NISSAN PATROL 2006 Service Manual

PATROL 2006

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57368/w960_57368-0.png

NISSAN PATROL 2006 Service Manual

Trending: radiator cap, spare wheel, Heating, coolant level, changing engine coolant, air suspension, roof

Page 761 of 1226

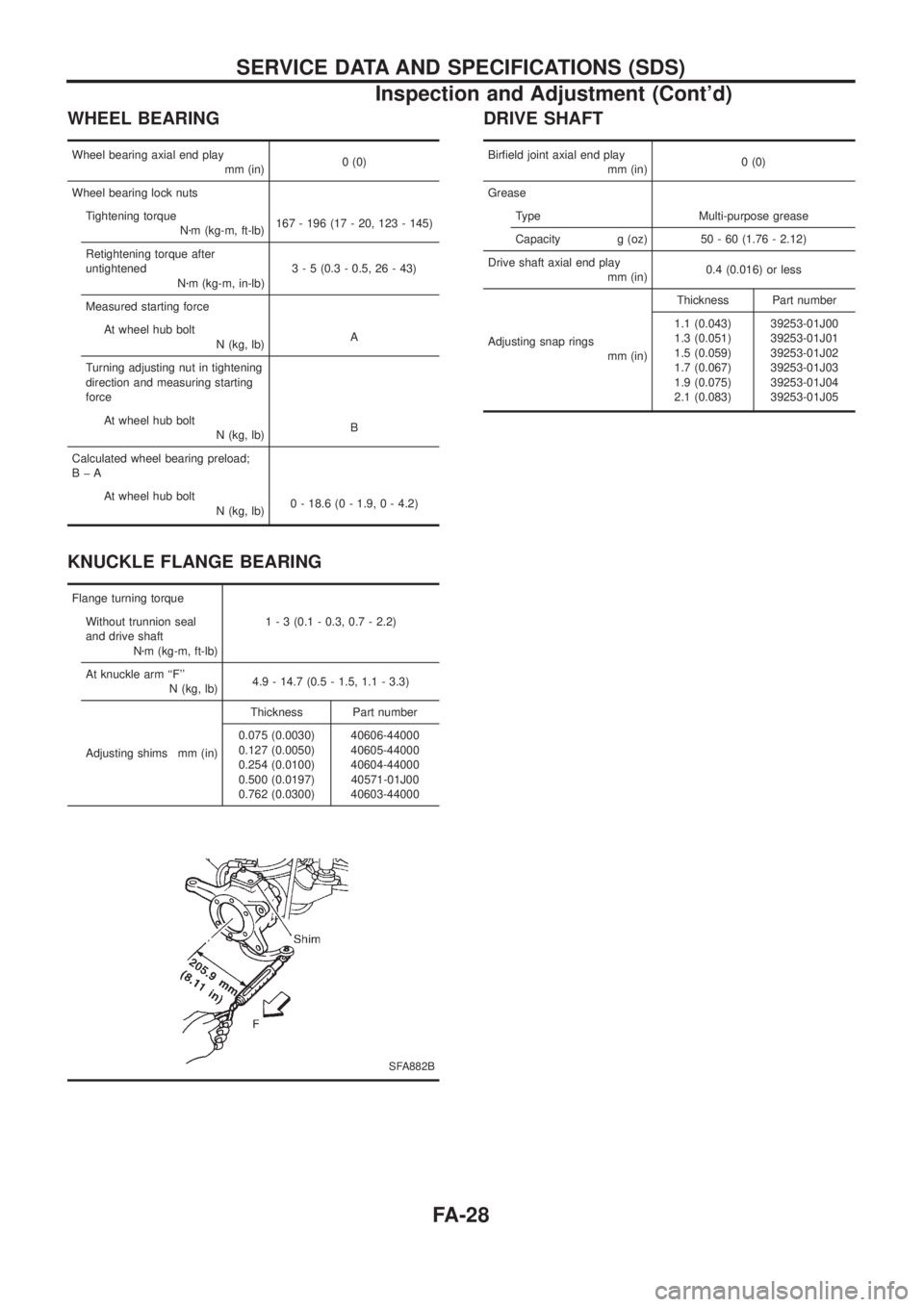

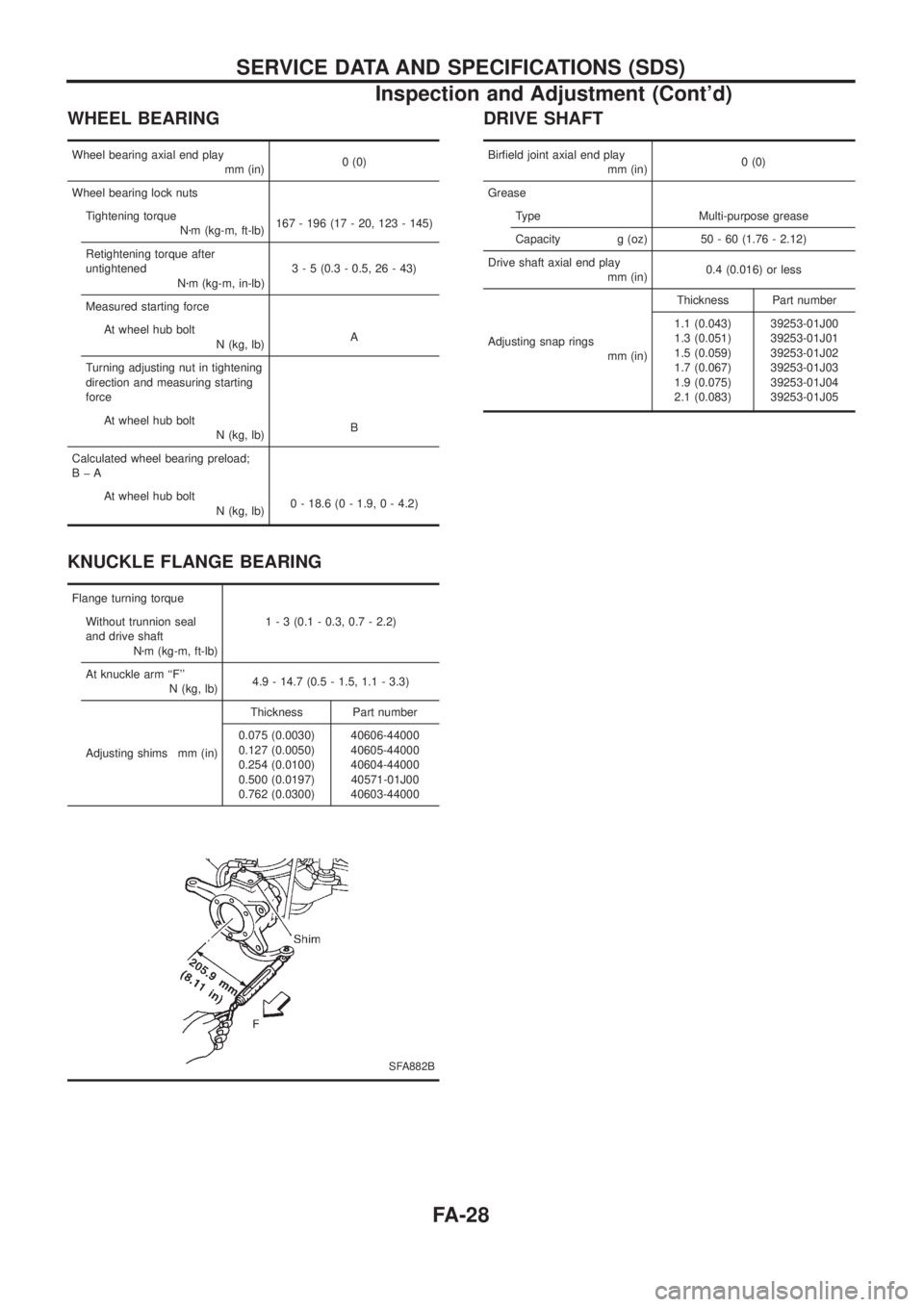

WHEEL BEARING

Wheel bearing axial end play

mm (in)0 (0)

Wheel bearing lock nuts

Tightening torque

Nzm (kg-m, ft-lb)167 - 196 (17 - 20, 123 - 145)

Retightening torque after

untightened

Nzm (kg-m, in-lb)3 - 5 (0.3 - 0.5, 26 - 43)

Measured starting force

At wheel hub bolt

N (kg, lb)A

Turning adjusting nut in tightening

direction and measuring starting

force

At wheel hub bolt

N (kg, lb)B

Calculated wheel bearing preload;

BþA

At wheel hub bolt

N (kg, lb)0 - 18.6 (0 - 1.9, 0 - 4.2)

KNUCKLE FLANGE BEARING

Flange turning torque

Without trunnion seal

and drive shaft

Nzm (kg-m, ft-lb)1 - 3 (0.1 - 0.3, 0.7 - 2.2)

At knuckle arm ``F''

