height NISSAN PATROL 2006 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 700 of 1226

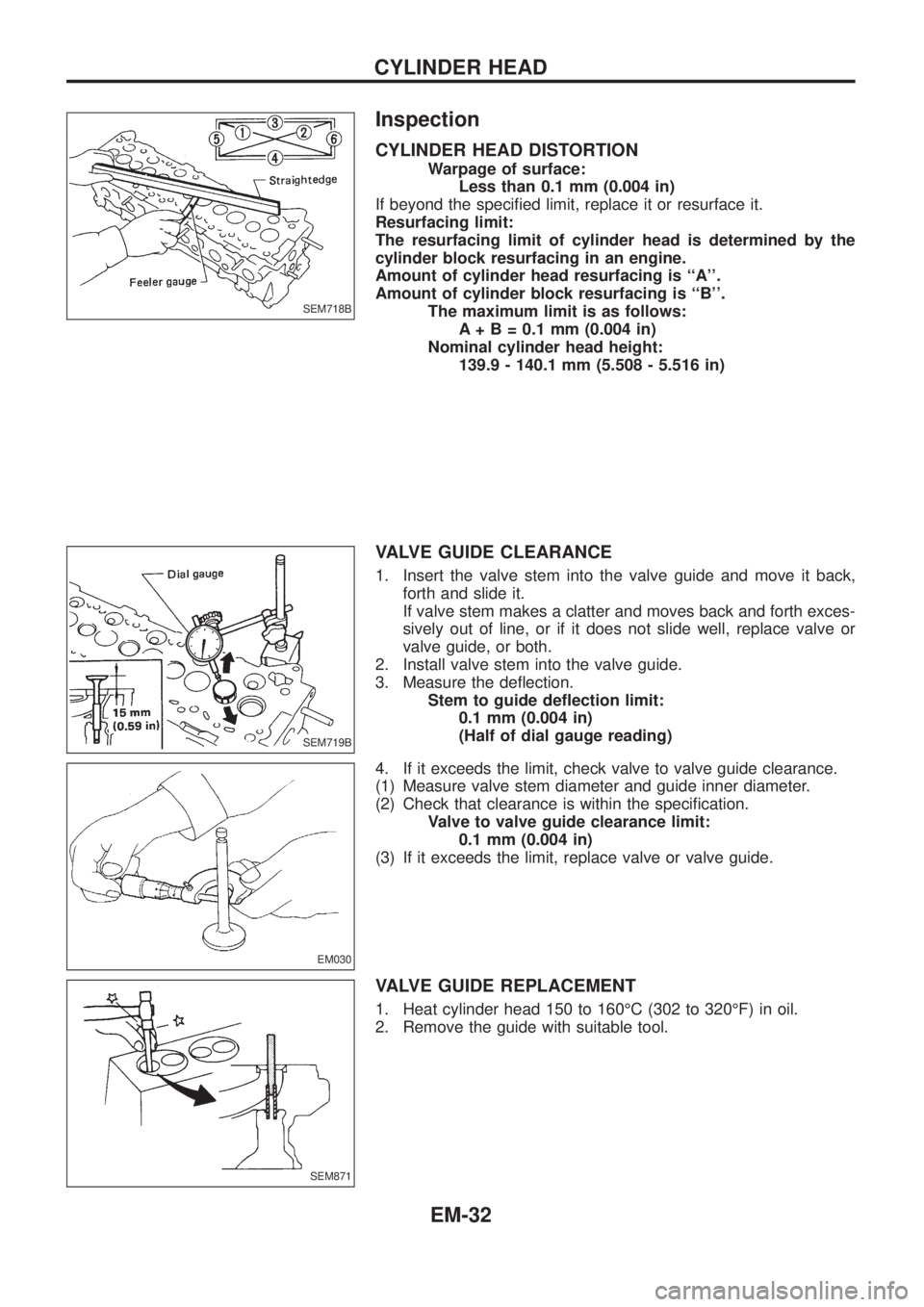

Inspection

CYLINDER HEAD DISTORTION

Warpage of surface:

Less than 0.1 mm (0.004 in)

If beyond the speci®ed limit, replace it or resurface it.

Resurfacing limit:

The resurfacing limit of cylinder head is determined by the

cylinder block resurfacing in an engine.

Amount of cylinder head resurfacing is ``A''.

Amount of cylinder block resurfacing is ``B''.

The maximum limit is as follows:

A + B = 0.1 mm (0.004 in)

Nominal cylinder head height:

139.9 - 140.1 mm (5.508 - 5.516 in)

VALVE GUIDE CLEARANCE

1. Insert the valve stem into the valve guide and move it back,

forth and slide it.

If valve stem makes a clatter and moves back and forth exces-

sively out of line, or if it does not slide well, replace valve or

valve guide, or both.

2. Install valve stem into the valve guide.

3. Measure the de¯ection.

Stem to guide de¯ection limit:

0.1 mm (0.004 in)

(Half of dial gauge reading)

4. If it exceeds the limit, check valve to valve guide clearance.

(1) Measure valve stem diameter and guide inner diameter.

(2) Check that clearance is within the speci®cation.

Valve to valve guide clearance limit:

0.1 mm (0.004 in)

(3) If it exceeds the limit, replace valve or valve guide.

