meter NISSAN PATROL 2004 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: PATROL, Model: NISSAN PATROL 2004Pages: 579, PDF Size: 26.61 MB

Page 20 of 579

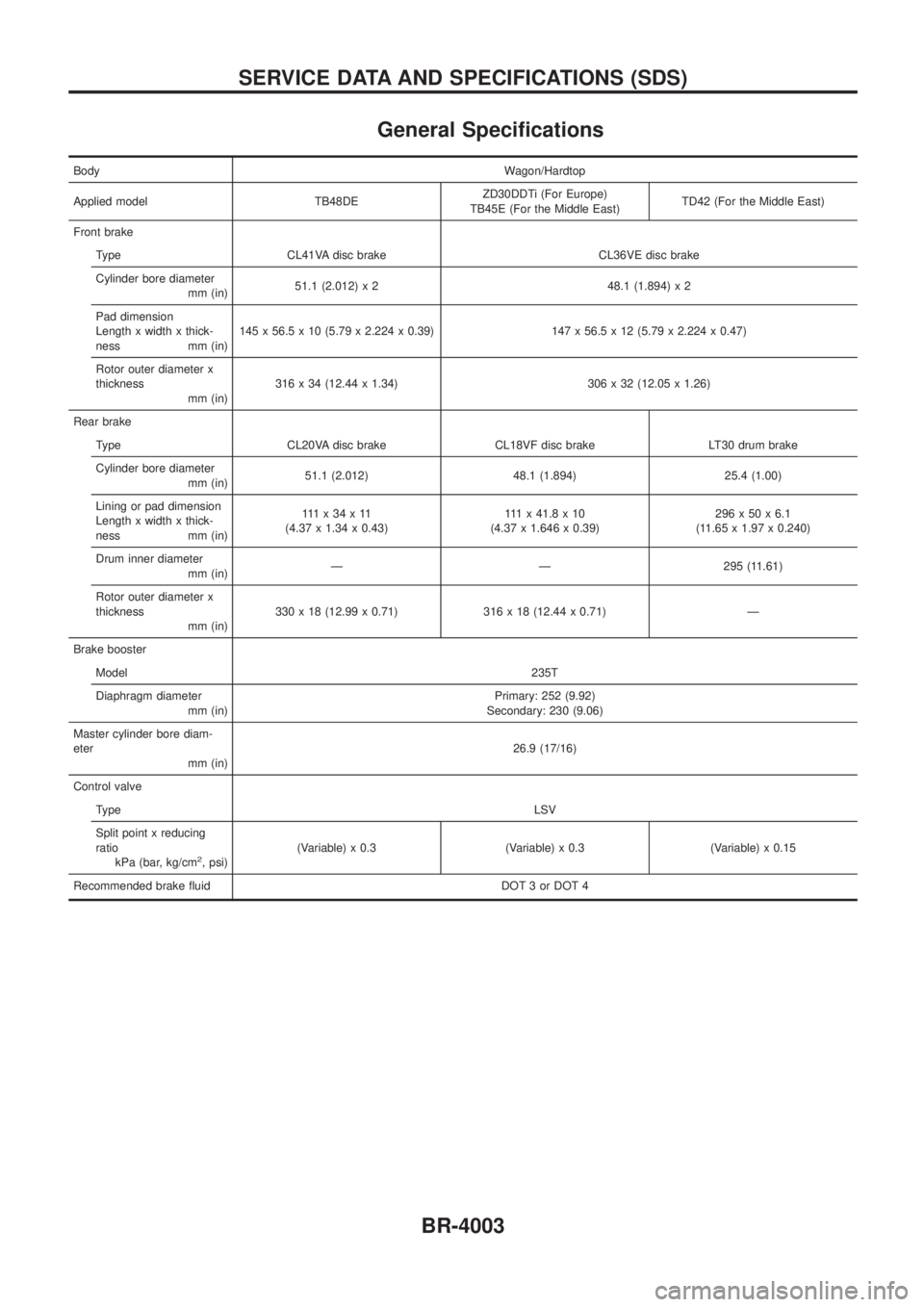

General Speci®cations

BodyWagon/Hardtop

Applied model TB48DEZD30DDTi (For Europe)

TB45E (For the Middle East)TD42 (For the Middle East)

Front brake

Type CL41VA disc brake CL36VE disc brake

Cylinder bore diameter

mm (in)51.1 (2.012) x 2 48.1 (1.894) x 2

Pad dimension

Length x width x thick-

ness mm (in)145 x 56.5 x 10 (5.79 x 2.224 x 0.39) 147 x 56.5 x 12 (5.79 x 2.224 x 0.47)

Rotor outer diameter x

thickness

mm (in)316 x 34 (12.44 x 1.34) 306 x 32 (12.05 x 1.26)

Rear brake

Type CL20VA disc brake CL18VF disc brake LT30 drum brake

Cylinder bore diameter

mm (in)51.1 (2.012) 48.1 (1.894) 25.4 (1.00)

Lining or pad dimension

Length x width x thick-

ness mm (in)111x34x11

(4.37 x 1.34 x 0.43)111x41.8x10

(4.37 x 1.646 x 0.39)296x50x6.1

(11.65 x 1.97 x 0.240)

Drum inner diameter

mm (in)Ð Ð 295 (11.61)

Rotor outer diameter x

thickness

mm (in)330 x 18 (12.99 x 0.71) 316 x 18 (12.44 x 0.71) Ð

Brake booster

Model235T

Diaphragm diameter

mm (in)Primary: 252 (9.92)

Secondary: 230 (9.06)

