main NISSAN PATROL 2006 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 1 of 1226

Edition: February 1998

Release: February 1998 (01)

Publication No.: SM8E-0Y61E0E

Reference No.: 7711346063GENERAL INFORMATIONGI

MAINTENANCEMA

ENGINE MECHANICALEM

ENGINE LUBRICATION &

COOLING SYSTEMSLC

ENGINE CONTROL SYSTEMEC

ACCELERATOR CONTROL,

FUEL & EXHAUST SYSTEMFE

CLUTCHCL

MANUAL TRANSMISSIONMT

AUTOMATIC TRANSMISSIONAT

TRANSFERTF

PROPELLER SHAFT &

DIFFERENTIAL CARRIERPD

FRONT AXLE & FRONT SUSPENSIONFA

REAR AXLE & REAR SUSPENSIONRA

BRAKE SYSTEMBR

STEERING SYSTEMST

RESTRAINT SYSTEMRS

BODY & TRIMBT

HEATER & AIR CONDITIONERHA

ELECTRICAL SYSTEMEL

ALPHABETICAL INDEXIDX

PATROL GR

MODEL Y61 SERIES

NISSAN EUROPE S.A.S.

1998 NISSAN EUROPE S.A.S.

Produced in The Netherlands

Not to be reproduced in whole or in part

without the prior written permission of

Nissan Europe S.A.S., Paris, France.

QUICK REFERENCE INDEX

Page 2 of 1226

FOREWORD

This manual contains maintenance and repair procedures for NISSAN

PATROL GR,modelY61 series.

In order to assure your safety and the efficient functioning of the vehicle,

this manual should be read thoroughly. It is especially important that the

PRECAUTIONS in the GI section be completely understood before starting

any repair task.

All information in this manual is based on the latest product information

at the time of publication. The right is reserved to make changes in speci-

®cations and methods at any time without notice.

IMPORTANT SAFETY NOTICE

The proper performance of service is essential for both the safety of the

technician and the efficient functioning of the vehicle.

The service methods in this Service Manual are described in such a man-

ner that the service may be performed safely and accurately.

Service varies with the procedures used, the skills of the technician and the

tools and parts available. Accordingly, anyone using service procedures,

tools or parts which are not speci®cally recommended by NISSAN must

®rst completely satisfy himself that neither his safety nor the vehicle's

safety will be jeopardized by the service method selected.

NISSAN EUROPE S.A.S.

Service Engineering SectionParis, France

Page 5 of 1226

Supplemental Restraint System (SRS) ``AIR

BAG'' and ``SEAT BELT PRE-TENSIONER''

The Supplemental Restraint System such as ``AIR BAG'' and ``SEAT BELT PRE-TENSIONER'' used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger in a frontal collision.

The SRS system composition which is available to NISSAN MODEL Y61 is as follows (The composition var-

ies according to the destination.):

Driver air bag module (located in the center of the steering wheel), front passenger air bag module (located

on the instrument panel on passenger side), seat belt pre-tensioner, a diagnosis sensor unit, warning lamp,

wiring harness and spiral cable.

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+ To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag in¯ation, all maintenance must be performed

by an authorized NISSAN dealer.

+ Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+ Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral Cable and wiring harnesses covered with yellow insulation either just before

the harness connectors or for the complete harness are related to the SRS.

