engine NISSAN PATROL 2006 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 969 of 1226

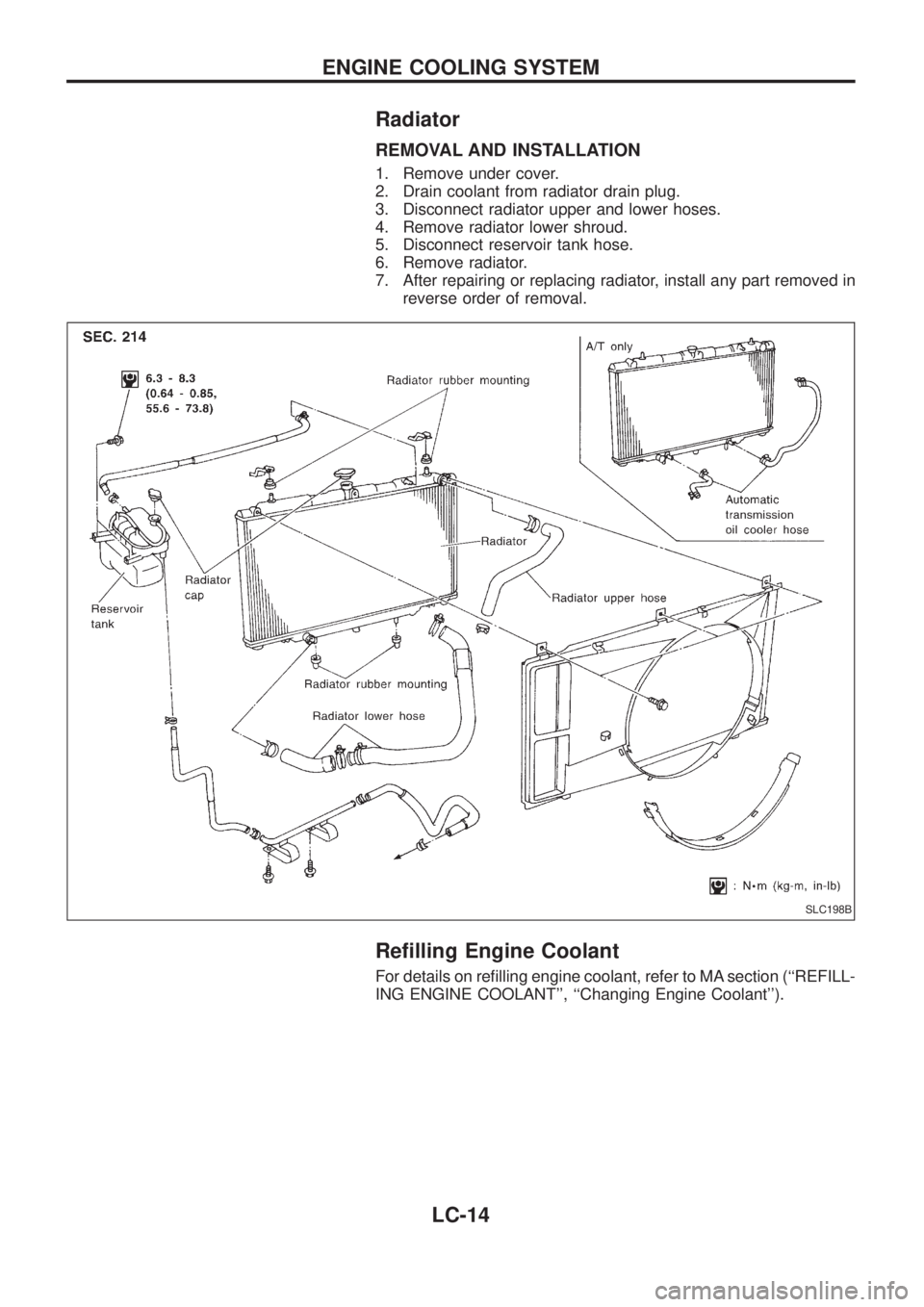

Radiator

REMOVAL AND INSTALLATION

1. Remove under cover.

2. Drain coolant from radiator drain plug.

3. Disconnect radiator upper and lower hoses.

4. Remove radiator lower shroud.

5. Disconnect reservoir tank hose.

6. Remove radiator.

7. After repairing or replacing radiator, install any part removed in

reverse order of removal.

Re®lling Engine Coolant

For details on re®lling engine coolant, refer to MA section (``REFILL-

ING ENGINE COOLANT'', ``Changing Engine Coolant'').

