NISSAN PICK-UP 1998 Repair Manual

PICK-UP 1998

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57374/w960_57374-0.png

NISSAN PICK-UP 1998 Repair Manual

Page 950 of 1659

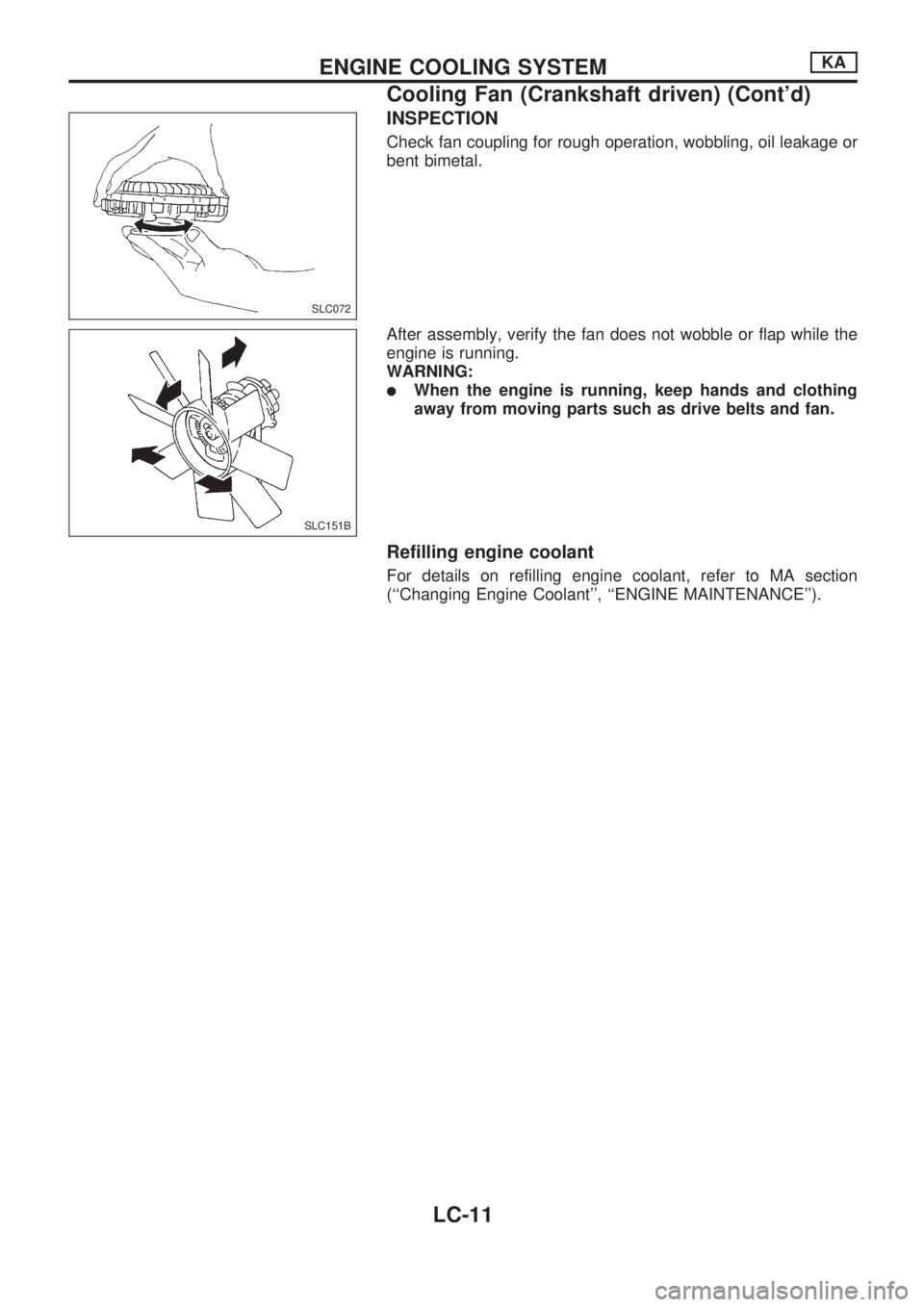

INSPECTION

Check fan coupling for rough operation, wobbling, oil leakage or

bent bimetal.

After assembly, verify the fan does not wobble or flap while the

engine is running.

WARNING:

lWhen the engine is running, keep hands and clothing

away from moving parts such as drive belts and fan.

Refilling engine coolant

For details on refilling engine coolant, refer to MA section

(``Changing Engine Coolant'', ``ENGINE MAINTENANCE'').

SLC072

SLC151B

ENGINE COOLING SYSTEMKA

Cooling Fan (Crankshaft driven) (Cont'd)

