transfer NISSAN PATROL 2006 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 985 of 1226

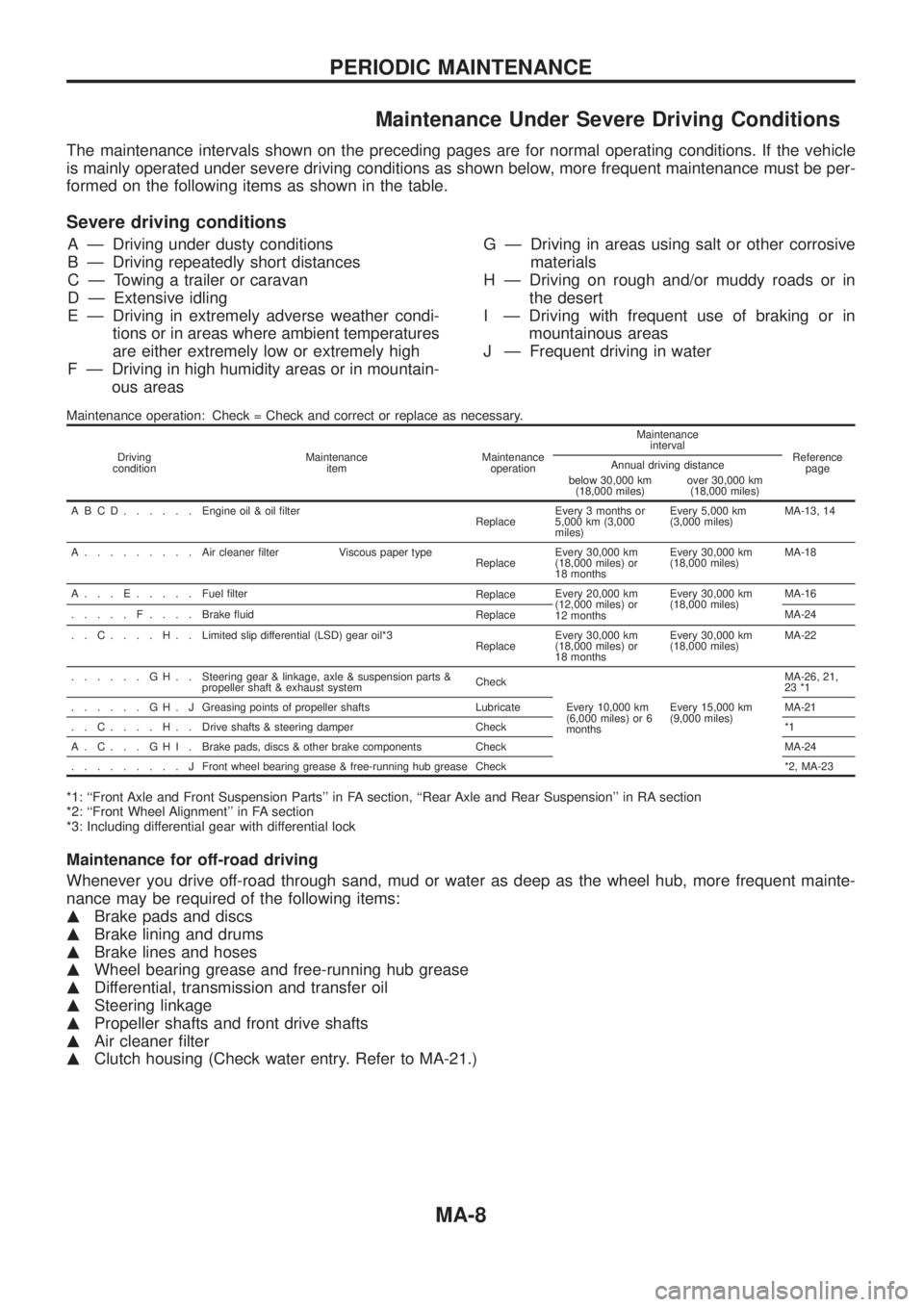

Maintenance Under Severe Driving Conditions

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle

is mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

Severe driving conditions

A Ð Driving under dusty conditions

B Ð Driving repeatedly short distances

C Ð Towing a trailer or caravan

D Ð Extensive idling

E Ð Driving in extremely adverse weather condi-

tions or in areas where ambient temperatures

are either extremely low or extremely high

F Ð Driving in high humidity areas or in mountain-

ous areasG Ð Driving in areas using salt or other corrosive

materials

H Ð Driving on rough and/or muddy roads or in

the desert

I Ð Driving with frequent use of braking or in

mountainous areas

J Ð Frequent driving in water

Maintenance operation: Check = Check and correct or replace as necessary.

Driving

conditionMaintenance

itemMaintenance

operationMaintenance

interval

Reference

page Annual driving distance

below 30,000 km

(18,000 miles)over 30,000 km

(18,000 miles)

ABCD......Engine oil & oil ®lter

ReplaceEvery 3 months or

5,000 km (3,000

miles)Every 5,000 km

(3,000 miles)MA-13, 14

A.........Aircleaner ®lter Viscous paper type

ReplaceEvery 30,000 km

(18,000 miles) or

18 monthsEvery 30,000 km

(18,000 miles)MA-18

A...E.....Fuel ®lter

ReplaceEvery 20,000 km

(12,000 miles) or

12 monthsEvery 30,000 km

(18,000 miles)MA-16

.....F....Brake ¯uid

ReplaceMA-24

..C....H..Limited slip differential (LSD) gear oil*3

ReplaceEvery 30,000 km

(18,000 miles) or

18 monthsEvery 30,000 km

(18,000 miles)MA-22

......GH..Steering gear & linkage, axle & suspension parts &

propeller shaft & exhaust systemCheck

Every 10,000 km

(6,000 miles) or 6

monthsEvery 15,000 km

(9,000 miles)MA-26, 21,

23 *1

......GH.JGreasing points of propeller shafts Lubricate MA-21

..C....H..Drive shafts & steering damper Check *1

A.C...GHI.Brake pads, discs & other brake components Check MA-24

.........JFront wheel bearing grease & free-running hub grease Check *2, MA-23

*1: ``Front Axle and Front Suspension Parts'' in FA section, ``Rear Axle and Rear Suspension'' in RA section

*2: ``Front Wheel Alignment'' in FA section

*3: Including differential gear with differential lock

Maintenance for off-road driving

Whenever you drive off-road through sand, mud or water as deep as the wheel hub, more frequent mainte-

nance may be required of the following items:

mBrake pads and discs

mBrake lining and drums

mBrake lines and hoses

mWheel bearing grease and free-running hub grease

mDifferential, transmission and transfer oil

mSteering linkage

mPropeller shafts and front drive shafts

mAir cleaner ®lter

mClutch housing (Check water entry. Refer to MA-21.)