N (kg, lb)4.9 - 14.7 (0.5 - 1.5, 1.1 - 3.3)

Adjusting shims mm (in)Thickness Part number

0.075 (0.0030)

0.127 (0.0050)

0.254 (0.0100)

0.500 (0.0197)

0.762 (0.0300)40606-44000

40605-44000

40604-44000

40571-01J00

40603-44000

SFA882B

DRIVE SHAFT

Bir®eld joint axial end play

mm (in)0 (0)

Grease

Type Multi-purpose grease

Capacity g (oz) 50 - 60 (1.76 - 2.12)

Drive shaft axial end play

mm (in)0.4 (0.016) or less

Adjusting snap rings

mm (in)Thickness Part number

1.1 (0.043)

1.3 (0.051)

1.5 (0.059)

1.7 (0.067)

1.9 (0.075)

2.1 (0.083)39253-01J00

39253-01J01

39253-01J02

39253-01J03

39253-01J04

39253-01J05

SERVICE DATA AND SPECIFICATIONS (SDS)

Inspection and Adjustment (Cont'd)

FA-28

Page 762 of 1226

ACCELERATOR CONTROL, FUEL &

EXHAUST SYSTEMS

SECTION

FE

CONTENTS

ACCELERATOR CONTROL SYSTEM...........................1

Accelerator Control System .........................................1FUEL SYSTEM................................................................2