LC-11

Page 952 of 1659

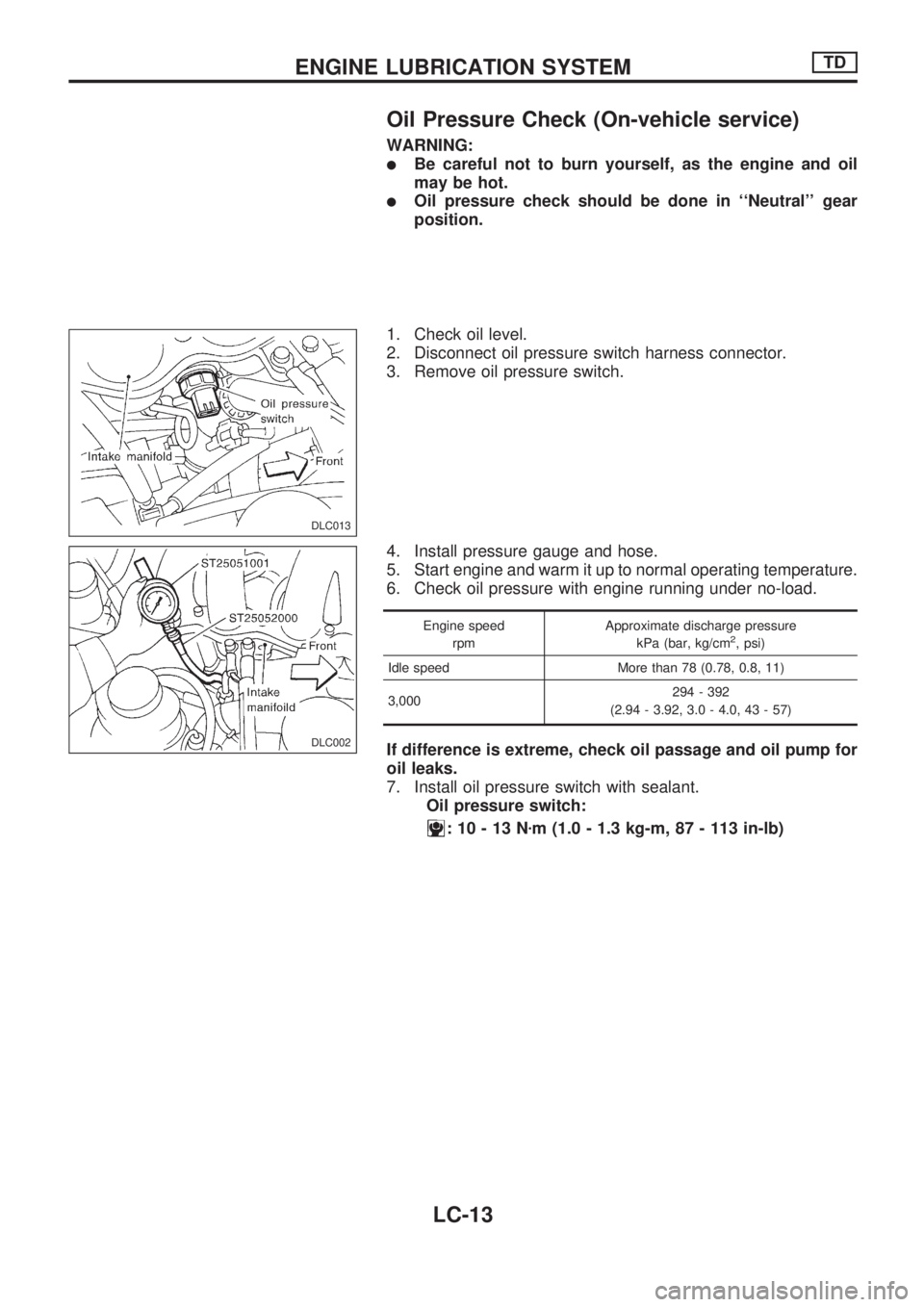

Oil Pressure Check (On-vehicle service)

WARNING:

lBe careful not to burn yourself, as the engine and oil

may be hot.

lOil pressure check should be done in ``Neutral'' gear

position.

1. Check oil level.

2. Disconnect oil pressure switch harness connector.

3. Remove oil pressure switch.

4. Install pressure gauge and hose.

5. Start engine and warm it up to normal operating temperature.

6. Check oil pressure with engine running under no-load.

Engine speed

rpmApproximate discharge pressure

kPa (bar, kg/cm2, psi)

Idle speed More than 78 (0.78, 0.8, 11)

3,000294 - 392

(2.94 - 3.92, 3.0 - 4.0, 43 - 57)

If difference is extreme, check oil passage and oil pump for

oil leaks.

7. Install oil pressure switch with sealant.

Oil pressure switch:

:10-13Nzm (1.0 - 1.3 kg-m, 87 - 113 in-lb)

