height NISSAN PATROL 2006 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 950 of 1226

Combination meter........................................EL-102

Combination switch .........................................EL-57

Combustion chamber replacement ................EM-32

Compass .......................................................EL-116

Compression pressure ...................................EM-10

Compressor special service tool ......................HA-6

Connecting rod...............................................EM-47

Connecting rod...............................................EM-51

Connector inspection .......................................GI-17

Console box - See Instrument panel ..............BT-11

Control lever (Transfer) .....................................TF-9

Control sleeve position sensor .......................EC-86

Coolant mixture ratio ......................................MA-11

Coolant replacement ......................................MA-14

Cooling circuit (engine) .....................................LC-9

Cooling fan control .......................................EC-112

Cooling fan motor .........................................EC-120

Cooling fan relay ..........................................EC-120

Cooling fan......................................................LC-15

Counter gear (M/T).........................................MT-10

Counter gear (Transfer) ..................................TF-11

Coupling sleeve (M/T) ....................................MT-10

Crankcase emission control system -

See Positive crankcase ventilation.............EC-21

Crankcase ventilation system - See

Positive crankcase ventilation ....................EC-21

Crankshaft position sensor (TDC)................EC-143

Crankshaft ......................................................EM-50

Cylinder block ..........................................EM-45, 48

Cylinder head .................................................EM-28

D

D/LOCK - Wiring diagram .............................EL-205

DEF - Wiring diagram ...................................EL-159

DEICER - Wiring diagram.............................EL-167

DTRL - Wiring diagram ...................................EL-67

Data link connector for Consult......................EC-36

Daytime light system.......................................EL-65

Diagnosis sensor unit .....................................RS-12

Diagnostic trouble code (DTC) for

ECCS OBD system ....................................EC-30

Differential carrier assembly...........................PD-31

Differential carrier disassembly ......................PD-14

Differential gear oil replacement ....................MA-22

Dimensions ......................................................GI-38

Dome light - See Interior lamp .......................EL-93

Door glass .........................................................BT-9

Door lock ...........................................................BT-9

Door mirror ......................................................BT-46

Door trim .........................................................BT-18

Door, front .........................................................BT-9

Door, rear ........................................................BT-10

Drive belt inspection ......................................MA-12

Drive chain (Transfer) .....................................TF-11

Drive pinion diff. inspection ............................PD-19

Drive pinion height .........................................PD-27

Drive shaft (front) ............................................FA-23

Dual pressure switch ......................................HA-11Dual pressure switch ......................................HA-97

