lock NISSAN PATROL 2006 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 1091 of 1226

Electrical Components Inspection

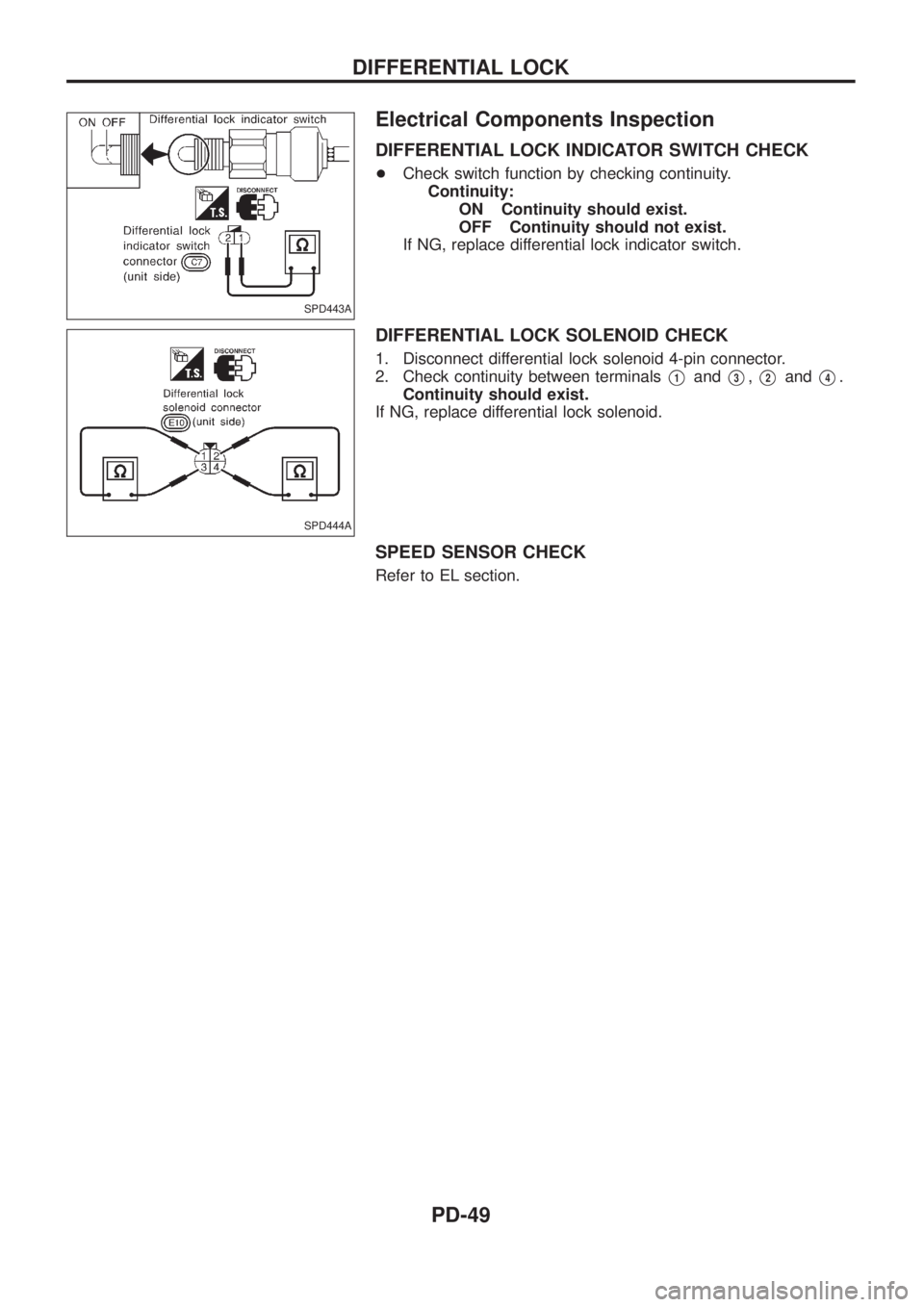

DIFFERENTIAL LOCK INDICATOR SWITCH CHECK

+Check switch function by checking continuity.

Continuity:

ON Continuity should exist.

OFF Continuity should not exist.

If NG, replace differential lock indicator switch.