DLC013

DLC002

ENGINE LUBRICATION SYSTEMTD

LC-13

Page 953 of 1659

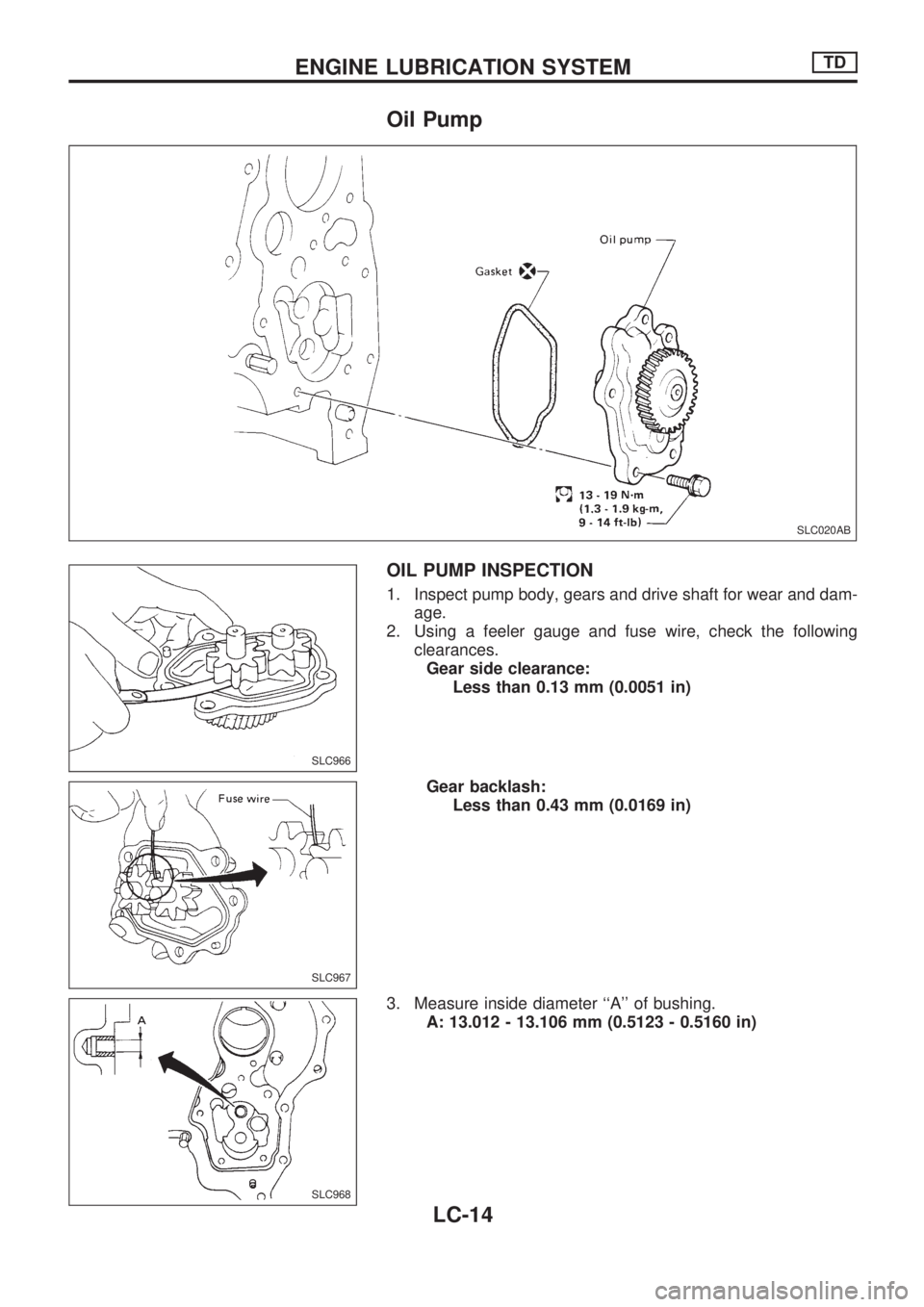

Oil Pump

OIL PUMP INSPECTION

1. Inspect pump body, gears and drive shaft for wear and dam-

age.

2. Using a feeler gauge and fuse wire, check the following

clearances.

Gear side clearance:

Less than 0.13 mm (0.0051 in)

Gear backlash:

Less than 0.43 mm (0.0169 in)

3. Measure inside diameter ``A'' of bushing.

A: 13.012 - 13.106 mm (0.5123 - 0.5160 in)

SLC020AB

SLC966

SLC967

SLC968

ENGINE LUBRICATION SYSTEMTD

LC-14

Page 955 of 1659

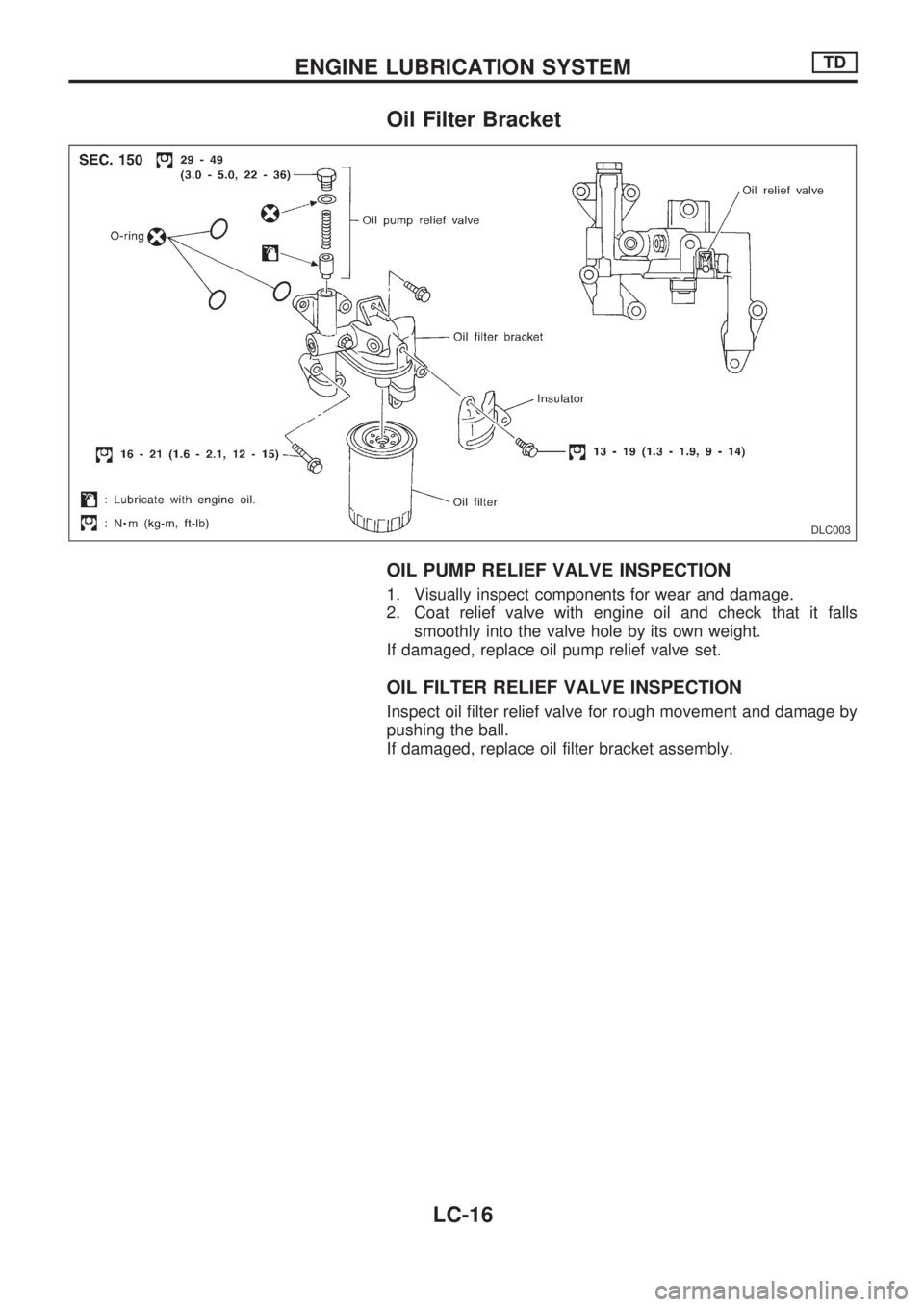

Oil Filter Bracket

OIL PUMP RELIEF VALVE INSPECTION

1. Visually inspect components for wear and damage.

2. Coat relief valve with engine oil and check that it falls

smoothly into the valve hole by its own weight.

If damaged, replace oil pump relief valve set.

OIL FILTER RELIEF VALVE INSPECTION

Inspect oil filter relief valve for rough movement and damage by

pushing the ball.

If damaged, replace oil filter bracket assembly.