Master cylinder bore diam-

eter

mm (in)26.9 (17/16)

Control valve

TypeLSV

Split point x reducing

ratio

kPa (bar, kg/cm

2, psi)(Variable) x 0.3 (Variable) x 0.3 (Variable) x 0.15

Recommended brake ¯uid DOT 3 or DOT 4

SERVICE DATA AND SPECIFICATIONS (SDS)

BR-4003

Page 26 of 579

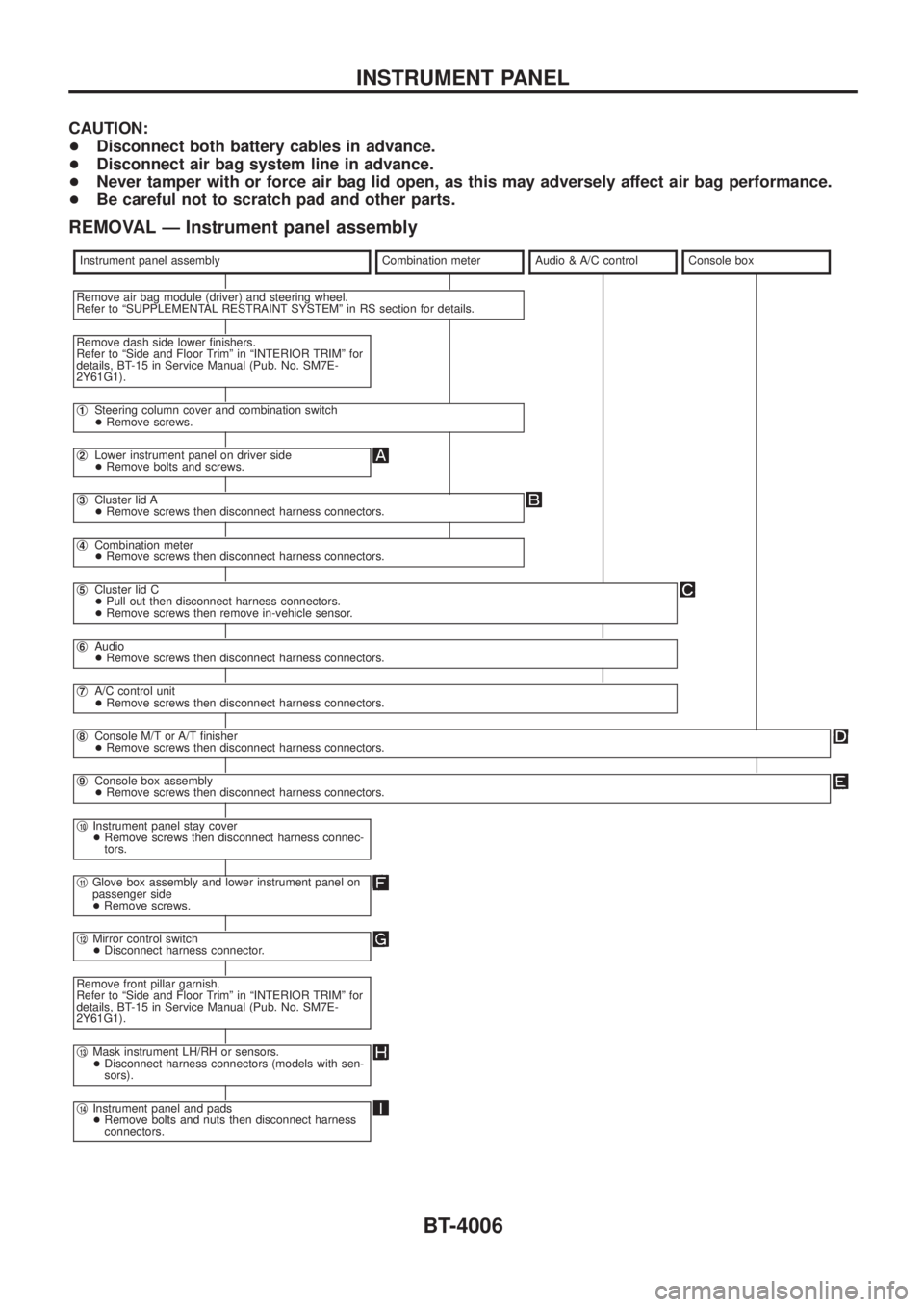

CAUTION:

+Disconnect both battery cables in advance.

+Disconnect air bag system line in advance.

+Never tamper with or force air bag lid open, as this may adversely affect air bag performance.

+Be careful not to scratch pad and other parts.

REMOVAL Ð Instrument panel assembly

Instrument panel assemblyCombination meterAudio & A/C controlConsole box

Remove air bag module (driver) and steering wheel.

Refer to ªSUPPLEMENTAL RESTRAINT SYSTEMº in RS section for details.

Remove dash side lower ®nishers.

Refer to ªSide and Floor Trimº in ªINTERIOR TRIMº for

details, BT-15 in Service Manual (Pub. No. SM7E-

2Y61G1).

j1Steering column cover and combination switch

+Remove screws.

j2Lower instrument panel on driver side

+Remove bolts and screws.

j3Cluster lid A

+Remove screws then disconnect harness connectors.

j4Combination meter

+Remove screws then disconnect harness connectors.

j5Cluster lid C

+Pull out then disconnect harness connectors.

+Remove screws then remove in-vehicle sensor.

j6Audio

+Remove screws then disconnect harness connectors.

j7A/C control unit

+Remove screws then disconnect harness connectors.

j8Console M/T or A/T ®nisher

+Remove screws then disconnect harness connectors.

j9Console box assembly

+Remove screws then disconnect harness connectors.

j10Instrument panel stay cover

+Remove screws then disconnect harness connec-

tors.

j11Glove box assembly and lower instrument panel on

passenger side

+Remove screws.

j12Mirror control switch

+Disconnect harness connector.

