lock NISSAN PATROL 2006 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 1059 of 1226

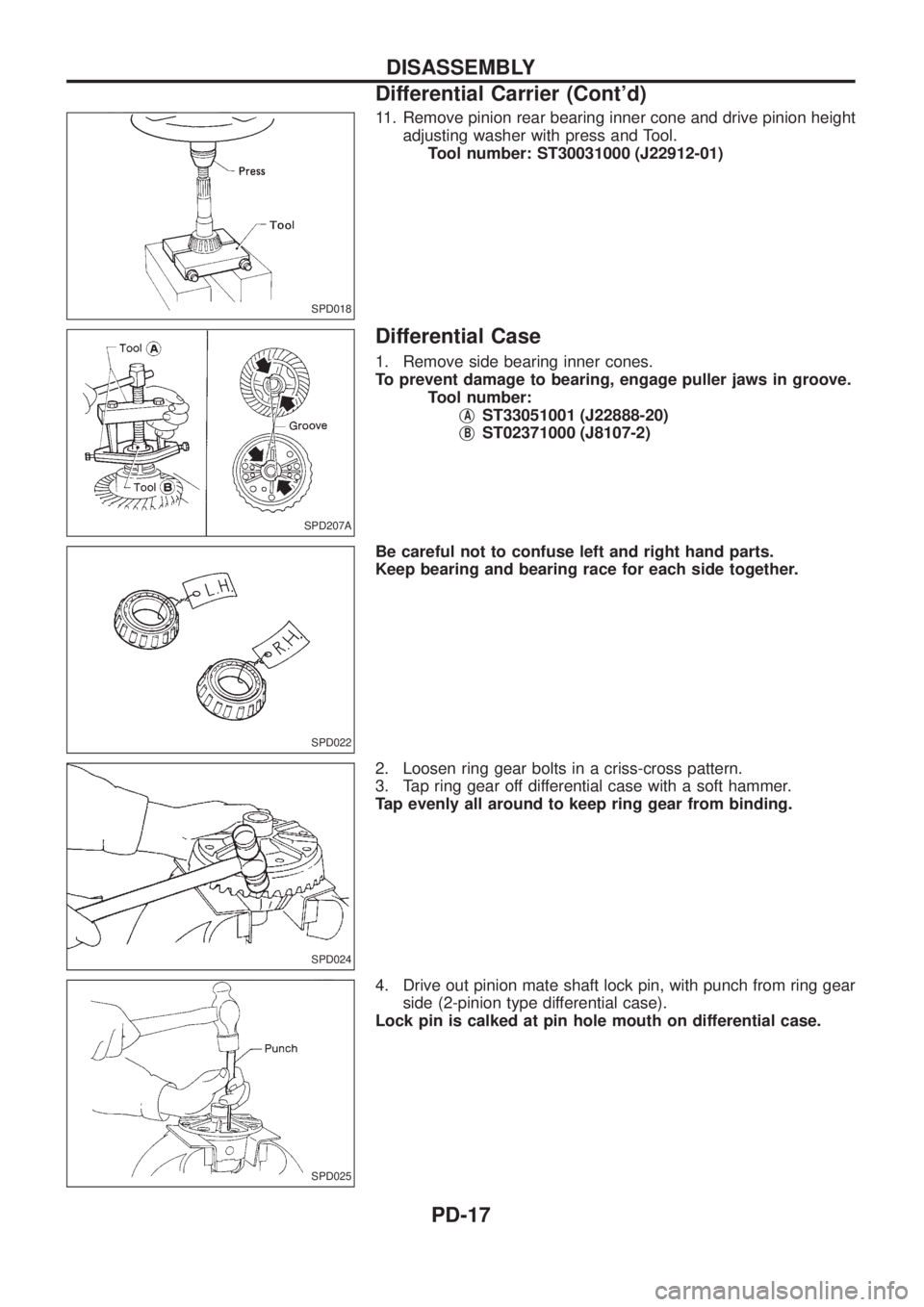

11. Remove pinion rear bearing inner cone and drive pinion heightadjusting washer with press and Tool.Toolnumber:ST30031000 (J22912-01)

Differential Case

1. Remove side bearing inner cones.

To prevent damage to bearing, engage puller jaws in groove. Tool number:j

AST33051001 (J22888-20)

j

BST02371000 (J8107-2)

Be careful not to confuse left and right hand parts.

Keep bearing and bearing race for each side together.

2. Loosen ring gear bolts in a criss-cross pattern.

3. Tap ring gear off differential case with a soft hammer.

Tap evenly all around to keep ring gear from binding.

4. Drive out pinion mate shaft lock pin, with punch from ring gear side (2-pinion type differential case).

Lock pin is calked at pin hole mouth on differential case.