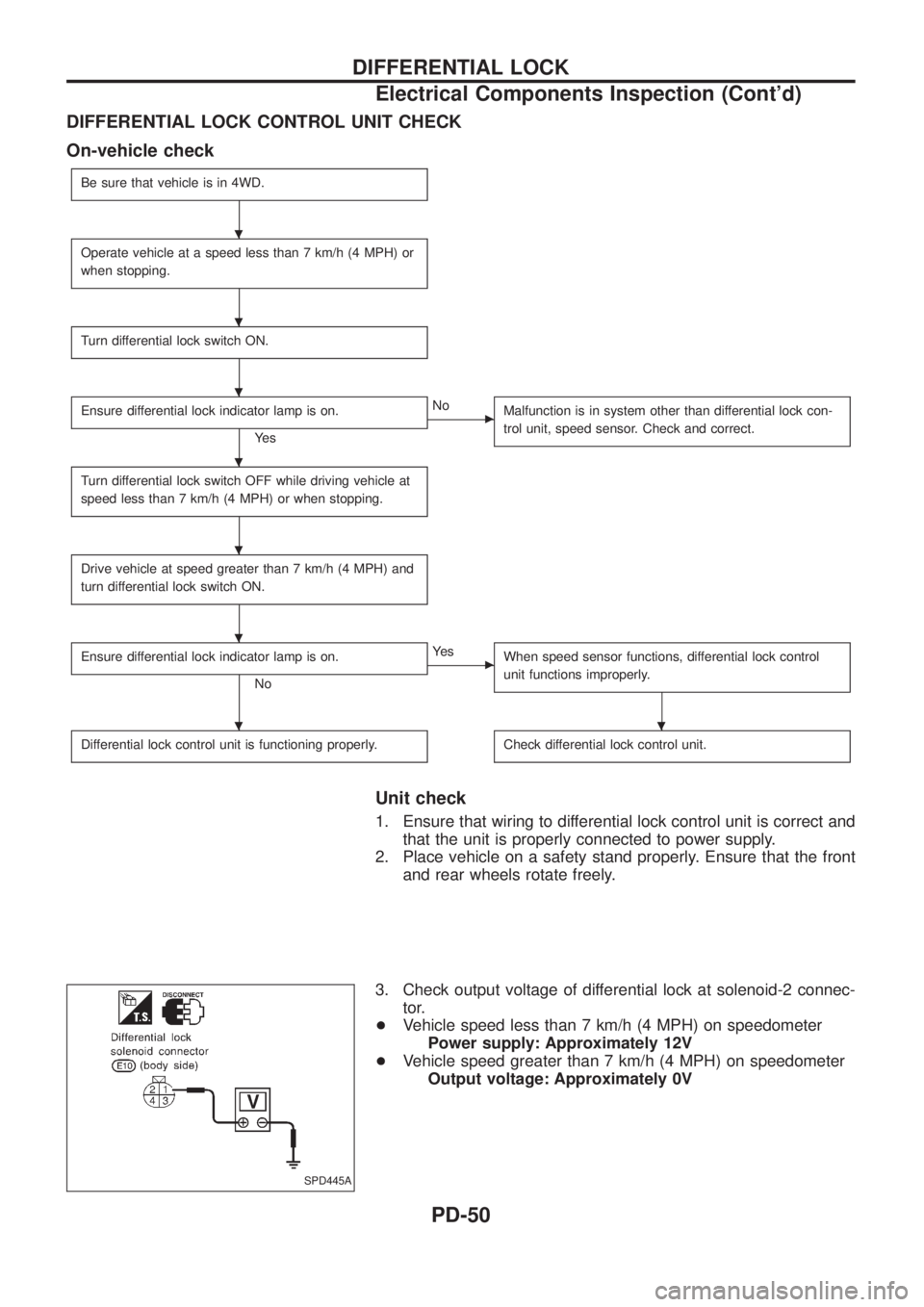

DIFFERENTIAL LOCK SOLENOID CHECK

1. Disconnect differential lock solenoid 4-pin connector.

2. Check continuity between terminals

V1andV3,V2andV4.

Continuity should exist.

If NG, replace differential lock solenoid.

SPEED SENSOR CHECK

Refer to EL section.

SPD443A

SPD444A

DIFFERENTIAL LOCK

PD-49

Page 1092 of 1226

DIFFERENTIAL LOCK CONTROL UNIT CHECK

On-vehicle check

Be sure that vehicle is in 4WD.

Operate vehicle at a speed less than 7 km/h (4 MPH) or

when stopping.

Turn differential lock switch ON.

Ensure differential lock indicator lamp is on.

Ye s

cNo

Malfunction is in system other than differential lock con-

trol unit, speed sensor. Check and correct.

Turn differential lock switch OFF while driving vehicle at

speed less than 7 km/h (4 MPH) or when stopping.

Drive vehicle at speed greater than 7 km/h (4 MPH) and

turn differential lock switch ON.

Ensure differential lock indicator lamp is on.

No

cYe s

When speed sensor functions, differential lock control

unit functions improperly.

Differential lock control unit is functioning properly.Check differential lock control unit.

Unit check

1. Ensure that wiring to differential lock control unit is correct and

that the unit is properly connected to power supply.

2. Place vehicle on a safety stand properly. Ensure that the front

and rear wheels rotate freely.

3. Check output voltage of differential lock at solenoid-2 connec-

tor.

+Vehicle speed less than 7 km/h (4 MPH) on speedometer

Power supply: Approximately 12V

+Vehicle speed greater than 7 km/h (4 MPH) on speedometer

Output voltage: Approximately 0V

SPD445A

.

.

.

.

.

.

..

DIFFERENTIAL LOCK

Electrical Components Inspection (Cont'd)

