Indicator NISSAN PATROL 2006 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 28 of 1226

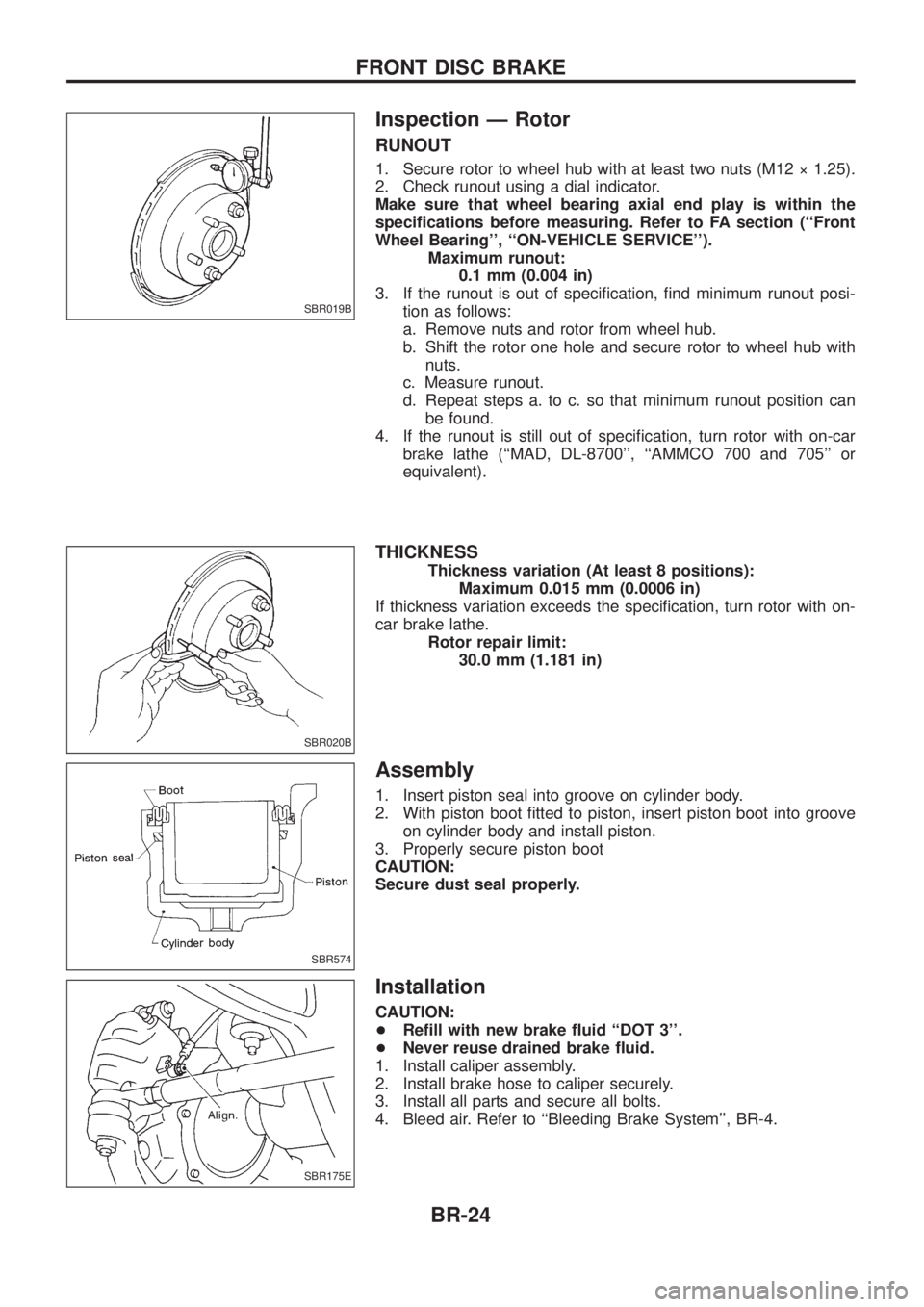

Inspection Ð Rotor

RUNOUT

1. Secure rotor to wheel hub with at least two nuts (M12 ý 1.25).

2. Check runout using a dial indicator.

Make sure that wheel bearing axial end play is within the

speci®cations before measuring. Refer to FA section (``Front

Wheel Bearing'', ``ON-VEHICLE SERVICE'').Maximum runout:0.1 mm (0.004 in)

3. If the runout is out of speci®cation, ®nd minimum runout posi- tion as follows:

a. Remove nuts and rotor from wheel hub.

b. Shift the rotor one hole and secure rotor to wheel hub withnuts.

c. Measure runout.

d. Repeat steps a. to c. so that minimum runout position can be found.

4. If the runout is still out of speci®cation, turn rotor with on-car brake lathe (``MAD, DL-8700'', ``AMMCO 700 and 705'' or

equivalent).

