NISSAN PATROL 2001 Electronic Owner's Guide

Manufacturer: NISSAN, Model Year: 2001, Model line: PATROL, Model: NISSAN PATROL 2001Pages: 273, PDF Size: 9.05 MB

Page 31 of 273

CLUTCH

SECTION

CL

MODIFICATION NOTICE:

+Service Data and Specifications (SDS) have been changed.

CONTENTS

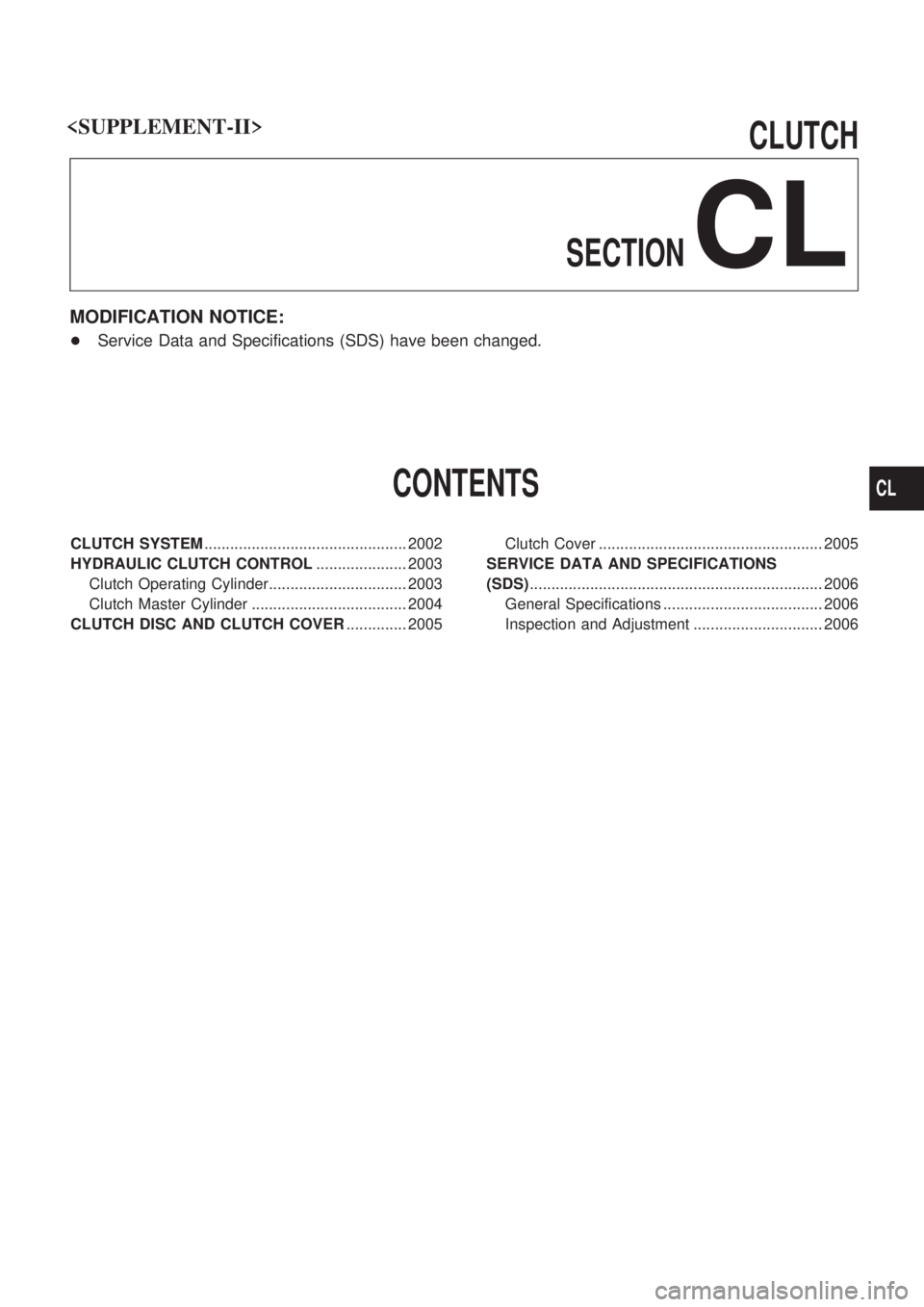

CLUTCH SYSTEM............................................... 2002

HYDRAULIC CLUTCH CONTROL..................... 2003

Clutch Operating Cylinder................................ 2003

Clutch Master Cylinder .................................... 2004

CLUTCH DISC AND CLUTCH COVER.............. 2005Clutch Cover .................................................... 2005