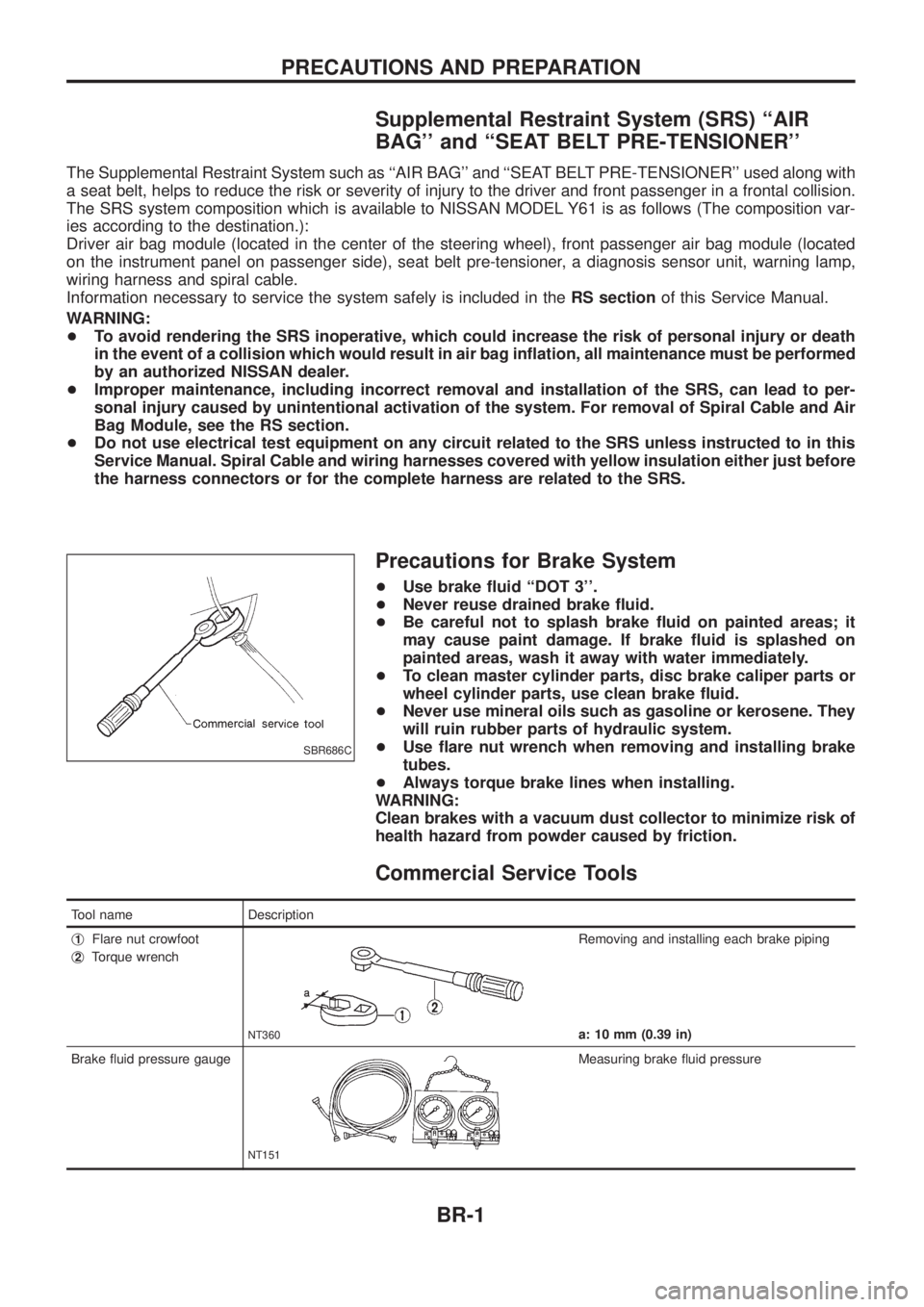

Precautions for Brake System

+Use brake ¯uid ``DOT 3''.

+ Never reuse drained brake ¯uid.

+ Be careful not to splash brake ¯uid on painted areas; it

may cause paint damage. If brake ¯uid is splashed on

painted areas, wash it away with water immediately.

+ To clean master cylinder parts, disc brake caliper parts or

wheel cylinder parts, use clean brake ¯uid.

+ Never use mineral oils such as gasoline or kerosene. They

will ruin rubber parts of hydraulic system.

+ Use ¯are nut wrench when removing and installing brake

tubes.

+ Always torque brake lines when installing.

WARNING:

Clean brakes with a vacuum dust collector to minimize risk of

health hazard from powder caused by friction.

Commercial Service Tools

Tool name Description

j

1Flare nut crowfoot

j

2Torque wrench

NT360

Removing and installing each brake piping

a: 10 mm (0.39 in)