EXHAUST SYSTEM........................................................3

FE

Page 763 of 1226

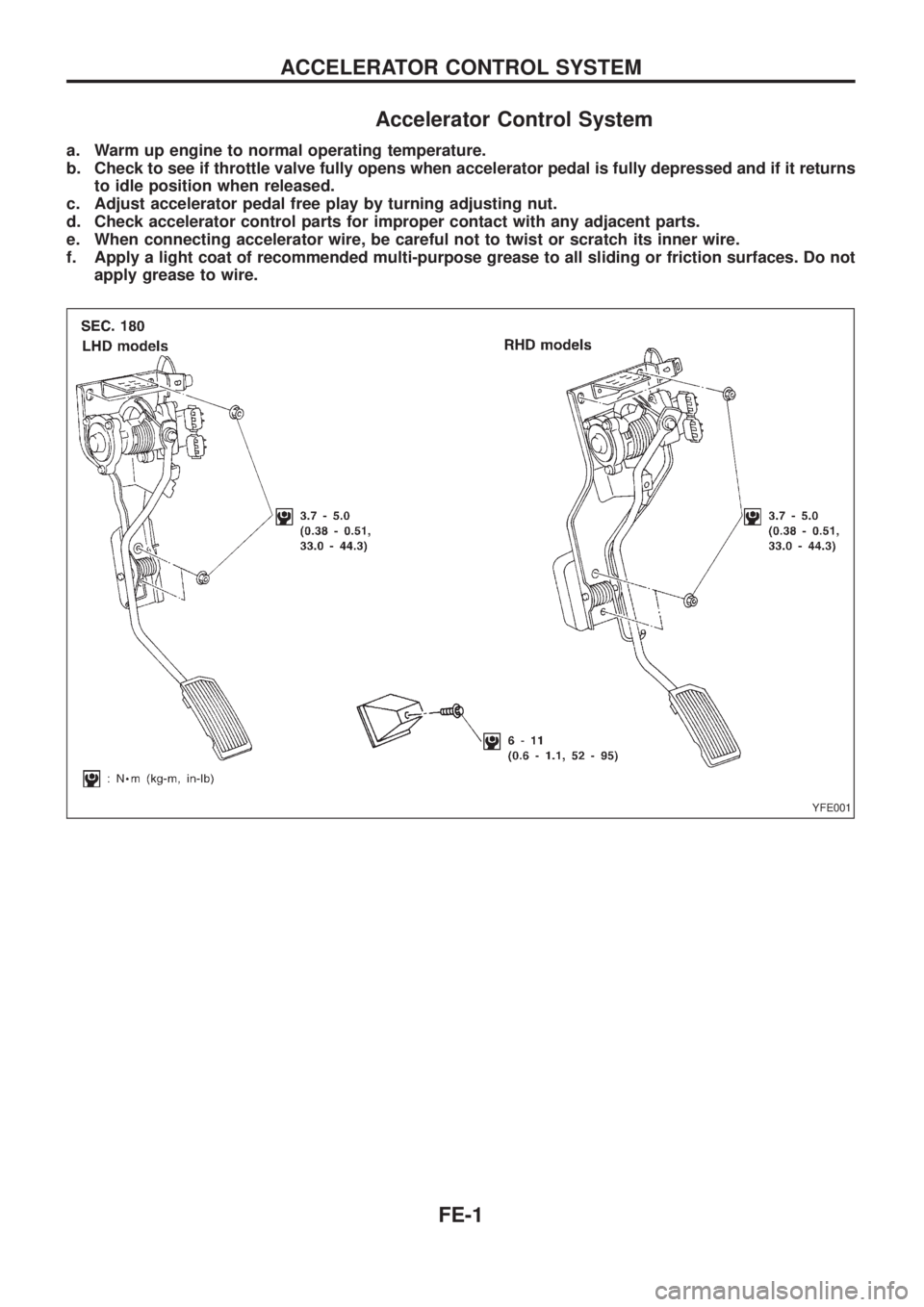

Accelerator Control System

a. Warm up engine to normal operating temperature.

b. Check to see if throttle valve fully opens when accelerator pedal is fully depressed and if it returns

to idle position when released.

c. Adjust accelerator pedal free play by turning adjusting nut.

d. Check accelerator control parts for improper contact with any adjacent parts.

e. When connecting accelerator wire, be careful not to twist or scratch its inner wire.

f. Apply a light coat of recommended multi-purpose grease to all sliding or friction surfaces. Do not

apply grease to wire.