PERIODIC MAINTENANCE

MA-8

Page 986 of 1226

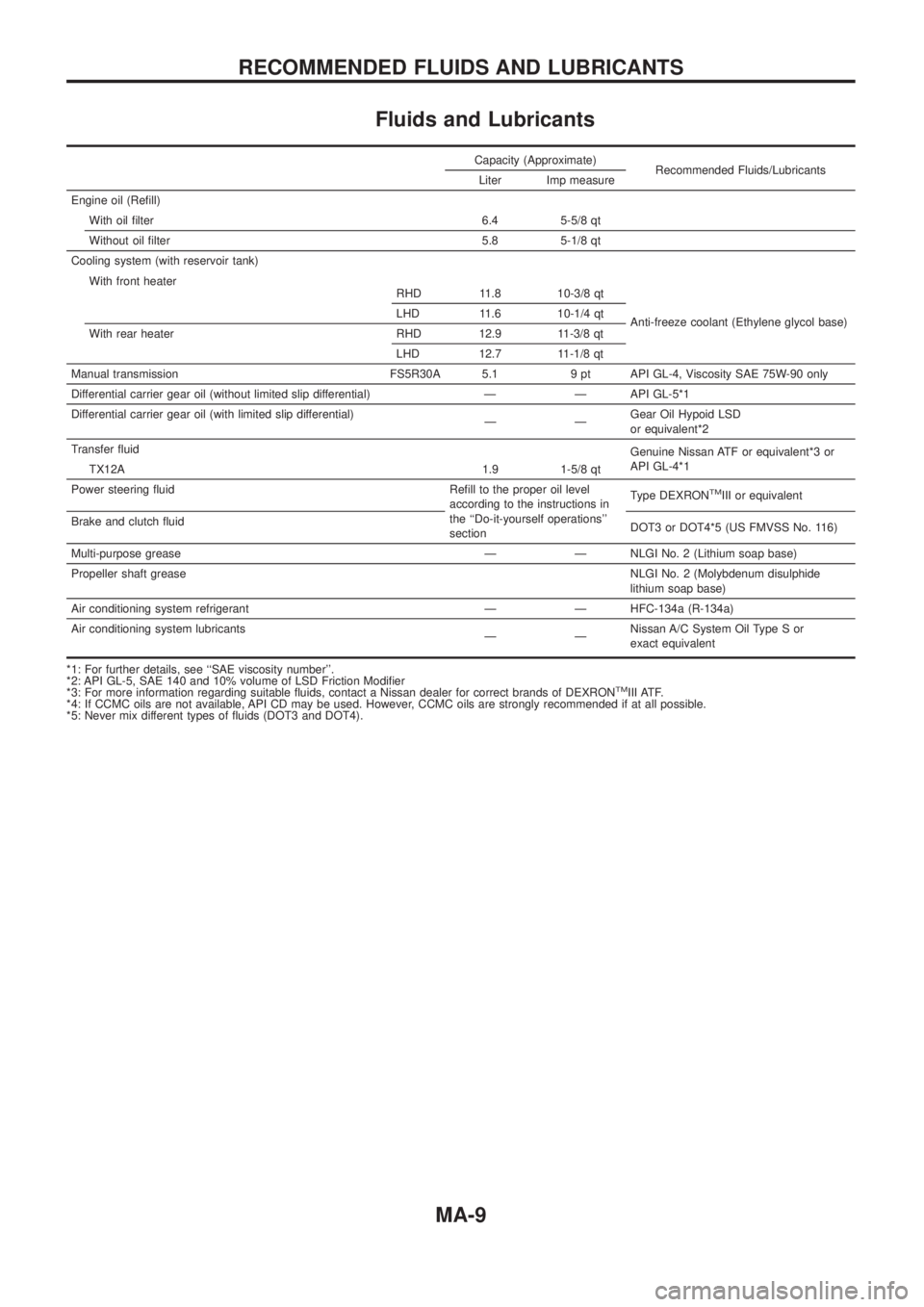

Fluids and Lubricants

Capacity (Approximate)Recommended Fluids/Lubricants

Liter Imp measure

Engine oil (Re®ll) With oil ®lter 6.4 5-5/8 qt

Without oil ®lter 5.8 5-1/8 qt

Cooling system (with reservoir tank)

Anti-freeze coolant (Ethylene glycol base)

With front heater

RHD 11.8 10-3/8 qt

LHD 11.6 10-1/4 qt

With rear heater RHD 12.9 11-3/8 qt LHD 12.7 11-1/8 qt

Manual transmission FS5R30A 5.1 9 pt API GL-4, Viscosity SAE 75W-90 only

Differential carrier gear oil (without limited slip differential) Ð Ð API GL-5*1

Differential carrier gear oil (with limited slip differential) ÐÐGearOilHypoidLSD

orequivalent*2

Transfer ¯uid Genuine Nissan ATF or equivalent*3 or

API GL-4*1

TX12A 1.9 1-5/8 qt

Power steering ¯uid Re®ll to the proper oil level according to the instructions in

the ``Do-it-yourself operations''

sectionType DEXRON

TMIII or equivalent

Brake and clutch ¯uid DOT3 or DOT4*5 (US FMVSS No. 116)

Multi-purpose grease Ð Ð NLGI No. 2 (Lithium soap base)

Propeller shaft grease NLGI No. 2 (Molybdenum disulphide

lithium soap base)

Air conditioning system refrigerant Ð Ð HFC-134a (R-134a)

Air conditioning system lubricants ÐÐNissan A/C System Oil Type S or

exact equivalent

*1: For further details, see ``SAE viscosity number''.