E

ECCS basic inspection...................................EC-46

ECCS circuit diagram .....................................EC-11

ECCS component parts location ......................EC-8

ECCS on board diagnostic system ................EC-30

ECCS symptom matrix chart..........................EC-48

ECCS system diagram and chart ..................EC-12

ECCS-D control module .........................EC-54, 110

ECM input/output signal .................................EC-54

ECTS - Wiring diagram ..................................EC-78

EGR control (EGRC) - solenoid valve .........EC-155

EGR control valve ........................................EC-161

EGRC/V - Wiring diagram ............................EC-155

Electric governor ....................................EC-95, 148

Electric sunroof .............................................EL-186

Electrical diagnoses.........................................GI-20

Electrical unit.................................................EL-321

Electrical units location .................................EL-269

Electronic fuel injection pump ........................EC-27

Engine compartment .......................................BT-49

Engine coolant temperature sensor

(ECTS) ........................................................EC-78

Engine oil ®lter replacement ..........................MA-14

Engine oil precautions .......................................GI-4

Engine oil replacement ..................................MA-13

Engine outer component parts ........................EM-8

Engine removal ..............................................EM-43

Engine room - See Engine

compartment ...............................................BT-49

Engine serial number ......................................GI-37

Exhaust system inspection ............................MA-20

Exhaust system ................................................FE-3

Exterior ............................................................BT-26

F

FCUT - Wiring diagram ................................EC-129

FTS - Wiring diagram ...................................EC-134

Fan control amp. ............................................HA-88

Final drive disassembly ..................................PD-14

Final drive removal and installation................PD-11

Finisher, interior - See Trim ............................BT-14

Floor trim .........................................................BT-14

Flow charts ......................................................GI-30

Fluids................................................................MA-9

Flywheel (clutch).......................................CL-13, 14

Flywheel runout..............................................EM-52

Fog lamp, rear ................................................EL-80

Fork rod (M/T) ................................................MT-12

Front axle ........................................................FA-10

Front bumper ....................................................BT-4

Front case (Transfer) ......................................TF-10

Front disc brake .............................................BR-20

Front door .........................................................BT-9

ALPHABETICAL INDEX

IDX-3

Page 952 of 1226

M

M/T major overhaul ..........................................MT-9

M/T removal and installation ............................MT-5

MAFS - Wiring diagram..................................EC-73

MAIN - Wiring diagram...................................EC-62

METER - Wiring diagram..............................EL-104

MIL & Data link connectors circuit ...............EC-187

MIL/DL - Wiring diagram ..............................EC-187

MIRROR - Wiring diagram............................EL-188

Main drive gear (M/T).....................................MT-10

Main gear (Transfer) .......................................TF-11

Mainshaft (M/T) ..............................................MT-10

Mainshaft (Transfer) ........................................TF-11

Maintenance (engine) ....................................MA-12

Major overhaul (Transfer) ...............................TF-10

Malfunction indicator lamp (MIL) ....................EC-31

Manifold tightening torque (intake &

exhaust)......................................................MA-12

Manual lock free running hub .........................FA-11

Manual transmission number ..........................GI-37

Mass air ¯ow sensor (MAFS).........................EC-73

Master cylinder (brake) ..................................BR-12

Meter .............................................................EL-102

Mirror, door......................................................BT-46

Mirror, outside .................................................BT-46

Mode door control linkage adjustment ...........HA-77

Model variation ................................................GI-35

Molding - See Exterior ....................................BT-26

Multiport fuel injection precautions ....................GI-3

N

NATS (Nissan Anti-theft System)..................EL-240

NATS - Wiring diagram .................................EL-241

NLS - Wiring diagram...................................EC-125

NVH Troubleshooting (PD)...............................PD-4

NVH troubleshooting (BR)................................BR-2

NVH troubleshooting (EM) ...............................EM-6

NVH troubleshooting (FA) .................................FA-3

NVH troubleshooting (MT) ...............................MT-3

NVH troubleshooting (RA)................................RA-3

NVH troubleshooting (RA)................................RA-3

NVH troubleshooting (ST).................................ST-3

NVH troubleshooting (Transfer) ........................TF-3

NVH troubleshooting CL ...................................CL-3

Needle lift sensor .........................................EC-125

Neutral position switch (M/T) ...........................MT-4

Neutral position switch .................................EC-169

O

Oil change (capacity) .......................................MA-9

Oil cooler (engine) ............................................LC-7

Oil jet.................................................................LC-7

Oil pan (engine) .............................................EM-13Oil pressure (engine) ........................................LC-3

