main NISSAN PATROL 2006 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 150 of 1226

ENGINE CONTROL SYSTEMSECTION

EC

CONTENTS

DIAGNOSTIC TROUBLE CODE INDEX .........................1

Alphabetical & Numerical Index for DTC ....................1

PRECAUTIONS AND PREPARATION ............................2

Special Service Tools ..................................................2

Commercial Service Tool .............................................3

Supplemental Restraint System (SRS) ``AIR

BAG'' and ``SEAT BELT PRE-TENSIONER''...............4

PRECAUTIONS AND PREPARATION ............................5

Engine Fuel & Emission Control System ....................5

Precautions ..................................................................6

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM ........................................................................\

...8

ECCS-D Component Parts Location ...........................8

Circuit Diagram .......................................................... 11

System Diagram ........................................................12

Vacuum Hose Drawing ..............................................13

System Chart .............................................................14

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION ...............................................15

Fuel Injection System ................................................15

Fuel Injection Timing System ....................................18

Air Conditioning Cut Control ......................................19

Fuel Cut Control (at no load & high engine

speed) ........................................................................\

20

CRANKCASE VENTILATION SYSTEM ........................21

Description .................................................................21

Inspection...................................................................21

INJECTION NOZZLE .....................................................22

Removal and Installation ...........................................22

Disassembly (No. 2 - 4 nozzles) ...............................22

Inspection (No. 2 - 4 nozzles) ...................................23

Cleaning (No. 2 - 4 nozzles) .....................................23

Assembly (No. 2 - 4 nozzles) ....................................24

Test and Adjustment ..................................................25

ELECTRONIC FUEL INJECTION PUMP ......................27

Removal .....................................................................27

Installation ..................................................................28

Disassembly and Assembly .......................................29

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION ...............................................................30

DTC and MIL Detection Logic ...................................30

Diagnostic Trouble Code (DTC) ................................30 Malfunction Indicator Lamp (MIL) ..............................31

CONSULT ..................................................................36

TROUBLE DIAGNOSIS Ð Introduction ......................42

Introduction ................................................................42

Diagnostic Worksheet ................................................43

TROUBLE DIAGNOSIS Ð Work Flow ........................44

Work Flow ..................................................................44

Description for Work Flow .........................................45

TROUBLE DIAGNOSIS Ð Basic Inspection ..............46

Basic Inspection.........................................................46

TROUBLE DIAGNOSIS Ð General Description ........48

Symptom Matrix Chart ...............................................48

CONSULT Reference Value in Data Monitor

Mode ........................................................................\

..51

Major Sensor Reference Graph in Data Monitor

Mode ........................................................................\

..53

ECM Terminals and Reference Value .......................54

TROUBLEDIAGNOSISFORPOWERSUPPLY ..........63

MainPowerSupplyandGroundCircuit....................63

TROUBLE DIAGNOSIS FOR ``CAM POS SEN

(PUMP)''(DTC11) .........................................................69

CamshaftPositionSensor(CMPS)(PUMP).............69

TROUBLEDIAGNOSISFOR``MASSAIRFLOW

SEN''(DTC12) ..............................................................74

MassAirFlowSensor(MAFS)..................................74

TROUBLEDIAGNOSISFOR``COOLANTTEMP

SEN''(DTC13) ..............................................................79

EngineCoolantTemperature(ECT)Sensor.............79

TROUBLEDIAGNOSISFOR``VEHICLESPEED

SEN''(DTC14) ..............................................................83

VehicleSpeedSensor(VSS)....................................83

TROUBLEDIAGNOSISFOR``CONTSLEEVPOS

SEN''(DTC15) ..............................................................87

ControlSleevePositionSensor(CSPS)...................87

TROUBLEDIAGNOSISFOR``ADJUST

RESISTOR''(DTC17) ...................................................92

AdjustmentResistor...................................................92

TROUBLEDIAGNOSISFOR``F/INJF/B2''

(DTC18),``F/INJF/B''(DTC22),``ELECTRIC

GOV''(DTC25) ..............................................................96

ElectricGovernor.......................................................96

EC

Page 155 of 1226

Supplemental Restraint System (SRS) ``AIR

BAG'' and ``SEAT BELT PRE-TENSIONER''

The Supplemental Restraint System such as ``AIR BAG'' and ``SEAT BELT PRE-TENSIONER'' used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger in a frontal collision.

The SRS system composition which is available to NISSAN MODEL Y61 is as follows (The composition var-

ies according to the destination.):

Driver air bag module (located in the center of the steering wheel), front passenger air bag module (located

on the instrument panel on passenger side), seat belt pre-tensioner, a diagnosis sensor unit, warning lamp,

wiring harness and spiral cable.

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag in¯ation, all maintenance must be performed

by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation either just before

the harness connectors or for the complete harness are related to the SRS.