PD-50

Page 1094 of 1226

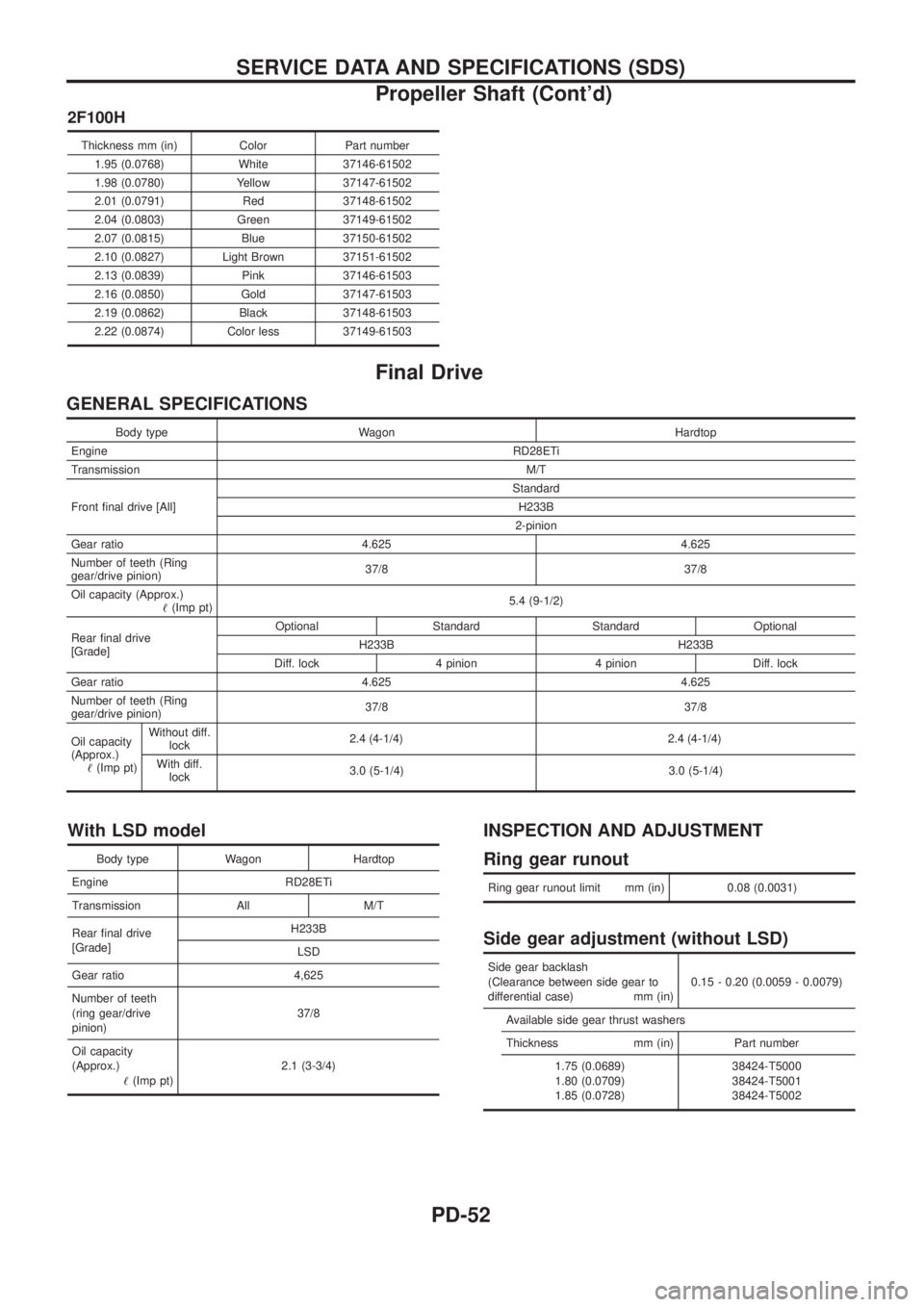

2F100H

Thickness mm (in) Color Part number1.95 (0.0768) White 37146-61502

1.98 (0.0780) Yellow 37147-61502

2.01 (0.0791) Red 37148-61502

2.04 (0.0803) Green 37149-61502

2.07 (0.0815) Blue 37150-61502

2.10 (0.0827) Light Brown 37151-61502

2.13 (0.0839) Pink 37146-61503

2.16 (0.0850) Gold 37147-61503

2.19 (0.0862) Black 37148-61503

2.22 (0.0874) Color less 37149-61503

Final Drive

GENERAL SPECIFICATIONS

Body type Wagon Hardtop

Engine RD28ETi

Transmission M/T

Front ®nal drive [All] Standard

H233B

2-pinion

Gear ratio 4.625 4.625

Number of teeth (Ring

gear/drive pinion) 37/8 37/8

Oil capacity (Approx.) !(Imp pt) 5.4 (9-1/2)

Rear ®nal drive

[Grade] Optional Standard Standard Optional

H233B H233B

Diff. lock 4 pinion 4 pinion Diff. lock

Gear ratio 4.625 4.625

Number of teeth (Ring

gear/drive pinion) 37/8 37/8

Oil capacity

(Approx.) !(Imp pt) Without diff.

lock 2.4 (4

-1/4)2.4 (4-1/4)

With diff.lock 3.0 (5-1/4) 3.0 (5-1/4)

With LSD model

Body type Wagon Hardtop

Engine RD28ETi

Transmission All M/T

Rear ®nal drive

[Grade] H233B

LSD

Gear ratio 4,625

Number of teeth

(ring gear/drive

pinion) 37/8

Oil capacity

(Approx.) !(Imp pt) 2.1 (3-3/4)

INSPECTION AND ADJUSTMENT

Ring gear runout

Ring gear runout limit mm (in) 0.08 (0.0031)

Side gear adjustment (without LSD)

Side gear backlash

(Clearance between side gear to

differential case) mm (in) 0.15 - 0.20 (0.0059 - 0.0079)

Available side gear thrust washers

Thickness mm (in) Part number 1.75 (0.0689)

1.80 (0.0709)

1.85 (0.0728) 38424-T5000

38424-T5001

38424-T5002

SERVICE DATA AND SPECIFICATIONS (SDS)

Propeller Shaft (Cont'd)

