Electrical NISSAN PATROL 2006 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 151 of 1226

TROUBLEDIAGNOSISFOR``F/INJTIMGF/B''

(DTC21).......................................................................101

InjectionTimingControlValve.................................101

TROUBLEDIAGNOSISFOR``ACCELPOSSW

(F/C)''(DTC23) ...........................................................106

AcceleratorSwitch(F/C)..........................................106

TROUBLEDIAGNOSISFOR``ECM1''(DTC27),

``ECM2''(DTC31) .......................................................111

EngineControlModule(ECM)-ECCS-DControl

Module.....................................................................111

TROUBLEDIAGNOSISFOR``OVERHEAT''

(DTC28) .......................................................................113

CoolingFan(Overheat)...........................................113

TROUBLEDIAGNOSISFOR``I/CINT/ATEMP

SEN''(DTC33) ............................................................122

ChargeAirTemperatureSensor..............................122

TROUBLEDIAGNOSISFOR``NEEDLELIFT

SEN''(DTC34) ............................................................126

NeedleLiftSensor(NLS)........................................126

TROUBLE DIAGNOSIS FOR ``FUEL CUT S/V 1''

(DTC 36), ``FCV SHORT'' (DTC 37), ``FUEL CUT

S/V2''(DTC38) ...........................................................130

FuelCutSolenoidValve..........................................130

TROUBLE DIAGNOSIS FOR ``FUEL TEMP

SENSOR''(DTC42) ....................................................135

FuelTemperatureSensor(FTS)..............................135 TROUBLE DIAGNOSIS FOR ``ACCEL POS

SENSOR''(DTC43)

....................................................139

AcceleratorPositionSensor....................................139

TROUBLE DIAGNOSIS FOR ``CRANK POS SEN

(TDC)''(DTC47) ..........................................................144

CrankshaftPositionSensor(TDC)..........................144

TROUBLEDIAGNOSISFOR``GOVCUT

CIRCUIT''(DTC48) .....................................................149

GovernorCutCircuit................................................149

TROUBLEDIAGNOSESFORNON-DETECTABLE

ITEMS ........................................................................\

...151

GlowControlSystem...............................................151

EGRC-SolenoidValveA,BandThrottleControl

SolenoidValve.........................................................156

StartSignal..............................................................163

AcceleratorPositionSwitch.....................................165

Park/NeutralPositionSwitch...................................170

A/TControl...............................................................175

ChargeAirCoolerFanControl................................178

HeatUpSwitch........................................................183

AirConditionerControl............................................187

MIL&DataLinkConnectors...................................188

SERVICEDATAANDSPECIFICATIONS(SDS) ........189

GeneralSpeci®cations.............................................189

InjectionNozzle.......................................................189

InspectionandAdjustment......................................189

When you read wiring diagrams:

+ Read GI section, ``HOW TO READ WIRING DIAGRAMS''.

+ See EL section, ``POWER SUPPLY ROUTING'' for power distribution circuit.

When you perform trouble diagnoses, read GI section, ``HOW TO FOLLOW FLOW CHART IN

TROUBLE DIAGNOSES'' and ``HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL

INCIDENT''.

Page 155 of 1226

Supplemental Restraint System (SRS) ``AIR

BAG'' and ``SEAT BELT PRE-TENSIONER''

The Supplemental Restraint System such as ``AIR BAG'' and ``SEAT BELT PRE-TENSIONER'' used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger in a frontal collision.

The SRS system composition which is available to NISSAN MODEL Y61 is as follows (The composition var-

ies according to the destination.):

Driver air bag module (located in the center of the steering wheel), front passenger air bag module (located

on the instrument panel on passenger side), seat belt pre-tensioner, a diagnosis sensor unit, warning lamp,

wiring harness and spiral cable.

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag in¯ation, all maintenance must be performed

by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation either just before

the harness connectors or for the complete harness are related to the SRS.