PRECAUTIONS AND PREPARATION

EC-4

Page 176 of 1226

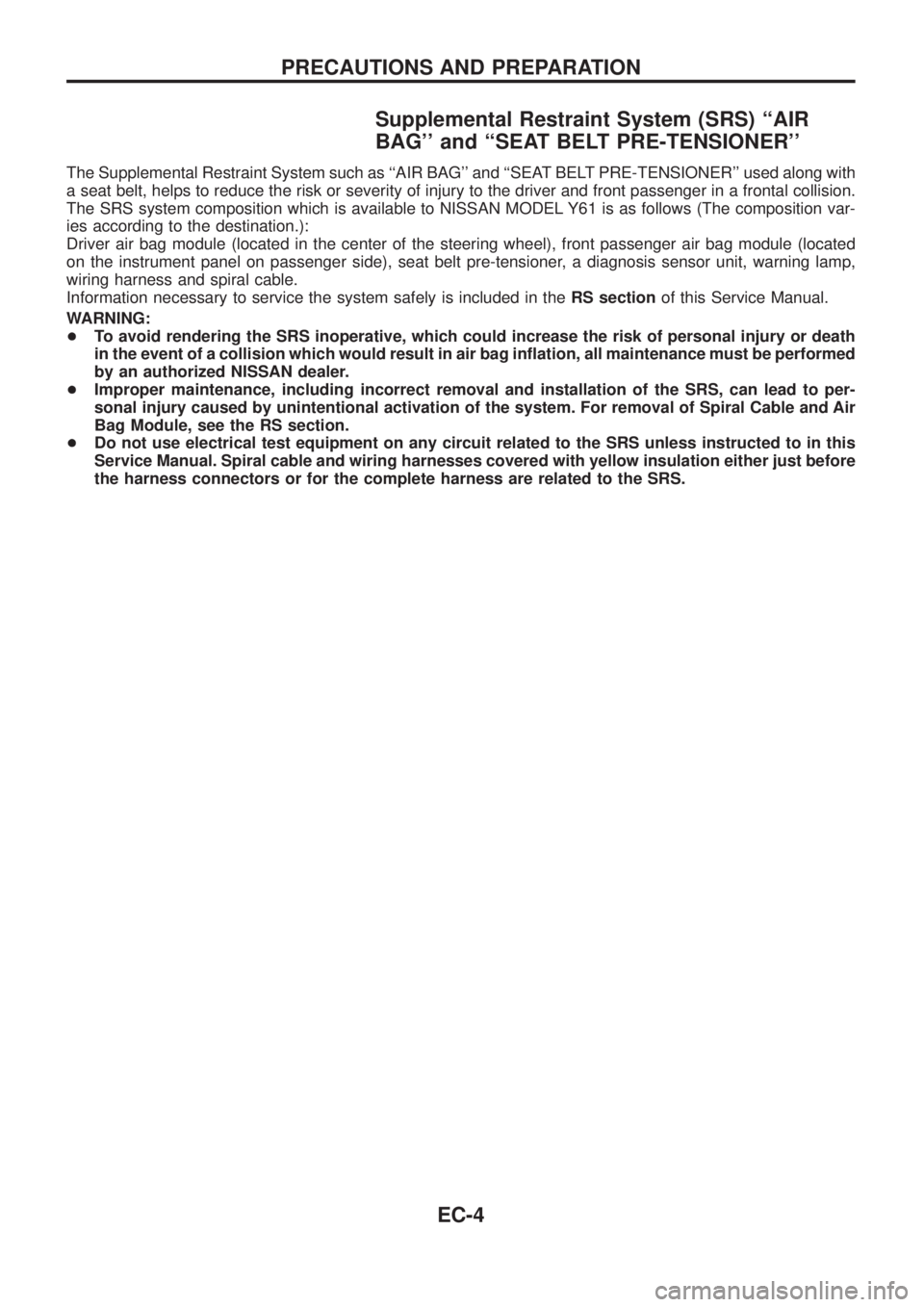

Test and Adjustment

WARNING:

When using nozzle tester, be careful not to allow diesel fuel

sprayed from nozzle to contact your hands or body, and make

sure your eyes are properly protected with goggles.

INJECTION PRESSURE TEST

1. Install nozzle to injection nozzle tester and bleed air from ¯are

nut.

2. Pump the tester handle slowly (one time per second) and watch

the pressure gauge.

3. Read the pressure gauge when the injection pressure just

starts dropping.

Initial injection pressure:

Used

14,220 kPa (142.2 bar, 145 kg/cm

2, 2,062 psi)

New

14,711 - 15,495 kPa (147.1 - 155.0 bar,

150 - 158 kg/cm

2, 2,133 - 2,247 psi)

Always check initial injection pressure using a new nozzle.

4. To adjust injection pressure, change adjusting shims (No. 2 - 4

nozzles).

a. Increasing the thickness of adjusting shims increases ini-

tial injection pressure. Decreasing thickness reduces ini-

tial pressure.

b. A shim thickness of 0.04 mm (0.0016 in) corresponds

approximately to a difference of 471 kPa (4.71 bar, 4.8

kg/cm

2, 68 psi) in initial injection pressure.

Refer to SDS for adjusting shim (EC-189).

LEAKAGE TEST

1. Maintain the pressure at about 981 to 1,961 kPa (9.8 to 19.6

bar, 10 to 20 kg/cm2, 142 to 284 psi) below initial injection

pressure.

2. Check that there is no dripping from the nozzle tip or around the

body.

