head NISSAN PATROL 2006 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 951 of 1226

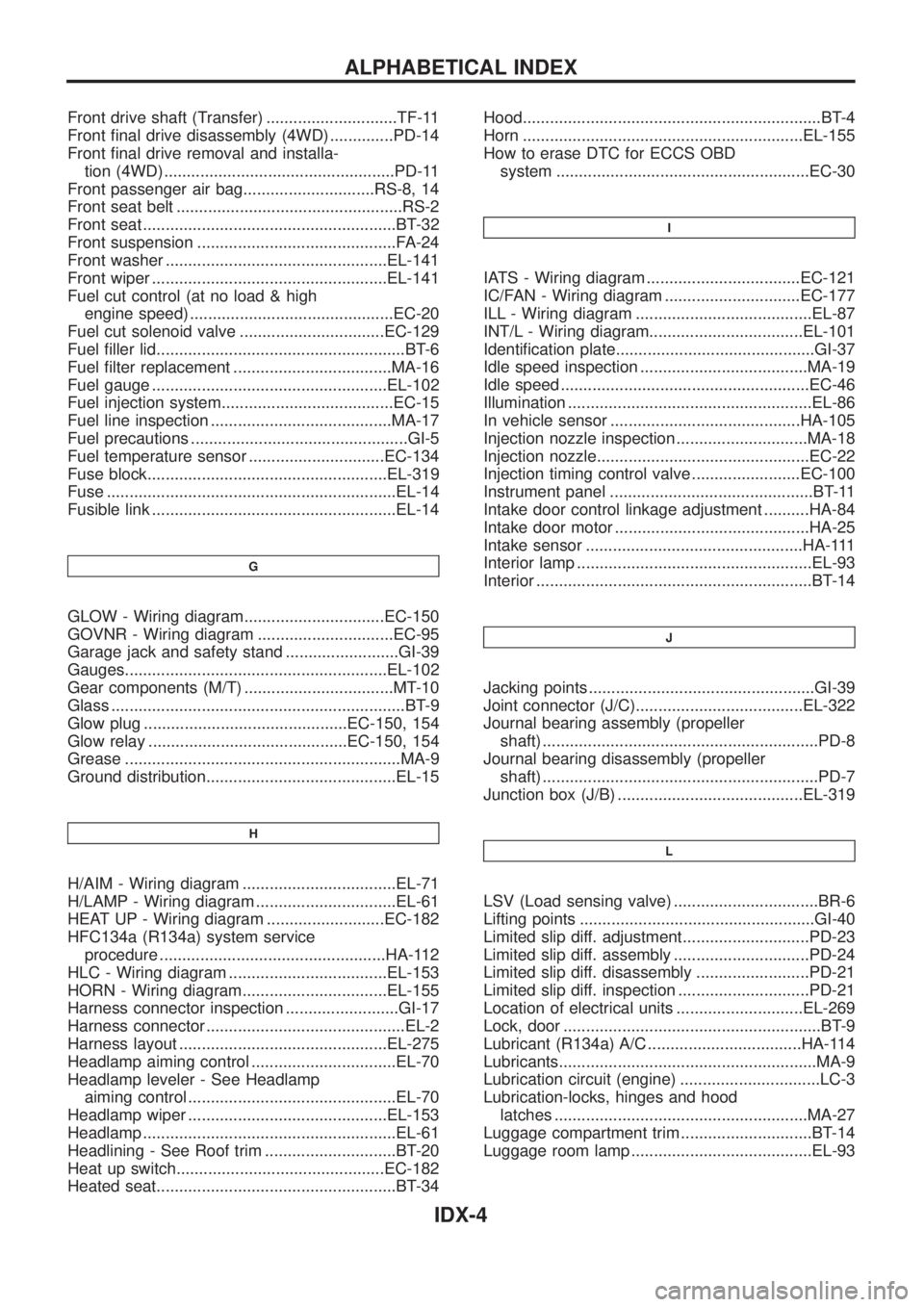

Front drive shaft (Transfer) .............................TF-11

Front ®nal drive disassembly (4WD) ..............PD-14

Front ®nal drive removal and installa-

tion (4WD)...................................................PD-11

Front passenger air bag.............................RS-8, 14

Front seat belt ..................................................RS-2

Front seat ........................................................BT-32

Front suspension ............................................FA-24

Front washer .................................................EL-141

Front wiper ....................................................EL-141

Fuel cut control (at no load & high

engine speed) .............................................EC-20

Fuel cut solenoid valve ................................EC-129

Fuel ®ller lid.......................................................BT-6

Fuel ®lter replacement ...................................MA-16

Fuel gauge ....................................................EL-102

Fuel injection system......................................EC-15

Fuel line inspection ........................................MA-17

Fuel precautions ................................................GI-5

Fuel temperature sensor ..............................EC-134

Fuse block.....................................................EL-319

Fuse ................................................................EL-14

Fusible link ......................................................EL-14

G

GLOW - Wiring diagram...............................EC-150

GOVNR - Wiring diagram ..............................EC-95

Garage jack and safety stand .........................GI-39

Gauges..........................................................EL-102

Gear components (M/T) .................................MT-10

Glass .................................................................BT-9

Glow plug .............................................EC-150, 154

Glow relay ............................................EC-150, 154

Grease .............................................................MA-9

Ground distribution..........................................EL-15

H

H/AIM - Wiring diagram ..................................EL-71

H/LAMP - Wiring diagram ...............................EL-61

HEAT UP - Wiring diagram ..........................EC-182

HFC134a (R134a) system service

procedure ..................................................HA-112

HLC - Wiring diagram ...................................EL-153

HORN - Wiring diagram................................EL-155

Harness connector inspection .........................GI-17

Harness connector ............................................EL-2

Harness layout ..............................................EL-275

Headlamp aiming control ................................EL-70

Headlamp leveler - See Headlamp

aiming control ..............................................EL-70

Headlamp wiper ............................................EL-153

Headlamp ........................................................EL-61

Headlining - See Roof trim .............................BT-20

Heat up switch..............................................EC-182

Heated seat.....................................................BT-34Hood..................................................................BT-4

