main NISSAN PATROL 2006 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 197 of 1226

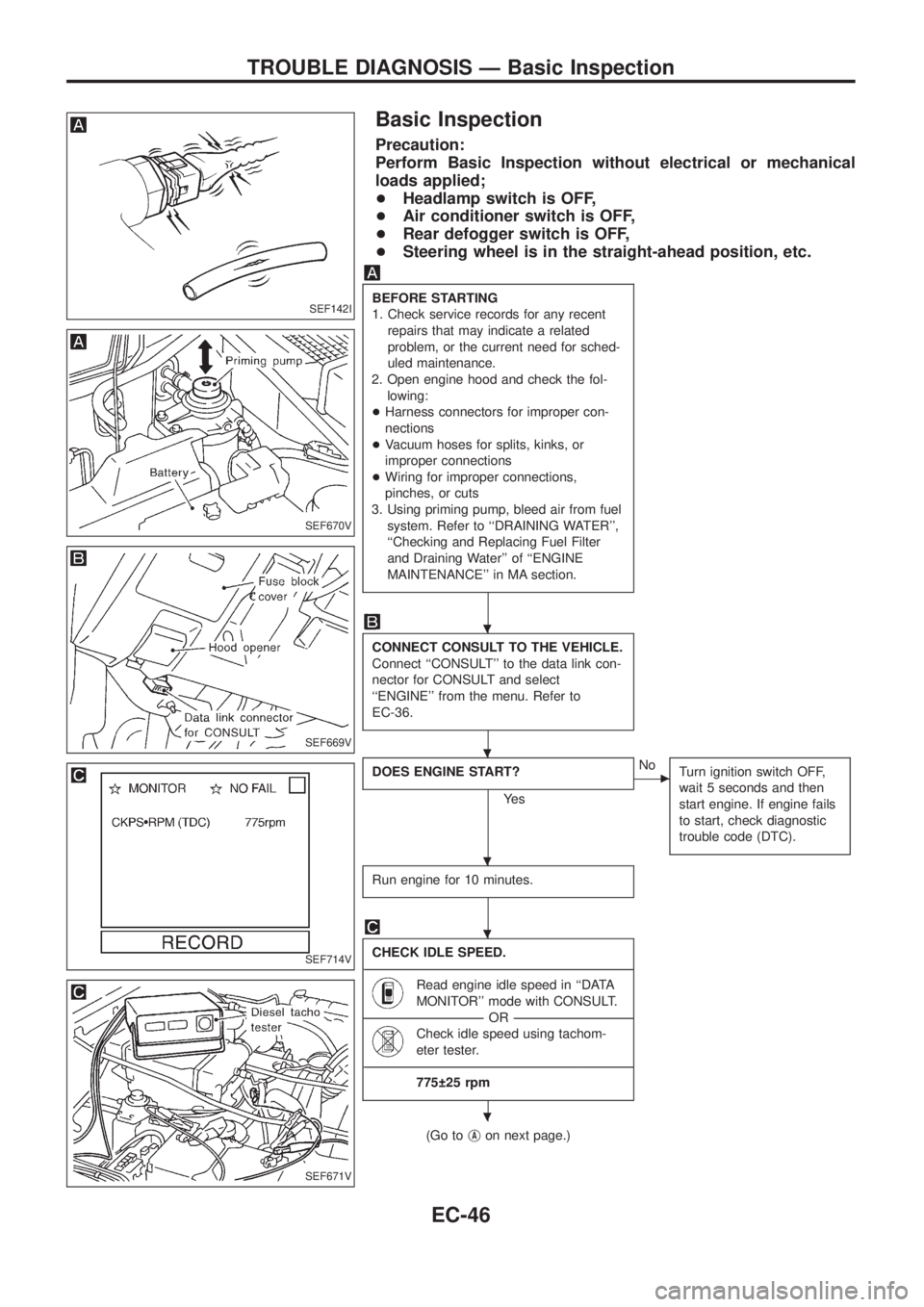

Basic Inspection

Precaution:

Perform Basic Inspection without electrical or mechanical

loads applied;

+Headlamp switch is OFF,

+Air conditioner switch is OFF,

+Rear defogger switch is OFF,

+Steering wheel is in the straight-ahead position, etc.

BEFORE STARTING

1. Check service records for any recent

repairs that may indicate a related

problem, or the current need for sched-

uled maintenance.

2. Open engine hood and check the fol-

lowing:

+Harness connectors for improper con-

nections

+Vacuum hoses for splits, kinks, or

improper connections

+Wiring for improper connections,

pinches, or cuts

3. Using priming pump, bleed air from fuel

system. Refer to ``DRAINING WATER'',

``Checking and Replacing Fuel Filter

and Draining Water'' of ``ENGINE

MAINTENANCE'' in MA section.

CONNECT CONSULT TO THE VEHICLE.

Connect ``CONSULT'' to the data link con-

nector for CONSULT and select

``ENGINE'' from the menu. Refer to

EC-36.

DOES ENGINE START?

Ye s

cNo

Turn ignition switch OFF,

wait 5 seconds and then

start engine. If engine fails

to start, check diagnostic

trouble code (DTC).

Run engine for 10 minutes.

CHECK IDLE SPEED.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Read engine idle speed in ``DATA

MONITOR'' mode with CONSULT.

--------------------------------------------------------------------------------------------------------------------------------------OR--------------------------------------------------------------------------------------------------------------------------------------

Check idle speed using tachom-

eter tester.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

775 25 rpm

(Go tojAon next page.)

SEF142I

SEF670V

SEF669V

SEF714V

SEF671V

.

.

.

.

.