Oil pump (engine) .............................................LC-4

Oil seal replacement (engine)........................EM-20

Oil seal replacement (front ®nal drive

4WD)...........................................................PD-10

Oil seal replacement (front of ®nal

drive) ...........................................................PD-10

Operating cylinder (clutch)................................CL-8

Outside mirror .................................................BT-46

P

P/ANT - Wiring diagram................................EL-181

PCV (positive crankcase ventilation) .............EC-21

PNP/SW - Wiring diagram ...........................EC-169

POWER - Wiring diagram.................................EL-6

Park/Neutral position switch .........................EC-169

Periodic maintenance (for Europe) ..................MA-4

Pinion bearing preload diff. ............................PD-27

Pinion gear height diff. ...................................PD-27

Piston assembly .............................................EM-46

Piston pin inspection ......................................EM-46

Piston ring inspection.....................................EM-47

Piston to bore clearance ................................EM-48

Power antenna ..............................................EL-181

Power door lock ............................................EL-204

Power door lock ............................................EL-211

Power door mirror .........................................EL-188

Power seat ....................................................EL-190

Power steering ¯uid level..................................ST-5

Power steering gear........................................ST-12

Power steering hydraulic pressure ...................ST-6

Power steering oil pump .................................ST-15

Power steering system bleeding.......................ST-6

Power supply routing ........................................EL-5

Power window ...............................................EL-196

Pre-delivery inspection.....................................MA-2

Precautions (General) .......................................GI-2

Pressure plate - See Clutch cover .................CL-14

Priming pump .................................................EC-46

Propeller shaft greasing .................................MA-21

Propeller shaft inspection ..............................MA-21

Propeller shaft on vehicle service ....................PD-6

Propeller shaft vibration ...................................PD-6

Propeller shaft ..................................................PD-5

Q

Quick-glow system check.............................EC-153

Quick-glow system .......................................EC-150

R

R/FOG - Wiring diagram .................................EL-80

R/HEAT - Wiring diagram ...............................HA-14

ALPHABETICAL INDEX

IDX-5

Page 973 of 1226

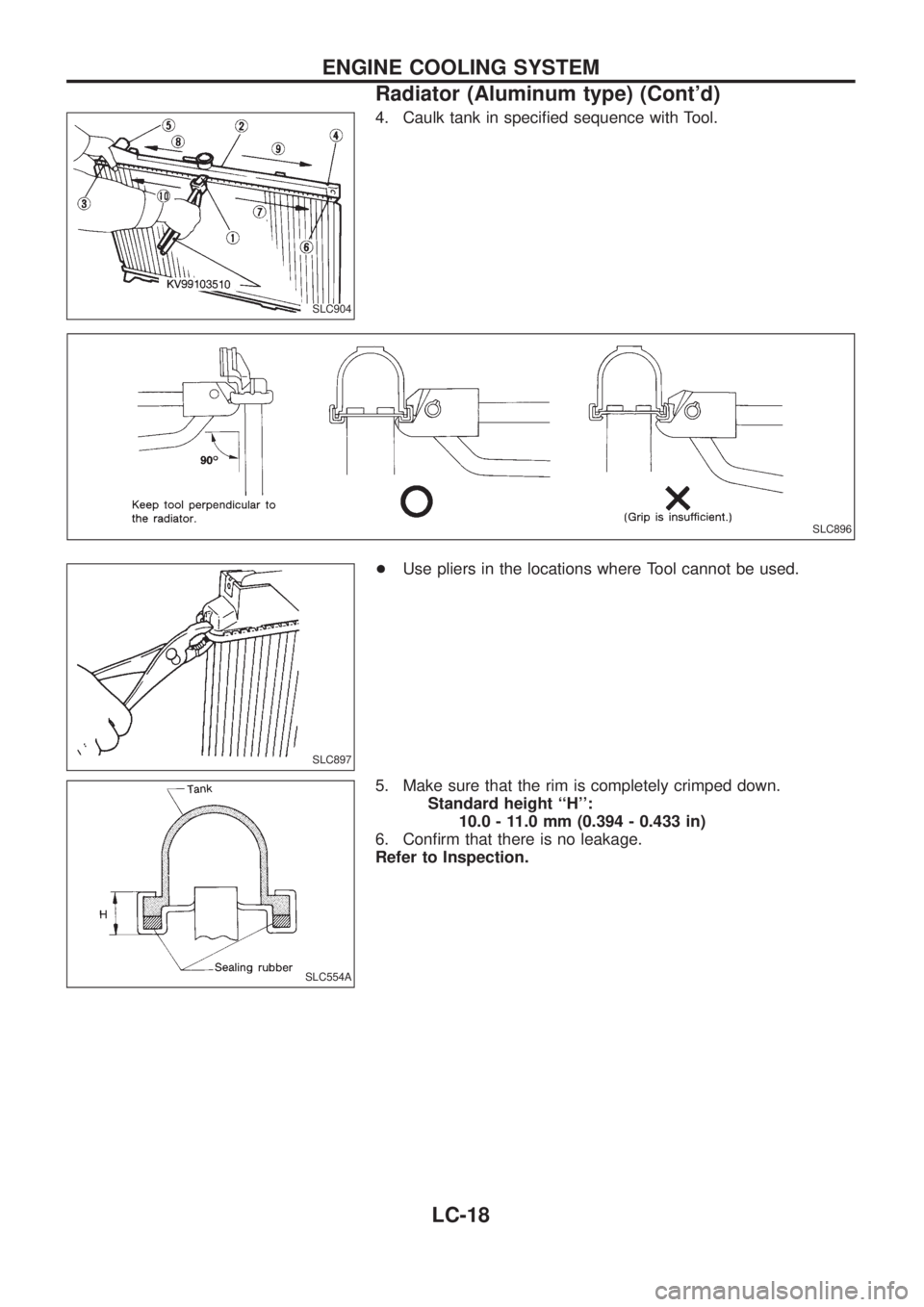

4. Caulk tank in speci®ed sequence with Tool.

+Use pliers in the locations where Tool cannot be used.

5. Make sure that the rim is completely crimped down.

Standard height ``H'':

10.0 - 11.0 mm (0.394 - 0.433 in)

6. Con®rm that there is no leakage.

Refer to Inspection.

SLC904

SLC896

SLC897

SLC554A

ENGINE COOLING SYSTEM

Radiator (Aluminum type) (Cont'd)

LC-18

Page 1042 of 1226

PROPELLER SHAFT &

DIFFERENTIAL CARRIER

SECTION

PD

CONTENTS

PREPARATION................................................................1

Special Service Tools ..................................................1

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................4

NVH Troubleshooting Chart.........................................4

PROPELLER SHAFT......................................................5

Front Propeller Shaft ...................................................5

Rear Propeller Shaft ....................................................5

On-vehicle Service.......................................................6

Removal and Installation .............................................7

Inspection.....................................................................7

Disassembly.................................................................7

Assembly .....................................................................8

ON-VEHICLE SERVICE (Final Drive)..........................10

Front Oil Seal Replacement ......................................10

REMOVAL AND INSTALLATION.................................. 11

Removal ..................................................................... 11

Installation .................................................................. 11

FRONT FINAL DRIVE...................................................12

REAR FINAL DRIVE.....................................................13

DISASSEMBLY..............................................................14

Pre-inspection ............................................................14

Differential Carrier......................................................15

Differential Case ........................................................17

INSPECTION..................................................................19

Ring Gear and Drive Pinion ......................................19

Differential Case Assembly........................................19Bearing.......................................................................19

