check engine NISSAN PATROL 2004 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: PATROL, Model: NISSAN PATROL 2004Pages: 579, PDF Size: 26.61 MB

Page 22 of 579

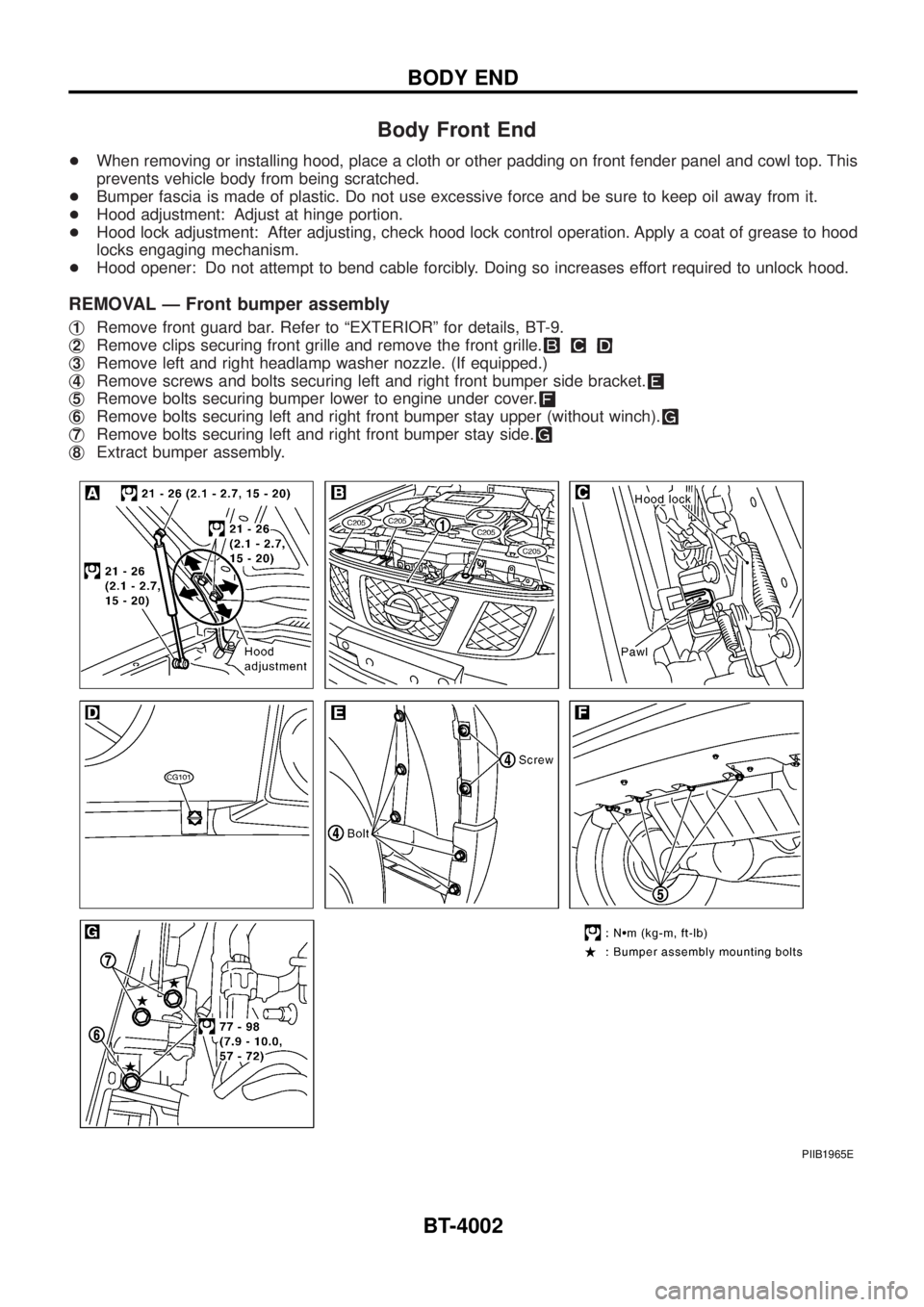

Body Front End

+When removing or installing hood, place a cloth or other padding on front fender panel and cowl top. This

prevents vehicle body from being scratched.

+Bumper fascia is made of plastic. Do not use excessive force and be sure to keep oil away from it.

+Hood adjustment: Adjust at hinge portion.

+Hood lock adjustment: After adjusting, check hood lock control operation. Apply a coat of grease to hood

locks engaging mechanism.

+Hood opener: Do not attempt to bend cable forcibly. Doing so increases effort required to unlock hood.

REMOVAL Ð Front bumper assembly

j1Remove front guard bar. Refer to ªEXTERIORº for details, BT-9.

j

2Remove clips securing front grille and remove the front grille.

j3Remove left and right headlamp washer nozzle. (If equipped.)

j

4Remove screws and bolts securing left and right front bumper side bracket.

j5Remove bolts securing bumper lower to engine under cover.

j6Remove bolts securing left and right front bumper stay upper (without winch).

j7Remove bolts securing left and right front bumper stay side.

j8Extract bumper assembly.