EF791A

SEF672A

SEF673A

Adjusting shim

SEF674A

INJECTION NOZZLE

EC-25

Page 177 of 1226

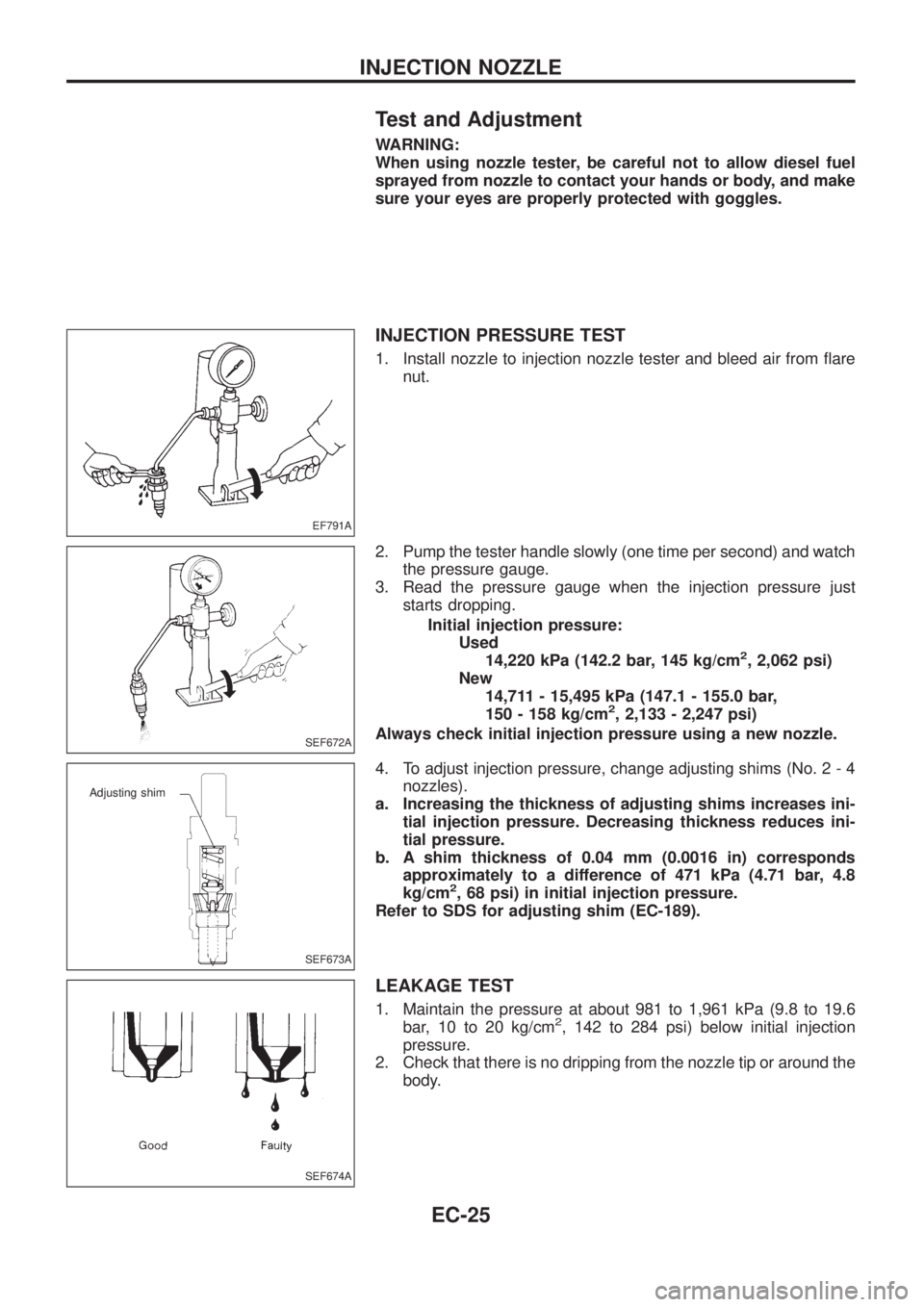

3. If there is leakage, clean, overhaul or replace nozzle.

SPRAY PATTERN TEST

1. Check spray pattern by pumping tester handle one full stroke

per second.

+If main spray angle is within 30 degrees as shown, injec-

tion nozzle is good.

+It is still normal even if a thin stream of spray deviates from

the main spray (pattern B).

2. If the spray pattern is not correct, disassemble and clean

nozzle.

3. Test again and if spray pattern is not corrected, replace nozzle.

SEF079S

INJECTION NOZZLE

Test and Adjustment (Cont'd)