LIMITED SLIP DIFFERENTIAL.....................................20

Preparation for Disassembly .....................................20

Disassembly...............................................................21

Inspection...................................................................21

Adjustment .................................................................23

Assembly ...................................................................24

ADJUSTMENT...............................................................27

Drive Pinion Height ....................................................27

Tooth Contact.............................................................29

ASSEMBLY....................................................................31

Differential Case Ð 4-pinion type Ð.........................31

Differential Case Ð 2-pinion type Ð.........................32

Differential Carrier......................................................33

DIFFERENTIAL LOCK..................................................37

Actuator and Fork ......................................................37

Disassembly...............................................................38

Inspection...................................................................39

Assembly ...................................................................40

System Description ....................................................43

Component Parts Location ........................................44

Wiring Diagram Ð DIFF/L Ð/LHD Models ...............45

Wiring Diagram Ð DIFF/L Ð/RHD Models ...............47

Electrical Components Inspection .............................49

SERVICE DATA AND SPECIFICATIONS (SDS)..........51

Propeller Shaft ...........................................................51

Final Drive..................................................................52

PD

Page 1044 of 1226

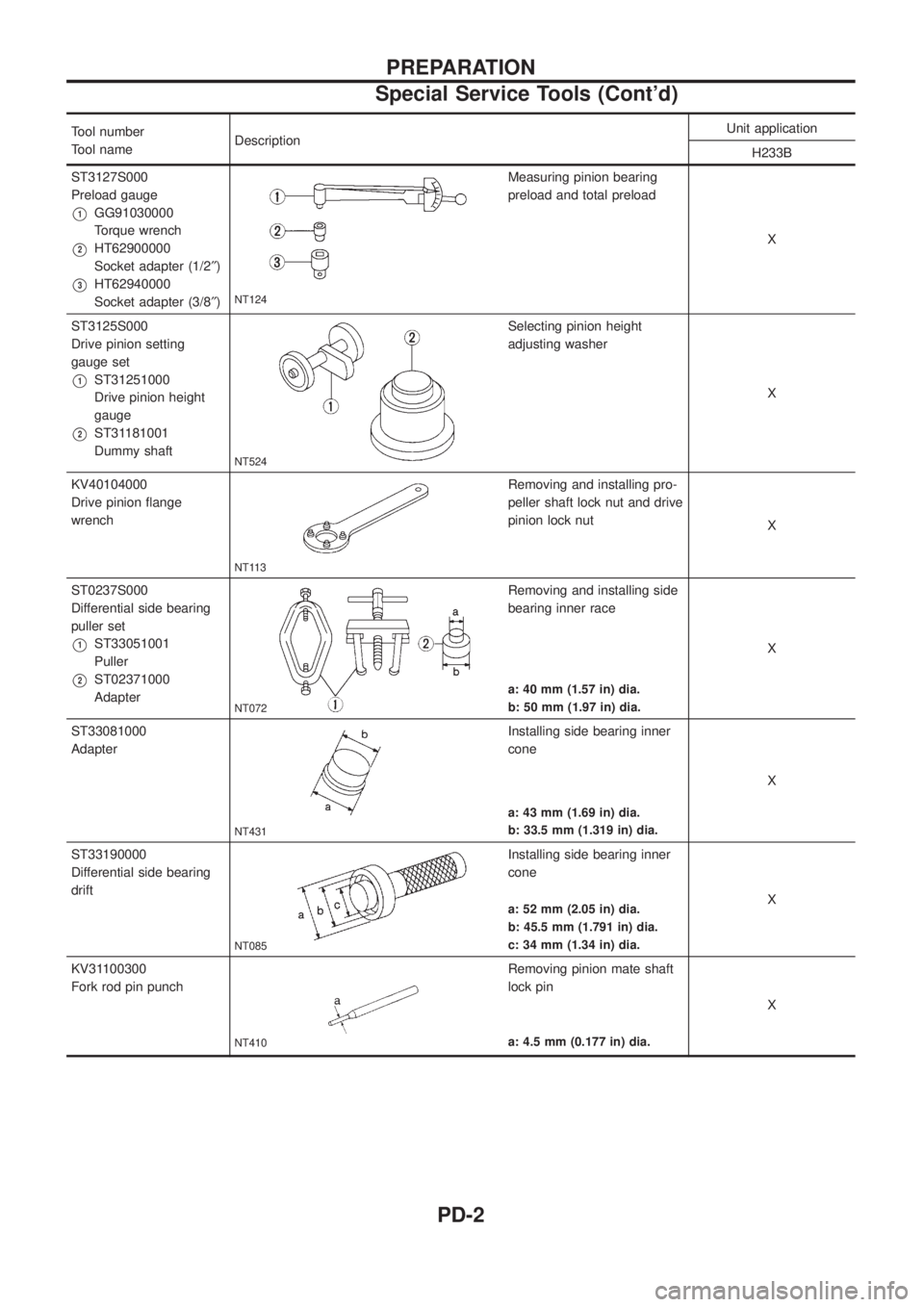

Tool number

Tool nameDescriptionUnit application

H233B

ST3127S000

Preload gauge

V1GG91030000

Torque wrench

V2HT62900000

Socket adapter (1/2²)

V3HT62940000

Socket adapter (3/8²)NT124

Measuring pinion bearing

preload and total preload

X

ST3125S000

Drive pinion setting

gauge set

V1ST31251000

Drive pinion height

gauge

V2ST31181001

Dummy shaft

NT524

Selecting pinion height

adjusting washer

X

KV40104000

Drive pinion ¯ange

wrench

NT113

Removing and installing pro-

peller shaft lock nut and drive

pinion lock nut

X

ST0237S000

Differential side bearing

puller set

V1ST33051001

Puller

V2ST02371000

Adapter

NT072

Removing and installing side

bearing inner race

X

a: 40 mm (1.57 in) dia.

b: 50 mm (1.97 in) dia.

ST33081000

Adapter

NT431

Installing side bearing inner

cone

X

a: 43 mm (1.69 in) dia.

b: 33.5 mm (1.319 in) dia.

ST33190000

Differential side bearing

drift

NT085

Installing side bearing inner

cone

X

a: 52 mm (2.05 in) dia.

b: 45.5 mm (1.791 in) dia.

c: 34 mm (1.34 in) dia.

KV31100300

Fork rod pin punch

NT410

Removing pinion mate shaft

lock pin

X

a: 4.5 mm (0.177 in) dia.