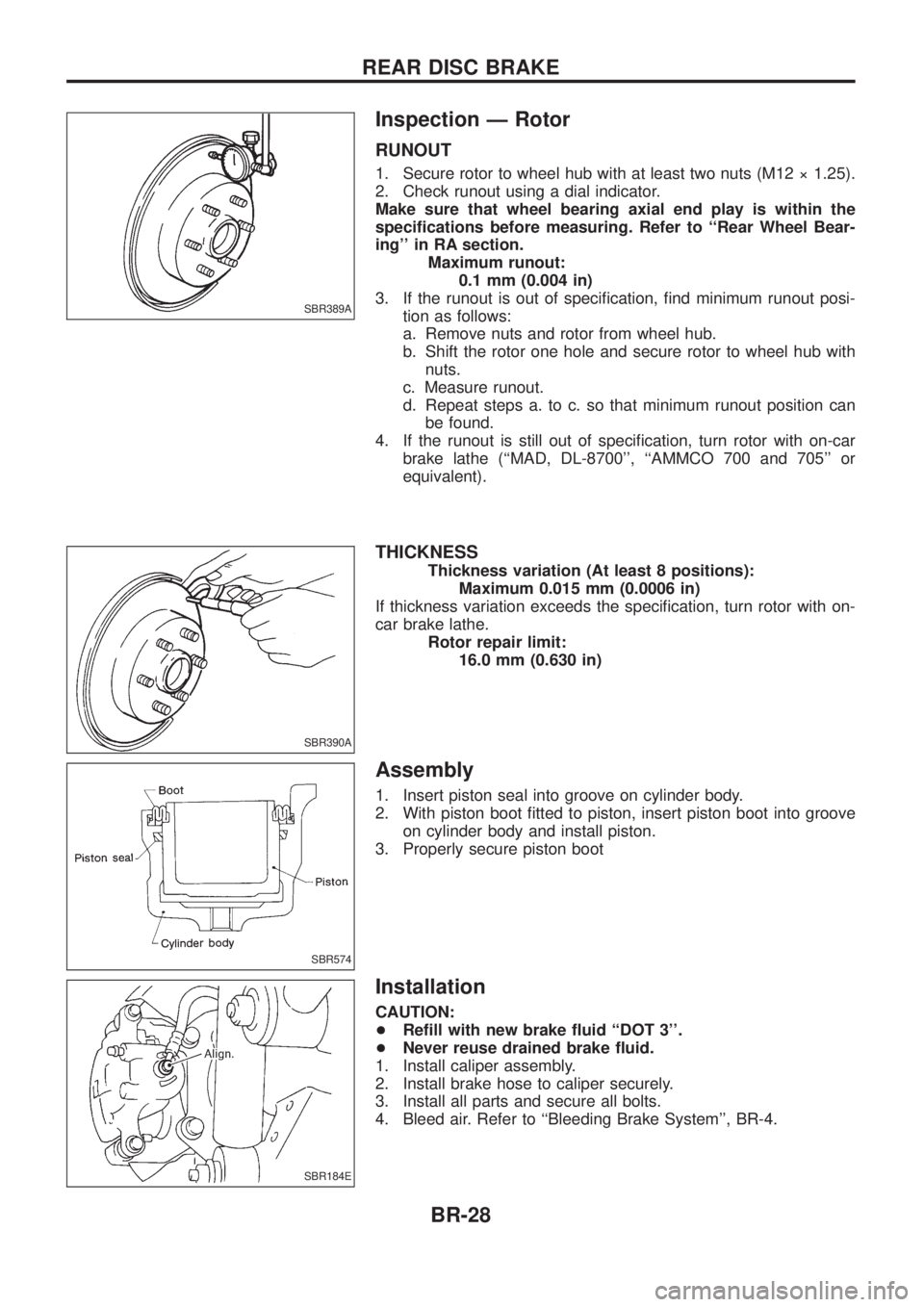

THICKNESS

Thickness variation (At least 8 positions): Maximum 0.015 mm (0.0006 in)

If thickness variation exceeds the speci®cation, turn rotor with on-

car brake lathe. Rotor repair limit:30.0 mm (1.181 in)

Assembly

1. Insert piston seal into groove on cylinder body.

2. With piston boot ®tted to piston, insert piston boot into grooveon cylinder body and install piston.

3. Properly secure piston boot

CAUTION:

Secure dust seal properly.

Installation

CAUTION:

+ Re®ll with new brake ¯uid ``DOT 3''.

+ Never reuse drained brake ¯uid.

1. Install caliper assembly.

2. Install brake hose to caliper securely.

3. Install all parts and secure all bolts.

4. Bleed air. Refer to ``Bleeding Brake System'', BR-4.

SBR019B

SBR020B

SBR574

SBR175E

FRONT DISC BRAKE

BR-24

Page 32 of 1226

Inspection Ð Rotor

RUNOUT

1. Secure rotor to wheel hub with at least two nuts (M12 ý 1.25).

2. Check runout using a dial indicator.

Make sure that wheel bearing axial end play is within the

speci®cations before measuring. Refer to ``Rear Wheel Bear-

ing'' in RA section.Maximum runout:0.1 mm (0.004 in)

3. If the runout is out of speci®cation, ®nd minimum runout posi- tion as follows:

a. Remove nuts and rotor from wheel hub.

b. Shift the rotor one hole and secure rotor to wheel hub withnuts.

c. Measure runout.

d. Repeat steps a. to c. so that minimum runout position can be found.

4. If the runout is still out of speci®cation, turn rotor with on-car brake lathe (``MAD, DL-8700'', ``AMMCO 700 and 705'' or

equivalent).

THICKNESS

Thickness variation (At least 8 positions): Maximum 0.015 mm (0.0006 in)

If thickness variation exceeds the speci®cation, turn rotor with on-

car brake lathe. Rotor repair limit:16.0 mm (0.630 in)

Assembly

1. Insert piston seal into groove on cylinder body.

2. With piston boot ®tted to piston, insert piston boot into grooveon cylinder body and install piston.

3. Properly secure piston boot

Installation

CAUTION:

+ Re®ll with new brake ¯uid ``DOT 3''.

+ Never reuse drained brake ¯uid.