Horn ..............................................................EL-155

How to erase DTC for ECCS OBD

system ........................................................EC-30

I

IATS - Wiring diagram ..................................EC-121

IC/FAN - Wiring diagram ..............................EC-177

ILL - Wiring diagram .......................................EL-87

INT/L - Wiring diagram..................................EL-101

Identi®cation plate............................................GI-37

Idle speed inspection .....................................MA-19

Idle speed .......................................................EC-46

Illumination ......................................................EL-86

In vehicle sensor ..........................................HA-105

Injection nozzle inspection .............................MA-18

Injection nozzle...............................................EC-22

Injection timing control valve ........................EC-100

Instrument panel .............................................BT-11

Intake door control linkage adjustment ..........HA-84

Intake door motor ...........................................HA-25

Intake sensor ................................................HA-111

Interior lamp ....................................................EL-93

Interior .............................................................BT-14

J

Jacking points ..................................................GI-39

Joint connector (J/C).....................................EL-322

Journal bearing assembly (propeller

shaft) .............................................................PD-8

Journal bearing disassembly (propeller

shaft) .............................................................PD-7

Junction box (J/B) .........................................EL-319

L

LSV (Load sensing valve) ................................BR-6

Lifting points ....................................................GI-40

Limited slip diff. adjustment............................PD-23

Limited slip diff. assembly ..............................PD-24

Limited slip diff. disassembly .........................PD-21

Limited slip diff. inspection .............................PD-21

Location of electrical units ............................EL-269

Lock, door .........................................................BT-9

Lubricant (R134a) A/C ..................................HA-114

Lubricants.........................................................MA-9

Lubrication circuit (engine) ...............................LC-3

Lubrication-locks, hinges and hood

latches ........................................................MA-27

Luggage compartment trim .............................BT-14

Luggage room lamp ........................................EL-93

ALPHABETICAL INDEX

IDX-4

Page 975 of 1226

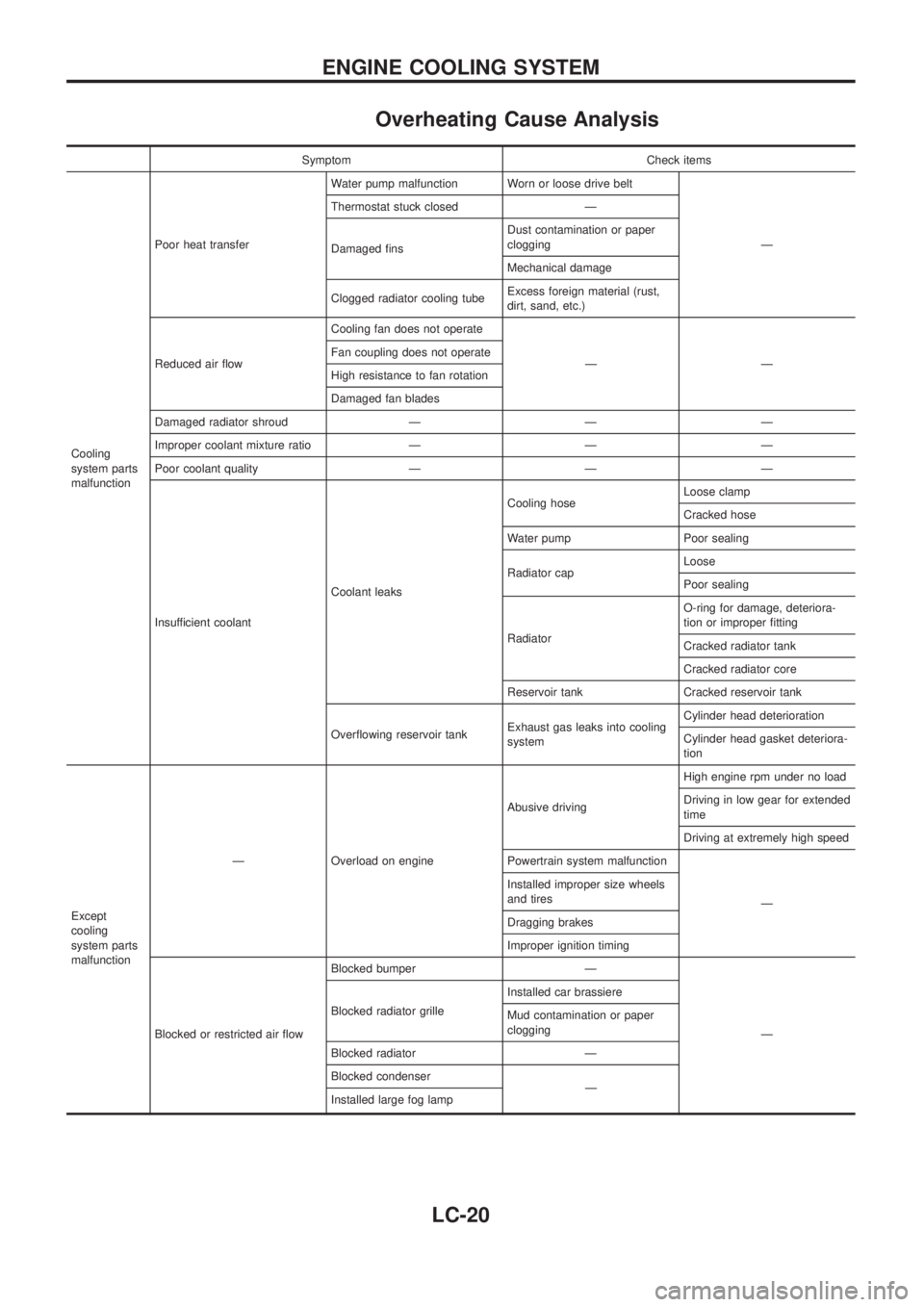

Overheating Cause Analysis

Symptom Check items

Cooling

system parts

malfunctionPoor heat transferWater pump malfunction Worn or loose drive belt

Ð Thermostat stuck closed Ð

Damaged ®nsDust contamination or paper

clogging

Mechanical damage

Clogged radiator cooling tubeExcess foreign material (rust,

dirt, sand, etc.)

