check engine NISSAN PICK-UP 1998 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 1010 of 1659

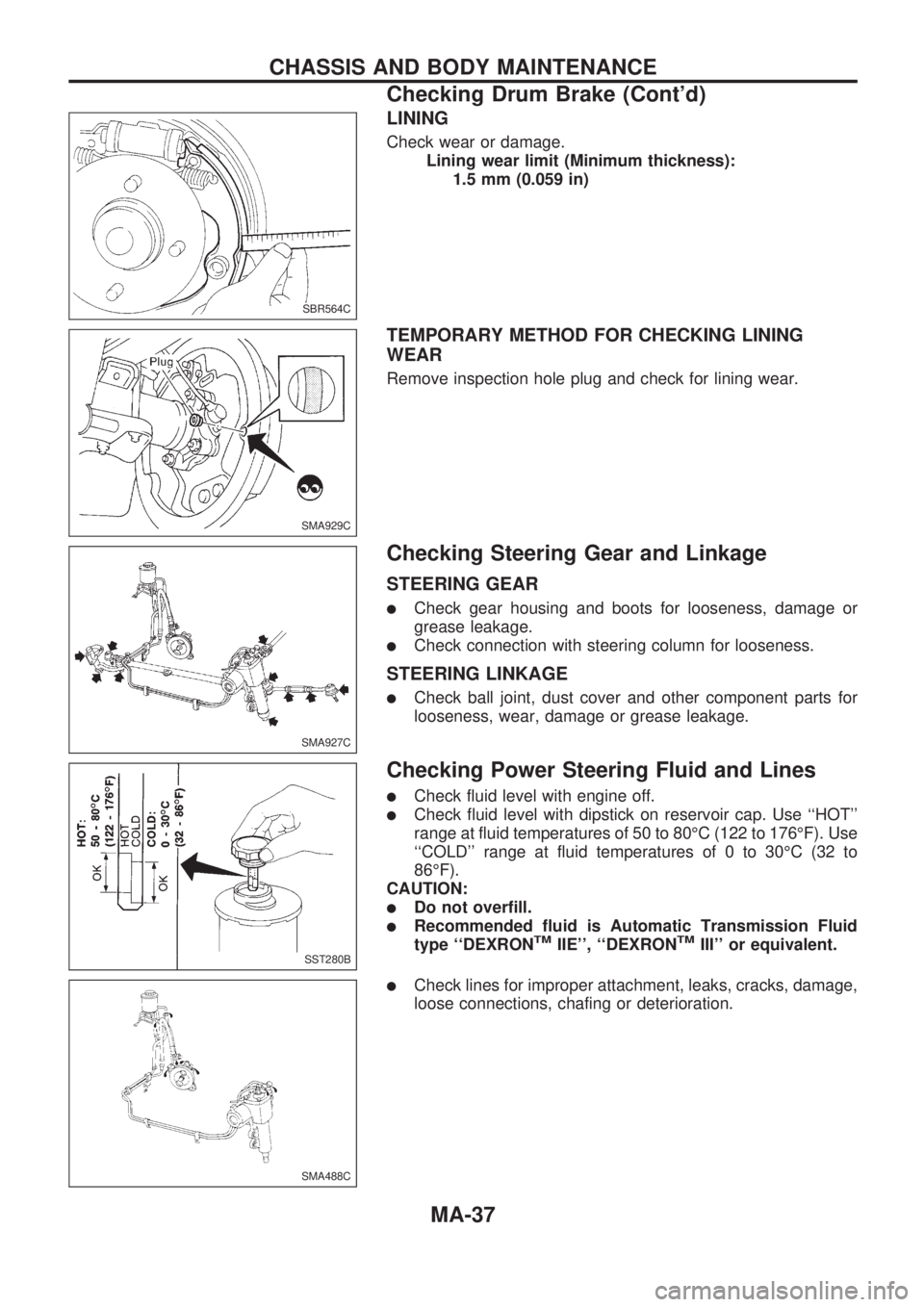

LINING

Check wear or damage.

Lining wear limit (Minimum thickness):

1.5 mm (0.059 in)

TEMPORARY METHOD FOR CHECKING LINING

WEAR

Remove inspection hole plug and check for lining wear.

Checking Steering Gear and Linkage

STEERING GEAR

lCheck gear housing and boots for looseness, damage or

grease leakage.

lCheck connection with steering column for looseness.

STEERING LINKAGE

lCheck ball joint, dust cover and other component parts for

looseness, wear, damage or grease leakage.

Checking Power Steering Fluid and Lines

lCheck fluid level with engine off.

lCheck fluid level with dipstick on reservoir cap. Use ``HOT''

range at fluid temperatures of 50 to 80ÉC (122 to 176ÉF). Use

``COLD'' range at fluid temperatures of 0 to 30ÉC (32 to

86ÉF).

CAUTION:

lDo not overfill.

lRecommended fluid is Automatic Transmission Fluid

type ``DEXRONTMIIE'', ``DEXRONTMIII'' or equivalent.

lCheck lines for improper attachment, leaks, cracks, damage,

loose connections, chafing or deterioration.

SBR564C

SMA929C

SMA927C

SST280B

SMA488C

CHASSIS AND BODY MAINTENANCE

Checking Drum Brake (Cont'd)

MA-37

Page 1014 of 1659

Checking Body Corrosion

Visually check the body sheet metal panel for corrosion, paint damage (scratches, chipping, rubbing, etc.)

or damage to the anti-corrosion materials. In particular, check the following locations.