1. Install caliper assembly.

2. Install brake hose to caliper securely.

3. Install all parts and secure all bolts.

4. Bleed air. Refer to ``Bleeding Brake System'', BR-4.

SBR389A

SBR390A

SBR574

SBR184E

REAR DISC BRAKE

BR-28

Page 36 of 1226

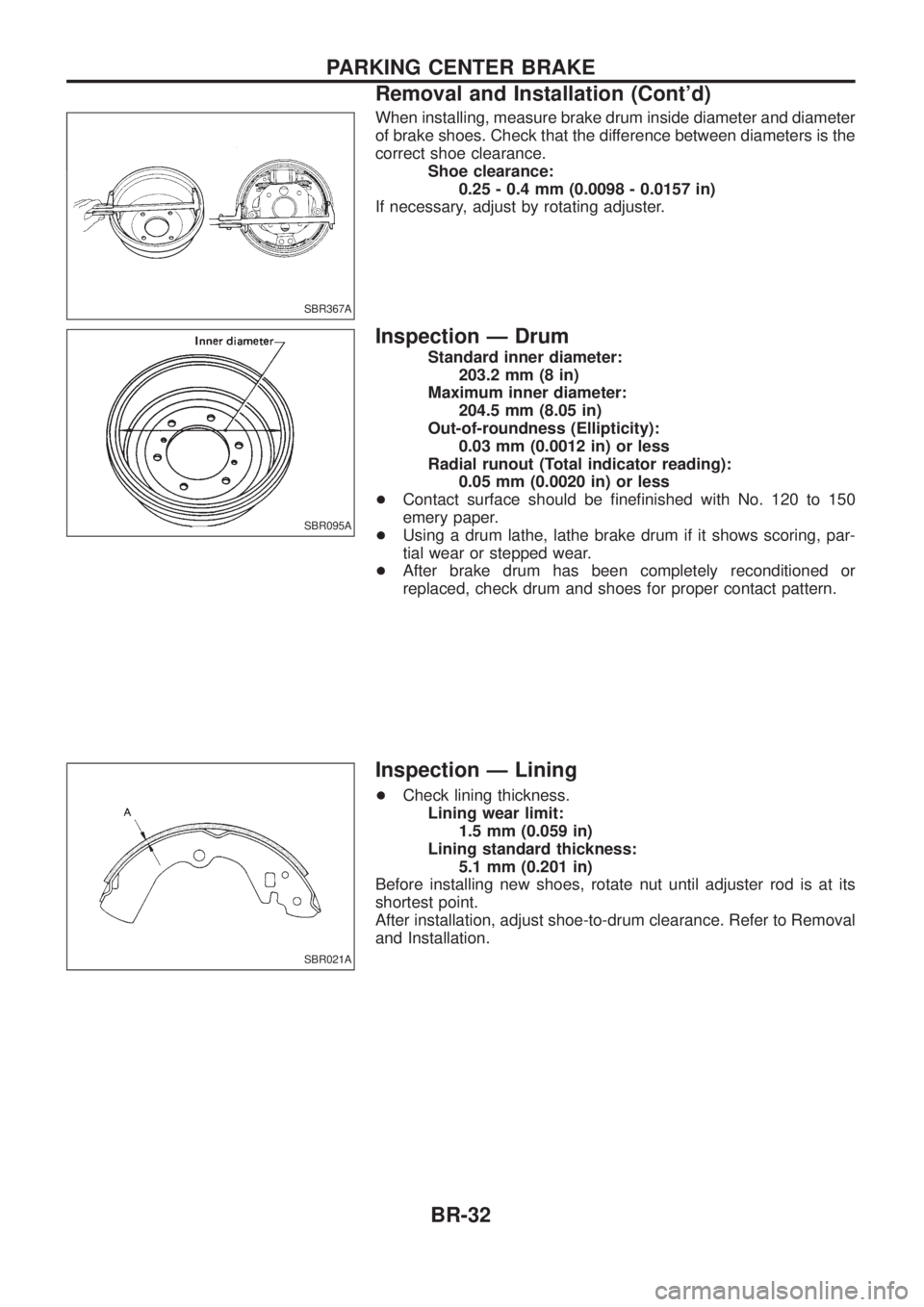

When installing, measure brake drum inside diameter and diameter

of brake shoes. Check that the difference between diameters is the

correct shoe clearance.Shoe clearance:0.25 - 0.4 mm (0.0098 - 0.0157 in)

If necessary, adjust by rotating adjuster.

Inspection Ð Drum

Standard inner diameter: 203.2 mm (8 in)

Maximum inner diameter: 204.5 mm (8.05 in)

Out-of-roundness (Ellipticity): 0.03 mm (0.0012 in) or less

Radial runout (Total indicator reading): 0.05 mm (0.0020 in) or less

+ Contact surface should be ®ne®nished with No. 120 to 150

emery paper.

+ Using a drum lathe, lathe brake drum if it shows scoring, par-

tial wear or stepped wear.

+ After brake drum has been completely reconditioned or

replaced, check drum and shoes for proper contact pattern.

Inspection Ð Lining

+Check lining thickness.

Lining wear limit: 1.5 mm (0.059 in)

Lining standard thickness: 5.1 mm (0.201 in)

Before installing new shoes, rotate nut until adjuster rod is at its

shortest point.

After installation, adjust shoe-to-drum clearance. Refer to Removal

and Installation.

SBR367A

SBR095A

SBR021A

PARKING CENTER BRAKE

Removal and Installation (Cont'd)

BR-32

Page 150 of 1226

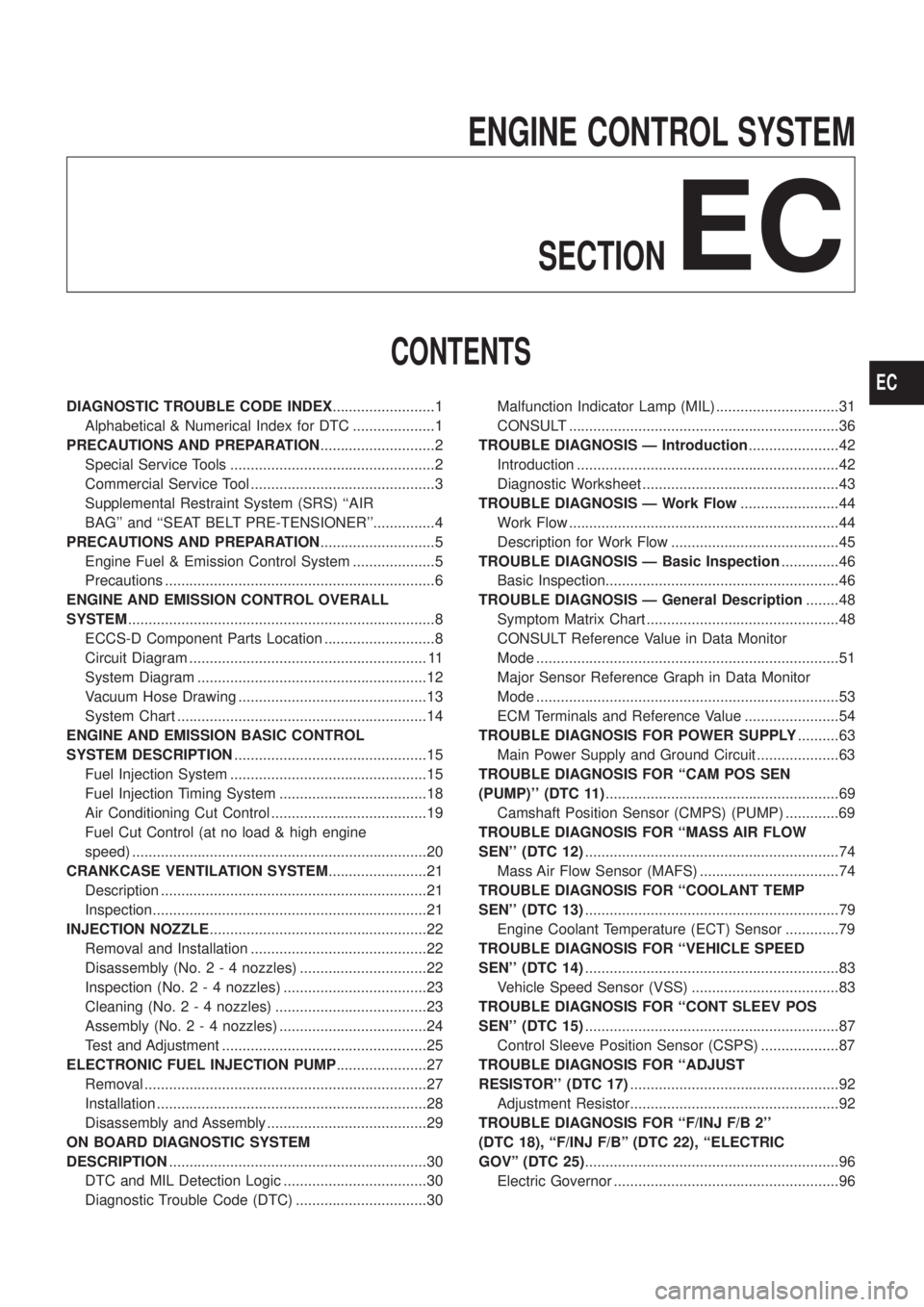

ENGINE CONTROL SYSTEMSECTION

EC

CONTENTS

DIAGNOSTIC TROUBLE CODE INDEX .........................1

Alphabetical & Numerical Index for DTC ....................1

PRECAUTIONS AND PREPARATION ............................2

Special Service Tools ..................................................2

Commercial Service Tool .............................................3

Supplemental Restraint System (SRS) ``AIR

BAG'' and ``SEAT BELT PRE-TENSIONER''...............4

PRECAUTIONS AND PREPARATION ............................5

Engine Fuel & Emission Control System ....................5

Precautions ..................................................................6

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM ........................................................................\