*2:APIGL-5,SAE140and10%volumeofLSDFrictionModi®er

*3: For more information regarding suitable ¯uids, contact a Nissan dealer for correct brands of DEXRON

TMIII ATF.

*4: If CCMC oils are not available, API CD may be used. However, CCMC oils are strongly recommended if at all possible.

*5: Never mix different types of ¯uids (DOT3 and DOT4).

RECOMMENDED FLUIDS AND LUBRICANTS

MA-9

Page 987 of 1226

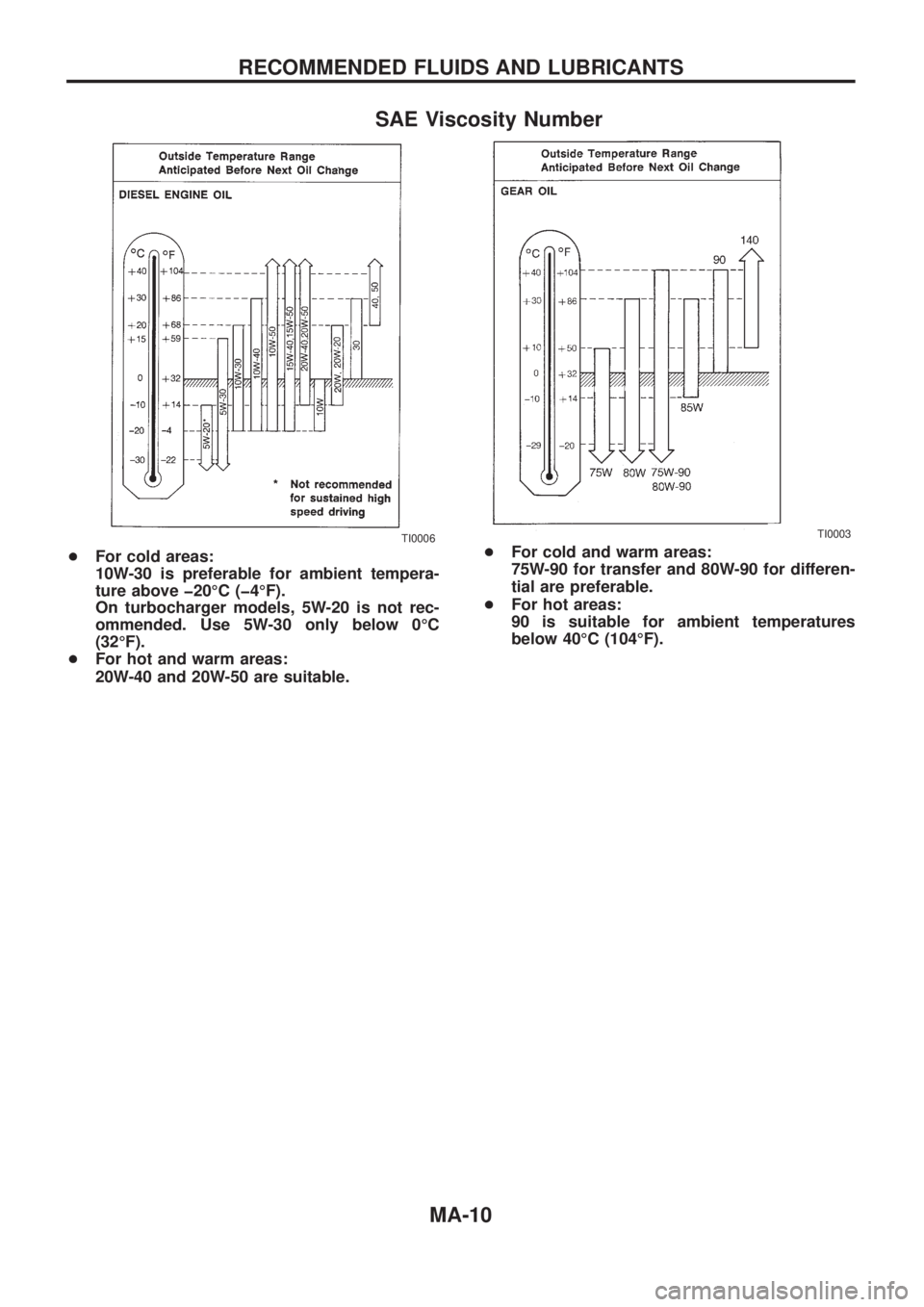

SAE Viscosity Number

+For cold areas:

10W-30 is preferable for ambient tempera-

ture above þ20ÉC (þ4ÉF).

On turbocharger models, 5W-20 is not rec-

ommended. Use 5W-30 only below 0ÉC

(32ÉF).

+For hot and warm areas:

20W-40 and 20W-50 are suitable.+For cold and warm areas:

75W-90 for transfer and 80W-90 for differen-

tial are preferable.

+For hot areas:

90 is suitable for ambient temperatures

below 40ÉC (104ÉF).