TROUBLE DIAGNOSIS Ð Basic Inspection

EC-46

Page 198 of 1226

jA

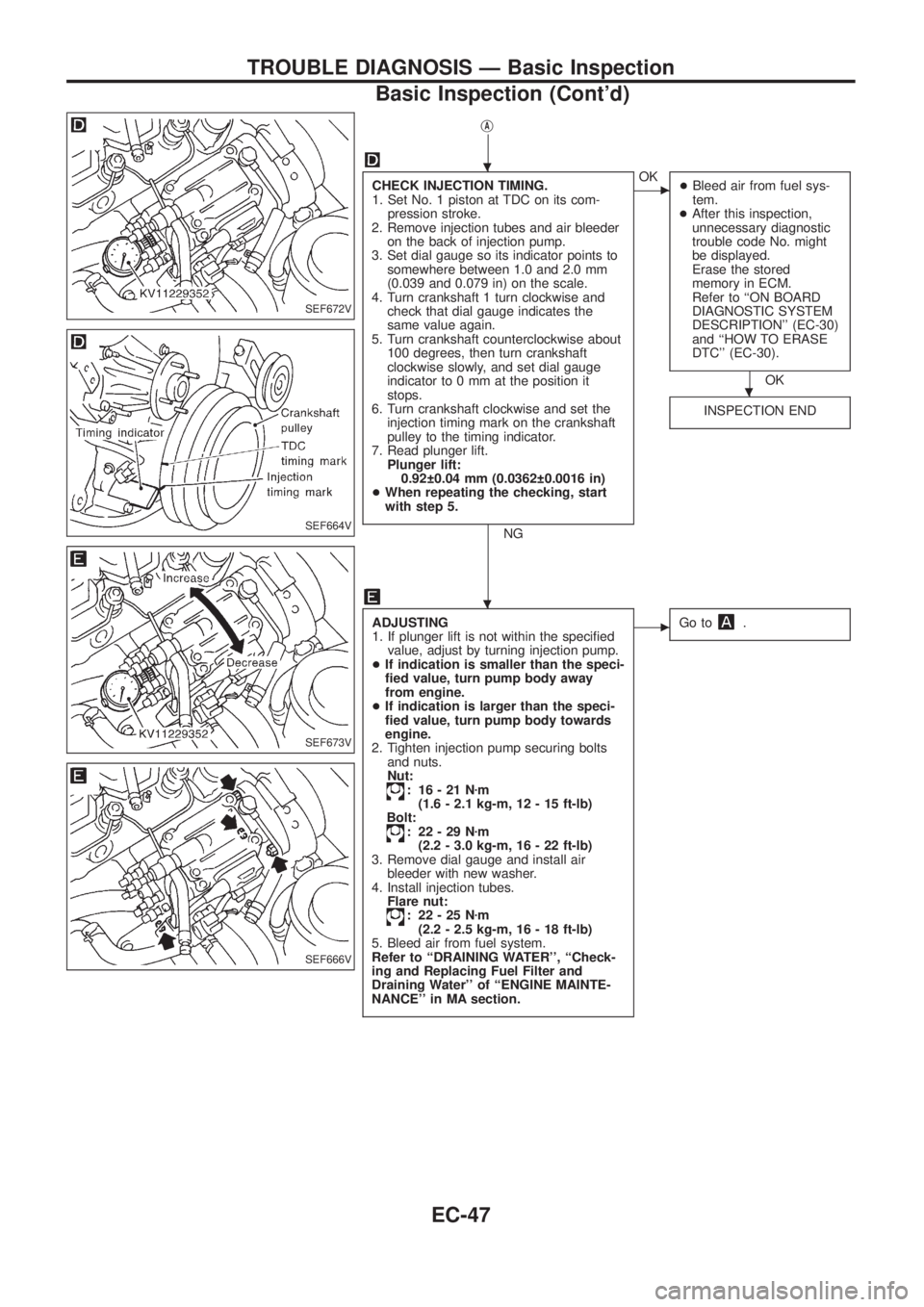

CHECK INJECTION TIMING.

1. Set No. 1 piston at TDC on its com-

pression stroke.

2. Remove injection tubes and air bleeder

on the back of injection pump.

3. Set dial gauge so its indicator points to

somewhere between 1.0 and 2.0 mm

(0.039 and 0.079 in) on the scale.

4. Turn crankshaft 1 turn clockwise and

check that dial gauge indicates the

same value again.

5. Turn crankshaft counterclockwise about

100 degrees, then turn crankshaft

clockwise slowly, and set dial gauge

indicator to 0 mm at the position it

stops.

6. Turn crankshaft clockwise and set the

injection timing mark on the crankshaft

pulley to the timing indicator.

7. Read plunger lift.

Plunger lift:

0.92 0.04 mm (0.0362 0.0016 in)

+When repeating the checking, start

with step 5.

NG

cOK

+Bleed air from fuel sys-

tem.

+After this inspection,

unnecessary diagnostic

trouble code No. might

be displayed.

Erase the stored

memory in ECM.

Refer to ``ON BOARD

DIAGNOSTIC SYSTEM

DESCRIPTION'' (EC-30)

and ``HOW TO ERASE

DTC'' (EC-30).

OK

INSPECTION END

ADJUSTING

1. If plunger lift is not within the speci®ed

value, adjust by turning injection pump.

+If indication is smaller than the speci-

®ed value, turn pump body away

from engine.

+If indication is larger than the speci-

®ed value, turn pump body towards

engine.

2. Tighten injection pump securing bolts

and nuts.

Nut:

: 16-21Nzm

(1.6 - 2.1 kg-m, 12 - 15 ft-lb)

Bolt:

: 22-29Nzm

(2.2 - 3.0 kg-m, 16 - 22 ft-lb)

3. Remove dial gauge and install air

bleeder with new washer.

4. Install injection tubes.

Flare nut:

: 22-25Nzm

(2.2 - 2.5 kg-m, 16 - 18 ft-lb)

5. Bleed air from fuel system.

Refer to ``DRAINING WATER'', ``Check-

ing and Replacing Fuel Filter and

Draining Water'' of ``ENGINE MAINTE-

NANCE'' in MA section.

cGo to.

SEF672V

SEF664V

SEF673V

SEF666V

.

.

.

TROUBLE DIAGNOSIS Ð Basic Inspection

Basic Inspection (Cont'd)