...8

ECCS-D Component Parts Location ...........................8

Circuit Diagram .......................................................... 11

System Diagram ........................................................12

Vacuum Hose Drawing ..............................................13

System Chart .............................................................14

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION ...............................................15

Fuel Injection System ................................................15

Fuel Injection Timing System ....................................18

Air Conditioning Cut Control ......................................19

Fuel Cut Control (at no load & high engine

speed) ........................................................................\

20

CRANKCASE VENTILATION SYSTEM ........................21

Description .................................................................21

Inspection...................................................................21

INJECTION NOZZLE .....................................................22

Removal and Installation ...........................................22

Disassembly (No. 2 - 4 nozzles) ...............................22

Inspection (No. 2 - 4 nozzles) ...................................23

Cleaning (No. 2 - 4 nozzles) .....................................23

Assembly (No. 2 - 4 nozzles) ....................................24

Test and Adjustment ..................................................25

ELECTRONIC FUEL INJECTION PUMP ......................27

Removal .....................................................................27

Installation ..................................................................28

Disassembly and Assembly .......................................29

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION ...............................................................30

DTC and MIL Detection Logic ...................................30

Diagnostic Trouble Code (DTC) ................................30 Malfunction Indicator Lamp (MIL) ..............................31

CONSULT ..................................................................36

TROUBLE DIAGNOSIS Ð Introduction ......................42

Introduction ................................................................42

Diagnostic Worksheet ................................................43

TROUBLE DIAGNOSIS Ð Work Flow ........................44

Work Flow ..................................................................44

Description for Work Flow .........................................45

TROUBLE DIAGNOSIS Ð Basic Inspection ..............46

Basic Inspection.........................................................46

TROUBLE DIAGNOSIS Ð General Description ........48

Symptom Matrix Chart ...............................................48

CONSULT Reference Value in Data Monitor

Mode ........................................................................\

..51

Major Sensor Reference Graph in Data Monitor

Mode ........................................................................\

..53

ECM Terminals and Reference Value .......................54

TROUBLEDIAGNOSISFORPOWERSUPPLY ..........63

MainPowerSupplyandGroundCircuit....................63

TROUBLE DIAGNOSIS FOR ``CAM POS SEN

(PUMP)''(DTC11) .........................................................69

CamshaftPositionSensor(CMPS)(PUMP).............69

TROUBLEDIAGNOSISFOR``MASSAIRFLOW

SEN''(DTC12) ..............................................................74

MassAirFlowSensor(MAFS)..................................74

TROUBLEDIAGNOSISFOR``COOLANTTEMP

SEN''(DTC13) ..............................................................79

EngineCoolantTemperature(ECT)Sensor.............79

TROUBLEDIAGNOSISFOR``VEHICLESPEED

SEN''(DTC14) ..............................................................83

VehicleSpeedSensor(VSS)....................................83

TROUBLEDIAGNOSISFOR``CONTSLEEVPOS

SEN''(DTC15) ..............................................................87

ControlSleevePositionSensor(CSPS)...................87

TROUBLEDIAGNOSISFOR``ADJUST

RESISTOR''(DTC17) ...................................................92

AdjustmentResistor...................................................92

TROUBLEDIAGNOSISFOR``F/INJF/B2''

(DTC18),``F/INJF/B''(DTC22),``ELECTRIC

GOV''(DTC25) ..............................................................96

ElectricGovernor.......................................................96

EC

Page 157 of 1226

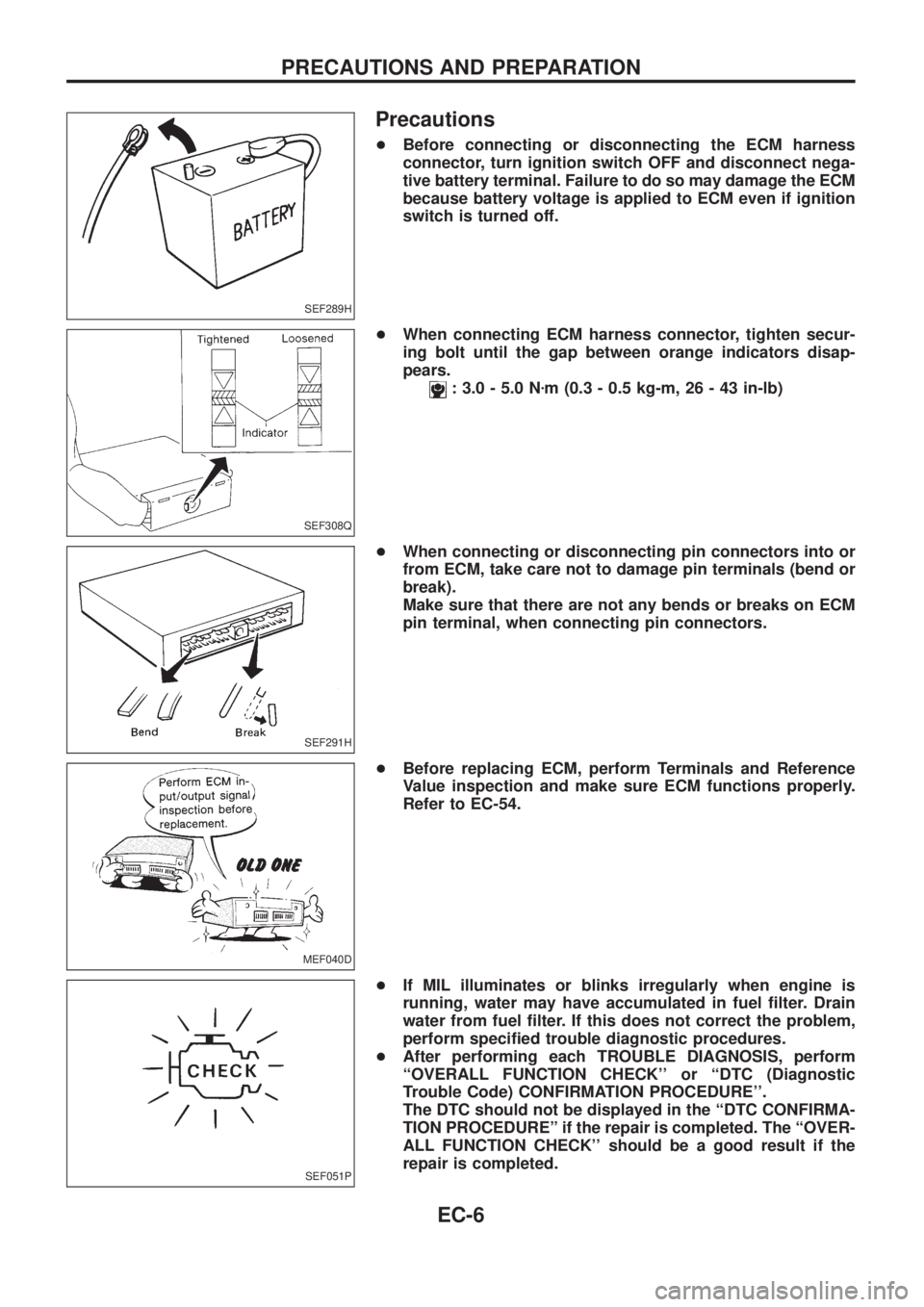

Precautions

+Before connecting or disconnecting the ECM harness

connector, turn ignition switch OFF and disconnect nega-

tive battery terminal. Failure to do so may damage the ECM

because battery voltage is applied to ECM even if ignition

switch is turned off.