TI0006TI0003

RECOMMENDED FLUIDS AND LUBRICANTS

MA-10

Page 998 of 1226

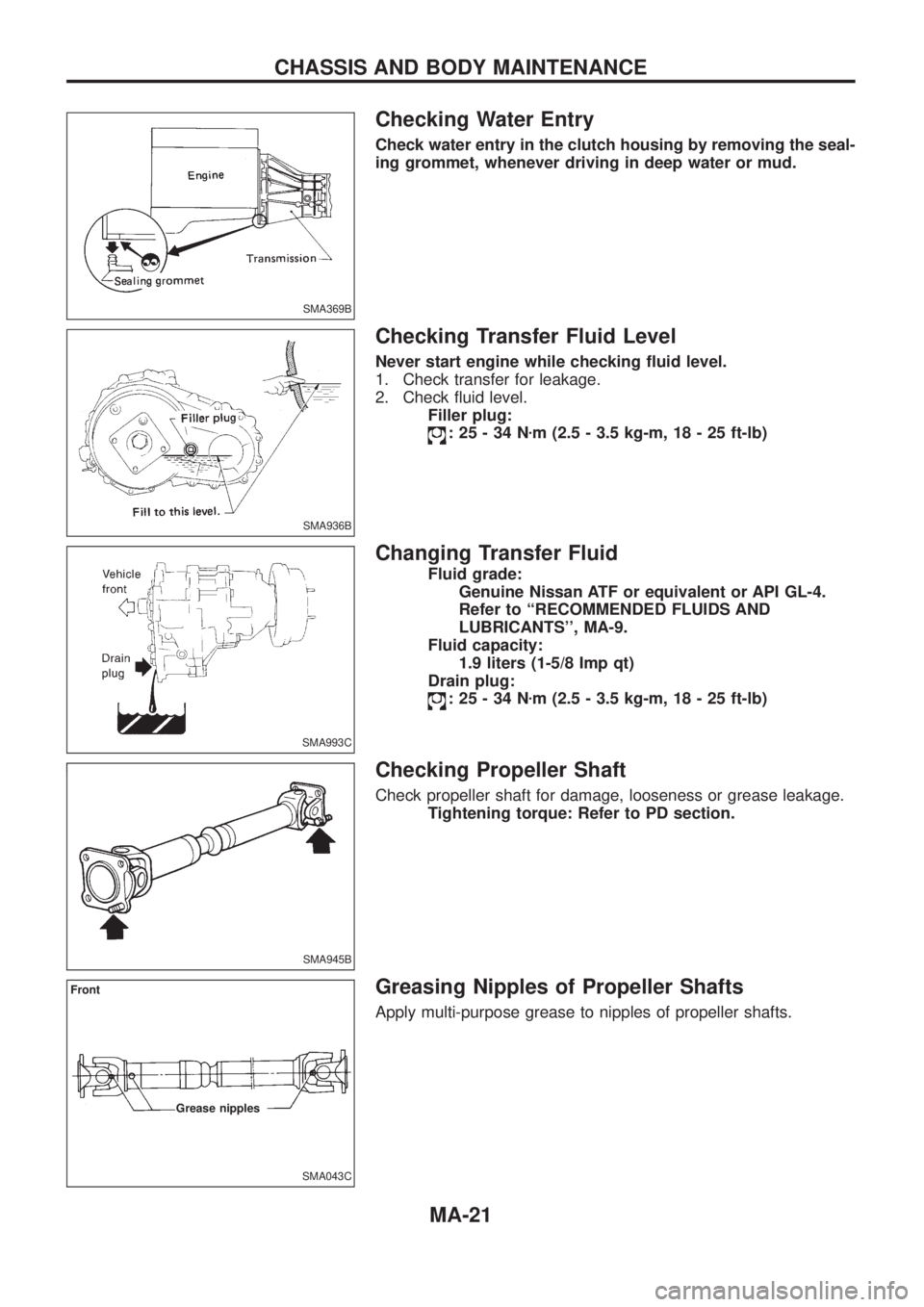

Checking Water Entry

Check water entry in the clutch housing by removing the seal-

ing grommet, whenever driving in deep water or mud.

Checking Transfer Fluid Level

Never start engine while checking ¯uid level.

1. Check transfer for leakage.

2. Check ¯uid level.

Filler plug:

:25-34Nzm (2.5 - 3.5 kg-m, 18 - 25 ft-lb)

Changing Transfer Fluid

Fluid grade:

Genuine Nissan ATF or equivalent or API GL-4.

Refer to ``RECOMMENDED FLUIDS AND

LUBRICANTS'', MA-9.

Fluid capacity:

1.9 liters (1-5/8 Imp qt)

Drain plug:

:25-34Nzm (2.5 - 3.5 kg-m, 18 - 25 ft-lb)

Checking Propeller Shaft

Check propeller shaft for damage, looseness or grease leakage.

Tightening torque: Refer to PD section.

Greasing Nipples of Propeller Shafts

Apply multi-purpose grease to nipples of propeller shafts.