SERVICE DATA AND SPECIFICATIONS

(SDS).................................................................... 2006

General Specifications ..................................... 2006

Inspection and Adjustment .............................. 2006

CL

Page 32 of 273

SCL906

CLUTCH SYSTEM

CL-2002

Page 33 of 273

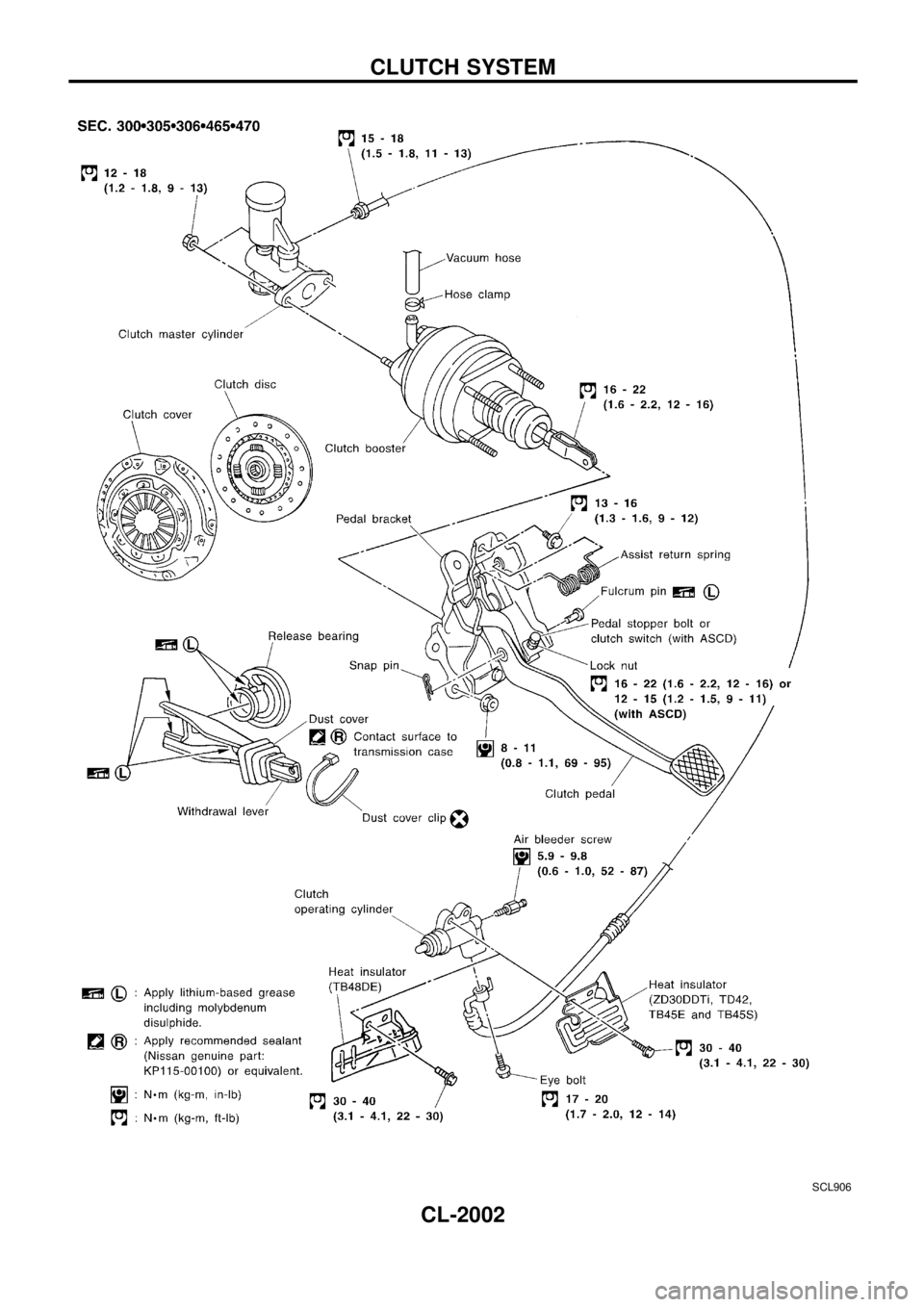