PD-52

Page 1097 of 1226

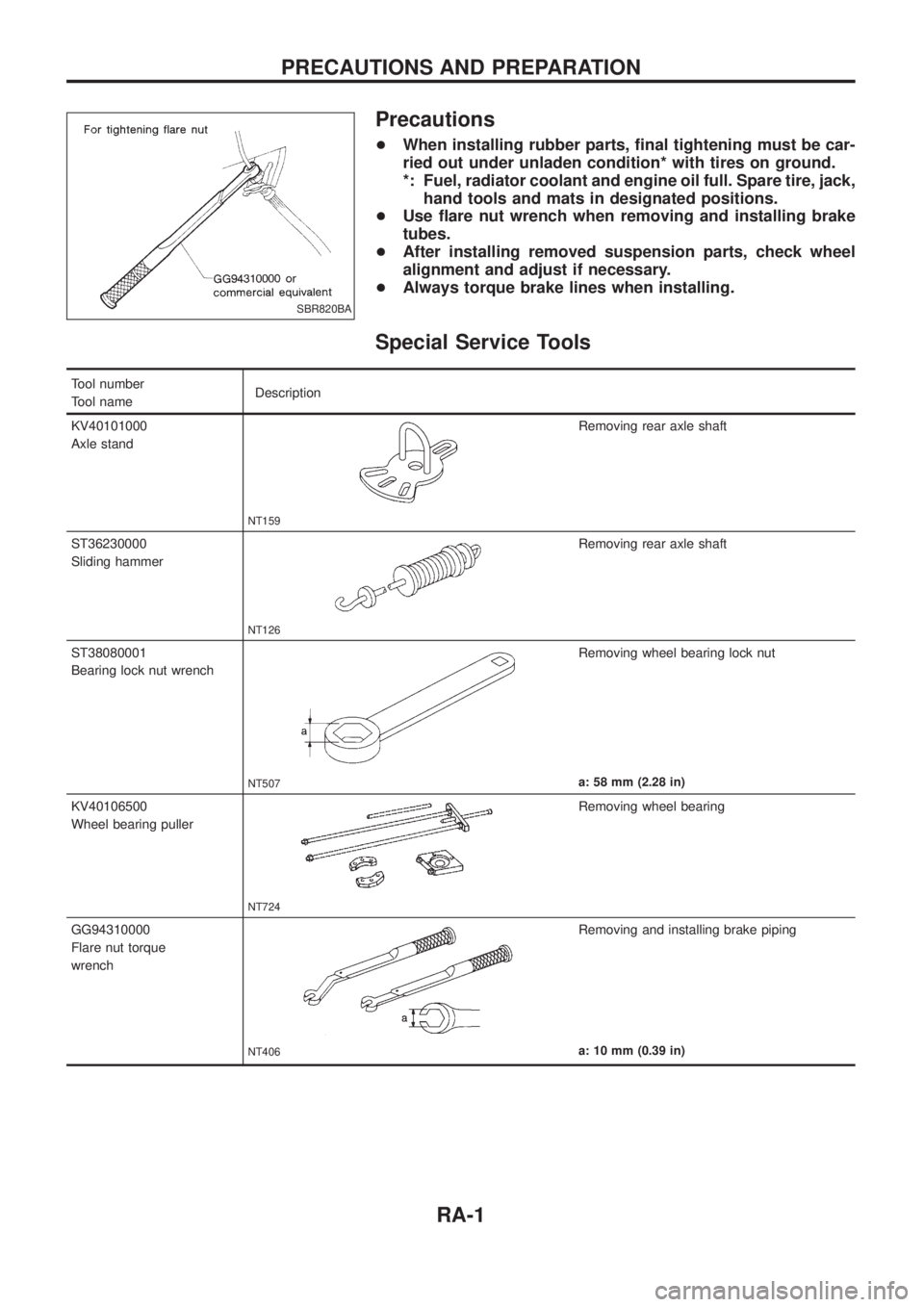

Precautions

+When installing rubber parts, ®nal tightening must be car-

ried out under unladen condition* with tires on ground.

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

+Use ¯are nut wrench when removing and installing brake

tubes.

+After installing removed suspension parts, check wheel

alignment and adjust if necessary.

+Always torque brake lines when installing.

Special Service Tools

Tool number

Tool nameDescription

KV40101000

Axle stand

NT159

Removing rear axle shaft

ST36230000

Sliding hammer

NT126

Removing rear axle shaft

ST38080001

Bearing lock nut wrench

NT507

Removing wheel bearing lock nut

a: 58 mm (2.28 in)

KV40106500

Wheel bearing puller

NT724

Removing wheel bearing

GG94310000

Flare nut torque

wrench

NT406

Removing and installing brake piping

a: 10 mm (0.39 in)

SBR820BA

PRECAUTIONS AND PREPARATION

RA-1

Page 1104 of 1226

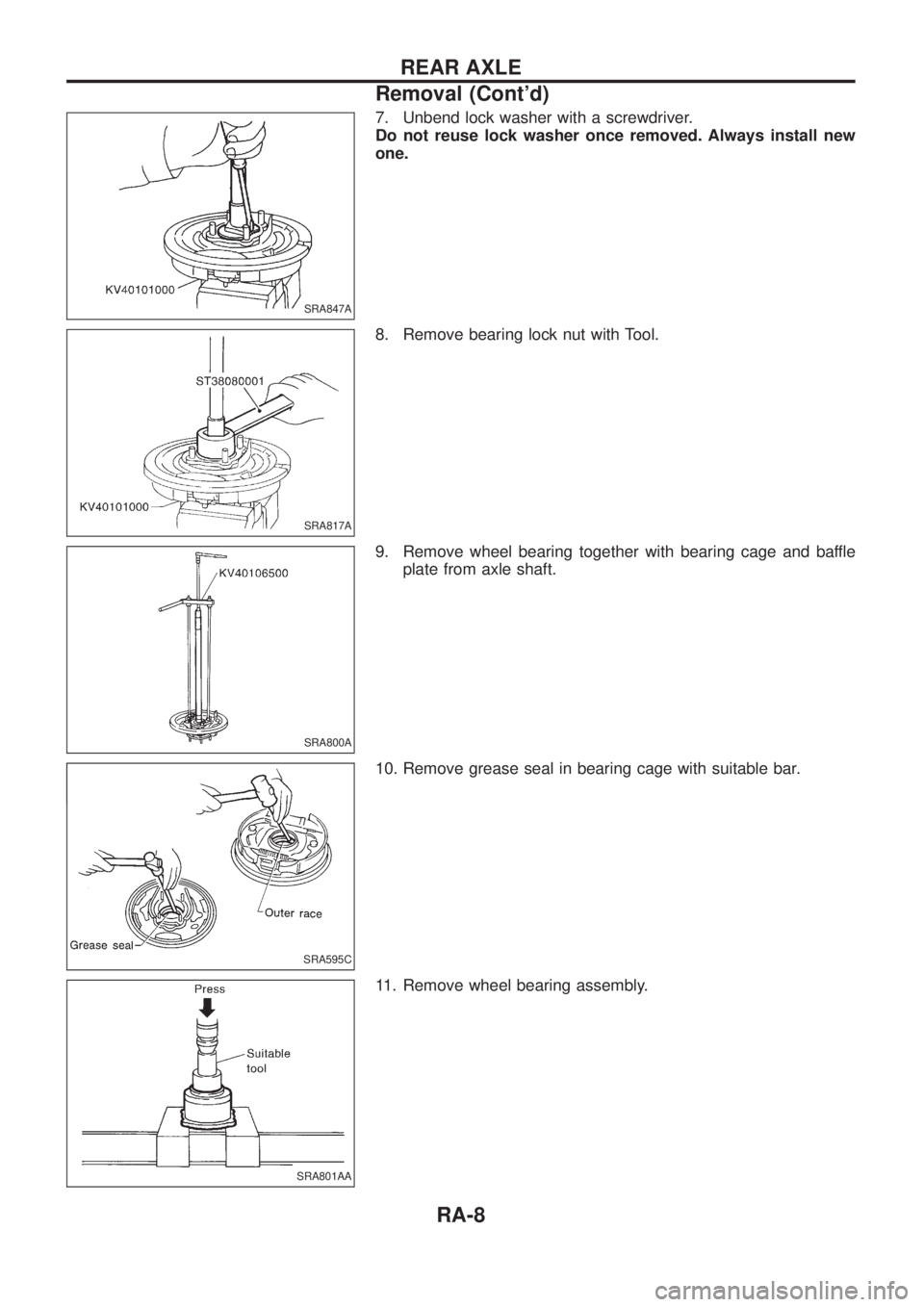

7. Unbend lock washer with a screwdriver.

Do not reuse lock washer once removed. Always install new

one.

8. Remove bearing lock nut with Tool.

9. Remove wheel bearing together with bearing cage and baffle

plate from axle shaft.