Reduced air ¯owCooling fan does not operate

ÐÐ Fan coupling does not operate

High resistance to fan rotation

Damaged fan blades

Damaged radiator shroud Ð Ð Ð

Improper coolant mixture ratio Ð Ð Ð

Poor coolant quality Ð Ð Ð

Insufficient coolantCoolant leaksCooling hoseLoose clamp

Cracked hose

Water pump Poor sealing

Radiator capLoose

Poor sealing

RadiatorO-ring for damage, deteriora-

tion or improper ®tting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Over¯owing reservoir tankExhaust gas leaks into cooling

systemCylinder head deterioration

Cylinder head gasket deteriora-

tion

Except

cooling

system parts

malfunctionÐ Overload on engineAbusive drivingHigh engine rpm under no load

Driving in low gear for extended

time

Driving at extremely high speed

Powertrain system malfunction

Ð Installed improper size wheels

and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air ¯owBlocked bumper Ð

Ð Blocked radiator grilleInstalled car brassiere

Mud contamination or paper

clogging

Blocked radiator Ð

Blocked condenser

Ð

Installed large fog lamp

ENGINE COOLING SYSTEM

LC-20

Page 979 of 1226

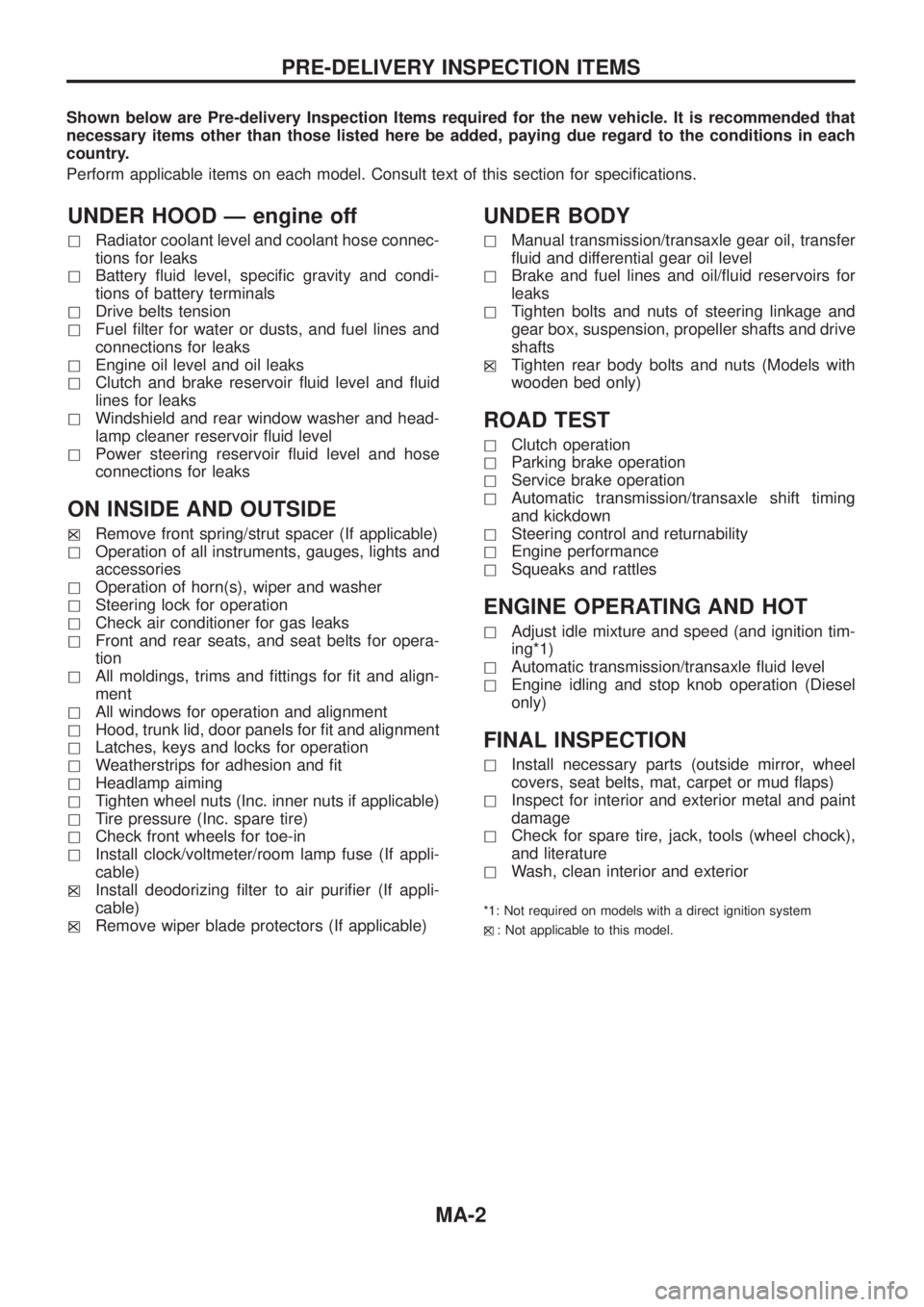

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for speci®cations.

UNDER HOOD Ð engine off

hRadiator coolant level and coolant hose connec-

tions for leaks

hBattery ¯uid level, speci®c gravity and condi-

tions of battery terminals

hDrive belts tension

hFuel ®lter for water or dusts, and fuel lines and

connections for leaks

hEngine oil level and oil leaks

hClutch and brake reservoir ¯uid level and ¯uid

lines for leaks

hWindshield and rear window washer and head-

lamp cleaner reservoir ¯uid level

hPower steering reservoir ¯uid level and hose

connections for leaks

ON INSIDE AND OUTSIDE

hXRemove front spring/strut spacer (If applicable)

hOperation of all instruments, gauges, lights and

accessories

hOperation of horn(s), wiper and washer

hSteering lock for operation

hCheck air conditioner for gas leaks

hFront and rear seats, and seat belts for opera-

tion

hAll moldings, trims and ®ttings for ®t and align-

ment

hAll windows for operation and alignment

hHood, trunk lid, door panels for ®t and alignment

hLatches, keys and locks for operation

hWeatherstrips for adhesion and ®t

hHeadlamp aiming

hTighten wheel nuts (Inc. inner nuts if applicable)

hTire pressure (Inc. spare tire)

hCheck front wheels for toe-in

hInstall clock/voltmeter/room lamp fuse (If appli-

cable)

h

XInstall deodorizing ®lter to air puri®er (If appli-

cable)

h

XRemove wiper blade protectors (If applicable)

UNDER BODY

hManual transmission/transaxle gear oil, transfer

¯uid and differential gear oil level

hBrake and fuel lines and oil/¯uid reservoirs for

leaks

hTighten bolts and nuts of steering linkage and

gear box, suspension, propeller shafts and drive

shafts

h

XTighten rear body bolts and nuts (Models with

wooden bed only)

ROAD TEST

hClutch operation

hParking brake operation

hService brake operation

hAutomatic transmission/transaxle shift timing

and kickdown

hSteering control and returnability

hEngine performance

hSqueaks and rattles

ENGINE OPERATING AND HOT

hAdjust idle mixture and speed (and ignition tim-

ing*1)

hAutomatic transmission/transaxle ¯uid level

hEngine idling and stop knob operation (Diesel

only)

FINAL INSPECTION

hInstall necessary parts (outside mirror, wheel

covers, seat belts, mat, carpet or mud ¯aps)

hInspect for interior and exterior metal and paint

damage

hCheck for spare tire, jack, tools (wheel chock),

and literature

hWash, clean interior and exterior

*1: Not required on models with a direct ignition system

h

X: Not applicable to this model.