Brake ¯uid pressure gauge

NT151

Measuring brake ¯uid pressure

SBR686C

PRECAUTIONS AND PREPARATION

BR-1

Page 26 of 1226

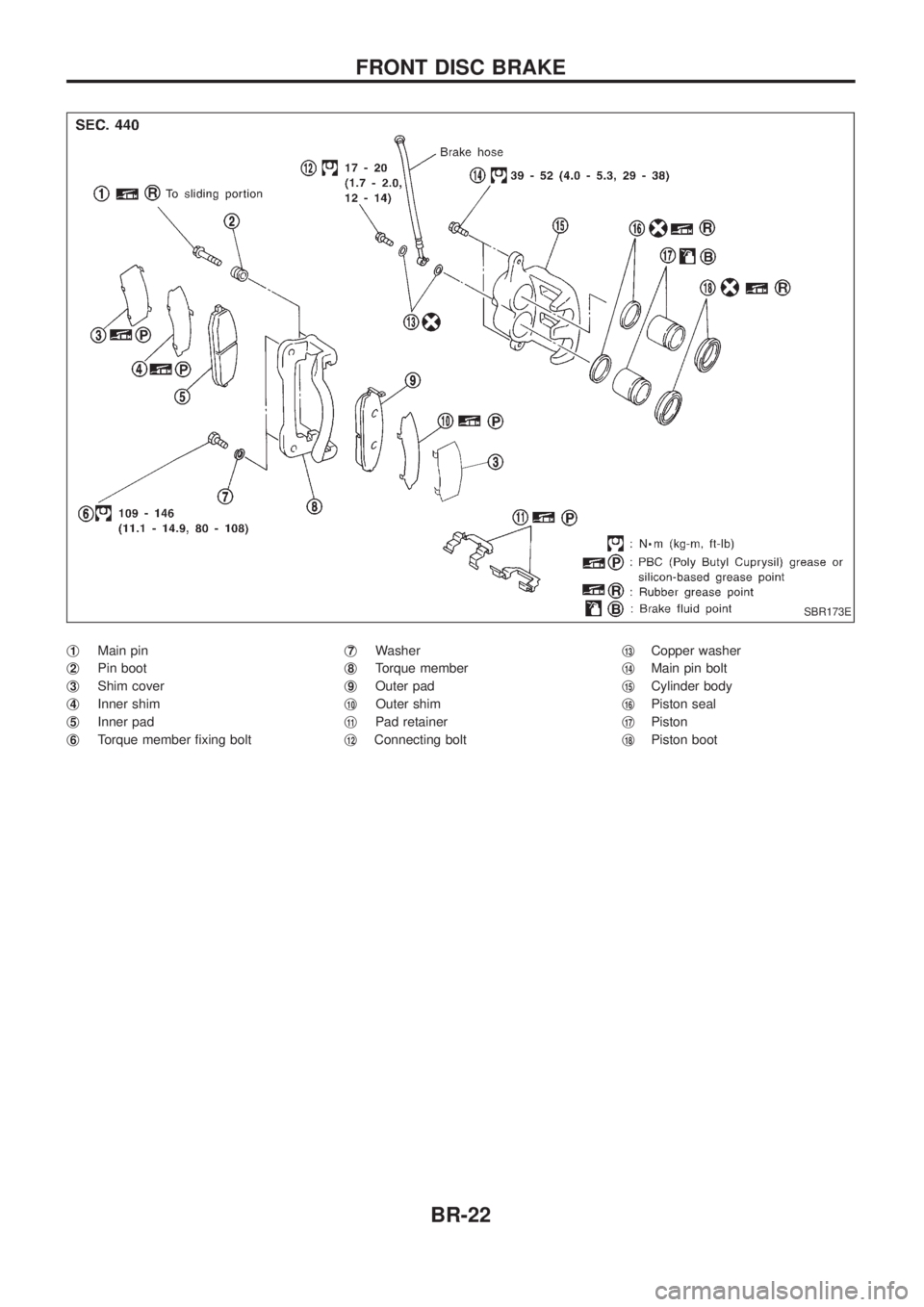

j1Main pin

j

2Pin boot

j

3Shim cover

j

4Inner shim

j

5Inner pad

j

6Torque member ®xing bolt j

7Washer

j

8Torque member

j

9Outer pad

j

10Outer shim

j

11Pad retainer

j

12Connecting bolt j

13Copper washer

j

14Main pin bolt

j

15Cylinder body

j

16Piston seal

j

17Piston

j

18Piston boot

SBR173E

FRONT DISC BRAKE

BR-22

Page 30 of 1226

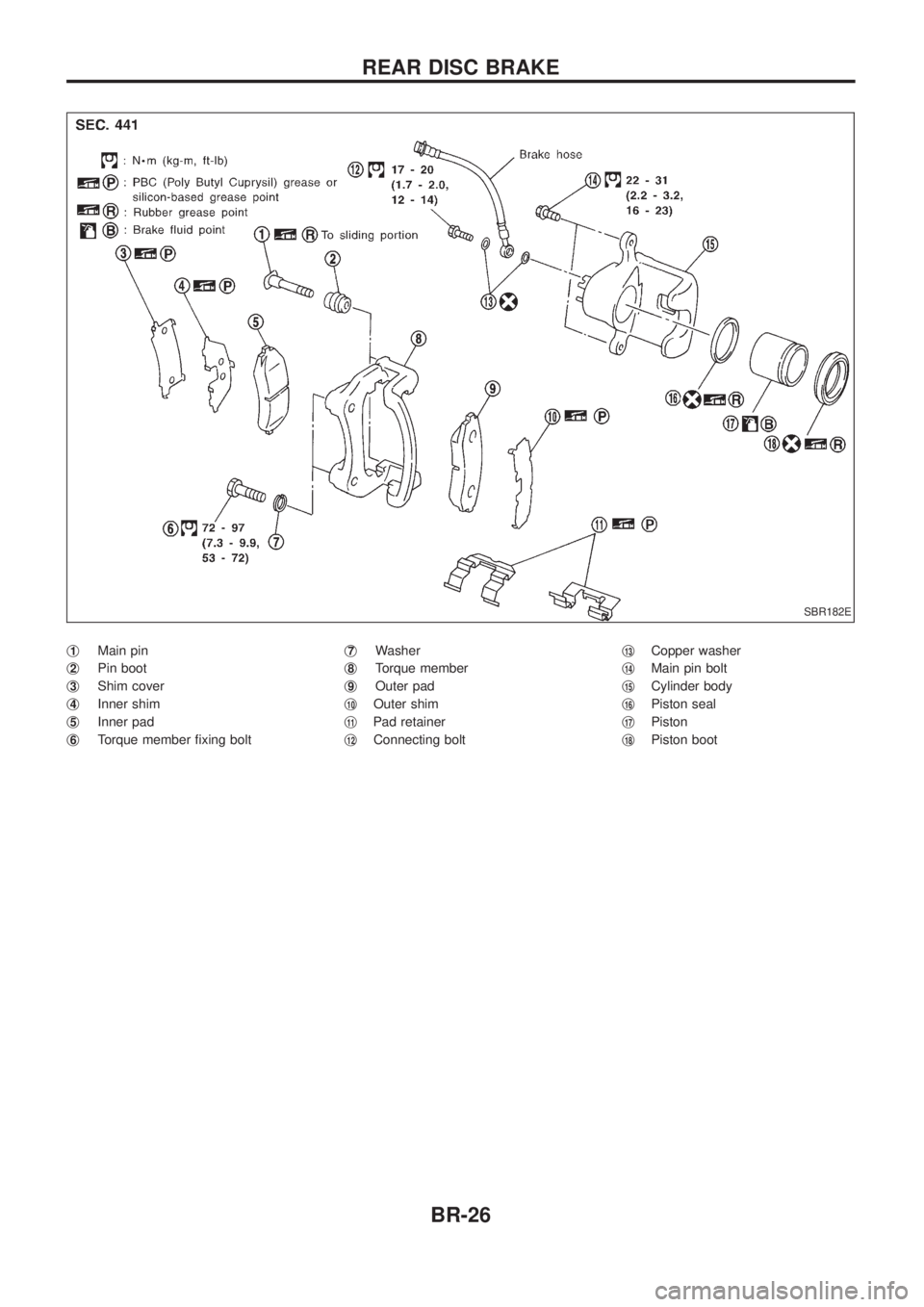

j1Main pin

j

2Pin boot

j

3Shim cover

j

4Inner shim

j

5Inner pad

j