Hemmed portion

Hood front end, door lower end, trunk lid rear end, etc.

Panel joint

Side sill of rear fender and center pillar, rear wheel housing of rear fender, around strut tower in engine

compartment, etc.

Panel edge

Trunk lid opening, sunroof opening, fender wheelarch flange, fuel filler lid flange, around holes in panel, etc.

Parts contact

Waist molding, windshield molding, bumper, etc.

Protectors

Damage or condition of mudguard, fender protector, chipping protector, etc.

Anti-corrosion materials

Damage or separation of anti-corrosion materials under the body.

Drain holes

Condition of drain holes at door and side sill.

When repairing corroded areas, refer to the Corrosion Repair Manual.

CHASSIS AND BODY MAINTENANCE

MA-41

Page 1026 of 1659

Replacing Rear Oil Seal Ð 2WD Model

REMOVAL

1. Remove the propeller shaft. Refer to PD section (``Removal

and Installation'', ``PROPELLER SHAFT'').

2. Remove rear oil seal using Tool.

lAlways replace with a new seal once it has been

removed.

INSTALLATION

1. Install new oil seal until it stops.

lApply multi-purpose grease to seal lip of oil seal before

installing.

2. Install any part removed.

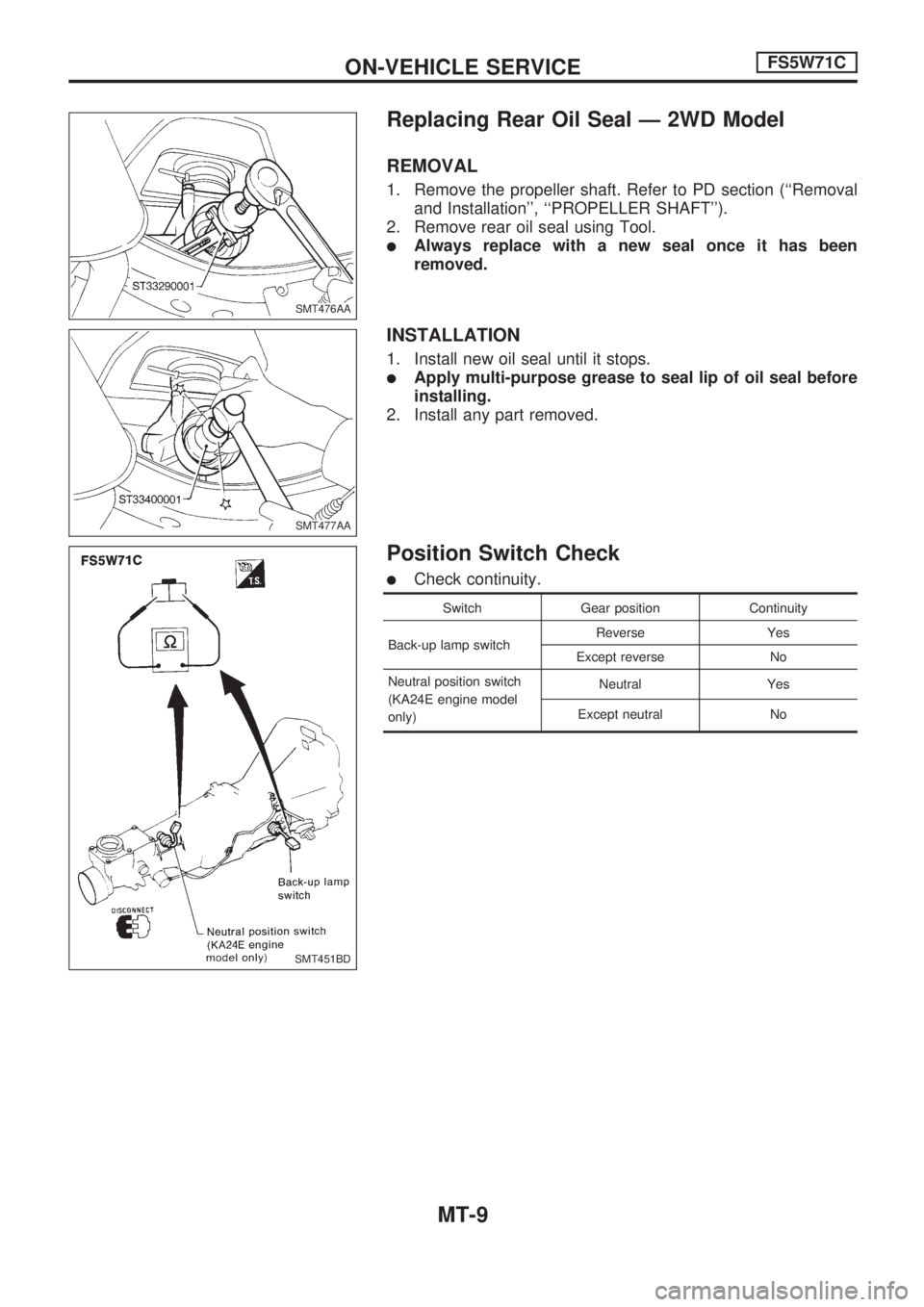

Position Switch Check

lCheck continuity.