PREPARATION

Special Service Tools (Cont'd)

PD-2

Page 1045 of 1226

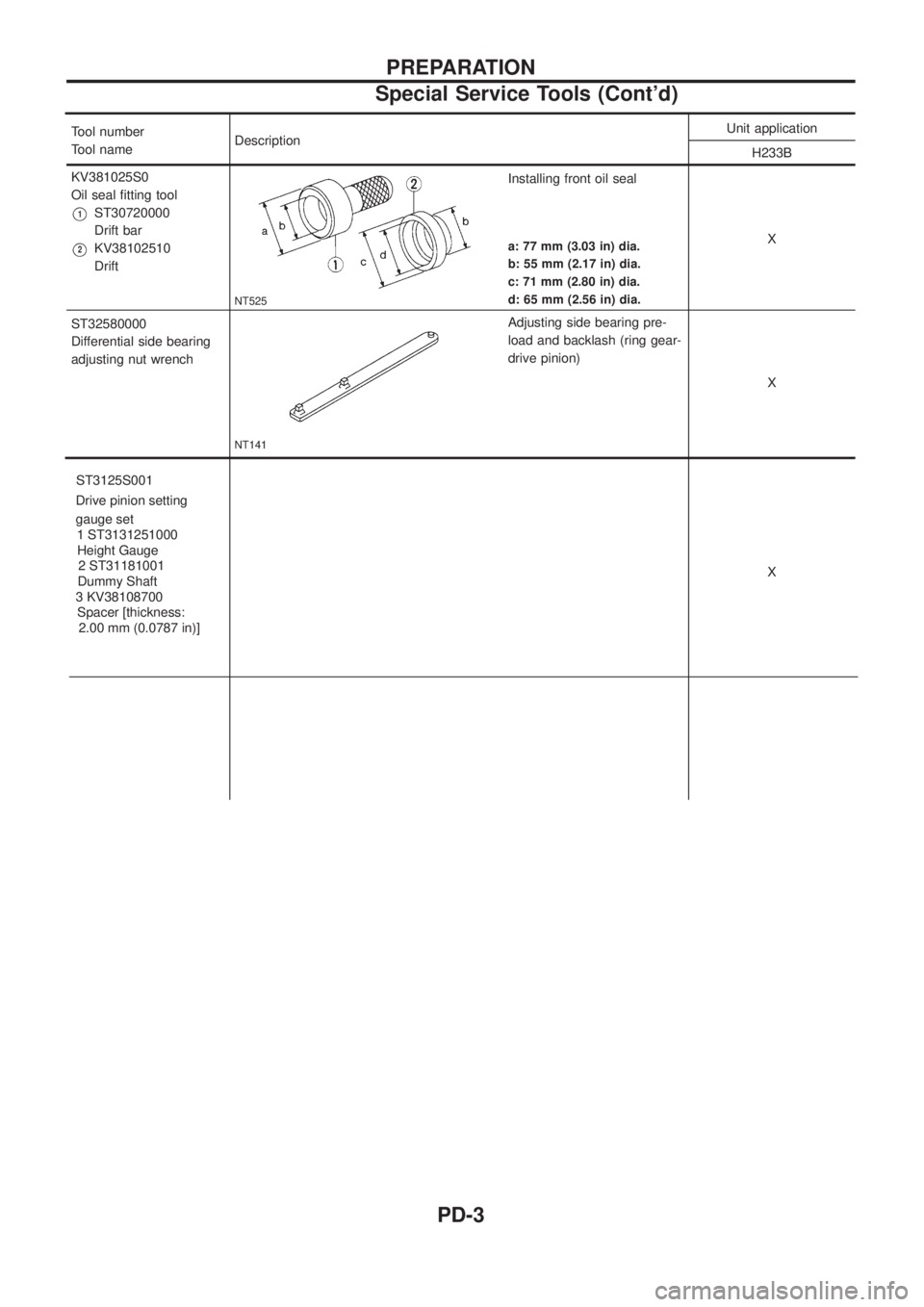

Tool number

Tool nameDescription Unit application

H233B

KV381025S0

Oil seal ®tting tool

V1ST30720000

Drift bar

V2KV38102510

Drift

NT525

Installing front oil seal

X

a: 77 mm (3.03 in) dia.

b: 55 mm (2.17 in) dia.

c: 71 mm (2.80 in) dia.

d: 65 mm (2.56 in) dia.

ST32580000

Differentialsidebearing

adjustingnutwrench

ST3125S001 Drive pinion setting gauge set 1 ST3131251000 Height Gauge 2 ST31181001

Dummy Shaft

3 KV38108700 Spacer [thickness: 2.00 mm (0.0787 in)]

NT141

Adjusting side bearing pre-

load and backlash (ring gear-

drive pinion)

X

X

PREPARATION

Special Service Tools (Cont'd)