DLC003

ENGINE LUBRICATION SYSTEMTD

LC-16

Page 956 of 1659

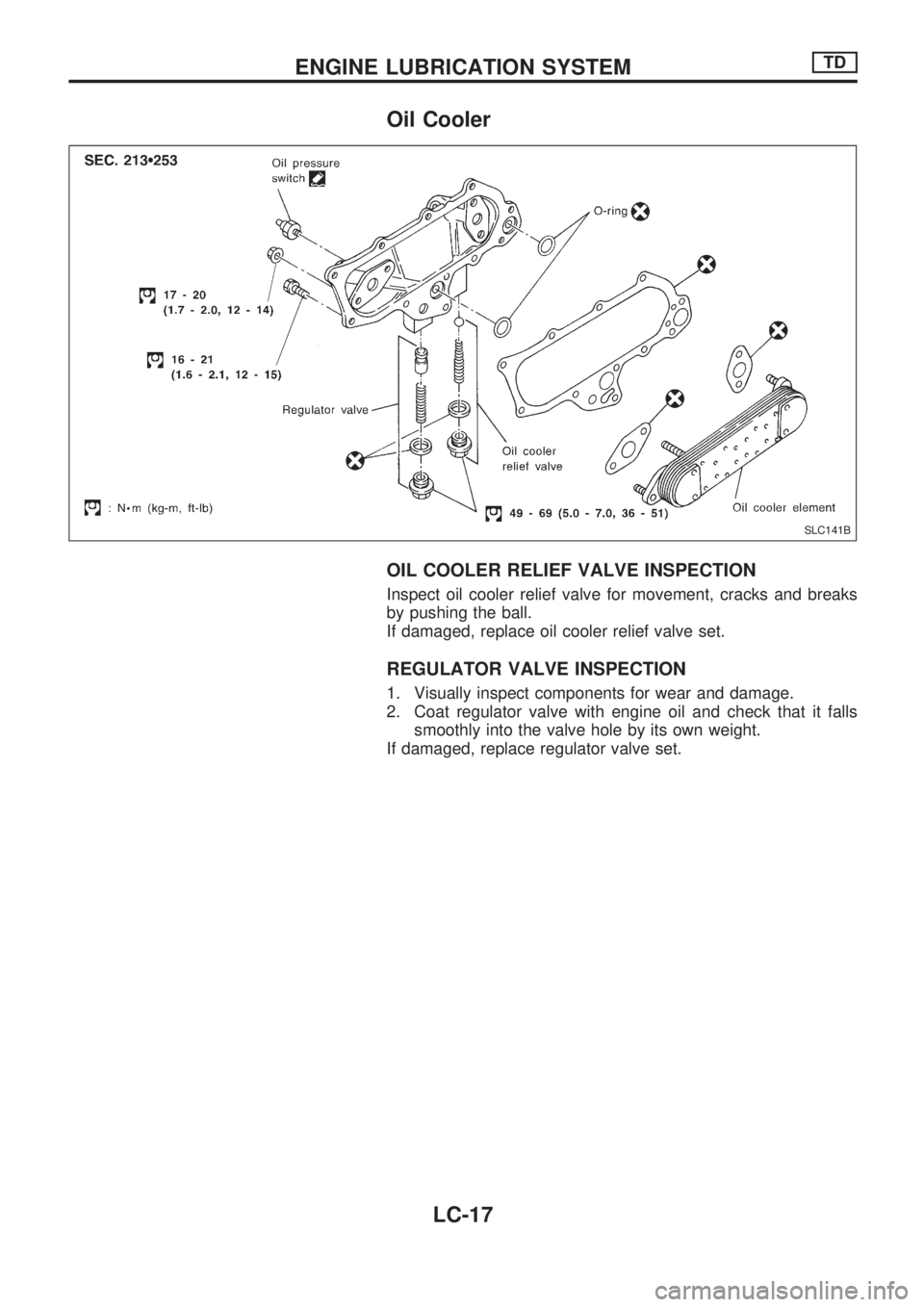

Oil Cooler

OIL COOLER RELIEF VALVE INSPECTION

Inspect oil cooler relief valve for movement, cracks and breaks

by pushing the ball.

If damaged, replace oil cooler relief valve set.

REGULATOR VALVE INSPECTION

1. Visually inspect components for wear and damage.

2. Coat regulator valve with engine oil and check that it falls

smoothly into the valve hole by its own weight.

If damaged, replace regulator valve set.

