Break NISSAN PATROL 2006 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 157 of 1226

Precautions

+Before connecting or disconnecting the ECM harness

connector, turn ignition switch OFF and disconnect nega-

tive battery terminal. Failure to do so may damage the ECM

because battery voltage is applied to ECM even if ignition

switch is turned off.

+When connecting ECM harness connector, tighten secur-

ing bolt until the gap between orange indicators disap-

pears.

: 3.0 - 5.0 Nzm (0.3 - 0.5 kg-m, 26 - 43 in-lb)

+When connecting or disconnecting pin connectors into or

from ECM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on ECM

pin terminal, when connecting pin connectors.

+Before replacing ECM, perform Terminals and Reference

Value inspection and make sure ECM functions properly.

Refer to EC-54.

+If MIL illuminates or blinks irregularly when engine is

running, water may have accumulated in fuel ®lter. Drain

water from fuel ®lter. If this does not correct the problem,

perform speci®ed trouble diagnostic procedures.

+After performing each TROUBLE DIAGNOSIS, perform

``OVERALL FUNCTION CHECK'' or ``DTC (Diagnostic

Trouble Code) CONFIRMATION PROCEDURE''.

The DTC should not be displayed in the ``DTC CONFIRMA-

TION PROCEDUREº if the repair is completed. The ``OVER-

ALL FUNCTION CHECK'' should be a good result if the

repair is completed.

SEF289H

SEF308Q

SEF291H

MEF040D

SEF051P

PRECAUTIONS AND PREPARATION

EC-6

Page 342 of 1226

ELECTRICAL SYSTEM

SECTION

EL

When you read wiring diagrams:

+Read GI section, ``HOW TO READ WIRING DIAGRAMS''.

When you perform trouble diagnoses, read GI section, ``HOW TO FOLLOW FLOW

CHART IN TROUBLE DIAGNOSES'' and ``HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT''.

+Check for any service bulletins before servicing the vehicle.

CONTENTS

PRECAUTIONS...............................................................1

Supplemental Restraint System (SRS) ``AIR

BAG'' and ``SEAT BELT PRE-TENSIONER''...............1

HARNESS CONNECTOR................................................2

Description ...................................................................2

STANDARDIZED RELAY................................................3

Description ...................................................................3

POWER SUPPLY ROUTING...........................................5

Schematic ....................................................................5

Wiring Diagram Ð POWER Ð....................................6

Fuse ...........................................................................14

Fusible Link................................................................14

Circuit Breaker Inspection .........................................14

GROUND DISTRIBUTION/LHD MODELS....................15

Engine Room Harness ..............................................15

Main Harness.............................................................19

Body Harness ............................................................22

Body No. 2 Harness ..................................................23

Back Door and Rear Window Defogger Harness .....24

Room Lamp Harness.................................................25

GROUND DISTRIBUTION/RHD MODELS...................26

Engine Room Harness ..............................................26

Main Harness.............................................................30

Body Harness ............................................................33

Body No. 2 Harness ..................................................34

Back Door and Rear Window Defogger Harness .....35

Room Lamp Harness.................................................36

BATTERY.......................................................................37

How to Handle Battery ..............................................37

Battery Test and Charging Chart ...............................40

Service Data and Speci®cations (SDS).....................44

STARTING SYSTEM.....................................................45

Wiring Diagram Ð START Ð ....................................45Trouble Diagnoses.....................................................46

Construction ...............................................................47

Removal and Installation ...........................................47

Inspection...................................................................47

Assembly ...................................................................50

Service Data and Speci®cations (SDS).....................51

CHARGING SYSTEM....................................................52

Wiring Diagram Ð CHARGE Ð ................................52

Trouble Diagnoses.....................................................53

Construction ...............................................................54

Removal and Installation ...........................................54

Disassembly...............................................................54

Inspection...................................................................55

Assembly ...................................................................56

Service Data and Speci®cations (SDS).....................56

COMBINATION SWITCH...............................................57

Check .........................................................................57

Replacement ..............................................................58

STEERING SWITCH......................................................59

Check .........................................................................59