10. Remove grease seal in bearing cage with suitable bar.

11. Remove wheel bearing assembly.

SRA847A

SRA817A

SRA800A

SRA595C

SRA801AA

REAR AXLE

Removal (Cont'd)

RA-8

Page 1106 of 1226

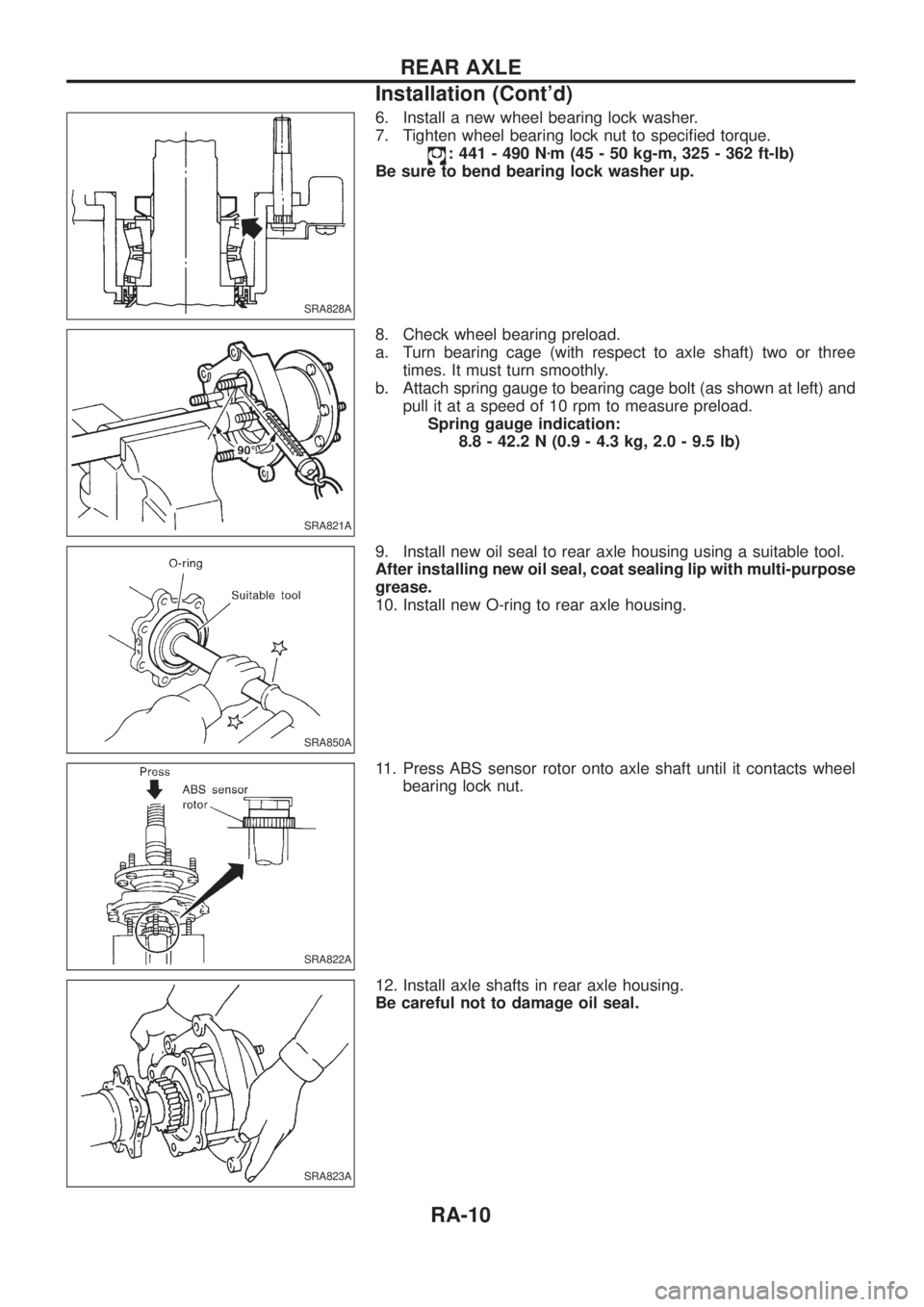

6. Install a new wheel bearing lock washer.

7. Tighten wheel bearing lock nut to speci®ed torque.

: 441 - 490 Nzm (45 - 50 kg-m, 325 - 362 ft-lb)

Be sure to bend bearing lock washer up.

8. Check wheel bearing preload.

a. Turn bearing cage (with respect to axle shaft) two or three

times. It must turn smoothly.

b. Attach spring gauge to bearing cage bolt (as shown at left) and

pull it at a speed of 10 rpm to measure preload.

Spring gauge indication:

8.8 - 42.2 N (0.9 - 4.3 kg, 2.0 - 9.5 lb)

9. Install new oil seal to rear axle housing using a suitable tool.

After installing new oil seal, coat sealing lip with multi-purpose

grease.

10. Install new O-ring to rear axle housing.

11. Press ABS sensor rotor onto axle shaft until it contacts wheel

bearing lock nut.

12. Install axle shafts in rear axle housing.

Be careful not to damage oil seal.

SRA828A

SRA821A

SRA850A

SRA822A

SRA823A

REAR AXLE

Installation (Cont'd)