PRE-DELIVERY INSPECTION ITEMS

MA-2

Page 980 of 1226

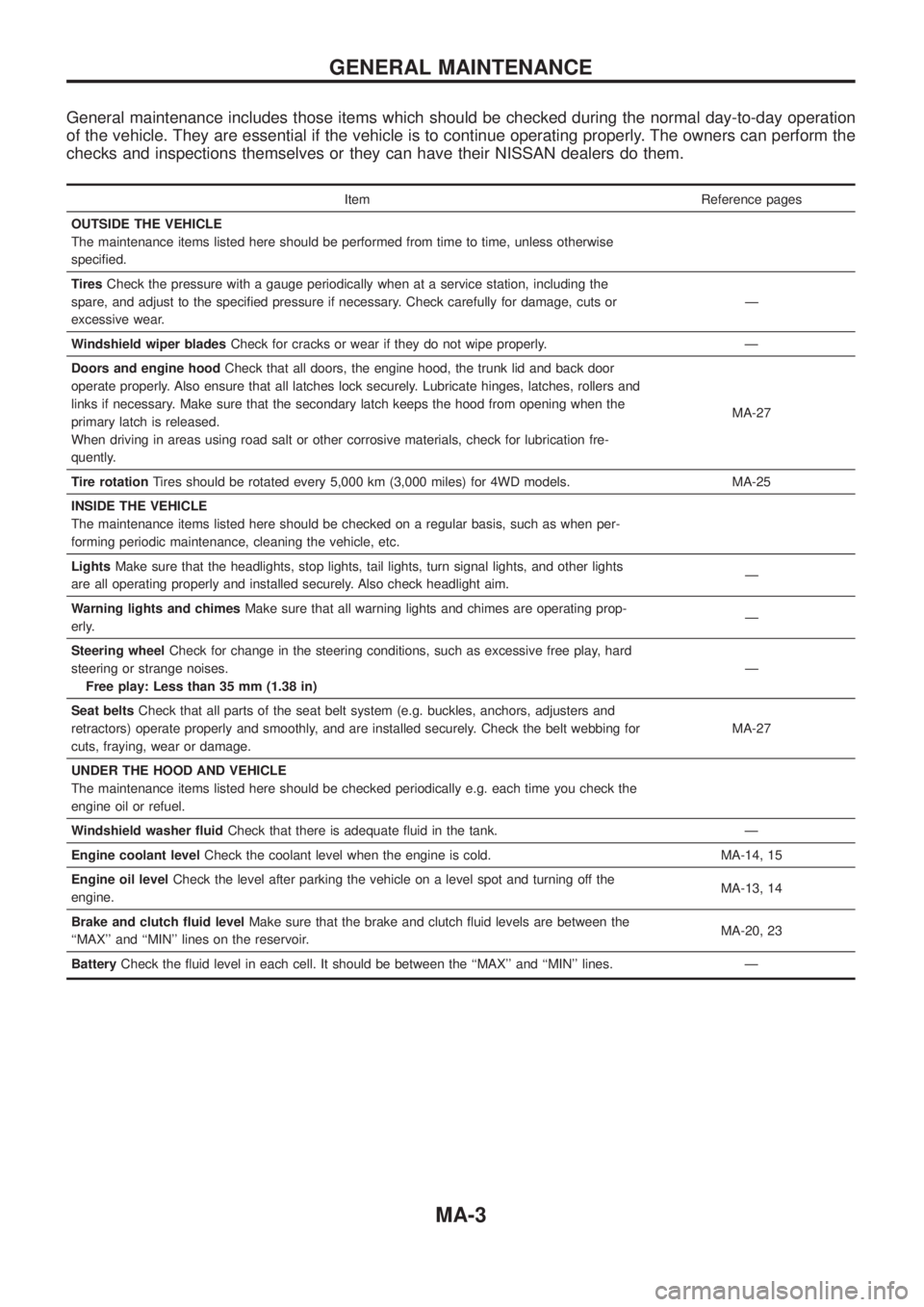

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform the

checks and inspections themselves or they can have their NISSAN dealers do them.

Item Reference pages

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise

speci®ed.

TiresCheck the pressure with a gauge periodically when at a service station, including the

spare, and adjust to the speci®ed pressure if necessary. Check carefully for damage, cuts or

excessive wear.Ð

Windshield wiper bladesCheck for cracks or wear if they do not wipe properly. Ð

Doors and engine hoodCheck that all doors, the engine hood, the trunk lid and back door

operate properly. Also ensure that all latches lock securely. Lubricate hinges, latches, rollers and

links if necessary. Make sure that the secondary latch keeps the hood from opening when the

primary latch is released.

When driving in areas using road salt or other corrosive materials, check for lubrication fre-

quently.MA-27

Tire rotationTires should be rotated every 5,000 km (3,000 miles) for 4WD models. MA-25

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when per-

forming periodic maintenance, cleaning the vehicle, etc.

LightsMake sure that the headlights, stop lights, tail lights, turn signal lights, and other lights

are all operating properly and installed securely. Also check headlight aim.Ð

Warning lights and chimesMake sure that all warning lights and chimes are operating prop-

erly.Ð

Steering wheelCheck for change in the steering conditions, such as excessive free play, hard

steering or strange noises.

Free play: Less than 35 mm (1.38 in)Ð

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly, and are installed securely. Check the belt webbing for

cuts, fraying, wear or damage.MA-27

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the

engine oil or refuel.