EC-47

Page 199 of 1226

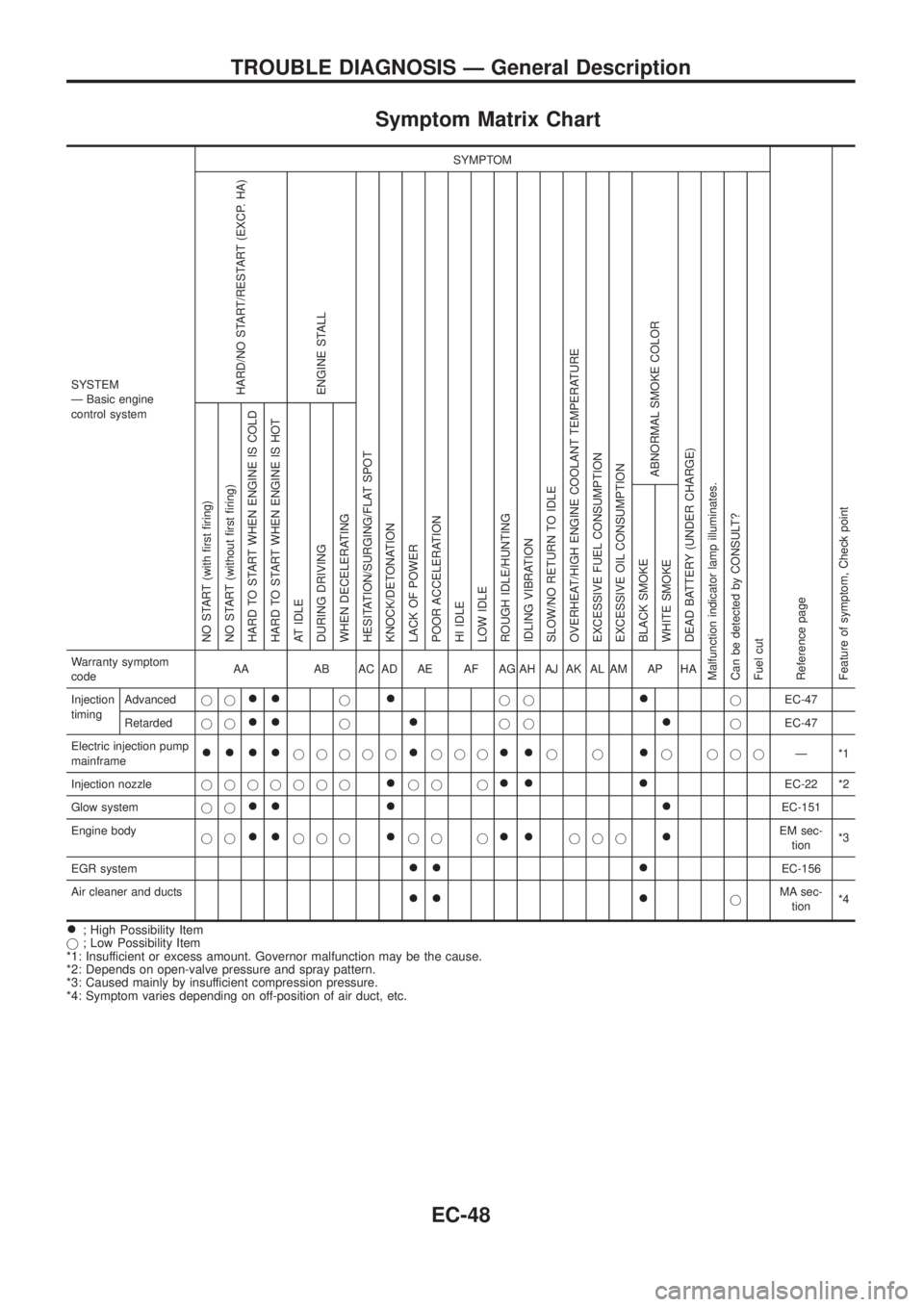

Symptom Matrix Chart

SYSTEM

Ð Basic engine

control systemSYMPTOM

Reference page

Feature of symptom, Check pointHARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

KNOCK/DETONATION

LACK OF POWER

POOR ACCELERATION

HI IDLE

LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEAT/HIGH ENGINE COOLANT TEMPERATURE

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

ABNORMAL SMOKE COLOR

DEAD BATTERY (UNDER CHARGE)

Malfunction indicator lamp illuminates.

Can be detected by CONSULT?

Fuel cutNO START (with ®rst ®ring)

NO START (without ®rst ®ring)

HARD TO START WHEN ENGINE IS COLD

HARD TO START WHEN ENGINE IS HOT

AT IDLE

DURING DRIVING

WHEN DECELERATING

BLACK SMOKE

WHITE SMOKEWarranty symptom

codeAA AB AC AD AE AF AG AH AJ AK AL AM AP HA

Injection

timingAdvancedjj

++j+jj+jEC-47

Retardedjj

++j+jj+jEC-47

Electric injection pump

mainframe

++++jjjjj+jjj++jj+j jjjÐ*1

Injection nozzlejjjjjjj

+jj j++ +EC-22 *2

Glow systemjj

++ + +EC-151

Engine body

jj

++jjj+jj j++jjj+EM sec-

tion*3

EGR system

++ +EC-156

Air cleaner and ducts

++ +jMA sec-

tion*4

+; High Possibility Item

j; Low Possibility Item

*1: Insufficient or excess amount. Governor malfunction may be the cause.

*2: Depends on open-valve pressure and spray pattern.

*3: Caused mainly by insufficient compression pressure.

*4: Symptom varies depending on off-position of air duct, etc.

