Electrical NISSAN PATROL 2006 Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 996 of 1226

6. Install all injection nozzles with Tool and securely connect fuel

spill tube and delivery tubes.

7. Bleed air from fuel system and check for fuel leakage with

engine running.

Injection nozzle to cylinder head:

:59-69Nzm (6.0 - 7.0 kg-m, 43 - 51 ft-lb)

Spill tube nut:

:39-49Nzm (4.0 - 5.0 kg-m, 29 - 36 ft-lb)

Injection tube:

:20-25Nzm (2.2 - 2.5 kg-m, 16 - 18 ft-lb)

Checking Idle Speed

Inspection should be carried out with gears in ``Neutral'' and

with air conditioner and other electrical loads off.

1. Warm up engine until engine coolant temperature indicator

points to the middle of gauge.

2. Attach a diesel tachotester's pick-up to No. 1 fuel injection tube.

3. Race engine two or three times and check idle speed.

Idle speed:

Unit: rpm

MT 750+50

þ0

Timing Belt Replacement

Refer to EM section.

ENGINE MAINTENANCE

Checking Injection Nozzle (Cont'd)

MA-19

Page 1042 of 1226

PROPELLER SHAFT &

DIFFERENTIAL CARRIER

SECTION

PD

CONTENTS

PREPARATION................................................................1

Special Service Tools ..................................................1

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................4

NVH Troubleshooting Chart.........................................4

PROPELLER SHAFT......................................................5

Front Propeller Shaft ...................................................5

Rear Propeller Shaft ....................................................5

On-vehicle Service.......................................................6

Removal and Installation .............................................7

Inspection.....................................................................7

Disassembly.................................................................7

Assembly .....................................................................8

ON-VEHICLE SERVICE (Final Drive)..........................10

Front Oil Seal Replacement ......................................10

REMOVAL AND INSTALLATION.................................. 11

Removal ..................................................................... 11

Installation .................................................................. 11

FRONT FINAL DRIVE...................................................12

REAR FINAL DRIVE.....................................................13

DISASSEMBLY..............................................................14

Pre-inspection ............................................................14

Differential Carrier......................................................15

Differential Case ........................................................17

INSPECTION..................................................................19

Ring Gear and Drive Pinion ......................................19

Differential Case Assembly........................................19Bearing.......................................................................19