Windshield washer ¯uidCheck that there is adequate ¯uid in the tank. Ð

Engine coolant levelCheck the coolant level when the engine is cold. MA-14, 15

Engine oil levelCheck the level after parking the vehicle on a level spot and turning off the

engine.MA-13, 14

Brake and clutch ¯uid levelMake sure that the brake and clutch ¯uid levels are between the

``MAX'' and ``MIN'' lines on the reservoir.MA-20, 23

BatteryCheck the ¯uid level in each cell. It should be between the ``MAX'' and ``MIN'' lines. Ð

GENERAL MAINTENANCE

MA-3

Page 983 of 1226

![NISSAN PATROL 2006 Repair Manual Chassis and Body Services

Annual driving distance below 30,000 km (18,000 miles)

Abbreviations: R = Replace, I = Inspect, and correct or replace as necessary, L = Lubricate,T=Tighten.

[ ]: At the spec NISSAN PATROL 2006 Repair Manual Chassis and Body Services

Annual driving distance below 30,000 km (18,000 miles)

Abbreviations: R = Replace, I = Inspect, and correct or replace as necessary, L = Lubricate,T=Tighten.

[ ]: At the spec](/img/5/57368/w960_57368-982.png)

Chassis and Body Services

Annual driving distance below 30,000 km (18,000 miles)

Abbreviations: R = Replace, I = Inspect, and correct or replace as necessary, L = Lubricate,T=Tighten.

[ ]: At the speci®ed mileage only

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page Perform either at number of kilometers (miles) or months,

whichever comes ®rst.km x 1,000 10 20 30 40 50 60 70 80 90

(Miles x 1,000) (6) (12) (18) (24) (30) (36) (42) (48) (54)

Months 6 12 18 24 30 36 42 48 54

CHASSIS AND BODY Underhood and under vehicle

Brake & clutch ¯uid (For level & leaks).I I I I MA-23, 20

Brake ¯uid.R R MA-24

Brake booster vacuum hoses, connections & check valve I I MA-24

Power steering ¯uid & lines (For level & leaks) I I I I MA-26

Brake & clutch systemsI I I I MA-24, 20

Manual transmission oil (For leaks) I I I I MA-20

Manual transmission oil[R] MA-20

Transfer ¯uidI I R I MA-21

Limited slip differential (LSD) gear oil (For level & leaks).*1 I I R I MA-22

Steering gear & linkage, axle & suspension parts, propeller shaft & exhaust system.I I I I MA-26, 20 *2

Greasing points of propeller shaftLLLLMA-21

Drive shafts & steering damper.IIII *3

Body mounting bolts & nutsTTTT *4

Outside and Inside

Wheel alignment (If necessary, rotate & balance wheels) I I I I MA-25, *5

Brake pads, discs & other brake components.I I I I MA-24

Front wheel bearing grease I R I R MA-22

Axle joint in knuckle ¯angeL L MA-23

Free running hub greaseI I I I MA-23

Headlamp aimingIIII *6

Foot brake, parking brake & clutch (For free play, stroke & operation) I I I I *7

Ventilation air ®lterRRR*8

Body corrosionAnnually MA-28

Air bag systemSee NOTE (1) *9

NOTE: (1) Inspect after 10 years, then every 2 years.

(2) Maintenance items with ``.'' should be performed more frequently according to ``Maintenance Under Severe Driv-

ing Conditions''.

*1: Including differential gear with differential lock

*2: ``Front Axle and Front Suspension Parts'' in FA section, ``Rear Axle and Rear Suspension Parts'' in RA section

*3: ``FRONT AXLE Ð Drive Shaft'' in FA section

*4: ``CAB BODY'' in BT section

*5: ``Front Wheel Alignment'' in FA section

*6: ``Aiming Adjustment'' in EL section

*7: ``Brake Pedal and Bracket'' in BR section, ``Adjusting Clutch Pedal'' in CL section