PIIB1965E

BODY END

BT-4002

Page 46 of 579

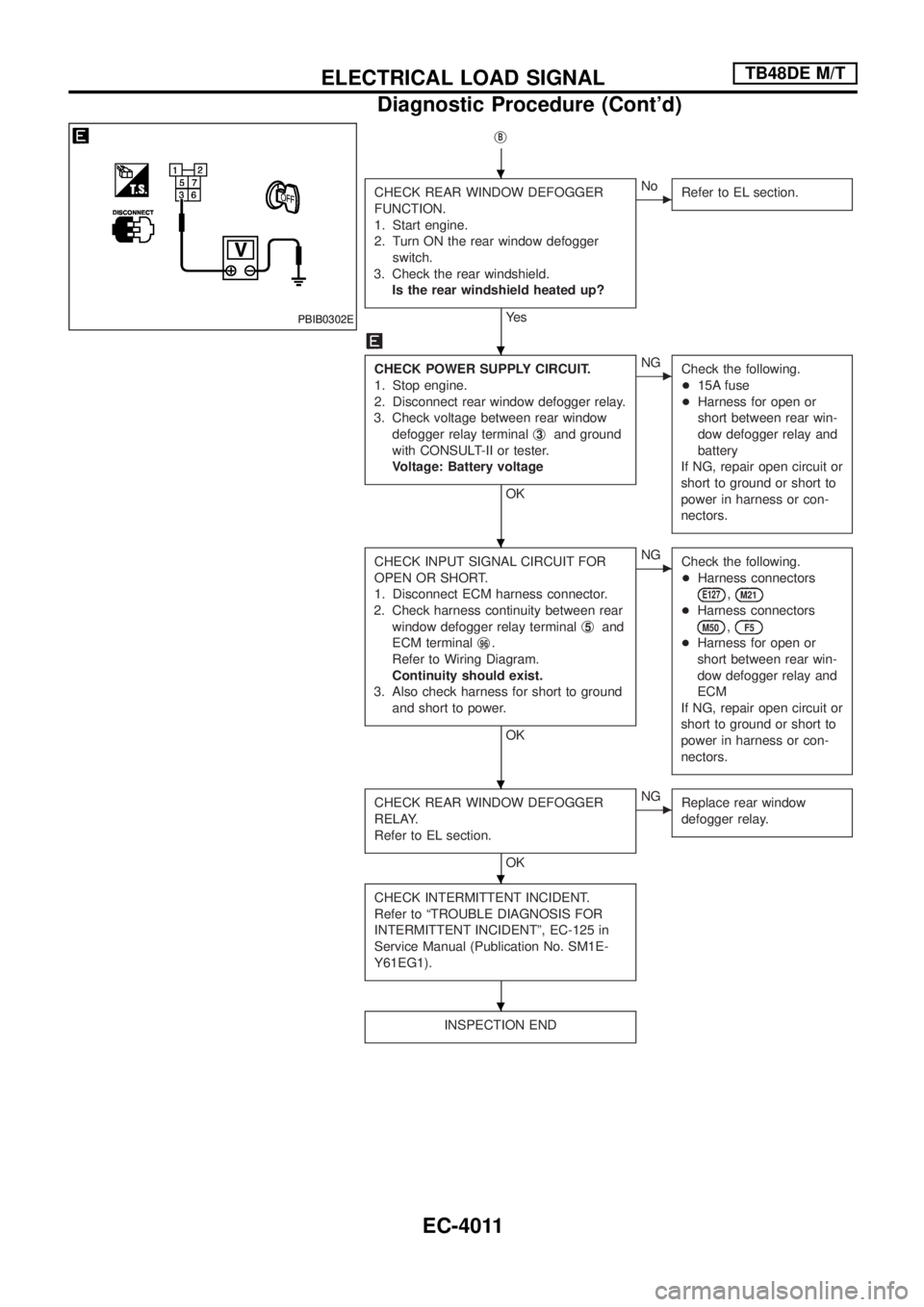

jB

CHECK REAR WINDOW DEFOGGER

FUNCTION.

1. Start engine.

2. Turn ON the rear window defogger

switch.

3. Check the rear windshield.

Is the rear windshield heated up?

Ye s

cNo

Refer to EL section.

CHECK POWER SUPPLY CIRCUIT.

1. Stop engine.

2. Disconnect rear window defogger relay.

3. Check voltage between rear window

defogger relay terminalj

3and ground

with CONSULT-II or tester.

Voltage: Battery voltage

OK

cNG

Check the following.

+15A fuse

+Harness for open or

short between rear win-

dow defogger relay and

battery

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

CHECK INPUT SIGNAL CIRCUIT FOR

OPEN OR SHORT.

1. Disconnect ECM harness connector.

2. Check harness continuity between rear

window defogger relay terminalj

5and

ECM terminalj

96.

Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground

and short to power.

OK

cNG

Check the following.

+Harness connectors

E127,M21

+Harness connectors

M50,F5

+Harness for open or

short between rear win-

dow defogger relay and

ECM

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

CHECK REAR WINDOW DEFOGGER

RELAY.

Refer to EL section.

OK

cNG

Replace rear window

defogger relay.

CHECK INTERMITTENT INCIDENT.

Refer to ªTROUBLE DIAGNOSIS FOR

INTERMITTENT INCIDENTº, EC-125 in

Service Manual (Publication No. SM1E-

Y61EG1).

INSPECTION END

PBIB0302E

.

.

.

.

.

.

ELECTRICAL LOAD SIGNALTB48DE M/T

Diagnostic Procedure (Cont'd)