SLC141B

ENGINE LUBRICATION SYSTEMTD

LC-17

Page 959 of 1659

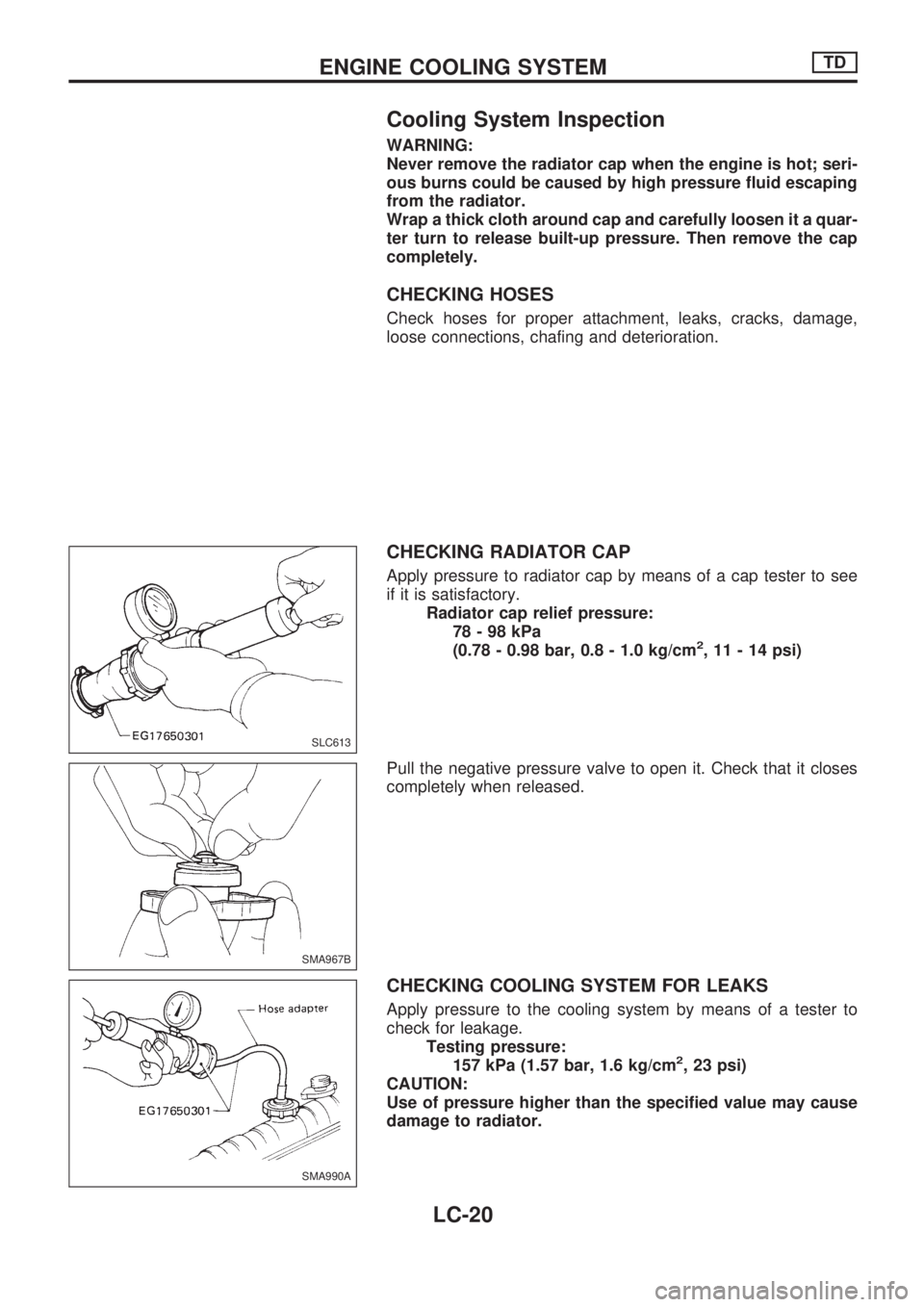

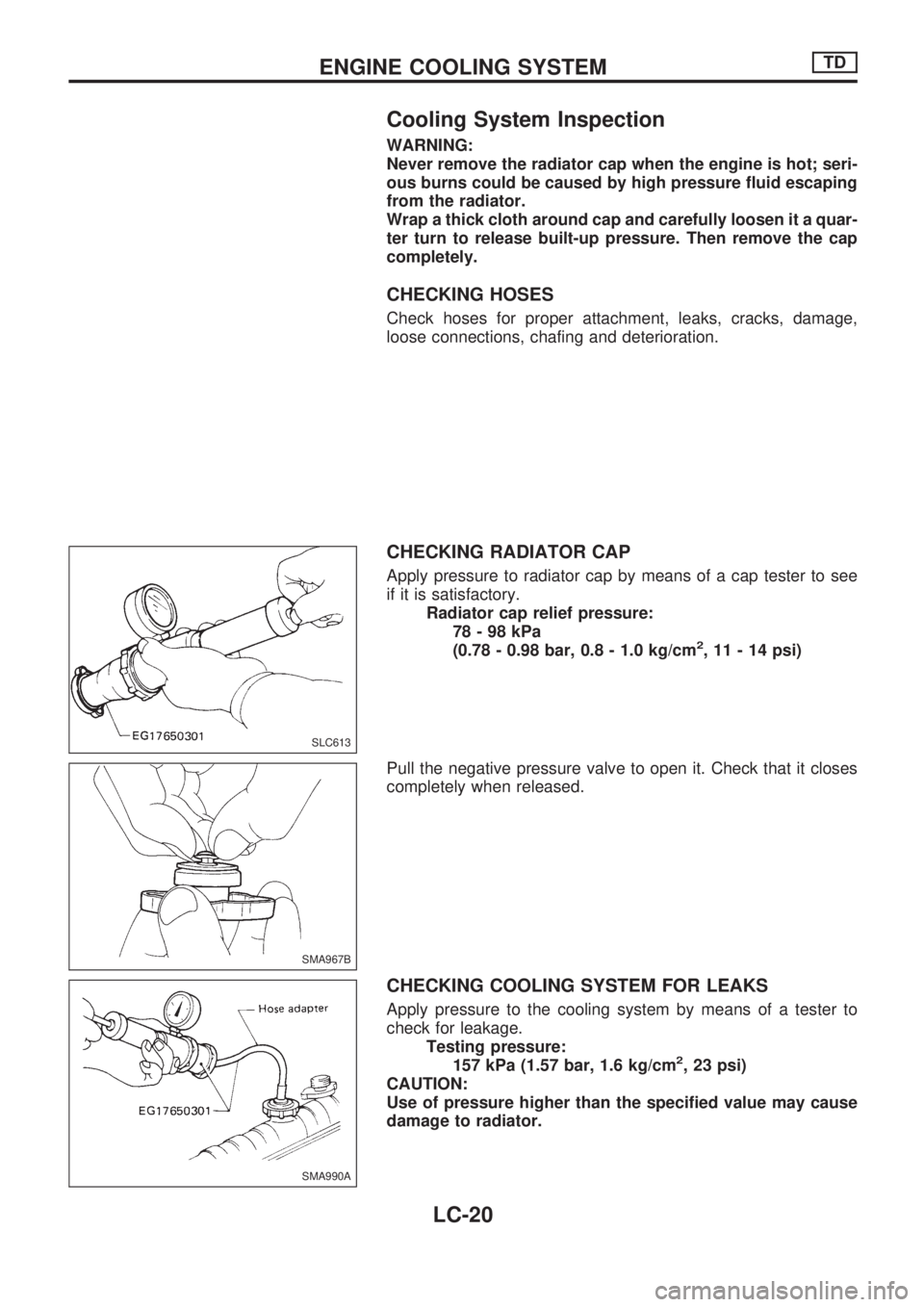

Cooling System Inspection

WARNING:

Never remove the radiator cap when the engine is hot; seri-

ous burns could be caused by high pressure fluid escaping

from the radiator.

Wrap a thick cloth around cap and carefully loosen it a quar-

ter turn to release built-up pressure. Then remove the cap

completely.

CHECKING HOSES

Check hoses for proper attachment, leaks, cracks, damage,

loose connections, chafing and deterioration.

CHECKING RADIATOR CAP

Apply pressure to radiator cap by means of a cap tester to see

if it is satisfactory.