VALVE GUIDE REPLACEMENT

1. Heat cylinder head 150 to 160ÉC (302 to 320ÉF) in oil.

2. Remove the guide with suitable tool.

SEM718B

SEM719B

EM030

SEM871

CYLINDER HEAD

EM-32

Page 705 of 1226

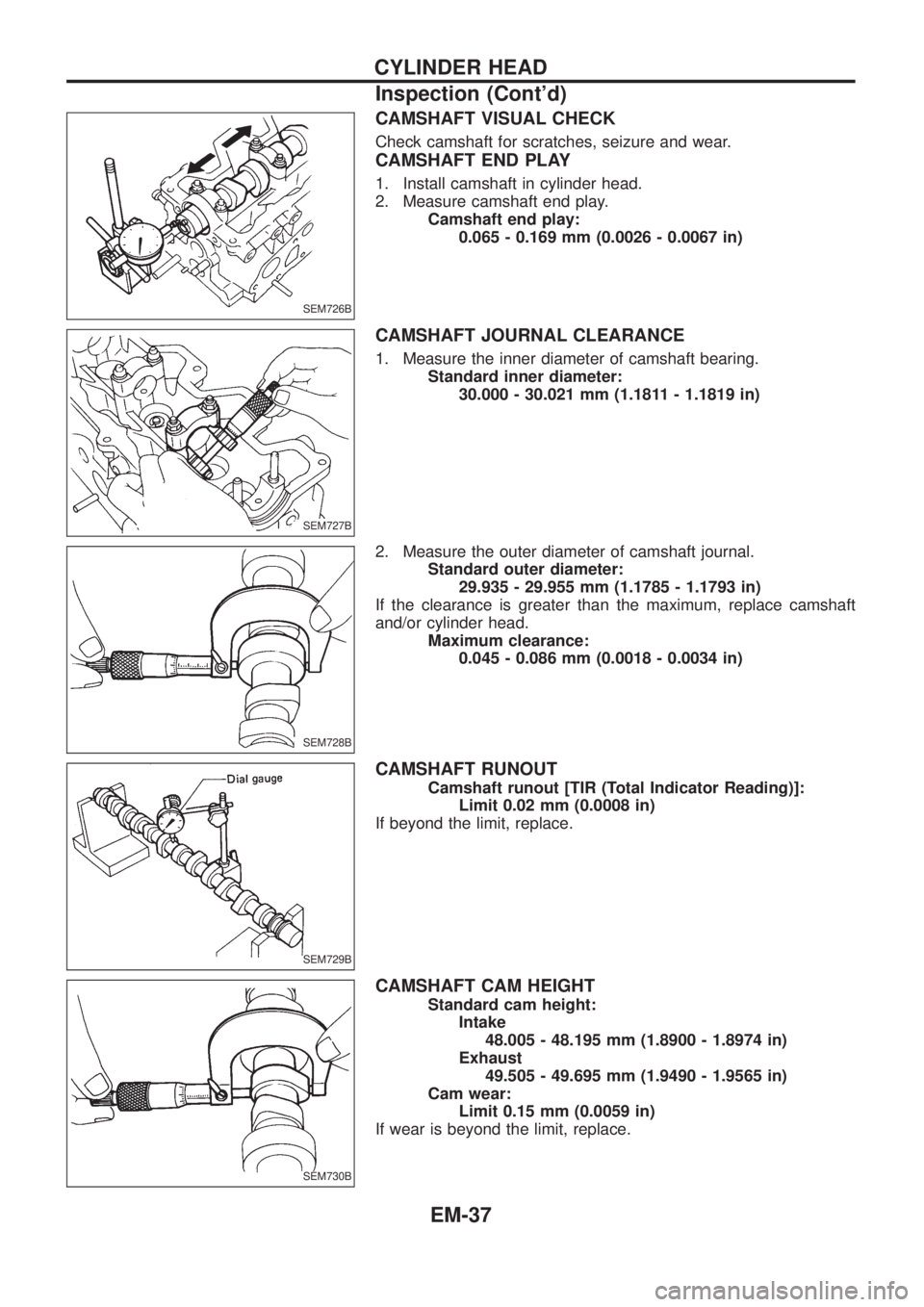

CAMSHAFT VISUAL CHECK

Check camshaft for scratches, seizure and wear.

CAMSHAFT END PLAY

1. Install camshaft in cylinder head.

2. Measure camshaft end play.

Camshaft end play:

0.065 - 0.169 mm (0.0026 - 0.0067 in)

CAMSHAFT JOURNAL CLEARANCE

1. Measure the inner diameter of camshaft bearing.

Standard inner diameter:

30.000 - 30.021 mm (1.1811 - 1.1819 in)

2. Measure the outer diameter of camshaft journal.

Standard outer diameter:

29.935 - 29.955 mm (1.1785 - 1.1793 in)

If the clearance is greater than the maximum, replace camshaft

and/or cylinder head.

Maximum clearance:

0.045 - 0.086 mm (0.0018 - 0.0034 in)

CAMSHAFT RUNOUT

Camshaft runout [TIR (Total Indicator Reading)]:

Limit 0.02 mm (0.0008 in)

If beyond the limit, replace.

CAMSHAFT CAM HEIGHT

Standard cam height:

Intake

48.005 - 48.195 mm (1.8900 - 1.8974 in)

Exhaust

49.505 - 49.695 mm (1.9490 - 1.9565 in)

Cam wear:

Limit 0.15 mm (0.0059 in)

If wear is beyond the limit, replace.