SLC198B

ENGINE COOLING SYSTEM

LC-14

Page 970 of 1226

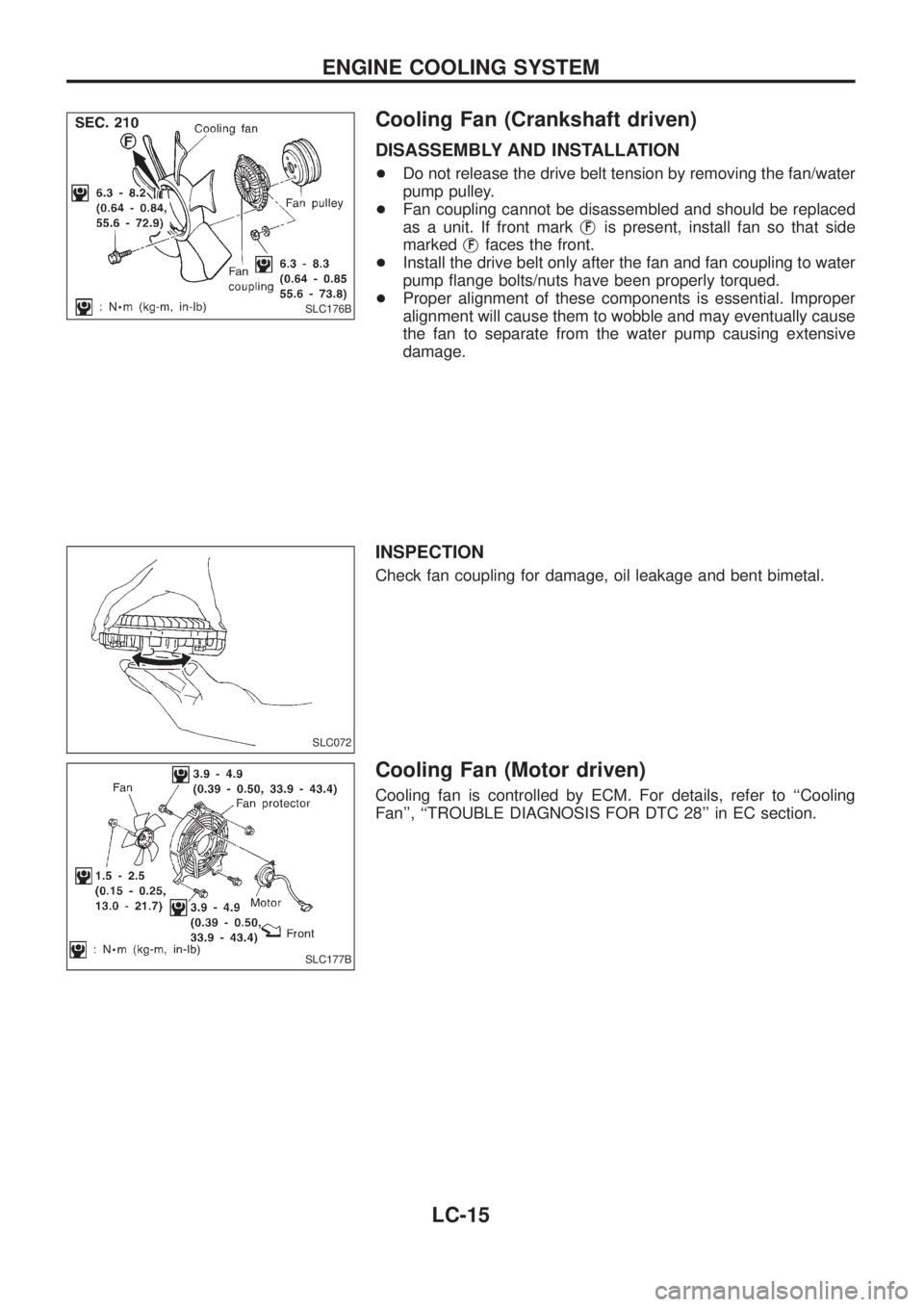

Cooling Fan (Crankshaft driven)

DISASSEMBLY AND INSTALLATION

+Do not release the drive belt tension by removing the fan/water

pump pulley.

+Fan coupling cannot be disassembled and should be replaced

as a unit. If front markj

Fis present, install fan so that side

markedj

Ffaces the front.

+Install the drive belt only after the fan and fan coupling to water

pump ¯ange bolts/nuts have been properly torqued.

+Proper alignment of these components is essential. Improper

alignment will cause them to wobble and may eventually cause

the fan to separate from the water pump causing extensive

damage.

INSPECTION

Check fan coupling for damage, oil leakage and bent bimetal.

Cooling Fan (Motor driven)

Cooling fan is controlled by ECM. For details, refer to ``Cooling

Fan'', ``TROUBLE DIAGNOSIS FOR DTC 28'' in EC section.