Switch Gear position Continuity

Back-up lamp switchReverse Yes

Except reverse No

Neutral position switch

(KA24E engine model

only)Neutral Yes

Except neutral No

SMT476AA

SMT477AA

SMT451BD

ON-VEHICLE SERVICEFS5W71C

MT-9

Page 1120 of 1659

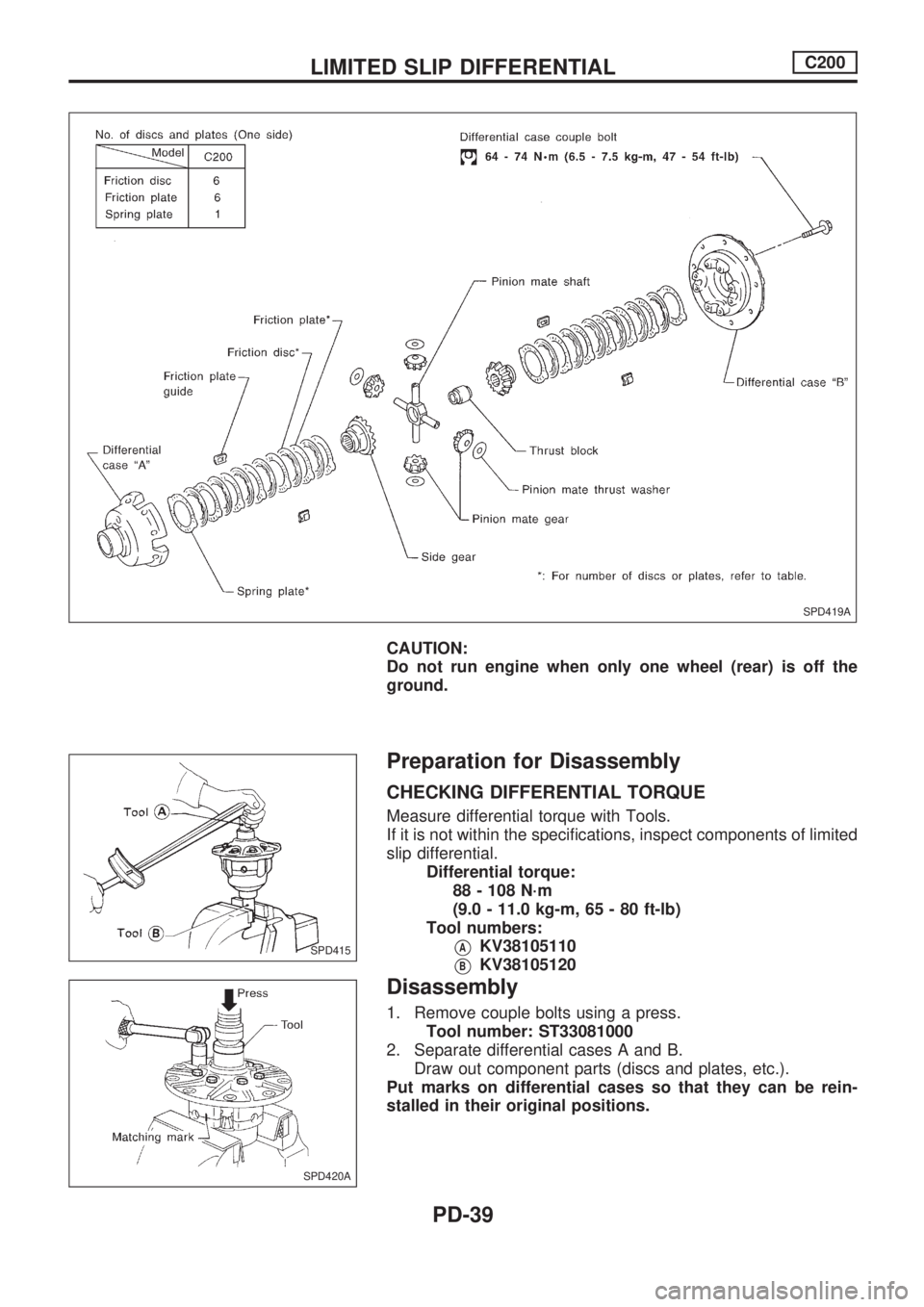

CAUTION:

Do not run engine when only one wheel (rear) is off the

ground.

Preparation for Disassembly

CHECKING DIFFERENTIAL TORQUE

Measure differential torque with Tools.

If it is not within the specifications, inspect components of limited

slip differential.

Differential torque:

88 - 108 N´m

(9.0 - 11.0 kg-m, 65 - 80 ft-lb)

Tool numbers:

VAKV38105110

VBKV38105120

Disassembly

1. Remove couple bolts using a press.

Tool number: ST33081000

2. Separate differential cases A and B.

Draw out component parts (discs and plates, etc.).

Put marks on differential cases so that they can be rein-

stalled in their original positions.