LIMITED SLIP DIFFERENTIAL.....................................20

Preparation for Disassembly .....................................20

Disassembly...............................................................21

Inspection...................................................................21

Adjustment .................................................................23

Assembly ...................................................................24

ADJUSTMENT...............................................................27

Drive Pinion Height ....................................................27

Tooth Contact.............................................................29

ASSEMBLY....................................................................31

Differential Case Ð 4-pinion type Ð.........................31

Differential Case Ð 2-pinion type Ð.........................32

Differential Carrier......................................................33

DIFFERENTIAL LOCK..................................................37

Actuator and Fork ......................................................37

Disassembly...............................................................38

Inspection...................................................................39

Assembly ...................................................................40

System Description ....................................................43

Component Parts Location ........................................44

Wiring Diagram Ð DIFF/L Ð/LHD Models ...............45

Wiring Diagram Ð DIFF/L Ð/RHD Models ...............47

Electrical Components Inspection .............................49

SERVICE DATA AND SPECIFICATIONS (SDS)..........51

Propeller Shaft ...........................................................51

Final Drive..................................................................52

PD

Page 1091 of 1226

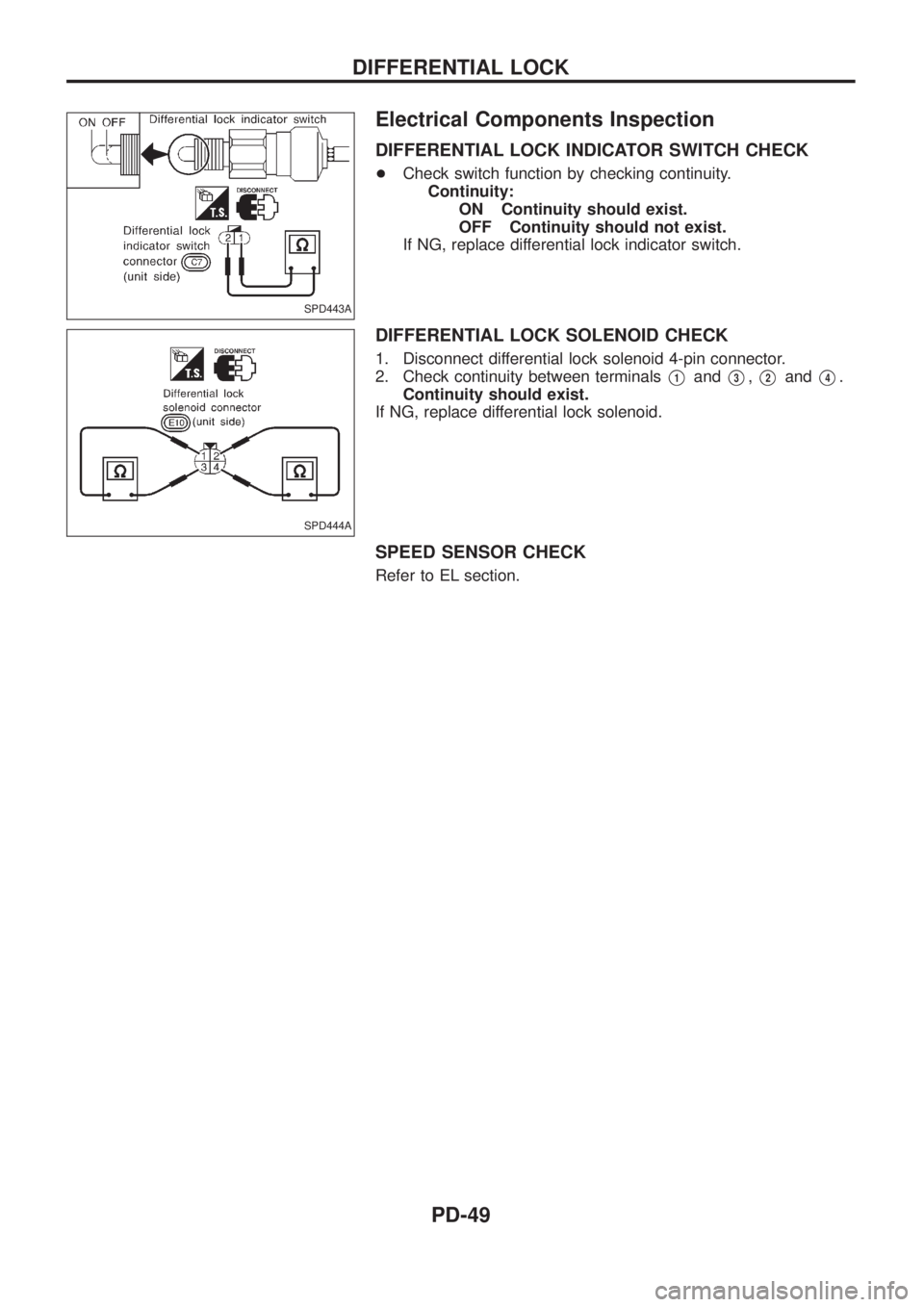

Electrical Components Inspection

DIFFERENTIAL LOCK INDICATOR SWITCH CHECK

+Check switch function by checking continuity.

Continuity:

ON Continuity should exist.

OFF Continuity should not exist.

If NG, replace differential lock indicator switch.

DIFFERENTIAL LOCK SOLENOID CHECK

1. Disconnect differential lock solenoid 4-pin connector.

2. Check continuity between terminals

V1andV3,V2andV4.

Continuity should exist.

If NG, replace differential lock solenoid.

SPEED SENSOR CHECK

Refer to EL section.