SLC176B

SLC072

SLC177B

ENGINE COOLING SYSTEM

LC-15

Page 971 of 1226

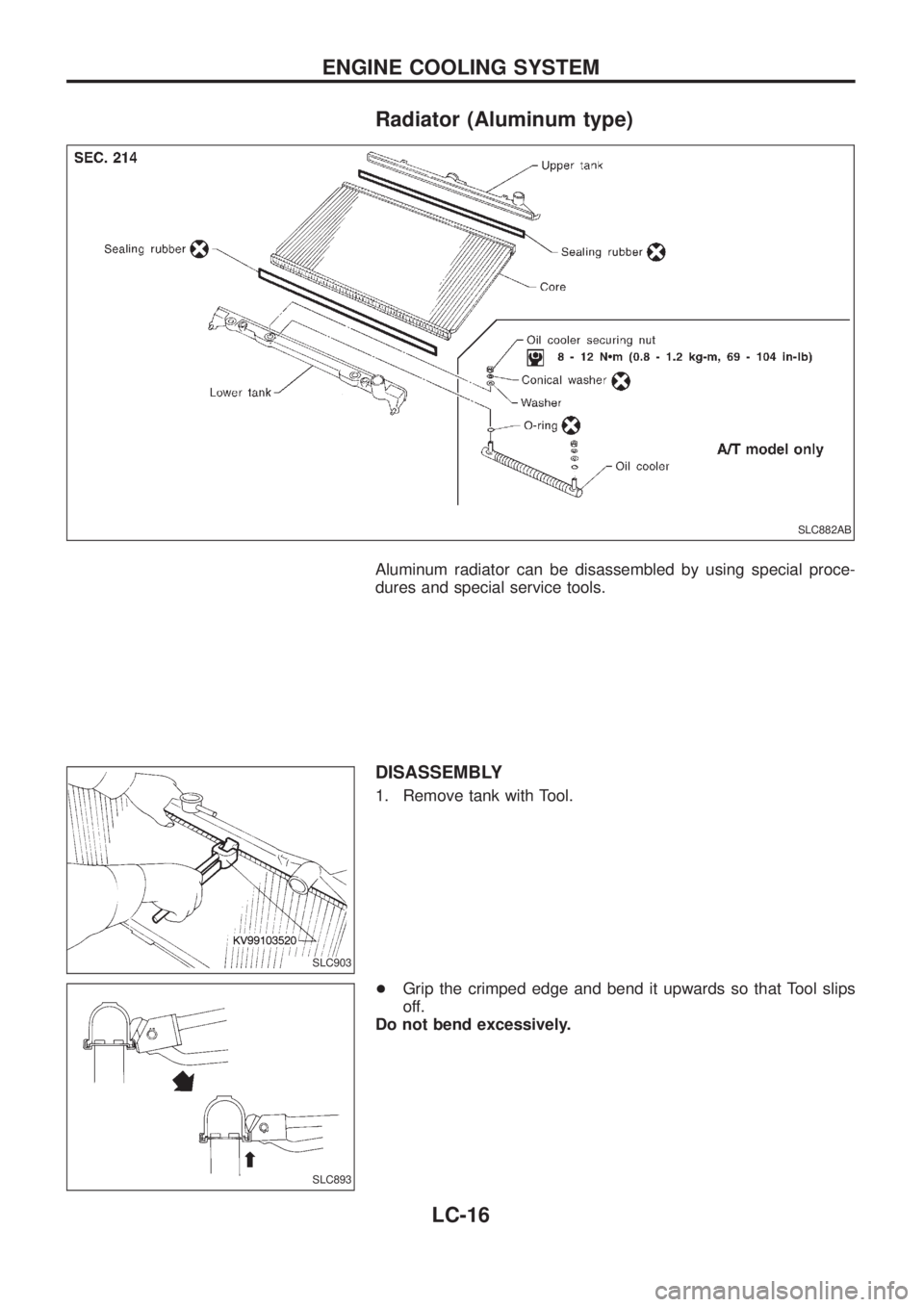

Radiator (Aluminum type)

Aluminum radiator can be disassembled by using special proce-

dures and special service tools.

DISASSEMBLY

1. Remove tank with Tool.

+Grip the crimped edge and bend it upwards so that Tool slips

off.

Do not bend excessively.