*8: ``Ventilation air ®lter'' in HA section

*9: ``Maintenance Items'' in RS section

PERIODIC MAINTENANCE

MA-6

Page 984 of 1226

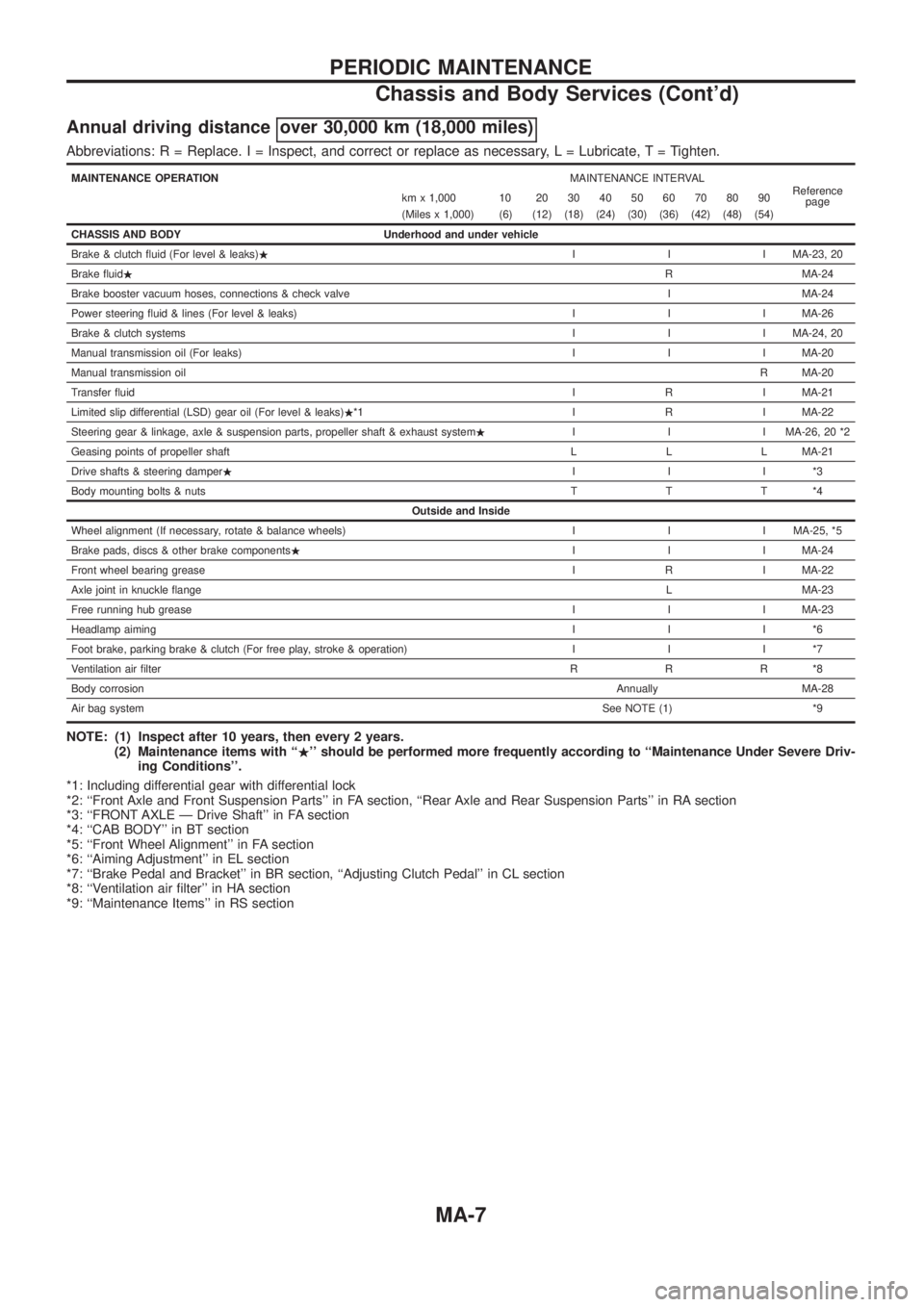

Annual driving distance over 30,000 km (18,000 miles)

Abbreviations: R = Replace. I = Inspect, and correct or replace as necessary, L = Lubricate,T=Tighten.

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page km x 1,000 10 20 30 40 50 60 70 80 90

(Miles x 1,000) (6) (12) (18) (24) (30) (36) (42) (48) (54)

CHASSIS AND BODY Underhood and under vehicle

Brake & clutch ¯uid (For level & leaks).I I I MA-23, 20

Brake ¯uid.R MA-24

Brake booster vacuum hoses, connections & check valve I MA-24

Power steering ¯uid & lines (For level & leaks) I I I MA-26

Brake & clutch systemsI I I MA-24, 20

Manual transmission oil (For leaks) I I I MA-20

Manual transmission oilR MA-20

Transfer ¯uidI R I MA-21

Limited slip differential (LSD) gear oil (For level & leaks).*1 I R I MA-22

Steering gear & linkage, axle & suspension parts, propeller shaft & exhaust system.I I I MA-26, 20 *2

Geasing points of propeller shaft L L L MA-21

Drive shafts & steering damper.III*3

Body mounting bolts & nutsTTT*4

Outside and Inside

Wheel alignment (If necessary, rotate & balance wheels) I I I MA-25, *5

Brake pads, discs & other brake components.I I I MA-24

Front wheel bearing greaseI R I MA-22

Axle joint in knuckle ¯angeL MA-23

Free running hub greaseI I I MA-23

Headlamp aimingIII*6

Foot brake, parking brake & clutch (For free play, stroke & operation) I I I *7

Ventilation air ®lterRRR*8

Body corrosionAnnually MA-28

Air bag systemSee NOTE (1) *9

NOTE: (1) Inspect after 10 years, then every 2 years.

(2) Maintenance items with ``.'' should be performed more frequently according to ``Maintenance Under Severe Driv-

ing Conditions''.

*1: Including differential gear with differential lock

*2: ``Front Axle and Front Suspension Parts'' in FA section, ``Rear Axle and Rear Suspension Parts'' in RA section

*3: ``FRONT AXLE Ð Drive Shaft'' in FA section

*4: ``CAB BODY'' in BT section

*5: ``Front Wheel Alignment'' in FA section

*6: ``Aiming Adjustment'' in EL section

*7: ``Brake Pedal and Bracket'' in BR section, ``Adjusting Clutch Pedal'' in CL section

*8: ``Ventilation air ®lter'' in HA section

*9: ``Maintenance Items'' in RS section

PERIODIC MAINTENANCE

Chassis and Body Services (Cont'd)

MA-7

Page 996 of 1226

6. Install all injection nozzles with Tool and securely connect fuel

spill tube and delivery tubes.

7. Bleed air from fuel system and check for fuel leakage with

engine running.

Injection nozzle to cylinder head:

:59-69Nzm (6.0 - 7.0 kg-m, 43 - 51 ft-lb)

Spill tube nut:

:39-49Nzm (4.0 - 5.0 kg-m, 29 - 36 ft-lb)

Injection tube:

:20-25Nzm (2.2 - 2.5 kg-m, 16 - 18 ft-lb)

Checking Idle Speed

Inspection should be carried out with gears in ``Neutral'' and

with air conditioner and other electrical loads off.

1. Warm up engine until engine coolant temperature indicator

points to the middle of gauge.

2. Attach a diesel tachotester's pick-up to No. 1 fuel injection tube.

3. Race engine two or three times and check idle speed.

Idle speed:

Unit: rpm

MT 750+50

þ0

Timing Belt Replacement

Refer to EM section.

ENGINE MAINTENANCE

Checking Injection Nozzle (Cont'd)