SPD443A

SPD444A

DIFFERENTIAL LOCK

PD-49

Page 1092 of 1226

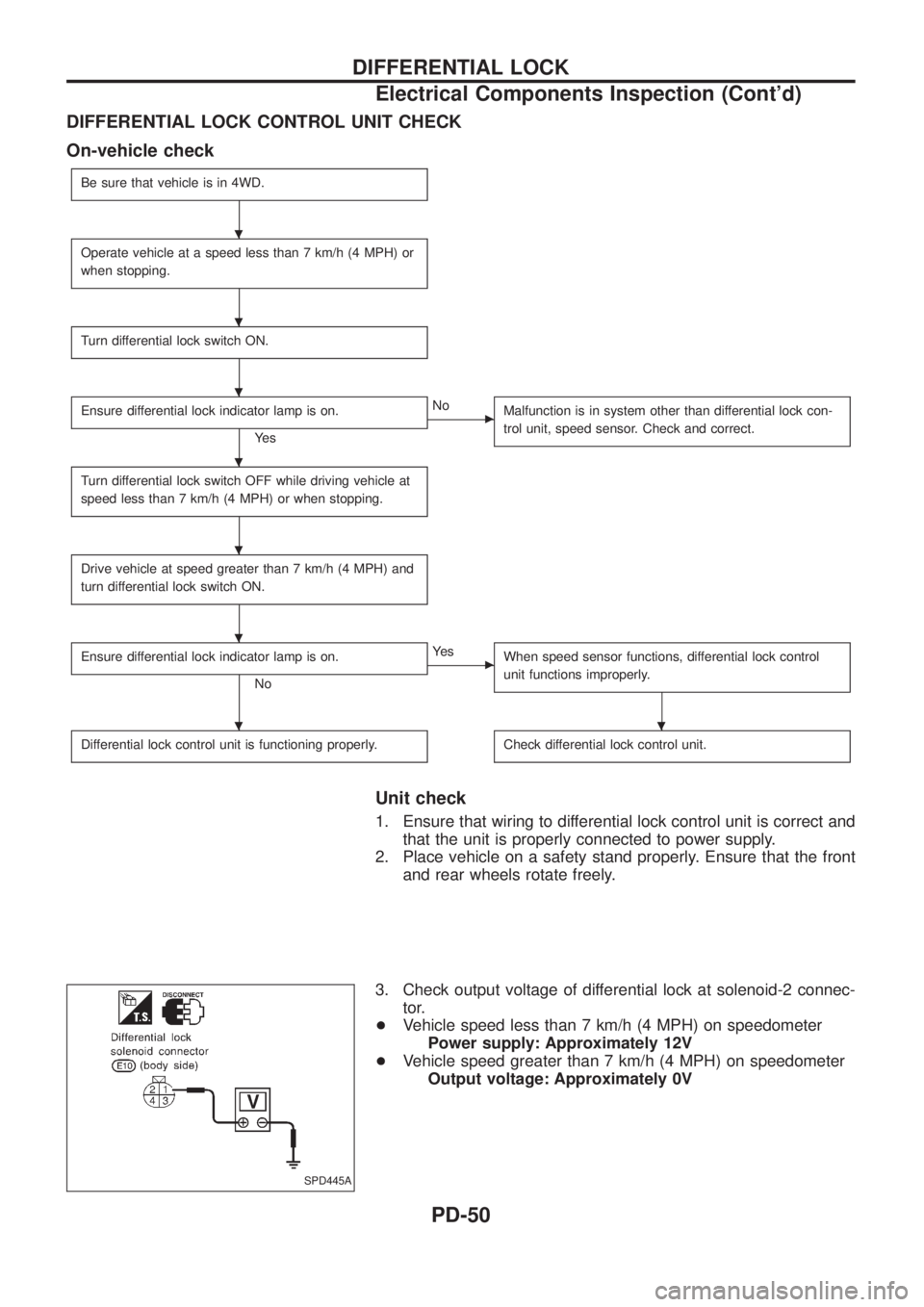

DIFFERENTIAL LOCK CONTROL UNIT CHECK

On-vehicle check

Be sure that vehicle is in 4WD.