Clutch Operating Cylinder

SCL907

HYDRAULIC CLUTCH CONTROL

CL-2003

Page 34 of 273

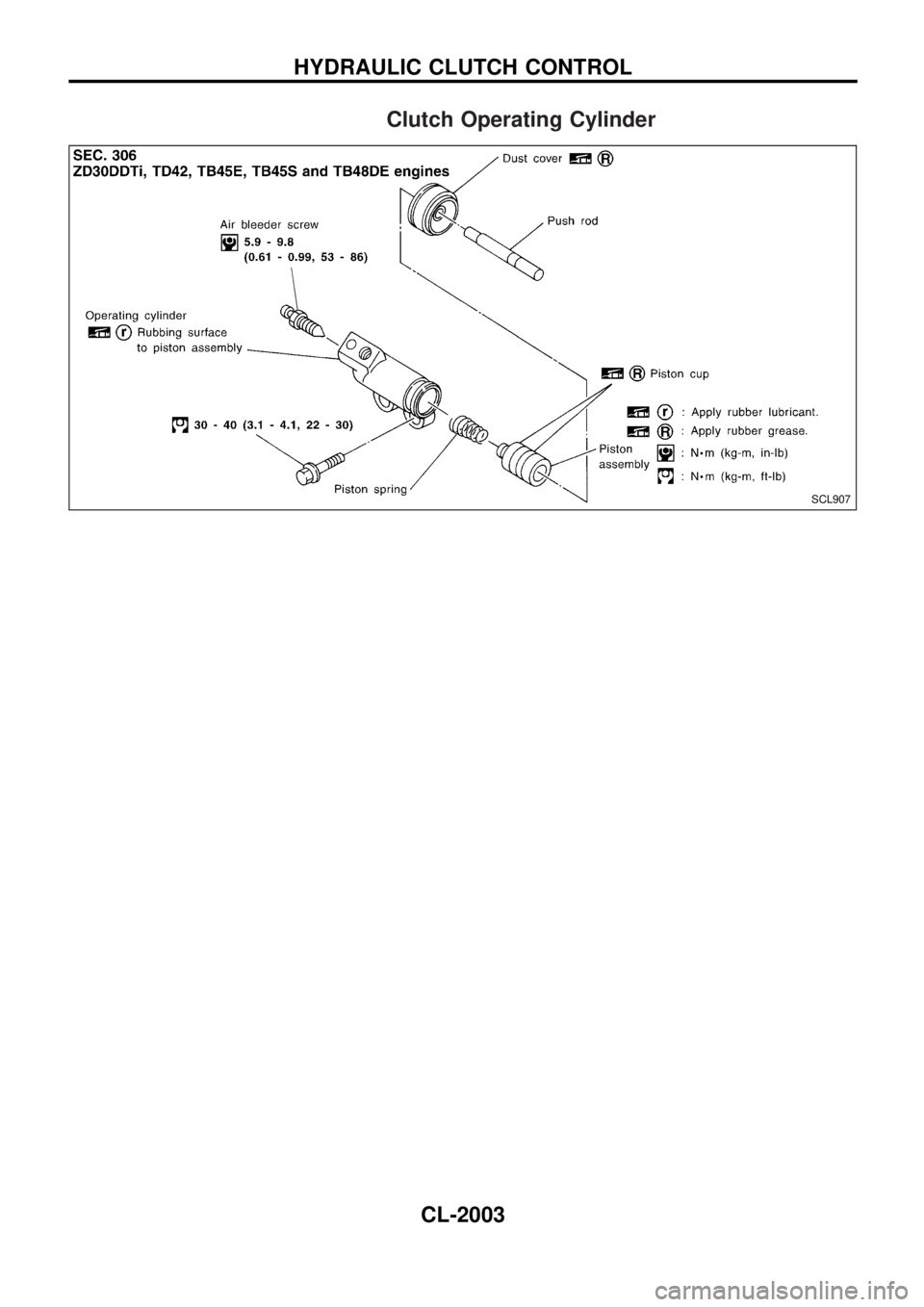

Clutch Master Cylinder

SCL908

HYDRAULIC CLUTCH CONTROL

CL-2004

Page 35 of 273

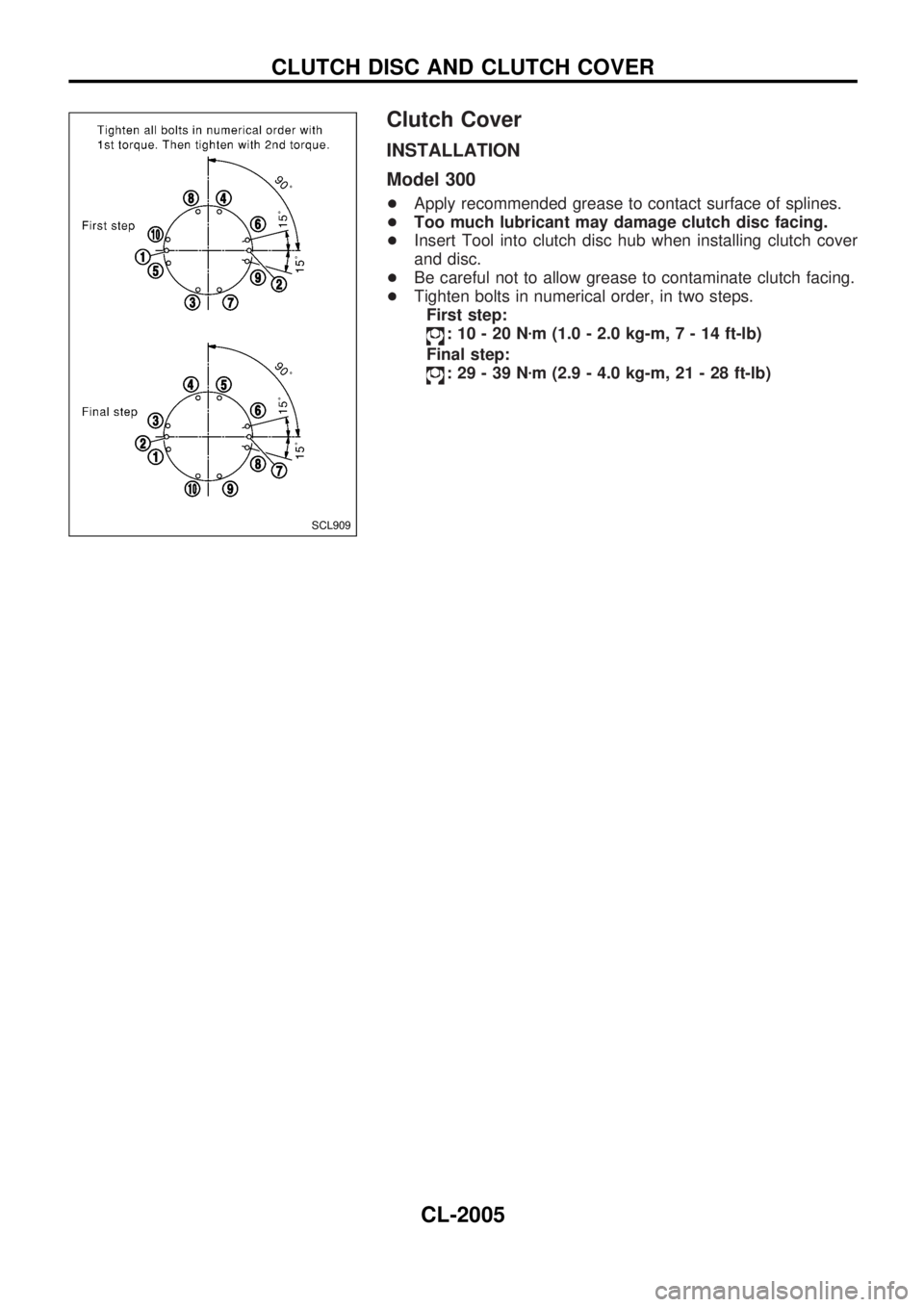

Clutch Cover

INSTALLATION

Model 300

+Apply recommended grease to contact surface of splines.

+Too much lubricant may damage clutch disc facing.

+Insert Tool into clutch disc hub when installing clutch cover

and disc.

+Be careful not to allow grease to contaminate clutch facing.

+Tighten bolts in numerical order, in two steps.

First step:

:10-20Nzm (1.0 - 2.0 kg-m,7-14ft-lb)

Final step:

:29-39Nzm (2.9 - 4.0 kg-m, 21 - 28 ft-lb)

