Indicator NISSAN PATROL 2006 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 837 of 1226

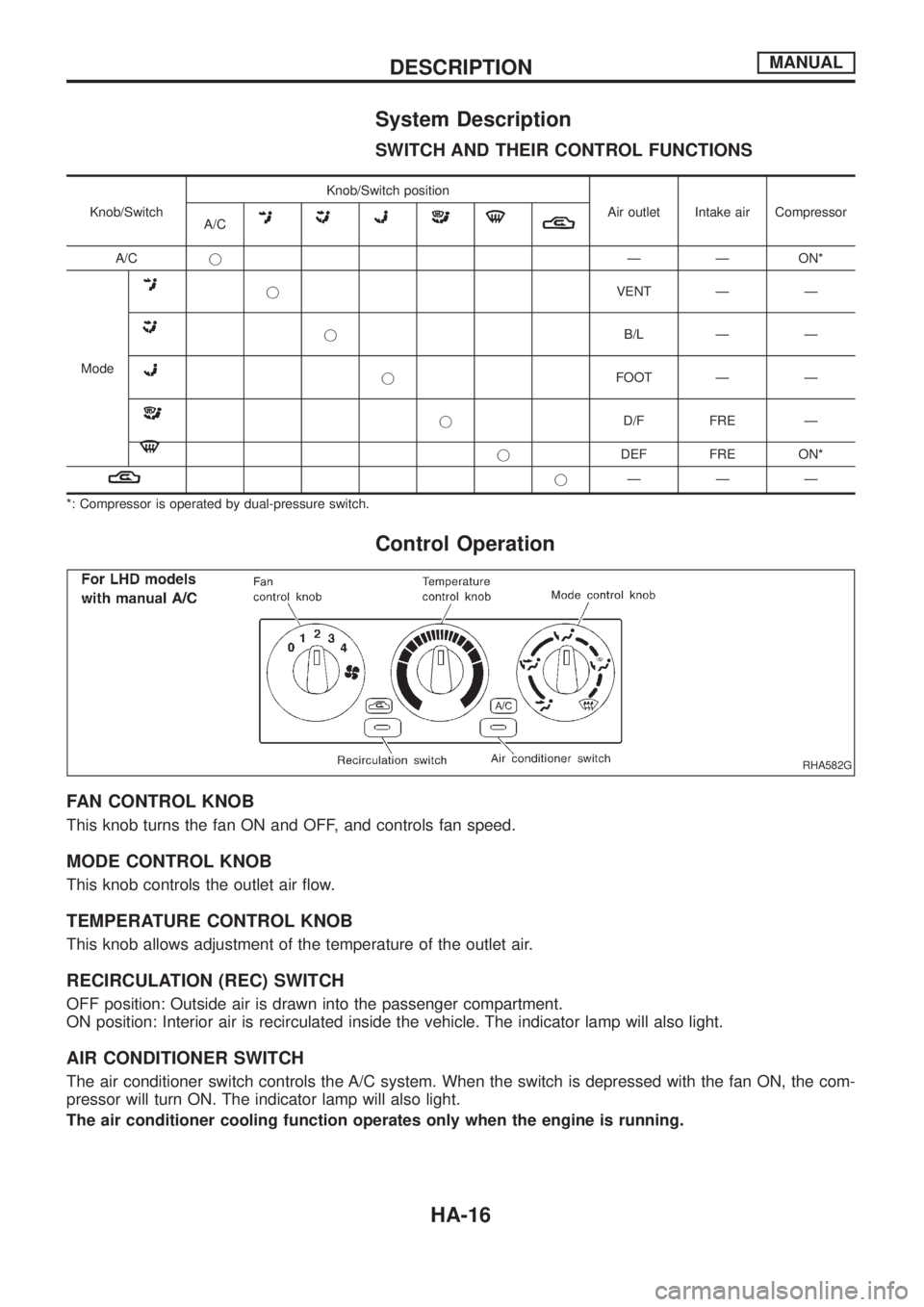

System Description

SWITCH AND THEIR CONTROL FUNCTIONS

Knob/SwitchKnob/Switch position

Air outlet Intake air Compressor

A/C

A/CjÐ Ð ON*

Mode

jVENT Ð Ð

jB/L Ð Ð

jFOOT Ð Ð

jD/F FRE Ð

jDEF FRE ON*

jÐÐÐ

*: Compressor is operated by dual-pressure switch.

Control Operation

FAN CONTROL KNOB

This knob turns the fan ON and OFF, and controls fan speed.

MODE CONTROL KNOB

This knob controls the outlet air ¯ow.

TEMPERATURE CONTROL KNOB

This knob allows adjustment of the temperature of the outlet air.

RECIRCULATION (REC) SWITCH

OFF position: Outside air is drawn into the passenger compartment.

ON position: Interior air is recirculated inside the vehicle. The indicator lamp will also light.

AIR CONDITIONER SWITCH

The air conditioner switch controls the A/C system. When the switch is depressed with the fan ON, the com-

pressor will turn ON. The indicator lamp will also light.