Operate vehicle at a speed less than 7 km/h (4 MPH) or

when stopping.

Turn differential lock switch ON.

Ensure differential lock indicator lamp is on.

Ye s

cNo

Malfunction is in system other than differential lock con-

trol unit, speed sensor. Check and correct.

Turn differential lock switch OFF while driving vehicle at

speed less than 7 km/h (4 MPH) or when stopping.

Drive vehicle at speed greater than 7 km/h (4 MPH) and

turn differential lock switch ON.

Ensure differential lock indicator lamp is on.

No

cYe s

When speed sensor functions, differential lock control

unit functions improperly.

Differential lock control unit is functioning properly.Check differential lock control unit.

Unit check

1. Ensure that wiring to differential lock control unit is correct and

that the unit is properly connected to power supply.

2. Place vehicle on a safety stand properly. Ensure that the front

and rear wheels rotate freely.

3. Check output voltage of differential lock at solenoid-2 connec-

tor.

+Vehicle speed less than 7 km/h (4 MPH) on speedometer

Power supply: Approximately 12V

+Vehicle speed greater than 7 km/h (4 MPH) on speedometer

Output voltage: Approximately 0V

SPD445A

.

.

.

.

.

.

..

DIFFERENTIAL LOCK

Electrical Components Inspection (Cont'd)