TROUBLE DIAGNOSIS Ð General Description

EC-48

Page 214 of 1226

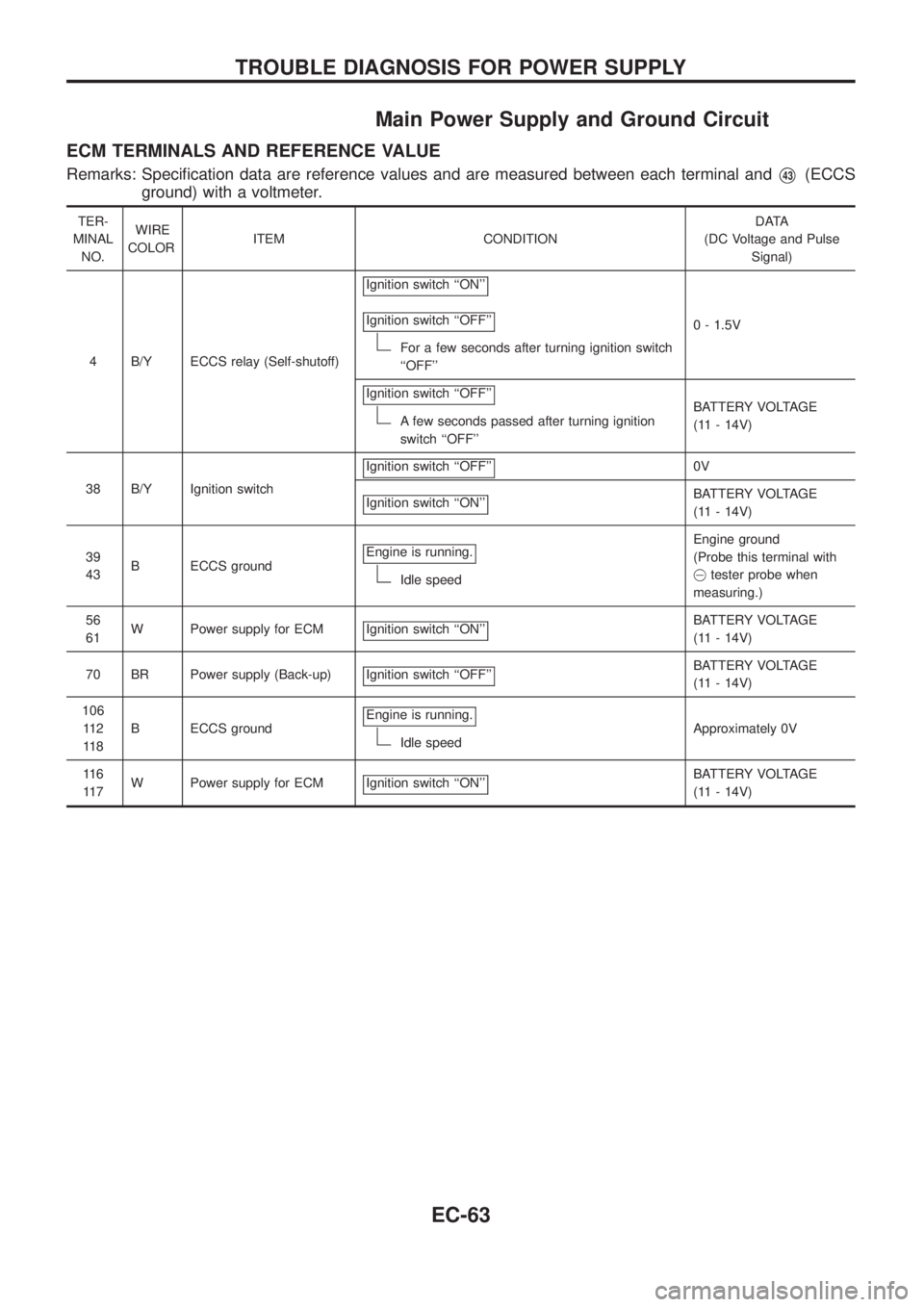

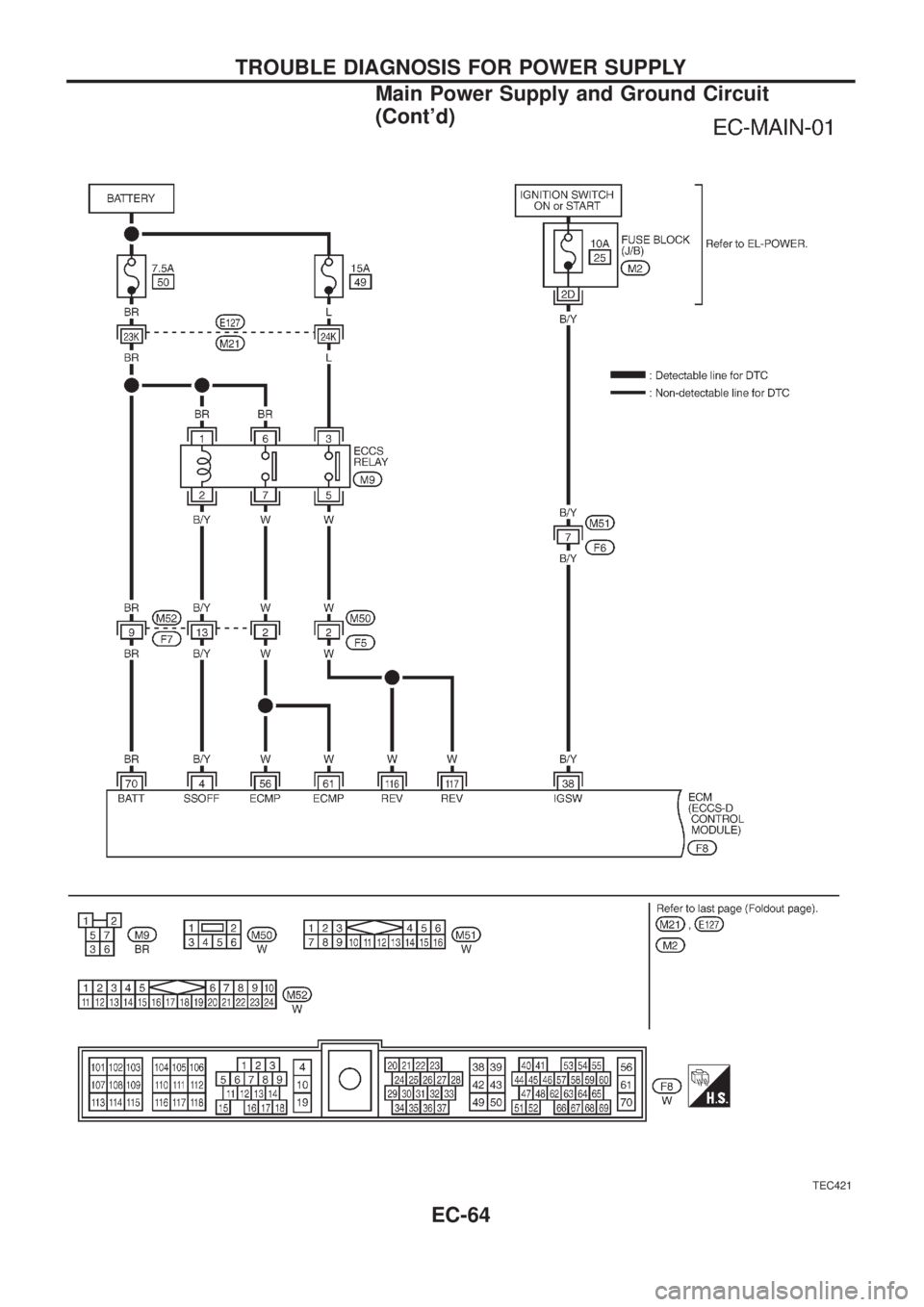

Main Power Supply and Ground Circuit

ECM TERMINALS AND REFERENCE VALUE

Remarks: Speci®cation data are reference values and are measured between each terminal andV43(ECCS

ground) with a voltmeter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse

Signal)

4 B/Y ECCS relay (Self-shutoff)Ignition switch ``ON''

Ignition switch ``OFF''

For a few seconds after turning ignition switch

``OFF''0 - 1.5V

Ignition switch ``OFF''

A few seconds passed after turning ignition

switch ``OFF''BATTERY VOLTAGE

(11 - 14V)

38 B/Y Ignition switchIgnition switch ``OFF''

0V

Ignition switch ``ON''

BATTERY VOLTAGE

(11 - 14V)

39

43B ECCS groundEngine is running.