The air conditioner cooling function operates only when the engine is running.

RHA582G

DESCRIPTIONMANUAL

HA-16

Page 844 of 1226

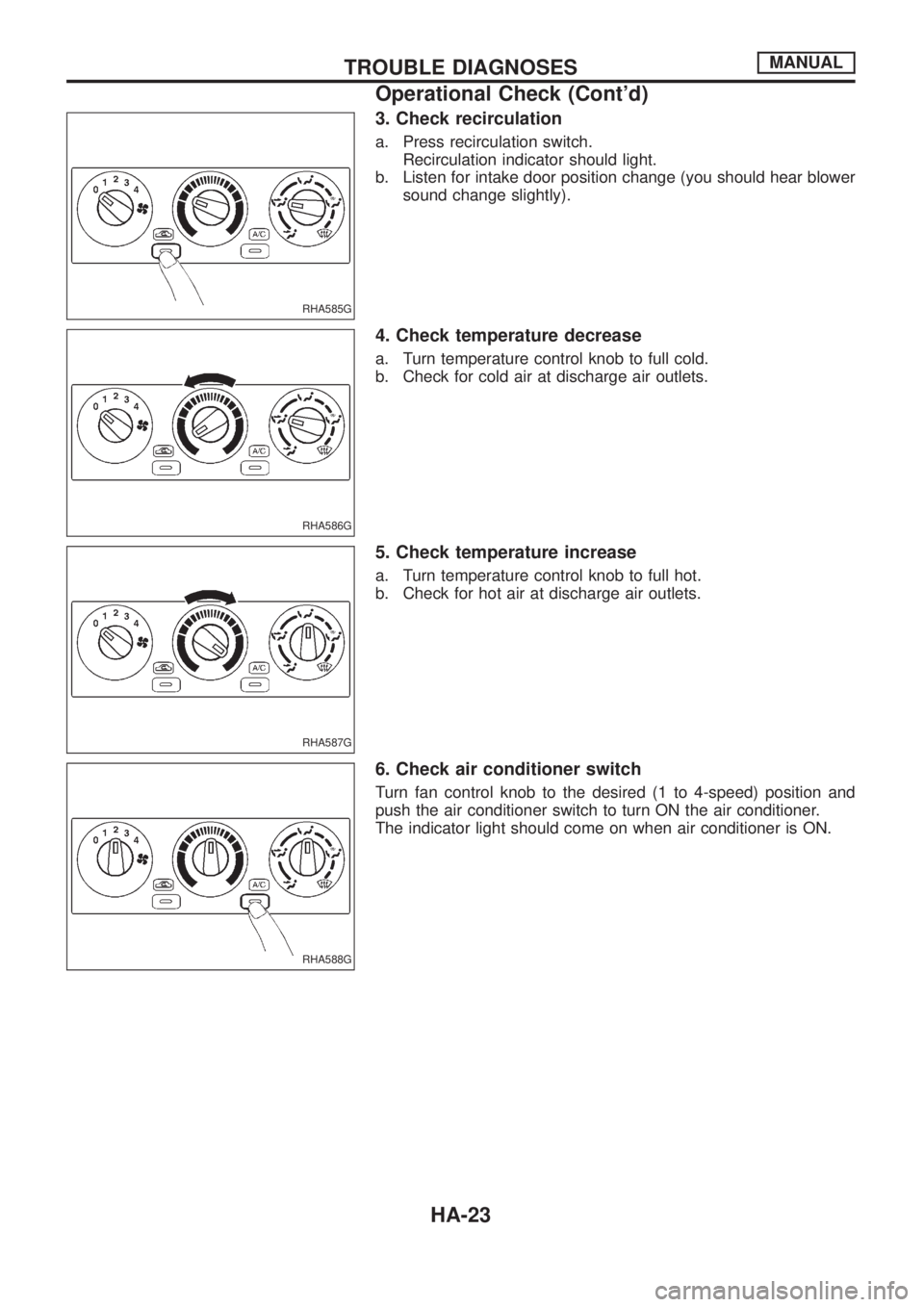

3. Check recirculation

a. Press recirculation switch.

Recirculation indicator should light.

b. Listen for intake door position change (you should hear blower

sound change slightly).

4. Check temperature decrease

a. Turn temperature control knob to full cold.

b. Check for cold air at discharge air outlets.

5. Check temperature increase

a. Turn temperature control knob to full hot.

b. Check for hot air at discharge air outlets.

6. Check air conditioner switch

Turn fan control knob to the desired (1 to 4-speed) position and

push the air conditioner switch to turn ON the air conditioner.

The indicator light should come on when air conditioner is ON.

RHA585G

RHA586G

RHA587G

RHA588G

TROUBLE DIAGNOSESMANUAL

Operational Check (Cont'd)

HA-23

Page 875 of 1226

FRESH switch

OFF position: Automatic control resumes.

ON position: Outside air is drawn into the passenger compartment.

