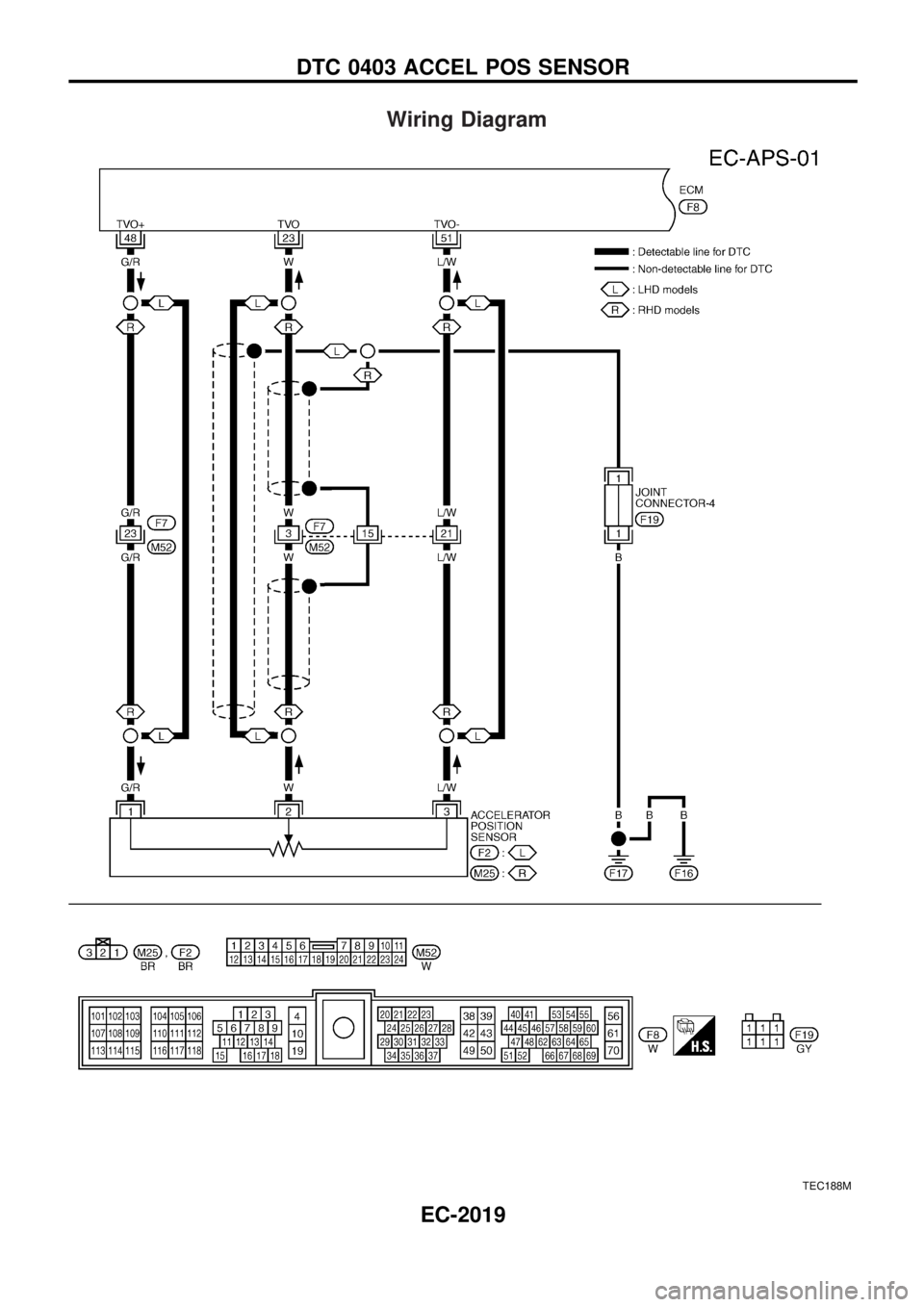

Wiring Diagram

TEC188M

DTC 0403 ACCEL POS SENSOR