Idle speedEngine ground

(Probe this terminal with

@tester probe when

measuring.)

56

61W Power supply for ECM Ignition switch ``ON''

BATTERY VOLTAGE

(11 - 14V)

70 BR Power supply (Back-up) Ignition switch ``OFF''

BATTERY VOLTAGE

(11 - 14V)

106

11 2

11 8B ECCS groundEngine is running.

Idle speedApproximately 0V

11 6

11 7W Power supply for ECM Ignition switch ``ON''

BATTERY VOLTAGE

(11 - 14V)

TROUBLE DIAGNOSIS FOR POWER SUPPLY

EC-63

Page 215 of 1226

TEC421

TROUBLE DIAGNOSIS FOR POWER SUPPLY

Main Power Supply and Ground Circuit

(Cont'd)

EC-64

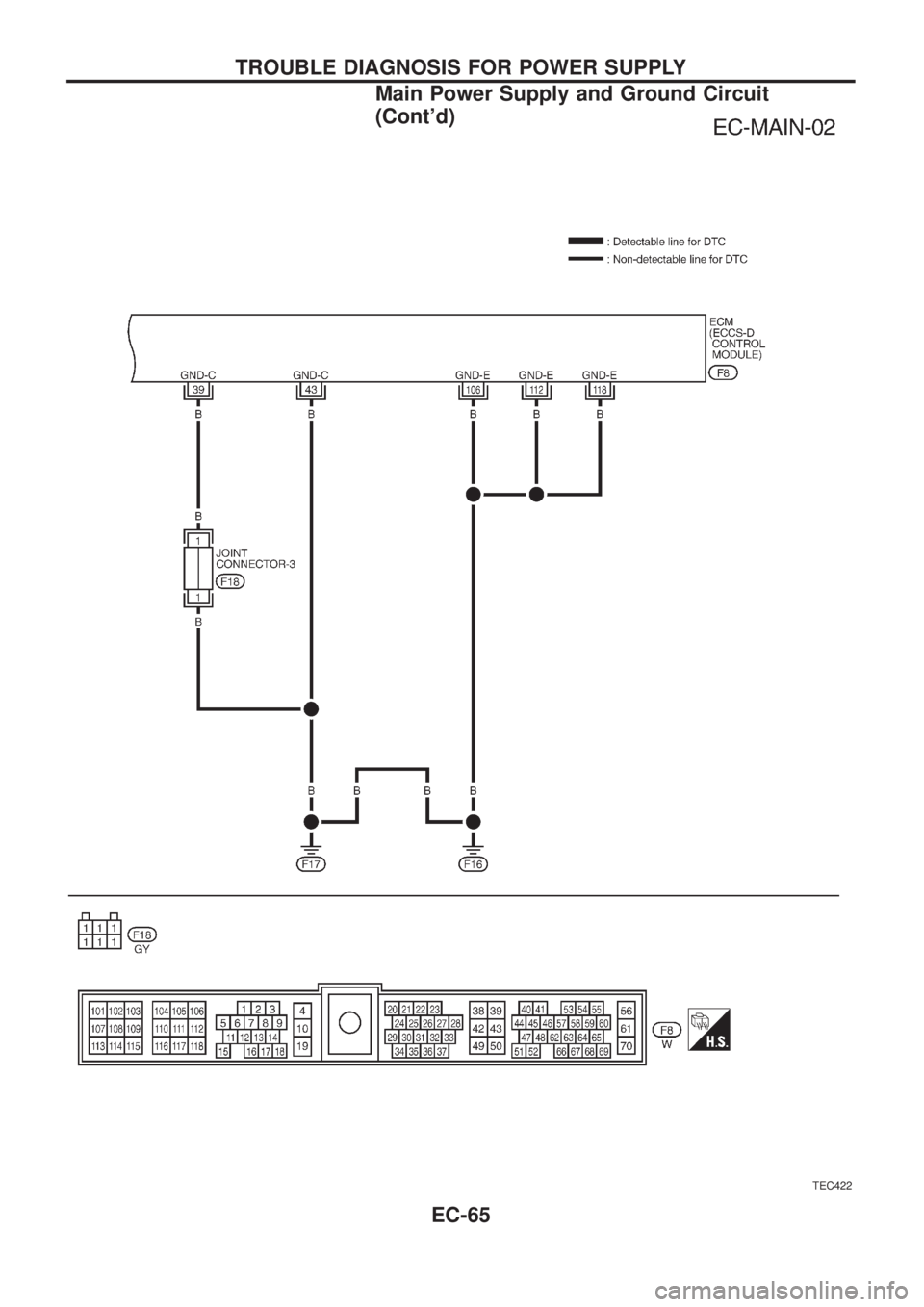

Page 216 of 1226

TEC422

TROUBLE DIAGNOSIS FOR POWER SUPPLY

Main Power Supply and Ground Circuit

(Cont'd)