A/C switch

Manual control of the compressor operation. When the A/C switch indicator illuminates, compressor operation

is being carried out.

DESCRIPTIONAUTO

Control Operation (Cont'd)

HA-54

Page 892 of 1226

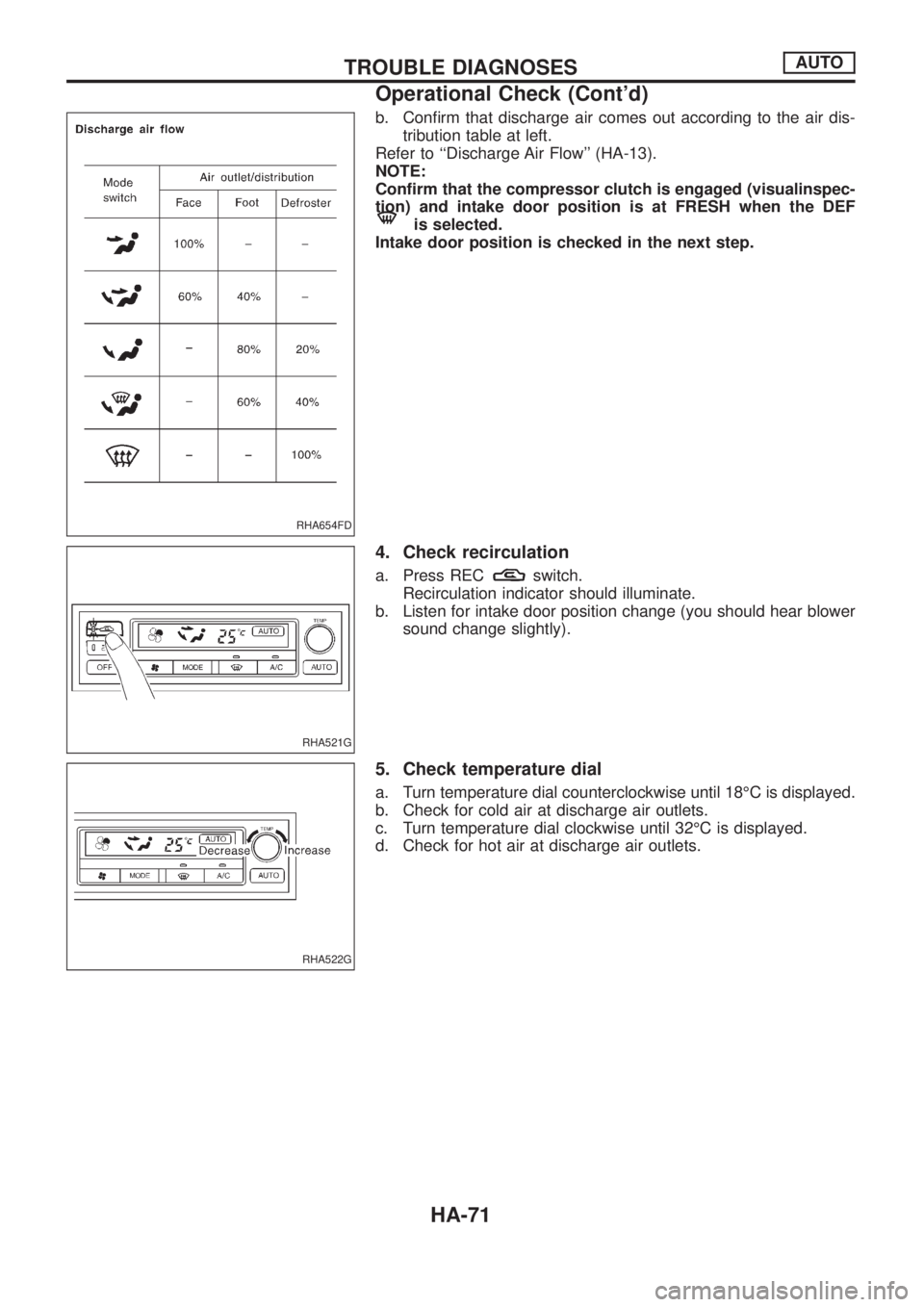

b. Con®rm that discharge air comes out according to the air dis-

tribution table at left.

Refer to ``Discharge Air Flow'' (HA-13).

NOTE:

Con®rm that the compressor clutch is engaged (visualinspec-

tion) and intake door position is at FRESH when the DEF

is selected.

Intake door position is checked in the next step.

4. Check recirculation

a. Press RECswitch.

Recirculation indicator should illuminate.

b. Listen for intake door position change (you should hear blower

sound change slightly).

5. Check temperature dial

a. Turn temperature dial counterclockwise until 18ÉC is displayed.

b. Check for cold air at discharge air outlets.

c. Turn temperature dial clockwise until 32ÉC is displayed.

d. Check for hot air at discharge air outlets.