+When connecting ECM harness connector, tighten secur-

ing bolt until the gap between orange indicators disap-

pears.

: 3.0 - 5.0 Nzm (0.3 - 0.5 kg-m, 26 - 43 in-lb)

+When connecting or disconnecting pin connectors into or

from ECM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on ECM

pin terminal, when connecting pin connectors.

+Before replacing ECM, perform Terminals and Reference

Value inspection and make sure ECM functions properly.

Refer to EC-54.

+If MIL illuminates or blinks irregularly when engine is

running, water may have accumulated in fuel ®lter. Drain

water from fuel ®lter. If this does not correct the problem,

perform speci®ed trouble diagnostic procedures.

+After performing each TROUBLE DIAGNOSIS, perform

``OVERALL FUNCTION CHECK'' or ``DTC (Diagnostic

Trouble Code) CONFIRMATION PROCEDURE''.

The DTC should not be displayed in the ``DTC CONFIRMA-

TION PROCEDUREº if the repair is completed. The ``OVER-

ALL FUNCTION CHECK'' should be a good result if the

repair is completed.

SEF289H

SEF308Q

SEF291H

MEF040D

SEF051P

PRECAUTIONS AND PREPARATION

EC-6

Page 165 of 1226

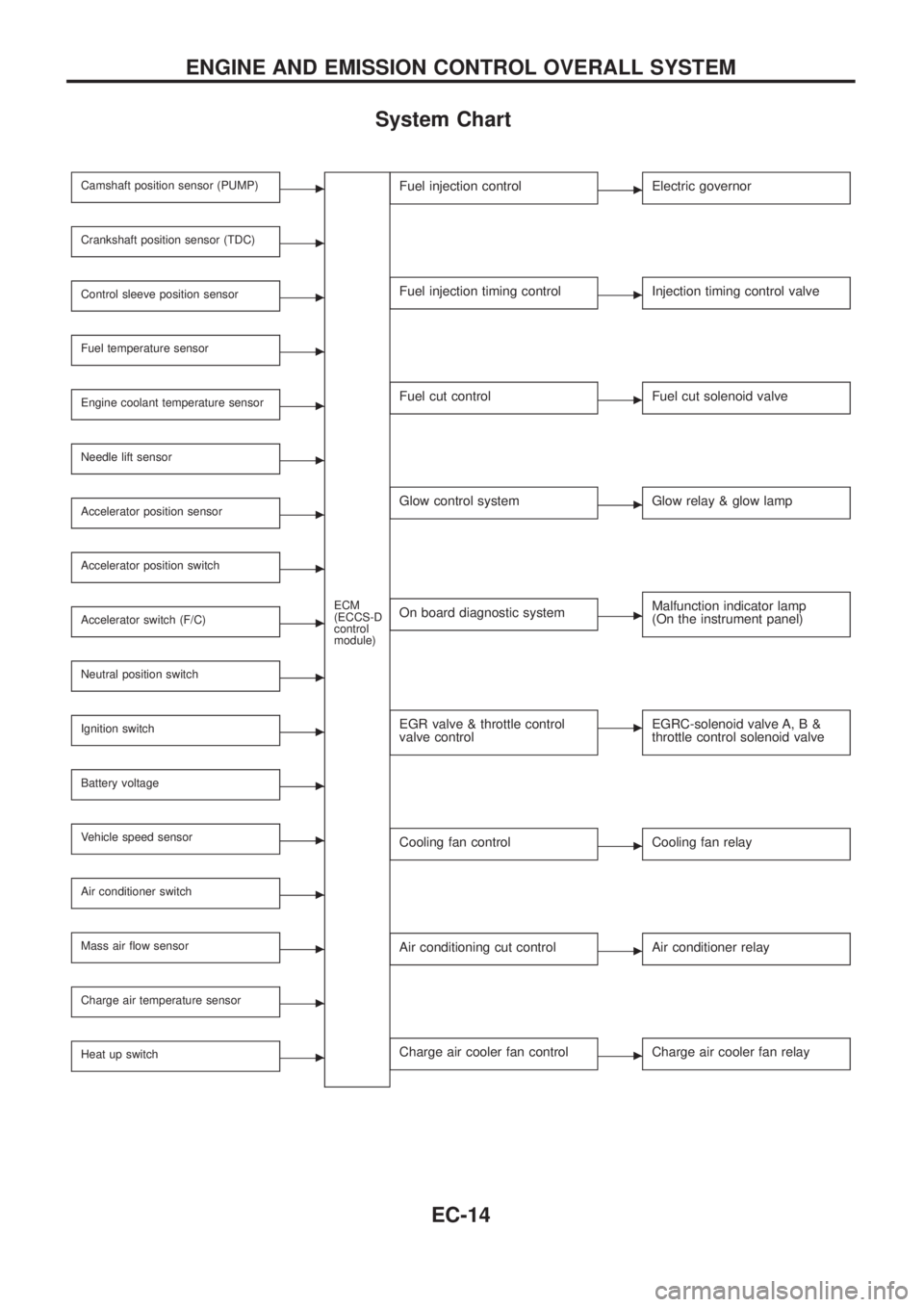

System Chart

Camshaft position sensor (PUMP)c

ECM

(ECCS-D

control

module)

Crankshaft position sensor (TDC)c

Control sleeve position sensorc

Fuel temperature sensorc

Engine coolant temperature sensorc

Needle lift sensorc

Accelerator position sensorc

Accelerator position switchc

Accelerator switch (F/C)c

Neutral position switchc

Ignition switchc

Battery voltagec

Vehicle speed sensorc

Air conditioner switchc

Mass air ¯ow sensorc

Charge air temperature sensorc

Heat up switchc

Fuel injection controlcElectric governor

Fuel injection timing controlcInjection timing control valve

Fuel cut controlcFuel cut solenoid valve

Glow control systemcGlow relay & glow lamp

On board diagnostic systemcMalfunction indicator lamp

(On the instrument panel)