EC-65

Page 217 of 1226

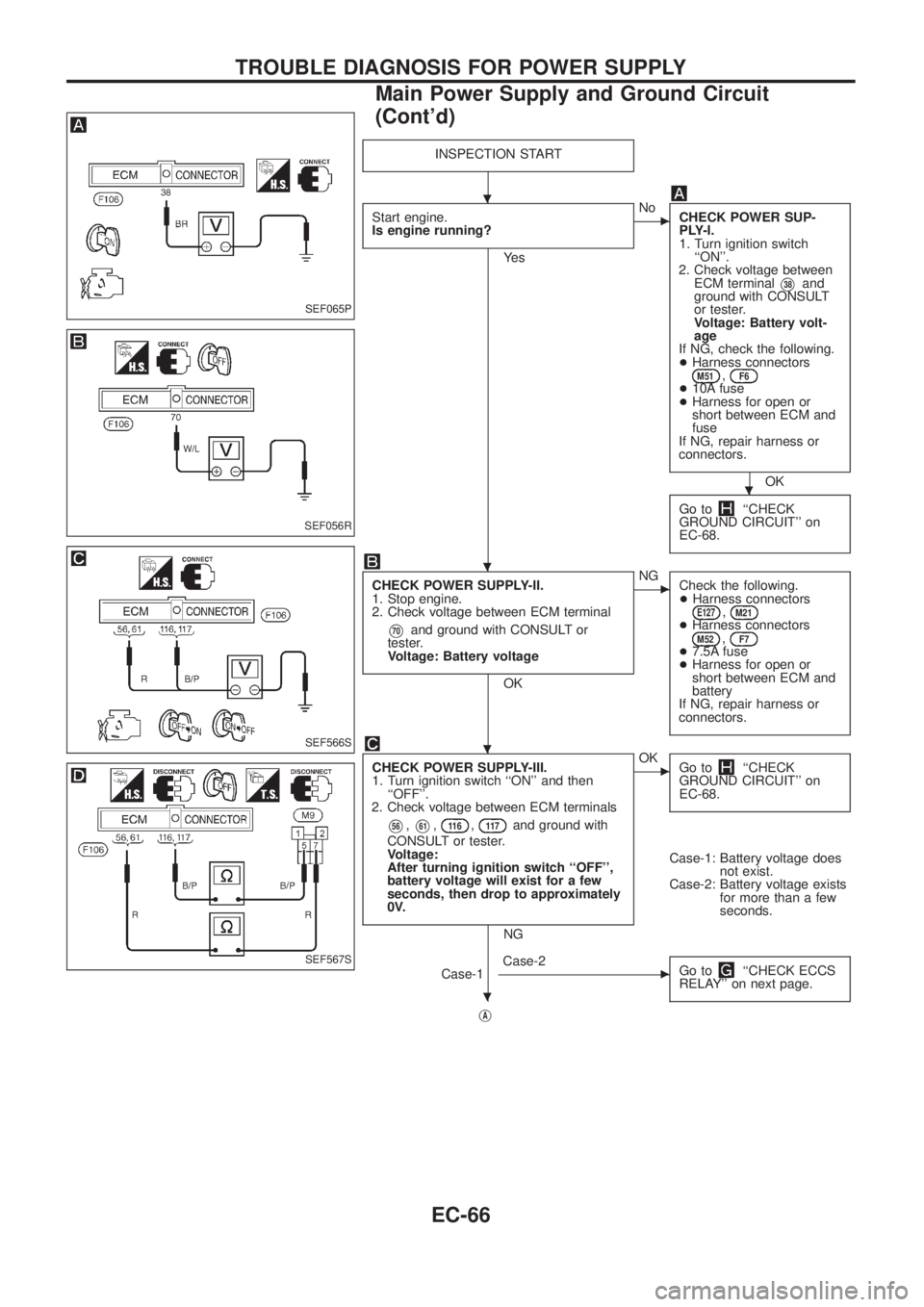

INSPECTION START

Start engine.

Is engine running?

Ye s

cNo

CHECK POWER SUP-

PLY-I.

1. Turn ignition switch

``ON''.

2. Check voltage between

ECM terminal

V38and

ground with CONSULT

or tester.

Voltage: Battery volt-

age

If NG, check the following.

+Harness connectors

M51,F6+10A fuse

+Harness for open or

short between ECM and

fuse

If NG, repair harness or

connectors.

OK

Go to

``CHECK

GROUND CIRCUIT'' on

EC-68.

CHECK POWER SUPPLY-II.

1. Stop engine.

2. Check voltage between ECM terminal

V70and ground with CONSULT or

tester.

Voltage: Battery voltage

OK

cNG

Check the following.

+Harness connectors

E127,M21+Harness connectorsM52,F7+7.5A fuse

+Harness for open or

short between ECM and

battery

If NG, repair harness or

connectors.

CHECK POWER SUPPLY-III.

1. Turn ignition switch ``ON'' and then

``OFF''.

2. Check voltage between ECM terminals

V56,V61,11 6,11 7and ground with

CONSULT or tester.

Voltage:

After turning ignition switch ``OFF'',

battery voltage will exist for a few

seconds, then drop to approximately

0V.

NG

cOK

Go to``CHECK

GROUND CIRCUIT'' on

EC-68.

Case-1: Battery voltage does

not exist.

Case-2: Battery voltage exists

for more than a few

seconds.

Case-1

cCase-2

Go to``CHECK ECCS

RELAY'' on next page.

jA

SEF065P

SEF056R

SEF566S

SEF567S

.

.

.

.

.

TROUBLE DIAGNOSIS FOR POWER SUPPLY

Main Power Supply and Ground Circuit

(Cont'd)