6Torque member ®xing bolt j

7Washer

j

8Torque member

j

9Outer pad

j

10Outer shim

j

11Pad retainer

j

12Connecting bolt j

13Copper washer

j

14Main pin bolt

j

15Cylinder body

j

16Piston seal

j

17Piston

j

18Piston boot

SBR182E

REAR DISC BRAKE

BR-26

Page 44 of 1226

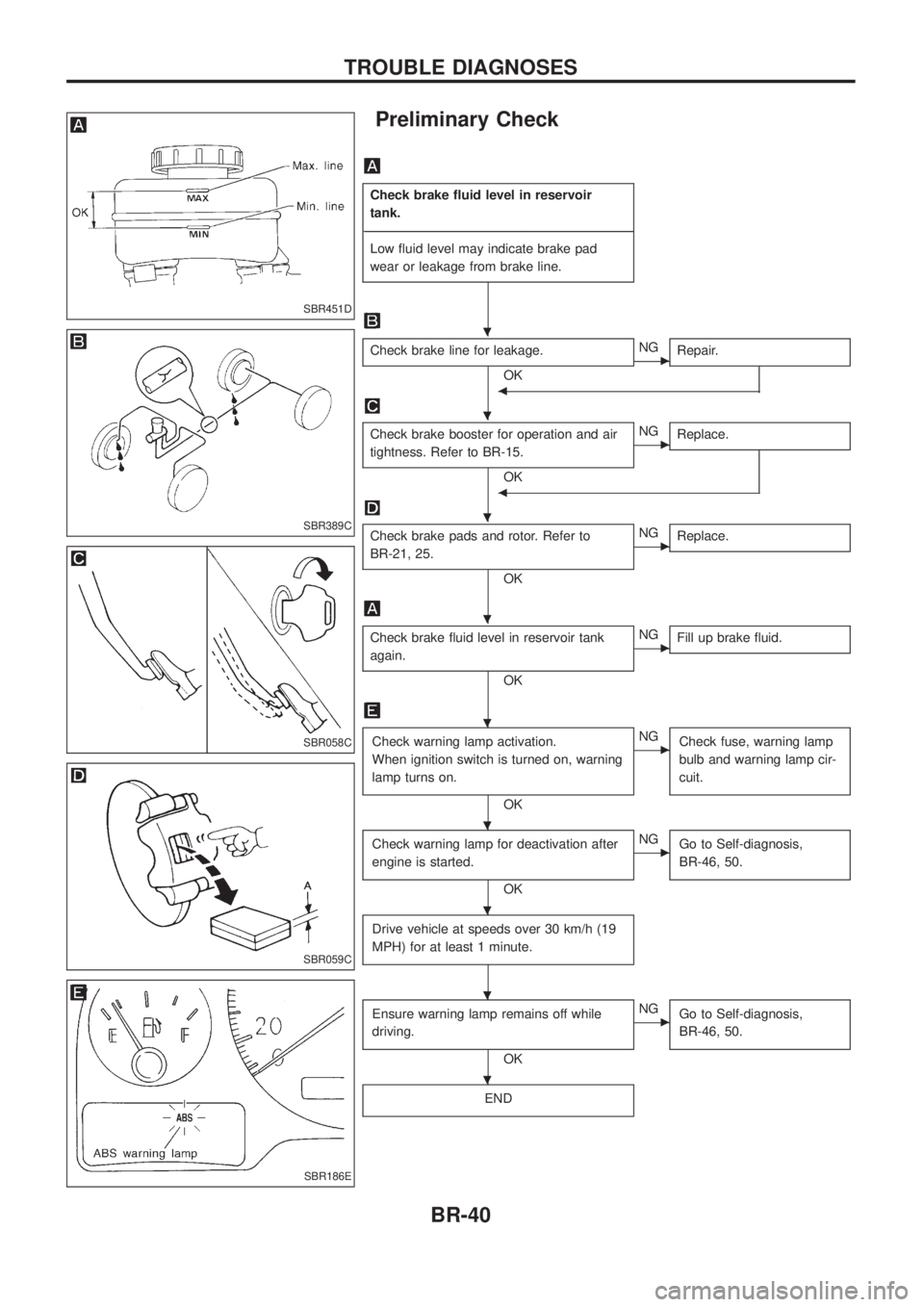

Preliminary Check

Check brake ¯uid level in reservoir

tank.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Low ¯uid level may indicate brake pad

wear or leakage from brake line.

Check brake line for leakage.

OKcNG Repair.

b

Check brake booster for operation and air

tightness. Refer to BR-15.

OK

cNGReplace.

b

Check brake pads and rotor. Refer to

BR-21, 25.

OK

cNGReplace.

Check brake ¯uid level in reservoir tank

again.

OK

cNGFill up brake ¯uid.

Check warning lamp activation.

When ignition switch is turned on, warning

lamp turns on.

OK

cNG

Check fuse, warning lamp

bulb and warning lamp cir-

cuit.

Check warning lamp for deactivation after

engine is started.

OK

cNGGo to Self-diagnosis,

BR-46, 50.

Drive vehicle at speeds over 30 km/h (19

MPH) for at least 1 minute.

Ensure warning lamp remains off while

driving.

OK

cNGGo to Self-diagnosis,

BR-46, 50.

END

SBR451D

SBR389C

SBR058C

SBR059C

SBR186E

.

.

.

.

.

.

.

.

.