PD-3

Page 1059 of 1226

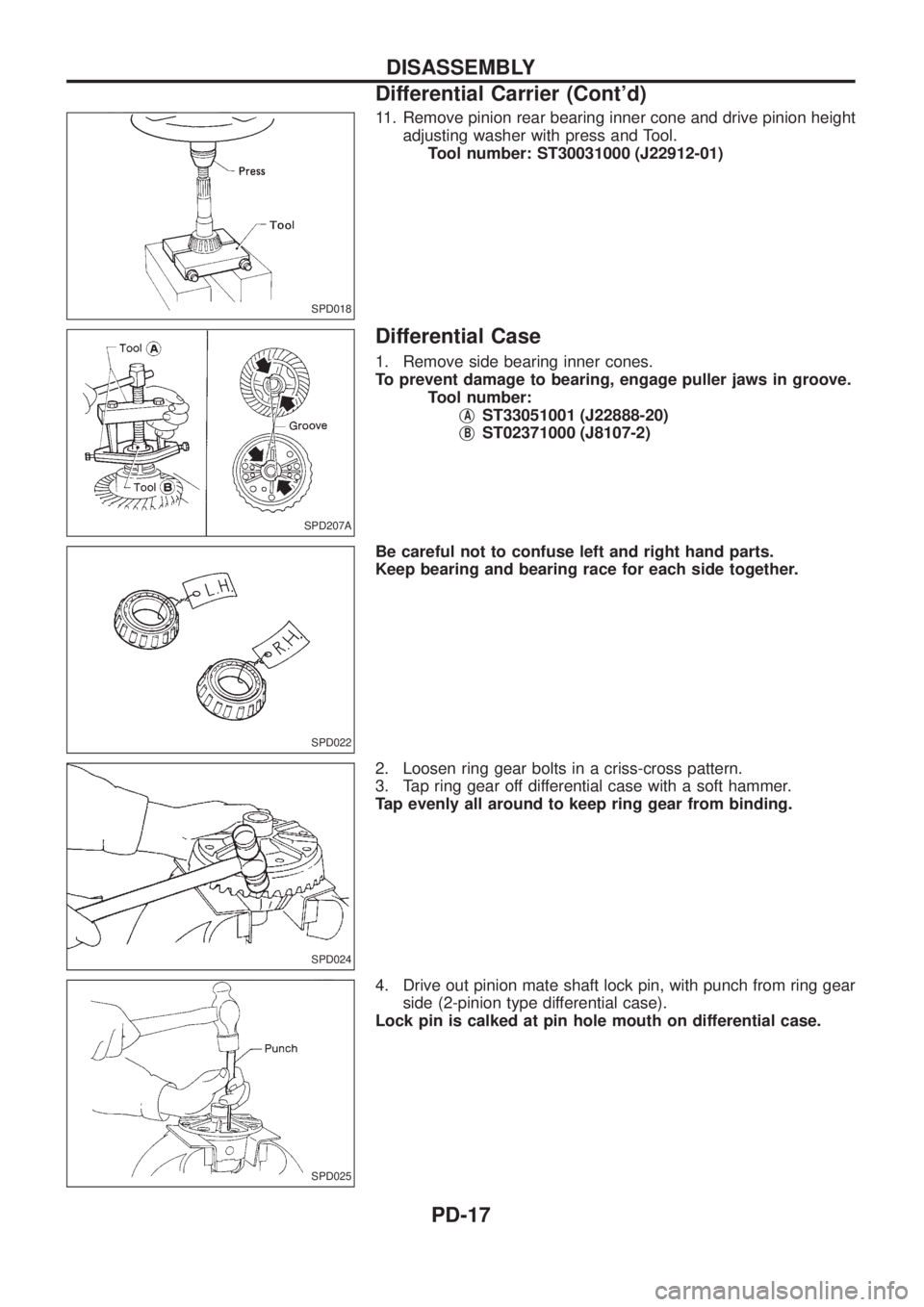

11. Remove pinion rear bearing inner cone and drive pinion heightadjusting washer with press and Tool.Toolnumber:ST30031000 (J22912-01)

Differential Case

1. Remove side bearing inner cones.

To prevent damage to bearing, engage puller jaws in groove. Tool number:j

AST33051001 (J22888-20)

j

BST02371000 (J8107-2)

Be careful not to confuse left and right hand parts.

Keep bearing and bearing race for each side together.

2. Loosen ring gear bolts in a criss-cross pattern.

3. Tap ring gear off differential case with a soft hammer.

Tap evenly all around to keep ring gear from binding.

4. Drive out pinion mate shaft lock pin, with punch from ring gear side (2-pinion type differential case).

Lock pin is calked at pin hole mouth on differential case.

SPD018

SPD207A

SPD022

SPD024

SPD025

DISASSEMBLY

Differential Carrier (Cont'd)