EC-66

Page 218 of 1226

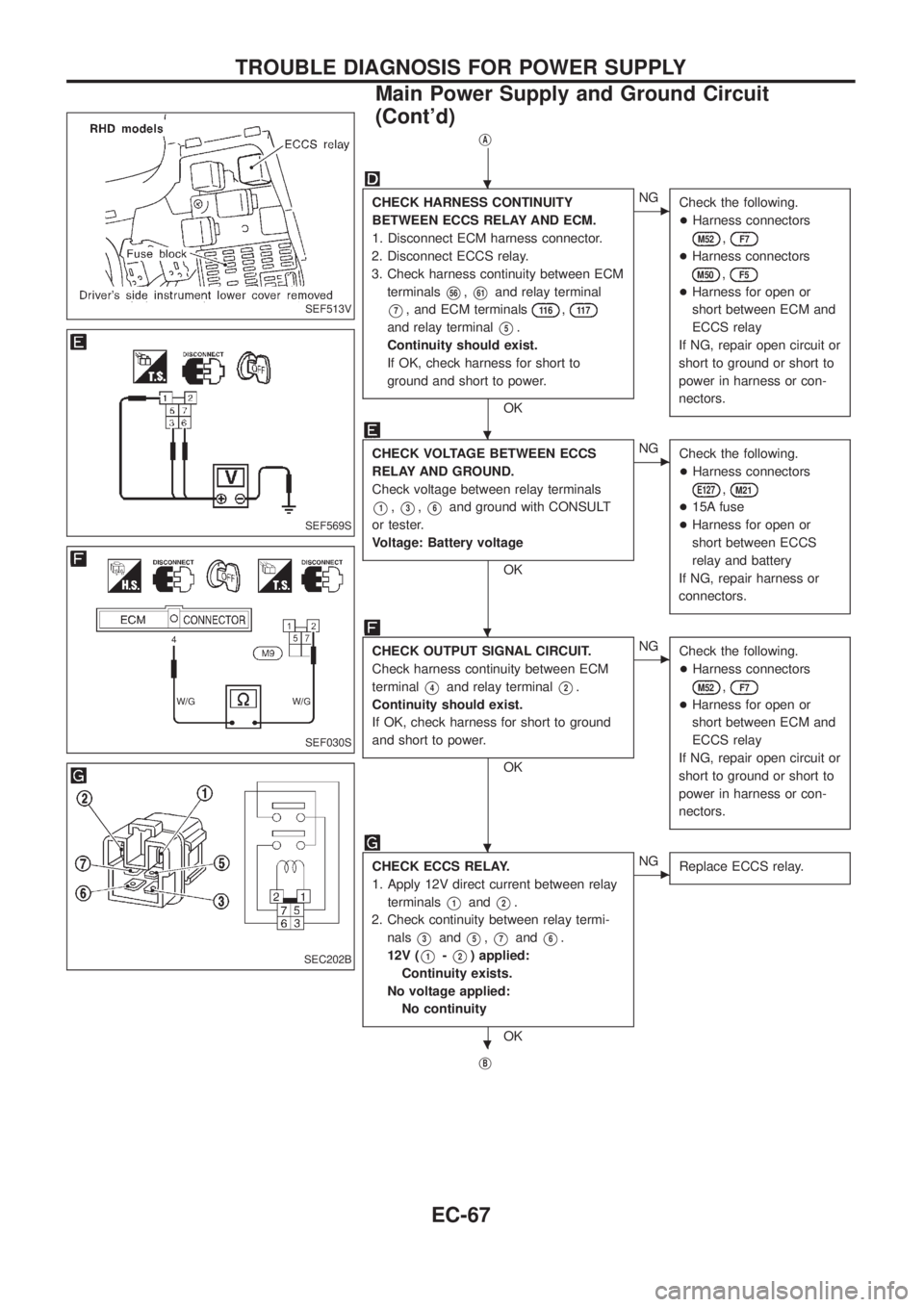

jA

CHECK HARNESS CONTINUITY

BETWEEN ECCS RELAY AND ECM.

1. Disconnect ECM harness connector.

2. Disconnect ECCS relay.

3. Check harness continuity between ECM

terminals

V56,V61and relay terminal

V7, and ECM terminals11 6,11 7

and relay terminalV5.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

+Harness connectors

M52,F7

+Harness connectors

M50,F5

+Harness for open or

short between ECM and

ECCS relay

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

CHECK VOLTAGE BETWEEN ECCS

RELAY AND GROUND.

Check voltage between relay terminals

V1,V3,V6and ground with CONSULT

or tester.

Voltage: Battery voltage

OK

cNG

Check the following.

+Harness connectors

E127,M21

+15A fuse

+Harness for open or

short between ECCS

relay and battery

If NG, repair harness or

connectors.

CHECK OUTPUT SIGNAL CIRCUIT.

Check harness continuity between ECM

terminal

V4and relay terminalV2.

Continuity should exist.

If OK, check harness for short to ground

and short to power.

OK

cNG

Check the following.

+Harness connectors

M52,F7

+Harness for open or

short between ECM and

ECCS relay

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

CHECK ECCS RELAY.

1. Apply 12V direct current between relay

terminals

V1andV2.

2. Check continuity between relay termi-

nals

V3andV5,V7andV6.

12V (

V1-V2) applied:

Continuity exists.

No voltage applied:

No continuity

OK

cNG

Replace ECCS relay.

jB

SEF513V

SEF569S

SEF030S

SEC202B

.

.

.

.

.

TROUBLE DIAGNOSIS FOR POWER SUPPLY

Main Power Supply and Ground Circuit

(Cont'd)

EC-67

Page 219 of 1226

jB

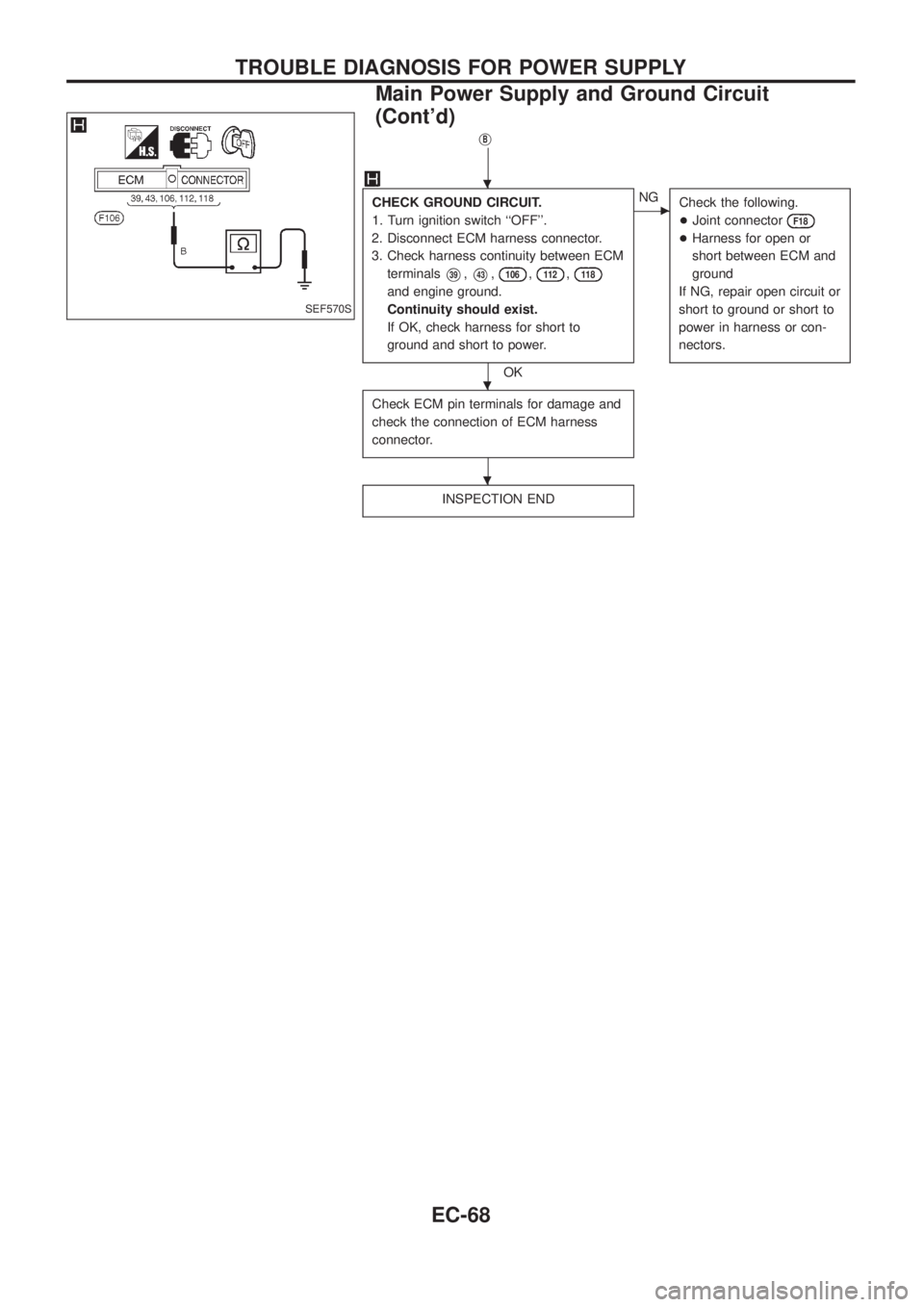

CHECK GROUND CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM

terminals

V39,V43,106,11 2,11 8

and engine ground.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

+Joint connector

F18

+Harness for open or

short between ECM and

ground

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

Check ECM pin terminals for damage and

check the connection of ECM harness

connector.