SEM726B

SEM727B

SEM728B

SEM729B

SEM730B

CYLINDER HEAD

Inspection (Cont'd)

EM-37

Page 717 of 1226

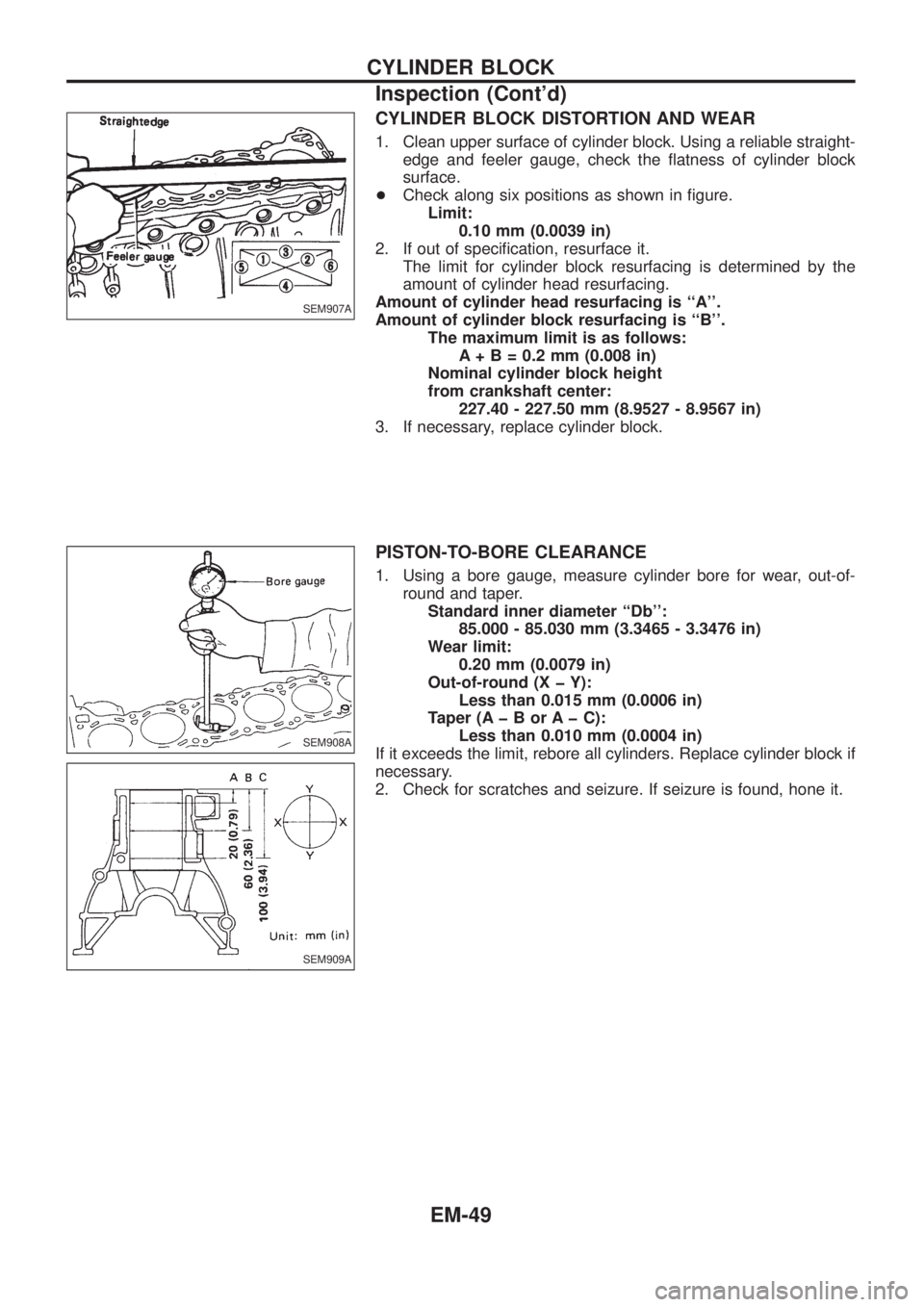

CYLINDER BLOCK DISTORTION AND WEAR

1. Clean upper surface of cylinder block. Using a reliable straight-

edge and feeler gauge, check the ¯atness of cylinder block

surface.

+Check along six positions as shown in ®gure.

Limit:

0.10 mm (0.0039 in)

2. If out of speci®cation, resurface it.

The limit for cylinder block resurfacing is determined by the

amount of cylinder head resurfacing.

Amount of cylinder head resurfacing is ``A''.

Amount of cylinder block resurfacing is ``B''.

The maximum limit is as follows:

A + B = 0.2 mm (0.008 in)

Nominal cylinder block height

from crankshaft center:

227.40 - 227.50 mm (8.9527 - 8.9567 in)

3. If necessary, replace cylinder block.

PISTON-TO-BORE CLEARANCE

1. Using a bore gauge, measure cylinder bore for wear, out-of-

round and taper.

Standard inner diameter ``Db'':

85.000 - 85.030 mm (3.3465 - 3.3476 in)

Wear limit:

0.20 mm (0.0079 in)

Out-of-round (X þ Y):

Less than 0.015 mm (0.0006 in)

Taper (A þ B or A þ C):

Less than 0.010 mm (0.0004 in)

If it exceeds the limit, rebore all cylinders. Replace cylinder block if

necessary.

2. Check for scratches and seizure. If seizure is found, hone it.

SEM907A

SEM908A

SEM909A

CYLINDER BLOCK

Inspection (Cont'd)