RA-10

Page 1109 of 1226

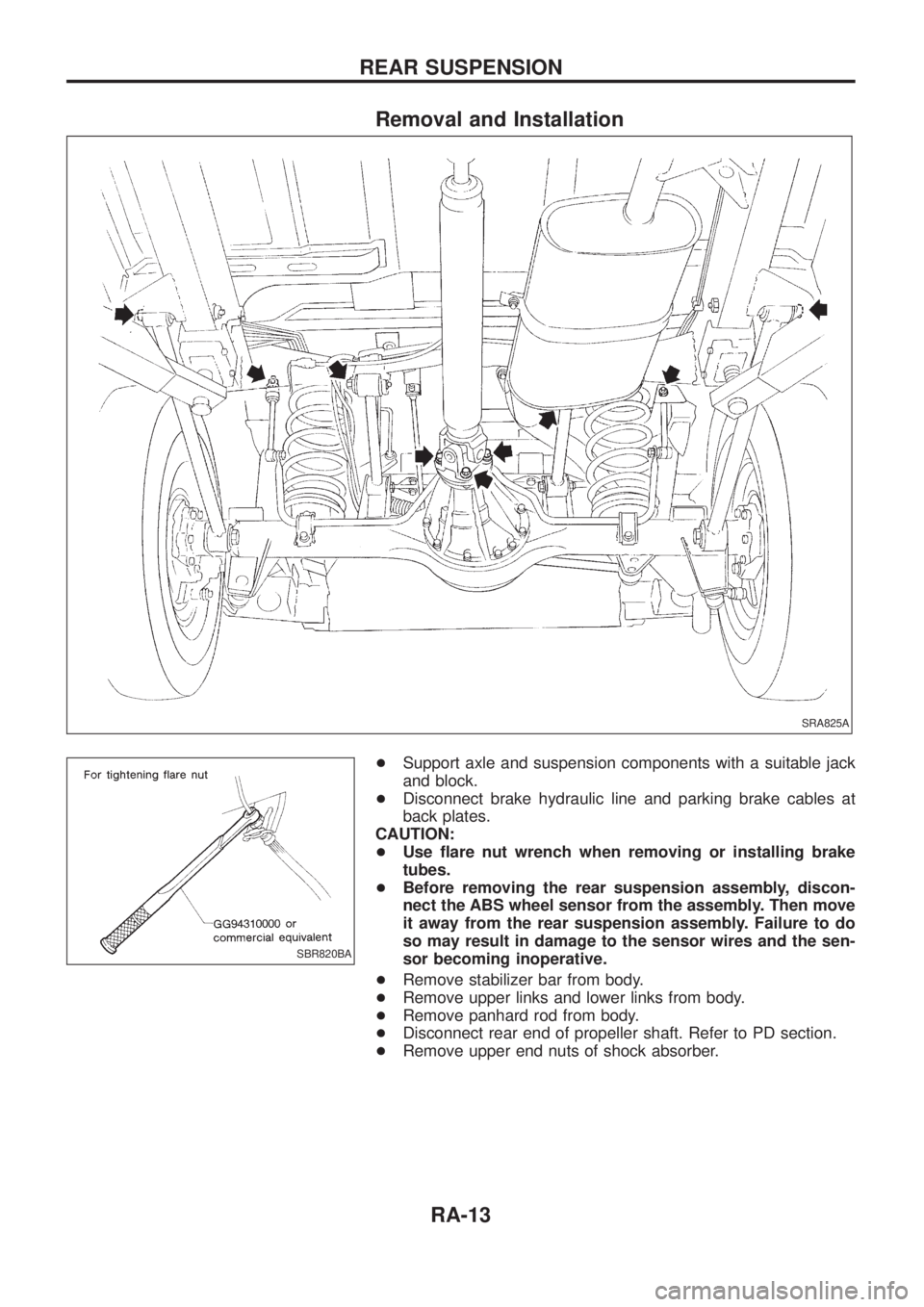

Removal and Installation

+Support axle and suspension components with a suitable jack

and block.

+Disconnect brake hydraulic line and parking brake cables at

back plates.

CAUTION:

+Use ¯are nut wrench when removing or installing brake

tubes.

+Before removing the rear suspension assembly, discon-

nect the ABS wheel sensor from the assembly. Then move

it away from the rear suspension assembly. Failure to do

so may result in damage to the sensor wires and the sen-

sor becoming inoperative.

+Remove stabilizer bar from body.

+Remove upper links and lower links from body.

+Remove panhard rod from body.

+Disconnect rear end of propeller shaft. Refer to PD section.

+Remove upper end nuts of shock absorber.

SRA825A

SBR820BA

REAR SUSPENSION

RA-13

Page 1113 of 1226

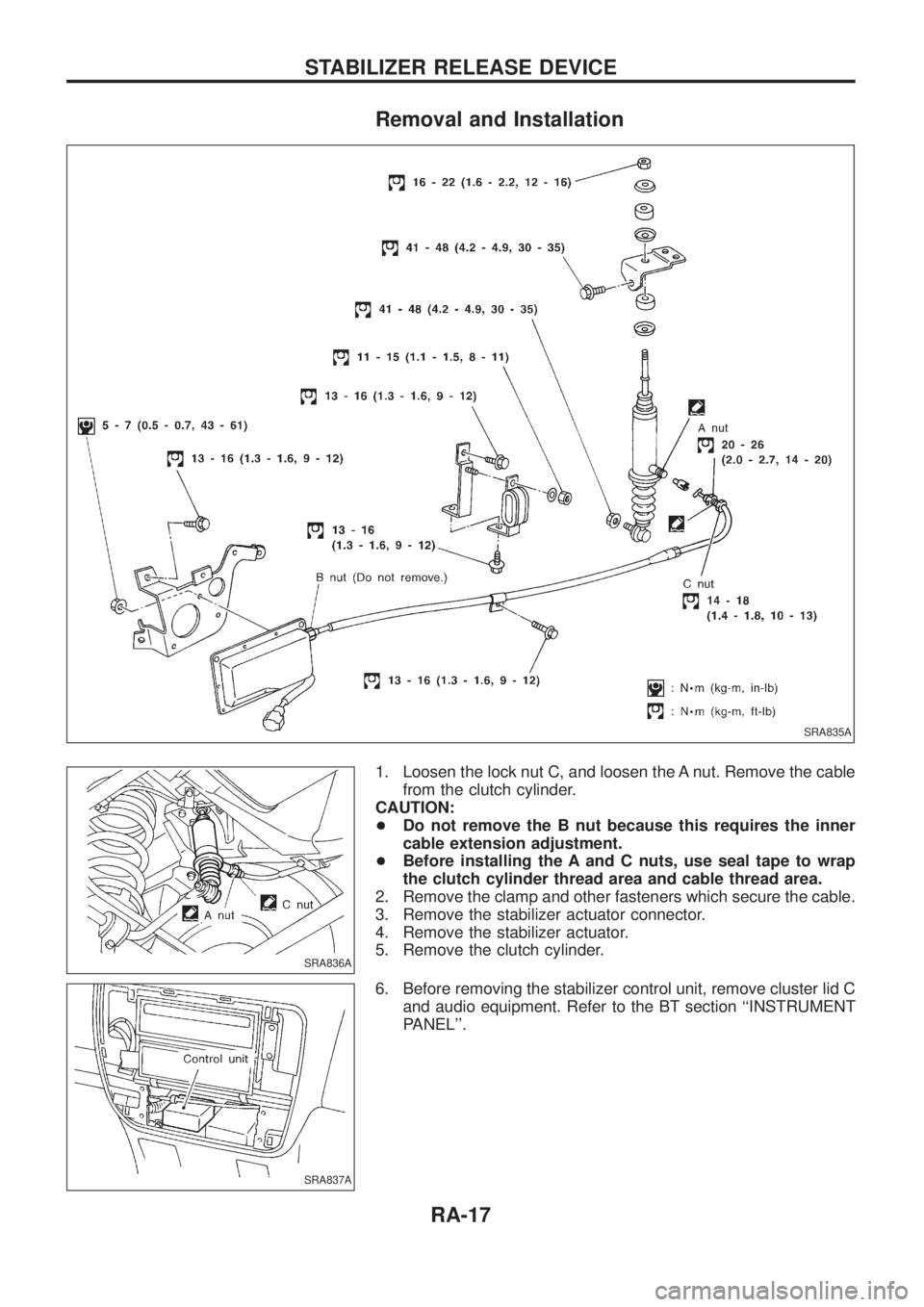

Removal and Installation

1. Loosen the lock nut C, and loosen the A nut. Remove the cable

from the clutch cylinder.