SMA369B

SMA936B

SMA993C

SMA945B

SMA043C

Front

Grease nipples

CHASSIS AND BODY MAINTENANCE

MA-21

Page 1011 of 1226

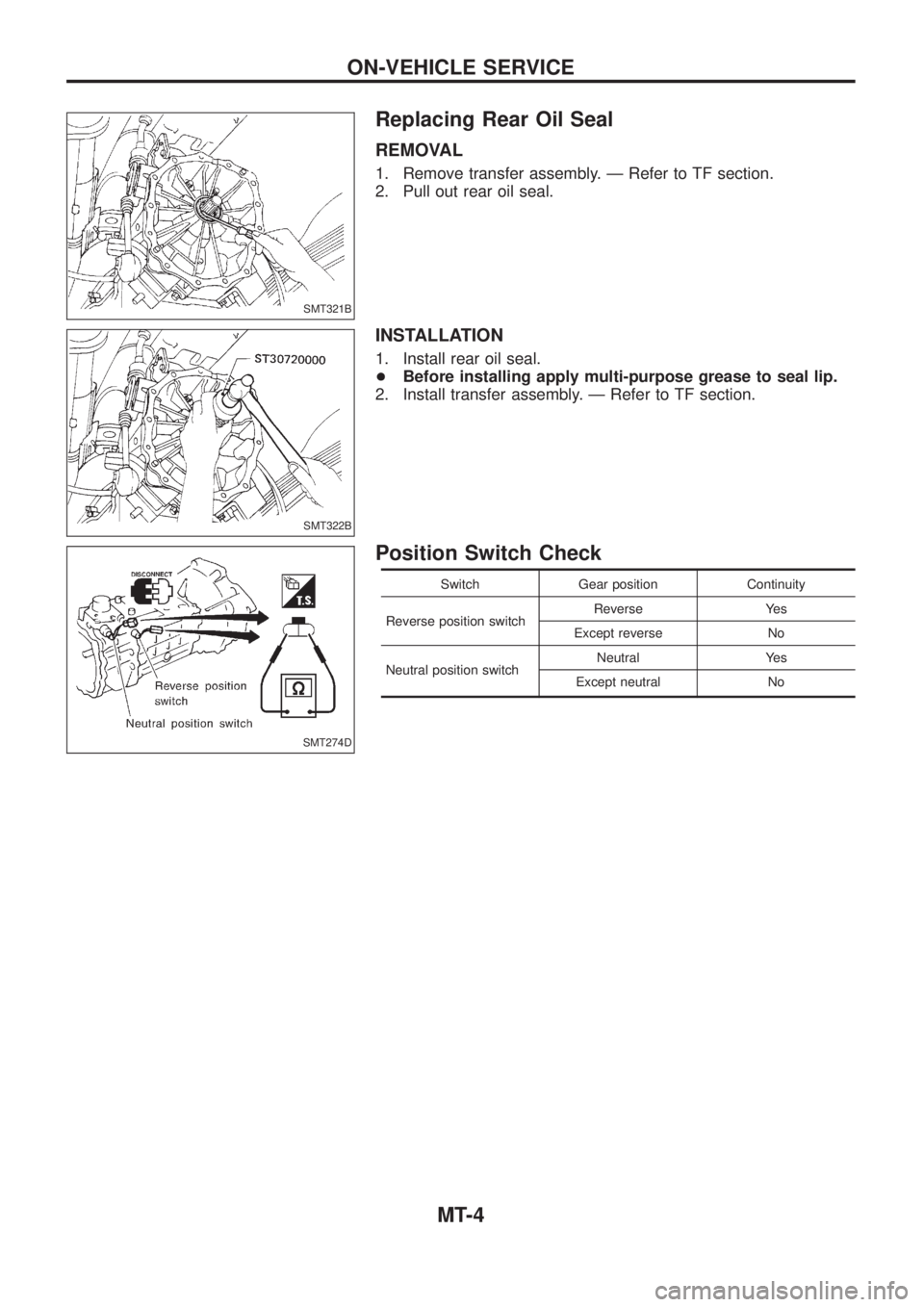

Replacing Rear Oil Seal

REMOVAL

1. Remove transfer assembly. Ð Refer to TF section.

2. Pull out rear oil seal.

INSTALLATION

1. Install rear oil seal.

+Before installing apply multi-purpose grease to seal lip.