Radiator cap relief pressure:

78-98kPa

(0.78 - 0.98 bar, 0.8 - 1.0 kg/cm

2, 11 - 14 psi)

Pull the negative pressure valve to open it. Check that it closes

completely when released.

CHECKING COOLING SYSTEM FOR LEAKS

Apply pressure to the cooling system by means of a tester to

check for leakage.

Testing pressure:

157 kPa (1.57 bar, 1.6 kg/cm

2, 23 psi)

CAUTION:

Use of pressure higher than the specified value may cause

damage to radiator.

SLC613

SMA967B

SMA990A

ENGINE COOLING SYSTEMTD

LC-20

Page 960 of 1659

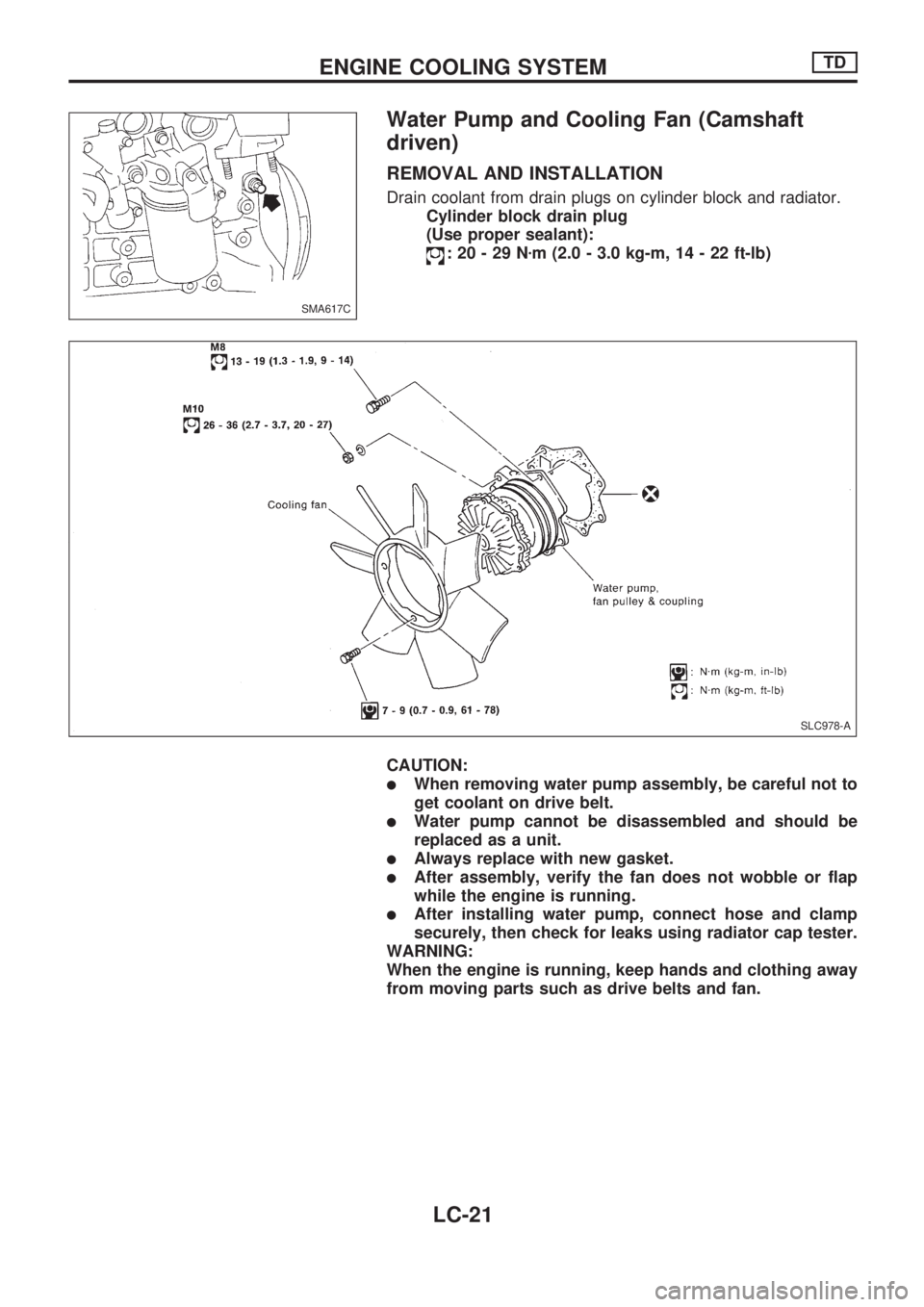

Water Pump and Cooling Fan (Camshaft

driven)

REMOVAL AND INSTALLATION

Drain coolant from drain plugs on cylinder block and radiator.

Cylinder block drain plug

(Use proper sealant):

:20-29Nzm (2.0 - 3.0 kg-m, 14 - 22 ft-lb)

CAUTION:

lWhen removing water pump assembly, be careful not to

get coolant on drive belt.

lWater pump cannot be disassembled and should be

replaced as a unit.

lAlways replace with new gasket.

lAfter assembly, verify the fan does not wobble or flap

while the engine is running.

lAfter installing water pump, connect hose and clamp

securely, then check for leaks using radiator cap tester.

WARNING:

When the engine is running, keep hands and clothing away

from moving parts such as drive belts and fan.