EC-4011

Page 54 of 579

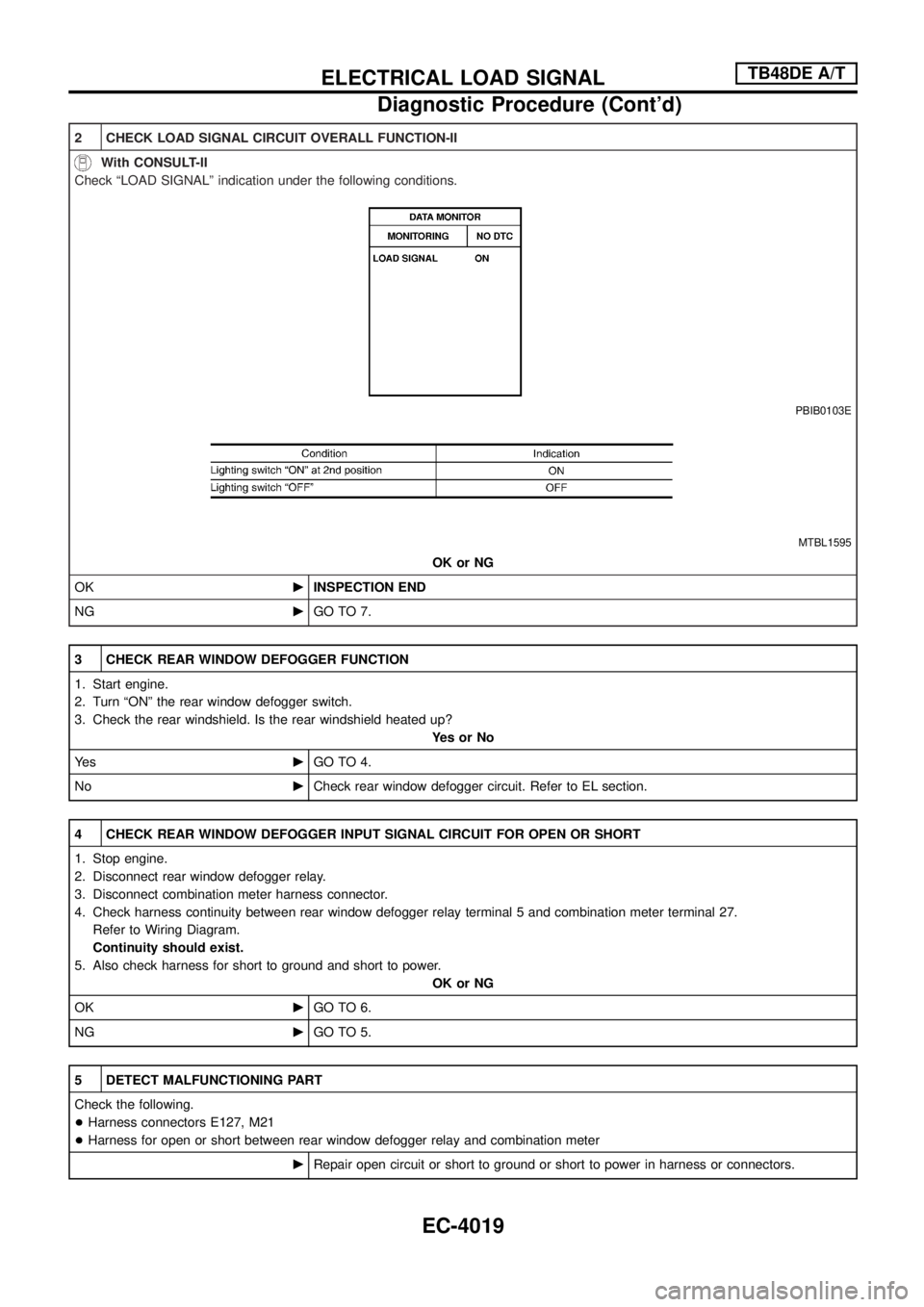

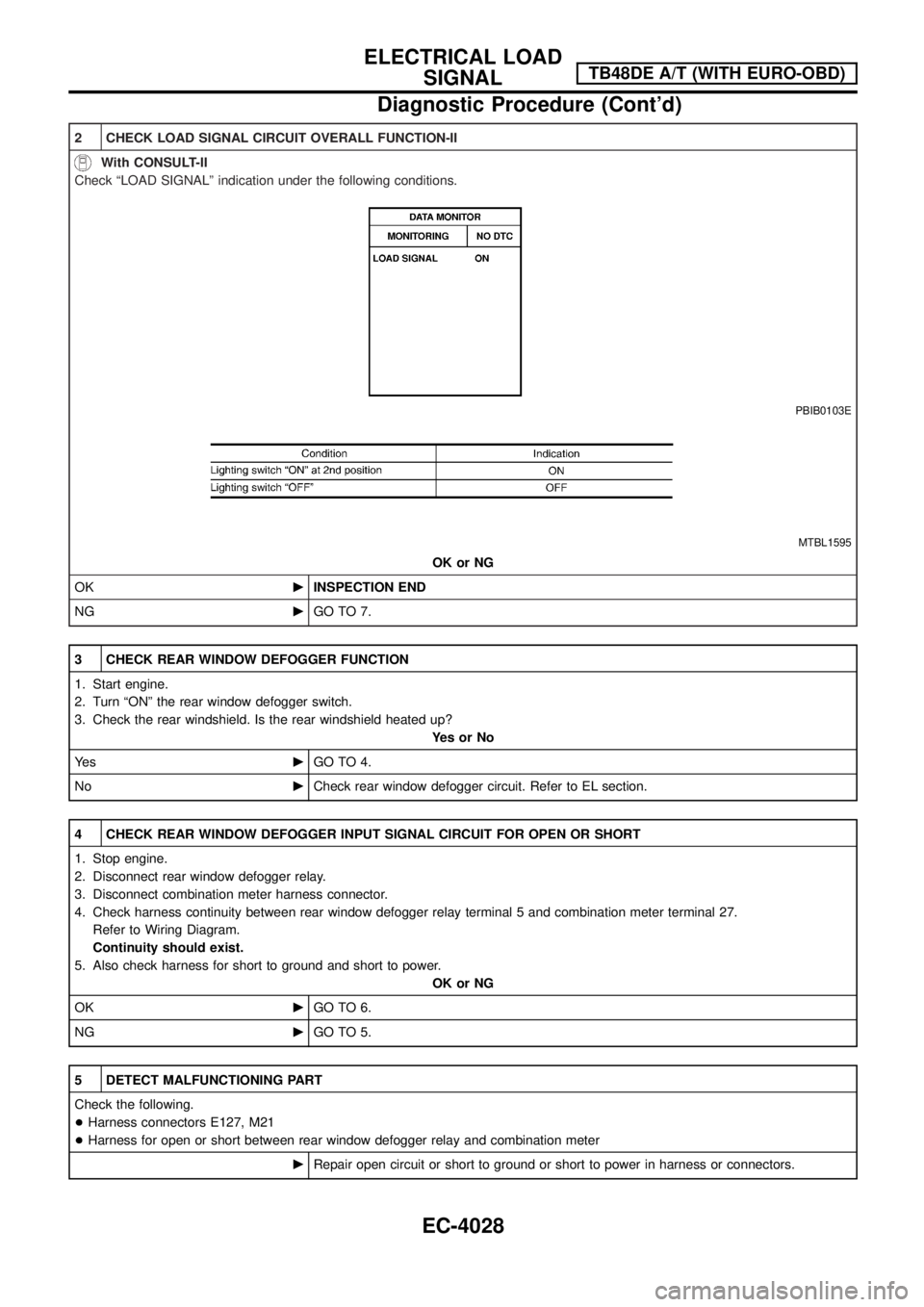

2 CHECK LOAD SIGNAL CIRCUIT OVERALL FUNCTION-II

With CONSULT-II

Check ªLOAD SIGNALº indication under the following conditions.

PBIB0103E

MTBL1595

OK or NG

OKcINSPECTION END

NGcGO TO 7.

3 CHECK REAR WINDOW DEFOGGER FUNCTION

1. Start engine.

2. Turn ªONº the rear window defogger switch.

3. Check the rear windshield. Is the rear windshield heated up?

YesorNo

Ye scGO TO 4.

NocCheck rear window defogger circuit. Refer to EL section.

4 CHECK REAR WINDOW DEFOGGER INPUT SIGNAL CIRCUIT FOR OPEN OR SHORT

1. Stop engine.

2. Disconnect rear window defogger relay.

3. Disconnect combination meter harness connector.

4. Check harness continuity between rear window defogger relay terminal 5 and combination meter terminal 27.

Refer to Wiring Diagram.

Continuity should exist.

5. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 6.

NGcGO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E127, M21

+Harness for open or short between rear window defogger relay and combination meter

cRepair open circuit or short to ground or short to power in harness or connectors.