Remove front pillar garnish.

Refer to ªSide and Floor Trimº in ªINTERIOR TRIMº for

details, BT-15 in Service Manual (Pub. No. SM7E-

2Y61G1).

j13Mask instrument LH/RH or sensors.

+Disconnect harness connectors (models with sen-

sors).

j14Instrument panel and pads

+Remove bolts and nuts then disconnect harness

connectors.

INSTRUMENT PANEL

BT-4006

Page 54 of 579

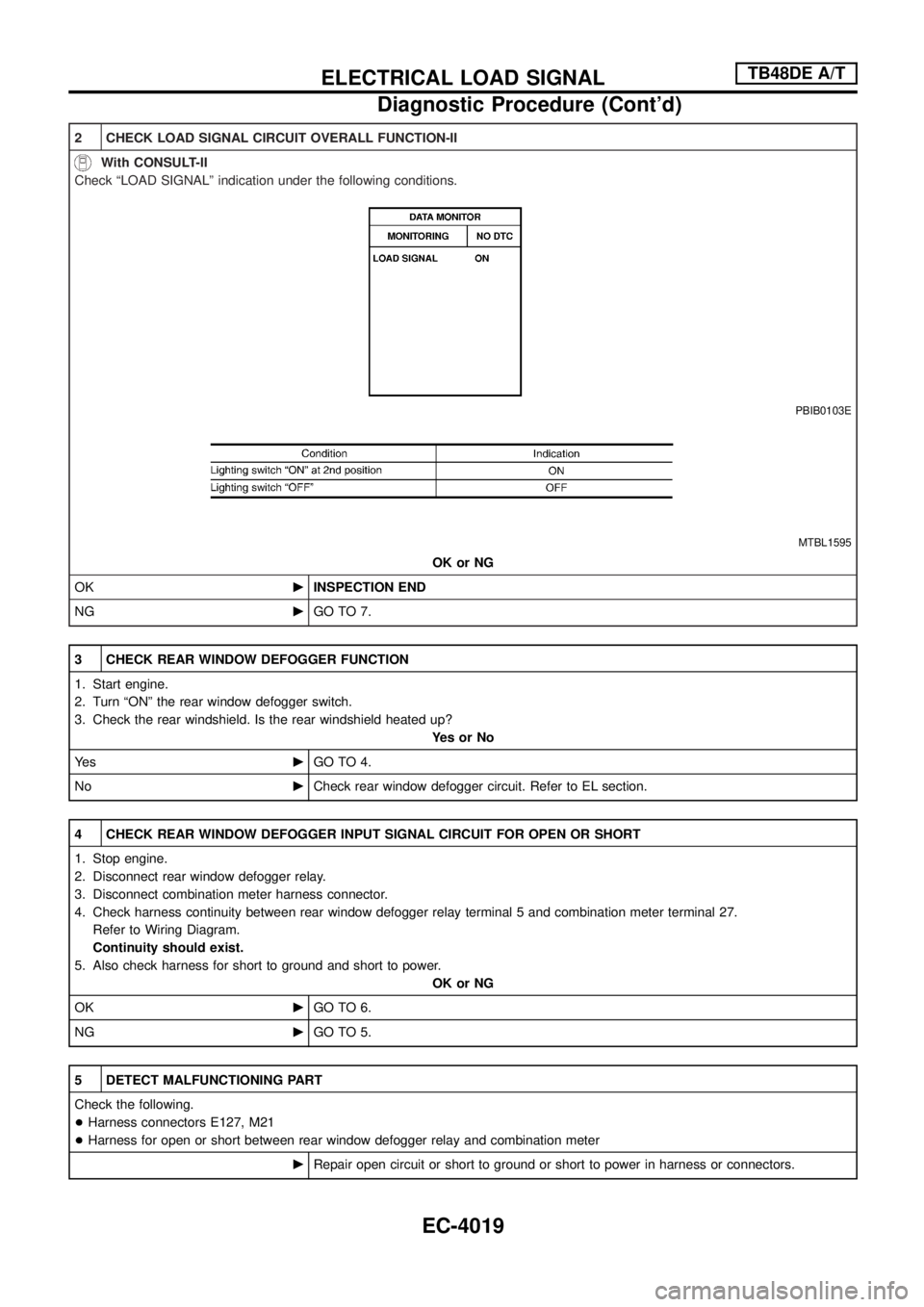

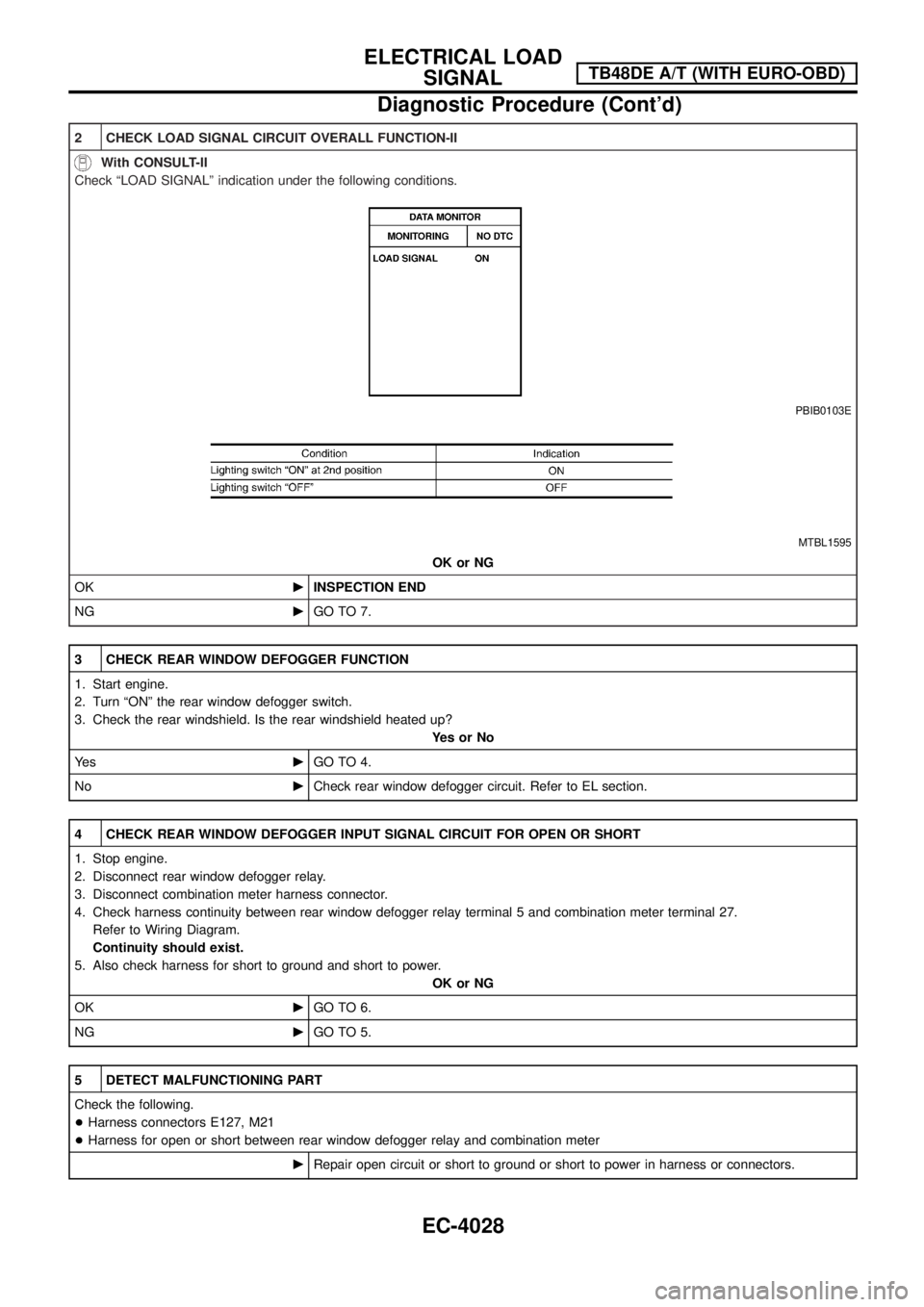

2 CHECK LOAD SIGNAL CIRCUIT OVERALL FUNCTION-II

With CONSULT-II

Check ªLOAD SIGNALº indication under the following conditions.

PBIB0103E

MTBL1595

OK or NG

OKcINSPECTION END

NGcGO TO 7.

3 CHECK REAR WINDOW DEFOGGER FUNCTION

1. Start engine.

2. Turn ªONº the rear window defogger switch.

3. Check the rear windshield. Is the rear windshield heated up?

YesorNo

Ye scGO TO 4.

NocCheck rear window defogger circuit. Refer to EL section.

4 CHECK REAR WINDOW DEFOGGER INPUT SIGNAL CIRCUIT FOR OPEN OR SHORT

1. Stop engine.

2. Disconnect rear window defogger relay.

3. Disconnect combination meter harness connector.

4. Check harness continuity between rear window defogger relay terminal 5 and combination meter terminal 27.

Refer to Wiring Diagram.

Continuity should exist.

5. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 6.

NGcGO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E127, M21

+Harness for open or short between rear window defogger relay and combination meter

cRepair open circuit or short to ground or short to power in harness or connectors.

ELECTRICAL LOAD SIGNALTB48DE A/T

Diagnostic Procedure (Cont'd)

EC-4019

Page 55 of 579

6 CHECK COMBINATION METER

Refer to EL section.

OK or NG

OKcGO TO 11.

NGcReplace combination meter.

7 CHECK HEADLAMP FUNCTION

1. Start engine.

2. Lighting switch ªONº at 2nd position.

3. Check that headlamp high beams are illuminated.

OK or NG

OKcGO TO 8.

NGcCheck headlamp circuit. Refer to EL section.