CAUTION:

+Do not remove the B nut because this requires the inner

cable extension adjustment.

+Before installing the A and C nuts, use seal tape to wrap

the clutch cylinder thread area and cable thread area.

2. Remove the clamp and other fasteners which secure the cable.

3. Remove the stabilizer actuator connector.

4. Remove the stabilizer actuator.

5. Remove the clutch cylinder.

6. Before removing the stabilizer control unit, remove cluster lid C

and audio equipment. Refer to the BT section ``INSTRUMENT

PANEL''.

SRA835A

SRA836A

SRA837A

STABILIZER RELEASE DEVICE

RA-17

Page 1136 of 1226

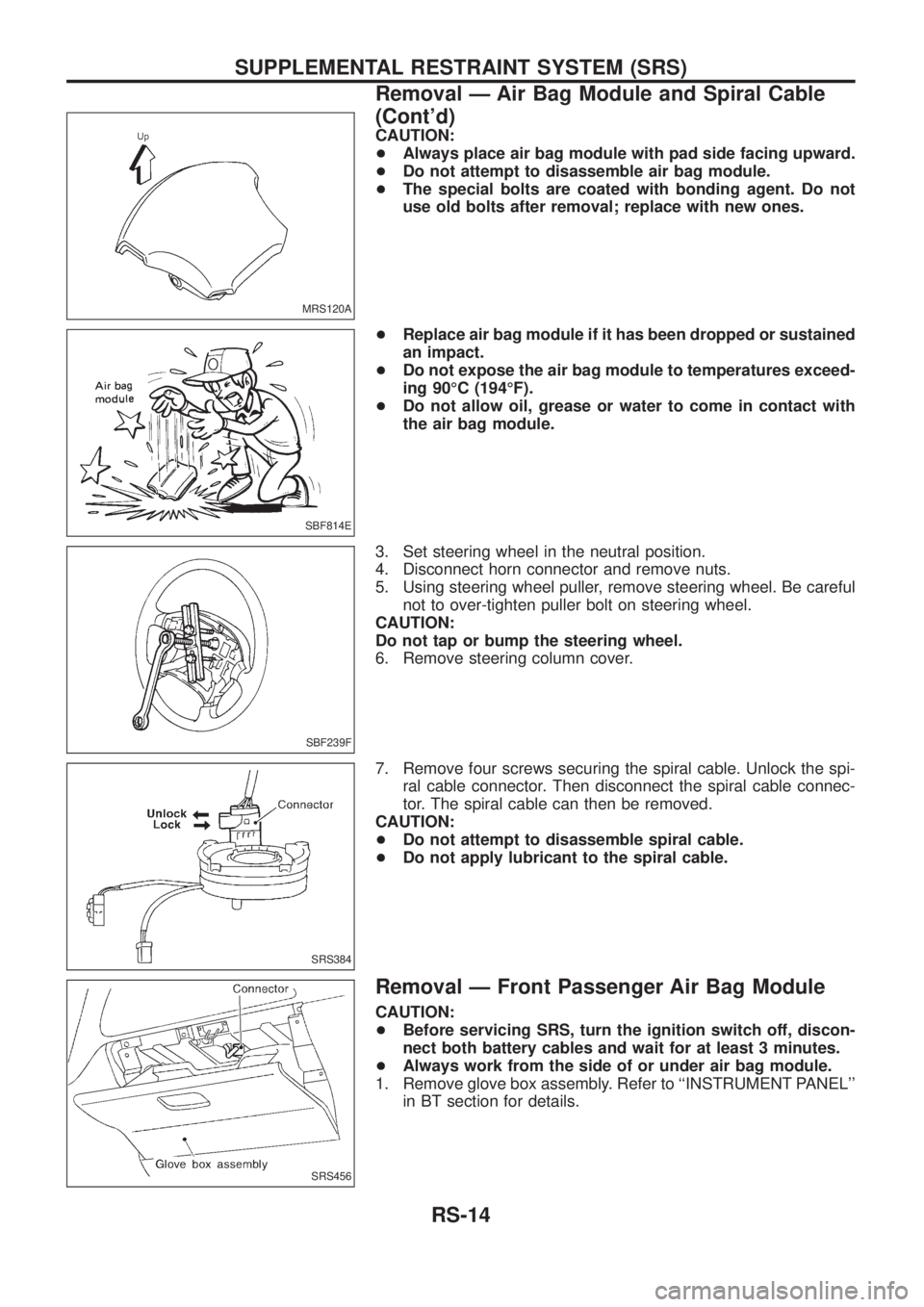

CAUTION:

+Always place air bag module with pad side facing upward.

+Do not attempt to disassemble air bag module.

+The special bolts are coated with bonding agent. Do not

use old bolts after removal; replace with new ones.

+Replace air bag module if it has been dropped or sustained

an impact.

+Do not expose the air bag module to temperatures exceed-

ing 90ÉC (194ÉF).

+Do not allow oil, grease or water to come in contact with

the air bag module.

3. Set steering wheel in the neutral position.

4. Disconnect horn connector and remove nuts.

5. Using steering wheel puller, remove steering wheel. Be careful

not to over-tighten puller bolt on steering wheel.

CAUTION:

Do not tap or bump the steering wheel.

6. Remove steering column cover.

7. Remove four screws securing the spiral cable. Unlock the spi-

ral cable connector. Then disconnect the spiral cable connec-

tor. The spiral cable can then be removed.

CAUTION:

+Do not attempt to disassemble spiral cable.

+Do not apply lubricant to the spiral cable.