ELECTRICAL LOAD SIGNALTB48DE A/T

Diagnostic Procedure (Cont'd)

EC-4019

Page 55 of 579

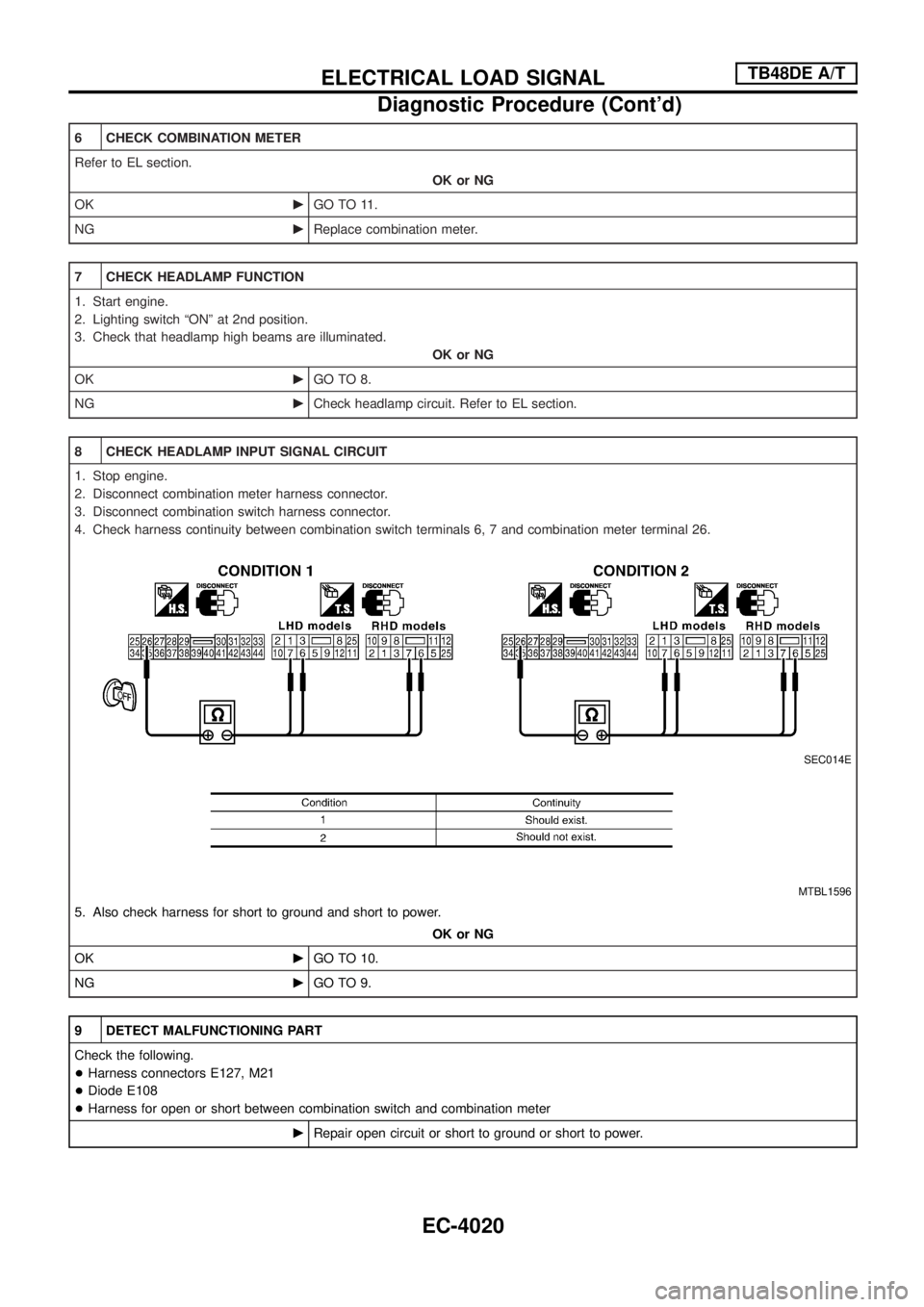

6 CHECK COMBINATION METER

Refer to EL section.

OK or NG

OKcGO TO 11.

NGcReplace combination meter.

7 CHECK HEADLAMP FUNCTION

1. Start engine.

2. Lighting switch ªONº at 2nd position.

3. Check that headlamp high beams are illuminated.

OK or NG

OKcGO TO 8.

NGcCheck headlamp circuit. Refer to EL section.