EC-2019

Page 57 of 273

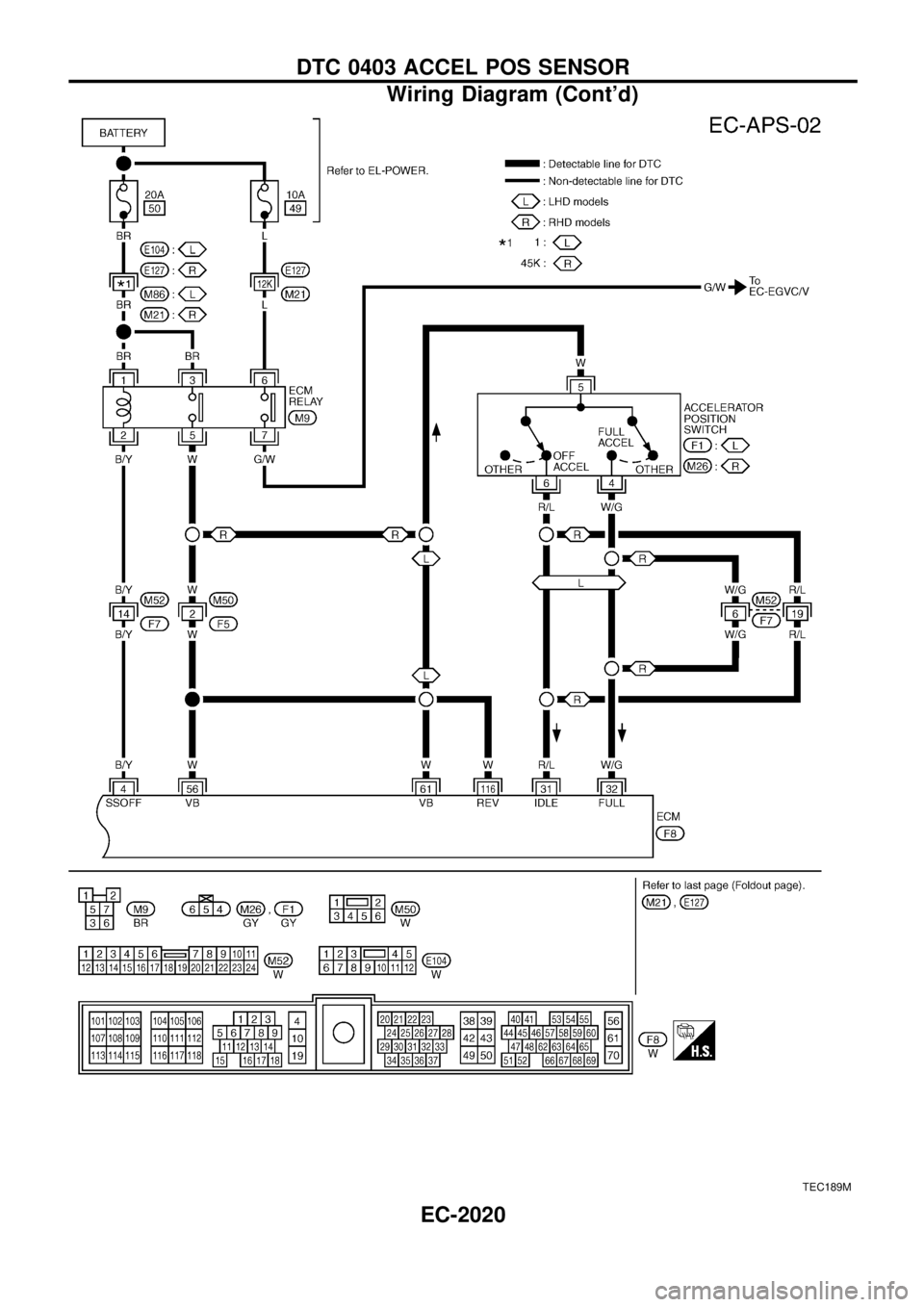