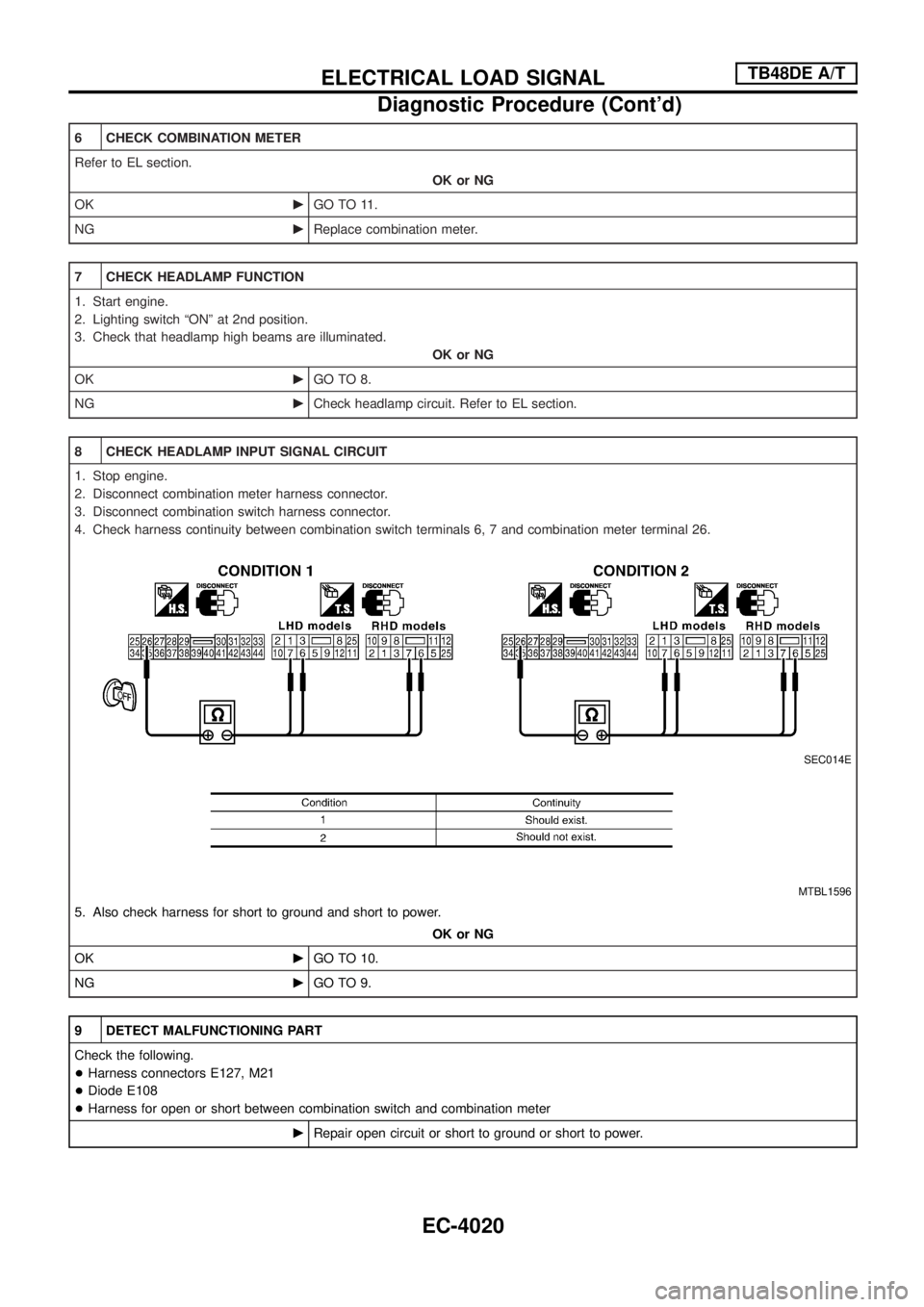

8 CHECK HEADLAMP INPUT SIGNAL CIRCUIT

1. Stop engine.

2. Disconnect combination meter harness connector.

3. Disconnect combination switch harness connector.

4. Check harness continuity between combination switch terminals 6, 7 and combination meter terminal 26.

SEC014E

MTBL1596

5. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 10.

NGcGO TO 9.

9 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E127, M21

+Diode E108

+Harness for open or short between combination switch and combination meter

cRepair open circuit or short to ground or short to power.

ELECTRICAL LOAD SIGNALTB48DE A/T

Diagnostic Procedure (Cont'd)

EC-4020

Page 56 of 579

10 CHECK COMBINATION METER

Refer to EL section.

OK or NG

OKcGO TO 11.

NGcReplace combination meter.

11 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-125 in Service Manual (Publication No. SM1E-Y61EG1).

cINSPECTION END

ELECTRICAL LOAD SIGNALTB48DE A/T

Diagnostic Procedure (Cont'd)

EC-4021

Page 63 of 579

2 CHECK LOAD SIGNAL CIRCUIT OVERALL FUNCTION-II

With CONSULT-II

Check ªLOAD SIGNALº indication under the following conditions.

PBIB0103E

MTBL1595

OK or NG

OKcINSPECTION END

NGcGO TO 7.

3 CHECK REAR WINDOW DEFOGGER FUNCTION

1. Start engine.

2. Turn ªONº the rear window defogger switch.

3. Check the rear windshield. Is the rear windshield heated up?

YesorNo

Ye scGO TO 4.

NocCheck rear window defogger circuit. Refer to EL section.

4 CHECK REAR WINDOW DEFOGGER INPUT SIGNAL CIRCUIT FOR OPEN OR SHORT

1. Stop engine.

2. Disconnect rear window defogger relay.

3. Disconnect combination meter harness connector.

4. Check harness continuity between rear window defogger relay terminal 5 and combination meter terminal 27.

Refer to Wiring Diagram.

Continuity should exist.

5. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 6.

NGcGO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E127, M21

+Harness for open or short between rear window defogger relay and combination meter

cRepair open circuit or short to ground or short to power in harness or connectors.