MA-19

Page 1038 of 1226

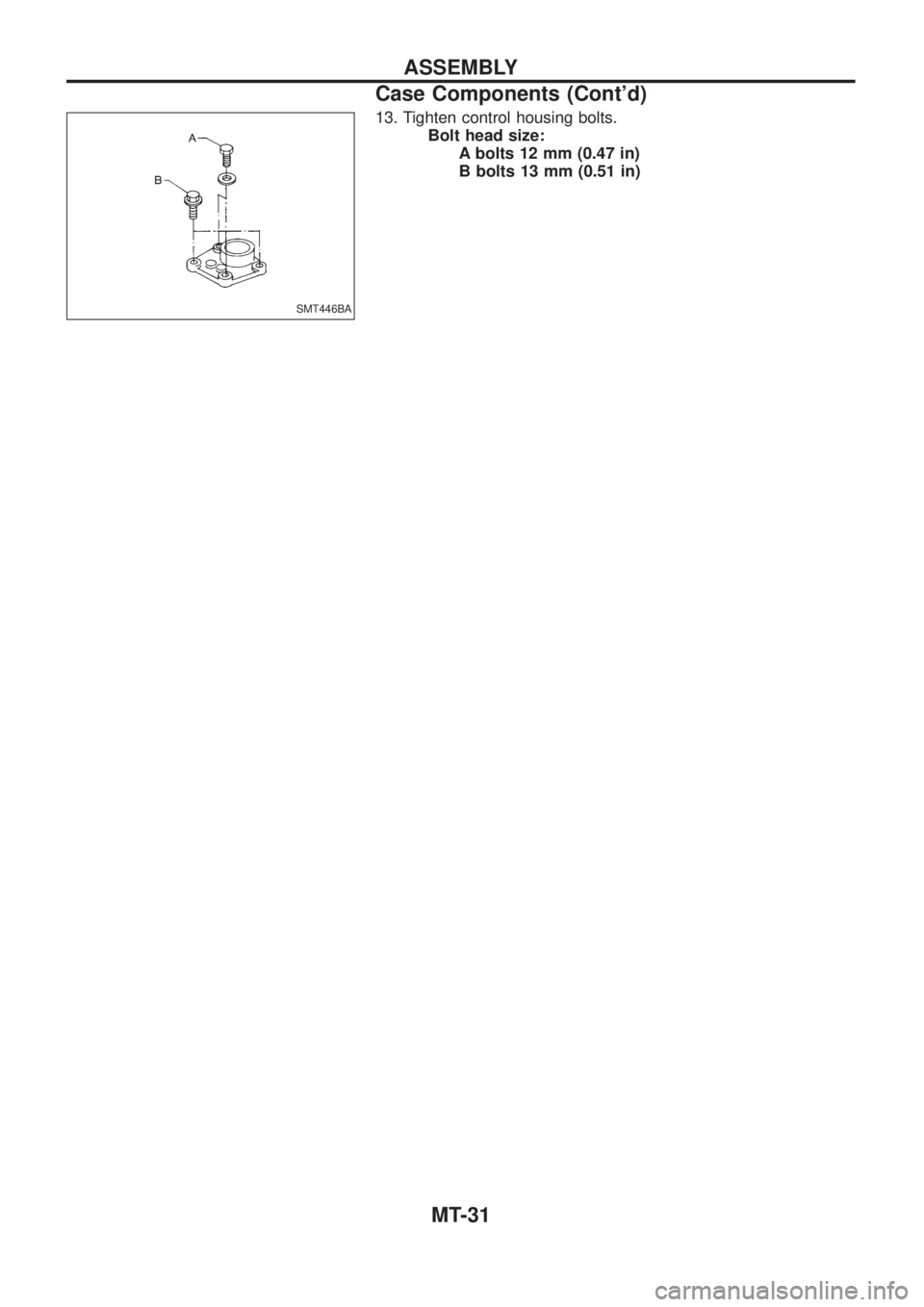

13. Tighten control housing bolts.

Bolt head size:

A bolts 12 mm (0.47 in)

B bolts 13 mm (0.51 in)

SMT446BA

ASSEMBLY

Case Components (Cont'd)

MT-31

Page 1069 of 1226

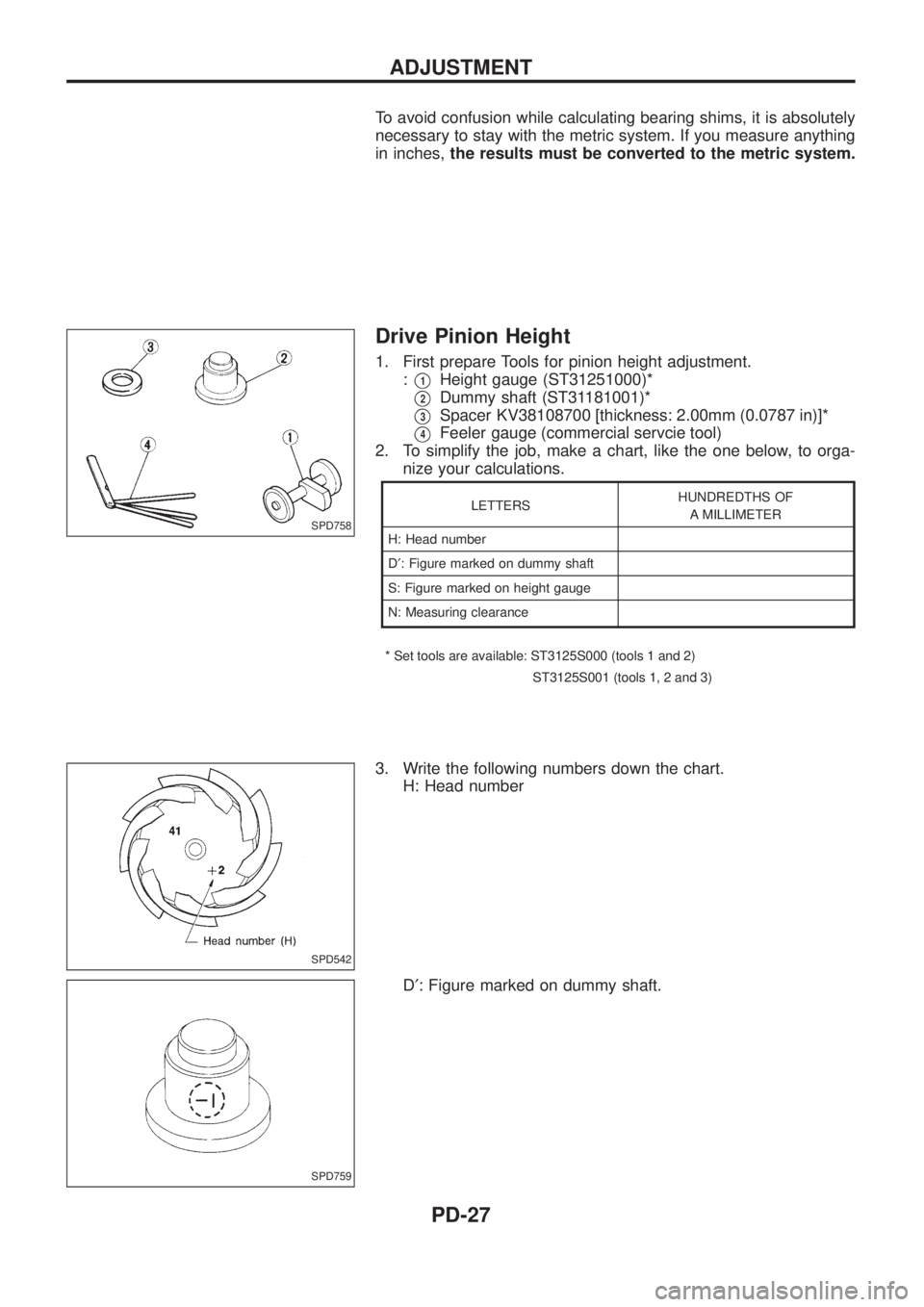

To avoid confusion while calculating bearing shims, it is absolutely

necessary to stay with the metric system. If you measure anything

in inches,the results must be converted to the metric system.