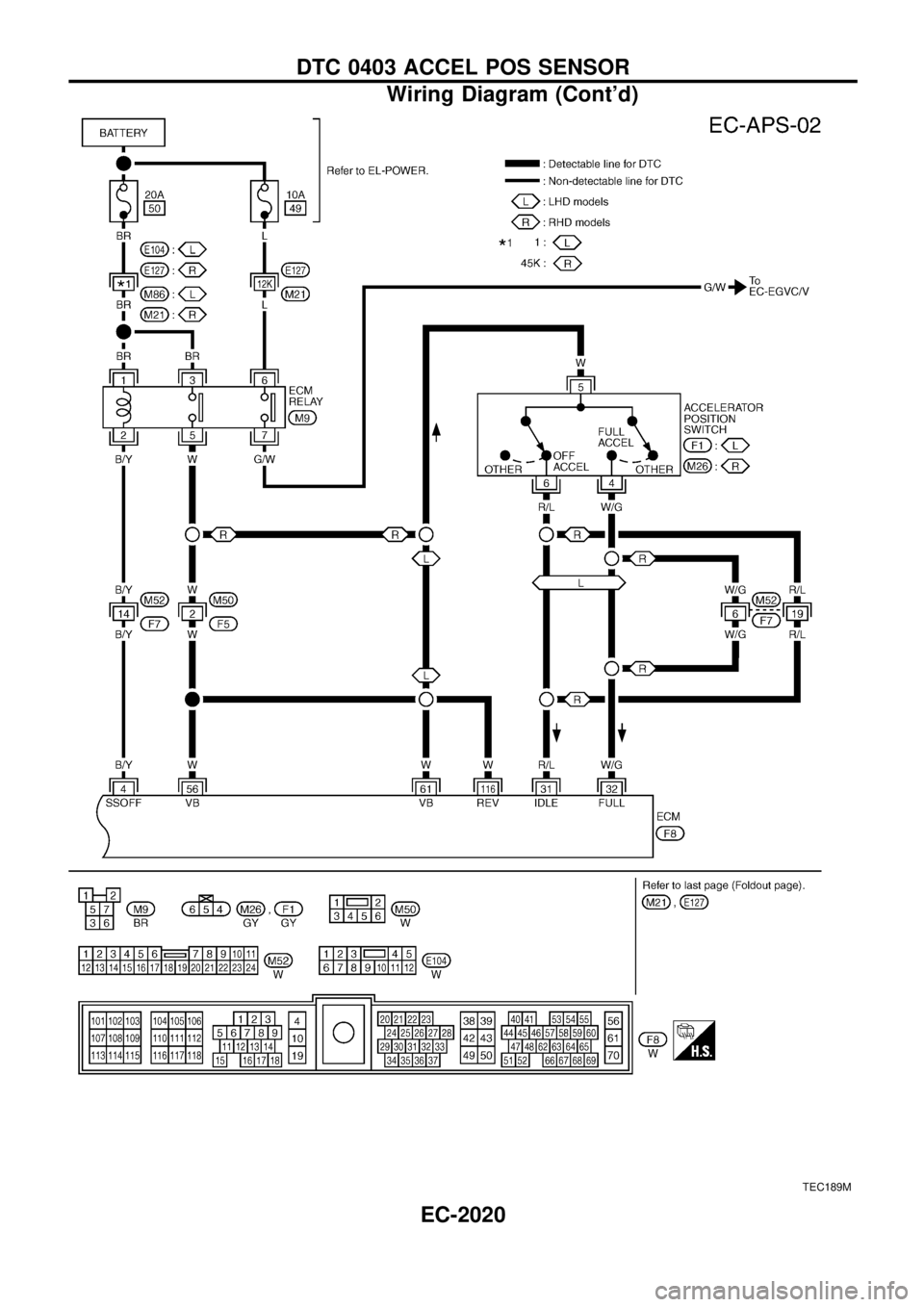

TEC189M

DTC 0403 ACCEL POS SENSOR

Wiring Diagram (Cont'd)