SPD018

SPD207A

SPD022

SPD024

SPD025

DISASSEMBLY

Differential Carrier (Cont'd)

PD-17

Page 1061 of 1226

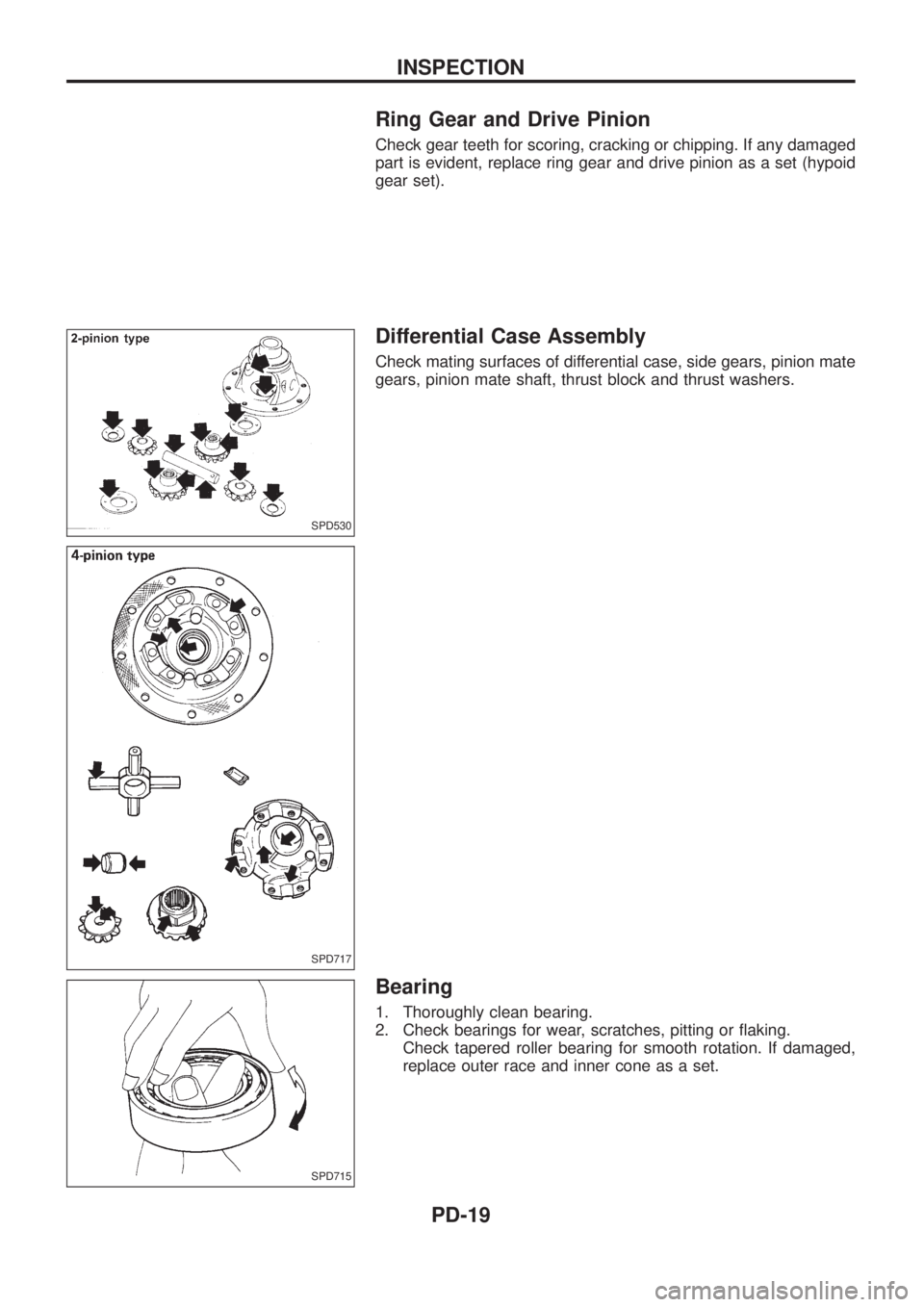

Ring Gear and Drive Pinion

Check gear teeth for scoring, cracking or chipping. If any damaged

part is evident, replace ring gear and drive pinion as a set (hypoid

gear set).

Differential Case Assembly

Check mating surfaces of differential case, side gears, pinion mate

gears, pinion mate shaft, thrust block and thrust washers.

Bearing

1. Thoroughly clean bearing.

2. Check bearings for wear, scratches, pitting or ¯aking.

Check tapered roller bearing for smooth rotation. If damaged,

replace outer race and inner cone as a set.

SPD530

SPD717

SPD715

INSPECTION

PD-19

Page 1063 of 1226

Disassembly

1. Remove side bearing inner cone with Tool.

2. Loosen ring gear bolts in a criss-cross pattern.

3. Tap ring gear off gear case with a soft hammer.

Tap evenly all around to keep ring gear from binding.

4. Loosen screws on differential cases A and B using a press.

5. Separate differential cases A and B. Draw out component parts

(discs and plates, etc.).

Put marks on gears, discs and plates so that they can be rein-

stalled in their original positions from which they were

removed.

Inspection

CONTACT SURFACES

1. Clean the disassembled parts in suitable solvent and blow dry

with compressed air.

2. If following surfaces are found with burrs or scratches, smooth

with oil stone.