HEADLAMP Ð Conventional Type Ð........................61

Wiring Diagram Ð H/LAMP Ð ..................................61

Trouble Diagnoses.....................................................62

Bulb Replacement .....................................................63

Aiming Adjustment .....................................................63

HEADLAMP Ð Daytime Light System Ð..................65

System Description ....................................................65

Wiring Diagram Ð DTRL Ð ......................................67

Trouble Diagnoses.....................................................69

Bulb Replacement .....................................................69

Aiming Adjustment .....................................................69

HEADLAMP Ð Headlamp Aiming Control Ð............70

System Description ....................................................70

EL

Page 348 of 1226

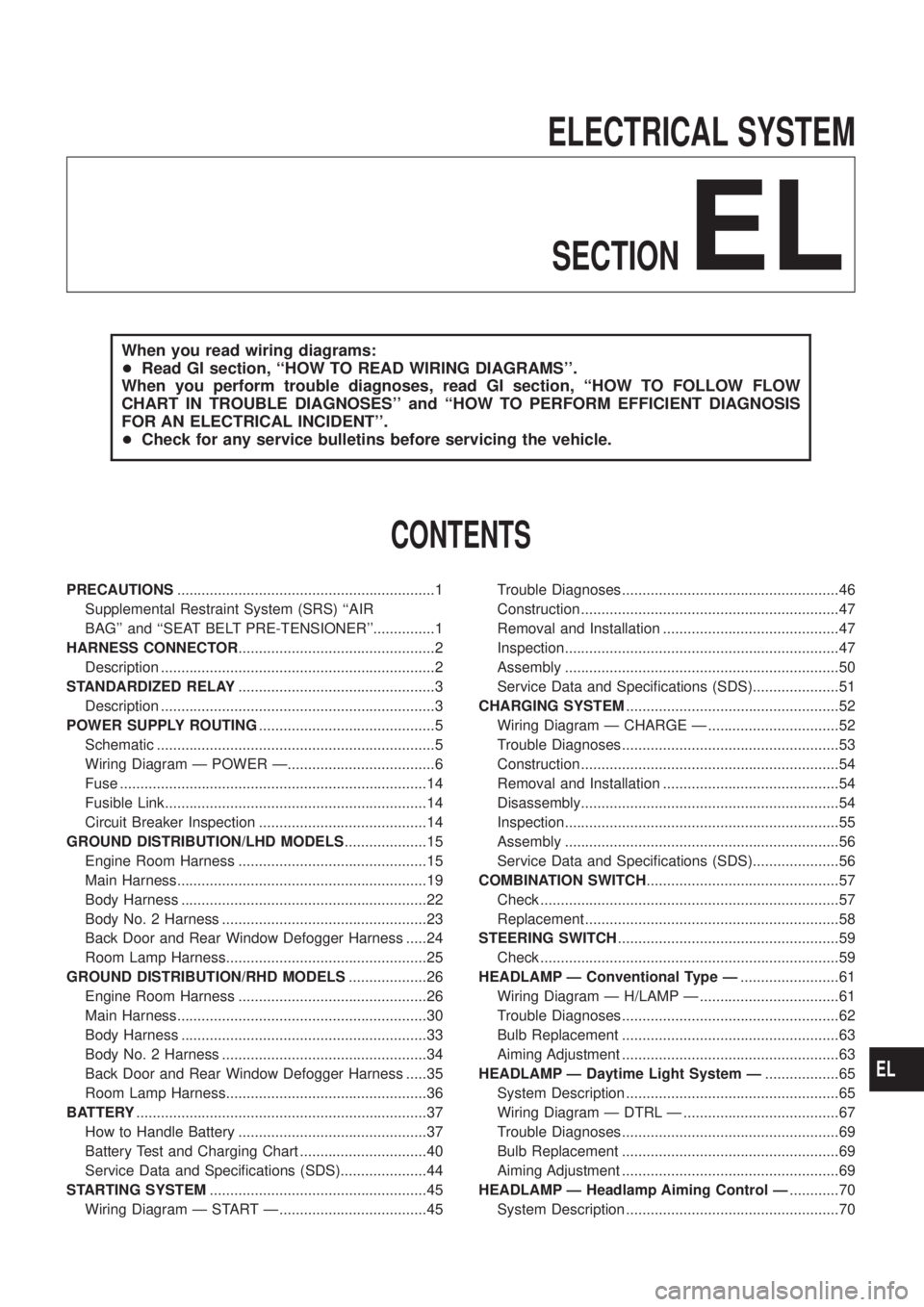

Description

NORMAL OPEN, NORMAL CLOSED AND MIXED TYPE RELAYS

Relays can mainly be divided into three types: normal open, normal closed and mixed type relays.