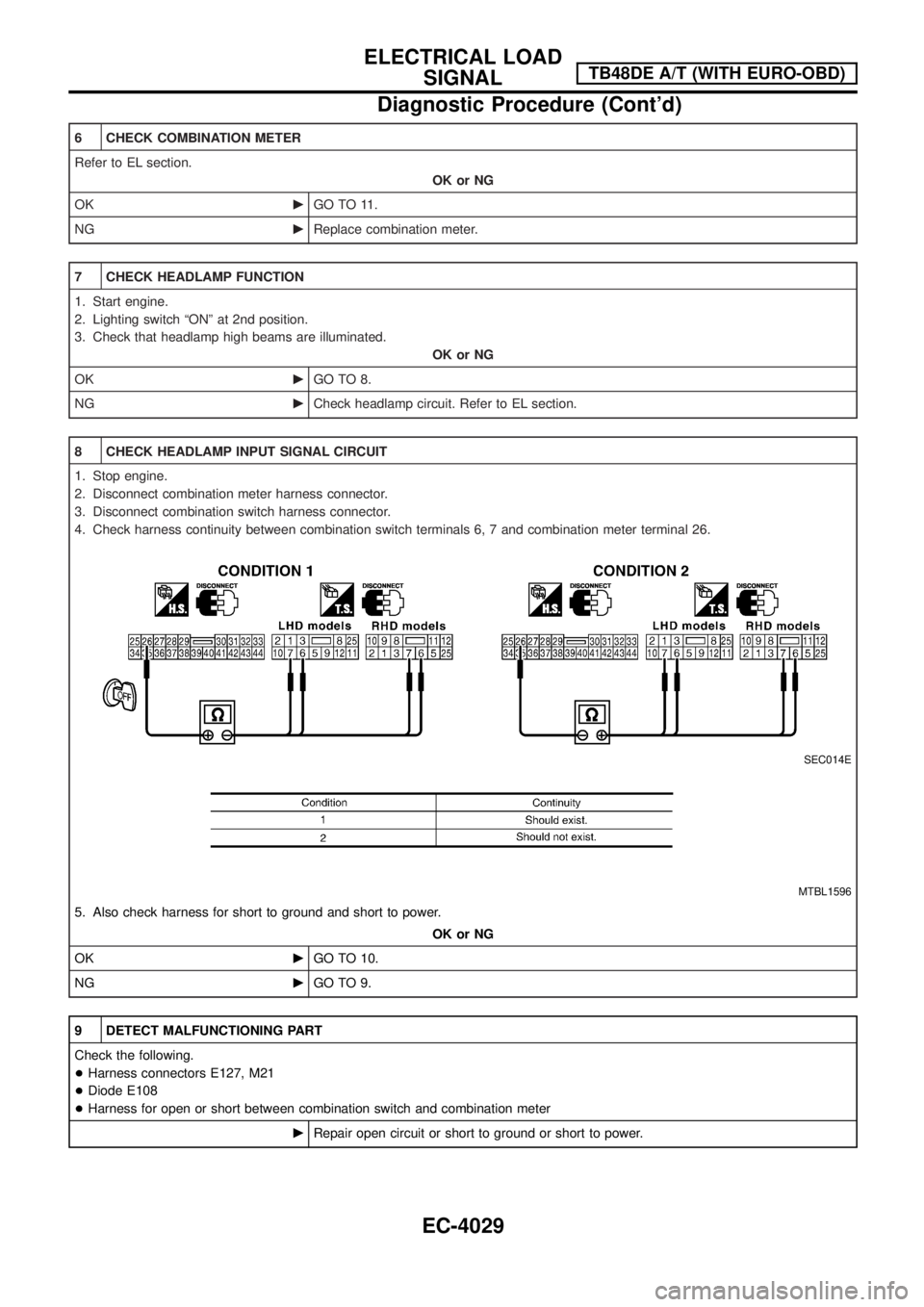

8 CHECK HEADLAMP INPUT SIGNAL CIRCUIT

1. Stop engine.

2. Disconnect combination meter harness connector.

3. Disconnect combination switch harness connector.

4. Check harness continuity between combination switch terminals 6, 7 and combination meter terminal 26.

SEC014E

MTBL1596

5. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 10.

NGcGO TO 9.

9 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E127, M21

+Diode E108

+Harness for open or short between combination switch and combination meter

cRepair open circuit or short to ground or short to power.

ELECTRICAL LOAD SIGNALTB48DE A/T

Diagnostic Procedure (Cont'd)

EC-4020

Page 63 of 579

2 CHECK LOAD SIGNAL CIRCUIT OVERALL FUNCTION-II

With CONSULT-II

Check ªLOAD SIGNALº indication under the following conditions.

PBIB0103E

MTBL1595

OK or NG

OKcINSPECTION END

NGcGO TO 7.

3 CHECK REAR WINDOW DEFOGGER FUNCTION

1. Start engine.

2. Turn ªONº the rear window defogger switch.

3. Check the rear windshield. Is the rear windshield heated up?

YesorNo

Ye scGO TO 4.

NocCheck rear window defogger circuit. Refer to EL section.

4 CHECK REAR WINDOW DEFOGGER INPUT SIGNAL CIRCUIT FOR OPEN OR SHORT

1. Stop engine.

2. Disconnect rear window defogger relay.

3. Disconnect combination meter harness connector.

4. Check harness continuity between rear window defogger relay terminal 5 and combination meter terminal 27.

Refer to Wiring Diagram.

Continuity should exist.

5. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 6.

NGcGO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E127, M21

+Harness for open or short between rear window defogger relay and combination meter

cRepair open circuit or short to ground or short to power in harness or connectors.

ELECTRICAL LOAD

SIGNALTB48DE A/T (WITH EURO-OBD)

Diagnostic Procedure (Cont'd)

EC-4028

Page 64 of 579

6 CHECK COMBINATION METER

Refer to EL section.

OK or NG

OKcGO TO 11.

NGcReplace combination meter.

7 CHECK HEADLAMP FUNCTION

1. Start engine.

2. Lighting switch ªONº at 2nd position.

3. Check that headlamp high beams are illuminated.

OK or NG

OKcGO TO 8.

NGcCheck headlamp circuit. Refer to EL section.

8 CHECK HEADLAMP INPUT SIGNAL CIRCUIT

1. Stop engine.

2. Disconnect combination meter harness connector.

3. Disconnect combination switch harness connector.

4. Check harness continuity between combination switch terminals 6, 7 and combination meter terminal 26.

SEC014E

MTBL1596

5. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 10.

NGcGO TO 9.

9 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E127, M21

+Diode E108

+Harness for open or short between combination switch and combination meter

cRepair open circuit or short to ground or short to power.

ELECTRICAL LOAD

SIGNALTB48DE A/T (WITH EURO-OBD)

Diagnostic Procedure (Cont'd)