PRECAUTIONS AND PREPARATION

EC-4

Page 192 of 1226

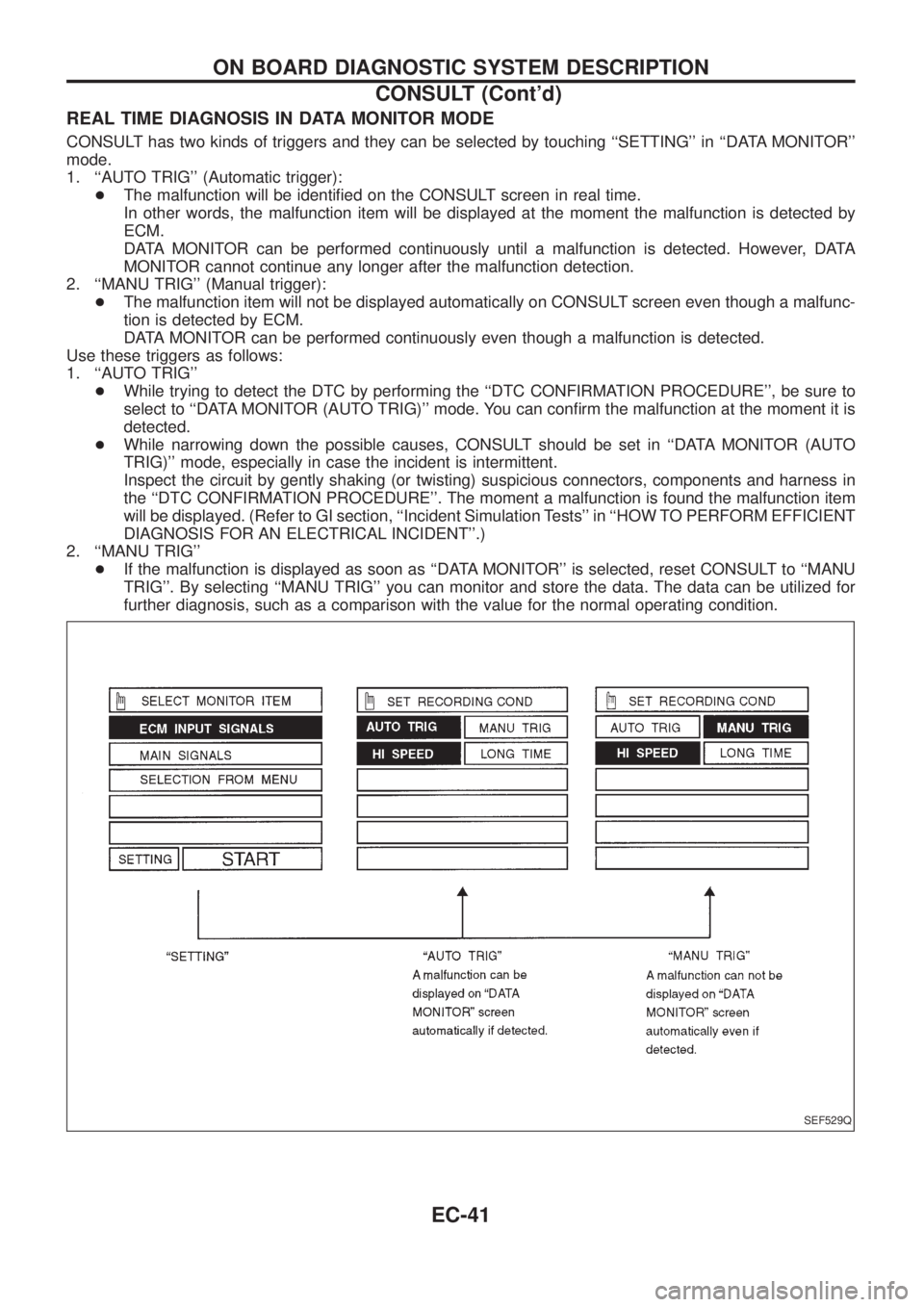

REAL TIME DIAGNOSIS IN DATA MONITOR MODE

CONSULT has two kinds of triggers and they can be selected by touching ``SETTING'' in ``DATA MONITOR''

mode.

1. ``AUTO TRIG'' (Automatic trigger):

+The malfunction will be identi®ed on the CONSULT screen in real time.

In other words, the malfunction item will be displayed at the moment the malfunction is detected by

ECM.

DATA MONITOR can be performed continuously until a malfunction is detected. However, DATA

MONITOR cannot continue any longer after the malfunction detection.

2. ``MANU TRIG'' (Manual trigger):

+The malfunction item will not be displayed automatically on CONSULT screen even though a malfunc-

tion is detected by ECM.

DATA MONITOR can be performed continuously even though a malfunction is detected.

Use these triggers as follows:

1. ``AUTO TRIG''

+While trying to detect the DTC by performing the ``DTC CONFIRMATION PROCEDURE'', be sure to

select to ``DATA MONITOR (AUTO TRIG)'' mode. You can con®rm the malfunction at the moment it is

detected.

+While narrowing down the possible causes, CONSULT should be set in ``DATA MONITOR (AUTO

TRIG)'' mode, especially in case the incident is intermittent.

Inspect the circuit by gently shaking (or twisting) suspicious connectors, components and harness in

the ``DTC CONFIRMATION PROCEDURE''. The moment a malfunction is found the malfunction item

will be displayed. (Refer to GI section, ``Incident Simulation Tests'' in ``HOW TO PERFORM EFFICIENT

DIAGNOSIS FOR AN ELECTRICAL INCIDENT''.)

2. ``MANU TRIG''

+If the malfunction is displayed as soon as ``DATA MONITOR'' is selected, reset CONSULT to ``MANU

TRIG''. By selecting ``MANU TRIG'' you can monitor and store the data. The data can be utilized for

further diagnosis, such as a comparison with the value for the normal operating condition.

SEF529Q

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT (Cont'd)