SPD419A

SPD415

SPD420A

LIMITED SLIP DIFFERENTIALC200

PD-39

Page 1142 of 1659

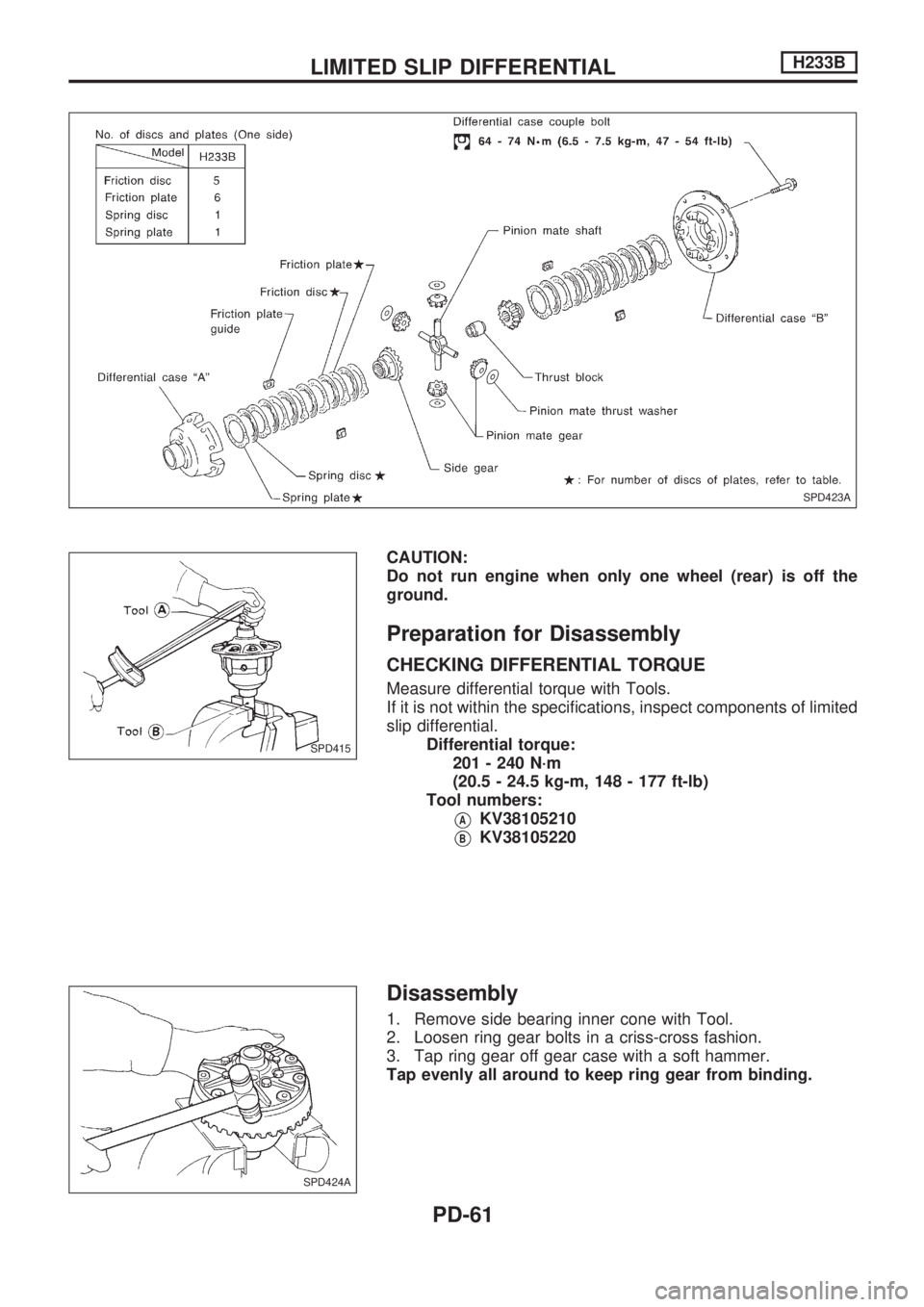

CAUTION:

Do not run engine when only one wheel (rear) is off the

ground.

Preparation for Disassembly

CHECKING DIFFERENTIAL TORQUE

Measure differential torque with Tools.

If it is not within the specifications, inspect components of limited

slip differential.

Differential torque:

201 - 240 N´m

(20.5 - 24.5 kg-m, 148 - 177 ft-lb)

Tool numbers:

VAKV38105210

VBKV38105220

Disassembly

1. Remove side bearing inner cone with Tool.

2. Loosen ring gear bolts in a criss-cross fashion.

3. Tap ring gear off gear case with a soft hammer.

Tap evenly all around to keep ring gear from binding.