PD-17

Page 1069 of 1226

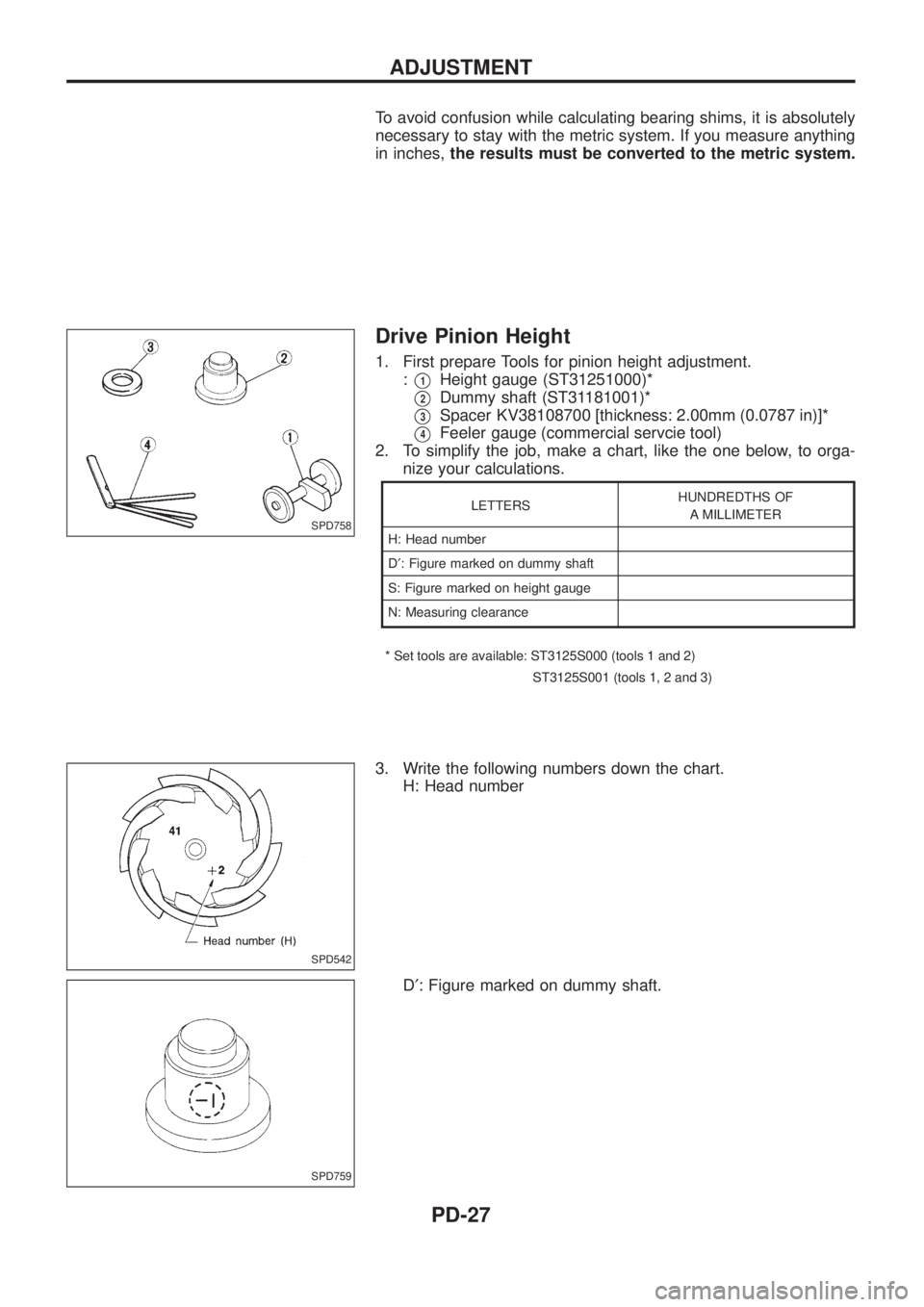

To avoid confusion while calculating bearing shims, it is absolutely

necessary to stay with the metric system. If you measure anything

in inches,the results must be converted to the metric system.

Drive Pinion Height

1. First prepare Tools for pinion height adjustment.

:

V1Heightgauge(ST31251000)*

V2Dummyshaft(ST31181001)*

V3SpacerKV38108700 [thickness: 2.00mm (0.0787 in)]*

V4Feelergauge (commercial servcie tool)

2. To simplify the job, make a chart, like the one below, to orga- nize your calculations.

LETTERS HUNDREDTHS OF

A MILLIMETER

H: Head number

D ¢: Figure marked on dummy shaft

S: Figure marked on height gauge

N:Measuringclearance

* Set tools are available: ST3125S000 (tools 1 and 2) ST3125S001 (tools 1, 2 and 3)

3. Write the following numbers down the chart.H: Head number

D¢: Figure marked on dummy shaft.