V1Differential case A

V2Differential case B

V3Pressure ring

V4Thrust washer

V5Pinion mate shaft

V6Thrust block

V7Pinion mate gear

V8Side gear

SPD476

SPD507

SPD503

LIMITED SLIP DIFFERENTIAL

PD-21

Page 1067 of 1226

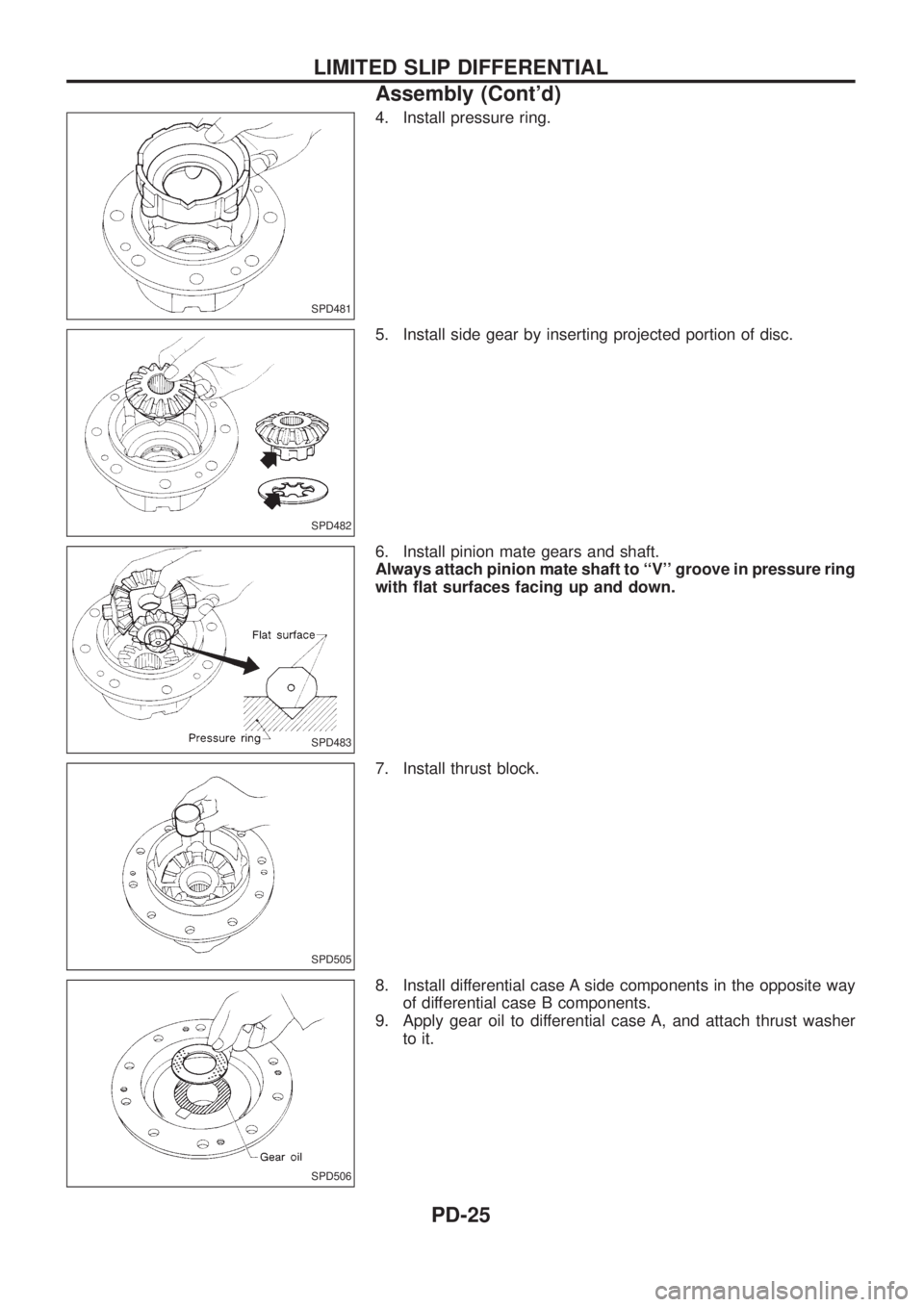

4. Install pressure ring.

5. Install side gear by inserting projected portion of disc.

6. Install pinion mate gears and shaft.

Always attach pinion mate shaft to ``V'' groove in pressure ring

with ¯at surfaces facing up and down.

7. Install thrust block.

8. Install differential case A side components in the opposite way

of differential case B components.

9. Apply gear oil to differential case A, and attach thrust washer

to it.

SPD481

SPD482

SPD483

SPD505

SPD506

LIMITED SLIP DIFFERENTIAL

Assembly (Cont'd)