SPD423A

SPD415

SPD424A

LIMITED SLIP DIFFERENTIALH233B

PD-61

Page 1207 of 1659

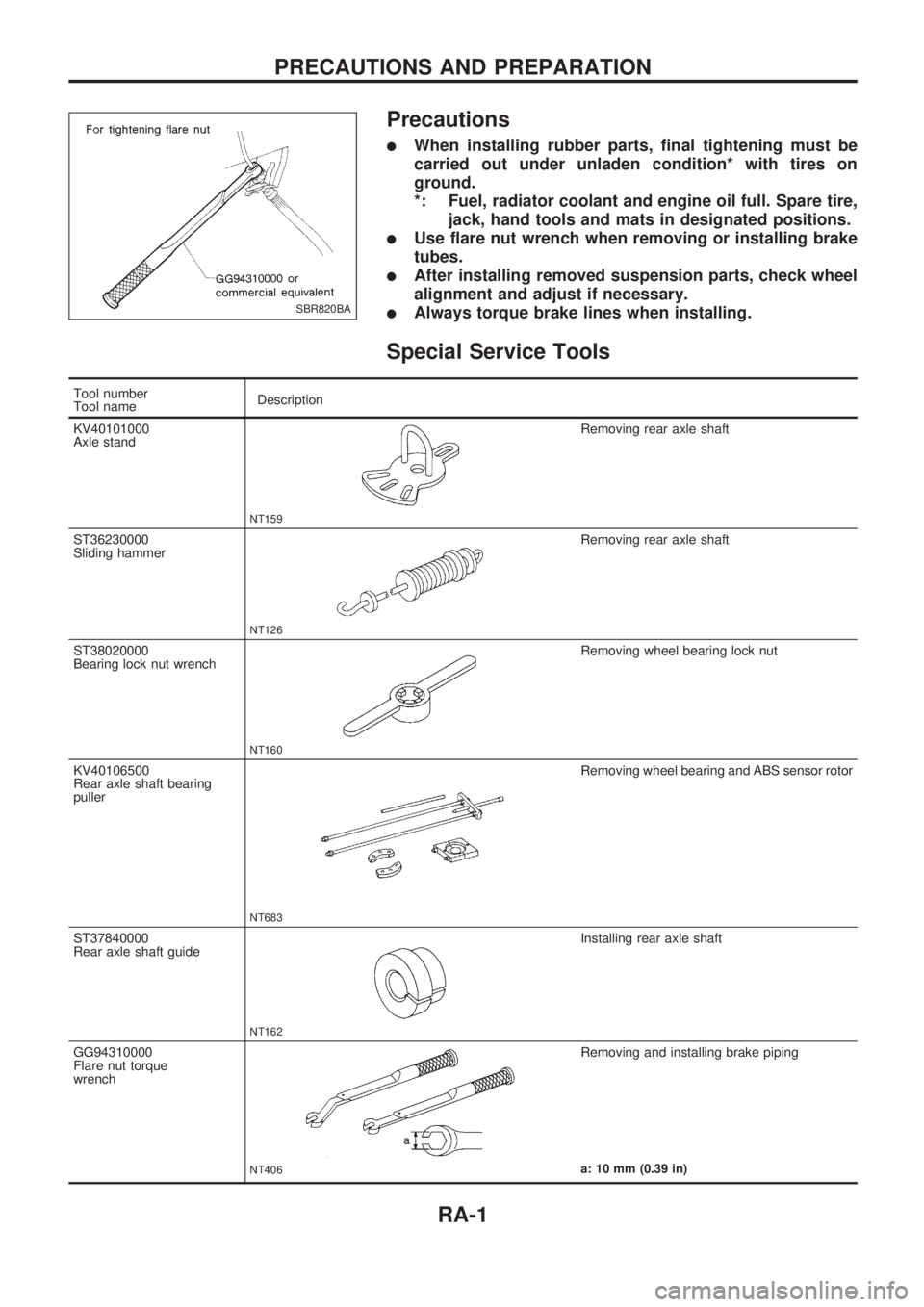

Precautions

lWhen installing rubber parts, final tightening must be

carried out under unladen condition* with tires on

ground.

*: Fuel, radiator coolant and engine oil full. Spare tire,

jack, hand tools and mats in designated positions.

lUse flare nut wrench when removing or installing brake

tubes.

lAfter installing removed suspension parts, check wheel

alignment and adjust if necessary.

lAlways torque brake lines when installing.

Special Service Tools

Tool number

Tool nameDescription

KV40101000

Axle stand

NT159

Removing rear axle shaft

ST36230000

Sliding hammer

NT126

Removing rear axle shaft

ST38020000

Bearing lock nut wrench

NT160

Removing wheel bearing lock nut

KV40106500

Rear axle shaft bearing

puller

NT683

Removing wheel bearing and ABS sensor rotor

ST37840000

Rear axle shaft guide

NT162

Installing rear axle shaft

GG94310000

Flare nut torque

wrench

NT406

Removing and installing brake piping

a: 10 mm (0.39 in)