EC-26

Page 182 of 1226

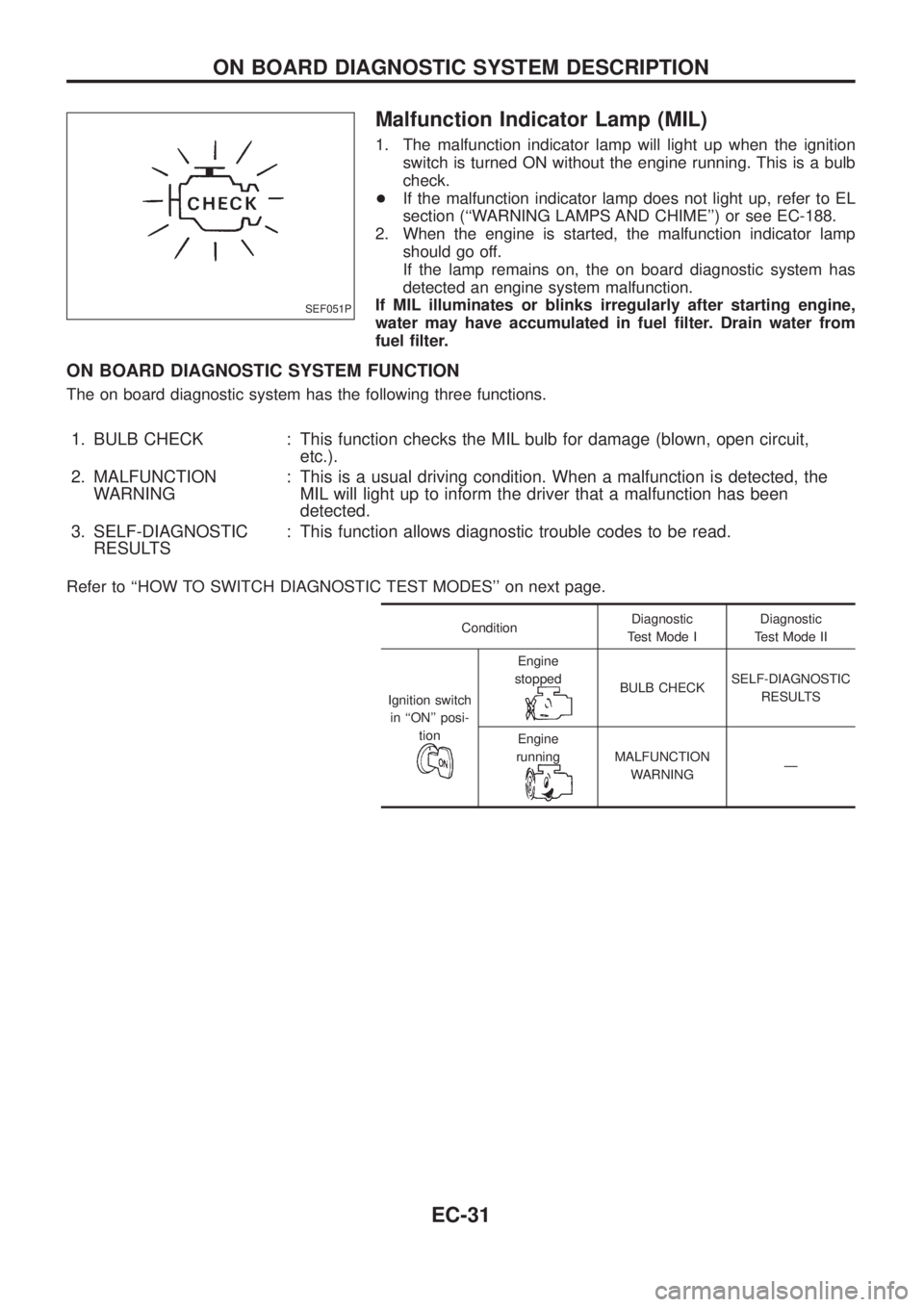

Malfunction Indicator Lamp (MIL)

1. The malfunction indicator lamp will light up when the ignition

switch is turned ON without the engine running. This is a bulb

check.

+If the malfunction indicator lamp does not light up, refer to EL

section (``WARNING LAMPS AND CHIME'') or see EC-188.

2. When the engine is started, the malfunction indicator lamp

should go off.

If the lamp remains on, the on board diagnostic system has

detected an engine system malfunction.

If MIL illuminates or blinks irregularly after starting engine,

water may have accumulated in fuel ®lter. Drain water from

fuel ®lter.

ON BOARD DIAGNOSTIC SYSTEM FUNCTION

The on board diagnostic system has the following three functions.

1. BULB CHECK : This function checks the MIL bulb for damage (blown, open circuit,

etc.).

2. MALFUNCTION

WARNING: This is a usual driving condition. When a malfunction is detected, the

MIL will light up to inform the driver that a malfunction has been

detected.

3. SELF-DIAGNOSTIC

RESULTS: This function allows diagnostic trouble codes to be read.

Refer to ``HOW TO SWITCH DIAGNOSTIC TEST MODES'' on next page.