ELECTRICAL LOAD

SIGNALTB48DE A/T (WITH EURO-OBD)

Diagnostic Procedure (Cont'd)

EC-4028

Page 64 of 579

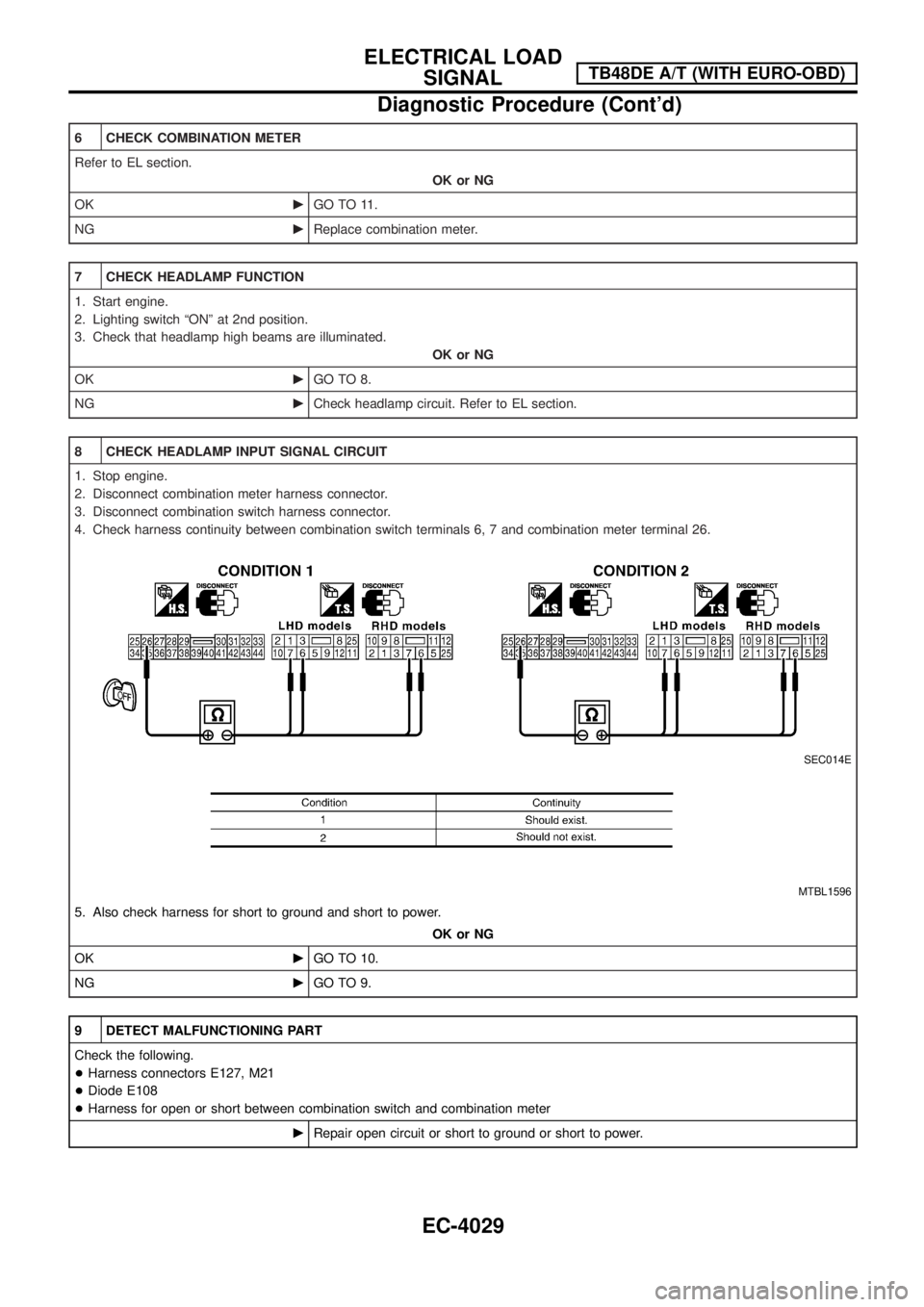

6 CHECK COMBINATION METER

Refer to EL section.

OK or NG

OKcGO TO 11.

NGcReplace combination meter.

7 CHECK HEADLAMP FUNCTION

1. Start engine.

2. Lighting switch ªONº at 2nd position.

3. Check that headlamp high beams are illuminated.

OK or NG

OKcGO TO 8.

NGcCheck headlamp circuit. Refer to EL section.

8 CHECK HEADLAMP INPUT SIGNAL CIRCUIT

1. Stop engine.

2. Disconnect combination meter harness connector.

3. Disconnect combination switch harness connector.

4. Check harness continuity between combination switch terminals 6, 7 and combination meter terminal 26.

SEC014E

MTBL1596

5. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 10.

NGcGO TO 9.

9 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E127, M21

+Diode E108

+Harness for open or short between combination switch and combination meter

cRepair open circuit or short to ground or short to power.

ELECTRICAL LOAD

SIGNALTB48DE A/T (WITH EURO-OBD)

Diagnostic Procedure (Cont'd)

EC-4029

Page 65 of 579

10 CHECK COMBINATION METER

Refer to EL section.

OK or NG

OKcGO TO 11.

NGcReplace combination meter.