SPD758

SPD542

SPD759

ADJUSTMENT

PD-27

Page 1070 of 1226

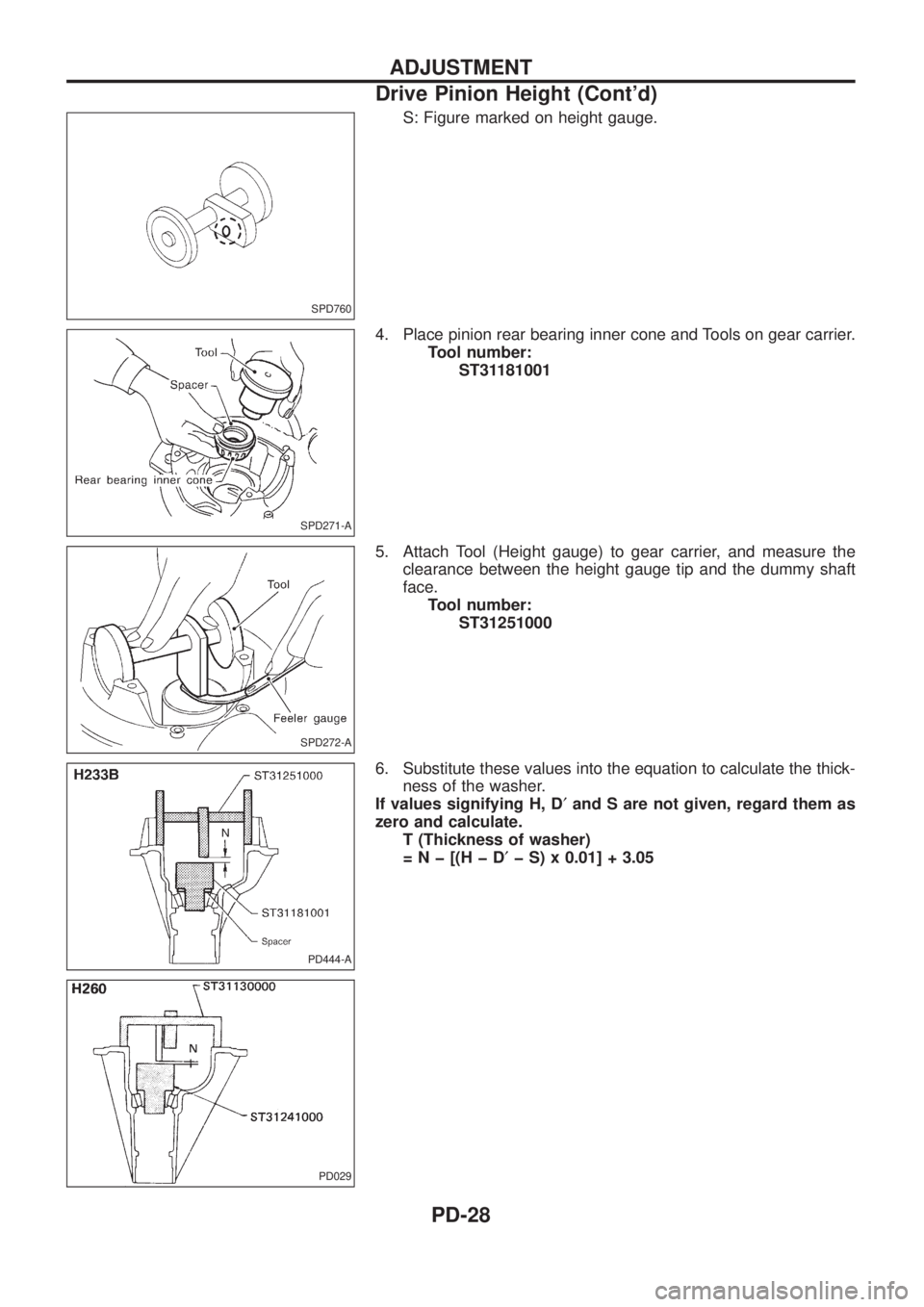

S: Figure marked on height gauge.

4. Place pinion rear bearing inner cone and Tools on gear carrier.

Tool number:

ST31181001

5. Attach Tool (Height gauge) to gear carrier, and measure the

clearance between the height gauge tip and the dummy shaft

face.

Tool number:

ST31251000

6. Substitute these values into the equation to calculate the thick-

ness of the washer.

If values signifying H, D¢and S are not given, regard them as

zero and calculate.

T (Thickness of washer)

=Nþ[(HþD¢þ S) x 0.01] + 3.05

SPD760

SPD271-A

SPD272-A

PD444-A

PD029

ADJUSTMENT

Drive Pinion Height (Cont'd)

PD-28

Page 1071 of 1226

![NISSAN PATROL 2006 Owners Manual Example (H233B):N = 0.30

H=2

D¢=þ1

S=0

T=Nþ[(HþD ¢þS)x0.01]+2.75

=0.40þ[{2þ(þ1)þ0}x0.01]+2.75

(1) H ........................................................................\

2 þD¢........ NISSAN PATROL 2006 Owners Manual Example (H233B):N = 0.30

H=2

D¢=þ1

S=0

T=Nþ[(HþD ¢þS)x0.01]+2.75

=0.40þ[{2þ(þ1)þ0}x0.01]+2.75

(1) H ........................................................................\

2 þD¢........](/img/5/57368/w960_57368-1070.png)

Example (H233B):N = 0.30

H=2

D¢=þ1

S=0

T=Nþ[(HþD ¢þS)x0.01]+2.75

=0.40þ[{2þ(þ1)þ0}x0.01]+2.75

(1) H ........................................................................\

2 þD¢................................................................. þ(þ1)

3

þS ...................................................................... þ0

3

(2) 3 x 0.01

0.03

(3)N...................................................................0.40 þ0.03

0.37

(4)0.37 +2.75

3.12

\ T=3.12

7. Select the proper pinion height washer. Drive pinion height adjusting washer:Refer to SDS (PD-0, 53).

If you cannot ®nd the desired thickness of washer, use washer

with thickness closest to the calculated value.

Example (H233B): Calculatedvalue...T=3.12 mm

Usedwasher...T=3.12 mm

Tooth Contact

Gear tooth contact pattern check is necessary to verify correct

relationship between ring gear and drive pinion.

Hypoid gear sets which are not positioned properly in relation to

one another may be noisy, or have short life or both. With a pat-

tern check, the most desirable contact for low noise level and long

life can be assured.

1. Thoroughly clean ring gear and drive pinion teeth.

2. Sparingly apply a mixture of powdered ferric oxide and oil orequivalent to 3 or 4 teeth of ring gear drive side.

SPD005

ADJUSTMENT

Drive Pinion Height (Cont'd)

PD-29