TROUBLE DIAGNOSES

BR-40

Page 71 of 1226

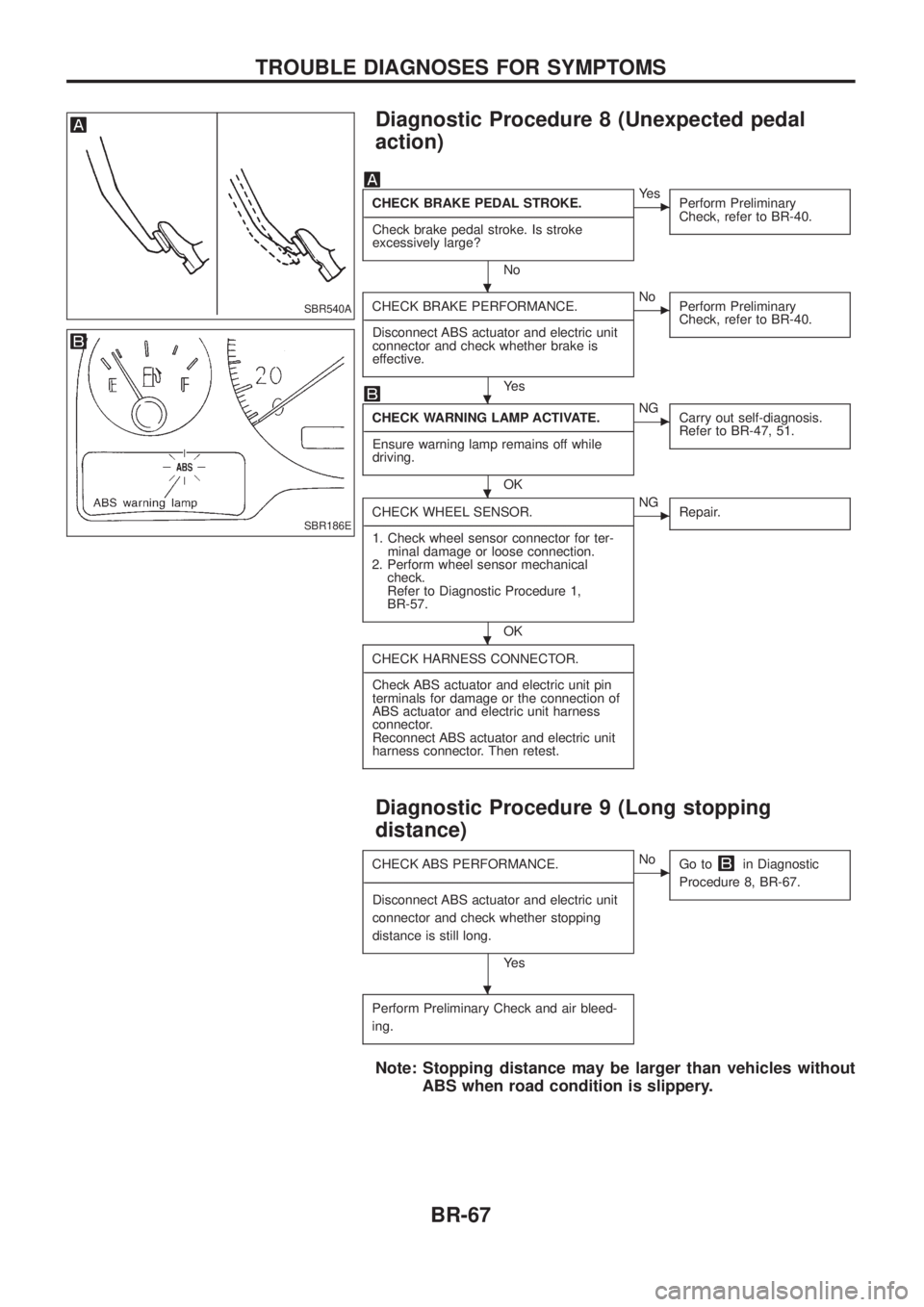

Diagnostic Procedure 8 (Unexpected pedal

action)

CHECK BRAKE PEDAL STROKE.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check brake pedal stroke. Is stroke

excessively large?

No

cYe s Perform Preliminary

Check, refer to BR-40.

CHECK BRAKE PERFORMANCE.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Disconnect ABS actuator and electric unit

connector and check whether brake is

effective.

Ye s

cNo Perform Preliminary

Check, refer to BR-40.

CHECK WARNING LAMP ACTIVATE.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Ensure warning lamp remains off while

driving.

OK

cNG Carry out self-diagnosis.

Refer to BR-47, 51.

CHECK WHEEL SENSOR.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Check wheel sensor connector for ter- minal damage or loose connection.

2. Perform wheel sensor mechanical check.

Refer to Diagnostic Procedure 1,

BR-57.

OK

cNG Repair.

CHECK HARNESS CONNECTOR.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check ABS actuator and electric unit pin

terminals for damage or the connection of

ABS actuator and electric unit harness

connector.

Reconnect ABS actuator and electric unit

harness connector. Then retest.

Diagnostic Procedure 9 (Long stopping

distance)

CHECK ABS PERFORMANCE.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Disconnect ABS actuator and electric unit

connector and check whether stopping

distance is still long.

Ye s

cNo Go toin Diagnostic

Procedure 8, BR-67.

Perform Preliminary Check and air bleed-

ing.

Note: Stopping distance may be larger than vehicles without ABS when road condition is slippery.

SBR540A

SBR186E

.

.

.

.

.

TROUBLE DIAGNOSES FOR SYMPTOMS

BR-67

Page 79 of 1226

Service Notice

+When removing or installing various parts, place a cloth or padding onto the vehicle body to prevent

scratches.

+Handle trim, molding, instruments, grille, etc. carefully during removing or installing. Be careful not to soil

or damage them.

+Apply sealing compound where necessary when installing parts.

+When applying sealing compound, be careful that the sealing compound does not protrude from parts.

+When replacing any metal parts (for example body outer panel, members, etc.), be sure to take rust pre-

vention measures.

Supplemental Restraint System (SRS) ``AIR

BAG'' and ``SEAT BELT PRE-TENSIONER''

The Supplemental Restraint System such as ``AIR BAG'' and ``SEAT BELT PRE-TENSIONER'' used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger in a frontal collision.

The SRS system composition which is available to NISSAN MODEL Y61 is as follows (The composition var-

ies according to the destination.):

Driver air bag module (located in the center of the steering wheel), front passenger air bag module (located

on the instrument panel on passenger side), seat belt pre-tensioner, a diagnosis sensor unit, warning lamp,

wiring harness and spiral cable.

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag in¯ation, all maintenance must be performed

by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation either just before

the harness connectors or for the complete harness are related to the SRS.