PD-25

Page 1068 of 1226

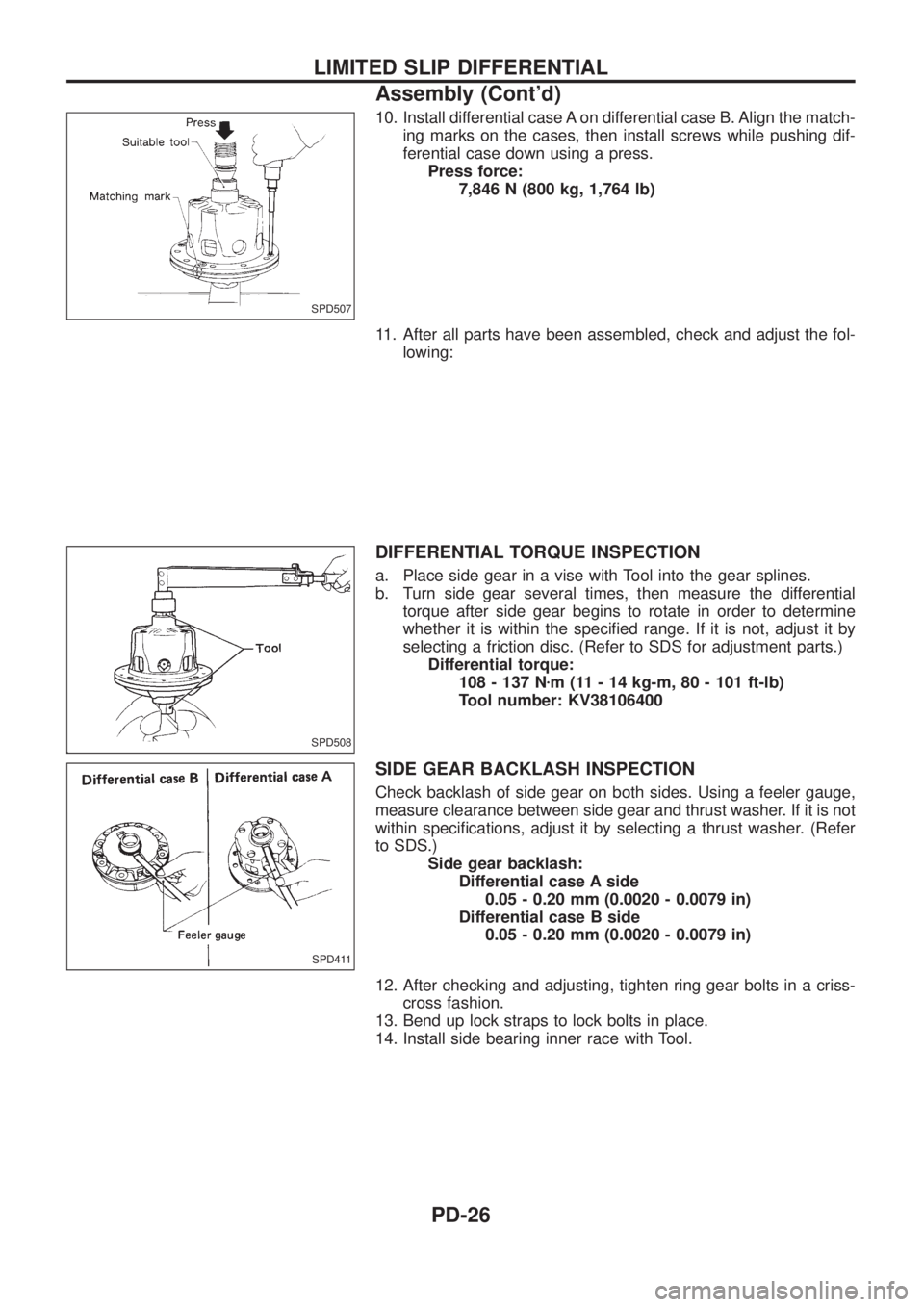

10. Install differential case A on differential case B. Align the match-

ing marks on the cases, then install screws while pushing dif-

ferential case down using a press.

Press force:

7,846 N (800 kg, 1,764 lb)

11. After all parts have been assembled, check and adjust the fol-

lowing:

DIFFERENTIAL TORQUE INSPECTION

a. Place side gear in a vise with Tool into the gear splines.

b. Turn side gear several times, then measure the differential

torque after side gear begins to rotate in order to determine

whether it is within the speci®ed range. If it is not, adjust it by

selecting a friction disc. (Refer to SDS for adjustment parts.)

Differential torque:

108 - 137 Nzm (11 - 14 kg-m, 80 - 101 ft-lb)

Tool number: KV38106400

SIDE GEAR BACKLASH INSPECTION

Check backlash of side gear on both sides. Using a feeler gauge,

measure clearance between side gear and thrust washer. If it is not

within speci®cations, adjust it by selecting a thrust washer. (Refer

to SDS.)

Side gear backlash:

Differential case A side

0.05 - 0.20 mm (0.0020 - 0.0079 in)

Differential case B side

0.05 - 0.20 mm (0.0020 - 0.0079 in)

12. After checking and adjusting, tighten ring gear bolts in a criss-

cross fashion.

13. Bend up lock straps to lock bolts in place.

14. Install side bearing inner race with Tool.

SPD507

SPD508

SPD411

LIMITED SLIP DIFFERENTIAL

Assembly (Cont'd)