SLC882AB

SLC903

SLC893

ENGINE COOLING SYSTEM

LC-16

Page 972 of 1226

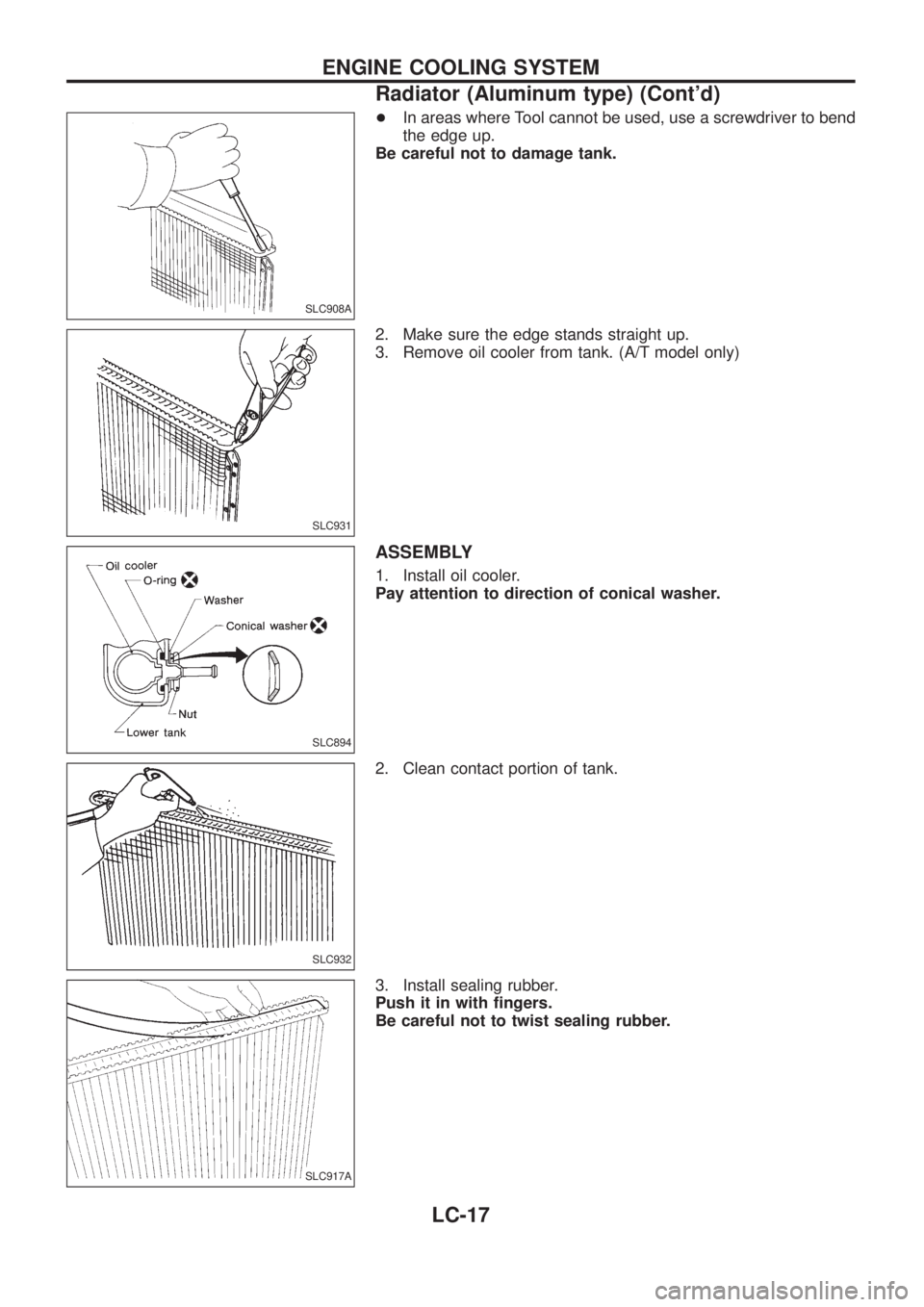

+In areas where Tool cannot be used, use a screwdriver to bend

the edge up.

Be careful not to damage tank.

2. Make sure the edge stands straight up.

3. Remove oil cooler from tank. (A/T model only)

ASSEMBLY

1. Install oil cooler.

Pay attention to direction of conical washer.

2. Clean contact portion of tank.

3. Install sealing rubber.

Push it in with ®ngers.

Be careful not to twist sealing rubber.

SLC908A

SLC931

SLC894

SLC932

SLC917A

ENGINE COOLING SYSTEM

Radiator (Aluminum type) (Cont'd)

LC-17

Page 973 of 1226

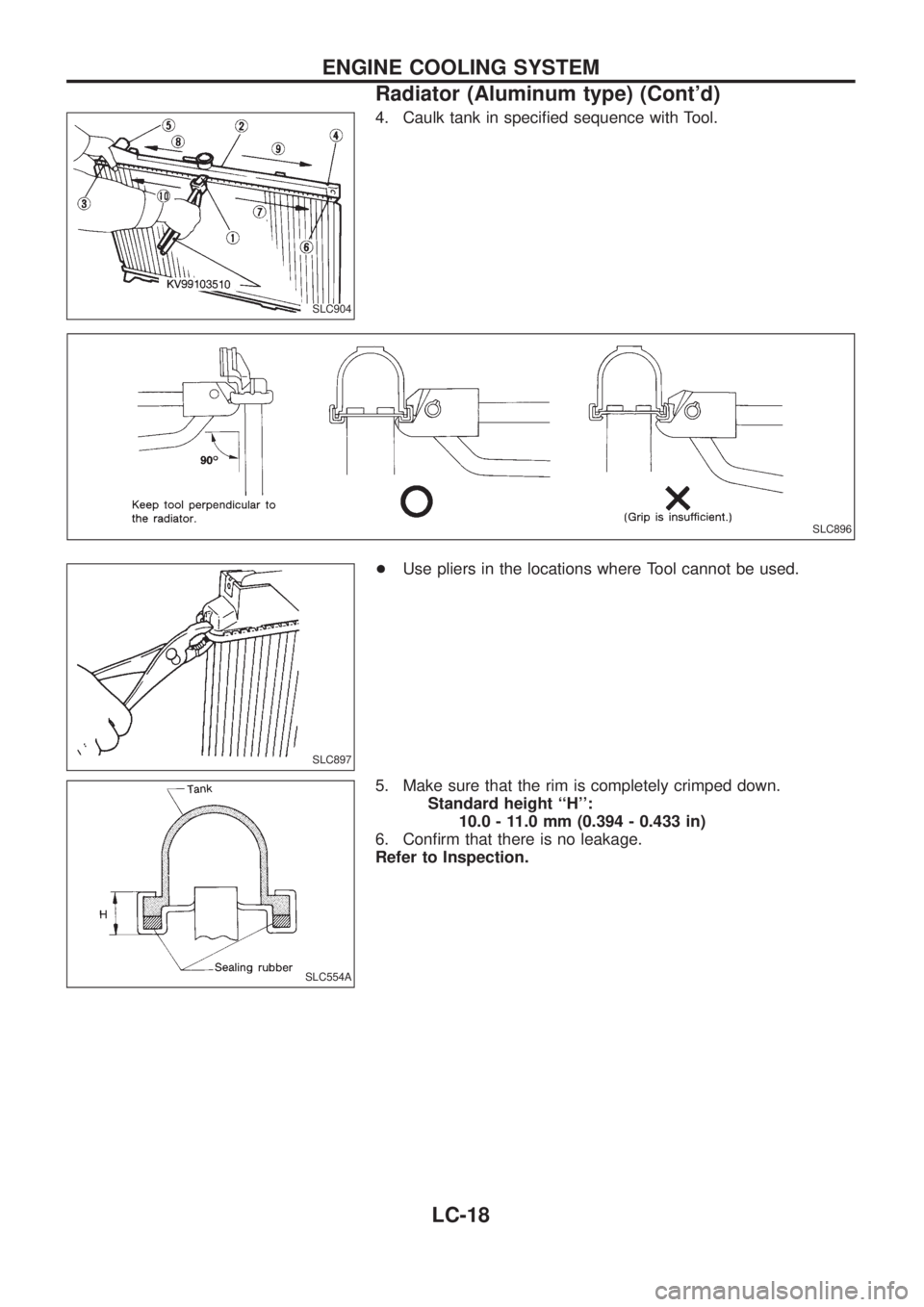

4. Caulk tank in speci®ed sequence with Tool.

+Use pliers in the locations where Tool cannot be used.