EC-41

Page 195 of 1226

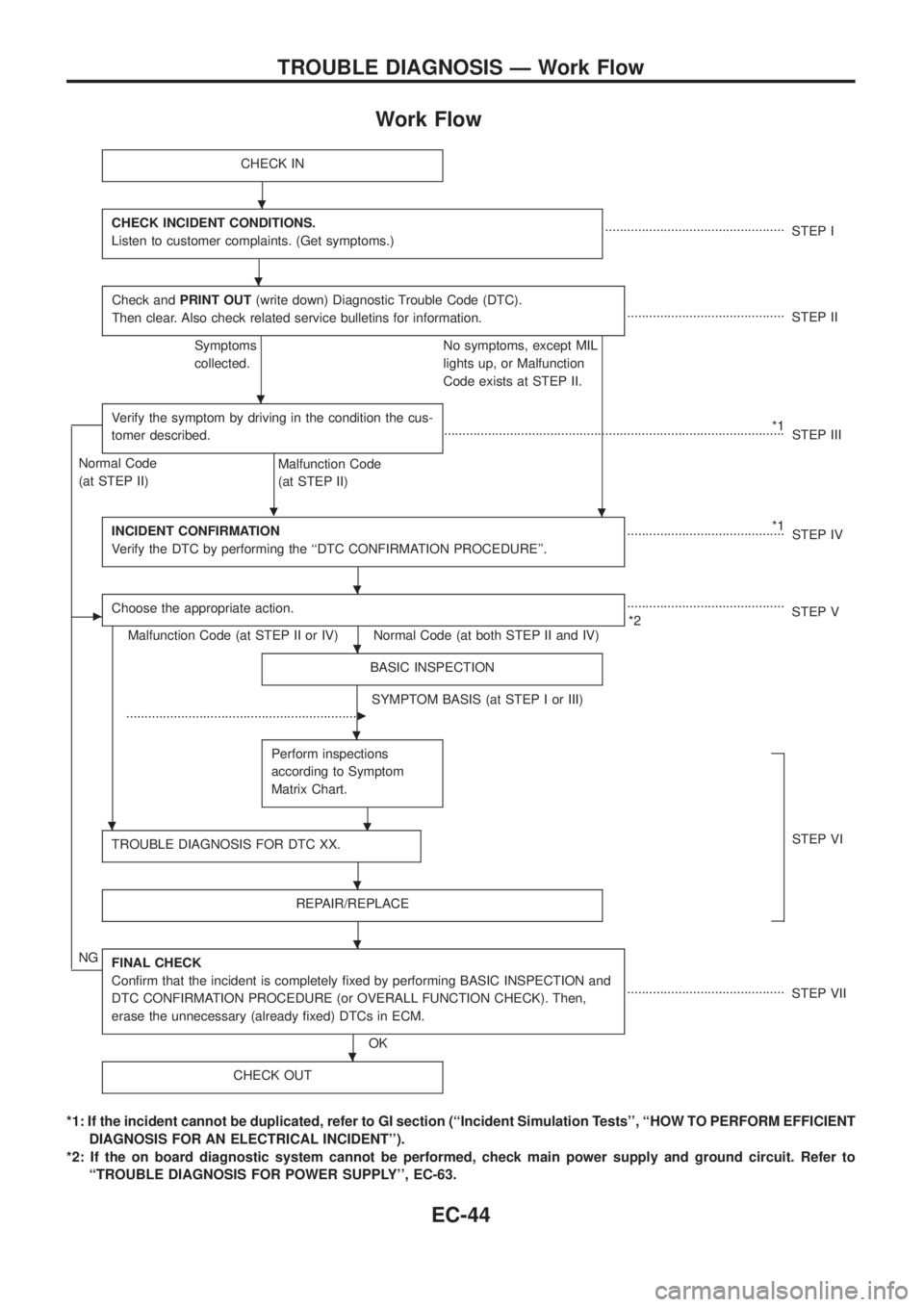

Work Flow

CHECK IN

CHECK INCIDENT CONDITIONS.

Listen to customer complaints. (Get symptoms.).................................................

STEP I

Check andPRINT OUT(write down) Diagnostic Trouble Code (DTC).

Then clear. Also check related service bulletins for information.

...........................................

STEP II

Symptoms

collected.No symptoms, except MIL

lights up, or Malfunction

Code exists at STEP II.

Verify the symptom by driving in the condition the cus-

tomer described.

.

*1

.............................................................................................

STEP III

Normal Code

(at STEP II)

Malfunction Code

(at STEP II)

INCIDENT CONFIRMATION

Verify the DTC by performing the ``DTC CONFIRMATION PROCEDURE''.

*1

...........................................

STEP IV

cChoose the appropriate action.

Malfunction Code (at STEP II or IV) Normal Code (at both STEP II and IV)...........................................

*2STEP V

BASIC INSPECTION

SYMPTOM BASIS (at STEP I or III)

................................................................

c

Perform inspections

according to Symptom

Matrix Chart.

.

TROUBLE DIAGNOSIS FOR DTC XX.STEP VI

REPAIR/REPLACE

NGFINAL CHECK

Con®rm that the incident is completely ®xed by performing BASIC INSPECTION and

DTC CONFIRMATION PROCEDURE (or OVERALL FUNCTION CHECK). Then,

erase the unnecessary (already ®xed) DTCs in ECM.

OK...........................................

STEP VII

CHECK OUT

*1: If the incident cannot be duplicated, refer to GI section (``Incident Simulation Tests'', ``HOW TO PERFORM EFFICIENT

DIAGNOSIS FOR AN ELECTRICAL INCIDENT'').

*2: If the on board diagnostic system cannot be performed, check main power supply and ground circuit. Refer to

``TROUBLE DIAGNOSIS FOR POWER SUPPLY'', EC-63.

.

.

.

.

.

.

.

.

.

.

.

TROUBLE DIAGNOSIS Ð Work Flow

EC-44

Page 196 of 1226

Description for Work Flow

STEP DESCRIPTION

STEP IGet detailed information about the conditions and the environment when the incident/symptom occurred using the

``DIAGNOSTIC WORKSHEET'' as shown on EC-43.

STEP IIBefore con®rming the concern, check and write down (print out using CONSULT) the Diagnostic Trouble Code

(DTC), then erase the code. Refer to EC-30.

Study the relationship between the cause, speci®ed by DTC, and the symptom described by the customer. (The

``Symptom Matrix Chart'' will be useful. Refer to EC-48.)

STEP IIITry to con®rm the symptom and under what conditions the incident occurs.

The ``DIAGNOSTIC WORK SHEET'' is useful to verify the incident. Connect CONSULT to the vehicle in DATA

MONITOR (AUTO TRIG) mode and check real time diagnosis results.

If the incident cannot be veri®ed, perform INCIDENT SIMULATION TESTS. Refer to GI section.

If the malfunction code is detected, skip STEP IV and perform STEP V.

STEP IVTry to detect the Diagnostic Trouble Code (DTC) by driving in (or performing) the ``DTC CONFIRMATION PROCE-

DURE''. Check and read the DTC by using CONSULT.

During the DTC veri®cation, be sure to connect CONSULT to the vehicle in DATA MONITOR (AUTO TRIG) mode

and check real time diagnosis results.

If the incident cannot be veri®ed, perform INCIDENT SIMULATION TESTS. Refer to GI section.

In case the ``DTC CONFIRMATION PROCEDURE'' is not available, perform the ``OVERALL FUNCTION CHECK''

instead. The DTC cannot be displayed by this check, however, this simpli®ed ``check'' is an effective alternative.

The ``NG'' result of the ``OVERALL FUNCTION CHECK'' is the same as the DTC detection.

STEP VTake the appropriate action based on the results of STEP I through IV.

If the malfunction code is indicated, proceed to TROUBLE DIAGNOSIS FOR DTC XX.

If the normal code is indicated, proceed to the BASIC INSPECTION. Refer to EC-46. Then perform inspections

according to the Symptom Matrix Chart. Refer to EC-48.

STEP VIIdentify where to begin diagnosis based on the relationship study between symptom and possible causes. Inspect

the system for mechanical binding, loose connectors or wiring damage using (tracing) ``Harness Layouts''.

Gently shake the related connectors, components or wiring harness with CONSULT set in ``DATA MONITOR

(AUTO TRIG)'' mode.

Check the voltage of the related ECM terminals or monitor the output data from the related sensors with CON-

SULT. Refer to EC-54.

The ``DIAGNOSTIC PROCEDURE'' in EC section contains a description based on open circuit inspection. A short

circuit inspection is also required for the circuit check in the DIAGNOSTIC PROCEDURE. For details, refer to GI

section (``Circuit Inspection'', ``HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT'').

Repair or replace the malfunction parts.