Removal Ð Front Passenger Air Bag Module

CAUTION:

+Before servicing SRS, turn the ignition switch off, discon-

nect both battery cables and wait for at least 3 minutes.

+Always work from the side of or under air bag module.

1. Remove glove box assembly. Refer to ``INSTRUMENT PANEL''

in BT section for details.

MRS120A

SBF814E

SBF239F

SRS384

SRS456

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Removal Ð Air Bag Module and Spiral Cable

(Cont'd)

RS-14

Page 1138 of 1226

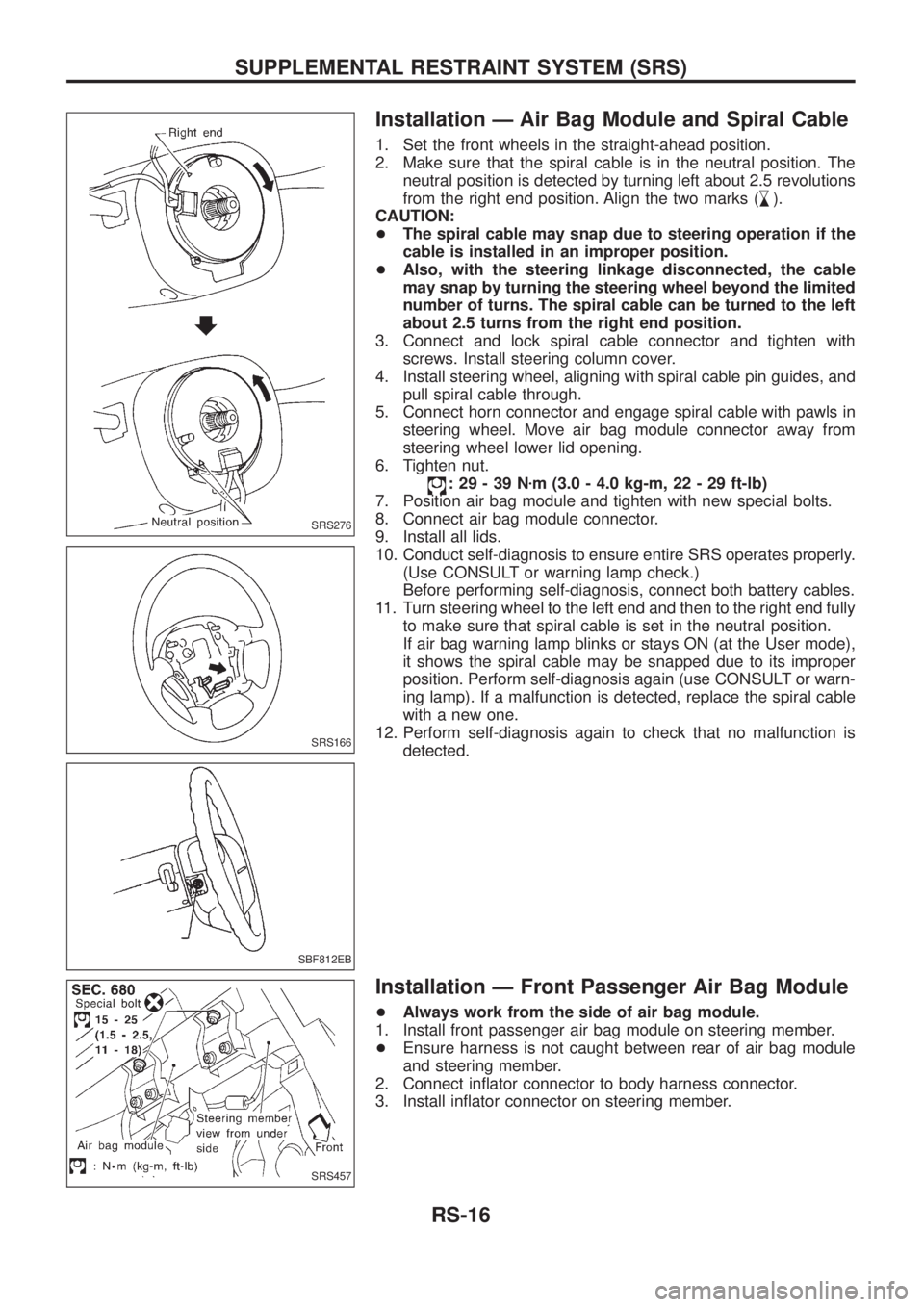

Installation Ð Air Bag Module and Spiral Cable

1. Set the front wheels in the straight-ahead position.

2. Make sure that the spiral cable is in the neutral position. The

neutral position is detected by turning left about 2.5 revolutions

from the right end position. Align the two marks (

,

m).

CAUTION:

+The spiral cable may snap due to steering operation if the

cable is installed in an improper position.

+Also, with the steering linkage disconnected, the cable

may snap by turning the steering wheel beyond the limited

number of turns. The spiral cable can be turned to the left

about 2.5 turns from the right end position.

3. Connect and lock spiral cable connector and tighten with

screws. Install steering column cover.

4. Install steering wheel, aligning with spiral cable pin guides, and

pull spiral cable through.

5. Connect horn connector and engage spiral cable with pawls in

steering wheel. Move air bag module connector away from

steering wheel lower lid opening.

6. Tighten nut.

:29-39Nzm (3.0 - 4.0 kg-m, 22 - 29 ft-lb)

7. Position air bag module and tighten with new special bolts.

8. Connect air bag module connector.

9. Install all lids.

10. Conduct self-diagnosis to ensure entire SRS operates properly.

(Use CONSULT or warning lamp check.)

Before performing self-diagnosis, connect both battery cables.

11. Turn steering wheel to the left end and then to the right end fully

to make sure that spiral cable is set in the neutral position.

If air bag warning lamp blinks or stays ON (at the User mode),

it shows the spiral cable may be snapped due to its improper

position. Perform self-diagnosis again (use CONSULT or warn-

ing lamp). If a malfunction is detected, replace the spiral cable

with a new one.

12. Perform self-diagnosis again to check that no malfunction is

detected.

Installation Ð Front Passenger Air Bag Module

+Always work from the side of air bag module.

1. Install front passenger air bag module on steering member.

+Ensure harness is not caught between rear of air bag module

and steering member.

2. Connect in¯ator connector to body harness connector.

3. Install in¯ator connector on steering member.

SRS276

SRS166

SBF812EB

SRS457

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

RS-16