EM-49

Page 725 of 1226

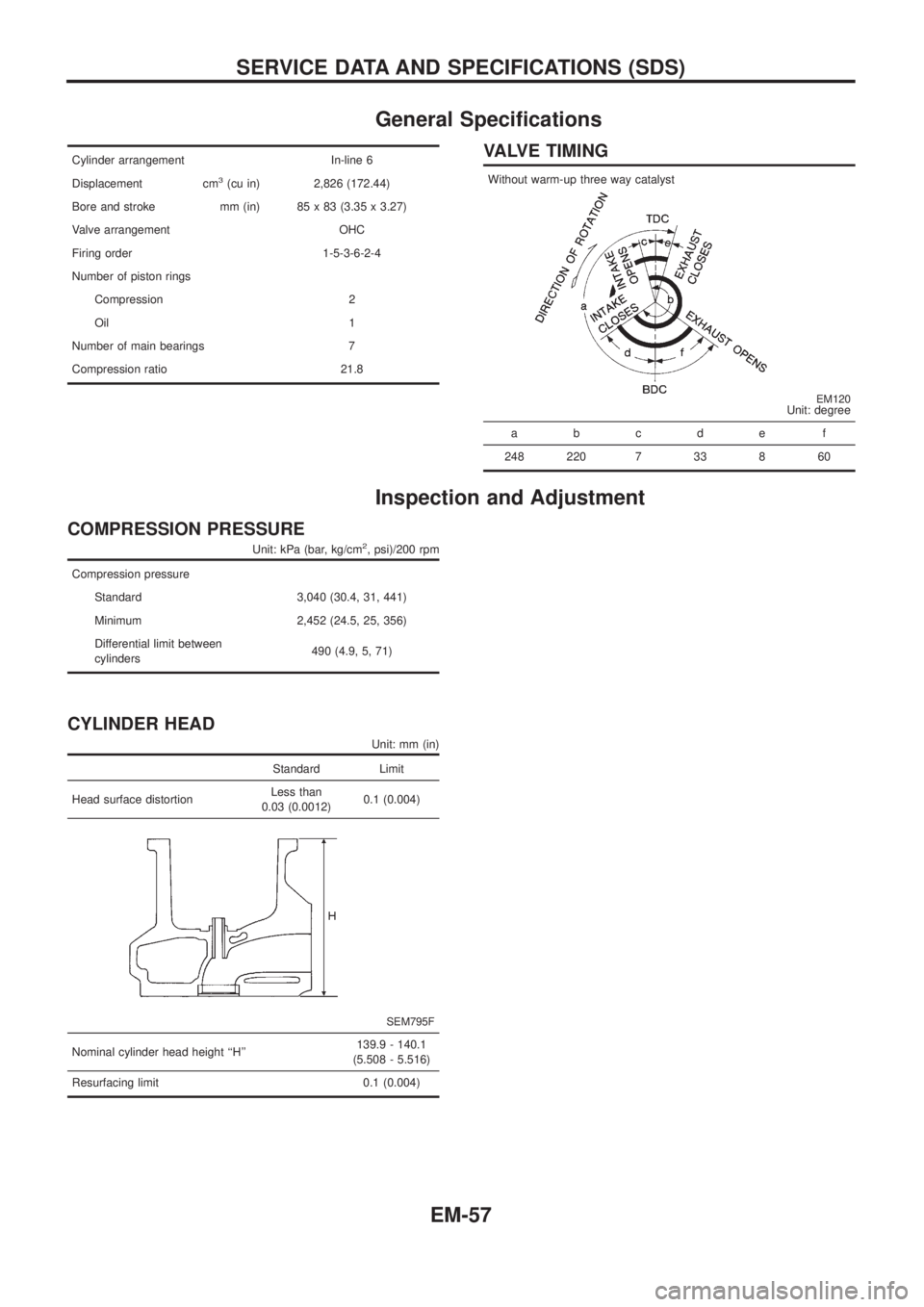

General Speci®cations

Cylinder arrangement In-line 6

Displacement cm

3(cu in) 2,826 (172.44)

Bore and stroke mm (in) 85 x 83 (3.35 x 3.27)

Valve arrangement OHC

Firing order 1-5-3-6-2-4

Number of piston rings

Compression 2

Oil 1

Number of main bearings 7

Compression ratio 21.8

VALVE TIMING

Without warm-up three way catalyst

EM120Unit: degree

abcde f

248 220 7 33 8 60

Inspection and Adjustment

COMPRESSION PRESSURE

Unit: kPa (bar, kg/cm2, psi)/200 rpm

Compression pressure

Standard 3,040 (30.4, 31, 441)

Minimum 2,452 (24.5, 25, 356)

Differential limit between

cylinders490 (4.9, 5, 71)

CYLINDER HEAD

Unit: mm (in)

Standard Limit

Head surface distortionLess than

0.03 (0.0012)0.1 (0.004)

SEM795F

Nominal cylinder head height ``H''139.9 - 140.1

(5.508 - 5.516)

Resurfacing limit 0.1 (0.004)

SERVICE DATA AND SPECIFICATIONS (SDS)