STEP VIIOnce you have repaired the circuit or replaced a component, you need to run the engine in the same conditions

and circumstances which resulted in the customer's initial complaint.

Perform the ``DTC CONFIRMATION PROCEDURE'' and con®rm the normal code (Diagnostic trouble code No. 55)

is detected. If the incident is still detected in the ®nal check, perform STEP VI by using a different method from the

previous one.

Before returning the vehicle to the customer, be sure to erase the unnecessary (already ®xed) DTC in ECM. (Refer

to EC-30.)

TROUBLE DIAGNOSIS Ð Work Flow

EC-45

Page 197 of 1226

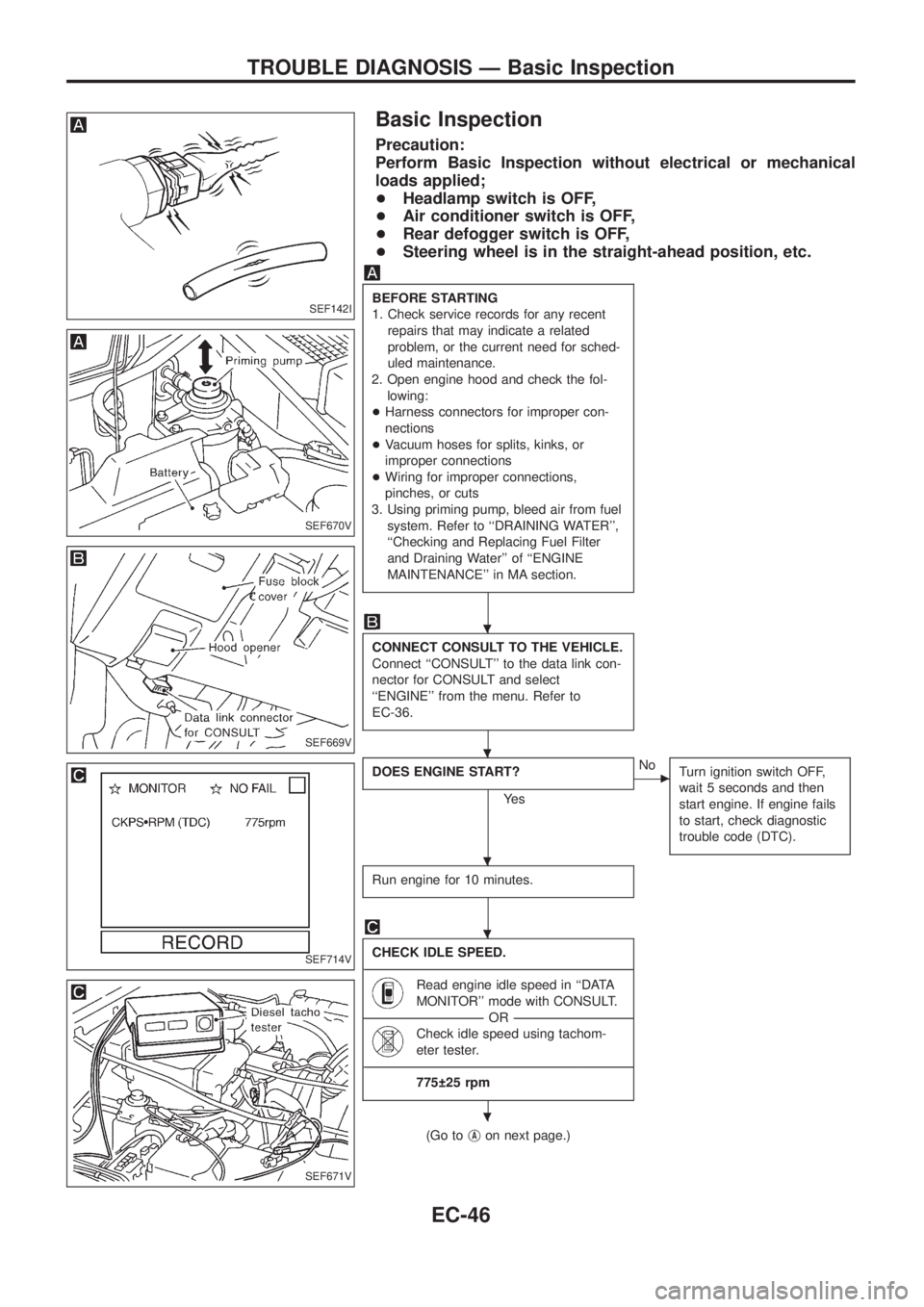

Basic Inspection

Precaution:

Perform Basic Inspection without electrical or mechanical

loads applied;

+Headlamp switch is OFF,

+Air conditioner switch is OFF,

+Rear defogger switch is OFF,

+Steering wheel is in the straight-ahead position, etc.

BEFORE STARTING

1. Check service records for any recent

repairs that may indicate a related

problem, or the current need for sched-

uled maintenance.

2. Open engine hood and check the fol-

lowing:

+Harness connectors for improper con-

nections

+Vacuum hoses for splits, kinks, or

improper connections

+Wiring for improper connections,

pinches, or cuts

3. Using priming pump, bleed air from fuel

system. Refer to ``DRAINING WATER'',

``Checking and Replacing Fuel Filter

and Draining Water'' of ``ENGINE

MAINTENANCE'' in MA section.

CONNECT CONSULT TO THE VEHICLE.

Connect ``CONSULT'' to the data link con-

nector for CONSULT and select

``ENGINE'' from the menu. Refer to

EC-36.

DOES ENGINE START?

Ye s

cNo

Turn ignition switch OFF,

wait 5 seconds and then

start engine. If engine fails

to start, check diagnostic

trouble code (DTC).

Run engine for 10 minutes.

CHECK IDLE SPEED.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Read engine idle speed in ``DATA

MONITOR'' mode with CONSULT.

--------------------------------------------------------------------------------------------------------------------------------------OR--------------------------------------------------------------------------------------------------------------------------------------

Check idle speed using tachom-

eter tester.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

775 25 rpm

(Go tojAon next page.)

SEF142I

SEF670V

SEF669V

SEF714V

SEF671V

.

.

.

.

.