RHA654FD

RHA521G

RHA522G

TROUBLE DIAGNOSESAUTO

Operational Check (Cont'd)

HA-71

Page 893 of 1226

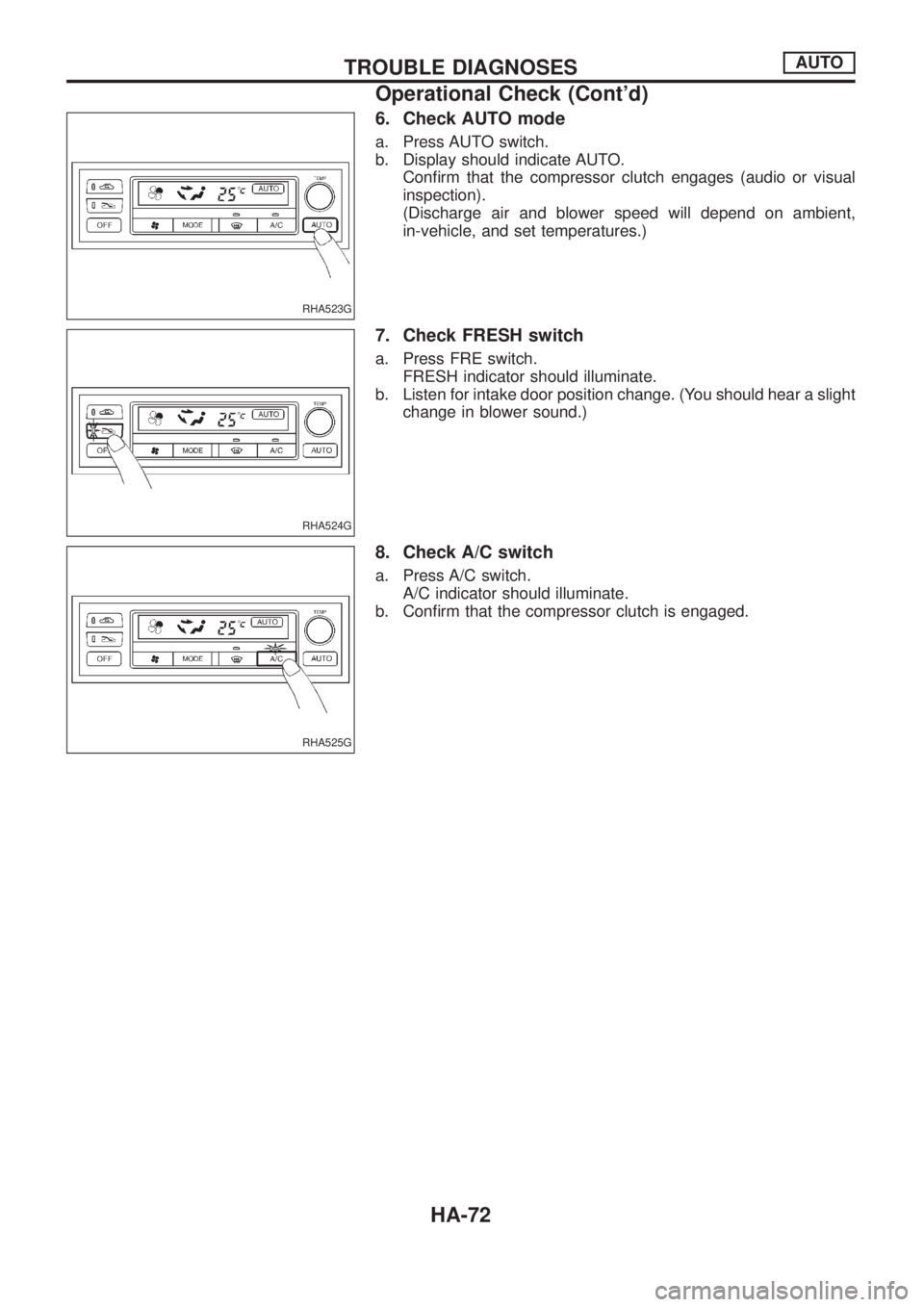

6. Check AUTO mode

a. Press AUTO switch.

b. Display should indicate AUTO.

Con®rm that the compressor clutch engages (audio or visual

inspection).

(Discharge air and blower speed will depend on ambient,

in-vehicle, and set temperatures.)

7. Check FRESH switch

a. Press FRE switch.

FRESH indicator should illuminate.

b. Listen for intake door position change. (You should hear a slight

change in blower sound.)

8. Check A/C switch

a. Press A/C switch.

A/C indicator should illuminate.

b. Con®rm that the compressor clutch is engaged.