YFE001

ACCELERATOR CONTROL SYSTEM

FE-1

Page 764 of 1226

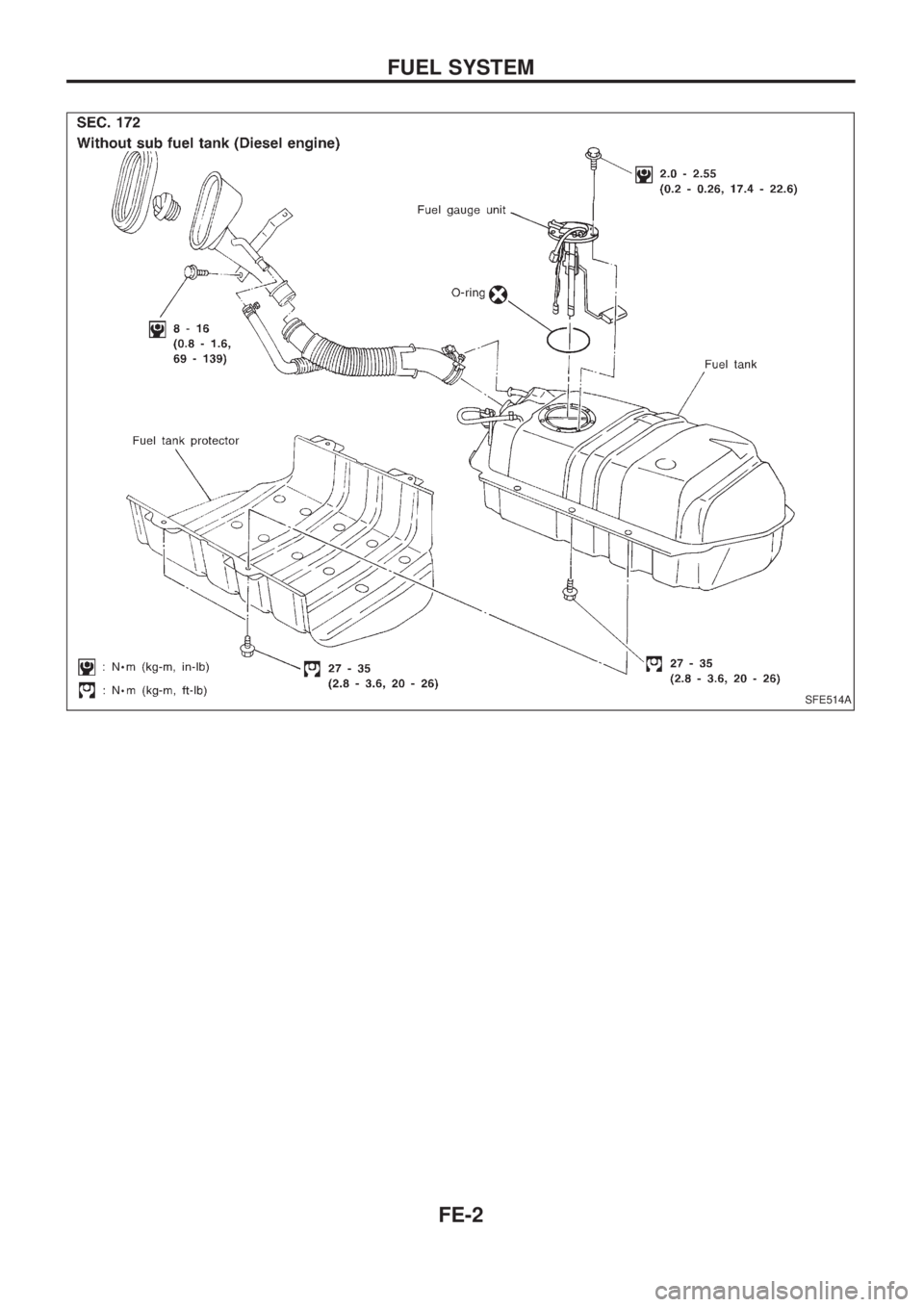

Page 765 of 1226

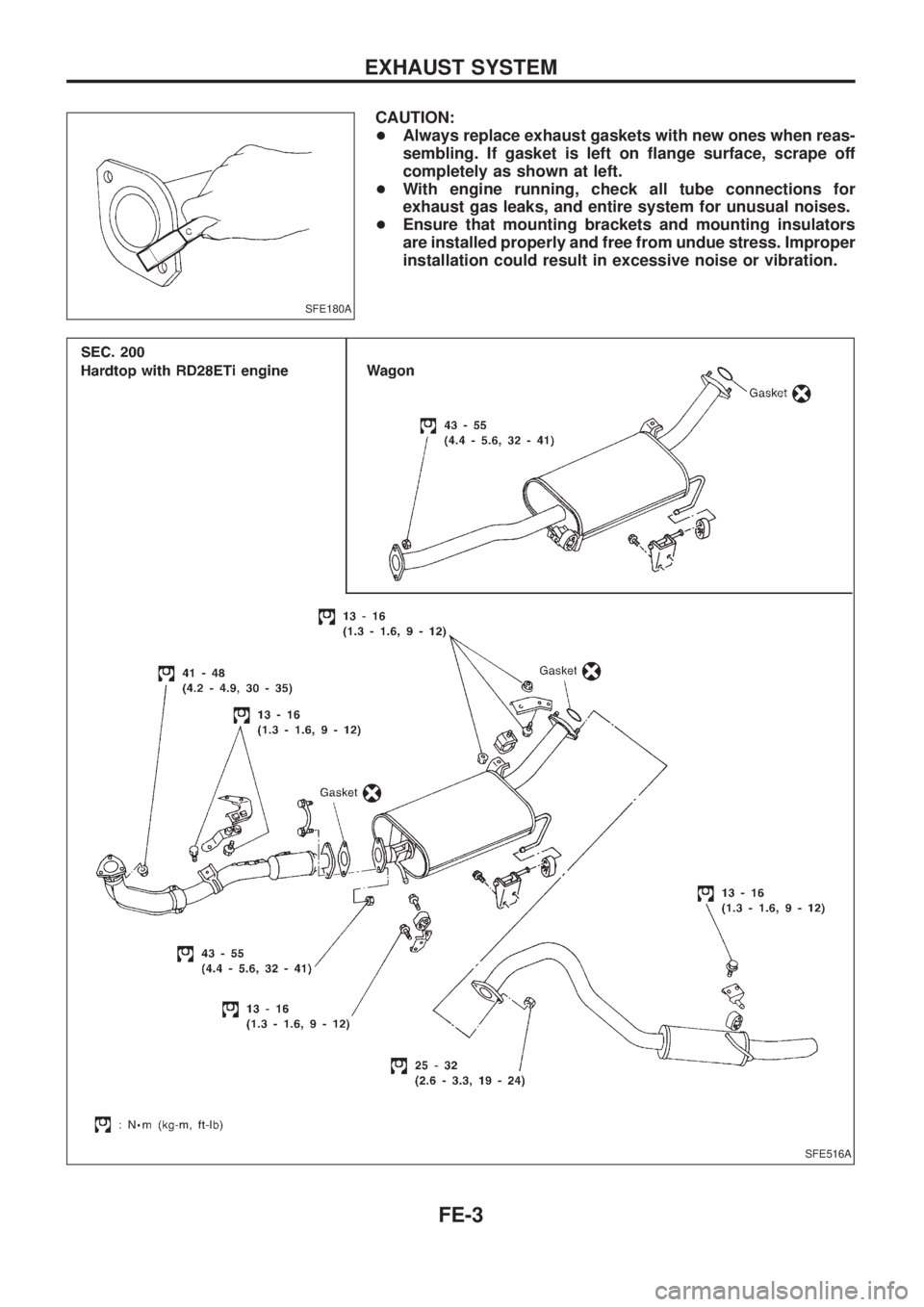

CAUTION:

+Always replace exhaust gaskets with new ones when reas-

sembling. If gasket is left on ¯ange surface, scrape off

completely as shown at left.

+With engine running, check all tube connections for

exhaust gas leaks, and entire system for unusual noises.

+Ensure that mounting brackets and mounting insulators

are installed properly and free from undue stress. Improper

installation could result in excessive noise or vibration.

SFE180A

SFE516A

EXHAUST SYSTEM

FE-3

Page 766 of 1226

PLEASE HELP US TO IMPROVE THIS

SERVICE MANUAL ON CD!

Your comments are important to NISSAN and will help us to improve our

Service Manuals on CD. Use this form to report any issues or comments you

may have regarding this Service Manual publication.

Please print this form and type or print your comments below. Mail or fax to:

NISSAN EUROPE S.A.S.

S320 Service Engineering

2, Avenue de Denis Papin

ZIPEC - F92350 Le Plessis Robinson

France

Fax: + 33(0)141071681

SERVICE MANUAL: Model:Language:

Publication Number:

Please describe any issues or problems in detail:

Page number(s):

Note: Please include a copy of each page, marked with your comments.

Is the organization of the manual clear and easy to follow? (circle your answer) YES NO

Please comment:

What information should be included in NISSAN Service Manuals to better support you in

servicing or repairing customer vehicles?

Date :

Your Name :Position :

Dealer :Dealer No. :

Address :

City :Country :

Telephone :

Fax :

E-mail :