PD-50

Page 1112 of 1226

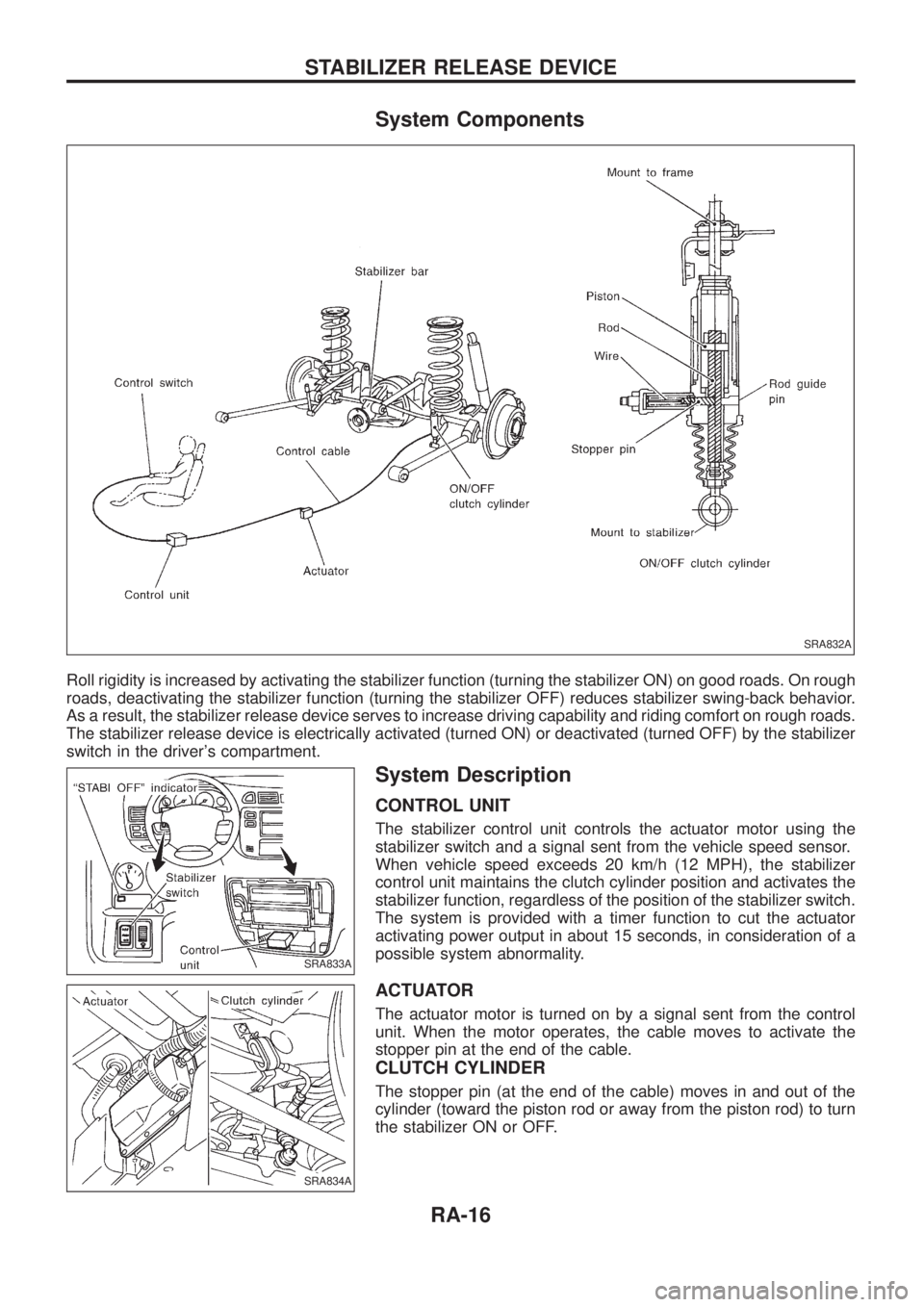

System Components

Roll rigidity is increased by activating the stabilizer function (turning the stabilizer ON) on good roads. On rough

roads, deactivating the stabilizer function (turning the stabilizer OFF) reduces stabilizer swing-back behavior.

As a result, the stabilizer release device serves to increase driving capability and riding comfort on rough roads.

The stabilizer release device is electrically activated (turned ON) or deactivated (turned OFF) by the stabilizer

switch in the driver's compartment.

System Description

CONTROL UNIT

The stabilizer control unit controls the actuator motor using the

stabilizer switch and a signal sent from the vehicle speed sensor.

When vehicle speed exceeds 20 km/h (12 MPH), the stabilizer

control unit maintains the clutch cylinder position and activates the

stabilizer function, regardless of the position of the stabilizer switch.

The system is provided with a timer function to cut the actuator

activating power output in about 15 seconds, in consideration of a

possible system abnormality.

ACTUATOR

The actuator motor is turned on by a signal sent from the control

unit. When the motor operates, the cable moves to activate the

stopper pin at the end of the cable.

CLUTCH CYLINDER

The stopper pin (at the end of the cable) moves in and out of the

cylinder (toward the piston rod or away from the piston rod) to turn

the stabilizer ON or OFF.

SRA832A

SRA833A

SRA834A

STABILIZER RELEASE DEVICE

RA-16

Page 1122 of 1226

RESTRAINT SYSTEM

SECTION

RS

CONTENTS

PRECAUTION..................................................................1

Supplemental Restraint System (SRS) ``AIR

BAG'' and ``SEAT BELT PRE-TENSIONER''...............1

SEAT BELTS...................................................................2

Front Seat Belt.............................................................3

Rear Seat Belt .............................................................5

3rd Seat Belt ................................................................7

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)............8

Precautions for SRS ``AIR BAG'' and ``Seat Belt

Pre-tensioner'' Service.................................................8

Special Service Tools ..................................................8

Description .................................................................10

SRS Component Parts Location ...............................10

Maintenance Items .................................................... 11

Removal and Installation Ð Diagnosis Sensor

Unit and Seat Belt Pre-tensioner...............................12

Removal and Installation Ð Air Bag Module and

Spiral Cable ...............................................................13

Removal Ð Air Bag Module and Spiral Cable ..........13

Removal Ð Front Passenger Air Bag Module ..........14

Installation Ð Air Bag Module and Spiral Cable .......16Installation Ð Front Passenger Air Bag Module .......16