RHA523G

RHA524G

RHA525G

TROUBLE DIAGNOSESAUTO

Operational Check (Cont'd)

HA-72

Page 952 of 1226

M

M/T major overhaul ..........................................MT-9

M/T removal and installation ............................MT-5

MAFS - Wiring diagram..................................EC-73

MAIN - Wiring diagram...................................EC-62

METER - Wiring diagram..............................EL-104

MIL & Data link connectors circuit ...............EC-187

MIL/DL - Wiring diagram ..............................EC-187

MIRROR - Wiring diagram............................EL-188

Main drive gear (M/T).....................................MT-10

Main gear (Transfer) .......................................TF-11

Mainshaft (M/T) ..............................................MT-10

Mainshaft (Transfer) ........................................TF-11

Maintenance (engine) ....................................MA-12

Major overhaul (Transfer) ...............................TF-10

Malfunction indicator lamp (MIL) ....................EC-31

Manifold tightening torque (intake &

exhaust)......................................................MA-12

Manual lock free running hub .........................FA-11

Manual transmission number ..........................GI-37

Mass air ¯ow sensor (MAFS).........................EC-73

Master cylinder (brake) ..................................BR-12

Meter .............................................................EL-102

Mirror, door......................................................BT-46

Mirror, outside .................................................BT-46

Mode door control linkage adjustment ...........HA-77

Model variation ................................................GI-35

Molding - See Exterior ....................................BT-26

Multiport fuel injection precautions ....................GI-3

N

NATS (Nissan Anti-theft System)..................EL-240

NATS - Wiring diagram .................................EL-241

NLS - Wiring diagram...................................EC-125

NVH Troubleshooting (PD)...............................PD-4

NVH troubleshooting (BR)................................BR-2

NVH troubleshooting (EM) ...............................EM-6

NVH troubleshooting (FA) .................................FA-3

NVH troubleshooting (MT) ...............................MT-3

NVH troubleshooting (RA)................................RA-3

NVH troubleshooting (RA)................................RA-3

NVH troubleshooting (ST).................................ST-3

NVH troubleshooting (Transfer) ........................TF-3

NVH troubleshooting CL ...................................CL-3

Needle lift sensor .........................................EC-125

Neutral position switch (M/T) ...........................MT-4

Neutral position switch .................................EC-169

O

Oil change (capacity) .......................................MA-9

Oil cooler (engine) ............................................LC-7

Oil jet.................................................................LC-7

Oil pan (engine) .............................................EM-13Oil pressure (engine) ........................................LC-3

Oil pump (engine) .............................................LC-4

Oil seal replacement (engine)........................EM-20

Oil seal replacement (front ®nal drive

4WD)...........................................................PD-10

Oil seal replacement (front of ®nal

drive) ...........................................................PD-10

Operating cylinder (clutch)................................CL-8

Outside mirror .................................................BT-46

P

P/ANT - Wiring diagram................................EL-181

PCV (positive crankcase ventilation) .............EC-21

PNP/SW - Wiring diagram ...........................EC-169

POWER - Wiring diagram.................................EL-6

Park/Neutral position switch .........................EC-169

Periodic maintenance (for Europe) ..................MA-4

Pinion bearing preload diff. ............................PD-27

Pinion gear height diff. ...................................PD-27

Piston assembly .............................................EM-46

Piston pin inspection ......................................EM-46

Piston ring inspection.....................................EM-47

Piston to bore clearance ................................EM-48

Power antenna ..............................................EL-181

Power door lock ............................................EL-204

Power door lock ............................................EL-211

Power door mirror .........................................EL-188

Power seat ....................................................EL-190

Power steering ¯uid level..................................ST-5

Power steering gear........................................ST-12

Power steering hydraulic pressure ...................ST-6

Power steering oil pump .................................ST-15

Power steering system bleeding.......................ST-6

Power supply routing ........................................EL-5

Power window ...............................................EL-196

Pre-delivery inspection.....................................MA-2

Precautions (General) .......................................GI-2

Pressure plate - See Clutch cover .................CL-14

Priming pump .................................................EC-46

Propeller shaft greasing .................................MA-21

Propeller shaft inspection ..............................MA-21

Propeller shaft on vehicle service ....................PD-6

Propeller shaft vibration ...................................PD-6

Propeller shaft ..................................................PD-5

Q

Quick-glow system check.............................EC-153

Quick-glow system .......................................EC-150

R

R/FOG - Wiring diagram .................................EL-80

R/HEAT - Wiring diagram ...............................HA-14

ALPHABETICAL INDEX

IDX-5

Page 996 of 1226

6. Install all injection nozzles with Tool and securely connect fuel

spill tube and delivery tubes.

7. Bleed air from fuel system and check for fuel leakage with

engine running.

Injection nozzle to cylinder head:

:59-69Nzm (6.0 - 7.0 kg-m, 43 - 51 ft-lb)

Spill tube nut:

:39-49Nzm (4.0 - 5.0 kg-m, 29 - 36 ft-lb)

Injection tube:

:20-25Nzm (2.2 - 2.5 kg-m, 16 - 18 ft-lb)

Checking Idle Speed

Inspection should be carried out with gears in ``Neutral'' and

with air conditioner and other electrical loads off.

1. Warm up engine until engine coolant temperature indicator

points to the middle of gauge.

2. Attach a diesel tachotester's pick-up to No. 1 fuel injection tube.

3. Race engine two or three times and check idle speed.

Idle speed:

Unit: rpm

MT 750+50

þ0

Timing Belt Replacement

Refer to EM section.