TROUBLE DIAGNOSIS Ð Basic Inspection

EC-46

Page 230 of 1226

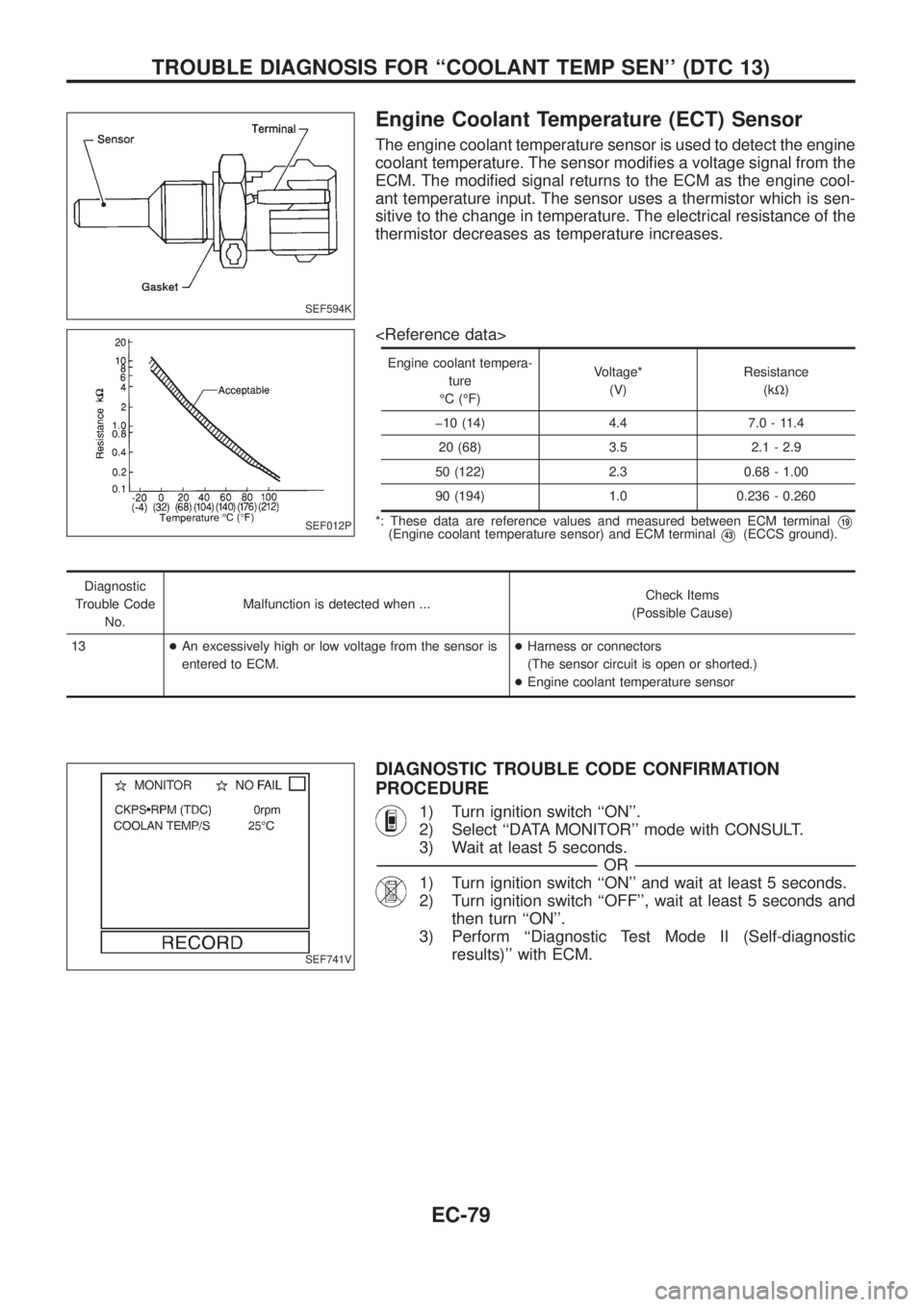

Engine Coolant Temperature (ECT) Sensor

The engine coolant temperature sensor is used to detect the engine

coolant temperature. The sensor modi®es a voltage signal from the

ECM. The modi®ed signal returns to the ECM as the engine cool-

ant temperature input. The sensor uses a thermistor which is sen-

sitive to the change in temperature. The electrical resistance of the

thermistor decreases as temperature increases.

Engine coolant tempera-

ture

ÉC (ÉF)Voltage*

(V)Resistance

(kW)

þ10 (14) 4.4 7.0 - 11.4

20 (68) 3.5 2.1 - 2.9

50 (122) 2.3 0.68 - 1.00

90 (194) 1.0 0.236 - 0.260

*: These data are reference values and measured between ECM terminal

V19(Engine coolant temperature sensor) and ECM terminalV43(ECCS ground).

Diagnostic

Trouble Code

No.Malfunction is detected when ...Check Items

(Possible Cause)

13+An excessively high or low voltage from the sensor is

entered to ECM.+Harness or connectors

(The sensor circuit is open or shorted.)

+Engine coolant temperature sensor

DIAGNOSTIC TROUBLE CODE CONFIRMATION

PROCEDURE

1) Turn ignition switch ``ON''.

2) Select ``DATA MONITOR'' mode with CONSULT.

3) Wait at least 5 seconds.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Turn ignition switch ``ON'' and wait at least 5 seconds.

2) Turn ignition switch ``OFF'', wait at least 5 seconds and

then turn ``ON''.

3) Perform ``Diagnostic Test Mode II (Self-diagnostic

results)'' with ECM.