EC-4029

Page 73 of 579

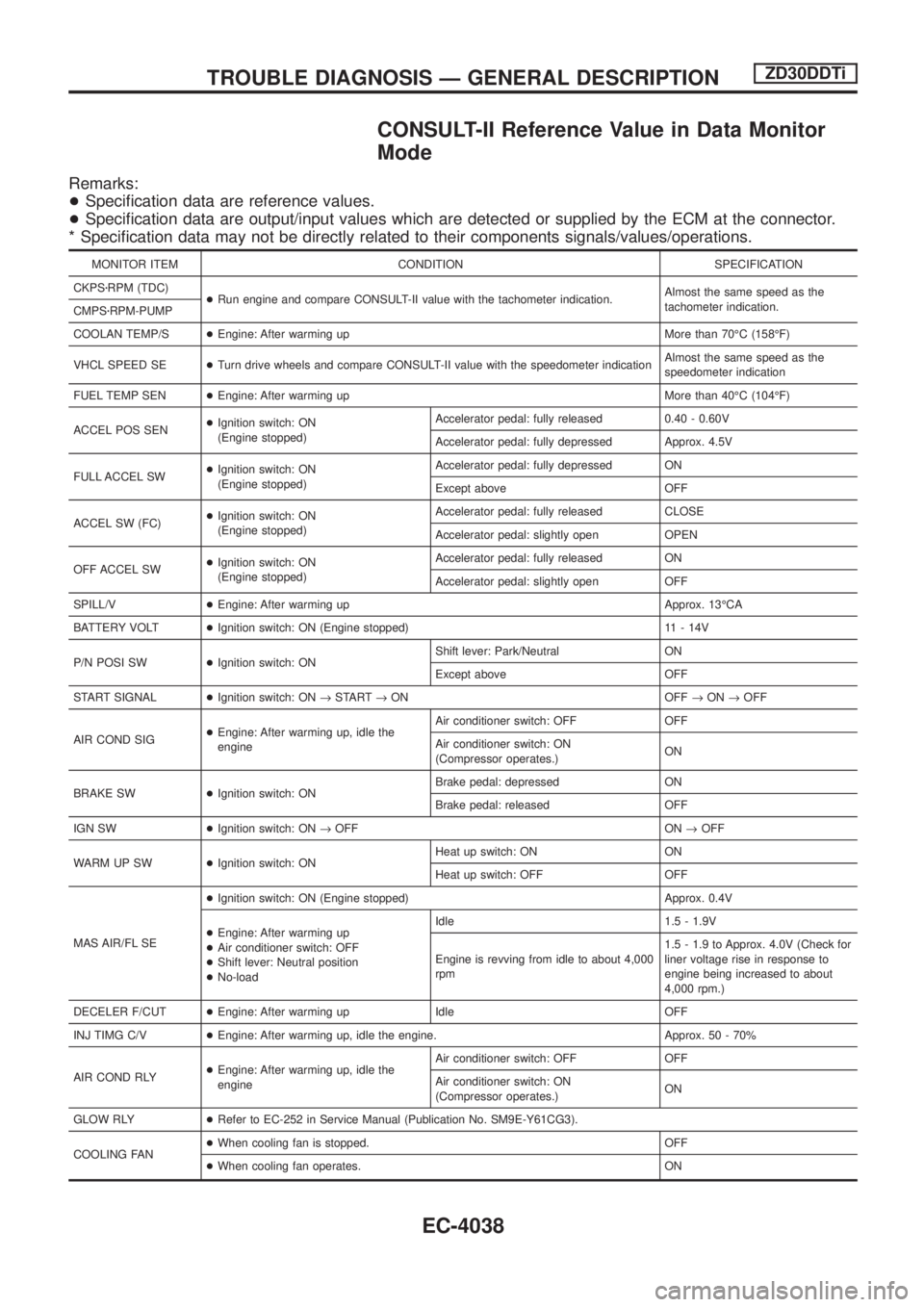

CONSULT-II Reference Value in Data Monitor

Mode

Remarks:

+Speci®cation data are reference values.

+Speci®cation data are output/input values which are detected or supplied by the ECM at the connector.

* Speci®cation data may not be directly related to their components signals/values/operations.

MONITOR ITEM CONDITION SPECIFICATION

CKPSzRPM (TDC)

+Run engine and compare CONSULT-II value with the tachometer indication.Almost the same speed as the

tachometer indication.

CMPSzRPM-PUMP

COOLAN TEMP/S+Engine: After warming up More than 70ÉC (158ÉF)

VHCL SPEED SE+Turn drive wheels and compare CONSULT-II value with the speedometer indicationAlmost the same speed as the

speedometer indication

FUEL TEMP SEN+Engine: After warming up More than 40ÉC (104ÉF)

ACCEL POS SEN+Ignition switch: ON

(Engine stopped)Accelerator pedal: fully released 0.40 - 0.60V

Accelerator pedal: fully depressed Approx. 4.5V

FULL ACCEL SW+Ignition switch: ON

(Engine stopped)Accelerator pedal: fully depressed ON

Except above OFF

ACCEL SW (FC)+Ignition switch: ON

(Engine stopped)Accelerator pedal: fully released CLOSE

Accelerator pedal: slightly open OPEN

OFF ACCEL SW+Ignition switch: ON

(Engine stopped)Accelerator pedal: fully released ON

Accelerator pedal: slightly open OFF

SPILL/V+Engine: After warming up Approx. 13ÉCA

BATTERY VOLT+Ignition switch: ON (Engine stopped) 11 - 14V

P/N POSI SW+Ignition switch: ONShift lever: Park/Neutral ON

Except above OFF

START SIGNAL+Ignition switch: ON®START®ON OFF®ON®OFF

AIR COND SIG+Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)ON

BRAKE SW+Ignition switch: ONBrake pedal: depressed ON

Brake pedal: released OFF

IGN SW+Ignition switch: ON®OFF ON®OFF

WARM UP SW+Ignition switch: ONHeat up switch: ON ON

Heat up switch: OFF OFF

MAS AIR/FL SE+Ignition switch: ON (Engine stopped) Approx. 0.4V

+Engine: After warming up

+Air conditioner switch: OFF

+Shift lever: Neutral position

+No-loadIdle 1.5 - 1.9V

Engine is revving from idle to about 4,000

rpm1.5 - 1.9 to Approx. 4.0V (Check for

liner voltage rise in response to

engine being increased to about

4,000 rpm.)

DECELER F/CUT+Engine: After warming up Idle OFF

INJ TIMG C/V+Engine: After warming up, idle the engine. Approx. 50 - 70%

AIR COND RLY+Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)ON

GLOW RLY+Refer to EC-252 in Service Manual (Publication No. SM9E-Y61CG3).