TYPE OF STANDARDIZED RELAYS

1M .................... 1 Make 2M .................... 2 Make

1T .................... 1 Transfer 1Mz1B .................... 1 Make 1 Break

SEL881H

SEL882H

STANDARDIZED RELAY

EL-3

Page 359 of 1226

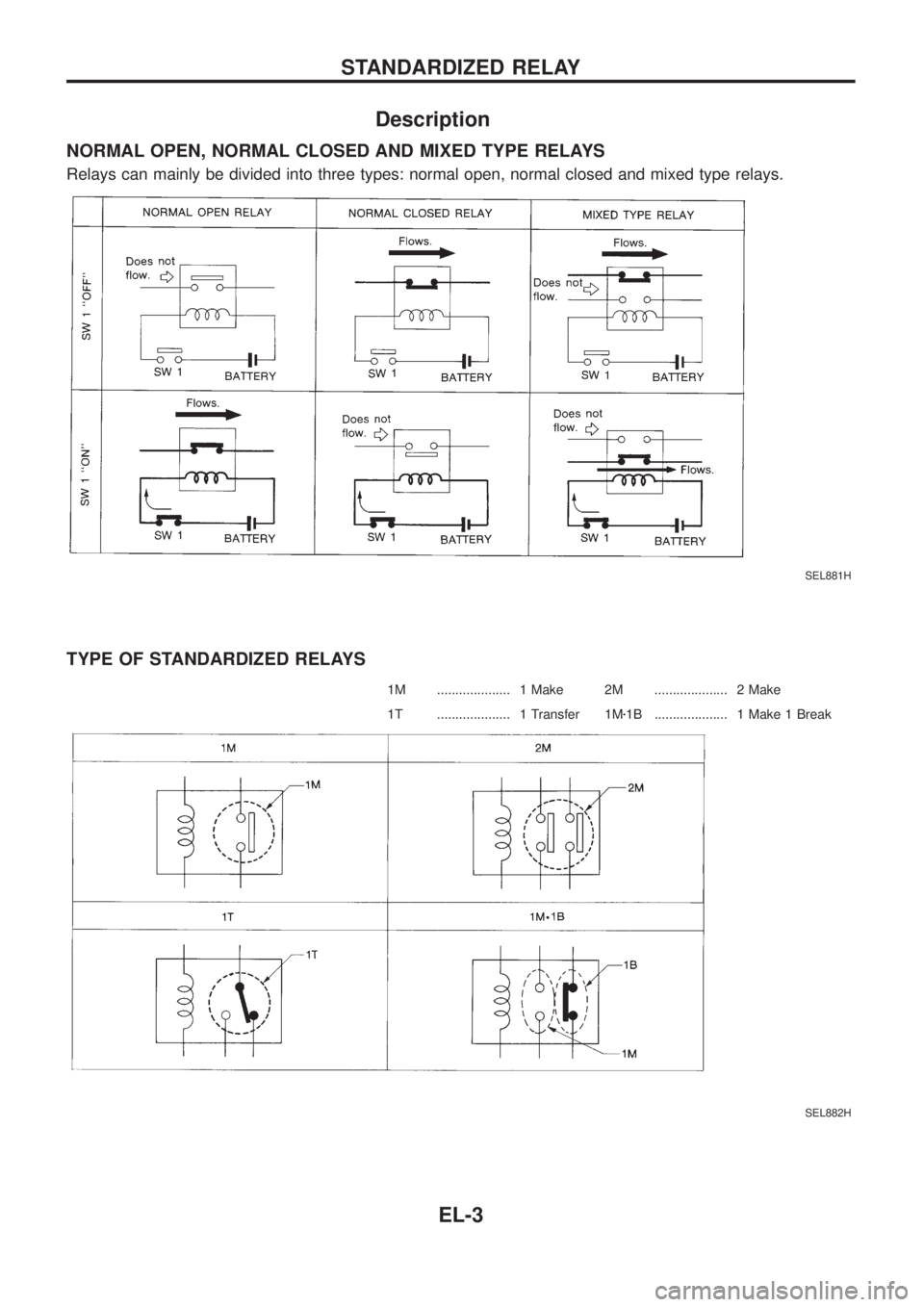

Fuse

a. If fuse is blown, be sure to eliminate cause of problem

before installing new fuse.

b. Use fuse of speci®ed rating. Never use fuse of more than

speci®ed rating.

c. Do not partially install fuse; always insert it into fuse

holder properly.

d. Remove fuse for ``ELECTRICAL PARTS (BAT)'' if vehicle is

not used for a long period of time.

Fusible Link

A melted fusible link can be detected either by visual inspection or

by feeling with ®nger tip. If its condition is questionable, use circuit

tester or test lamp.

CAUTION:

+If fusible link should melt, it is possible that critical circuit

(power supply or large current carrying circuit) is shorted.

In such a case, carefully check and eliminate cause of

problem.

+Never wrap outside of fusible link with vinyl tape. Impor-

tant: Never let fusible link touch any other wiring harness,

vinyl or rubber parts.

Circuit Breaker Inspection

For example, when current is 30A, the circuit is broken within 8 to

20 seconds.