EGR valve & throttle control

valve controlcEGRC-solenoid valve A, B &

throttle control solenoid valve

Cooling fan controlcCooling fan relay

Air conditioning cut controlcAir conditioner relay

Charge air cooler fan controlcCharge air cooler fan relay

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

EC-14

Page 181 of 1226

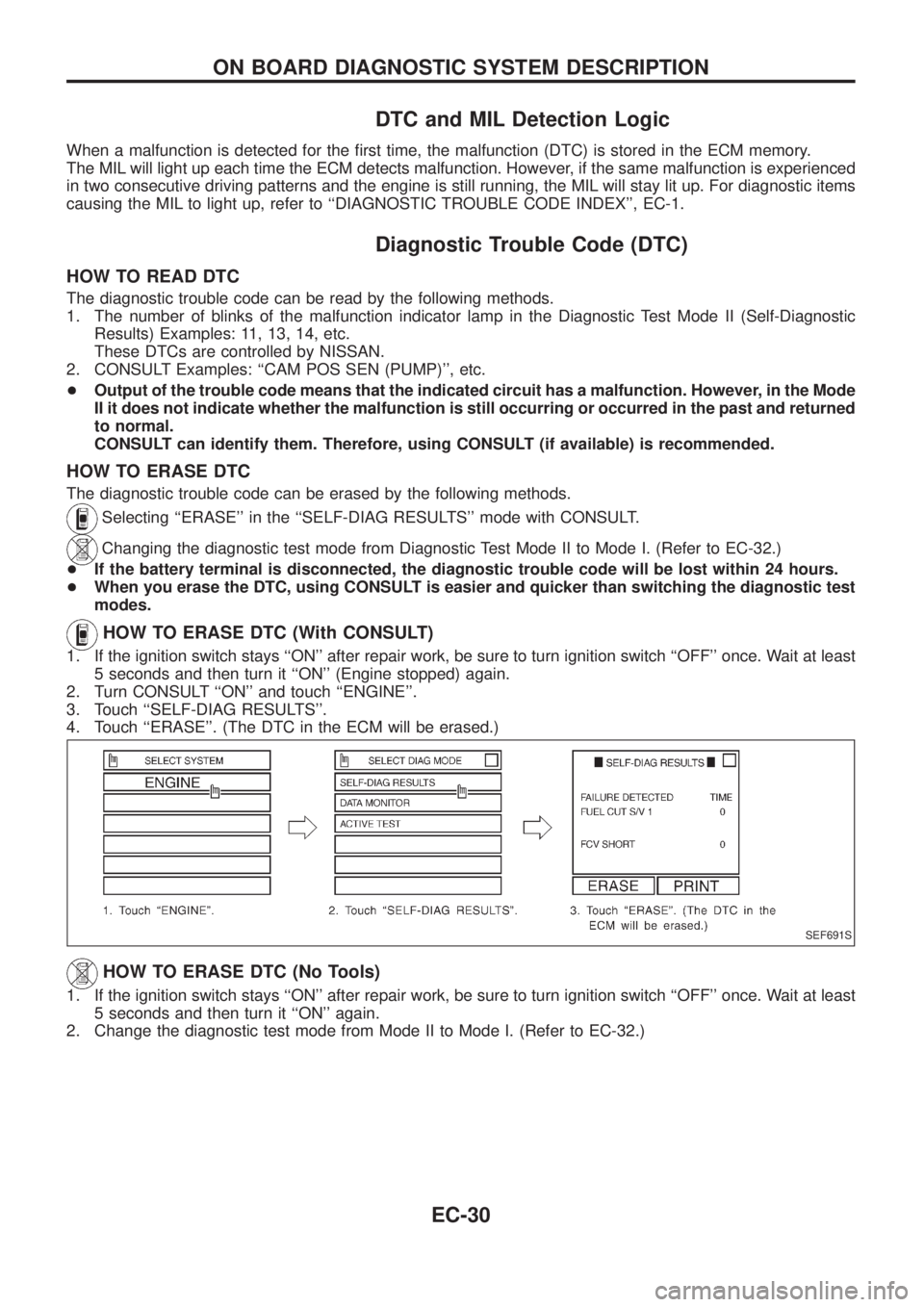

DTC and MIL Detection Logic

When a malfunction is detected for the ®rst time, the malfunction (DTC) is stored in the ECM memory.

The MIL will light up each time the ECM detects malfunction. However, if the same malfunction is experienced

in two consecutive driving patterns and the engine is still running, the MIL will stay lit up. For diagnostic items

causing the MIL to light up, refer to ``DIAGNOSTIC TROUBLE CODE INDEX'', EC-1.

Diagnostic Trouble Code (DTC)

HOW TO READ DTC

The diagnostic trouble code can be read by the following methods.

1. The number of blinks of the malfunction indicator lamp in the Diagnostic Test Mode II (Self-Diagnostic

Results) Examples: 11, 13, 14, etc.

These DTCs are controlled by NISSAN.

2. CONSULT Examples: ``CAM POS SEN (PUMP)'', etc.

+Output of the trouble code means that the indicated circuit has a malfunction. However, in the Mode

II it does not indicate whether the malfunction is still occurring or occurred in the past and returned

to normal.

CONSULT can identify them. Therefore, using CONSULT (if available) is recommended.

HOW TO ERASE DTC

The diagnostic trouble code can be erased by the following methods.

Selecting ``ERASE'' in the ``SELF-DIAG RESULTS'' mode with CONSULT.

Changing the diagnostic test mode from Diagnostic Test Mode II to Mode I. (Refer to EC-32.)

+If the battery terminal is disconnected, the diagnostic trouble code will be lost within 24 hours.

+When you erase the DTC, using CONSULT is easier and quicker than switching the diagnostic test

modes.

HOW TO ERASE DTC (With CONSULT)

1. If the ignition switch stays ``ON'' after repair work, be sure to turn ignition switch ``OFF'' once. Wait at least

5 seconds and then turn it ``ON'' (Engine stopped) again.

2. Turn CONSULT ``ON'' and touch ``ENGINE''.

3. Touch ``SELF-DIAG RESULTS''.

4. Touch ``ERASE''. (The DTC in the ECM will be erased.)

HOW TO ERASE DTC (No Tools)

1. If the ignition switch stays ``ON'' after repair work, be sure to turn ignition switch ``OFF'' once. Wait at least

5 seconds and then turn it ``ON'' again.