SCL909

CLUTCH DISC AND CLUTCH COVER

CL-2005

Page 36 of 273

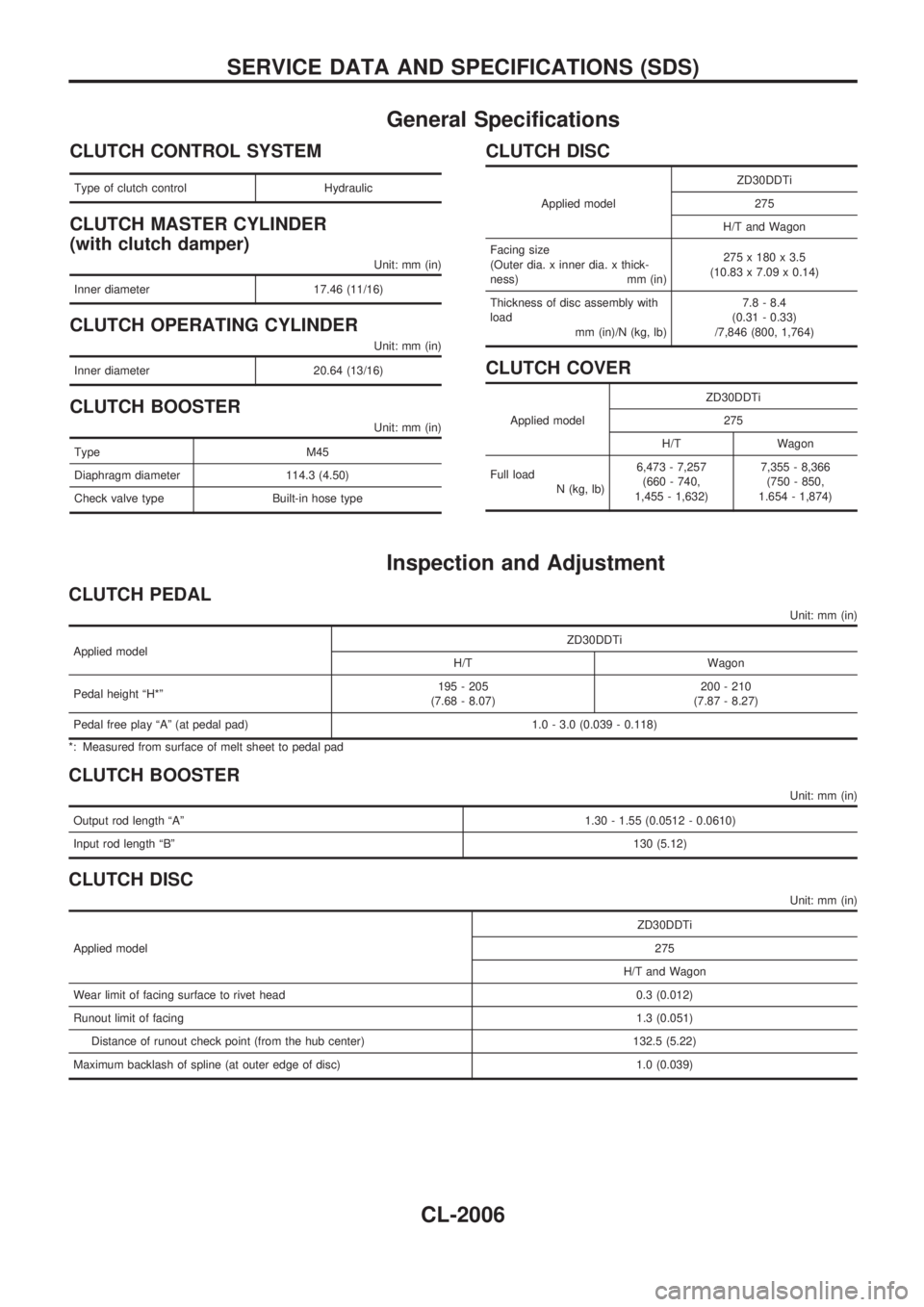

General Specifications

CLUTCH CONTROL SYSTEM

Type of clutch control Hydraulic

CLUTCH MASTER CYLINDER

(with clutch damper)

Unit: mm (in)

Inner diameter 17.46 (11/16)

CLUTCH OPERATING CYLINDER

Unit: mm (in)

Inner diameter 20.64 (13/16)

CLUTCH BOOSTER

Unit: mm (in)

Type M45

Diaphragm diameter 114.3 (4.50)

Check valve type Built-in hose type

CLUTCH DISC

Applied modelZD30DDTi

275

H/T and Wagon

Facing size

(Outer dia. x inner dia. x thick-

ness) mm (in)275 x 180 x 3.5

(10.83 x 7.09 x 0.14)

Thickness of disc assembly with

load

mm (in)/N (kg, lb)7.8 - 8.4

(0.31 - 0.33)

/7,846 (800, 1,764)

CLUTCH COVER

Applied modelZD30DDTi

275

H/T Wagon

Full load

N (kg, lb)6,473 - 7,257

(660 - 740,

1,455 - 1,632)7,355 - 8,366

(750 - 850,

1.654 - 1,874)

Inspection and Adjustment

CLUTCH PEDAL

Unit: mm (in)

Applied modelZD30DDTi

H/T Wagon

Pedal height ªH*º195 - 205

(7.68 - 8.07)200 - 210

(7.87 - 8.27)

Pedal free play ªAº (at pedal pad) 1.0 - 3.0 (0.039 - 0.118)

*: Measured from surface of melt sheet to pedal pad

CLUTCH BOOSTER

Unit: mm (in)

Output rod length ªAº1.30 - 1.55 (0.0512 - 0.0610)

Input rod length ªBº130 (5.12)

CLUTCH DISC

Unit: mm (in)

Applied modelZD30DDTi

275

H/T and Wagon

Wear limit of facing surface to rivet head 0.3 (0.012)

Runout limit of facing1.3 (0.051)

Distance of runout check point (from the hub center) 132.5 (5.22)

Maximum backlash of spline (at outer edge of disc) 1.0 (0.039)

SERVICE DATA AND SPECIFICATIONS (SDS)