5. Make sure that the rim is completely crimped down.

Standard height ``H'':

10.0 - 11.0 mm (0.394 - 0.433 in)

6. Con®rm that there is no leakage.

Refer to Inspection.

SLC904

SLC896

SLC897

SLC554A

ENGINE COOLING SYSTEM

Radiator (Aluminum type) (Cont'd)

LC-18

Page 974 of 1226

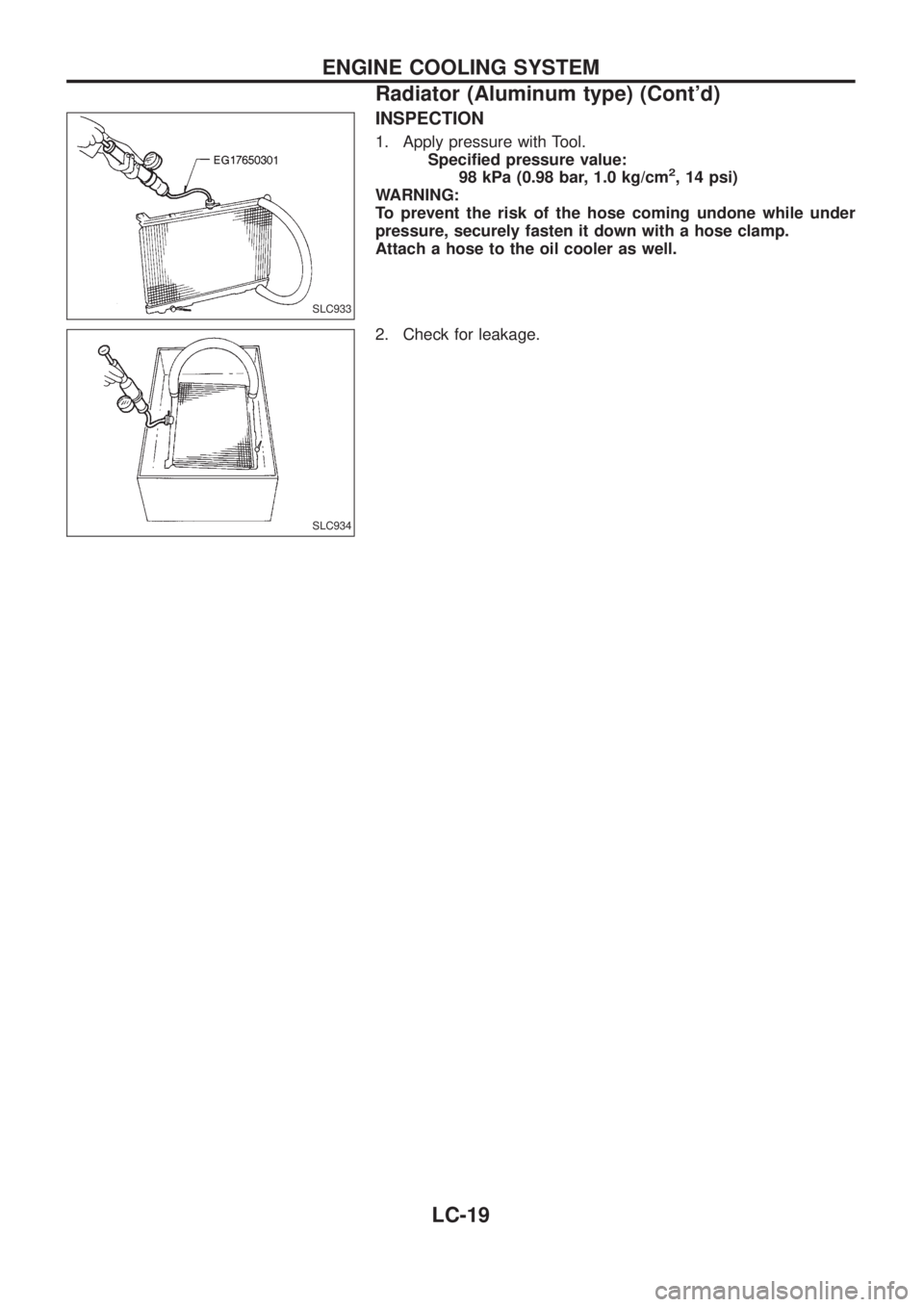

INSPECTION

1. Apply pressure with Tool.

Speci®ed pressure value:

98 kPa (0.98 bar, 1.0 kg/cm

2, 14 psi)

WARNING:

To prevent the risk of the hose coming undone while under

pressure, securely fasten it down with a hose clamp.

Attach a hose to the oil cooler as well.