2. Change the diagnostic test mode from Mode II to Mode I. (Refer to EC-32.)

SEF691S

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

EC-30

Page 182 of 1226

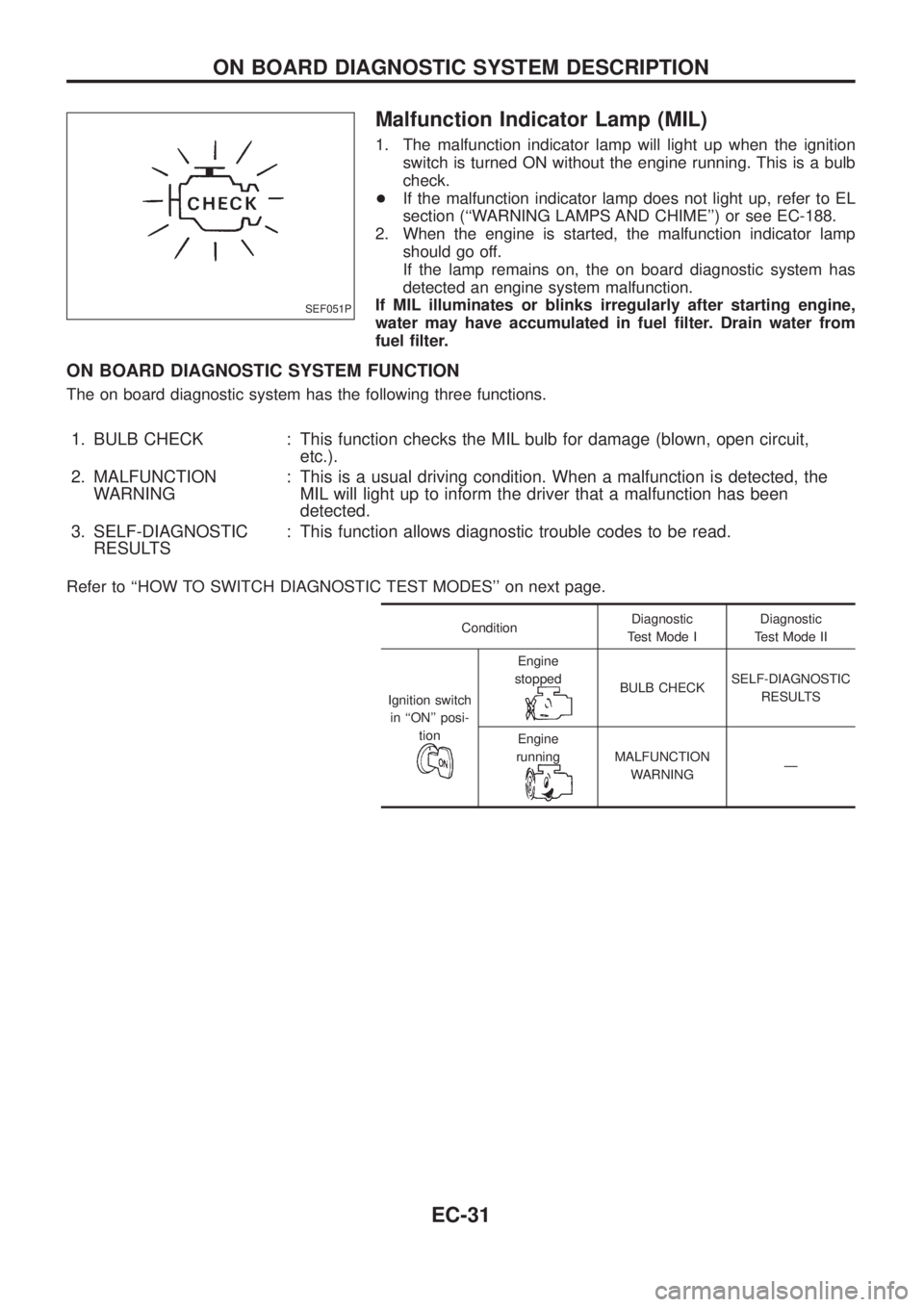

Malfunction Indicator Lamp (MIL)

1. The malfunction indicator lamp will light up when the ignition

switch is turned ON without the engine running. This is a bulb

check.

+If the malfunction indicator lamp does not light up, refer to EL

section (``WARNING LAMPS AND CHIME'') or see EC-188.

2. When the engine is started, the malfunction indicator lamp

should go off.

If the lamp remains on, the on board diagnostic system has

detected an engine system malfunction.

If MIL illuminates or blinks irregularly after starting engine,

water may have accumulated in fuel ®lter. Drain water from

fuel ®lter.

ON BOARD DIAGNOSTIC SYSTEM FUNCTION

The on board diagnostic system has the following three functions.

1. BULB CHECK : This function checks the MIL bulb for damage (blown, open circuit,

etc.).

2. MALFUNCTION

WARNING: This is a usual driving condition. When a malfunction is detected, the

MIL will light up to inform the driver that a malfunction has been

detected.

3. SELF-DIAGNOSTIC

RESULTS: This function allows diagnostic trouble codes to be read.

Refer to ``HOW TO SWITCH DIAGNOSTIC TEST MODES'' on next page.