EM-57

Page 727 of 1226

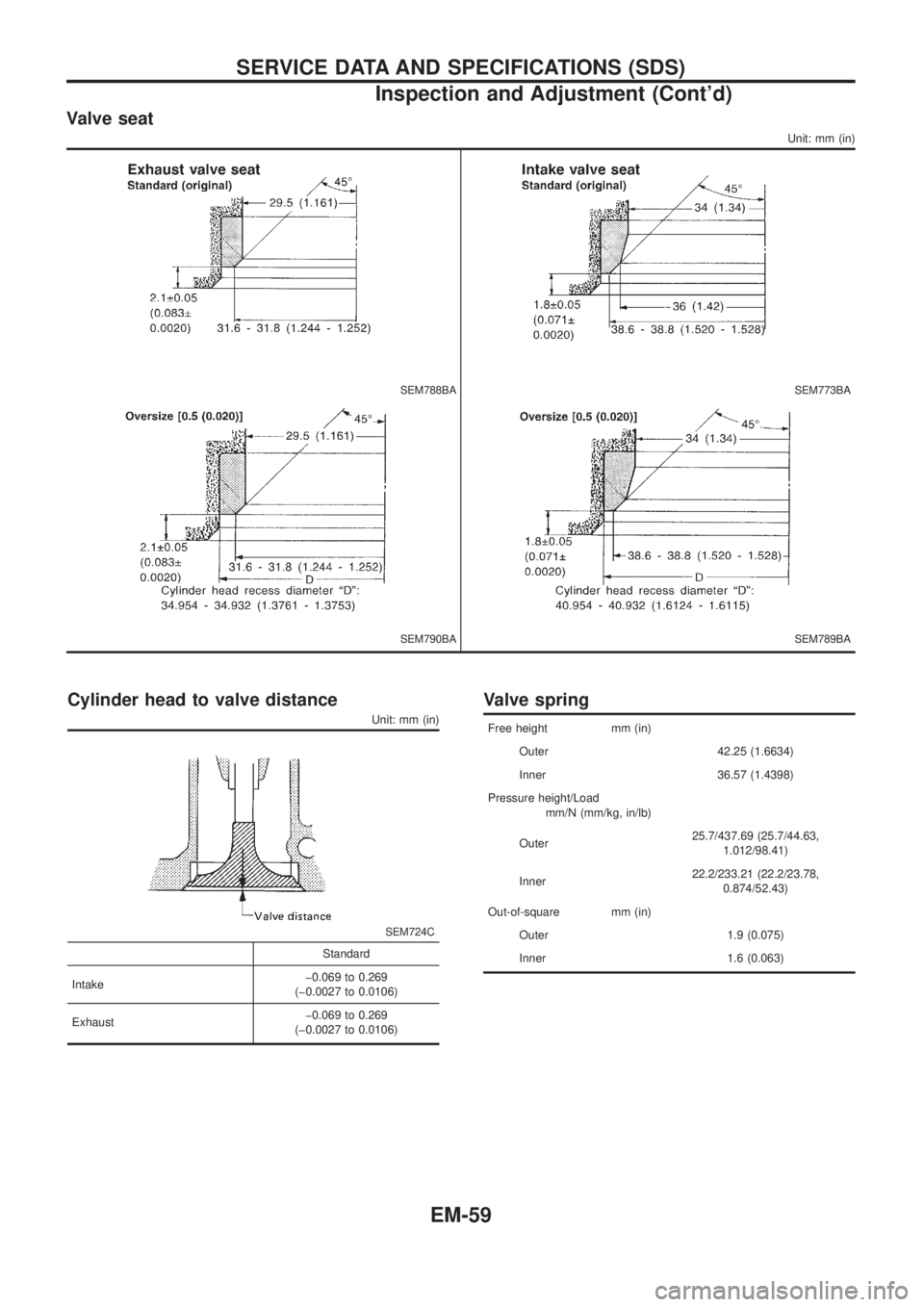

Valve seat

Unit: mm (in)

SEM788BASEM773BA

SEM790BASEM789BA

Cylinder head to valve distance

Unit: mm (in)

SEM724C

Standard

Intakeþ0.069 to 0.269

(þ0.0027 to 0.0106)

Exhaustþ0.069 to 0.269

(þ0.0027 to 0.0106)

Valve spring

Free height mm (in)

Outer 42.25 (1.6634)

Inner 36.57 (1.4398)

Pressure height/Load

mm/N (mm/kg, in/lb)

Outer25.7/437.69 (25.7/44.63,

1.012/98.41)

Inner22.2/233.21 (22.2/23.78,

0.874/52.43)

Out-of-square mm (in)

Outer 1.9 (0.075)

Inner 1.6 (0.063)

SERVICE DATA AND SPECIFICATIONS (SDS)

Inspection and Adjustment (Cont'd)