EC-2020

Page 58 of 273

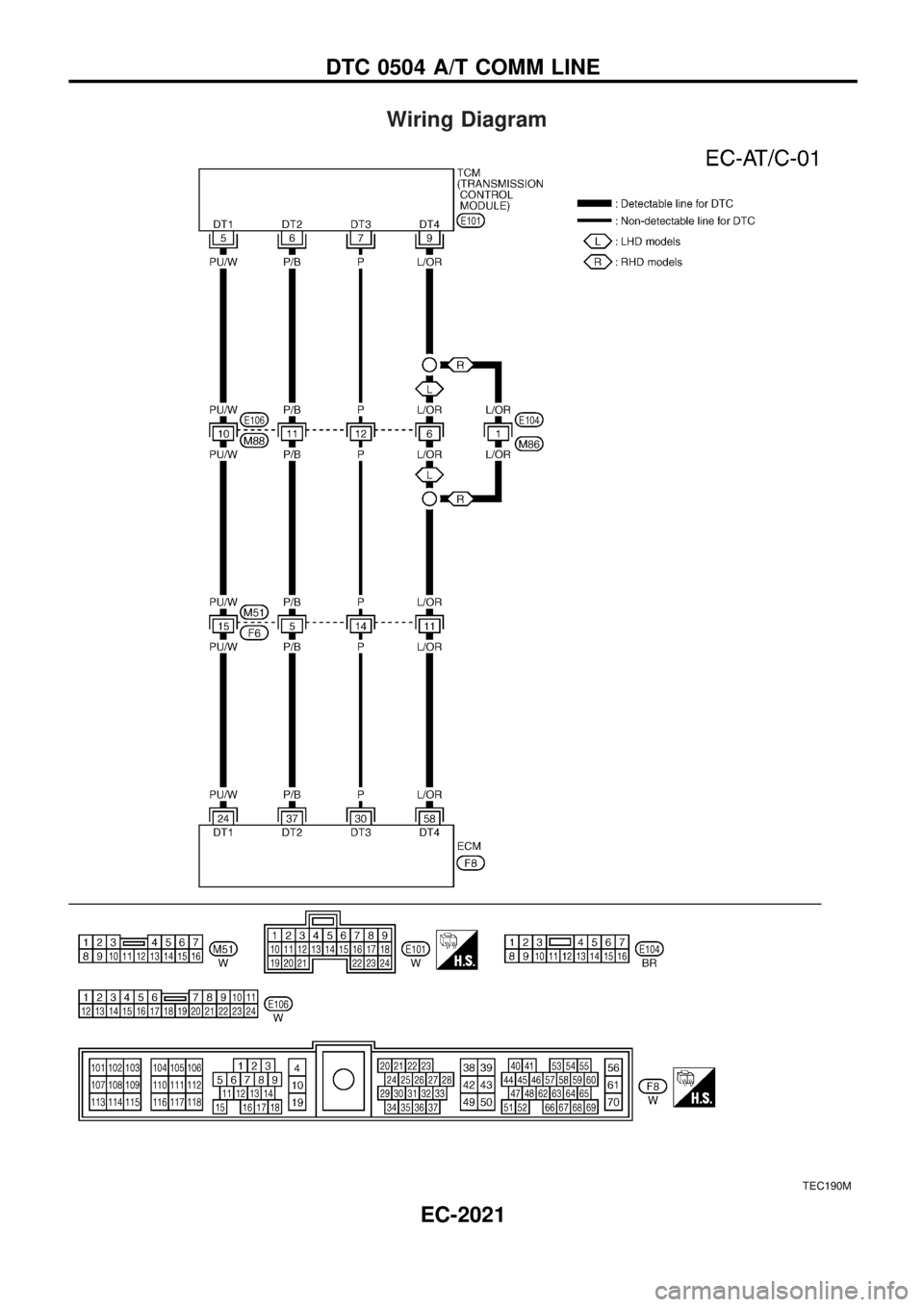

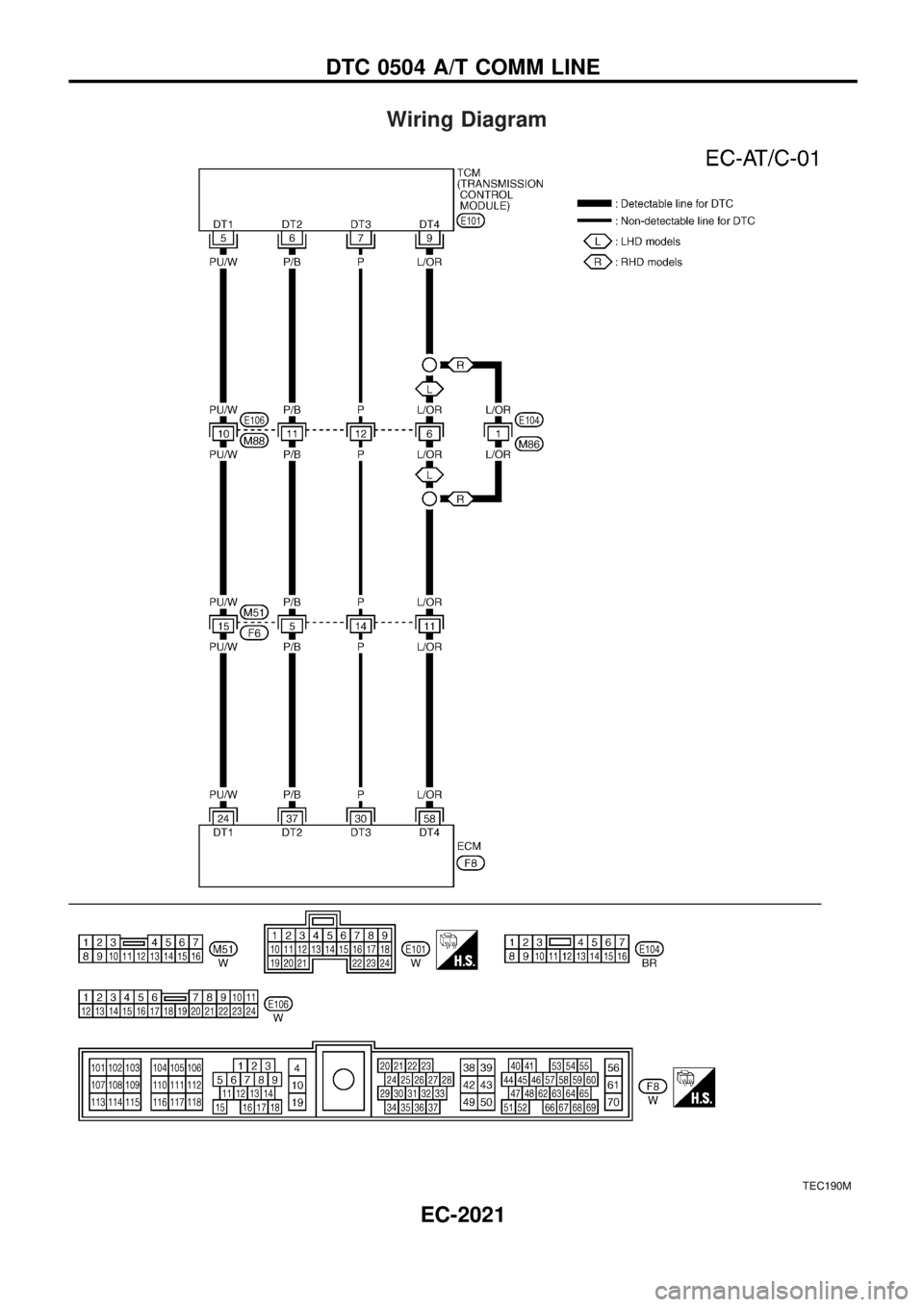