ConditionDiagnostic

Test Mode IDiagnostic

Test Mode II

Ignition switch

in ``ON'' posi-

tion

Engine

stopped

BULB CHECKSELF-DIAGNOSTIC

RESULTS

Engine

running

MALFUNCTION

WARNINGÐ

SEF051P

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

EC-31

Page 183 of 1226

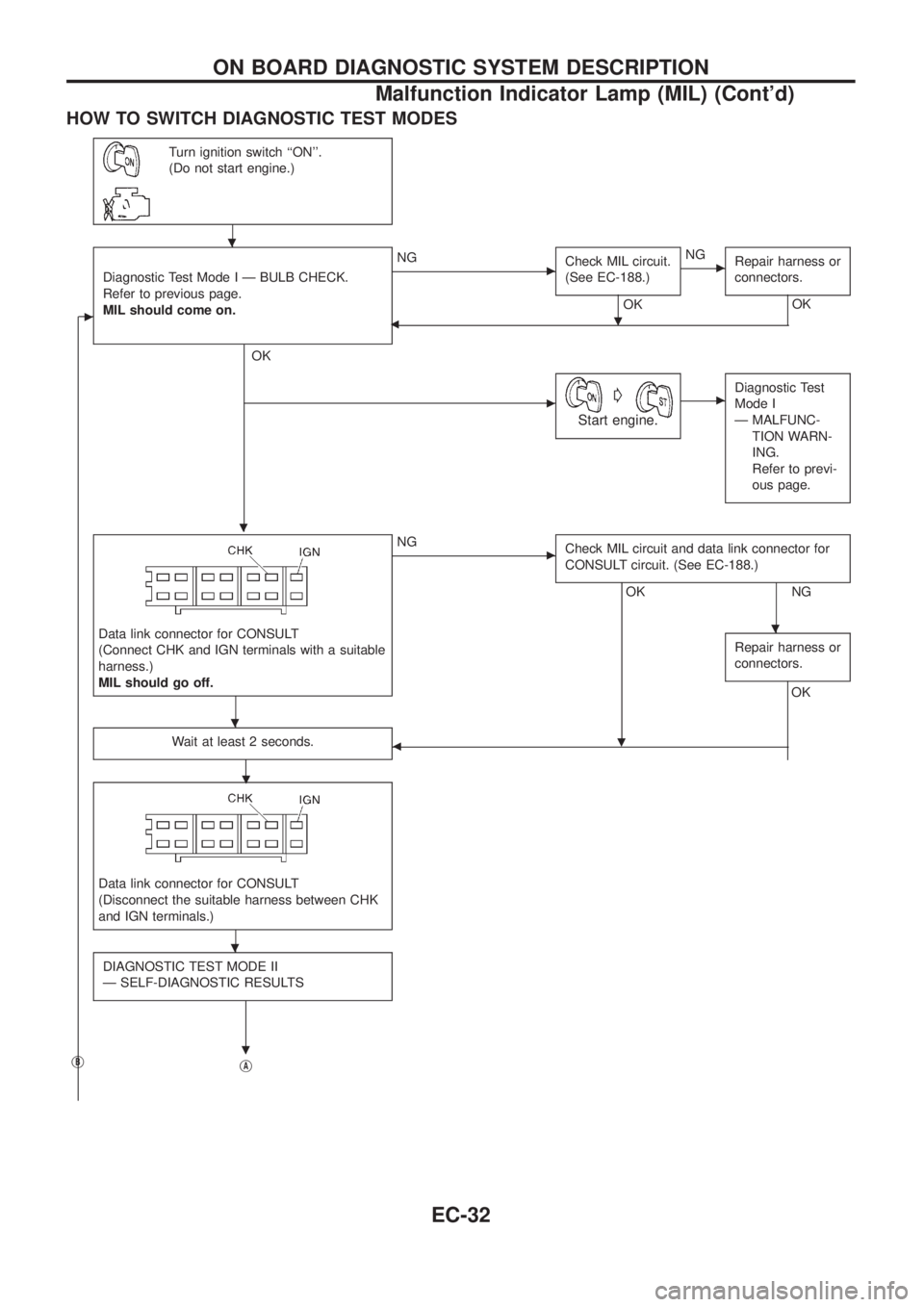

HOW TO SWITCH DIAGNOSTIC TEST MODES

Turn ignition switch ``ON''.

(Do not start engine.)

c

Diagnostic Test Mode I Ð BULB CHECK.

Refer to previous page.

MIL should come on.

.

OK

cNG

Check MIL circuit.

(See EC-188.)

OK

.

cNG

Repair harness or

connectors.

OK

b

cG

Start engine.

cDiagnostic Test

Mode I

Ð MALFUNC-

TION WARN-

ING.

Refer to previ-

ous page.

Data link connector for CONSULT

(Connect CHK and IGN terminals with a suitable

harness.)

MIL should go off.

cNG

Check MIL circuit and data link connector for

CONSULT circuit. (See EC-188.)

OK

.

NG

Repair harness or

connectors.

OK

Wait at least 2 seconds.

.b

Data link connector for CONSULT

(Disconnect the suitable harness between CHK

and IGN terminals.)

DIAGNOSTIC TEST MODE II

Ð SELF-DIAGNOSTIC RESULTS

.jBjA

.

.

.

.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Malfunction Indicator Lamp (MIL) (Cont'd)

EC-32

Page 184 of 1226

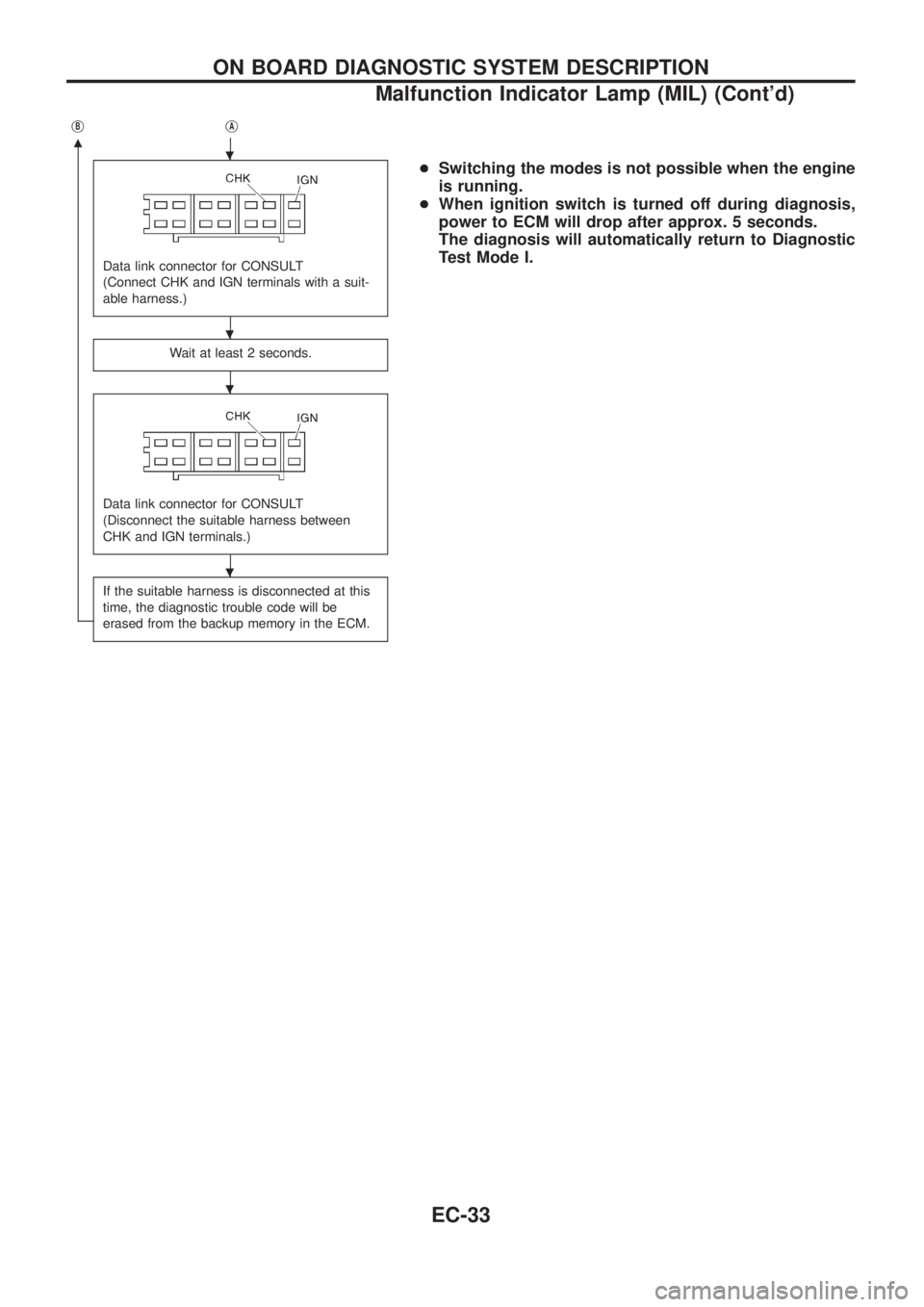

jB

m

jA

Data link connector for CONSULT

(Connect CHK and IGN terminals with a suit-

able harness.)

Wait at least 2 seconds.

Data link connector for CONSULT

(Disconnect the suitable harness between

CHK and IGN terminals.)

If the suitable harness is disconnected at this

time, the diagnostic trouble code will be

erased from the backup memory in the ECM.

+Switching the modes is not possible when the engine

is running.

+When ignition switch is turned off during diagnosis,

power to ECM will drop after approx. 5 seconds.

The diagnosis will automatically return to Diagnostic

Test Mode I..

.

.

.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Malfunction Indicator Lamp (MIL) (Cont'd)

EC-33