CEL083

MEL944F

SBF284E

POWER SUPPLY ROUTING

EL-14

Page 484 of 1226

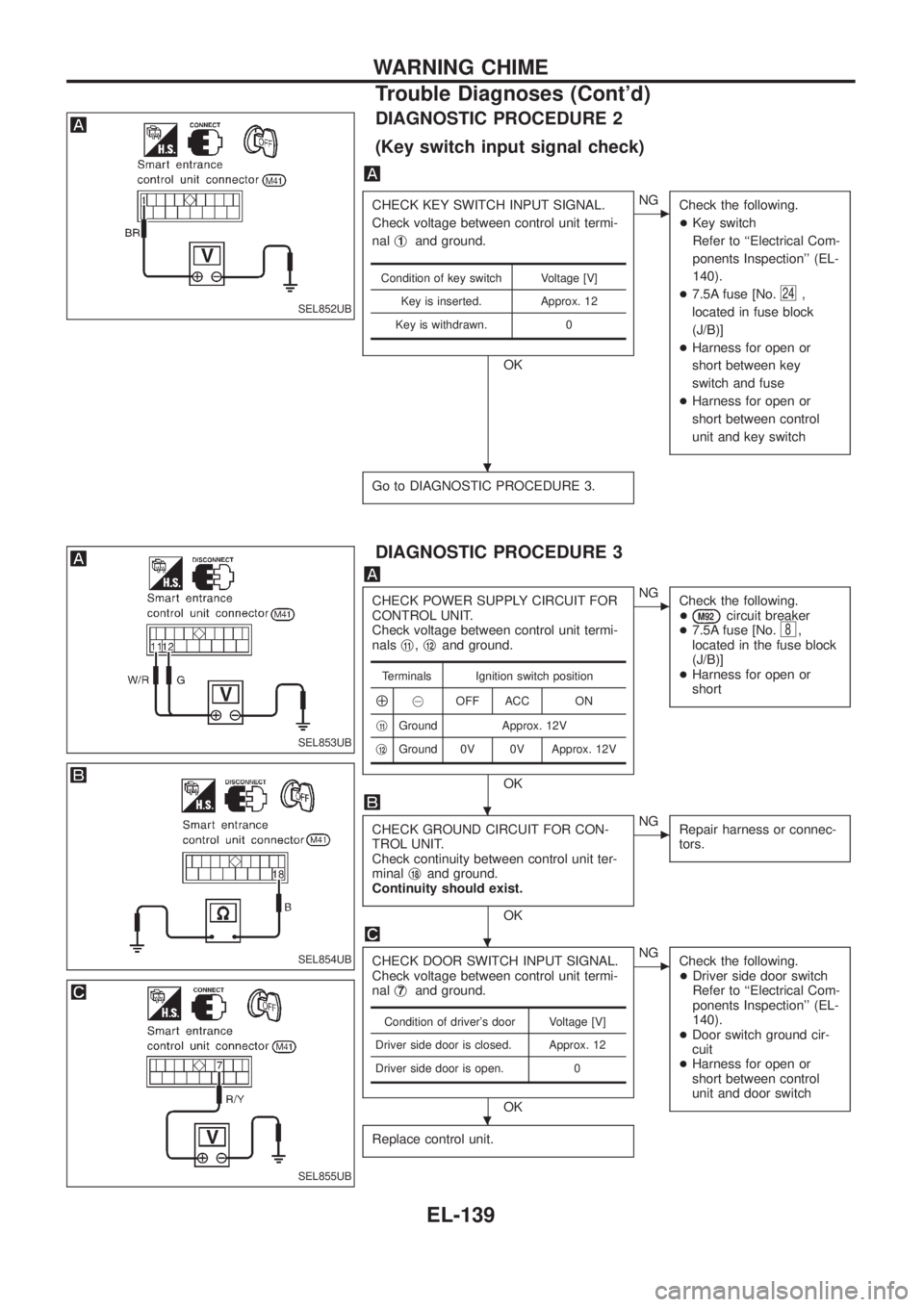

DIAGNOSTIC PROCEDURE 2

(Key switch input signal check)

CHECK KEY SWITCH INPUT SIGNAL.

Check voltage between control unit termi-

nalj

1and ground.

OK

cNG

Check the following.

+Key switch

Refer to ``Electrical Com-

ponents Inspection'' (EL-

140).

+7.5A fuse [No.

24,

located in fuse block

(J/B)]

+Harness for open or

short between key

switch and fuse

+Harness for open or

short between control

unit and key switch

Go to DIAGNOSTIC PROCEDURE 3.

Condition of key switch Voltage [V]

Key is inserted. Approx. 12

Key is withdrawn. 0

DIAGNOSTIC PROCEDURE 3

CHECK POWER SUPPLY CIRCUIT FOR

CONTROL UNIT.

Check voltage between control unit termi-

nalsj

11,j12and ground.

OK

cNG

Check the following.

+

M92circuit breaker

+7.5A fuse [No.8,

located in the fuse block

(J/B)]

+Harness for open or

short

CHECK GROUND CIRCUIT FOR CON-

TROL UNIT.

Check continuity between control unit ter-

minalj

18and ground.

Continuity should exist.

OK

cNG

Repair harness or connec-

tors.

CHECK DOOR SWITCH INPUT SIGNAL.

Check voltage between control unit termi-

nalj

7and ground.

OK

cNG

Check the following.

+Driver side door switch

Refer to ``Electrical Com-

ponents Inspection'' (EL-

140).

+Door switch ground cir-

cuit

+Harness for open or

short between control

unit and door switch

Replace control unit.

Terminals Ignition switch position

Å@OFF ACC ON

j

11Ground Approx. 12V

j

12Ground 0V 0V Approx. 12V

Condition of driver's door Voltage [V]

Driver side door is closed. Approx. 12

Driver side door is open. 0

SEL852UB

SEL853UB

SEL854UB

SEL855UB

.

.

.

.

WARNING CHIME

Trouble Diagnoses (Cont'd)