2. Check for leakage.

SLC933

SLC934

ENGINE COOLING SYSTEM

Radiator (Aluminum type) (Cont'd)

LC-19

Page 975 of 1226

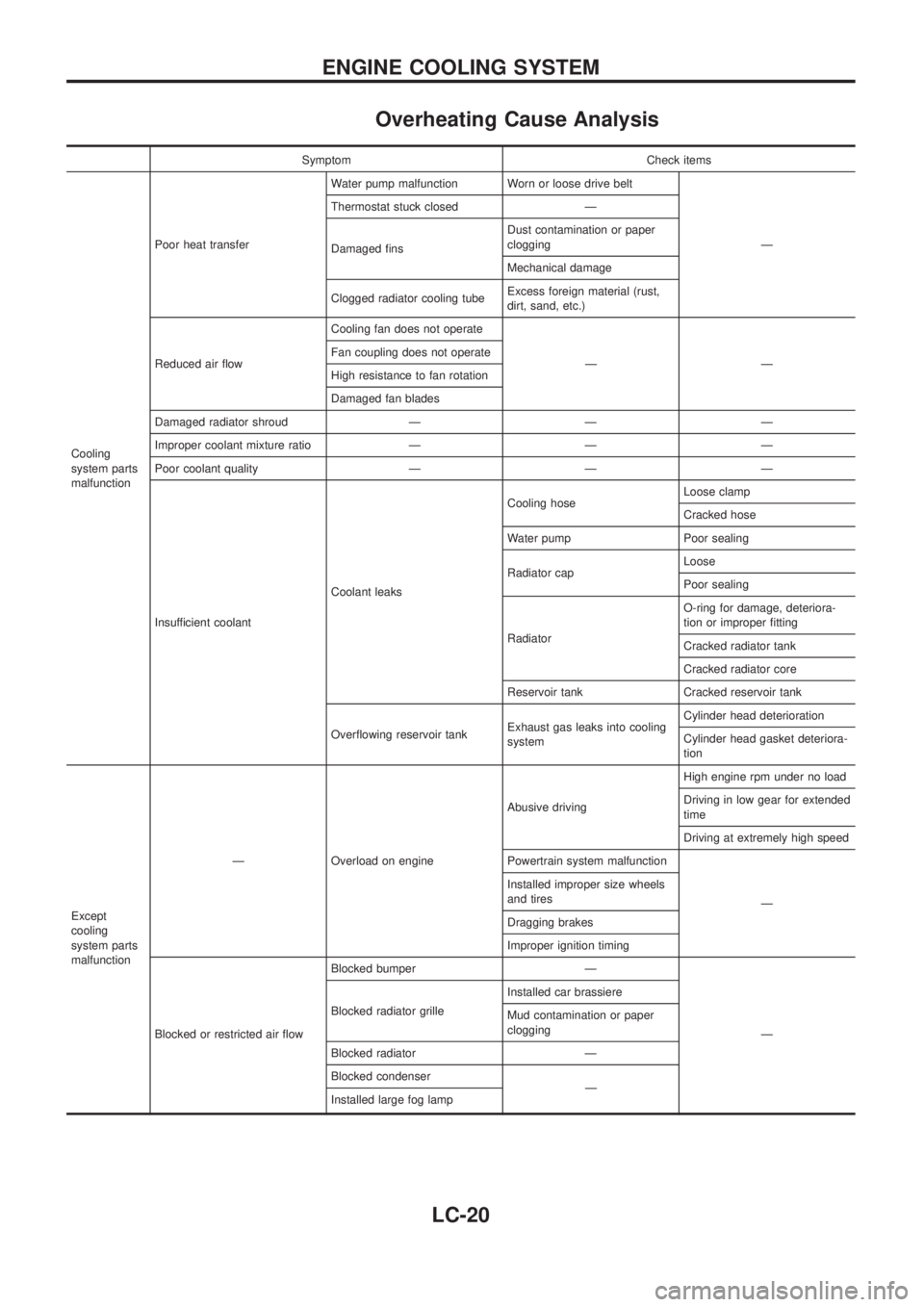

Overheating Cause Analysis

Symptom Check items

Cooling

system parts

malfunctionPoor heat transferWater pump malfunction Worn or loose drive belt

Ð Thermostat stuck closed Ð

Damaged ®nsDust contamination or paper

clogging

Mechanical damage

Clogged radiator cooling tubeExcess foreign material (rust,

dirt, sand, etc.)

Reduced air ¯owCooling fan does not operate

ÐÐ Fan coupling does not operate

High resistance to fan rotation

Damaged fan blades

Damaged radiator shroud Ð Ð Ð

Improper coolant mixture ratio Ð Ð Ð

Poor coolant quality Ð Ð Ð

Insufficient coolantCoolant leaksCooling hoseLoose clamp

Cracked hose

Water pump Poor sealing

Radiator capLoose

Poor sealing

RadiatorO-ring for damage, deteriora-

tion or improper ®tting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Over¯owing reservoir tankExhaust gas leaks into cooling