CL-2006

Page 37 of 273

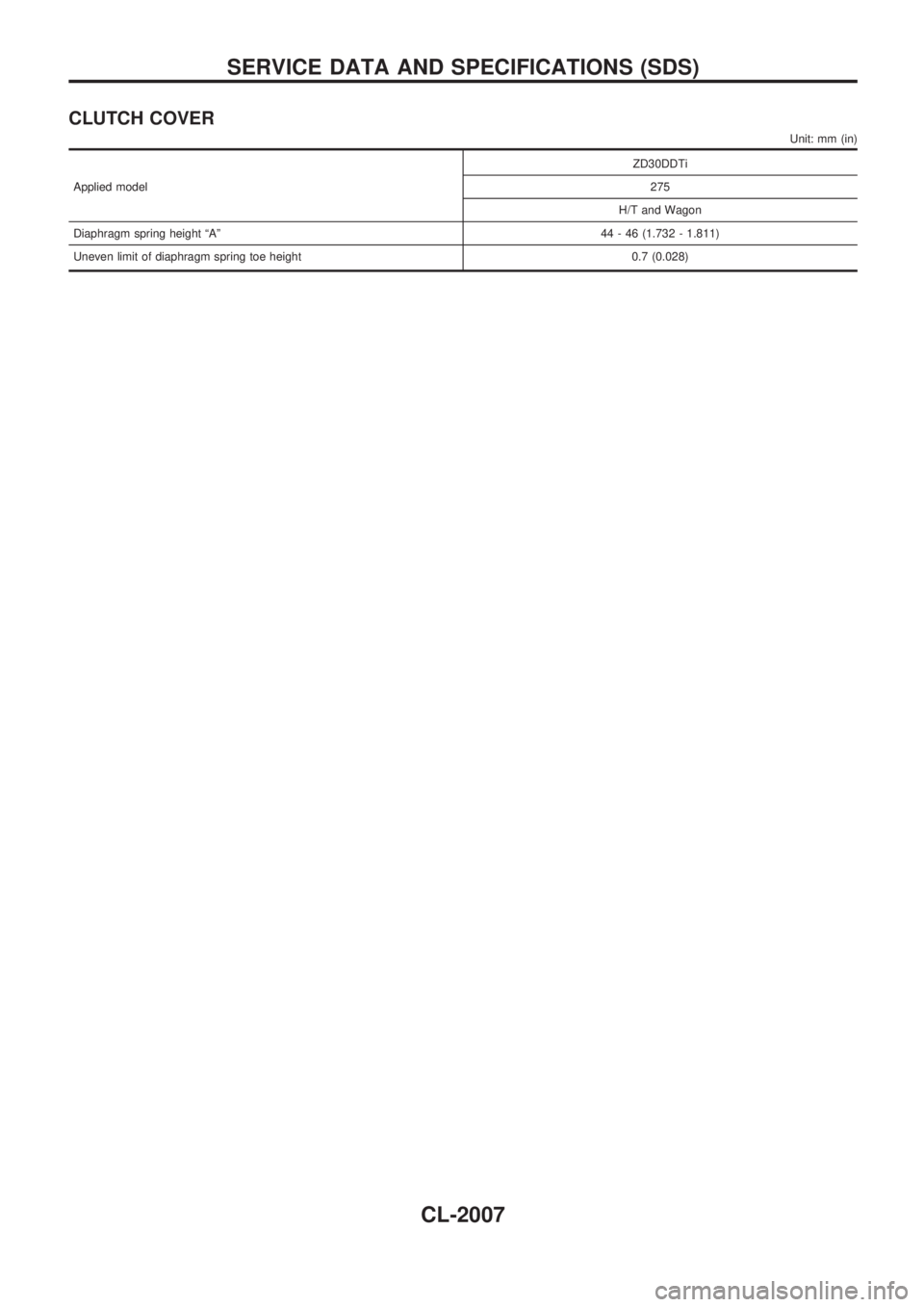

CLUTCH COVER

Unit: mm (in)

Applied modelZD30DDTi

275

H/T and Wagon

Diaphragm spring height ªAº44 - 46 (1.732 - 1.811)