SBR820BA

PRECAUTIONS AND PREPARATION

RA-1

Page 1220 of 1659

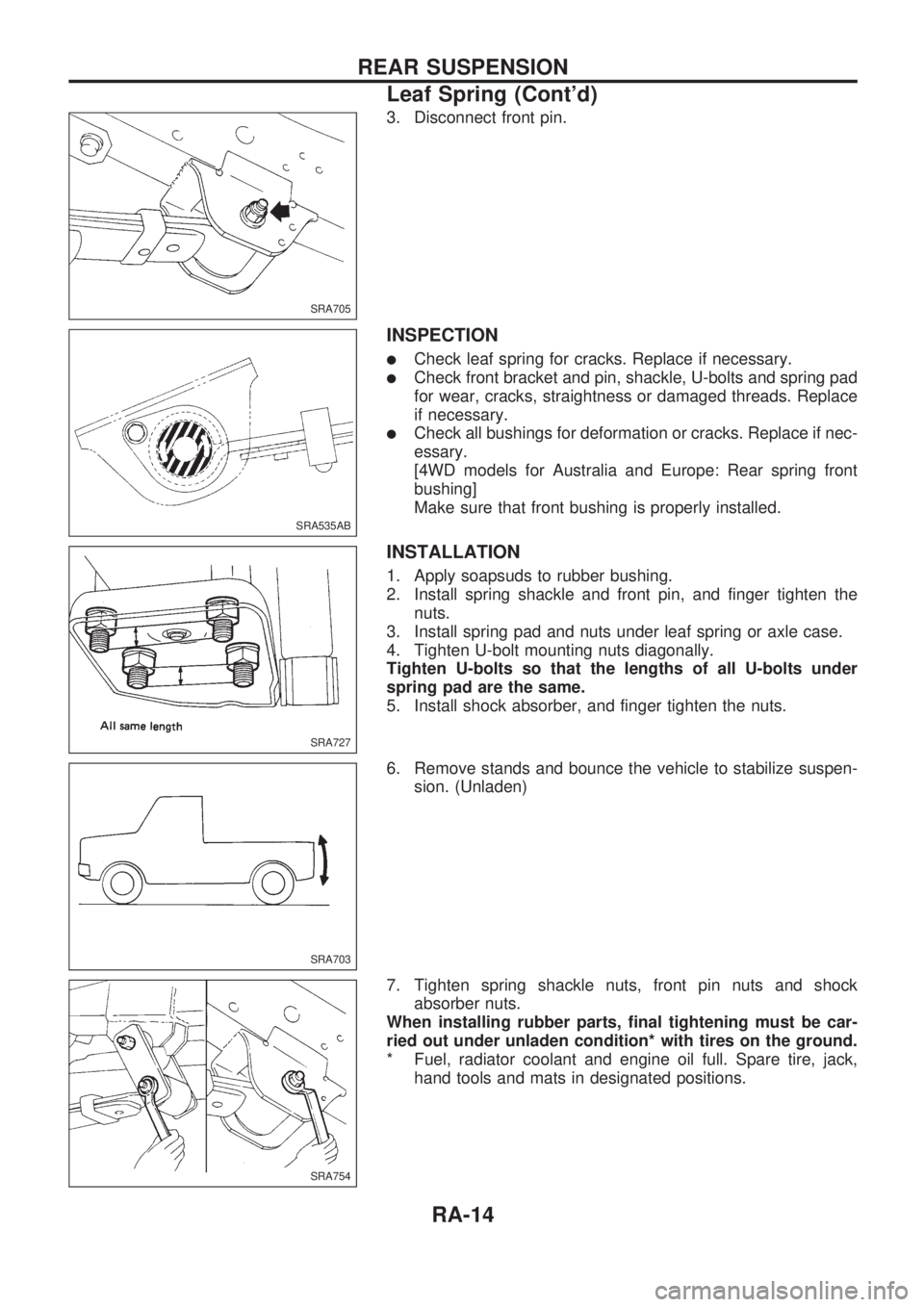

3. Disconnect front pin.

INSPECTION

lCheck leaf spring for cracks. Replace if necessary.

lCheck front bracket and pin, shackle, U-bolts and spring pad

for wear, cracks, straightness or damaged threads. Replace

if necessary.

lCheck all bushings for deformation or cracks. Replace if nec-

essary.

[4WD models for Australia and Europe: Rear spring front

bushing]

Make sure that front bushing is properly installed.

INSTALLATION

1. Apply soapsuds to rubber bushing.

2. Install spring shackle and front pin, and finger tighten the

nuts.

3. Install spring pad and nuts under leaf spring or axle case.

4. Tighten U-bolt mounting nuts diagonally.

Tighten U-bolts so that the lengths of all U-bolts under

spring pad are the same.

5. Install shock absorber, and finger tighten the nuts.

6. Remove stands and bounce the vehicle to stabilize suspen-

sion. (Unladen)

7. Tighten spring shackle nuts, front pin nuts and shock

absorber nuts.

When installing rubber parts, final tightening must be car-

ried out under unladen condition* with tires on the ground.

* Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

SRA705

SRA535AB

.

SRA727

SRA703

SRA754

REAR SUSPENSION

Leaf Spring (Cont'd)