EL-139

Page 489 of 1226

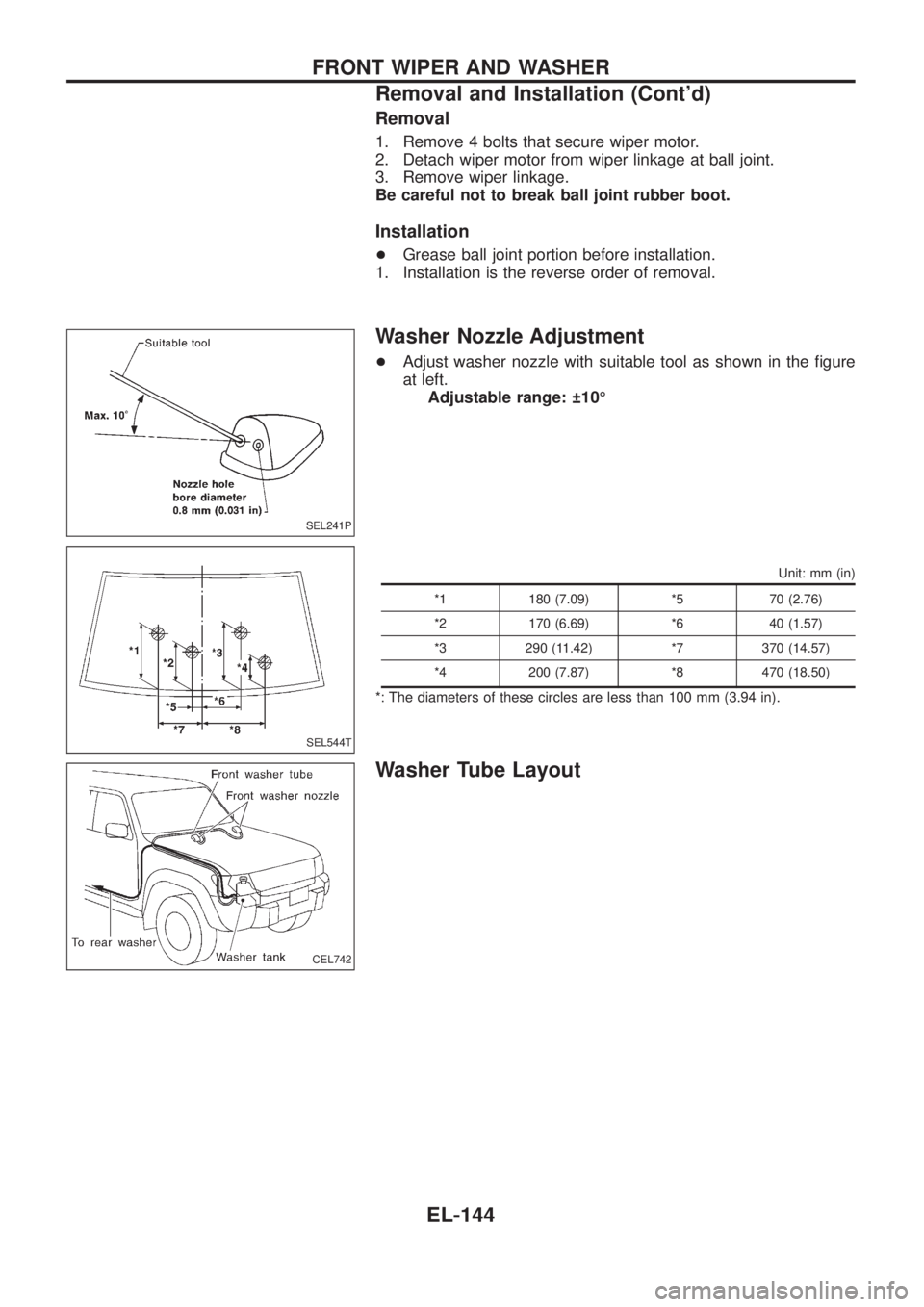

Removal

1. Remove 4 bolts that secure wiper motor.

2. Detach wiper motor from wiper linkage at ball joint.

3. Remove wiper linkage.

Be careful not to break ball joint rubber boot.

Installation

+Grease ball joint portion before installation.

1. Installation is the reverse order of removal.

Washer Nozzle Adjustment

+Adjust washer nozzle with suitable tool as shown in the ®gure

at left.

Adjustable range: 10É

Unit: mm (in)

*1 180 (7.09) *5 70 (2.76)

*2 170 (6.69) *6 40 (1.57)

*3 290 (11.42) *7 370 (14.57)

*4 200 (7.87) *8 470 (18.50)

*: The diameters of these circles are less than 100 mm (3.94 in).

Washer Tube Layout

SEL241P

SEL544T

CEL742

FRONT WIPER AND WASHER

Removal and Installation (Cont'd)