SEF594K

SEF012P

SEF741V

TROUBLE DIAGNOSIS FOR ``COOLANT TEMP SEN'' (DTC 13)

EC-79

Page 273 of 1226

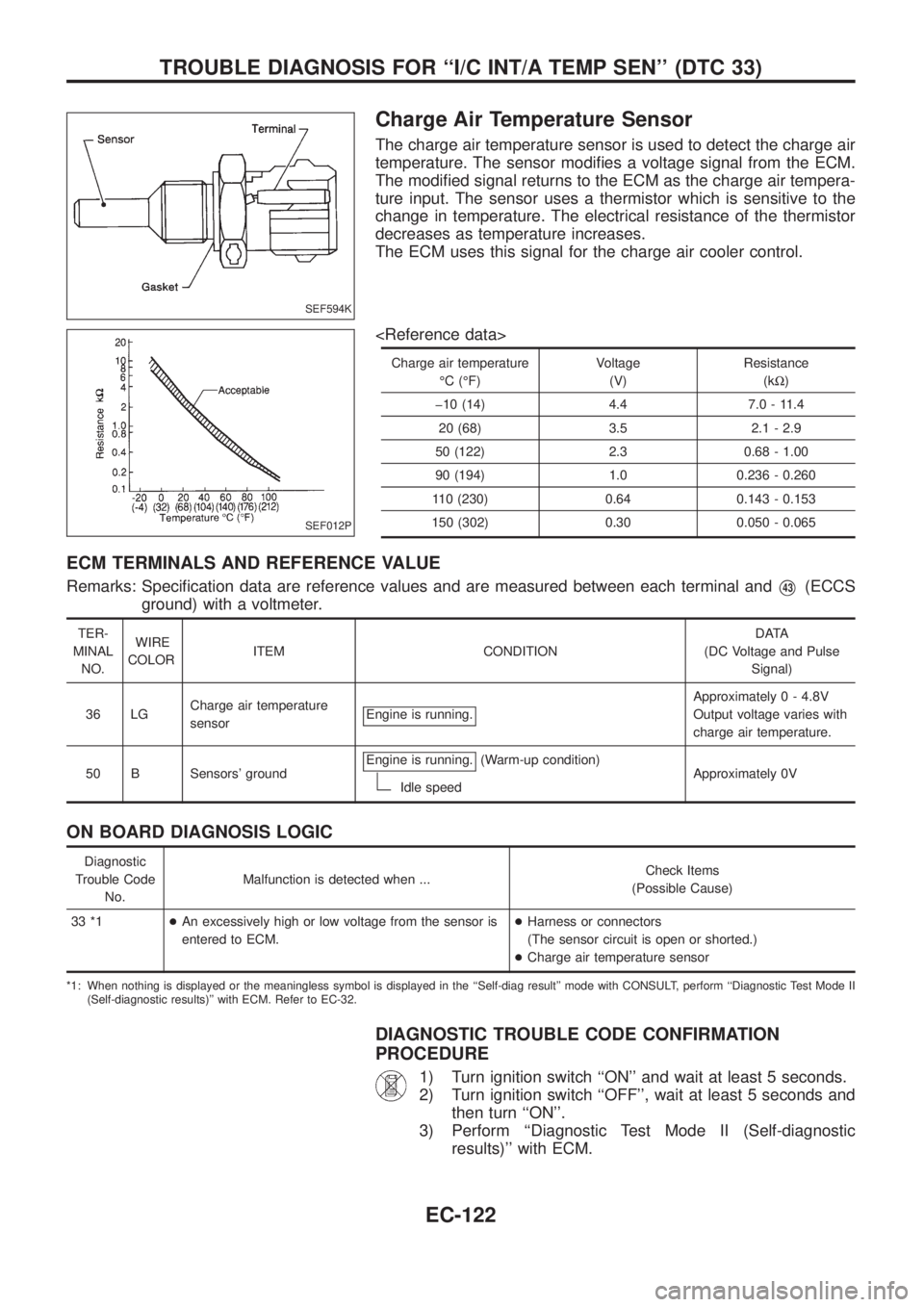

Charge Air Temperature Sensor

The charge air temperature sensor is used to detect the charge air

temperature. The sensor modi®es a voltage signal from the ECM.

The modi®ed signal returns to the ECM as the charge air tempera-

ture input. The sensor uses a thermistor which is sensitive to the

change in temperature. The electrical resistance of the thermistor

decreases as temperature increases.

The ECM uses this signal for the charge air cooler control.

Charge air temperatureÉC (ÉF) Voltage

(V) Resistance

(kW)

þ10 (14) 4.4 7.0 - 11.4 20 (68) 3.5 2.1 - 2.9

50 (122) 2.3 0.68 - 1.00

90 (194) 1.0 0.236 - 0.260

110 (230) 0.64 0.143 - 0.153

150 (302) 0.30 0.050 - 0.065

ECM TERMINALS AND REFERENCE VALUE

Remarks: Speci®cation data are reference values and are measured between each terminal andV43(ECCS

ground) with a voltmeter.

TER-

MINAL NO. WIRE

COLOR ITEM CONDITION DATA

(DC Voltage and Pulse Signal)

36 LG Charge air temperature

sensor Engine is running.

Approximatel

y 0 - 4.8V

Output voltage varies with

charge air temperature.

50 B Sensors' ground Engine is running.

(Warm-up condition)

Idle speed Approximately 0V

ON BOARD DIAGNOSIS LOGIC

Diagnostic

Trouble Code No. Malfunction is detected when ...

Check Items

(Possible Cause)

33 *1 +An excessively high or low voltage from the sensor is

entered to ECM. +

Harness or connectors

(The sensor circuit is open or shorted.)

+ Charge air temperature sensor

*1: When nothing is displayed or the meaningless symbol is displayed in the ``Self-diag result'' mode with CONSULT, perform ``Diagnostic Test Mode II

(Self-diagnostic results)'' with ECM. Refer to EC-32.

DIAGNOSTIC TROUBLE CODE CONFIRMATION

PROCEDURE

1) Turn ignition switch ``ON'' and wait at least 5 seconds.

2) Turn ignition switch ``OFF'', wait at least 5 seconds and then turn ``ON''.

3) Perform ``Diagnostic Test Mode II (Self-diagnostic results)'' with ECM.