COOLING FAN+When cooling fan is stopped. OFF

+When cooling fan operates. ON

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

EC-4038

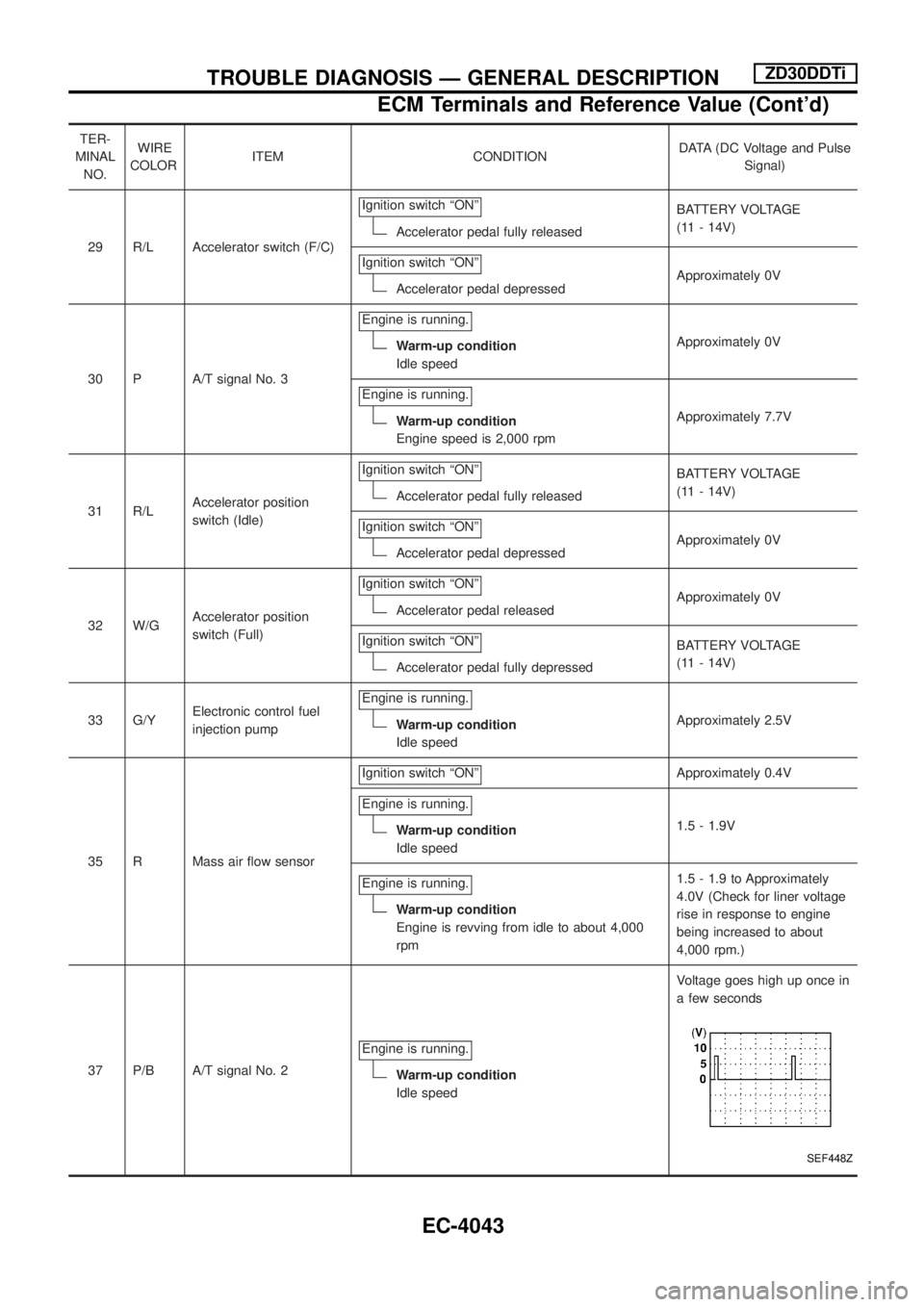

Page 78 of 579

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and Pulse

Signal)

29 R/L Accelerator switch (F/C)Ignition switch ªONº

Accelerator pedal fully releasedBATTERY VOLTAGE

(11 - 14V)

Ignition switch ªONº

Accelerator pedal depressedApproximately 0V

30 P A/T signal No. 3Engine is running.

Warm-up condition

Idle speedApproximately 0V

Engine is running.

Warm-up condition

Engine speed is 2,000 rpmApproximately 7.7V

31 R/LAccelerator position

switch (Idle)Ignition switch ªONº

Accelerator pedal fully releasedBATTERY VOLTAGE

(11 - 14V)

Ignition switch ªONº

Accelerator pedal depressedApproximately 0V

32 W/GAccelerator position

switch (Full)Ignition switch ªONº

Accelerator pedal releasedApproximately 0V

Ignition switch ªONº

Accelerator pedal fully depressedBATTERY VOLTAGE

(11 - 14V)

33 G/YElectronic control fuel

injection pumpEngine is running.

Warm-up condition

Idle speedApproximately 2.5V

35 R Mass air ¯ow sensorIgnition switch ªONº

Approximately 0.4V

Engine is running.

Warm-up condition

Idle speed1.5 - 1.9V

Engine is running.

Warm-up condition

Engine is revving from idle to about 4,000

rpm1.5 - 1.9 to Approximately

4.0V (Check for liner voltage

rise in response to engine

being increased to about

4,000 rpm.)

37 P/B A/T signal No. 2Engine is running.

Warm-up condition

Idle speedVoltage goes high up once in

a few seconds

SEF448Z

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

ECM Terminals and Reference Value (Cont'd)

EC-4043

Page 82 of 579

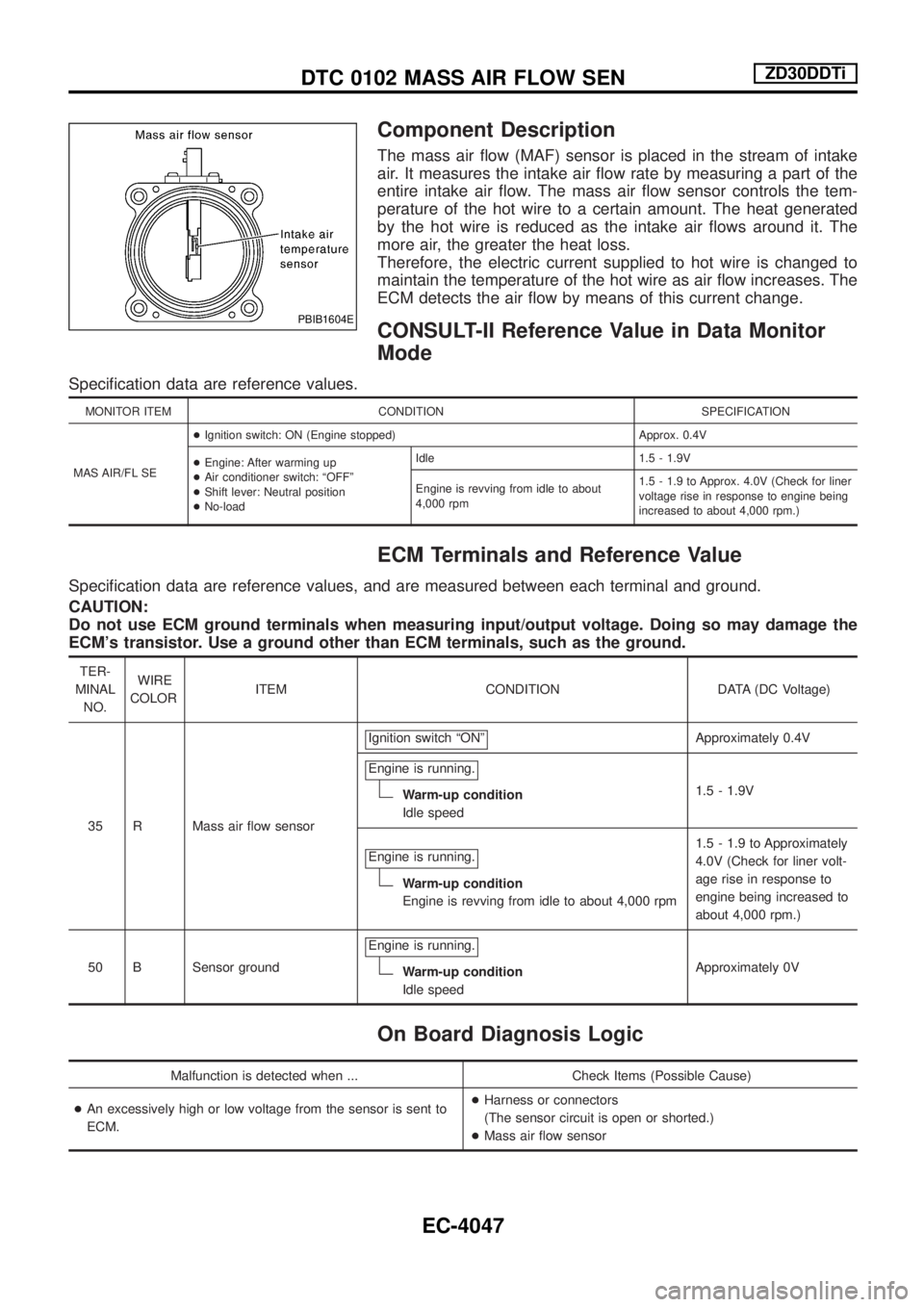

Component Description

The mass air ¯ow (MAF) sensor is placed in the stream of intake

air. It measures the intake air ¯ow rate by measuring a part of the

entire intake air ¯ow. The mass air ¯ow sensor controls the tem-

perature of the hot wire to a certain amount. The heat generated

by the hot wire is reduced as the intake air ¯ows around it. The

more air, the greater the heat loss.