ConditionDiagnostic

Test Mode IDiagnostic

Test Mode II

Ignition switch

in ``ON'' posi-

tion

Engine

stopped

BULB CHECKSELF-DIAGNOSTIC

RESULTS

Engine

running

MALFUNCTION

WARNINGÐ

SEF051P

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

EC-31

Page 185 of 1226

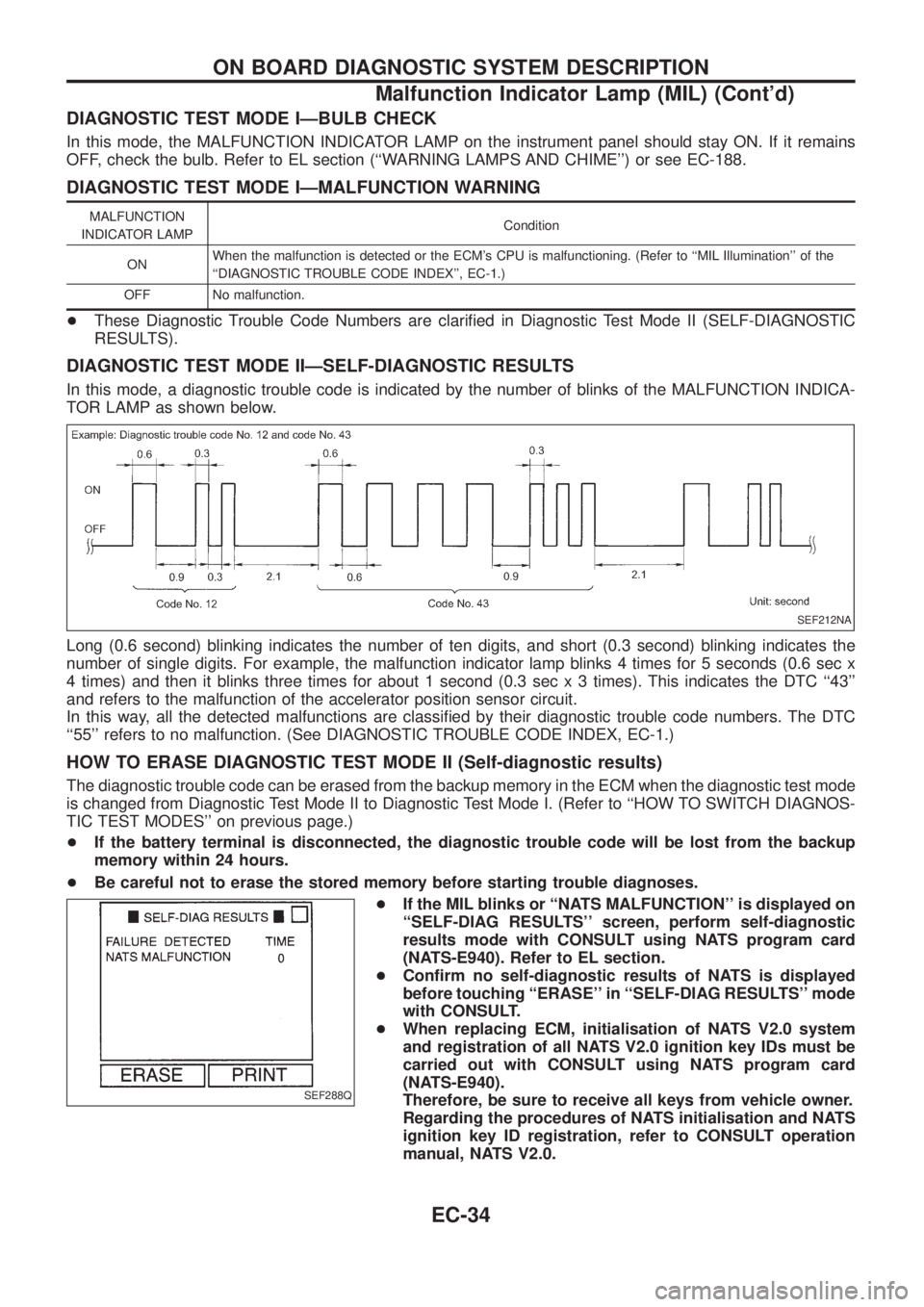

DIAGNOSTIC TEST MODE IÐBULB CHECK

In this mode, the MALFUNCTION INDICATOR LAMP on the instrument panel should stay ON. If it remains

OFF, check the bulb. Refer to EL section (``WARNING LAMPS AND CHIME'') or see EC-188.

DIAGNOSTIC TEST MODE IÐMALFUNCTION WARNING

MALFUNCTION

INDICATOR LAMPCondition

ONWhen the malfunction is detected or the ECM's CPU is malfunctioning. (Refer to ``MIL Illumination'' of the

``DIAGNOSTIC TROUBLE CODE INDEX'', EC-1.)

OFF No malfunction.

+These Diagnostic Trouble Code Numbers are clari®ed in Diagnostic Test Mode II (SELF-DIAGNOSTIC

RESULTS).

DIAGNOSTIC TEST MODE IIÐSELF-DIAGNOSTIC RESULTS

In this mode, a diagnostic trouble code is indicated by the number of blinks of the MALFUNCTION INDICA-

TOR LAMP as shown below.

Long (0.6 second) blinking indicates the number of ten digits, and short (0.3 second) blinking indicates the

number of single digits. For example, the malfunction indicator lamp blinks 4 times for 5 seconds (0.6 sec x

4 times) and then it blinks three times for about 1 second (0.3 sec x 3 times). This indicates the DTC ``43''

and refers to the malfunction of the accelerator position sensor circuit.

In this way, all the detected malfunctions are classi®ed by their diagnostic trouble code numbers. The DTC

``55'' refers to no malfunction. (See DIAGNOSTIC TROUBLE CODE INDEX, EC-1.)

HOW TO ERASE DIAGNOSTIC TEST MODE II (Self-diagnostic results)

The diagnostic trouble code can be erased from the backup memory in the ECM when the diagnostic test mode

is changed from Diagnostic Test Mode II to Diagnostic Test Mode I. (Refer to ``HOW TO SWITCH DIAGNOS-

TIC TEST MODES'' on previous page.)

+If the battery terminal is disconnected, the diagnostic trouble code will be lost from the backup

memory within 24 hours.

+Be careful not to erase the stored memory before starting trouble diagnoses.

+If the MIL blinks or ``NATS MALFUNCTION'' is displayed on

``SELF-DIAG RESULTS'' screen, perform self-diagnostic

results mode with CONSULT using NATS program card

(NATS-E940). Refer to EL section.

+Con®rm no self-diagnostic results of NATS is displayed

before touching ``ERASE'' in ``SELF-DIAG RESULTS'' mode

with CONSULT.

+When replacing ECM, initialisation of NATS V2.0 system

and registration of all NATS V2.0 ignition key IDs must be

carried out with CONSULT using NATS program card

(NATS-E940).

Therefore, be sure to receive all keys from vehicle owner.

Regarding the procedures of NATS initialisation and NATS

ignition key ID registration, refer to CONSULT operation

manual, NATS V2.0.