ENGINE MAINTENANCE

Checking Injection Nozzle (Cont'd)

MA-19

Page 1027 of 1226

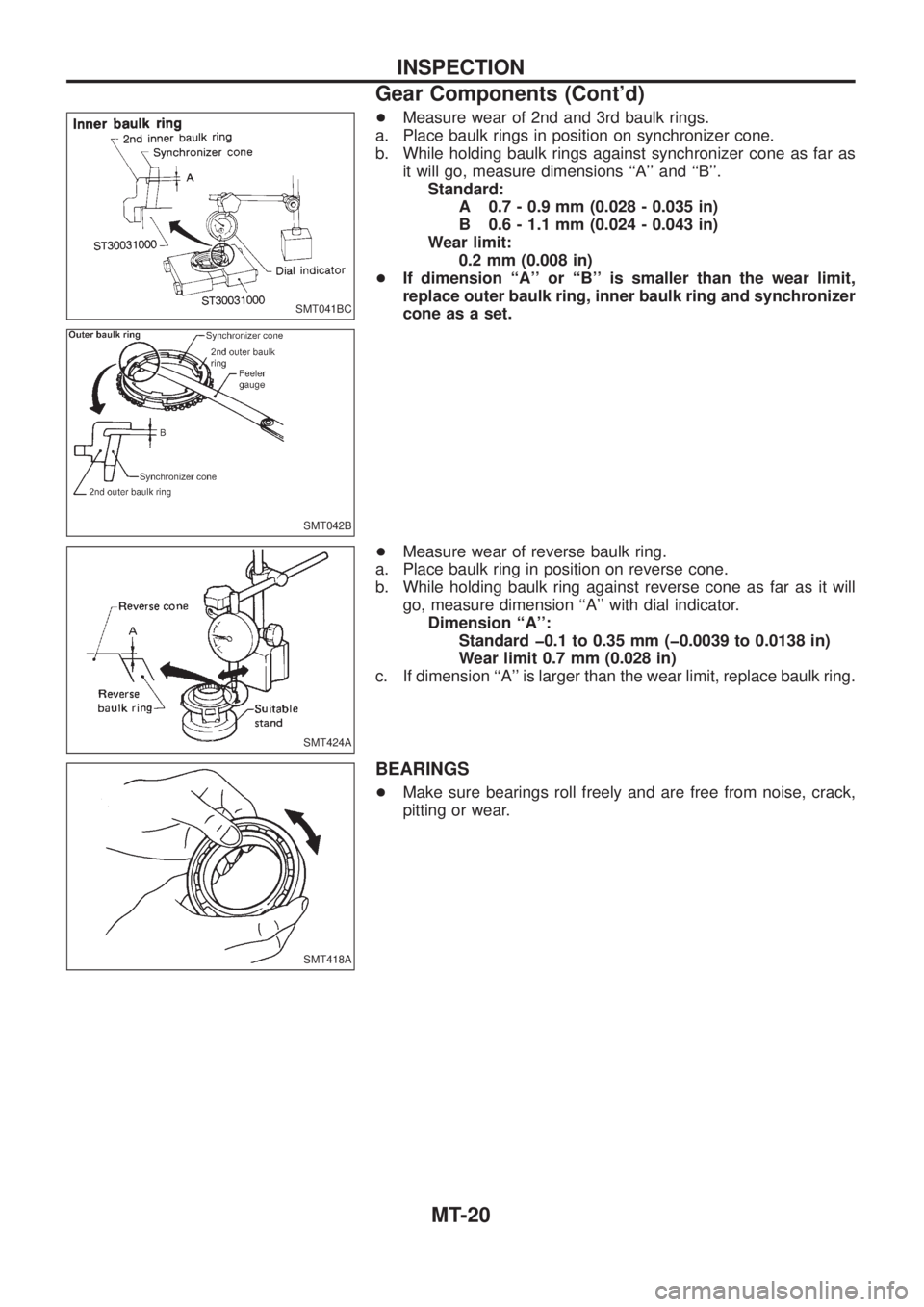

+Measure wear of 2nd and 3rd baulk rings.

a. Place baulk rings in position on synchronizer cone.

b. While holding baulk rings against synchronizer cone as far as

it will go, measure dimensions ``A'' and ``B''.

Standard:

A 0.7 - 0.9 mm (0.028 - 0.035 in)

B 0.6 - 1.1 mm (0.024 - 0.043 in)

Wear limit:

0.2 mm (0.008 in)

+If dimension ``A'' or ``B'' is smaller than the wear limit,

replace outer baulk ring, inner baulk ring and synchronizer

cone as a set.

+Measure wear of reverse baulk ring.

a. Place baulk ring in position on reverse cone.

b. While holding baulk ring against reverse cone as far as it will

go, measure dimension ``A'' with dial indicator.

Dimension ``A'':

Standard þ0.1 to 0.35 mm (þ0.0039 to 0.0138 in)

Wear limit 0.7 mm (0.028 in)

c. If dimension ``A'' is larger than the wear limit, replace baulk ring.