Uneven limit of diaphragm spring toe height 0.7 (0.028)

SERVICE DATA AND SPECIFICATIONS (SDS)

CL-2007

Page 38 of 273

ENGINE CONTROL SYSTEM

SECTION

EC

CONTENTS

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM............................................................... 2003

Circuit Diagram ................................................ 2003

TROUBLE DIAGNOSIS FOR POWER

SUPPLY............................................................... 2004

Main Power Supply and Ground Circuit .......... 2004

DTC 0102 MASS AIR FLOW SEN...................... 2006

Wiring Diagram ................................................ 2006

DTC 0103 COOLANT TEMP SEN...................... 2007

Wiring Diagram ................................................ 2007

DTC 0104 VEHICLE SPEED SEN...................... 2008

Wiring Diagram ................................................ 2008

DTC 0203 ACCEL POS SW (F/C)...................... 2009

Wiring Diagram ................................................ 2009

DTC 0208 OVER HEAT....................................... 2010

Wiring Diagram ................................................ 2010

Diagnostic Procedure....................................... 2011

Component Inspection ..................................... 2016

Main 12 Causes of Overheating ...................... 2017

DTC 0402 P9zFUEL TEMP SEN......................... 2018

Wiring Diagram ................................................ 2018

DTC 0403 ACCEL POS SENSOR...................... 2019

Wiring Diagram ................................................ 2019

DTC 0504 A/T COMM LINE................................ 2021

Wiring Diagram ................................................ 2021

DTC 0701 P1zCAM POS SEN............................. 2022

Wiring Diagram ................................................ 2022

DTC 0702 P2zTDC PULSE SIG........................... 2023

Wiring Diagram ................................................ 2023

DTC 0703 P3zPUMP COMM LINE...................... 2024

Wiring Diagram ................................................ 2024

DTC 0704 P4zSPILL/V CIRC, DTC 0706

P6zSPILL VALVE................................................. 2025Wiring Diagram ................................................ 2025

DTC 0707 P7zF/INJ TIMG FB.............................. 2026

Wiring Diagram ................................................ 2026

DTC 0807 ECM 14............................................... 2027

Wiring Diagram ................................................ 2027

DTC 0902 ECM RLY........................................... 2028

Wiring Diagram ................................................ 2028

DTC 0905 TURBO PRESSURE.......................... 2029

Wiring Diagram ................................................ 2029

DTC 1003 EGR VOLUME CONT/V..................... 2030

Wiring Diagram ................................................ 2030

DTC 1004 FUEL CUT SYSTEM1........................ 2031

Wiring Diagram ................................................ 2031

GLOW CONTROL SYSTEM............................... 2032

Wiring Diagram ................................................ 2032

START SIGNAL................................................... 2033

Wiring Diagram ................................................ 2033

PARK/NEUTRAL POSITION (PNP) SWITCH.... 2034

Wiring Diagram ................................................ 2034

HEAT UP SWITCH.............................................. 2035

Wiring Diagram ................................................ 2035

SWIRL CONTROL VALVE CONTROL

SOLENOID VALVE.............................................. 2036

Wiring Diagram ................................................ 2036

INTAKE AIR CONTROL VALVE CONTROL

SOLENOID VALVE.............................................. 2037

Wiring Diagram ................................................ 2037

AIR CONDITIONER CONTROL.......................... 2038

Wiring Diagram ................................................ 2038

MI (MIL) & DATA LINK CONNECTORS............ 2039

Wiring Diagram ................................................ 2039

EC

Page 39 of 273

When you read wiring diagrams:

+Read GI section, ªHOW TO READ WIRING DIAGRAMSº.

+See EL section, ªPOWER SUPPLY ROUTINGº for power distribution circuit.

When you perform trouble diagnoses, read GI section, ªHOW TO FOLLOW FLOW CHART IN

TROUBLE DIAGNOSESº and ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL

INCIDENTº.

EC-2002

Page 40 of 273

Circuit Diagram

TEC095M

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

EC-2003