systemCylinder head deterioration

Cylinder head gasket deteriora-

tion

Except

cooling

system parts

malfunctionÐ Overload on engineAbusive drivingHigh engine rpm under no load

Driving in low gear for extended

time

Driving at extremely high speed

Powertrain system malfunction

Ð Installed improper size wheels

and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air ¯owBlocked bumper Ð

Ð Blocked radiator grilleInstalled car brassiere

Mud contamination or paper

clogging

Blocked radiator Ð

Blocked condenser

Ð

Installed large fog lamp

ENGINE COOLING SYSTEM

LC-20

Page 976 of 1226

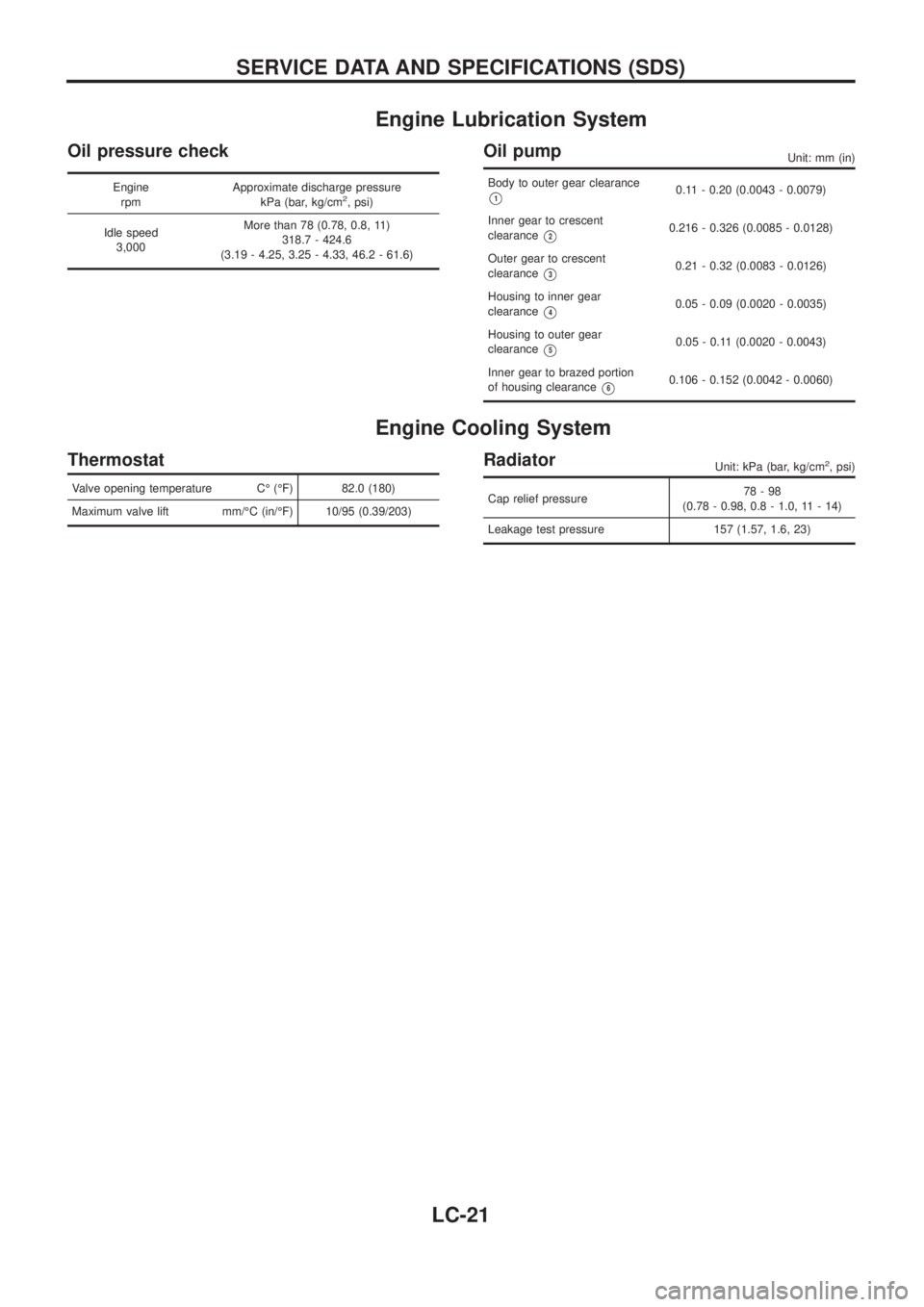

Engine Lubrication System

Oil pressure check

Engine

rpmApproximate discharge pressure

kPa (bar, kg/cm2, psi)

Idle speed

3,000More than 78 (0.78, 0.8, 11)

318.7 - 424.6

(3.19 - 4.25, 3.25 - 4.33, 46.2 - 61.6)

Oil pumpUnit: mm (in)

Body to outer gear clearance

V10.11 - 0.20 (0.0043 - 0.0079)

Inner gear to crescent

clearance

V20.216 - 0.326 (0.0085 - 0.0128)

Outer gear to crescent

clearance

V30.21 - 0.32 (0.0083 - 0.0126)

Housing to inner gear

clearance

V40.05 - 0.09 (0.0020 - 0.0035)

Housing to outer gear

clearance

V50.05 - 0.11 (0.0020 - 0.0043)

Inner gear to brazed portion

of housing clearance

V60.106 - 0.152 (0.0042 - 0.0060)

Engine Cooling System

Thermostat

Valve opening temperature CÉ (ÉF) 82.0 (180)

Maximum valve lift mm/ÉC (in/ÉF) 10/95 (0.39/203)

RadiatorUnit: kPa (bar, kg/cm2, psi)

Cap relief pressure78-98

(0.78 - 0.98, 0.8 - 1.0, 11 - 14)

Leakage test pressure 157 (1.57, 1.6, 23)

SERVICE DATA AND SPECIFICATIONS (SDS)