Disposal of Air Bag Module and Seat Belt Pre-

tensioner ....................................................................17

TROUBLE DIAGNOSES Ð Supplemental

Restraint System (SRS)...............................................22

Trouble Diagnoses Introduction.................................22

How to Perform Trouble Diagnoses for Quick

and Accurate Repair ..................................................24

Schematic ..................................................................26

Wiring Diagram Ð SRS Ð ........................................27

SRS Operation Check ...............................................30

Trouble Diagnoses with CONSULT ...........................32

Trouble Diagnoses without CONSULT ......................39

Trouble Diagnoses: ``AIR BAG'' Warning Lamp

Does Not Turn Off .....................................................43

Trouble Diagnoses: ``AIR BAG'' Warning Lamp

Does Not Turn On .....................................................43

Trouble Diagnoses: SRS Does Not Enter

Diagnosis Mode Using Door Switch ..........................44

COLLISION DIAGNOSIS...............................................45

When you read wiring diagrams:

+Read GI section, ``HOW TO READ WIRING DIAGRAMS''.

+See EL section, ``POWER SUPPLY ROUTING'' for power distribution circuit.

When you perform trouble diagnoses, read GI section, ``HOW TO FOLLOW FLOW

CHART IN TROUBLE DIAGNOSES'' and ``HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT''.

RS

Page 1123 of 1226

Supplemental Restraint System (SRS) ``AIR

BAG'' and ``SEAT BELT PRE-TENSIONER''

The Supplemental Restraint System such as ``AIR BAG'' and ``SEAT BELT PRE-TENSIONER'' used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger in a frontal collision.

The SRS composition which is available to NISSAN MODEL Y61 is as follows (The composition varies

according to the destination.):

Driver air bag module (located in the center of the steering wheel), front passenger air bag module (located

on the instrument panel on passenger side), seat belt pre-tensioner, a diagnosis sensor unit, warning lamp,

wiring harness and spiral cable.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag in¯ation, all maintenance must be performed

by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation either just before

the harness connectors or for the complete harness are related to the SRS.

PRECAUTION

RS-1

Page 1170 of 1226

Supplemental Restraint System (SRS) ``AIR

BAG'' and ``SEAT BELT PRE-TENSIONER''

The Supplemental Restraint System such as ``AIR BAG'' and ``SEAT BELT PRE-TENSIONER'' used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger in a frontal collision.

The SRS system composition which is available to NISSAN MODEL Y61 is as follows (The composition var-

ies according to the destination.):

Driver air bag module (located in the center of the steering wheel), front passenger air bag module (located

on the instrument panel on passenger side), seat belt pre-tensioner, a diagnosis sensor unit, warning lamp,

wiring harness and spiral cable.

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag in¯ation, all maintenance must be performed

by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation either just before

the harness connectors or for the complete harness are related to the SRS.

Precautions for Steering System

+Before disassembly, thoroughly clean the outside of the unit.

+Disassembly should be done in a clean work area. It is important to prevent the internal parts from

becoming contaminated by dirt or other foreign matter.

+Place disassembled parts in order, on a parts rack, for easier and proper assembly.

+Use nylon cloths or paper towels to clean the parts; common shop rags can leave lint that might

interfere with their operation.

+Before inspection or reassembly, carefully clean all parts with a general purpose, non-¯ammable

solvent.

+Before assembly, apply a coat of recommended ATF* to hydraulic parts. Vaseline may be applied

to O-rings and seals. Do not use any grease.

+Replace all gaskets, seals and O-rings. Avoid damaging O-rings, seals and gaskets during instal-

lation. Perform functional tests whenever designated.