PD-26

Page 1073 of 1226

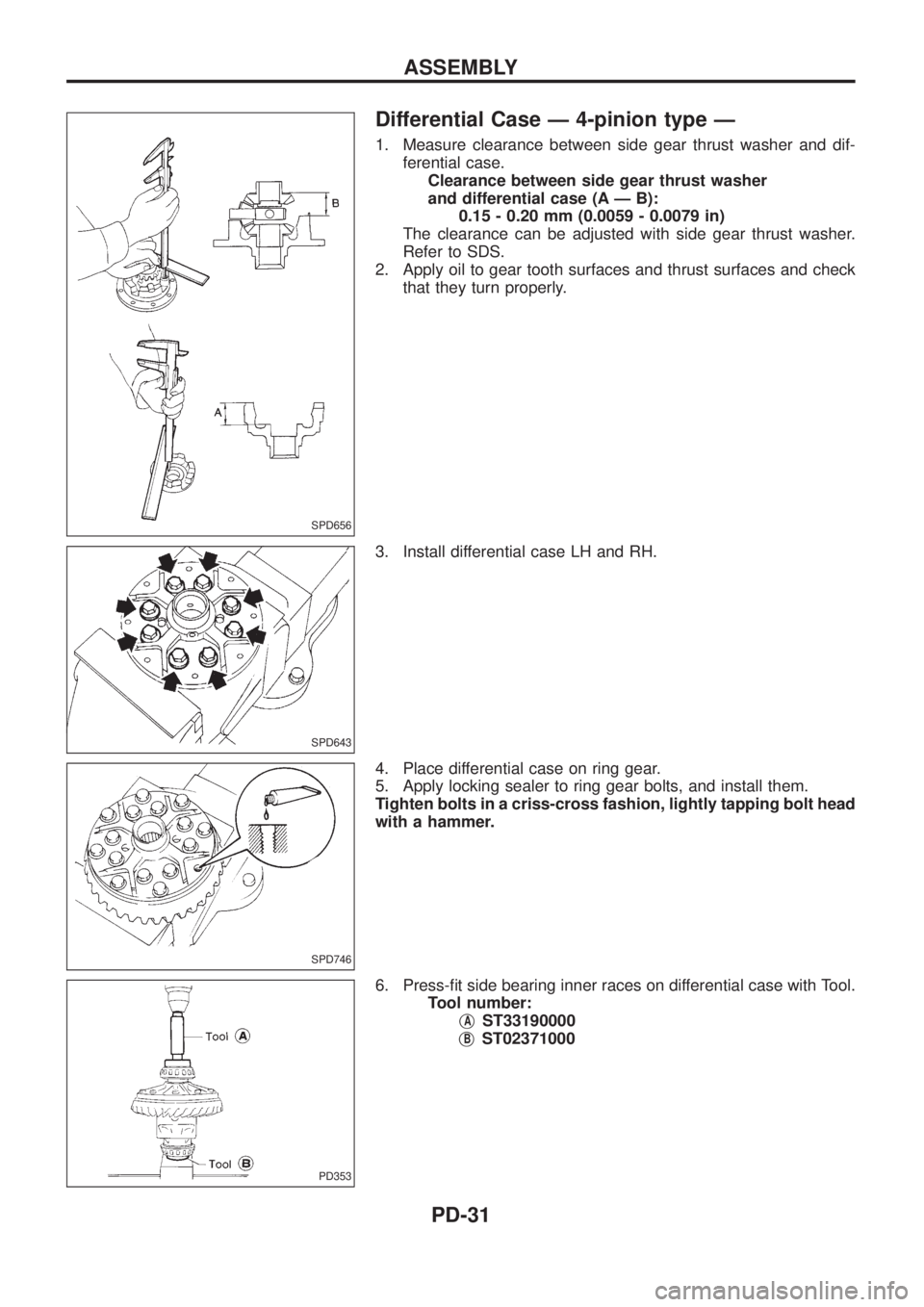

Differential Case Ð 4-pinion type Ð

1. Measure clearance between side gear thrust washer and dif-

ferential case.

Clearance between side gear thrust washer

and differential case (A Ð B):

0.15 - 0.20 mm (0.0059 - 0.0079 in)

The clearance can be adjusted with side gear thrust washer.

Refer to SDS.

2. Apply oil to gear tooth surfaces and thrust surfaces and check

that they turn properly.

3. Install differential case LH and RH.

4. Place differential case on ring gear.

5. Apply locking sealer to ring gear bolts, and install them.

Tighten bolts in a criss-cross fashion, lightly tapping bolt head

with a hammer.

6. Press-®t side bearing inner races on differential case with Tool.

Tool number:

j

AST33190000

j

BST02371000

SPD656

SPD643

SPD746

PD353

ASSEMBLY

PD-31

Page 1074 of 1226

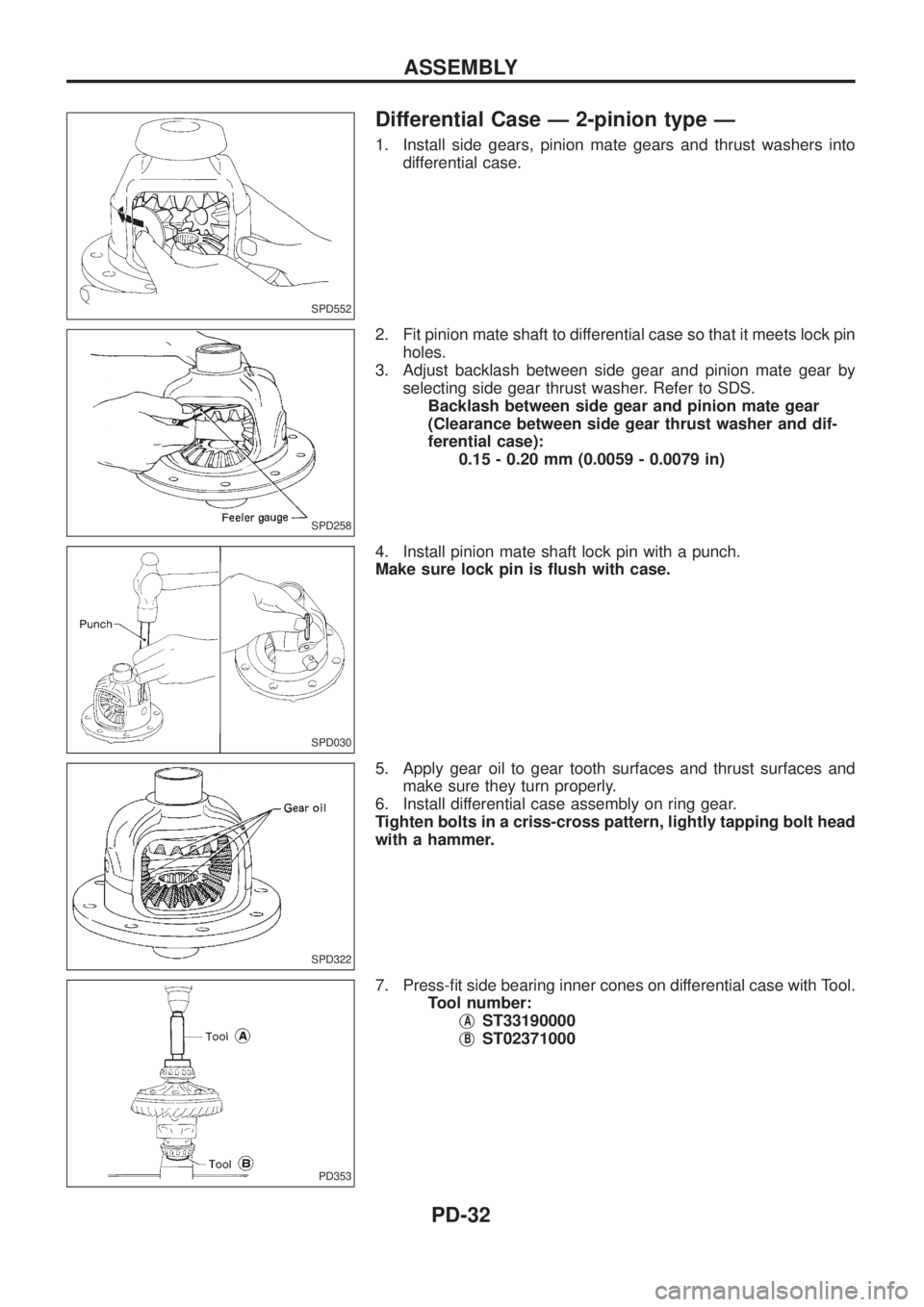

Differential Case Ð 2-pinion type Ð

1. Install side gears, pinion mate gears and thrust washers into

differential case.

2. Fit pinion mate shaft to differential case so that it meets lock pin

holes.

3. Adjust backlash between side gear and pinion mate gear by

selecting side gear thrust washer. Refer to SDS.

Backlash between side gear and pinion mate gear

(Clearance between side gear thrust washer and dif-

ferential case):

0.15 - 0.20 mm (0.0059 - 0.0079 in)

4. Install pinion mate shaft lock pin with a punch.

Make sure lock pin is ¯ush with case.

5. Apply gear oil to gear tooth surfaces and thrust surfaces and

make sure they turn properly.

6. Install differential case assembly on ring gear.

Tighten bolts in a criss-cross pattern, lightly tapping bolt head

with a hammer.

7. Press-®t side bearing inner cones on differential case with Tool.

Tool number:

j

AST33190000

j

BST02371000

SPD552

SPD258

SPD030

SPD322

PD353

ASSEMBLY

PD-32

Page 1078 of 1226

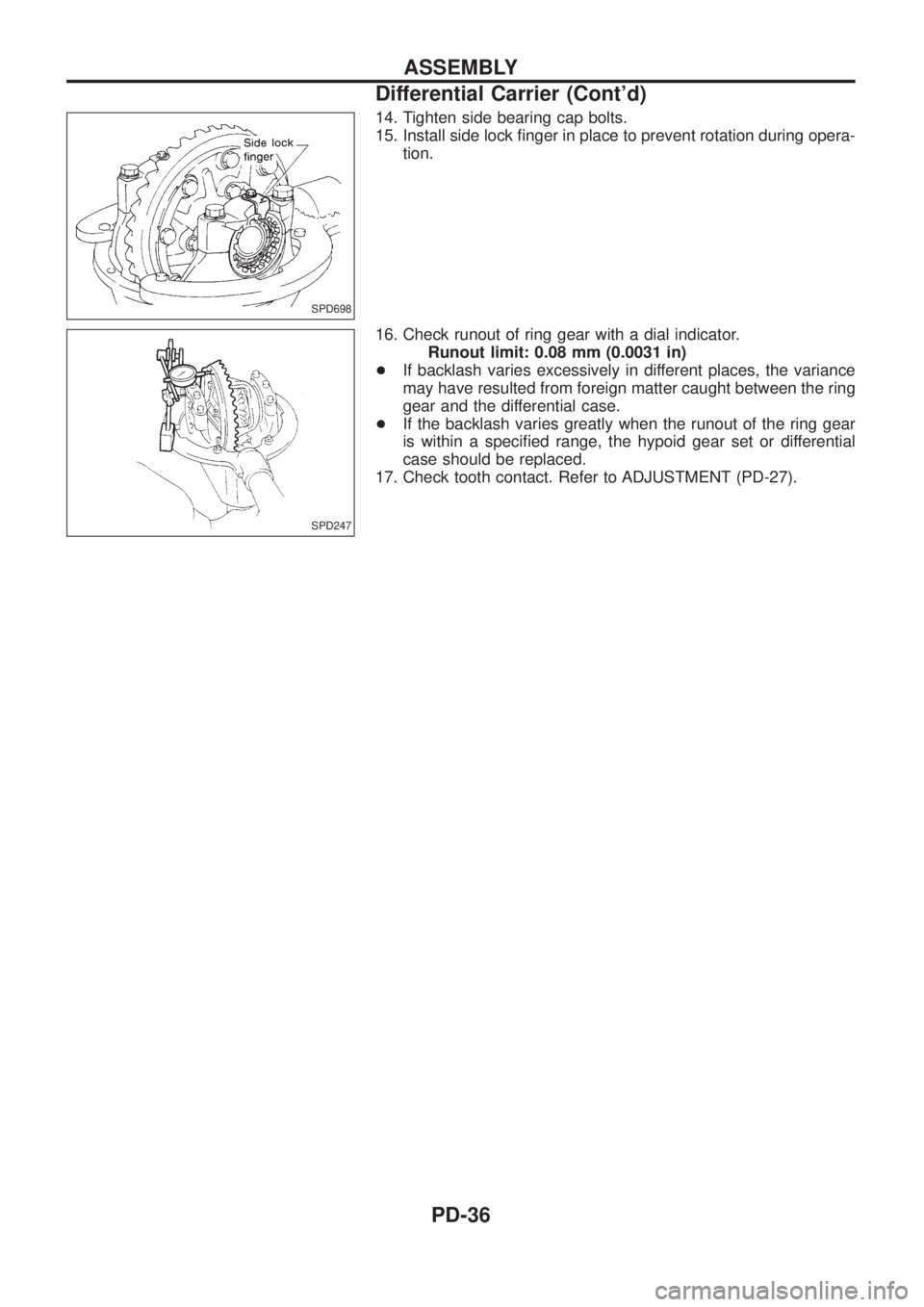

14. Tighten side bearing cap bolts.

15. Install side lock ®nger in place to prevent rotation during opera-

tion.

16. Check runout of ring gear with a dial indicator.

Runout limit: 0.08 mm (0.0031 in)

+If backlash varies excessively in different places, the variance

may have resulted from foreign matter caught between the ring

gear and the differential case.

+If the backlash varies greatly when the runout of the ring gear

is within a speci®ed range, the hypoid gear set or differential

case should be replaced.

17. Check tooth contact. Refer to ADJUSTMENT (PD-27).

SPD698

SPD247

ASSEMBLY

Differential Carrier (Cont'd)