EM-59

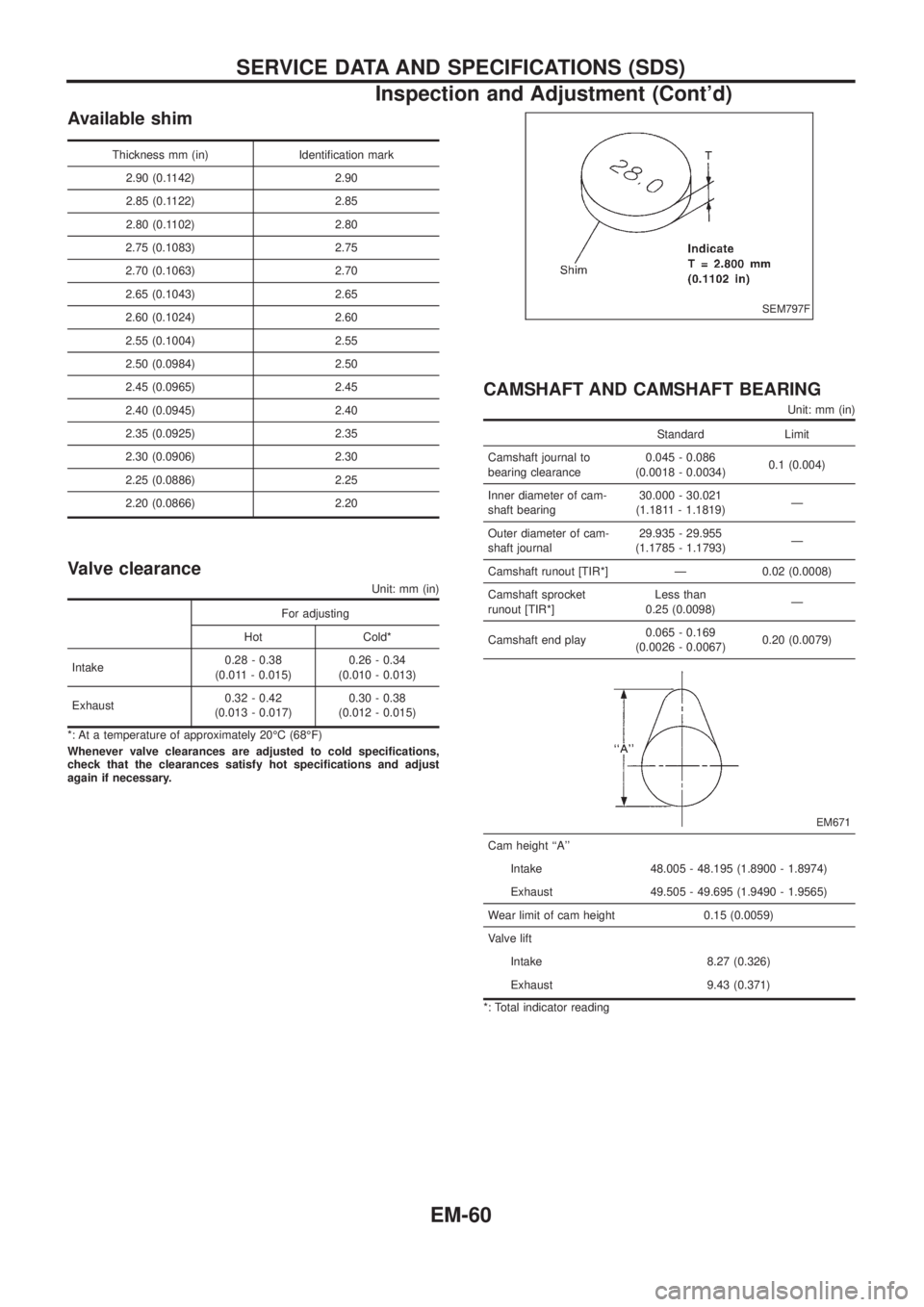

Page 728 of 1226

Available shim

Thickness mm (in) Identi®cation mark

2.90 (0.1142) 2.90

2.85 (0.1122) 2.85

2.80 (0.1102) 2.80

2.75 (0.1083) 2.75

2.70 (0.1063) 2.70

2.65 (0.1043) 2.65

2.60 (0.1024) 2.60

2.55 (0.1004) 2.55

2.50 (0.0984) 2.50

2.45 (0.0965) 2.45

2.40 (0.0945) 2.40

2.35 (0.0925) 2.35

2.30 (0.0906) 2.30

2.25 (0.0886) 2.25

2.20 (0.0866) 2.20

Valve clearance

Unit: mm (in)

For adjusting

Hot Cold*

Intake0.28 - 0.38

(0.011 - 0.015)0.26 - 0.34

(0.010 - 0.013)

Exhaust0.32 - 0.42

(0.013 - 0.017)0.30 - 0.38

(0.012 - 0.015)

*: At a temperature of approximately 20ÉC (68ÉF)

Whenever valve clearances are adjusted to cold speci®cations,

check that the clearances satisfy hot speci®cations and adjust

again if necessary.

CAMSHAFT AND CAMSHAFT BEARING

Unit: mm (in)

Standard Limit

Camshaft journal to

bearing clearance0.045 - 0.086

(0.0018 - 0.0034)0.1 (0.004)

Inner diameter of cam-

shaft bearing30.000 - 30.021

(1.1811 - 1.1819)Ð

Outer diameter of cam-

shaft journal29.935 - 29.955

(1.1785 - 1.1793)Ð

Camshaft runout [TIR*] Ð 0.02 (0.0008)

Camshaft sprocket

runout [TIR*]Less than

0.25 (0.0098)Ð

Camshaft end play0.065 - 0.169

(0.0026 - 0.0067)0.20 (0.0079)

EM671

Cam height ``A''

Intake 48.005 - 48.195 (1.8900 - 1.8974)

Exhaust 49.505 - 49.695 (1.9490 - 1.9565)

Wear limit of cam height 0.15 (0.0059)

Valve lift

Intake 8.27 (0.326)

Exhaust 9.43 (0.371)

*: Total indicator reading

SEM797F

SERVICE DATA AND SPECIFICATIONS (SDS)

Inspection and Adjustment (Cont'd)