2. Install transfer assembly. Ð Refer to TF section.

Position Switch Check

Switch Gear position Continuity

Reverse position switchReverse Yes

Except reverse No

Neutral position switchNeutral Yes

Except neutral No

SMT321B

SMT322B

SMT274D

ON-VEHICLE SERVICE

MT-4

Page 1012 of 1226

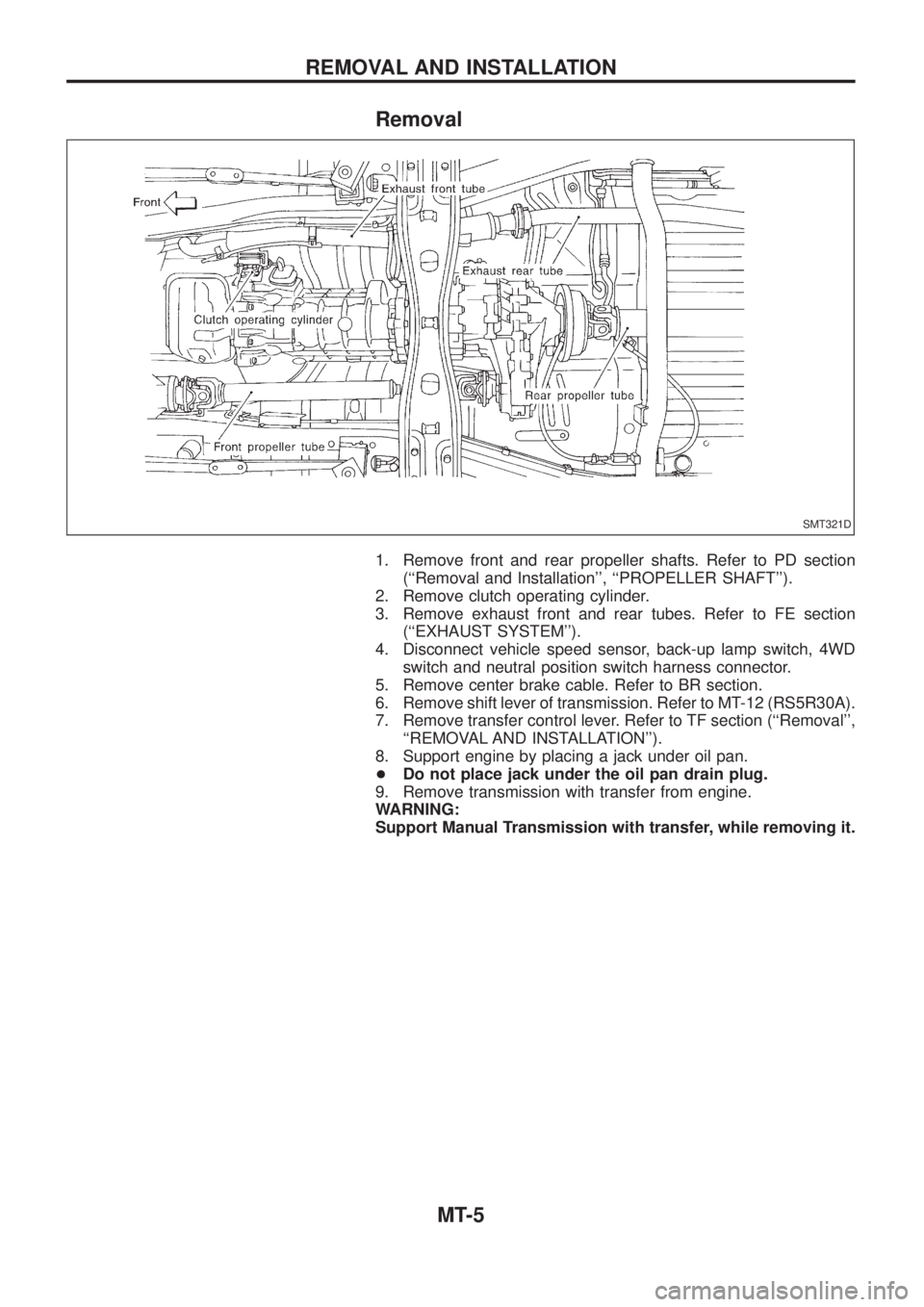

Removal

1. Remove front and rear propeller shafts. Refer to PD section

(``Removal and Installation'', ``PROPELLER SHAFT'').

2. Remove clutch operating cylinder.

3. Remove exhaust front and rear tubes. Refer to FE section

(``EXHAUST SYSTEM'').

4. Disconnect vehicle speed sensor, back-up lamp switch, 4WD

switch and neutral position switch harness connector.

5. Remove center brake cable. Refer to BR section.

6. Remove shift lever of transmission. Refer to MT-12 (RS5R30A).

7. Remove transfer control lever. Refer to TF section (``Removal'',

``REMOVAL AND INSTALLATION'').

8. Support engine by placing a jack under oil pan.

+Do not place jack under the oil pan drain plug.

9. Remove transmission with transfer from engine.

WARNING:

Support Manual Transmission with transfer, while removing it.

SMT321D

REMOVAL AND INSTALLATION

MT-5

Page 1193 of 1226

TRANSFER

SECTION

TF

CONTENTS

PREPARATION................................................................1

Special Service Tools ..................................................1

Commercial Service Tools ...........................................2

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................3

NVH Troubleshooting Chart.........................................3

DESCRIPTION.................................................................4

Cross-sectional View ...................................................4

ON-VEHICLE SERVICE..................................................5

Replacing Oil Seal .......................................................5

Checking Position Switch ............................................7

REMOVAL AND INSTALLATION....................................8

Removal .......................................................................8

Installation ....................................................................8

TRANSFER GEAR CONTROL.......................................9

MAJOR OVERHAUL.....................................................10

Case Components .....................................................10

Gear Components ..................................................... 11Shift Control Components .........................................12