SMA617C

SLC978-A

ENGINE COOLING SYSTEMTD

LC-21

Page 961 of 1659

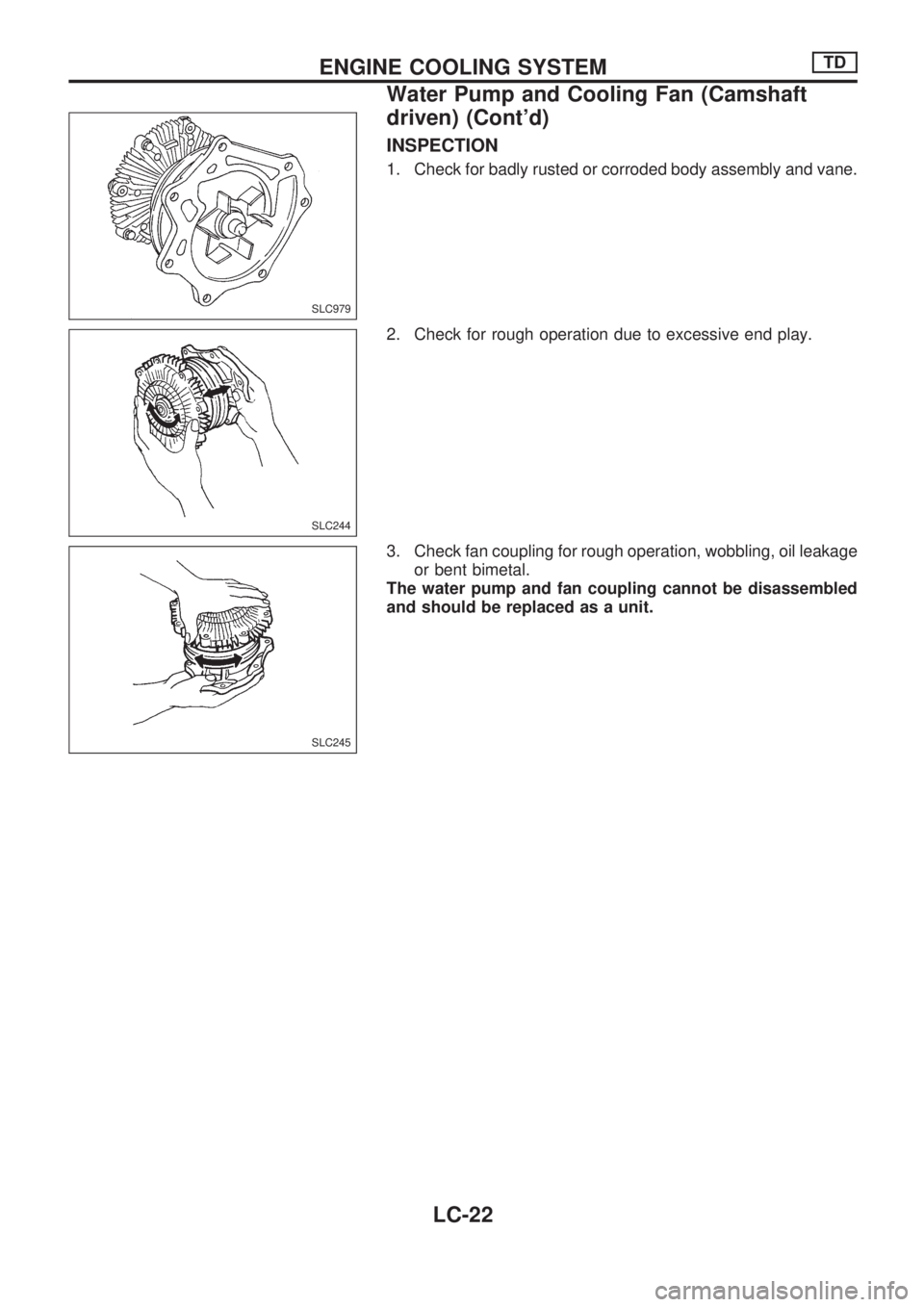

INSPECTION

1. Check for badly rusted or corroded body assembly and vane.

2. Check for rough operation due to excessive end play.

3. Check fan coupling for rough operation, wobbling, oil leakage

or bent bimetal.

The water pump and fan coupling cannot be disassembled

and should be replaced as a unit.

SLC979

SLC244

SLC245

ENGINE COOLING SYSTEMTD

Water Pump and Cooling Fan (Camshaft

driven) (Cont'd)