SEF594K

SEF012P

TROUBLE DIAGNOSIS FOR ``I/C INT/A TEMP SEN'' (DTC 33)

EC-122

Page 286 of 1226

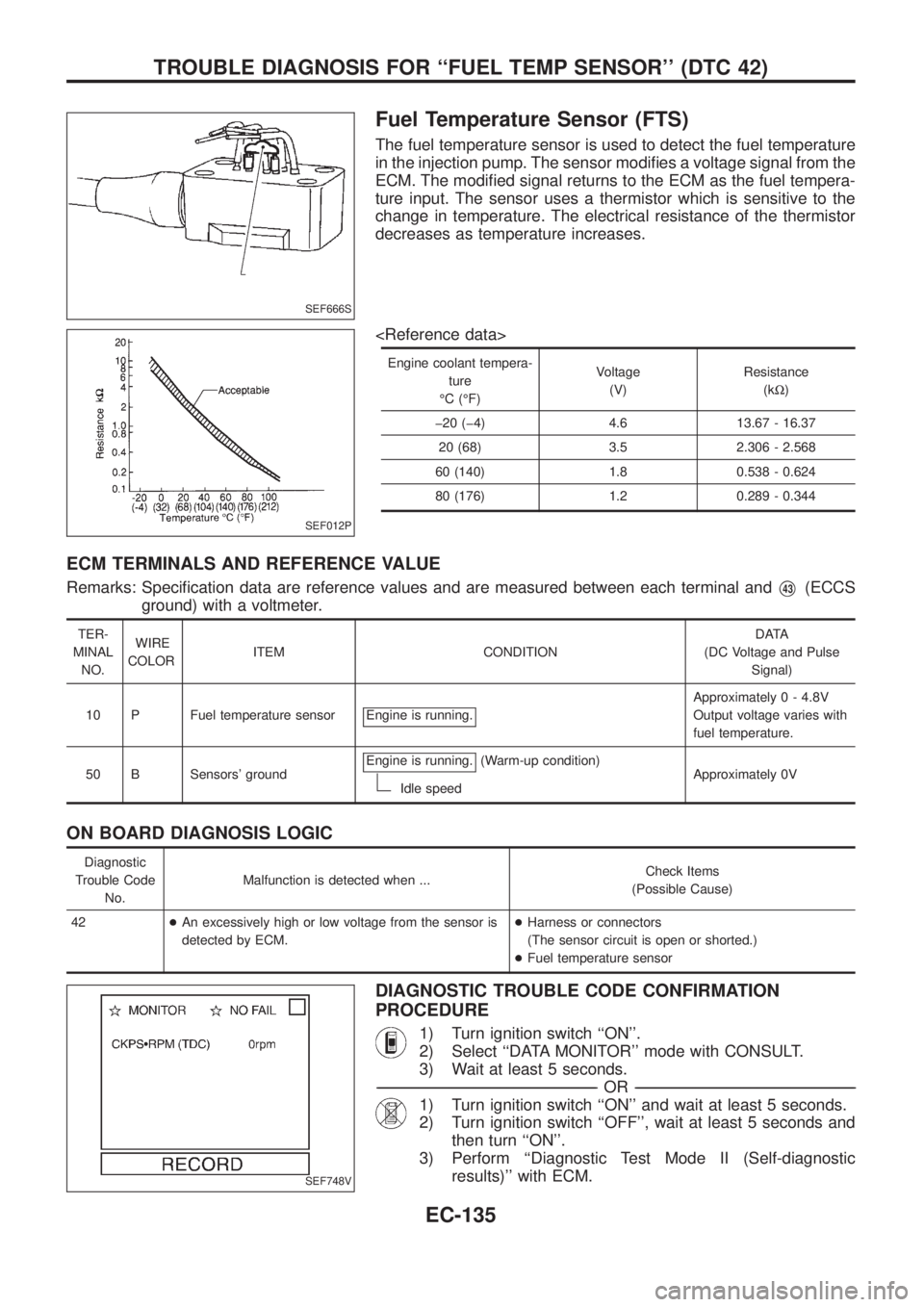

Fuel Temperature Sensor (FTS)

The fuel temperature sensor is used to detect the fuel temperature

in the injection pump. The sensor modi®es a voltage signal from the

ECM. The modi®ed signal returns to the ECM as the fuel tempera-

ture input. The sensor uses a thermistor which is sensitive to the

change in temperature. The electrical resistance of the thermistor

decreases as temperature increases.

Engine coolant tempera-

ture

ÉC (ÉF)Voltage

(V)Resistance

(kW)

þ20 (þ4) 4.6 13.67 - 16.37

20 (68) 3.5 2.306 - 2.568

60 (140) 1.8 0.538 - 0.624

80 (176) 1.2 0.289 - 0.344

ECM TERMINALS AND REFERENCE VALUE

Remarks: Speci®cation data are reference values and are measured between each terminal andV43(ECCS

ground) with a voltmeter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse

Signal)

10 P Fuel temperature sensor Engine is running.

Approximately 0 - 4.8V

Output voltage varies with

fuel temperature.

50 B Sensors' groundEngine is running.

(Warm-up condition)

Idle speedApproximately 0V

ON BOARD DIAGNOSIS LOGIC

Diagnostic

Trouble Code

No.Malfunction is detected when ...Check Items

(Possible Cause)

42+An excessively high or low voltage from the sensor is

detected by ECM.+Harness or connectors

(The sensor circuit is open or shorted.)

+Fuel temperature sensor

DIAGNOSTIC TROUBLE CODE CONFIRMATION

PROCEDURE

1) Turn ignition switch ``ON''.

2) Select ``DATA MONITOR'' mode with CONSULT.

3) Wait at least 5 seconds.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Turn ignition switch ``ON'' and wait at least 5 seconds.

2) Turn ignition switch ``OFF'', wait at least 5 seconds and

then turn ``ON''.

3) Perform ``Diagnostic Test Mode II (Self-diagnostic

results)'' with ECM.

SEF666S

SEF012P

SEF748V

TROUBLE DIAGNOSIS FOR ``FUEL TEMP SENSOR'' (DTC 42)