PD-36

Page 1079 of 1226

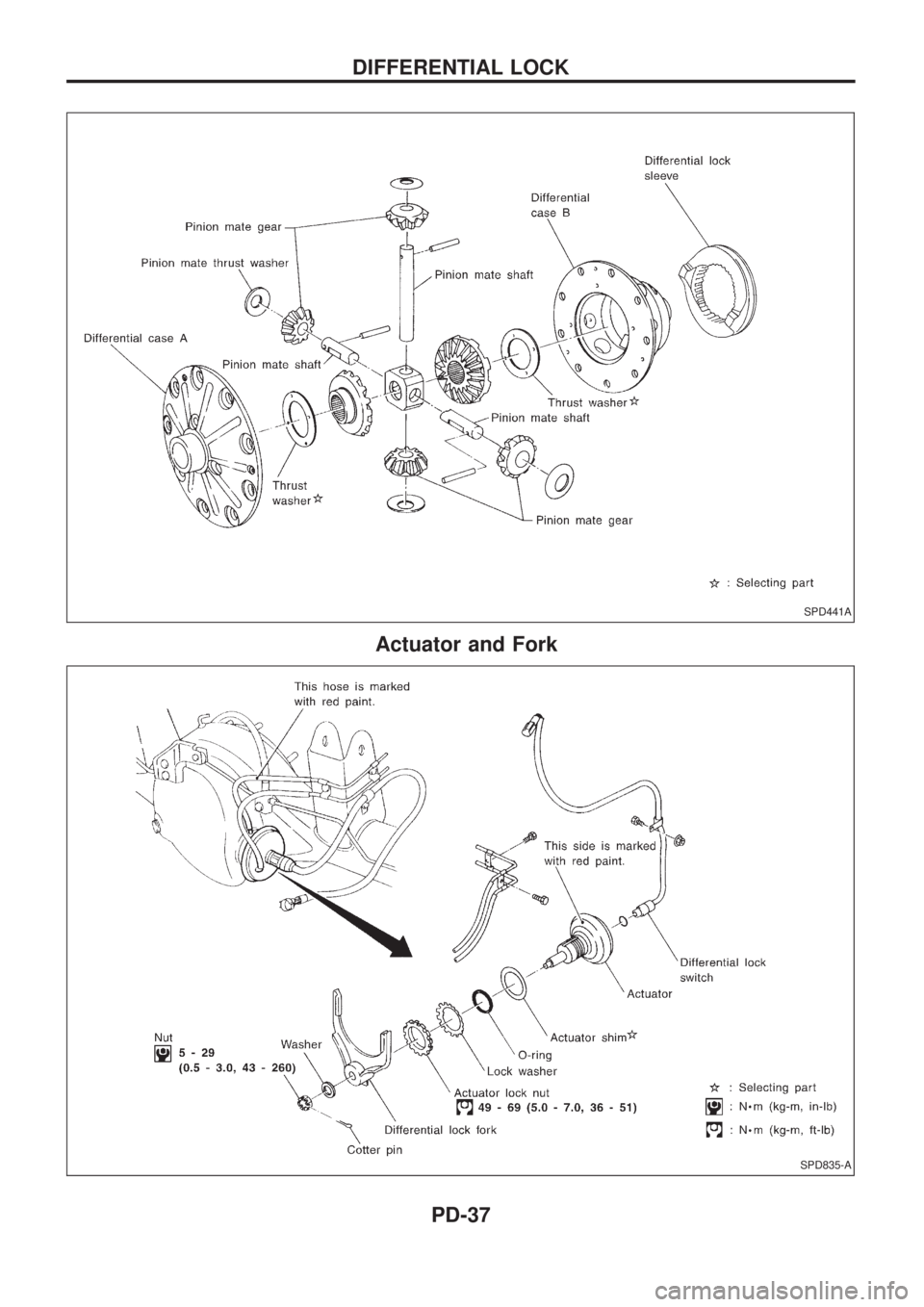

Actuator and Fork

SPD441A

SPD835-A

DIFFERENTIAL LOCK

PD-37

Page 1080 of 1226

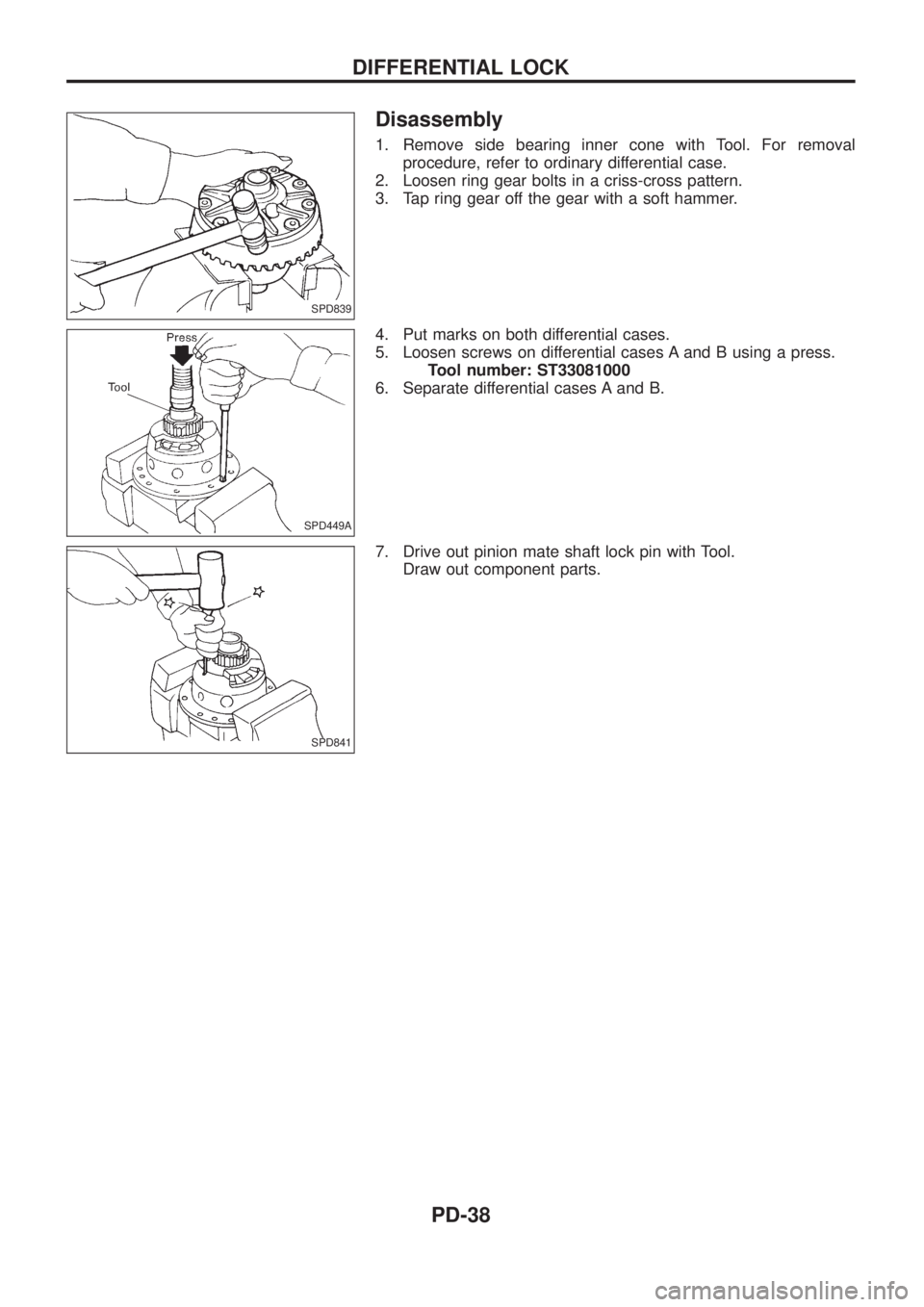

Disassembly

1. Remove side bearing inner cone with Tool. For removal

procedure, refer to ordinary differential case.

2. Loosen ring gear bolts in a criss-cross pattern.

3. Tap ring gear off the gear with a soft hammer.

4. Put marks on both differential cases.

5. Loosen screws on differential cases A and B using a press.

Tool number: ST33081000

6. Separate differential cases A and B.

7. Drive out pinion mate shaft lock pin with Tool.

Draw out component parts.

SPD839

SPD449A

SPD841

DIFFERENTIAL LOCK

PD-38