Page 767 of 1226

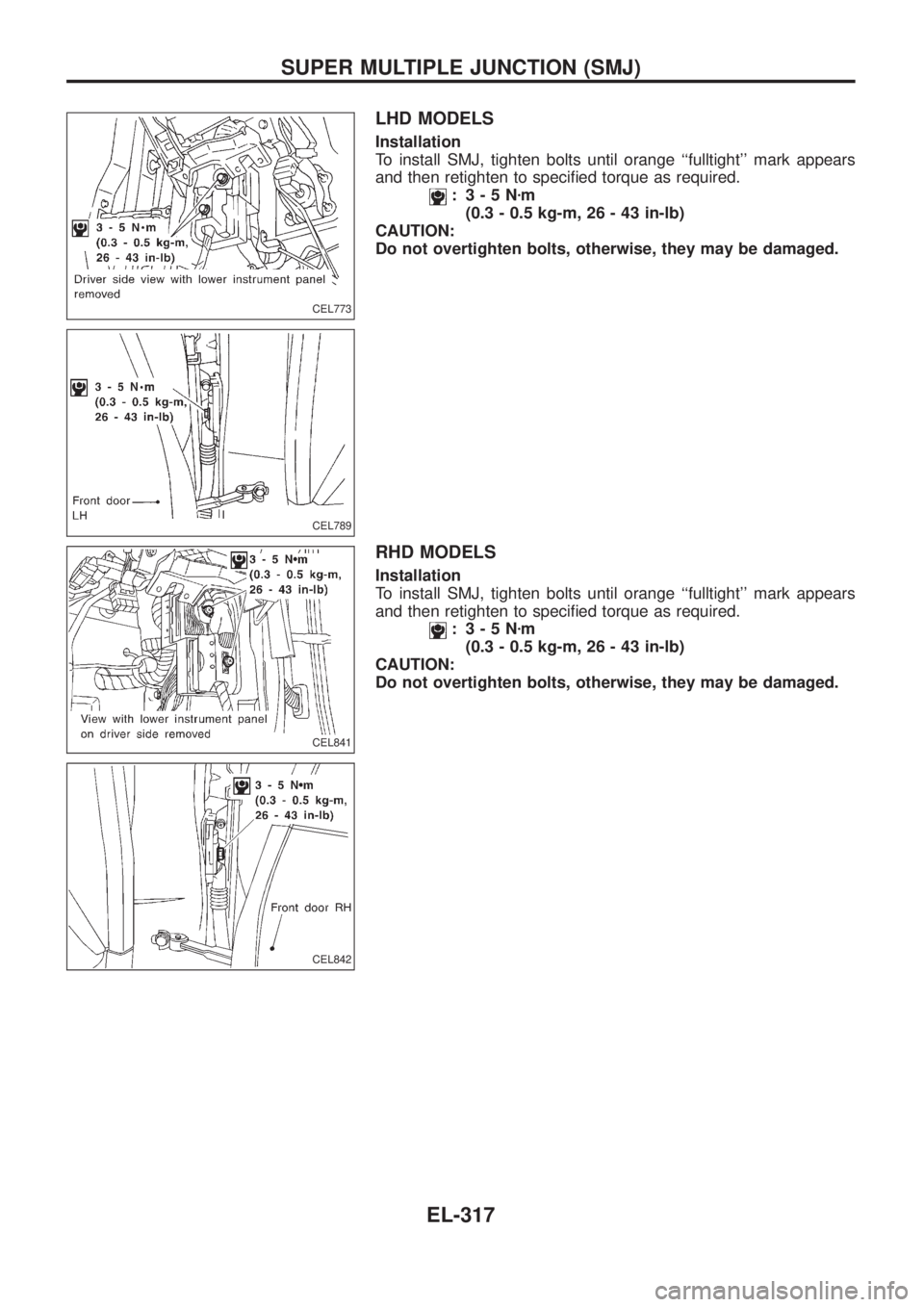

LHD MODELS

Installation

To install SMJ, tighten bolts until orange ``fulltight'' mark appears

and then retighten to speci®ed torque as required.

: 3-5Nzm

(0.3 - 0.5 kg-m, 26 - 43 in-lb)

CAUTION:

Do not overtighten bolts, otherwise, they may be damaged.

RHD MODELS

Installation

To install SMJ, tighten bolts until orange ``fulltight'' mark appears

and then retighten to speci®ed torque as required.

: 3-5Nzm

(0.3 - 0.5 kg-m, 26 - 43 in-lb)

CAUTION:

Do not overtighten bolts, otherwise, they may be damaged.

CEL773

CEL789

CEL841

CEL842

SUPER MULTIPLE JUNCTION (SMJ)