Wiring Diagram

TEC190M

DTC 0504 A/T COMM LINE

EC-2021

Page 59 of 273

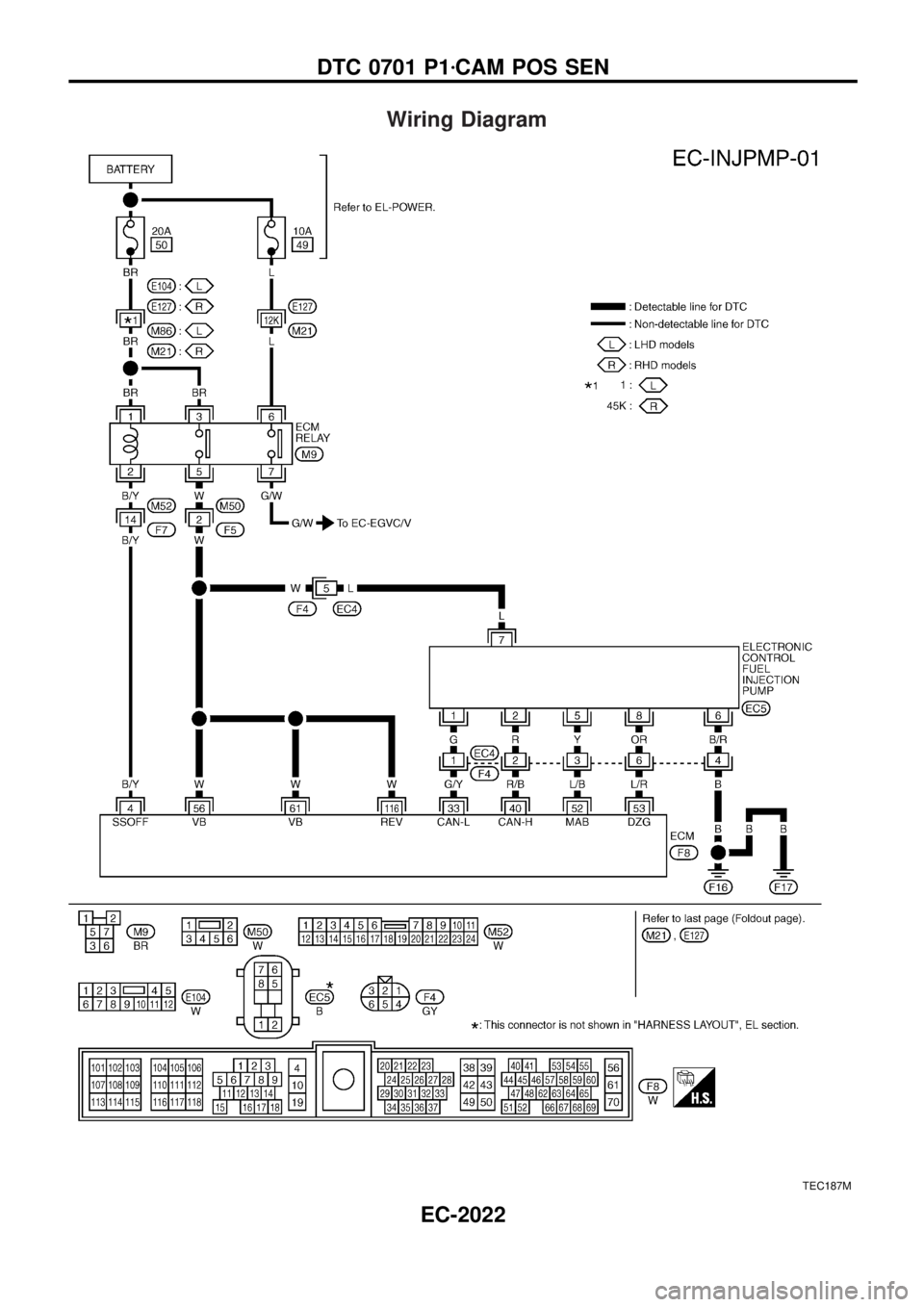