Drive Pinion Height

1. First prepare Tools for pinion height adjustment.

:

V1Heightgauge(ST31251000)*

V2Dummyshaft(ST31181001)*

V3SpacerKV38108700 [thickness: 2.00mm (0.0787 in)]*

V4Feelergauge (commercial servcie tool)

2. To simplify the job, make a chart, like the one below, to orga- nize your calculations.

LETTERS HUNDREDTHS OF

A MILLIMETER

H: Head number

D ¢: Figure marked on dummy shaft

S: Figure marked on height gauge

N:Measuringclearance

* Set tools are available: ST3125S000 (tools 1 and 2) ST3125S001 (tools 1, 2 and 3)

3. Write the following numbers down the chart.H: Head number

D¢: Figure marked on dummy shaft.

SPD758

SPD542

SPD759

ADJUSTMENT

PD-27

Page 1073 of 1226

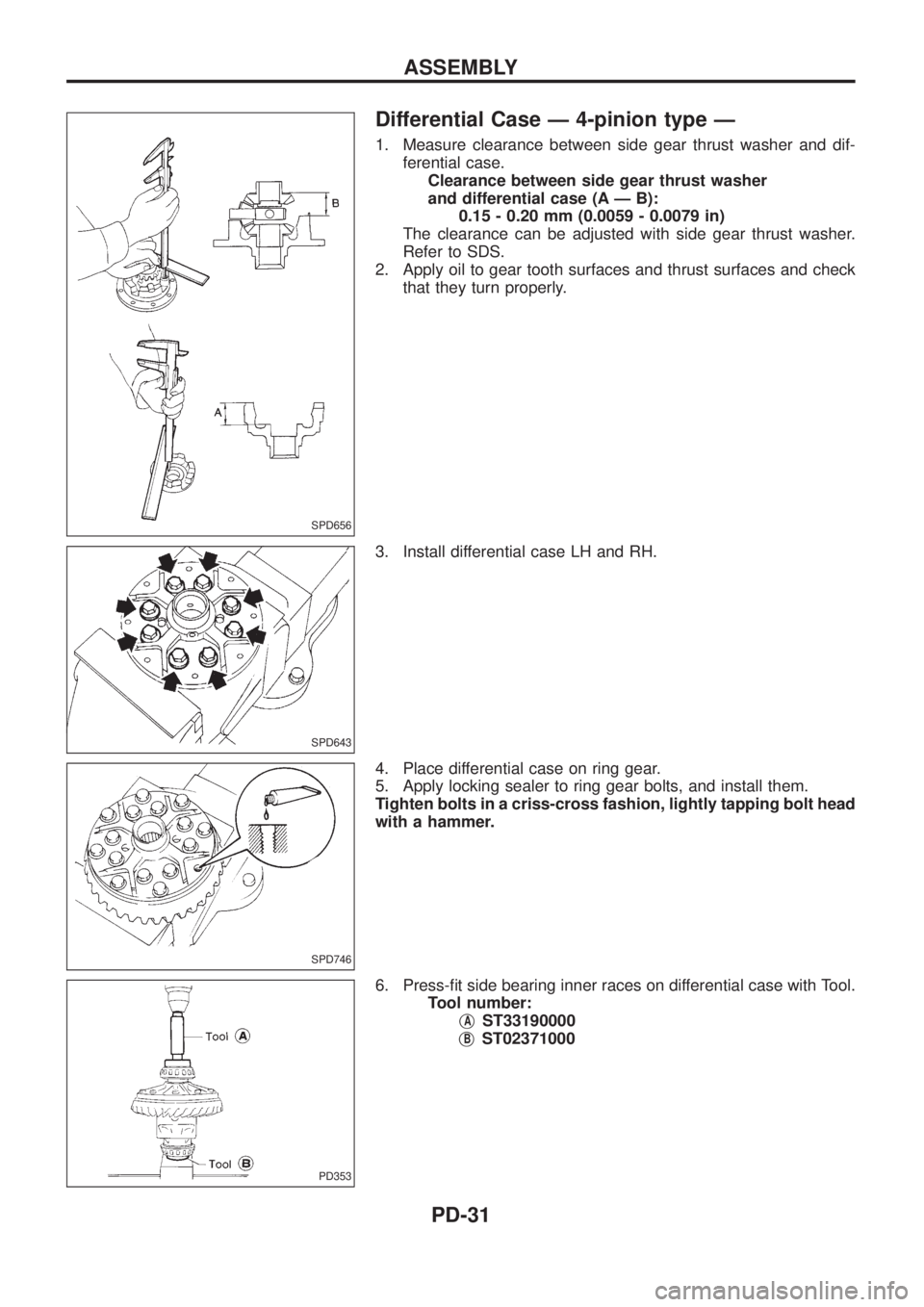

Differential Case Ð 4-pinion type Ð

1. Measure clearance between side gear thrust washer and dif-

ferential case.

Clearance between side gear thrust washer

and differential case (A Ð B):

0.15 - 0.20 mm (0.0059 - 0.0079 in)

The clearance can be adjusted with side gear thrust washer.

Refer to SDS.

2. Apply oil to gear tooth surfaces and thrust surfaces and check

that they turn properly.

3. Install differential case LH and RH.

4. Place differential case on ring gear.

5. Apply locking sealer to ring gear bolts, and install them.

Tighten bolts in a criss-cross fashion, lightly tapping bolt head

with a hammer.

6. Press-®t side bearing inner races on differential case with Tool.

Tool number:

j

AST33190000

j

BST02371000

SPD656

SPD643

SPD746

PD353

ASSEMBLY

PD-31