DISASSEMBLY..............................................................13

REPAIR FOR COMPONENT PARTS............................19

Mainshaft ...................................................................19

Front Drive Shaft .......................................................20

Counter Gear .............................................................21

Main Gear ..................................................................22

Front Case .................................................................24

Front Case Cover ......................................................24

Center Case...............................................................24

Bearing Retainer ........................................................25

Rear Case..................................................................25

Shift Control Components .........................................26

ASSEMBLY....................................................................27

SERVICE DATA AND SPECIFICATIONS (SDS)..........33

General Speci®cations ...............................................33

Inspection and Adjustment ........................................33

TF

Page 1196 of 1226

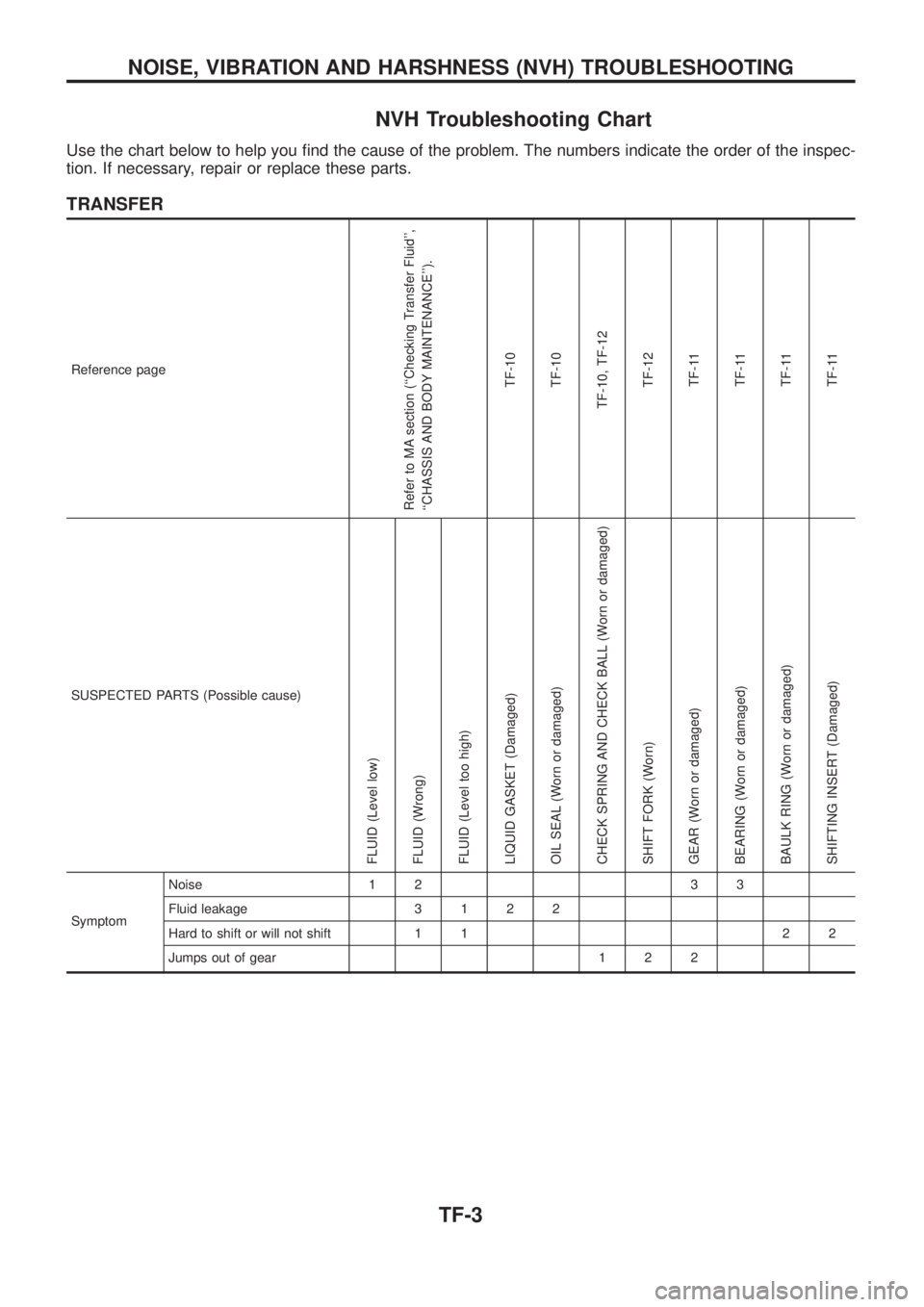

NVH Troubleshooting Chart

Use the chart below to help you ®nd the cause of the problem. The numbers indicate the order of the inspec-

tion. If necessary, repair or replace these parts.

TRANSFER

Reference page

Refer to MA section (``Checking Transfer Fluid'',

``CHASSIS AND BODY MAINTENANCE'').

TF-10

TF-10

TF-10, TF-12

TF-12

TF-11

TF-11

TF-11

TF-11

SUSPECTED PARTS (Possible cause)

FLUID (Level low)

FLUID (Wrong)

FLUID (Level too high)

LIQUID GASKET (Damaged)

OIL SEAL (Worn or damaged)

CHECK SPRING AND CHECK BALL (Worn or damaged)

SHIFT FORK (Worn)

GEAR (Worn or damaged)

BEARING (Worn or damaged)

BAULK RING (Worn or damaged)

SHIFTING INSERT (Damaged)

SymptomNoise 1 2 3 3

Fluid leakage3122

Hard to shift or will not shift 1 1 2 2

Jumps out of gear 1 2 2

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

TF-3

Page 1198 of 1226

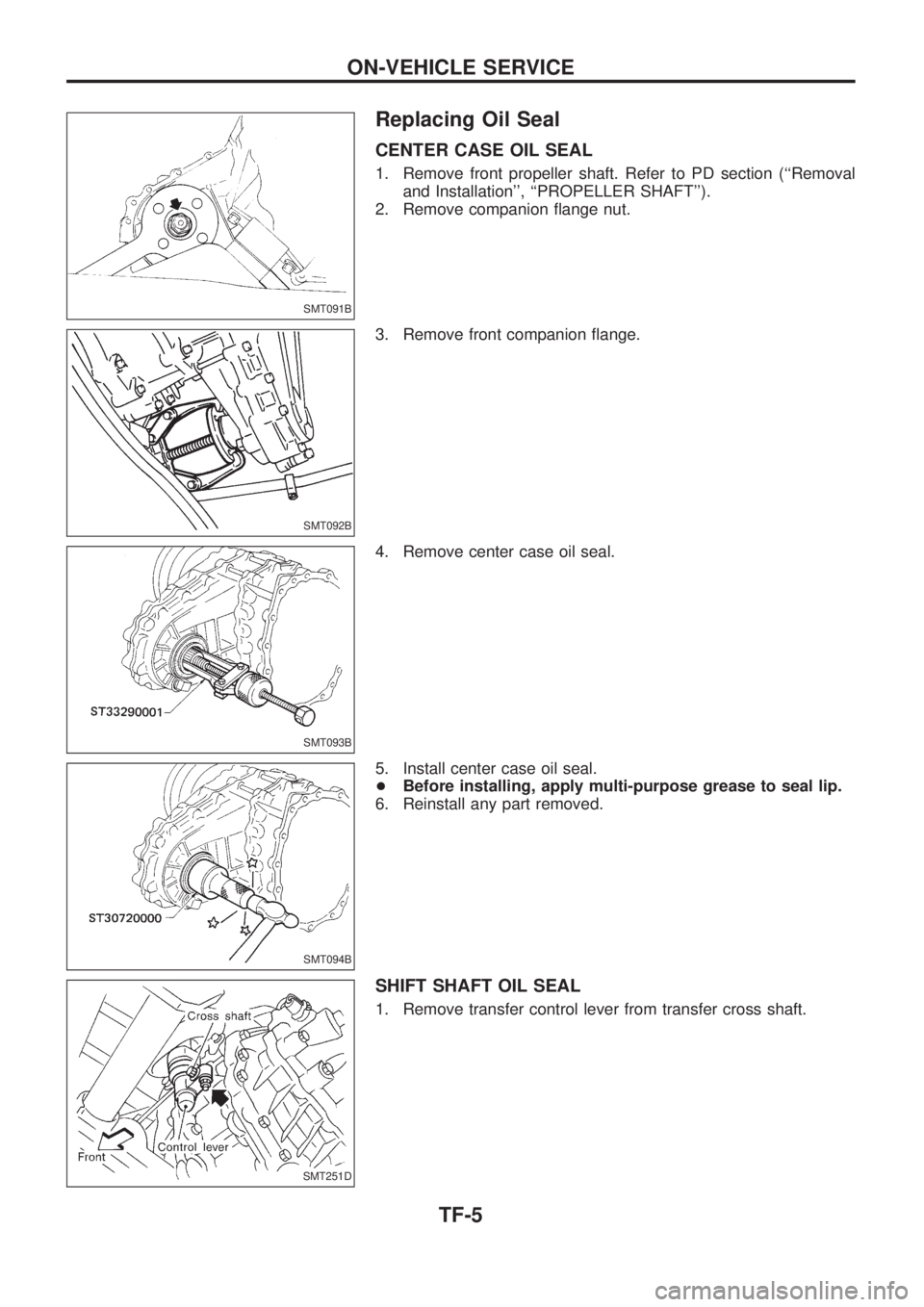

Replacing Oil Seal

CENTER CASE OIL SEAL

1. Remove front propeller shaft. Refer to PD section (``Removal

and Installation'', ``PROPELLER SHAFT'').