SEF212NA

SEF288Q

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Malfunction Indicator Lamp (MIL) (Cont'd)

EC-34

Page 186 of 1226

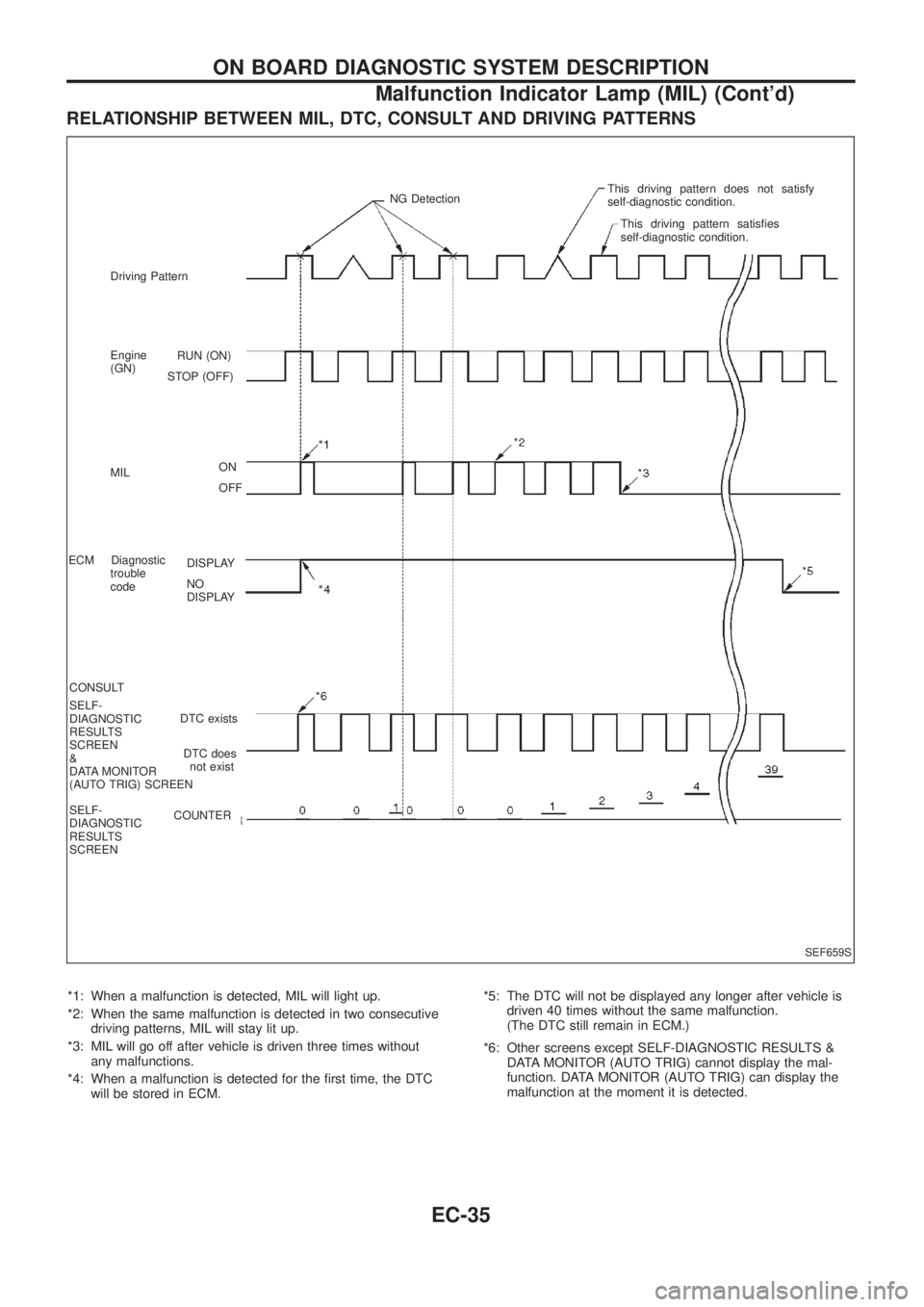

RELATIONSHIP BETWEEN MIL, DTC, CONSULT AND DRIVING PATTERNS

*1: When a malfunction is detected, MIL will light up.

*2: When the same malfunction is detected in two consecutive

driving patterns, MIL will stay lit up.

*3: MIL will go off after vehicle is driven three times without

any malfunctions.

*4: When a malfunction is detected for the ®rst time, the DTC

will be stored in ECM.*5: The DTC will not be displayed any longer after vehicle is

driven 40 times without the same malfunction.

(The DTC still remain in ECM.)

*6: Other screens except SELF-DIAGNOSTIC RESULTS &

DATA MONITOR (AUTO TRIG) cannot display the mal-

function. DATA MONITOR (AUTO TRIG) can display the

malfunction at the moment it is detected.

SEF659S

RUN (ON)

STOP (OFF)

ON

OFF

DISPLAY

NO

DISPLAY

DTC exists

DTC does

not exist

COUNTER Driving Pattern

Engine

(GN)

MIL

ECM Diagnostic

trouble

code

CONSULT

SELF-

DIAGNOSTIC

RESULTS

SCREEN

&

DATA MONITOR

(AUTO TRIG) SCREEN

SELF-

DIAGNOSTIC

RESULTS

SCREENNG DetectionThis driving pattern does not satisfy

self-diagnostic condition.

This driving pattern satis®es

self-diagnostic condition.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Malfunction Indicator Lamp (MIL) (Cont'd)

EC-35

Page 189 of 1226

![NISSAN PATROL 2006 User Guide SELF-DIAGNOSTIC MODE

Regarding items detected in ``SELF-DIAG RESULTS mode, refer to ``DIAGNOSTIC TROUBLE CODE

INDEX, EC-1.

DATA MONITOR MODE

Monitored item

[Unit]ECM

input

signalsMain

signalsDescr NISSAN PATROL 2006 User Guide SELF-DIAGNOSTIC MODE

Regarding items detected in ``SELF-DIAG RESULTS mode, refer to ``DIAGNOSTIC TROUBLE CODE

INDEX, EC-1.

DATA MONITOR MODE

Monitored item

[Unit]ECM

input

signalsMain

signalsDescr](/img/5/57368/w960_57368-188.png)

SELF-DIAGNOSTIC MODE

Regarding items detected in ``SELF-DIAG RESULTS'' mode, refer to ``DIAGNOSTIC TROUBLE CODE

INDEX'', EC-1.