LC-21

Page 977 of 1226

MAINTENANCE

SECTION

MA

CONTENTS

PRECAUTIONS AND PREPARATION............................1

Supplemental Restraint System (SRS) ``AIR

BAG'' and ``SEAT BELT PRE-TENSIONER''...............1

Special Service Tools ..................................................1

PRE-DELIVERY INSPECTION ITEMS............................2

GENERAL MAINTENANCE............................................3

PERIODIC MAINTENANCE............................................4

Engine Oil & Minor Service .........................................4

Engine and Emission Control Service .........................5

Chassis and Body Services.........................................6

Maintenance Under Severe Driving Conditions ..........8

RECOMMENDED FLUIDS AND LUBRICANTS.............9

Fluids and Lubricants ..................................................9

SAE Viscosity Number ..............................................10

Anti-freeze Coolant Mixture Ratio ............................. 11

ENGINE MAINTENANCE..............................................12

Checking Tightening Torque ......................................12

Checking Drive Belt ...................................................12

Changing Engine Oil..................................................13

Changing Engine Oil Filter ........................................14

Changing Engine Coolant..........................................14

Checking Cooling System .........................................16

Checking and Replacing Fuel Filter and Draining

Water .........................................................................16

Checking Fuel Lines ..................................................17

Cleaning and Replacing Air Cleaner Filter ................18

Checking Injection Nozzle .........................................18

Checking Idle Speed .................................................19

Timing Belt Replacement...........................................19

CHASSIS AND BODY MAINTENANCE.......................20

Checking Exhaust System.........................................20

Checking Clutch Fluid Level and Leaks ....................20

Checking Clutch System ...........................................20Checking M/T Oil Level and Leaks ...........................20

Changing M/T Oil.......................................................20

Checking Water Entry ................................................21

Checking Transfer Fluid Level ...................................21

Changing Transfer Fluid ............................................21

Checking Propeller Shaft ...........................................21

Greasing Nipples of Propeller Shafts ........................21

Checking Differential Gear Oil ...................................22

Changing Differential Gear Oil ..................................22

Checking Front Wheel Bearing Grease ....................22

Repacking Front Wheel Bearing and Axle Joint

Grease .......................................................................23

Checking Free-running Hub Grease .........................23

Checking Water Entry in Knuckle Flange..................23

Checking Brake Fluid Level and Leaks.....................23

Checking Brake System ............................................24

Changing Brake Fluid ................................................24

Checking Brake Booster, Vacuum Hoses,

Connections and Check Valve ..................................24

Checking Disc Brake .................................................24

Balancing Wheels ......................................................25

Tire Rotation ..............................................................25

Checking Power Steering Fluid and Lines ................26

Checking Steering Damper .......................................26

Checking Steering Gear Box and Linkage ................26

Lubricating Locks, Hinges and Hood Latches...........27

Checking Seat Belts, Buckles, Retractors,

Anchors and Adjusters...............................................27

Checking Body Corrosion ..........................................28

SERVICE DATA AND SPECIFICATIONS (SDS)..........29

Engine Maintenance ..................................................29

Chassis and Body Maintenance ................................29

MA

Page 979 of 1226

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for speci®cations.

UNDER HOOD Ð engine off

hRadiator coolant level and coolant hose connec-

tions for leaks

hBattery ¯uid level, speci®c gravity and condi-

tions of battery terminals

hDrive belts tension

hFuel ®lter for water or dusts, and fuel lines and

connections for leaks

hEngine oil level and oil leaks

hClutch and brake reservoir ¯uid level and ¯uid

lines for leaks

hWindshield and rear window washer and head-

lamp cleaner reservoir ¯uid level

hPower steering reservoir ¯uid level and hose

connections for leaks

ON INSIDE AND OUTSIDE

hXRemove front spring/strut spacer (If applicable)

hOperation of all instruments, gauges, lights and

accessories

hOperation of horn(s), wiper and washer

hSteering lock for operation

hCheck air conditioner for gas leaks

hFront and rear seats, and seat belts for opera-

tion

hAll moldings, trims and ®ttings for ®t and align-

ment

hAll windows for operation and alignment

hHood, trunk lid, door panels for ®t and alignment

hLatches, keys and locks for operation

hWeatherstrips for adhesion and ®t

hHeadlamp aiming

hTighten wheel nuts (Inc. inner nuts if applicable)

hTire pressure (Inc. spare tire)

hCheck front wheels for toe-in

hInstall clock/voltmeter/room lamp fuse (If appli-

cable)

h

XInstall deodorizing ®lter to air puri®er (If appli-

cable)

h

XRemove wiper blade protectors (If applicable)

UNDER BODY

hManual transmission/transaxle gear oil, transfer

¯uid and differential gear oil level

hBrake and fuel lines and oil/¯uid reservoirs for

leaks

hTighten bolts and nuts of steering linkage and

gear box, suspension, propeller shafts and drive

shafts

h

XTighten rear body bolts and nuts (Models with

wooden bed only)

ROAD TEST

hClutch operation

hParking brake operation

hService brake operation

hAutomatic transmission/transaxle shift timing

and kickdown

hSteering control and returnability

hEngine performance

hSqueaks and rattles

ENGINE OPERATING AND HOT

hAdjust idle mixture and speed (and ignition tim-

ing*1)

hAutomatic transmission/transaxle ¯uid level

hEngine idling and stop knob operation (Diesel

only)

FINAL INSPECTION

hInstall necessary parts (outside mirror, wheel

covers, seat belts, mat, carpet or mud ¯aps)

hInspect for interior and exterior metal and paint

damage

hCheck for spare tire, jack, tools (wheel chock),

and literature

hWash, clean interior and exterior

*1: Not required on models with a direct ignition system

h

X: Not applicable to this model.

PRE-DELIVERY INSPECTION ITEMS

MA-2