2. Remove companion ¯ange nut.

3. Remove front companion ¯ange.

4. Remove center case oil seal.

5. Install center case oil seal.

+Before installing, apply multi-purpose grease to seal lip.

6. Reinstall any part removed.

SHIFT SHAFT OIL SEAL

1. Remove transfer control lever from transfer cross shaft.

SMT091B

SMT092B

SMT093B

SMT094B

SMT251D

ON-VEHICLE SERVICE

TF-5

Page 1199 of 1226

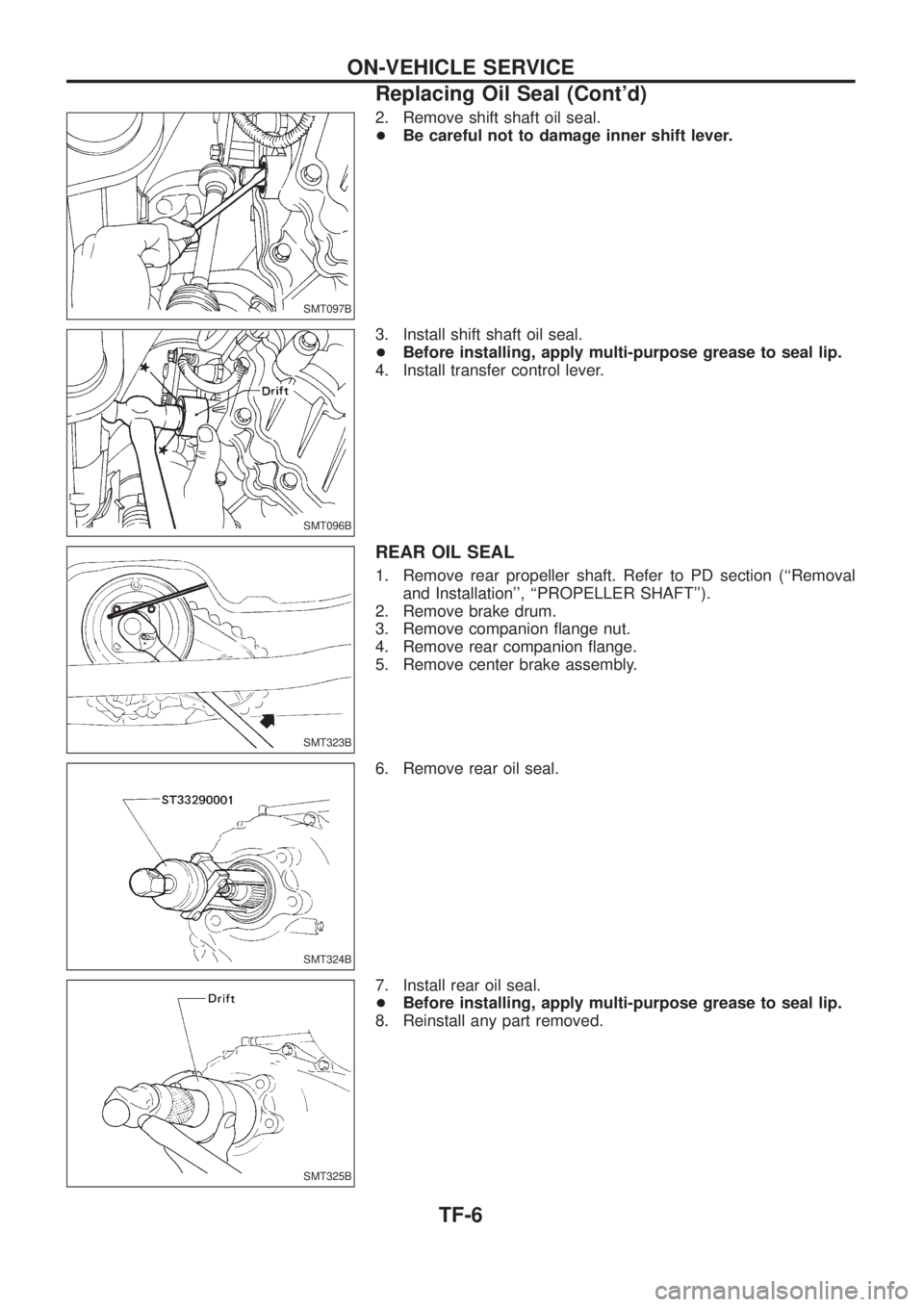

2. Remove shift shaft oil seal.

+Be careful not to damage inner shift lever.

3. Install shift shaft oil seal.

+Before installing, apply multi-purpose grease to seal lip.

4. Install transfer control lever.

REAR OIL SEAL

1. Remove rear propeller shaft. Refer to PD section (``Removal

and Installation'', ``PROPELLER SHAFT'').

2. Remove brake drum.

3. Remove companion ¯ange nut.

4. Remove rear companion ¯ange.

5. Remove center brake assembly.

6. Remove rear oil seal.

7. Install rear oil seal.

+Before installing, apply multi-purpose grease to seal lip.

8. Reinstall any part removed.

SMT097B

SMT096B

SMT323B

SMT324B

SMT325B

ON-VEHICLE SERVICE

Replacing Oil Seal (Cont'd)

TF-6