Therefore, the electric current supplied to hot wire is changed to

maintain the temperature of the hot wire as air ¯ow increases. The

ECM detects the air ¯ow by means of this current change.

CONSULT-II Reference Value in Data Monitor

Mode

Speci®cation data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

MAS AIR/FL SE+Ignition switch: ON (Engine stopped) Approx. 0.4V

+Engine: After warming up

+Air conditioner switch: ªOFFº

+Shift lever: Neutral position

+No-loadIdle 1.5 - 1.9V

Engine is revving from idle to about

4,000 rpm1.5 - 1.9 to Approx. 4.0V (Check for liner

voltage rise in response to engine being

increased to about 4,000 rpm.)

ECM Terminals and Reference Value

Speci®cation data are reference values, and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

35 R Mass air ¯ow sensorIgnition switch ªONº

Approximately 0.4V

Engine is running.

Warm-up condition

Idle speed1.5 - 1.9V

Engine is running.

Warm-up condition

Engine is revving from idle to about 4,000 rpm1.5 - 1.9 to Approximately

4.0V (Check for liner volt-

age rise in response to

engine being increased to

about 4,000 rpm.)

50 B Sensor groundEngine is running.

Warm-up condition

Idle speedApproximately 0V

On Board Diagnosis Logic

Malfunction is detected when ... Check Items (Possible Cause)

+An excessively high or low voltage from the sensor is sent to

ECM.+Harness or connectors

(The sensor circuit is open or shorted.)

+Mass air ¯ow sensor

PBIB1604E

DTC 0102 MASS AIR FLOW SENZD30DDTi

EC-4047

Page 86 of 579

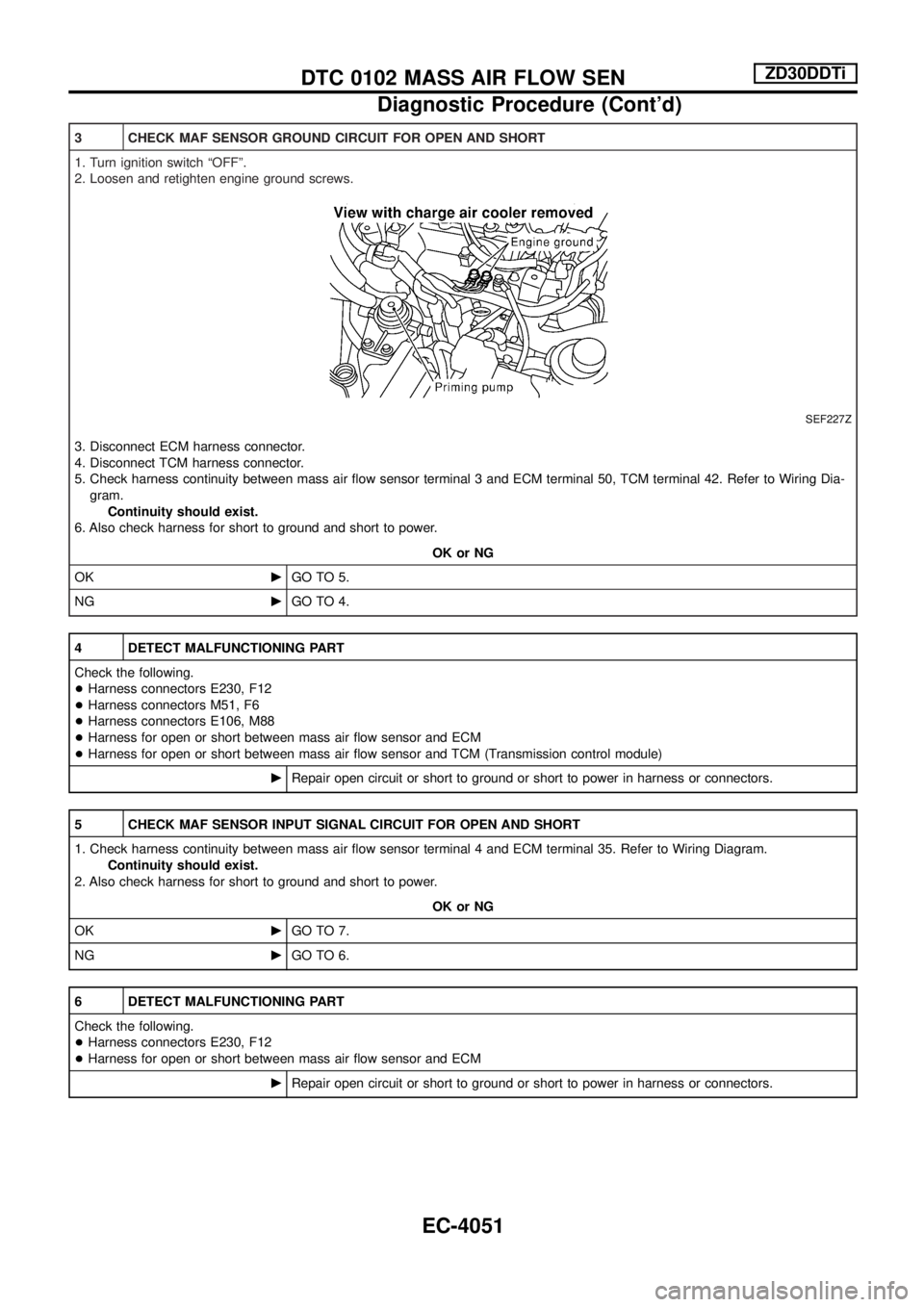

3 CHECK MAF SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

SEF227Z

3. Disconnect ECM harness connector.

4. Disconnect TCM harness connector.

5. Check harness continuity between mass air ¯ow sensor terminal 3 and ECM terminal 50, TCM terminal 42. Refer to Wiring Dia-

gram.

Continuity should exist.

6. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 5.

NGcGO TO 4.

4 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E230, F12

+Harness connectors M51, F6

+Harness connectors E106, M88

+Harness for open or short between mass air ¯ow sensor and ECM

+Harness for open or short between mass air ¯ow sensor and TCM (Transmission control module)

cRepair open circuit or short to ground or short to power in harness or connectors.

5 CHECK MAF SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between mass air ¯ow sensor terminal 4 and ECM terminal 35. Refer to Wiring Diagram.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 7.

NGcGO TO 6.

6 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E230, F12

+Harness for open or short between mass air ¯ow sensor and ECM

cRepair open circuit or short to ground or short to power in harness or connectors.

DTC 0102 MASS AIR FLOW SENZD30DDTi

Diagnostic Procedure (Cont'd)

EC-4051