BEARINGS

+Make sure bearings roll freely and are free from noise, crack,

pitting or wear.

SMT041BC

SMT042B

SMT424A

SMT418A

INSPECTION

Gear Components (Cont'd)

MT-20

Page 1031 of 1226

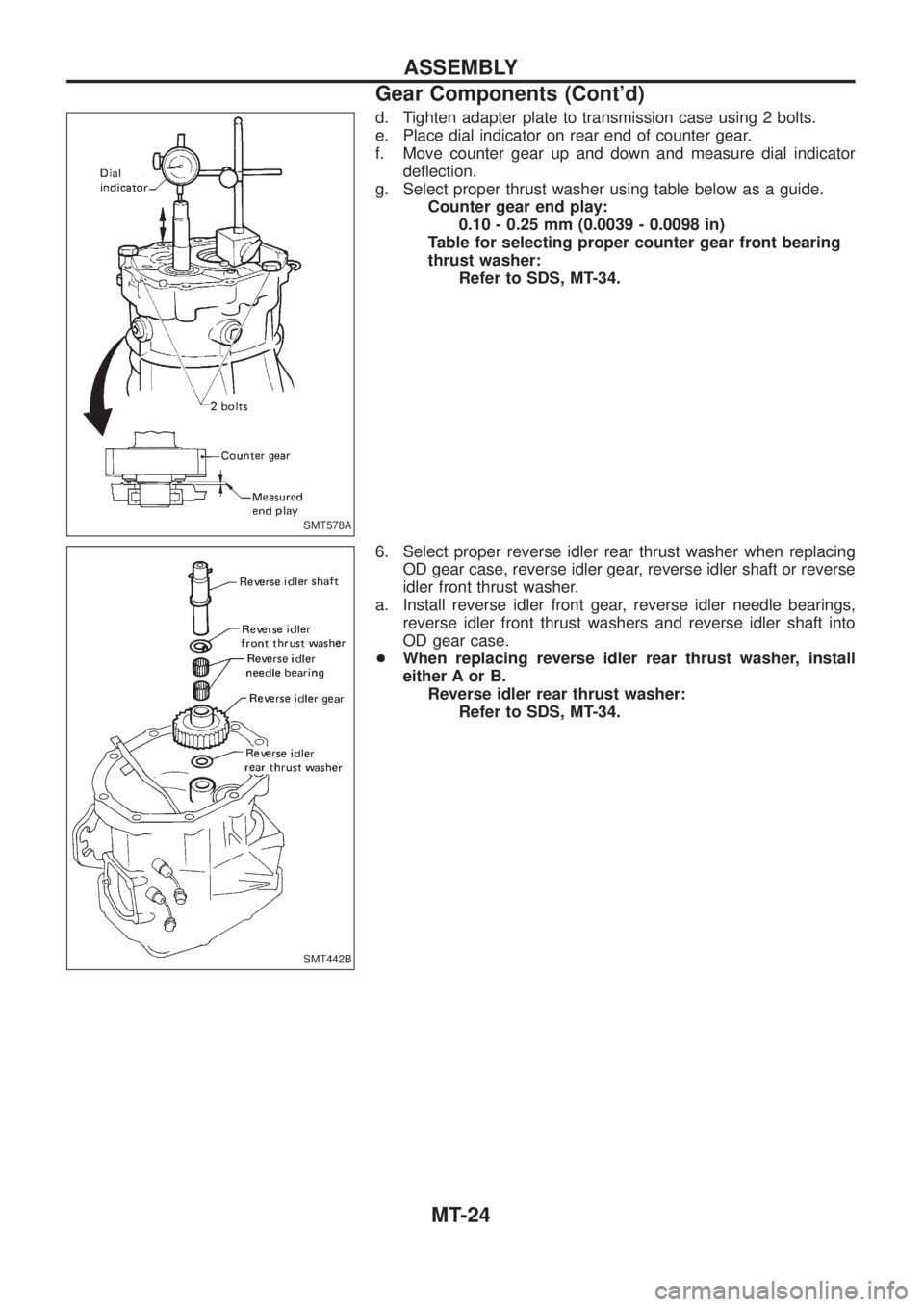

d. Tighten adapter plate to transmission case using 2 bolts.

e. Place dial indicator on rear end of counter gear.

f. Move counter gear up and down and measure dial indicator

de¯ection.

g. Select proper thrust washer using table below as a guide.

Counter gear end play:

0.10 - 0.25 mm (0.0039 - 0.0098 in)

Table for selecting proper counter gear front bearing

thrust washer:

Refer to SDS, MT-34.

6. Select proper reverse idler rear thrust washer when replacing

OD gear case, reverse idler gear, reverse idler shaft or reverse

idler front thrust washer.

a. Install reverse idler front gear, reverse idler needle bearings,

reverse idler front thrust washers and reverse idler shaft into

OD gear case.

+When replacing reverse idler rear thrust washer, install

either A or B.

Reverse idler rear thrust washer:

Refer to SDS, MT-34.