PRECAUTIONS

BT-1

Page 120 of 1226

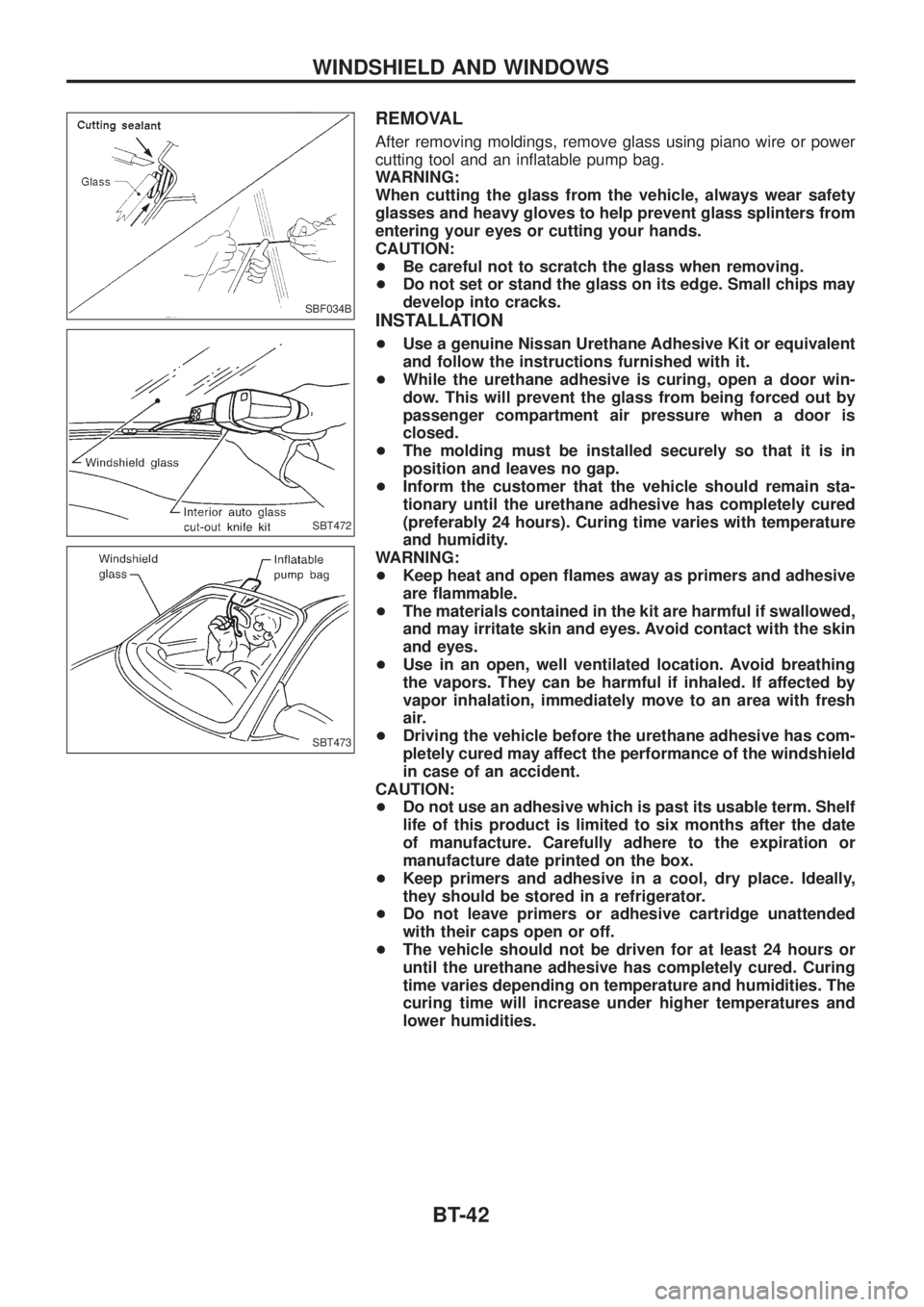

REMOVAL

After removing moldings, remove glass using piano wire or power

cutting tool and an in¯atable pump bag.

WARNING:

When cutting the glass from the vehicle, always wear safety

glasses and heavy gloves to help prevent glass splinters from

entering your eyes or cutting your hands.

CAUTION:

+Be careful not to scratch the glass when removing.

+Do not set or stand the glass on its edge. Small chips may

develop into cracks.

INSTALLATION

+Use a genuine Nissan Urethane Adhesive Kit or equivalent

and follow the instructions furnished with it.

+While the urethane adhesive is curing, open a door win-

dow. This will prevent the glass from being forced out by

passenger compartment air pressure when a door is

closed.

+The molding must be installed securely so that it is in

position and leaves no gap.

+Inform the customer that the vehicle should remain sta-

tionary until the urethane adhesive has completely cured

(preferably 24 hours). Curing time varies with temperature

and humidity.

WARNING:

+Keep heat and open ¯ames away as primers and adhesive

are ¯ammable.

+The materials contained in the kit are harmful if swallowed,

and may irritate skin and eyes. Avoid contact with the skin

and eyes.

+Use in an open, well ventilated location. Avoid breathing

the vapors. They can be harmful if inhaled. If affected by

vapor inhalation, immediately move to an area with fresh

air.

+Driving the vehicle before the urethane adhesive has com-

pletely cured may affect the performance of the windshield

in case of an accident.