LC-22

Page 962 of 1659

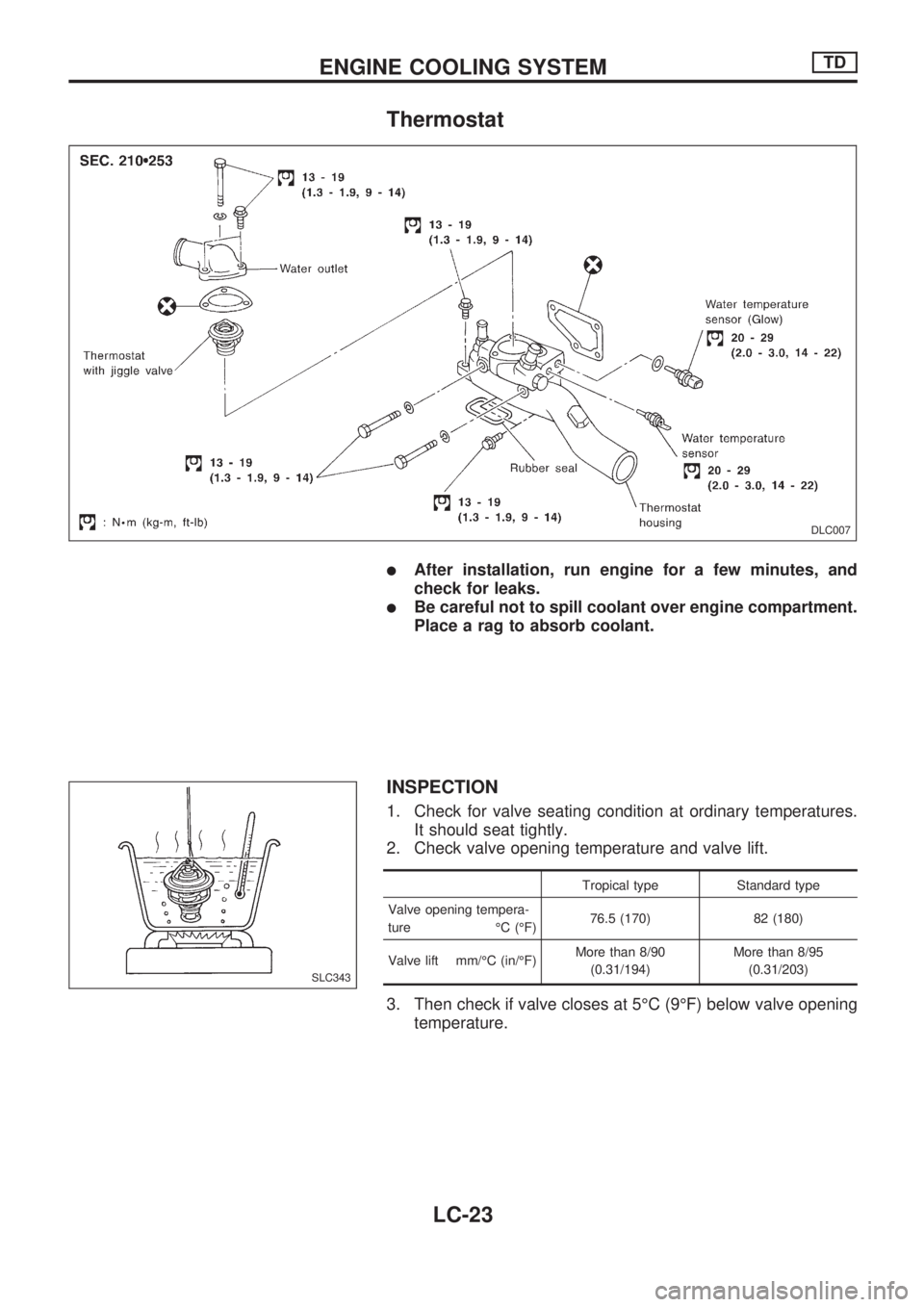

Thermostat

lAfter installation, run engine for a few minutes, and

check for leaks.

lBe careful not to spill coolant over engine compartment.

Place a rag to absorb coolant.

INSPECTION

1. Check for valve seating condition at ordinary temperatures.

It should seat tightly.

2. Check valve opening temperature and valve lift.

Tropical type Standard type

Valve opening tempera-

ture ÉC (ÉF)76.5 (170) 82 (180)

Valve lift mm/ÉC (in/ÉF)More than 8/90

(0.31/194)More than 8/95

(0.31/203)

3. Then check if valve closes at 5ÉC (9ÉF) below valve opening

temperature.

DLC007

SLC343

ENGINE COOLING SYSTEMTD

LC-23

Page 965 of 1659

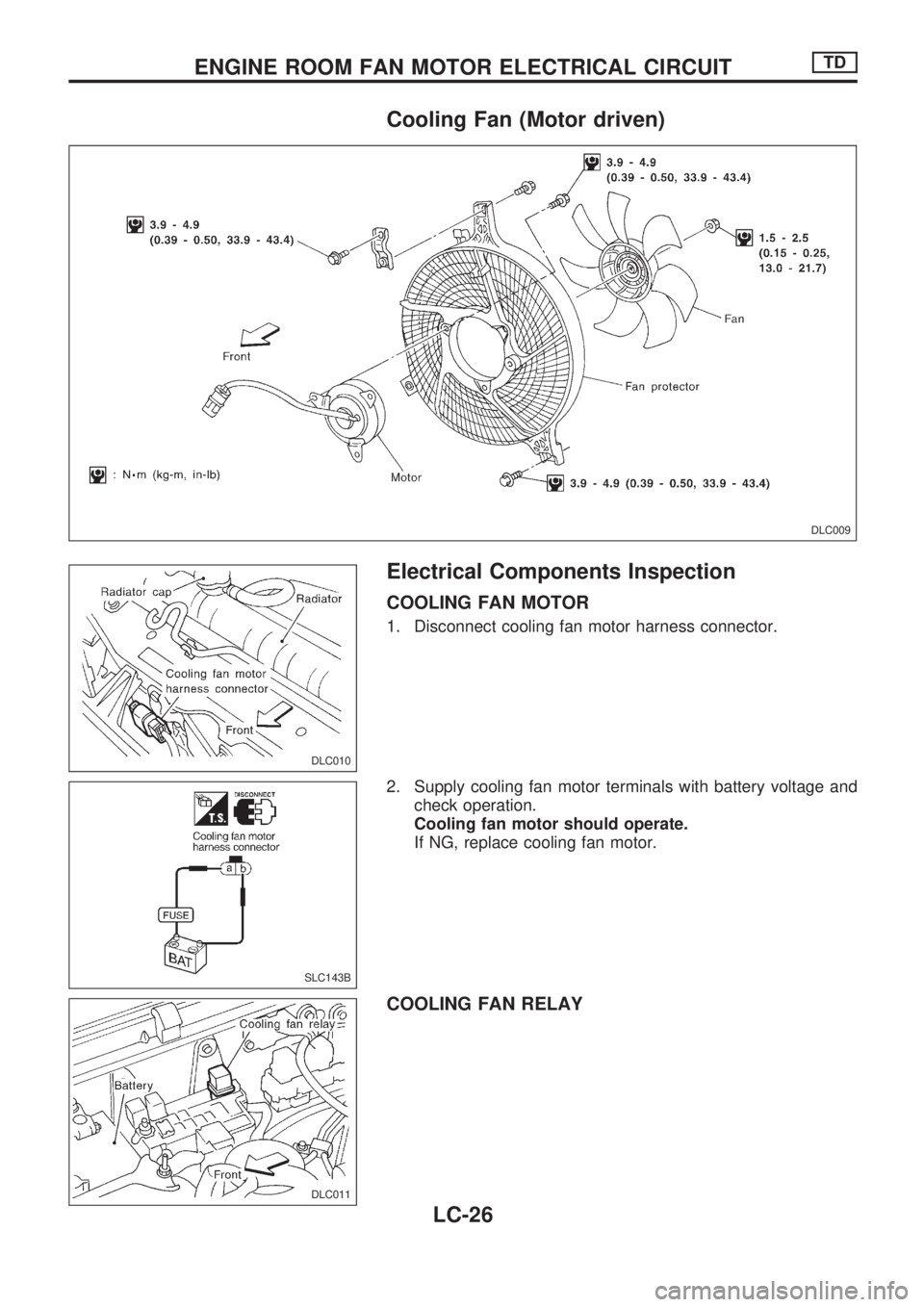

Cooling Fan (Motor driven)

Electrical Components Inspection

COOLING FAN MOTOR

1. Disconnect cooling fan motor harness connector.

2. Supply cooling fan motor terminals with battery voltage and

check operation.

Cooling fan motor should operate.

If NG, replace cooling fan motor.

COOLING FAN RELAY

DLC009

DLC010

SLC143B

DLC011

ENGINE ROOM FAN MOTOR ELECTRICAL CIRCUITTD

LC-26