SMT578A

SMT442B

ASSEMBLY

Gear Components (Cont'd)

MT-24

Page 1032 of 1226

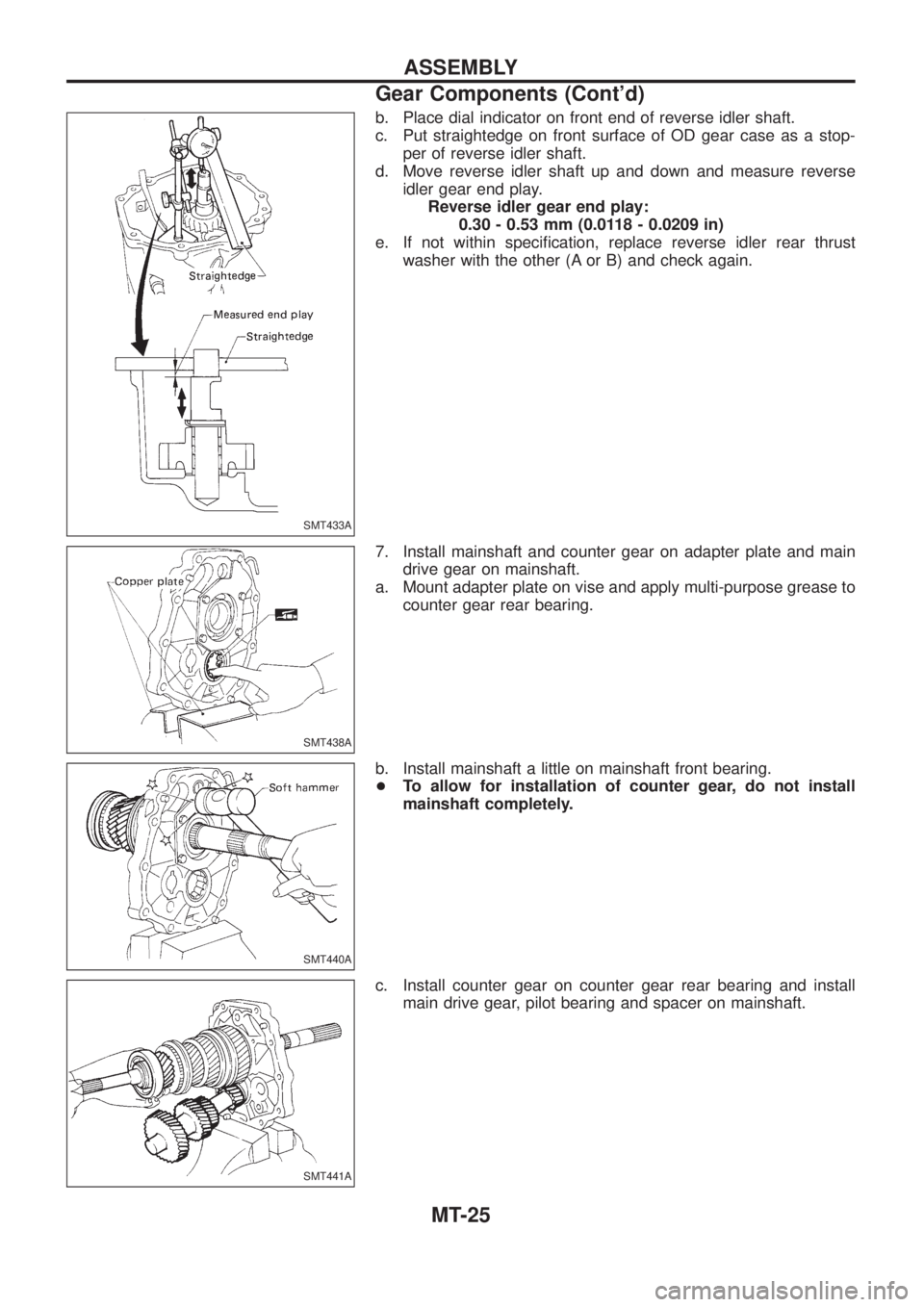

b. Place dial indicator on front end of reverse idler shaft.

c. Put straightedge on front surface of OD gear case as a stop-

per of reverse idler shaft.

d. Move reverse idler shaft up and down and measure reverse

idler gear end play.

Reverse idler gear end play:

0.30 - 0.53 mm (0.0118 - 0.0209 in)

e. If not within speci®cation, replace reverse idler rear thrust

washer with the other (A or B) and check again.

7. Install mainshaft and counter gear on adapter plate and main

drive gear on mainshaft.

a. Mount adapter plate on vise and apply multi-purpose grease to

counter gear rear bearing.

b. Install mainshaft a little on mainshaft front bearing.

+To allow for installation of counter gear, do not install

mainshaft completely.

c. Install counter gear on counter gear rear bearing and install

main drive gear, pilot bearing and spacer on mainshaft.

SMT433A

SMT438A

SMT440A

SMT441A

ASSEMBLY

Gear Components (Cont'd)

MT-25