CAUTION:

+Do not use an adhesive which is past its usable term. Shelf

life of this product is limited to six months after the date

of manufacture. Carefully adhere to the expiration or

manufacture date printed on the box.

+Keep primers and adhesive in a cool, dry place. Ideally,

they should be stored in a refrigerator.

+Do not leave primers or adhesive cartridge unattended

with their caps open or off.

+The vehicle should not be driven for at least 24 hours or

until the urethane adhesive has completely cured. Curing

time varies depending on temperature and humidities. The

curing time will increase under higher temperatures and

lower humidities.

SBF034B

SBT472

SBT473

WINDSHIELD AND WINDOWS

BT-42

Page 125 of 1226

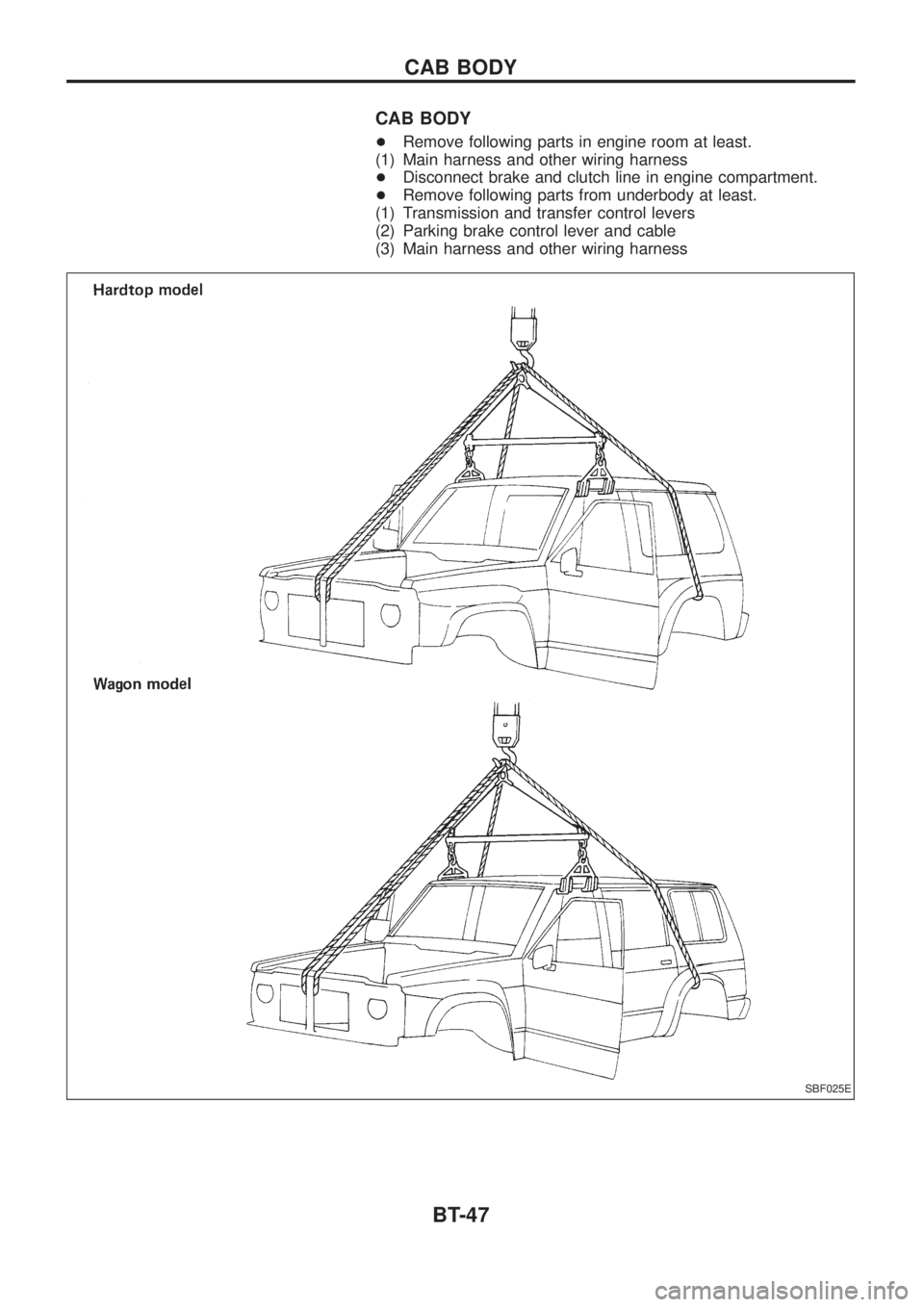

CAB BODY

+Remove following parts in engine room at least.

(1) Main harness and other wiring harness

+Disconnect brake and clutch line in engine compartment.

+Remove following parts from underbody at least.

(1) Transmission and transfer control levers

(2) Parking brake control lever and cable

(3) Main harness and other wiring harness

SBF025E

CAB BODY

BT-47