RA-14

Page 1226 of 1659

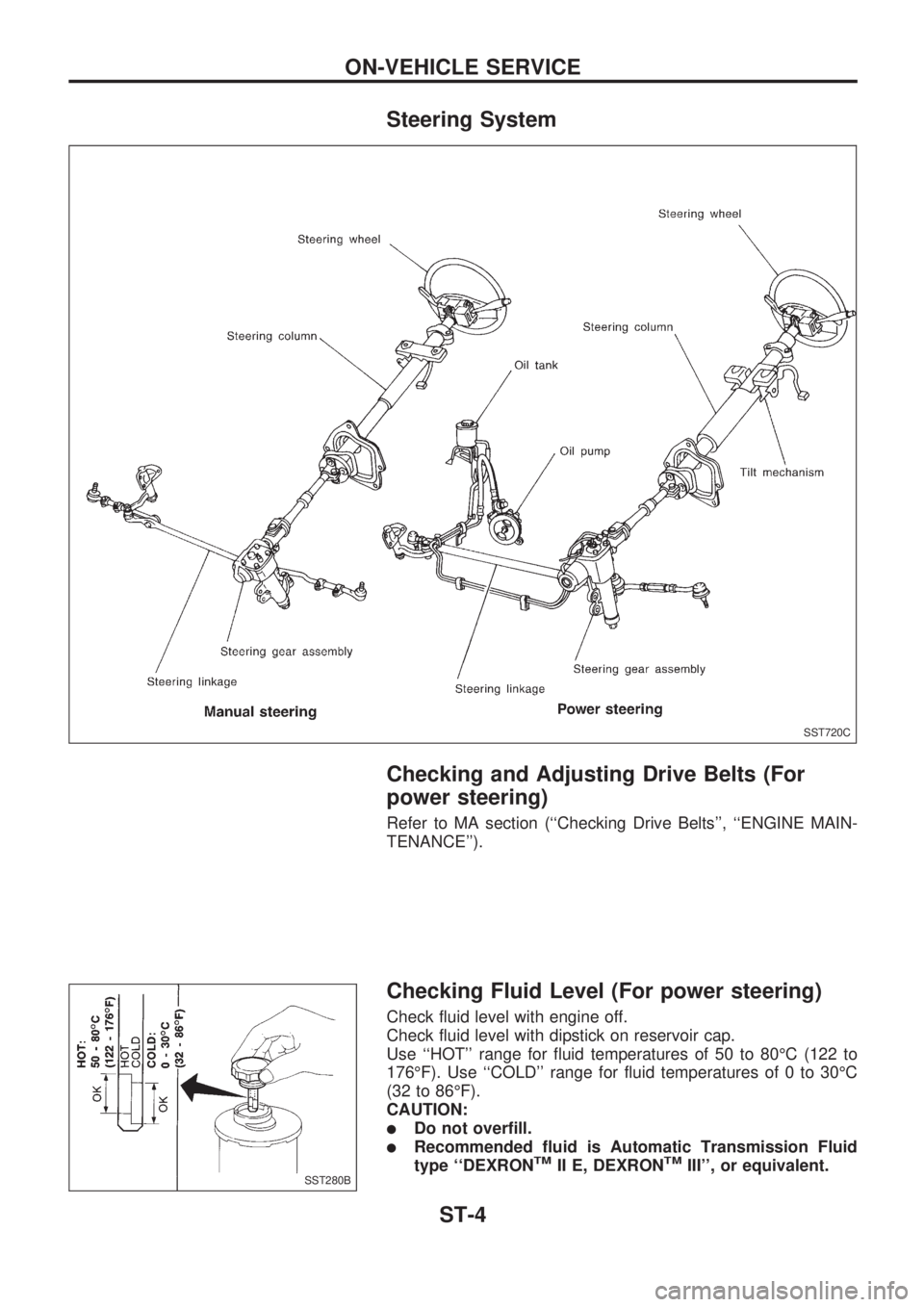

Steering System

Checking and Adjusting Drive Belts (For

power steering)

Refer to MA section (``Checking Drive Belts'', ``ENGINE MAIN-

TENANCE'').

Checking Fluid Level (For power steering)

Check fluid level with engine off.

Check fluid level with dipstick on reservoir cap.

Use ``HOT'' range for fluid temperatures of 50 to 80ÉC (122 to

176ÉF). Use ``COLD'' range for fluid temperatures of 0 to 30ÉC

(32 to 86ÉF).

CAUTION:

lDo not overfill.

lRecommended fluid is Automatic Transmission Fluid

type ``DEXRONTMII E, DEXRONTMIII'', or equivalent.

SST720C

SST280B

ON-VEHICLE SERVICE

ST-4

Page 1227 of 1659

Checking Fluid Leakage (For power steering)

Check lines for improper attachment, leaks, cracks, damage,

chafing or deterioration.

1. Run engine between idle speed and 1,000 rpm.

lMake sure temperature of fluid in reservoir tank rises to

60 to 80ÉC (140 to 176ÉF).

2. Turn steering wheel right-to-left several times.

3. Hold steering wheel at each ``lock'' position for five seconds

and carefully check for fluid leakage.

CAUTION:

Do not hold steering wheel at lock position for more than 15

seconds.

4. If fluid leakage from any line is noticed, loosen flare nut and

then retighten.

Do not overtighten connector as this can damage O-ring,

washer and connector.

5. If fluid leakage from power steering pump is noticed, check

power steering pump. Refer to ST-34.

6. If fluid leakage from power steering gear is noticed, check

power steering gear. Refer to ST-19 (PB48S), or ST-27

(PB59K).

Bleeding Hydraulic System (For power

steering)

1. Raise front end of vehicle until wheels are clear of the

ground.

2. Add fluid to reservoir tank to specified level. Then quickly turn

steering wheel fully to right and left and lightly touch steer-

ing stoppers.

Repeat steering wheel operation until fluid level no longer

decreases.

3. Start engine.

Repeat step 2 above.

lIncomplete air bleeding will cause the following to occur:

a. Air bubbles in reservoir tank

b. Clicking noise in power steering pump

c. Excessive buzzing in power steering pump

When this happens, bleed air again.

Fluid noise may occur in the valve or power steering pump. This

is common when the vehicle is stationary or while turning the

steering wheel slowly. This does not affect the performance or

durability of the system.