EL-317

Page 768 of 1226

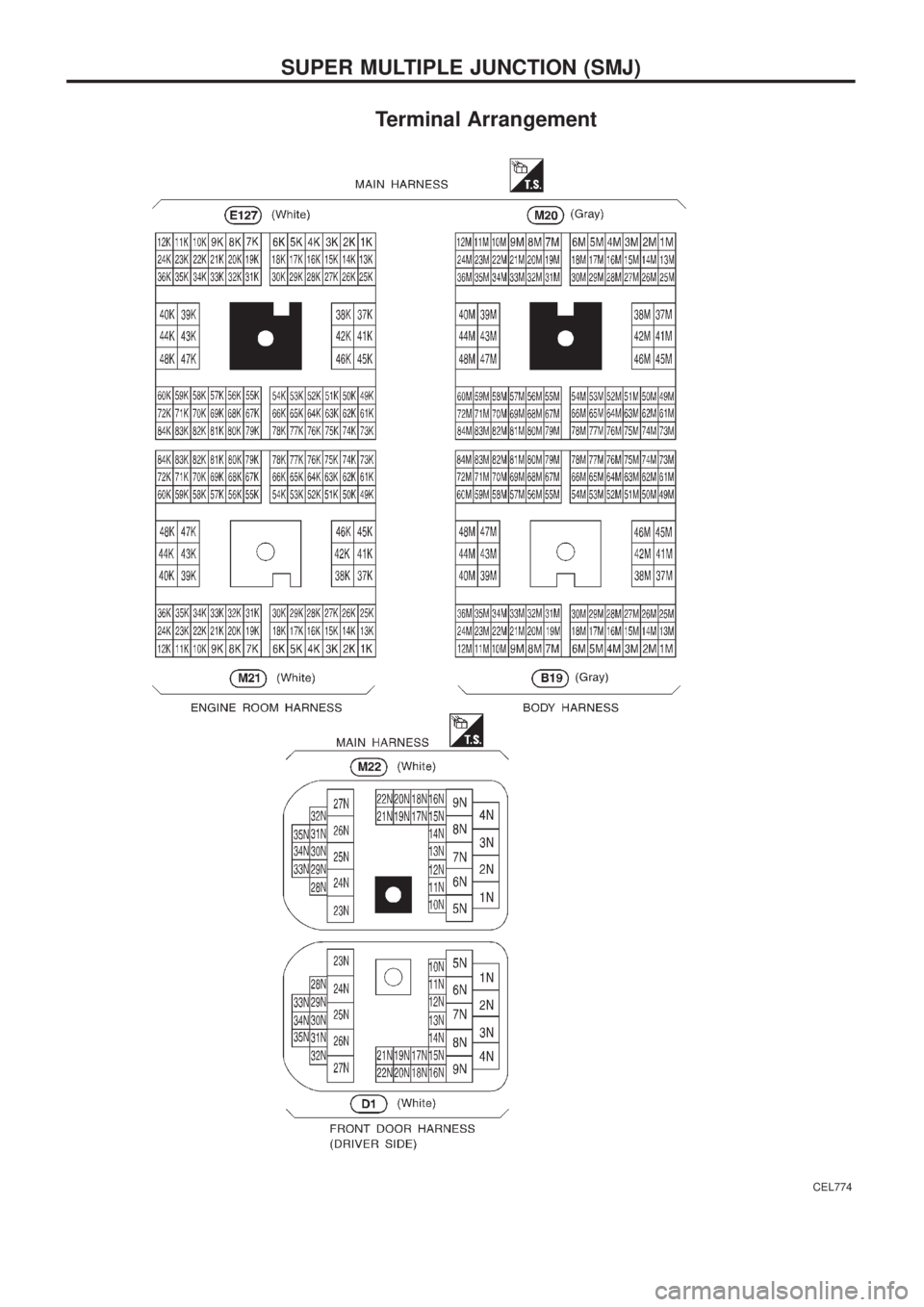

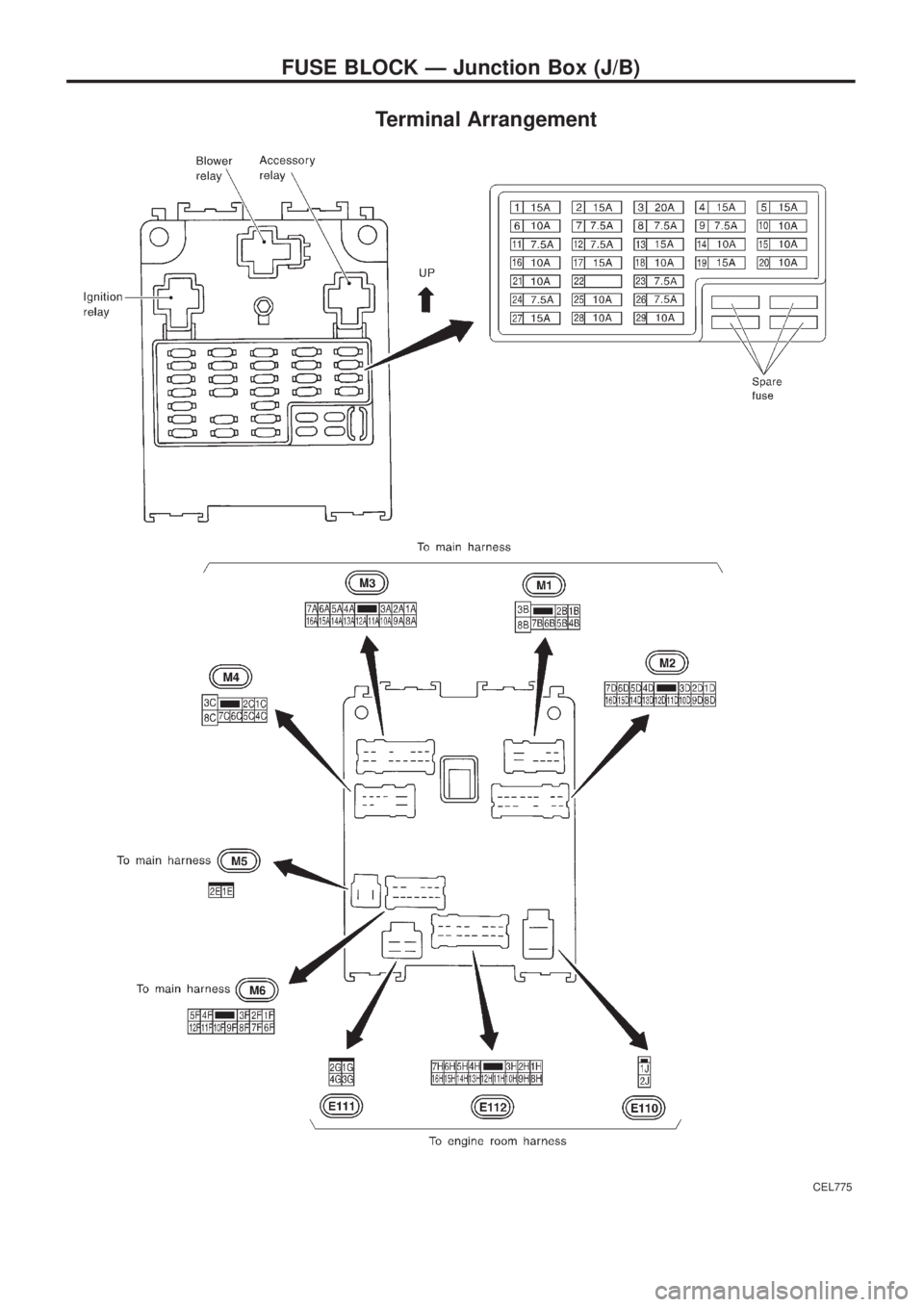

Terminal Arrangement

CEL774

SUPER MULTIPLE JUNCTION (SMJ)

Page 769 of 1226

Terminal Arrangement

CEL775