11 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-145 in Service Manual (Publication No. SM2E-Y61FG1).

cINSPECTION END

ELECTRICAL LOAD

SIGNALTB48DE A/T (WITH EURO-OBD)

Diagnostic Procedure (Cont'd)

EC-4030

Page 73 of 579

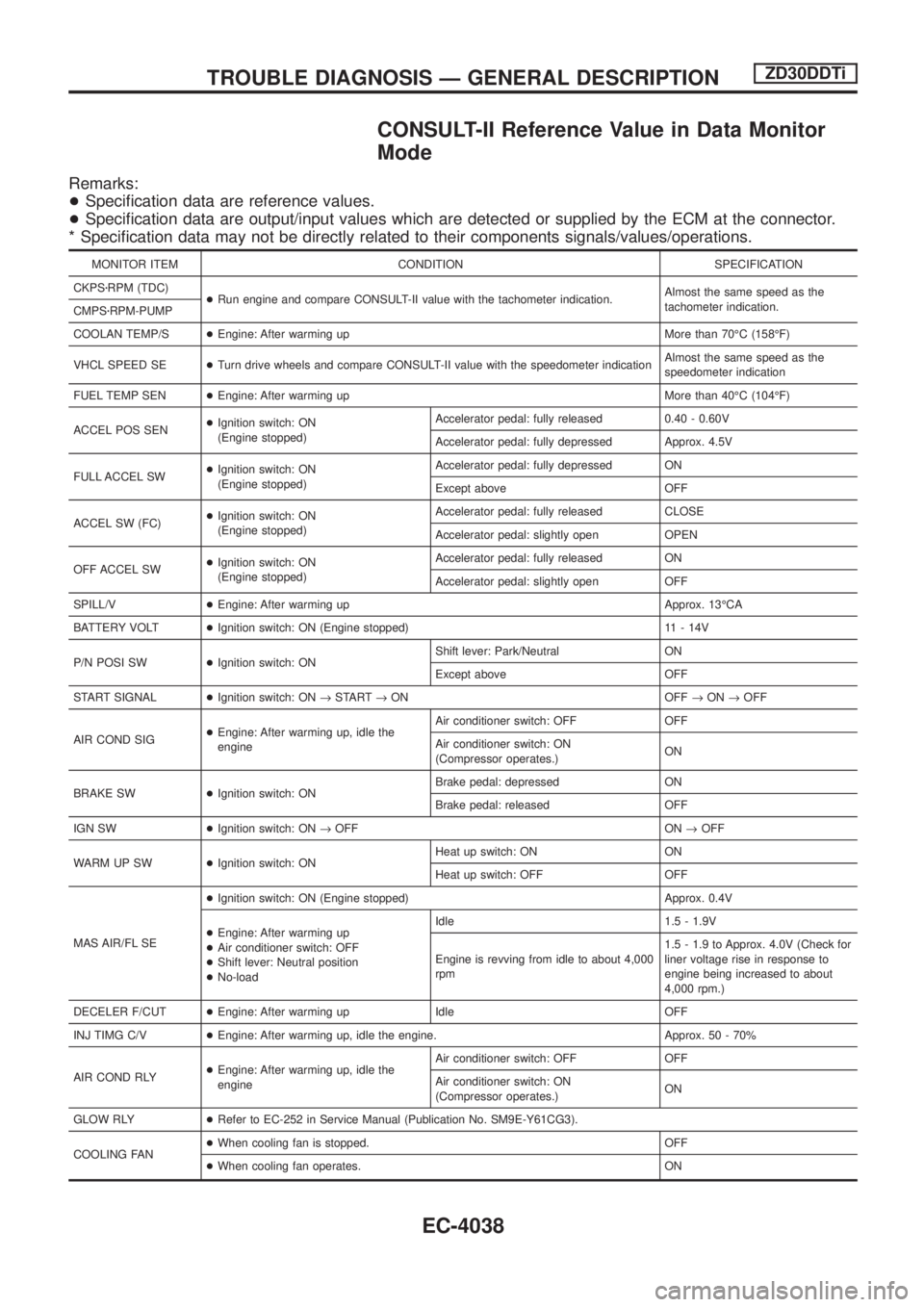

CONSULT-II Reference Value in Data Monitor

Mode

Remarks:

+Speci®cation data are reference values.

+Speci®cation data are output/input values which are detected or supplied by the ECM at the connector.

* Speci®cation data may not be directly related to their components signals/values/operations.

MONITOR ITEM CONDITION SPECIFICATION

CKPSzRPM (TDC)

+Run engine and compare CONSULT-II value with the tachometer indication.Almost the same speed as the

tachometer indication.

CMPSzRPM-PUMP

COOLAN TEMP/S+Engine: After warming up More than 70ÉC (158ÉF)

VHCL SPEED SE+Turn drive wheels and compare CONSULT-II value with the speedometer indicationAlmost the same speed as the

speedometer indication

FUEL TEMP SEN+Engine: After warming up More than 40ÉC (104ÉF)

ACCEL POS SEN+Ignition switch: ON

(Engine stopped)Accelerator pedal: fully released 0.40 - 0.60V

Accelerator pedal: fully depressed Approx. 4.5V

FULL ACCEL SW+Ignition switch: ON

(Engine stopped)Accelerator pedal: fully depressed ON

Except above OFF

ACCEL SW (FC)+Ignition switch: ON

(Engine stopped)Accelerator pedal: fully released CLOSE

Accelerator pedal: slightly open OPEN

OFF ACCEL SW+Ignition switch: ON

(Engine stopped)Accelerator pedal: fully released ON

Accelerator pedal: slightly open OFF

SPILL/V+Engine: After warming up Approx. 13ÉCA

BATTERY VOLT+Ignition switch: ON (Engine stopped) 11 - 14V

P/N POSI SW+Ignition switch: ONShift lever: Park/Neutral ON

Except above OFF

START SIGNAL+Ignition switch: ON®START®ON OFF®ON®OFF

AIR COND SIG+Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)ON

BRAKE SW+Ignition switch: ONBrake pedal: depressed ON

Brake pedal: released OFF

IGN SW+Ignition switch: ON®OFF ON®OFF

WARM UP SW+Ignition switch: ONHeat up switch: ON ON

Heat up switch: OFF OFF

MAS AIR/FL SE+Ignition switch: ON (Engine stopped) Approx. 0.4V

+Engine: After warming up

+Air conditioner switch: OFF

+Shift lever: Neutral position

+No-loadIdle 1.5 - 1.9V

Engine is revving from idle to about 4,000

rpm1.5 - 1.9 to Approx. 4.0V (Check for

liner voltage rise in response to

engine being increased to about

4,000 rpm.)