EC-135

Page 342 of 1226

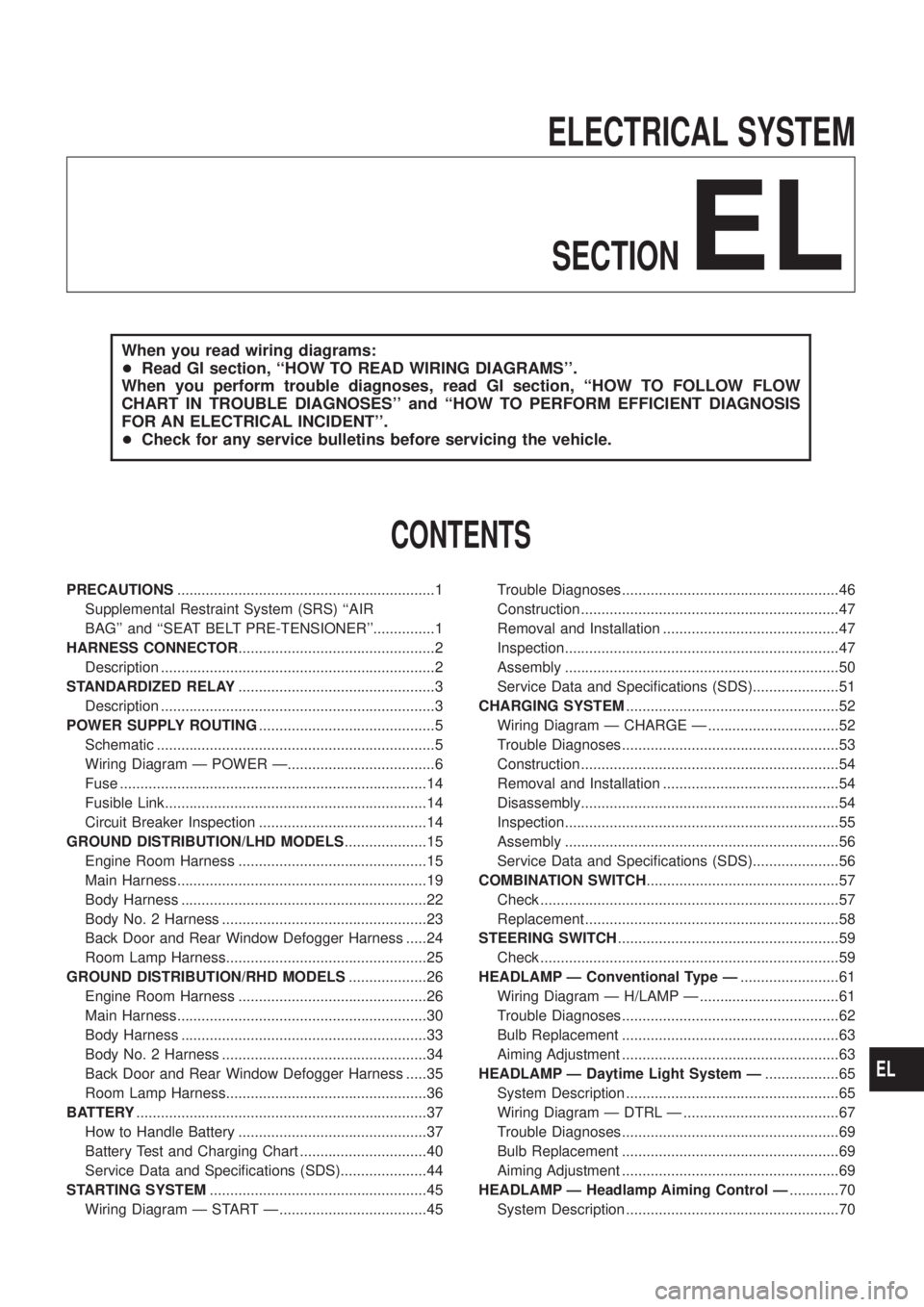

ELECTRICAL SYSTEM

SECTION

EL

When you read wiring diagrams:

+Read GI section, ``HOW TO READ WIRING DIAGRAMS''.

When you perform trouble diagnoses, read GI section, ``HOW TO FOLLOW FLOW

CHART IN TROUBLE DIAGNOSES'' and ``HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT''.

+Check for any service bulletins before servicing the vehicle.

CONTENTS

PRECAUTIONS...............................................................1

Supplemental Restraint System (SRS) ``AIR

BAG'' and ``SEAT BELT PRE-TENSIONER''...............1

HARNESS CONNECTOR................................................2

Description ...................................................................2

STANDARDIZED RELAY................................................3

Description ...................................................................3

POWER SUPPLY ROUTING...........................................5

Schematic ....................................................................5

Wiring Diagram Ð POWER Ð....................................6

Fuse ...........................................................................14

Fusible Link................................................................14

Circuit Breaker Inspection .........................................14

GROUND DISTRIBUTION/LHD MODELS....................15

Engine Room Harness ..............................................15

Main Harness.............................................................19

Body Harness ............................................................22

Body No. 2 Harness ..................................................23

Back Door and Rear Window Defogger Harness .....24

Room Lamp Harness.................................................25

GROUND DISTRIBUTION/RHD MODELS...................26

Engine Room Harness ..............................................26

Main Harness.............................................................30

Body Harness ............................................................33

Body No. 2 Harness ..................................................34

Back Door and Rear Window Defogger Harness .....35

Room Lamp Harness.................................................36

BATTERY.......................................................................37

How to Handle Battery ..............................................37

Battery Test and Charging Chart ...............................40

Service Data and Speci®cations (SDS).....................44

STARTING SYSTEM.....................................................45

Wiring Diagram Ð START Ð ....................................45Trouble Diagnoses.....................................................46

Construction ...............................................................47

Removal and Installation ...........................................47

Inspection...................................................................47

Assembly ...................................................................50

Service Data and Speci®cations (SDS).....................51

CHARGING SYSTEM....................................................52

Wiring Diagram Ð CHARGE Ð ................................52

Trouble Diagnoses.....................................................53

Construction ...............................................................54

Removal and Installation ...........................................54

Disassembly...............................................................54

Inspection...................................................................55

Assembly ...................................................................56

Service Data and Speci®cations (SDS).....................56

COMBINATION SWITCH...............................................57

Check .........................................................................57

Replacement ..............................................................58

STEERING SWITCH......................................................59

Check .........................................................................59

HEADLAMP Ð Conventional Type Ð........................61

Wiring Diagram Ð H/LAMP Ð ..................................61

Trouble Diagnoses.....................................................62

Bulb Replacement .....................................................63

Aiming Adjustment .....................................................63

HEADLAMP Ð Daytime Light System Ð..................65

System Description ....................................................65

Wiring Diagram Ð DTRL Ð ......................................67

Trouble Diagnoses.....................................................69

Bulb Replacement .....................................................69

Aiming Adjustment .....................................................69

HEADLAMP Ð Headlamp Aiming Control Ð............70

System Description ....................................................70

EL