EL-144

Page 510 of 1226

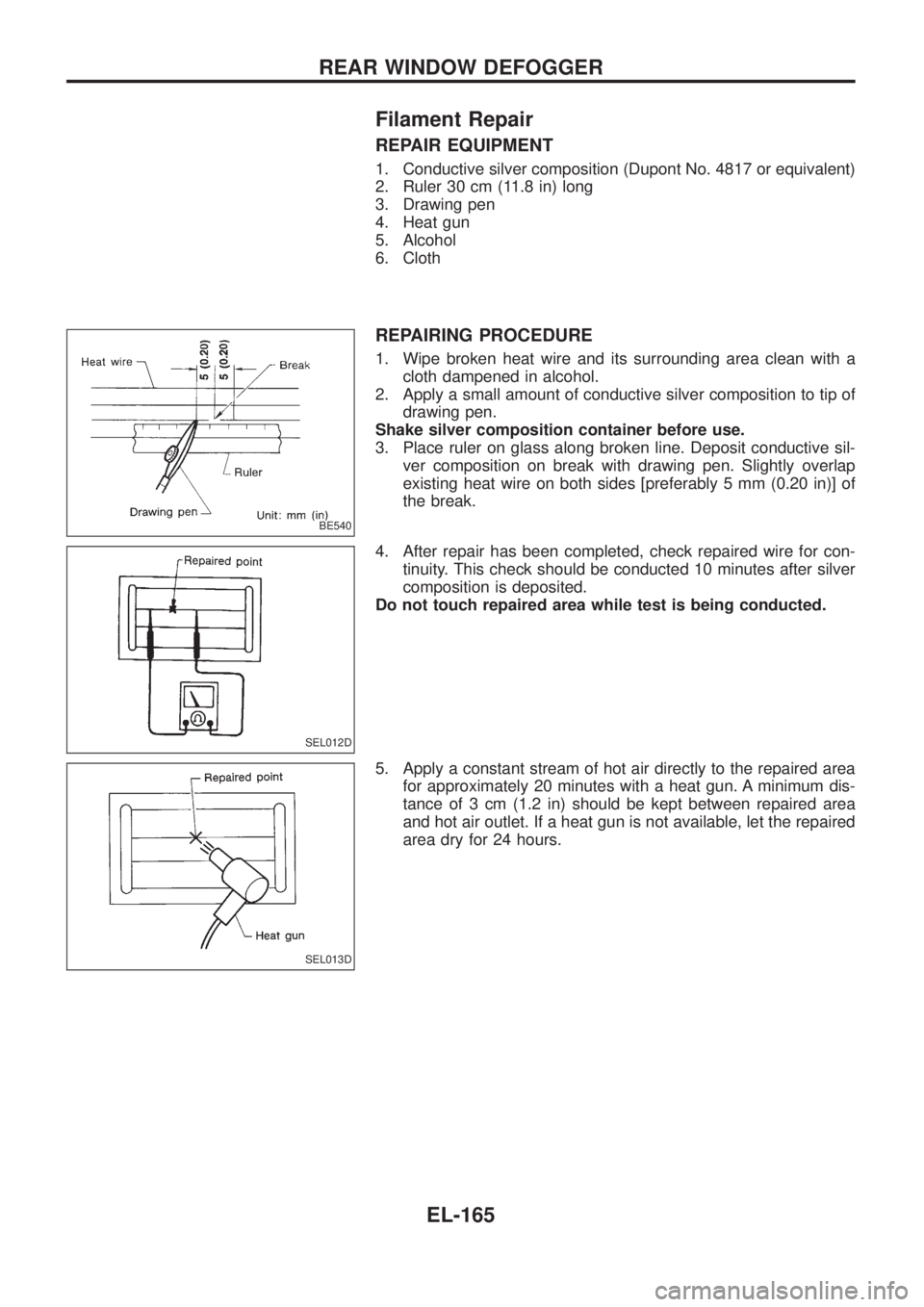

Filament Repair

REPAIR EQUIPMENT

1. Conductive silver composition (Dupont No. 4817 or equivalent)

2. Ruler 30 cm (11.8 in) long

3. Drawing pen

4. Heat gun

5. Alcohol

6. Cloth

REPAIRING PROCEDURE

1. Wipe broken heat wire and its surrounding area clean with a

cloth dampened in alcohol.

2. Apply a small amount of conductive silver composition to tip of

drawing pen.

Shake silver composition container before use.

3. Place ruler on glass along broken line. Deposit conductive sil-

ver composition on break with drawing pen. Slightly overlap

existing heat wire on both sides [preferably 5 mm (0.20 in)] of

the break.

4. After repair has been completed, check repaired wire for con-

tinuity. This check should be conducted 10 minutes after silver

composition is deposited.

Do not touch repaired area while test is being conducted.

5. Apply a constant stream of hot air directly to the repaired area

for approximately 20 minutes with a heat gun. A minimum dis-

tance of 3 cm (1.2 in) should be kept between repaired area

and hot air outlet. If a heat gun is not available, let the repaired

area dry for 24 hours.