DECELER F/CUT+Engine: After warming up Idle OFF

INJ TIMG C/V+Engine: After warming up, idle the engine. Approx. 50 - 70%

AIR COND RLY+Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)ON

GLOW RLY+Refer to EC-252 in Service Manual (Publication No. SM9E-Y61CG3).

COOLING FAN+When cooling fan is stopped. OFF

+When cooling fan operates. ON

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

EC-4038

Page 75 of 579

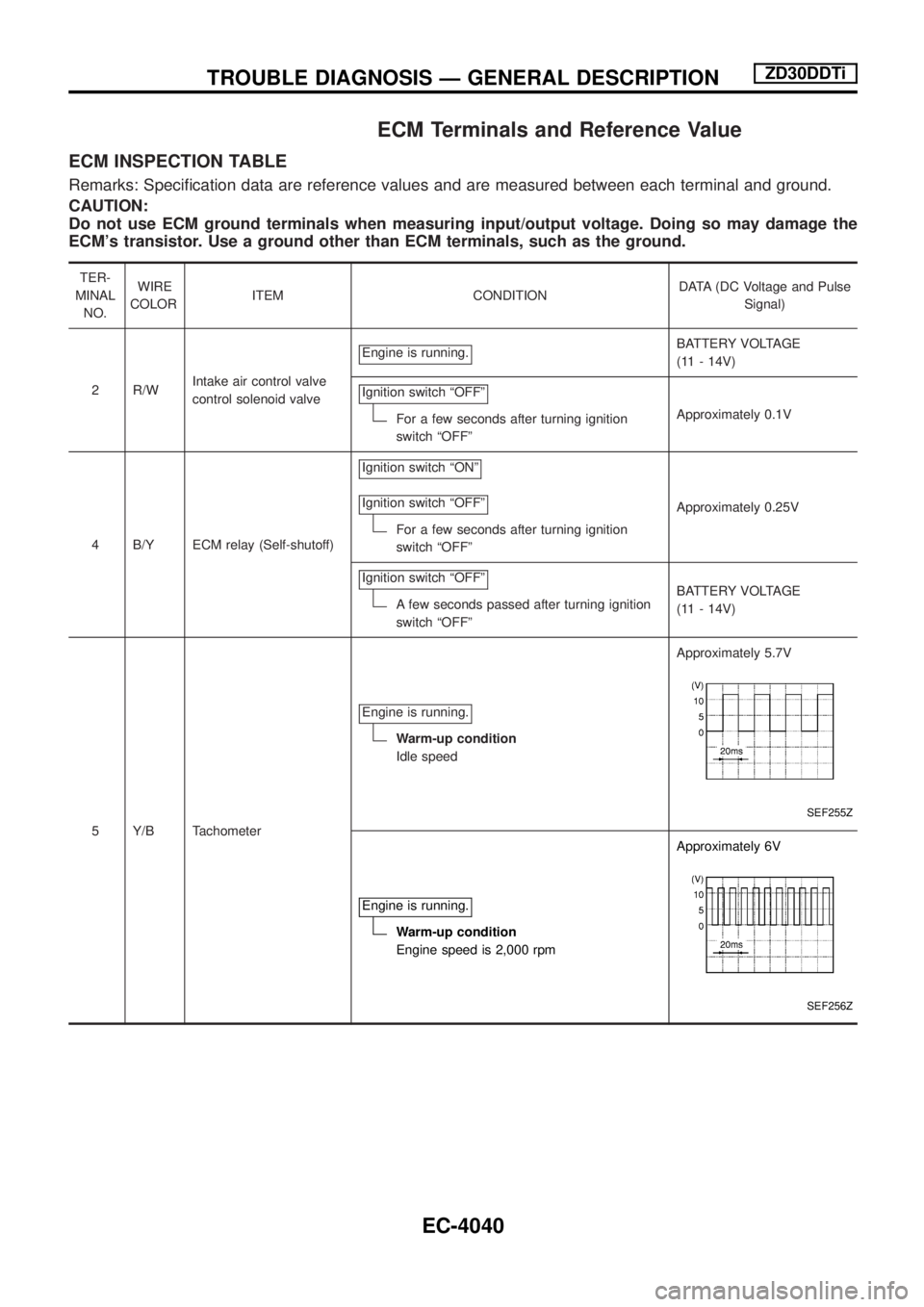

ECM Terminals and Reference Value

ECM INSPECTION TABLE

Remarks: Speci®cation data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and Pulse

Signal)

2 R/WIntake air control valve

control solenoid valveEngine is running.

BATTERY VOLTAGE

(11 - 14V)

Ignition switch ªOFFº

For a few seconds after turning ignition

switch ªOFFºApproximately 0.1V

4 B/Y ECM relay (Self-shutoff)Ignition switch ªONº

Ignition switch ªOFFº

For a few seconds after turning ignition

switch ªOFFºApproximately 0.25V

Ignition switch ªOFFº

A few seconds passed after turning ignition

switch ªOFFºBATTERY VOLTAGE

(11 - 14V)

5 Y/B TachometerEngine is running.

Warm-up condition

Idle speedApproximately 5.7V

SEF255Z

Engine is running.

Warm-up condition

Engine speed is 2,000 rpmApproximately 6V

SEF256Z

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

EC-4040