DATA MONITOR MODE

Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

CKPSzRPM

(TDC) [rpm]

jj

+The engine speed computed from the

crankshaft position sensor (TDC) signal

is displayed.

CKPSzRPM

(REF) [rpm]

jj

+The engine speed [determined by the

time between pulses from the crankshaft

position sensor (TDC) signal] is dis-

played.

CMPSzRPM -

PUMP [rpm]

jj

+The engine speed computed from the

camshaft position sensor (PUMP) signal

is displayed.

COOLAN TEMP/S

[ÉC] or [ÉF]

jj

+The engine coolant temperature (deter-

mined by the signal voltage of the engine

coolant temperature sensor) is displayed.+When the engine coolant temperature

sensor is open or short-circuited, ECM

enters fail-safe mode. The engine cool-

ant temperature determined by the ECM

is displayed.

VHCL SPEED SE

[km/h] or [mph]

jj+The vehicle speed computed from the

vehicle speed sensor signal is displayed.

FUEL TEMP SEN

[ÉC] or [ÉF]

jj

+The fuel temperature (determined by the

signal voltage of the fuel temperature

sensor) is displayed.

ACCEL POS SEN [V]

jj+The accelerator position sensor signal

voltage is displayed.

FULL ACCEL SW

[ON/OFF]

jj+Indicates [ON/OFF] condition from the

accelerator position switch signal.

ACCEL SW (FC)

[OPEN/CLOSE]

jj+Indicates [OPEN/CLOSE] condition from

the accelerator switch (FC) signal.

OFF ACCEL SW

[ON/OFF]

jj+Indicates [ON/OFF] condition from the

accelerator position switch signal.

C/SLEEV POS/S [V]

jj+The control sleeve position sensor signal

voltage is displayed.

BATTERY VOLT [V]

jj+The power supply voltage of ECM is dis-

played.

P/N POSI SW

[ON/OFF]

jj+Indicates [ON/OFF] condition from the

park/neutral position switch signal.

START SIGNAL

[ON/OFF]

jj+Indicates [ON/OFF] condition from the

starter signal.+After starting the engine, [OFF] is dis-

played regardless of the starter signal.

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT (Cont'd)

EC-38

Page 190 of 1226

![NISSAN PATROL 2006 User Guide Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

AIR COND SIG

[ON/OFF]

jj

+Indicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioner signal.

NISSAN PATROL 2006 User Guide Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

AIR COND SIG

[ON/OFF]

jj

+Indicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioner signal.](/img/5/57368/w960_57368-189.png)

Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

AIR COND SIG

[ON/OFF]

jj

+Indicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioner signal.

IGN SW

[ON/OFF]

jj+Indicates [ON/OFF] condition from igni-

tion switch signal.

MAS AIR/FL SE [V]

jj+The signal voltage of the mass air ¯ow

sensor is displayed.+When the engine is stopped, a certain

value is indicated.

ACT INJ TIMG [É]

jj

+The actual injection timing angle deter-

mined by the ECM (an approximate

average angle between injection start

and end from TDC) is displayed.

INJ TIMG C/V [%]+Indicates the duty ratio of fuel injection

timing control valve.

DECELER F/CUT

[ON/OFF]

j

+Indicates [ON/OFF] condition from decel-

eration fuel cut signal.+When the accelerator pedal is released

quickly with engine speed at 3,000 rpm

or more, ``ON'' is displayed.

FUEL CUT S/V

[ON/OFF]

j

+The control condition of the fuel cut sole-

noid valve (determined by ECM accord-

ing to the input signal) is indicted.

+OFF ... Fuel cut solenoid valve is not

operating.

ON ... Fuel cut solenoid valve is operat-

ing.+When the fuel cut solenoid valve is not

operating, fuel is not supplied to injection

nozzles.

GLOW RLY [ON/OFF]

j

+The glow relay control condition (deter-

mined by ECM according to the input

signal) is displayed.

COOLING FAN

[LOW/HI/OFF]

j

+Indicates the control condition of the

cooling fans (determined by ECM

according to the input signal).

+LOW ... Operates at low speed.

HI ... Operates at high speed.

OFF ... Stopped.

I/C FAN RLY

[ON/OFF]

j

+Indicates the control condition of the

charge air cooler fan (determined by

ECM according to the input signals).

EGRC SOL/V A

[ON/OFF]+The control condition of the EGRC-sole-

noid valve A (determined by ECM

according to the input signal) is indi-

cated.

+OFF ... EGRC-solenoid valve A is not

operating.

ON ... EGRC-solenoid valve A is operat-

ing.

EGRC SOL/V B

[ON/OFF]+The control condition of the EGRC-sole-

noid valve B (determined by ECM

according to the input signal) is indi-

cated.

+OFF ... EGRC-solenoid valve B is not

operating.

ON ... EGRC-solenoid valve B is operat-

ing.

THROT RLY

[ON/OFF]+The control condition of the throttle con-

trol solenoid valve (determined by ECM

according to the input signal) is indi-

cated.

+OFF ... Throttle control solenoid valve is

not operating.