INSPECTION END

SEF570S

.

.

.

TROUBLE DIAGNOSIS FOR POWER SUPPLY

Main Power Supply and Ground Circuit

(Cont'd)

EC-68

Page 225 of 1226

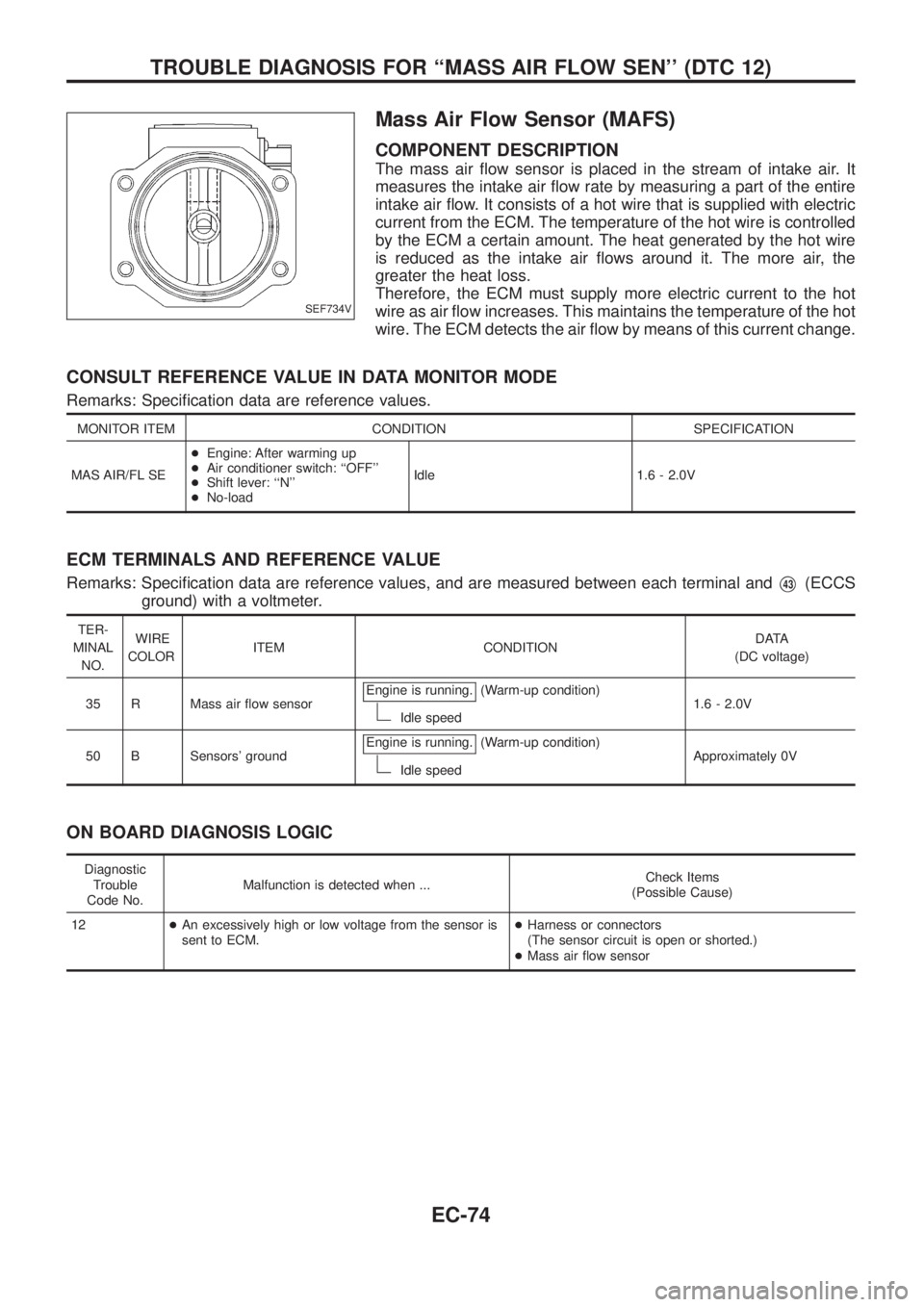

Mass Air Flow Sensor (MAFS)

COMPONENT DESCRIPTION

The mass air ¯ow sensor is placed in the stream of intake air. It

measures the intake air ¯ow rate by measuring a part of the entire

intake air ¯ow. It consists of a hot wire that is supplied with electric

current from the ECM. The temperature of the hot wire is controlled

by the ECM a certain amount. The heat generated by the hot wire

is reduced as the intake air ¯ows around it. The more air, the

greater the heat loss.

Therefore, the ECM must supply more electric current to the hot

wire as air ¯ow increases. This maintains the temperature of the hot

wire. The ECM detects the air ¯ow by means of this current change.

CONSULT REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Speci®cation data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

MAS AIR/FL SE+Engine: After warming up

+Air conditioner switch: ``OFF''

+Shift lever: ``N''

+No-loadIdle 1.6 - 2.0V

ECM TERMINALS AND REFERENCE VALUE

Remarks: Speci®cation data are reference values, and are measured between each terminal andV43(ECCS

ground) with a voltmeter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC voltage)

35 R Mass air ¯ow sensorEngine is running.

(Warm-up condition)

Idle speed1.6 - 2.0V

50 B Sensors' groundEngine is running.

(Warm-up condition)

Idle speedApproximately 0V

ON BOARD DIAGNOSIS LOGIC

Diagnostic

Trouble

Code No.Malfunction is detected when ...Check Items

(Possible Cause)

12+An excessively high or low voltage from the sensor is

sent to ECM.+Harness or connectors

(The sensor circuit is open or shorted.)

+Mass air ¯ow sensor

SEF734V

TROUBLE DIAGNOSIS FOR ``MASS AIR FLOW SEN'' (DTC 12)

EC-74