FUSE BLOCK Ð Junction Box (J/B)

Page 770 of 1226

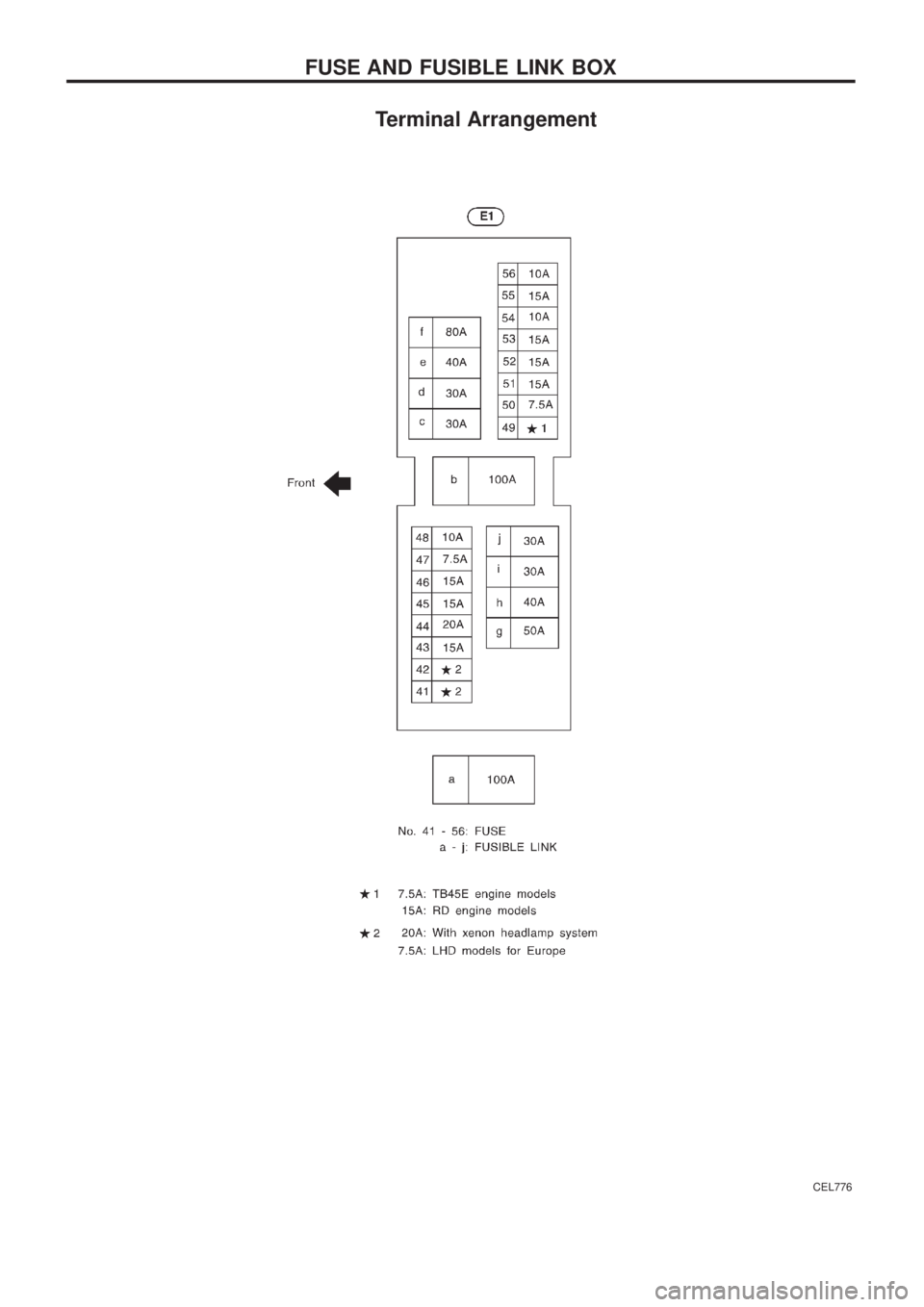

Terminal Arrangement

CEL776

FUSE AND FUSIBLE LINK BOX

Trending: relay, remove seats, alternator belt, torque, wheel bolts, alternator, headlights