EM-60

Page 742 of 1226

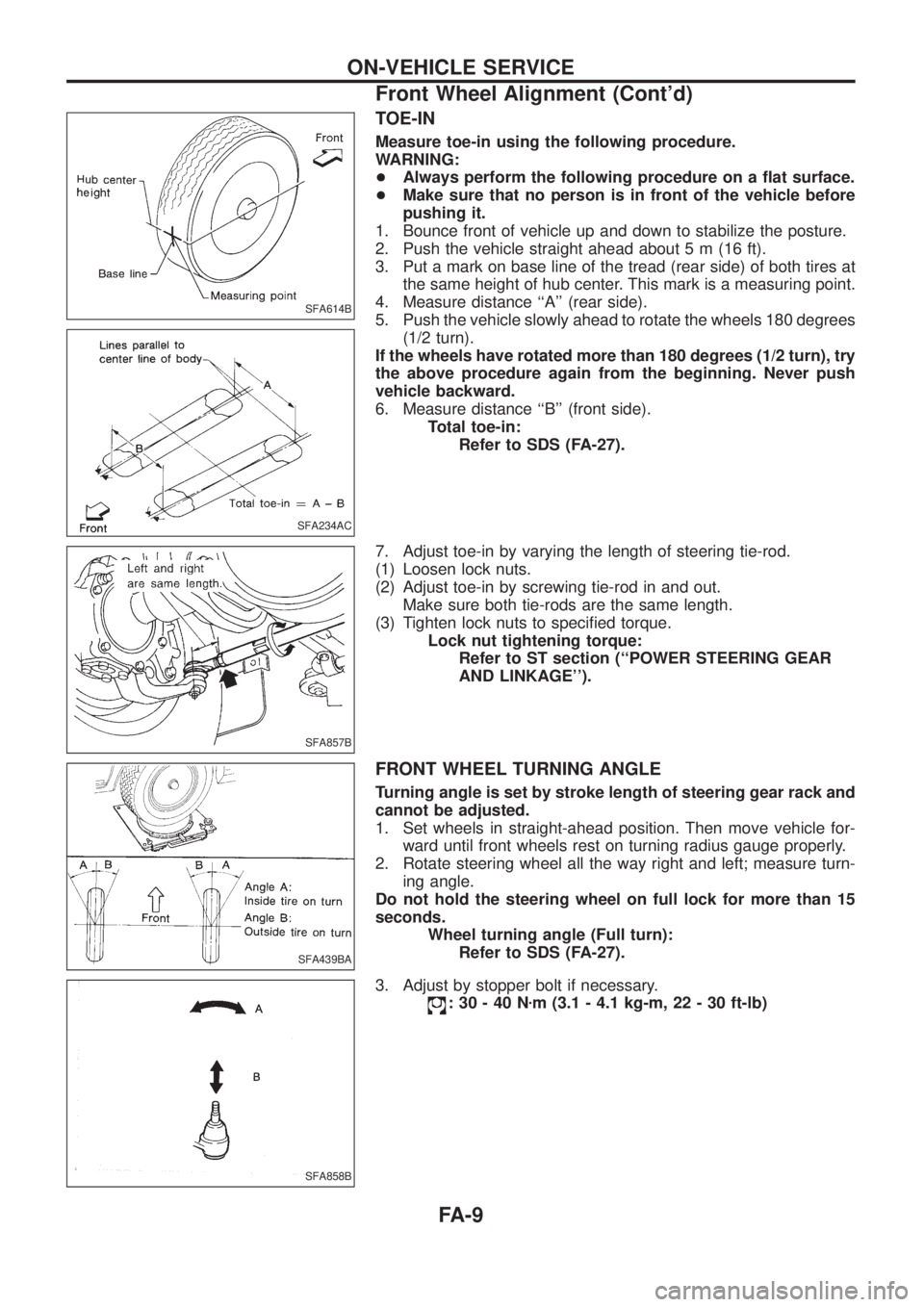

TOE-IN

Measure toe-in using the following procedure.

WARNING:

+Always perform the following procedure on a ¯at surface.

+Make sure that no person is in front of the vehicle before

pushing it.

1. Bounce front of vehicle up and down to stabilize the posture.

2. Push the vehicle straight ahead about 5 m (16 ft).

3. Put a mark on base line of the tread (rear side) of both tires at

the same height of hub center. This mark is a measuring point.

4. Measure distance ``A'' (rear side).

5. Push the vehicle slowly ahead to rotate the wheels 180 degrees

(1/2 turn).

If the wheels have rotated more than 180 degrees (1/2 turn), try

the above procedure again from the beginning. Never push

vehicle backward.

6. Measure distance ``B'' (front side).

Total toe-in:

Refer to SDS (FA-27).

7. Adjust toe-in by varying the length of steering tie-rod.

(1) Loosen lock nuts.

(2) Adjust toe-in by screwing tie-rod in and out.

Make sure both tie-rods are the same length.

(3) Tighten lock nuts to speci®ed torque.

Lock nut tightening torque:

Refer to ST section (``POWER STEERING GEAR

AND LINKAGE'').

FRONT WHEEL TURNING ANGLE

Turning angle is set by stroke length of steering gear rack and

cannot be adjusted.

1. Set wheels in straight-ahead position. Then move vehicle for-

ward until front wheels rest on turning radius gauge properly.

2. Rotate steering wheel all the way right and left; measure turn-

ing angle.

Do not hold the steering wheel on full lock for more than 15

seconds.

Wheel turning angle (Full turn):

Refer to SDS (FA-27).

3. Adjust by stopper bolt if necessary.

:30-40Nzm (3.1 - 4.1 kg-m, 22 - 30 ft-lb)

SFA614B

SFA234AC

SFA857B

SFA439BA

SFA858B

ON-VEHICLE SERVICE

Front Wheel Alignment (Cont'd)

FA-9

Page 811 of 1226

Dimensions

Wagon Hardtop

Overall length mm (in) 4,965 (195.5)

5,010 (197.2)*4,395 (173.0)

4,440 (174.8)*

Overall width mm (in) 1,840 (72.4)

1,930 (76.0)*1,840 (72.4)

1,930 (76.0)*

Overall height mm (in) 1,855 (73.0) 1,840 (72.4)

Front tread mm (in) 1,555 (61.2)

1,605 (63.2)*1,555 (61.2)

1,605 (63.2)*

Rear tread mm (in) 1,575 (62.0)

1,625 (64.0)*1,575 (62.0)

1,625 (64.0)*

Wheelbase mm (in) 2,970 (116.9) 2,400 (94.5)

*: For models equipped with 265/70R16 tires

Wheels & Tires

Road wheel

Size 6JJ-16*1 8JJ-16*1

Offset mm (in) 35 (1.38) 10 (0.39)