*: Automatic Transmission Fluid type DEXRON

TMIII or equivalent

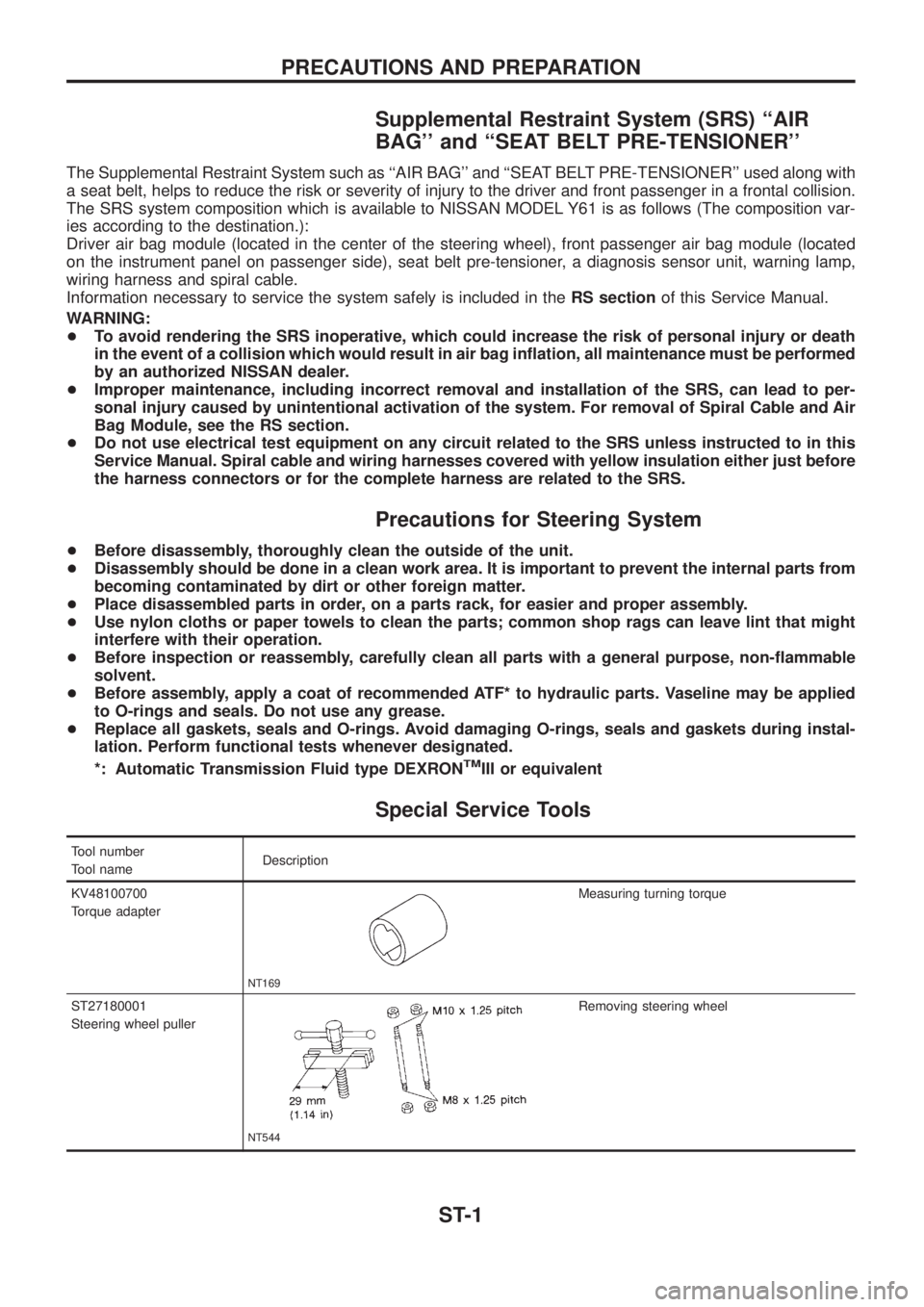

Special Service Tools

Tool number

Tool nameDescription

KV48100700

Torque adapter

NT169

Measuring turning torque

ST27180001

Steering wheel puller

NT544

Removing steering wheel

PRECAUTIONS AND PREPARATION

ST-1