ON ... Throttle control solenoid valve is

operating.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT (Cont'd)

EC-39

Page 195 of 1226

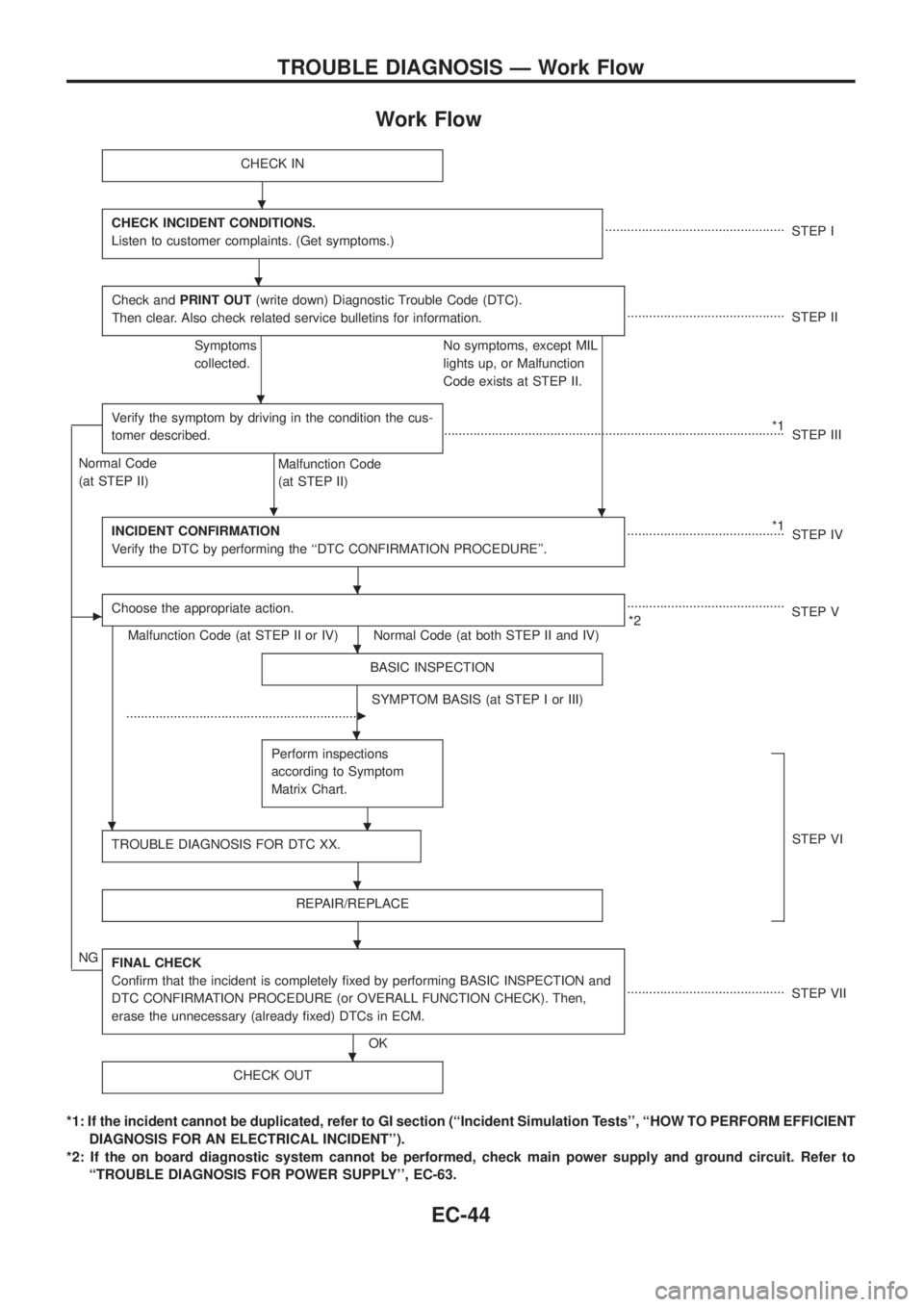

Work Flow

CHECK IN

CHECK INCIDENT CONDITIONS.

Listen to customer complaints. (Get symptoms.).................................................

STEP I

Check andPRINT OUT(write down) Diagnostic Trouble Code (DTC).

Then clear. Also check related service bulletins for information.

...........................................

STEP II

Symptoms

collected.No symptoms, except MIL

lights up, or Malfunction

Code exists at STEP II.

Verify the symptom by driving in the condition the cus-

tomer described.

.

*1

.............................................................................................

STEP III

Normal Code

(at STEP II)

Malfunction Code

(at STEP II)

INCIDENT CONFIRMATION

Verify the DTC by performing the ``DTC CONFIRMATION PROCEDURE''.

*1

...........................................

STEP IV

cChoose the appropriate action.

Malfunction Code (at STEP II or IV) Normal Code (at both STEP II and IV)...........................................

*2STEP V

BASIC INSPECTION

SYMPTOM BASIS (at STEP I or III)

................................................................

c

Perform inspections

according to Symptom

Matrix Chart.

.

TROUBLE DIAGNOSIS FOR DTC XX.STEP VI

REPAIR/REPLACE

NGFINAL CHECK

Con®rm that the incident is completely ®xed by performing BASIC INSPECTION and

DTC CONFIRMATION PROCEDURE (or OVERALL FUNCTION CHECK). Then,

erase the unnecessary (already ®xed) DTCs in ECM.

OK...........................................

STEP VII

CHECK OUT

*1: If the incident cannot be duplicated, refer to GI section (``Incident Simulation Tests'', ``HOW TO PERFORM EFFICIENT

DIAGNOSIS FOR AN ELECTRICAL INCIDENT'').

*2: If the on board diagnostic system cannot be performed, check main power supply and ground circuit. Refer to

``TROUBLE DIAGNOSIS FOR POWER SUPPLY'', EC-63.

.

.

.

.

.

.

.

.

.

.

.

TROUBLE DIAGNOSIS Ð Work Flow

EC-44