Wiring Diagram

TEC187M

DTC 0701 P1zCAM POS SEN

EC-2022

Page 60 of 273

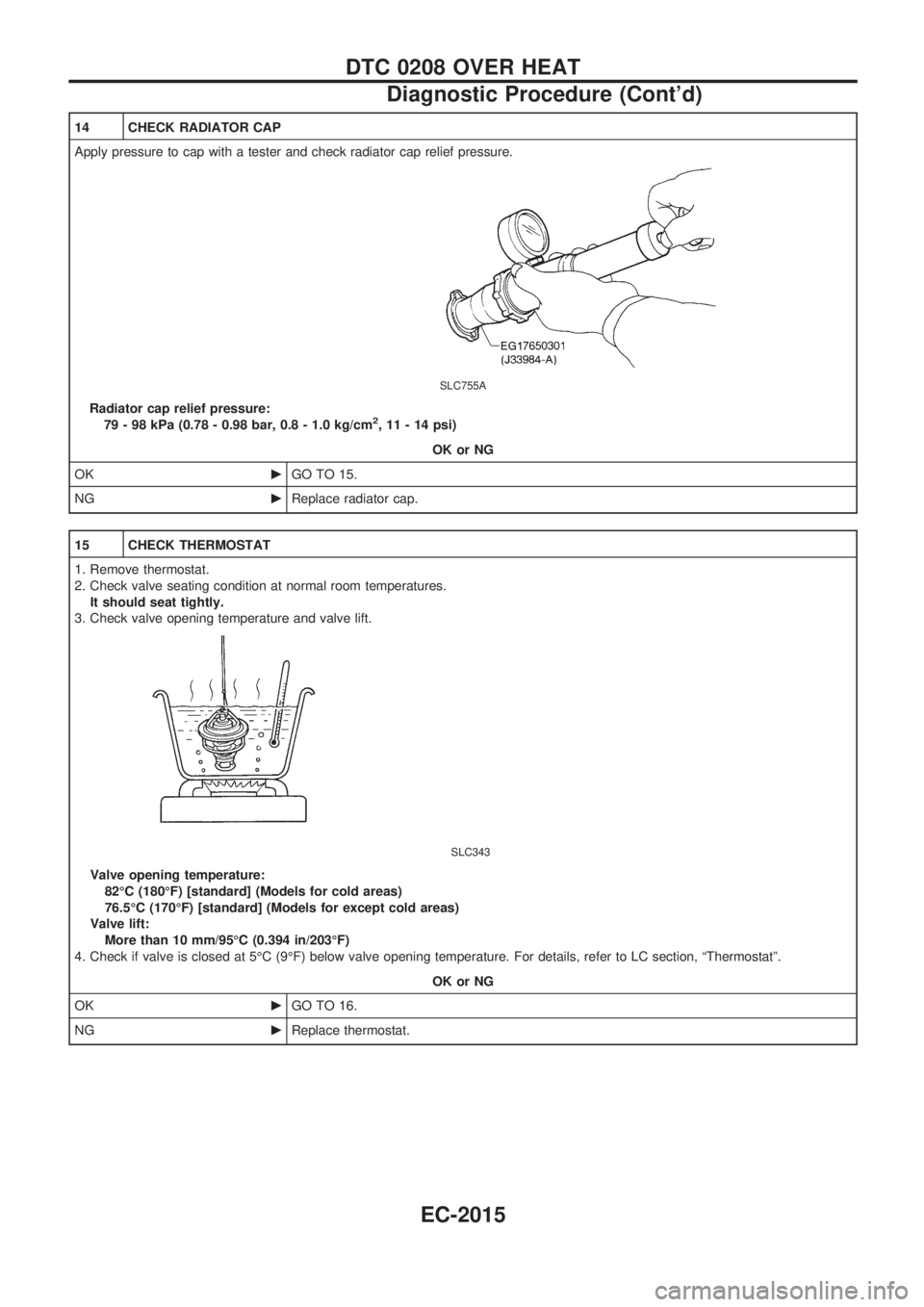

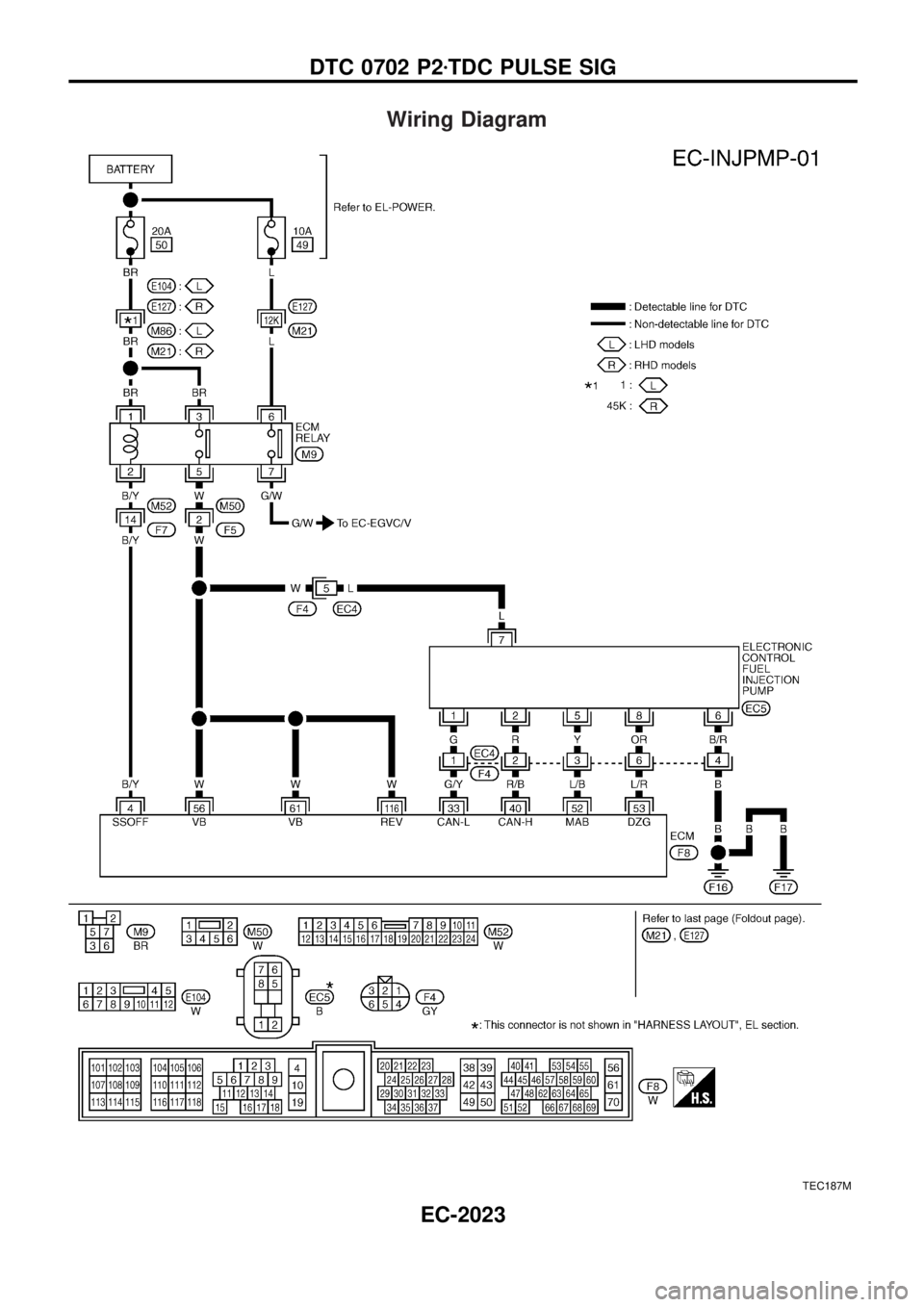

Wiring Diagram

TEC187M

DTC 0702 P2zTDC PULSE SIG

EC-2023

Trending: horn, oil temperature, ABS, oil change, fuse, wiring, overheating