Tire size 235/80R16 109S 265/70R16 112S

*1: Steel wheel and Aluminum wheel

IDENTIFICATION INFORMATION

GI-38

Page 814 of 1226

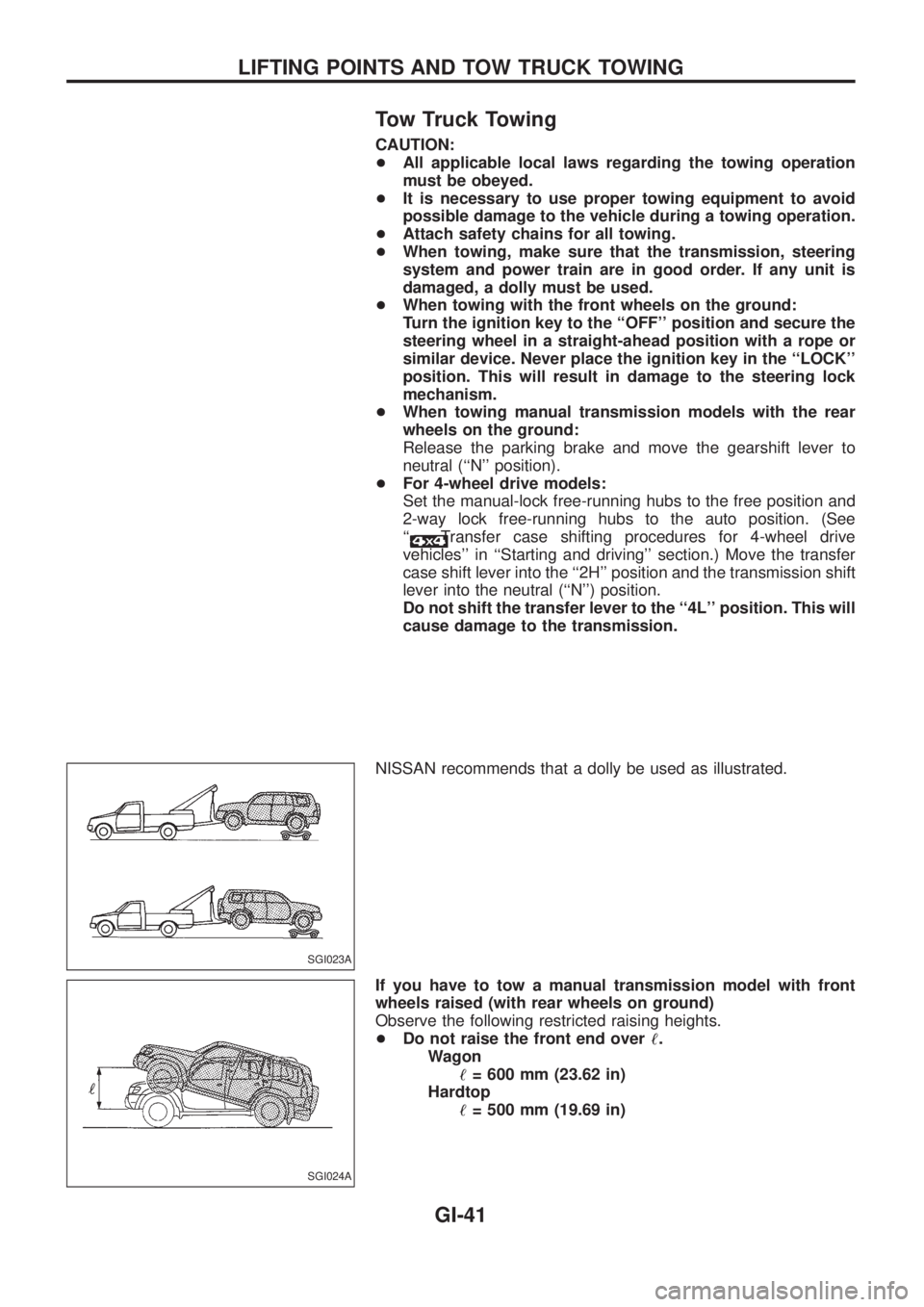

Tow Truck Towing

CAUTION:

+All applicable local laws regarding the towing operation

must be obeyed.

+It is necessary to use proper towing equipment to avoid

possible damage to the vehicle during a towing operation.

+Attach safety chains for all towing.

+When towing, make sure that the transmission, steering

system and power train are in good order. If any unit is

damaged, a dolly must be used.

+When towing with the front wheels on the ground:

Turn the ignition key to the ``OFF'' position and secure the

steering wheel in a straight-ahead position with a rope or

similar device. Never place the ignition key in the ``LOCK''

position. This will result in damage to the steering lock

mechanism.

+When towing manual transmission models with the rear

wheels on the ground:

Release the parking brake and move the gearshift lever to

neutral (``N'' position).

+For 4-wheel drive models:

Set the manual-lock free-running hubs to the free position and

2-way lock free-running hubs to the auto position. (See

``

Transfer case shifting procedures for 4-wheel drive

vehicles'' in ``Starting and driving'' section.) Move the transfer

case shift lever into the ``2H'' position and the transmission shift

lever into the neutral (``N'') position.

Do not shift the transfer lever to the ``4L'' position. This will

cause damage to the transmission.

NISSAN recommends that a dolly be used as illustrated.

If you have to tow a manual transmission model with front

wheels raised (with rear wheels on ground)

Observe the following restricted raising heights.

+Do not raise the front end over!.

Wagon

!= 600 mm (23.62 in)

Hardtop

!= 500 mm (19.69 in)

SGI023A

SGI024A

LIFTING POINTS AND TOW TRUCK TOWING

GI-41

Page 815 of 1226

If you have to tow an automatic transmission model

with four wheels on ground or tow an automatic

transmission model with front wheels raised (with rear

wheels on ground)

Observe the following restricted towing speeds, distances and rais-

ing heights.

+Speed: Below 50 km/h (30 MPH)

+Distance: Less than 65 km (40 miles)

+Do not raise the front end over!.

Wagon

!= 600 mm (23.62 in)

Hardtop

!= 500 mm (19.69 in)

If the speed, distance or height must necessarily be greater,

remove the propeller shaft beforehand to prevent damage to the

transmission.

CAUTION:

+Never tow your vehicle from the rear (i.e., backward) with

four wheels on the ground as this may cause serious and

expensive damage to the transmission.

+Be sure to place the transfer case shift lever into the ``2H''

position and the transmission shift lever into the neutral

(``N'') position if the vehicle is to be towed.

TOWING HOOKS

The towing hooks are provided only for emergency.

+Use the towing hooksonly, not other parts of the vehicle.

Otherwise, the vehicle body will be damaged.

+Use the towing hooksonlyto free a vehicle stuck in sand,

snow, mud, etc.Nevertow the vehicle for long distances using

only the towing hooks.

+The towing hook is under tremendous force when used to free

a stuck vehicle. Always pull the cable straight out from the front

or rear of the vehicle.Neverpull on the hook at a sideways

angle.

SGI025A

LIFTING POINTS AND TOW TRUCK TOWING

Tow Truck Towing (Cont'd)

GI-42