BE540

SEL012D

SEL013D

REAR WINDOW DEFOGGER

EL-165

Page 548 of 1226

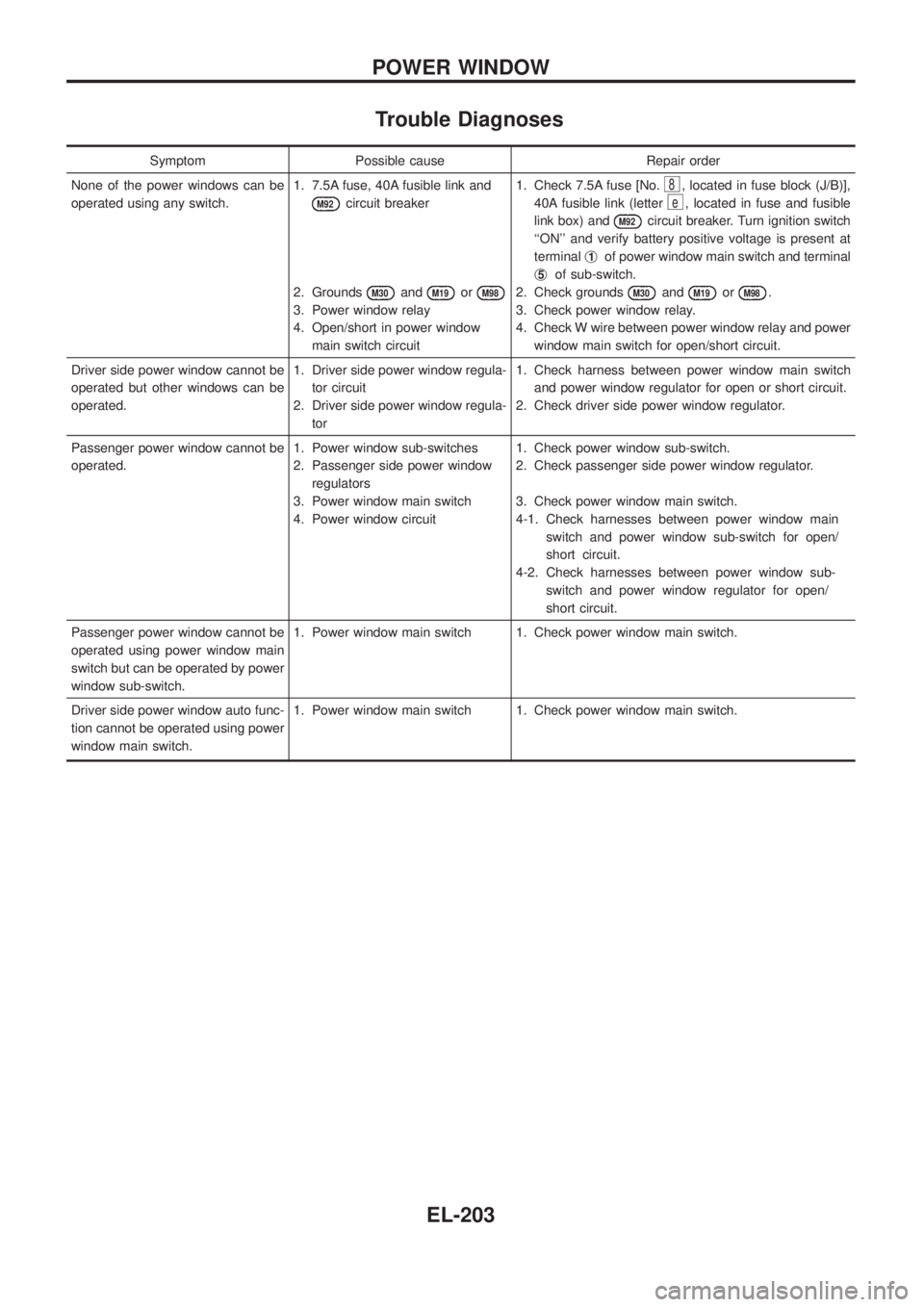

Trouble Diagnoses

Symptom Possible cause Repair order

None of the power windows can be

operated using any switch.1. 7.5A fuse, 40A fusible link and

M92circuit breaker

2. Grounds

M30andM19orM98

3. Power window relay

4. Open/short in power window

main switch circuit1. Check 7.5A fuse [No.

8, located in fuse block (J/B)],

40A fusible link (letter

e, located in fuse and fusible

link box) and

M92circuit breaker. Turn ignition switch

``ON'' and verify battery positive voltage is present at

terminalj

1of power window main switch and terminal

j

5of sub-switch.

2. Check grounds

M30andM19orM98.

3. Check power window relay.

4. Check W wire between power window relay and power

window main switch for open/short circuit.

Driver side power window cannot be

operated but other windows can be

operated.1. Driver side power window regula-

tor circuit

2. Driver side power window regula-

tor1. Check harness between power window main switch

and power window regulator for open or short circuit.

2. Check driver side power window regulator.

Passenger power window cannot be

operated.1. Power window sub-switches

2. Passenger side power window

regulators

3. Power window main switch

4. Power window circuit1. Check power window sub-switch.

2. Check passenger side power window regulator.

3. Check power window main switch.

4-1. Check harnesses between power window main

switch and power window sub-switch for open/

short circuit.

4-2. Check harnesses between power window sub-

switch and power window regulator for open/

short circuit.

Passenger power window cannot be

operated using power window main

switch but can be operated by power

window sub-switch.1. Power window main switch 1. Check power window main switch.

Driver side power window auto func-

tion cannot be operated using power

window main switch.1. Power window main switch 1. Check power window main switch.

POWER WINDOW

EL-203

Page 549 of 1226

System Description

Power is supplied at all times

+through 40A fusible link (Letter

e, located in the fuse and fusible link box)

+to circuit breaker terminalj

1

+through circuit breaker terminalj2

+to smart entrance control unit terminalj11.

Ground is supplied to smart entrance control unit terminalj

18through body grounds.

INPUT

When the door lock & unlock switch (power window main switch) is in LOCKED position, ground signal is

supplied

+to smart entrance control unit terminalj

4

+through door lock & unlock switch terminalj14.

When the door lock & unlock switch (power window main switch) is in UNLOCKED position, ground signal is

supplied

+to smart entrance control unit terminalj

5

+through door lock & unlock switch terminalj7.

Driver side door key cylinder and driver side lock knob are connected to driver side door lock switch with a

rod. When driver side door lock switch is in UNLOCKED position, ground signal is supplied

+to smart entrance control unit terminalj

2

+through driver side door lock switch terminalj1(without multi-remote control system) or

+through driver side door lock actuator terminalj

2(with multi-remote control system).

When driver side door lock switch is in LOCKED position, ground signal is interrupted.

Door lock operates according to the conditions of the door lock & unlock switch (power window main switch)

and driver side door lock switch.