SST621A

ON-VEHICLE SERVICE

ST-5

Page 1228 of 1659

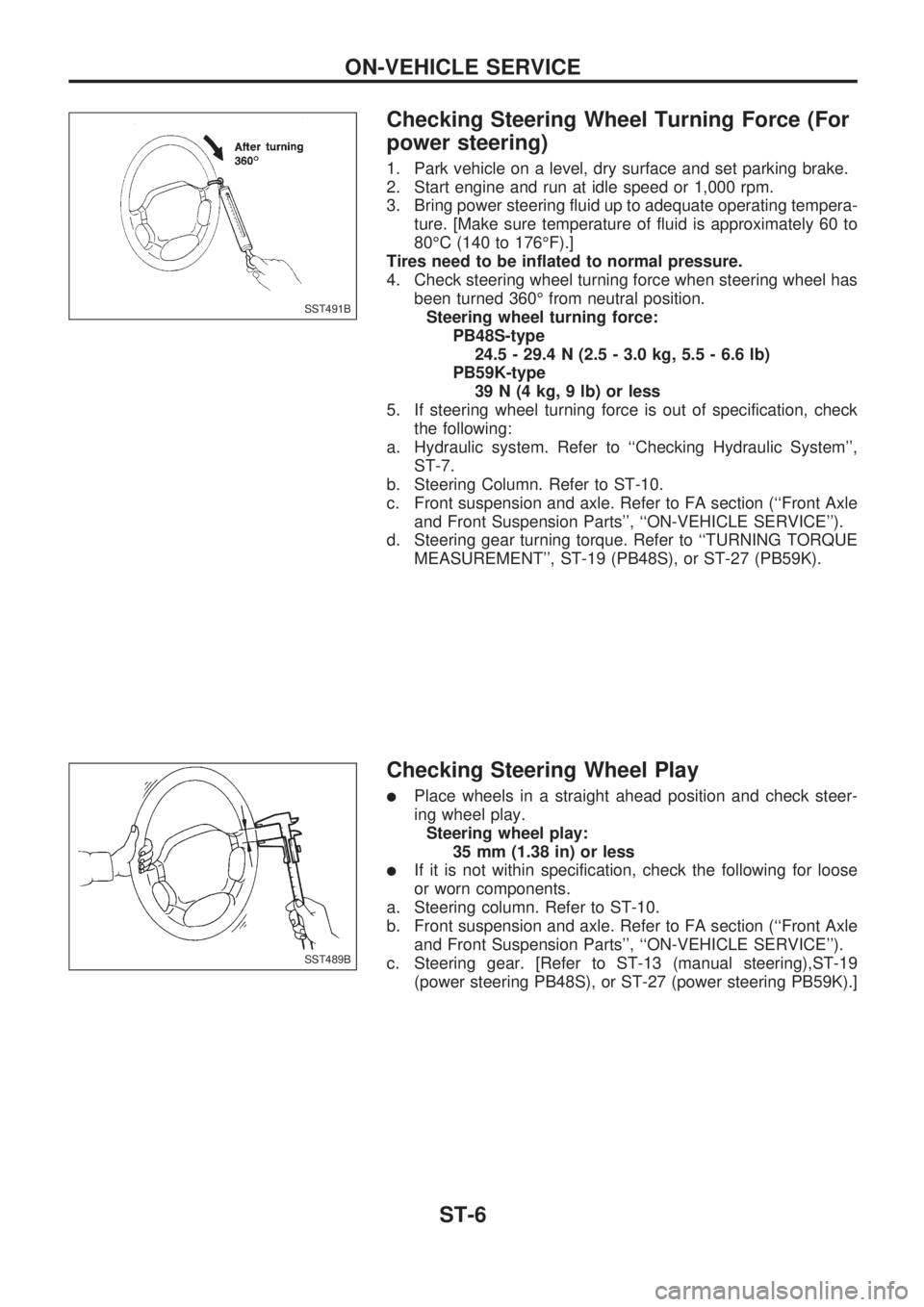

Checking Steering Wheel Turning Force (For

power steering)

1. Park vehicle on a level, dry surface and set parking brake.

2. Start engine and run at idle speed or 1,000 rpm.

3. Bring power steering fluid up to adequate operating tempera-

ture. [Make sure temperature of fluid is approximately 60 to

80ÉC (140 to 176ÉF).]

Tires need to be inflated to normal pressure.

4. Check steering wheel turning force when steering wheel has

been turned 360É from neutral position.

Steering wheel turning force:

PB48S-type

24.5 - 29.4 N (2.5 - 3.0 kg, 5.5 - 6.6 lb)

PB59K-type

39 N (4 kg, 9 lb) or less

5. If steering wheel turning force is out of specification, check

the following:

a. Hydraulic system. Refer to ``Checking Hydraulic System'',

ST-7.

b. Steering Column. Refer to ST-10.

c. Front suspension and axle. Refer to FA section (``Front Axle

and Front Suspension Parts'', ``ON-VEHICLE SERVICE'').

d. Steering gear turning torque. Refer to ``TURNING TORQUE

MEASUREMENT'', ST-19 (PB48S), or ST-27 (PB59K).

Checking Steering Wheel Play

lPlace wheels in a straight ahead position and check steer-

ing wheel play.

Steering wheel play:

35 mm (1.38 in) or less

lIf it is not within specification, check the following for loose

or worn components.

a. Steering column. Refer to ST-10.

b. Front suspension and axle. Refer to FA section (``Front Axle

and Front Suspension Parts'', ``ON-VEHICLE SERVICE'').

c. Steering gear. [Refer to ST-13 (manual steering),ST-19

(power steering PB48S), or ST-27 (power steering PB59K).]

SST491B

SST489B

ON-VEHICLE SERVICE

ST-6