OUTPUT

Unlock

Ground is supplied

+to passenger side door lock actuator, rear door lock actuator LH and RH terminalj

3

+through smart entrance control unit terminalj15.

Power is supplied

+to passenger side door lock actuator, rear door lock actuator LH and RH terminalj

1

+through smart entrance control unit terminalj16.

Then, the doors are unlocked.

Lock

Ground is supplied

+to passenger side door lock actuator, rear door lock actuator LH and RH terminalj

1

+through smart entrance control unit terminalj16.

Power is supplied

+to passenger side door lock actuator, rear door lock actuator LH and RH terminalj

3

+through smart entrance control unit terminalj15.

Then, the doors are locked.

POWER DOOR LOCK

EL-204

Page 679 of 1226

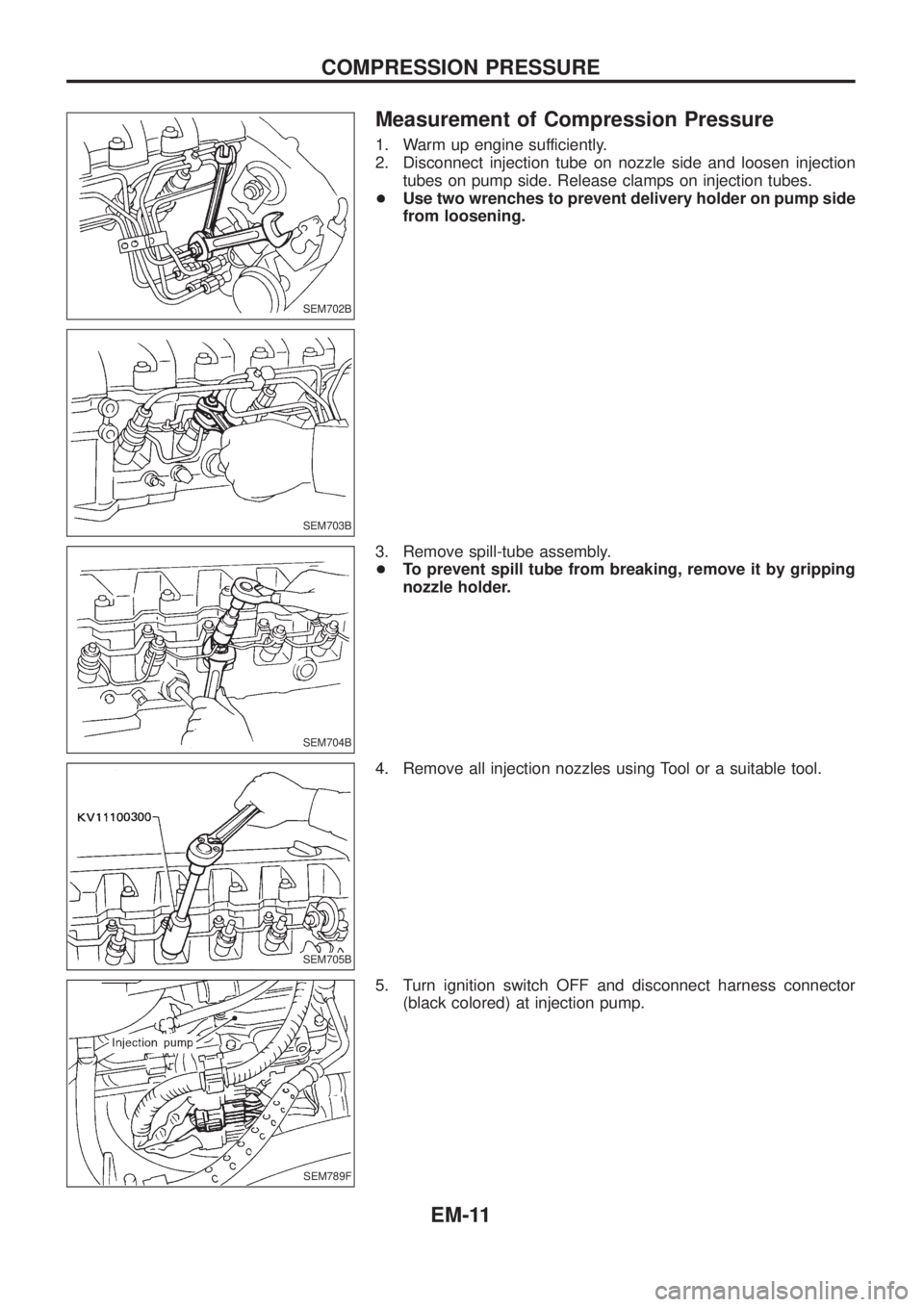

Measurement of Compression Pressure

1. Warm up engine sufficiently.

2. Disconnect injection tube on nozzle side and loosen injection

tubes on pump side. Release clamps on injection tubes.

+Use two wrenches to prevent delivery holder on pump side

from loosening.

3. Remove spill-tube assembly.

+To prevent spill tube from breaking, remove it by gripping

nozzle holder.

4. Remove all injection nozzles using Tool or a suitable tool.

5. Turn ignition switch OFF and disconnect harness connector

(black colored) at injection pump.

SEM702B

SEM703B

SEM704B

SEM705B

SEM789F

COMPRESSION PRESSURE

EM-11