wheel size NISSAN PICK-UP 1998 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 68 of 1659

VA

Note

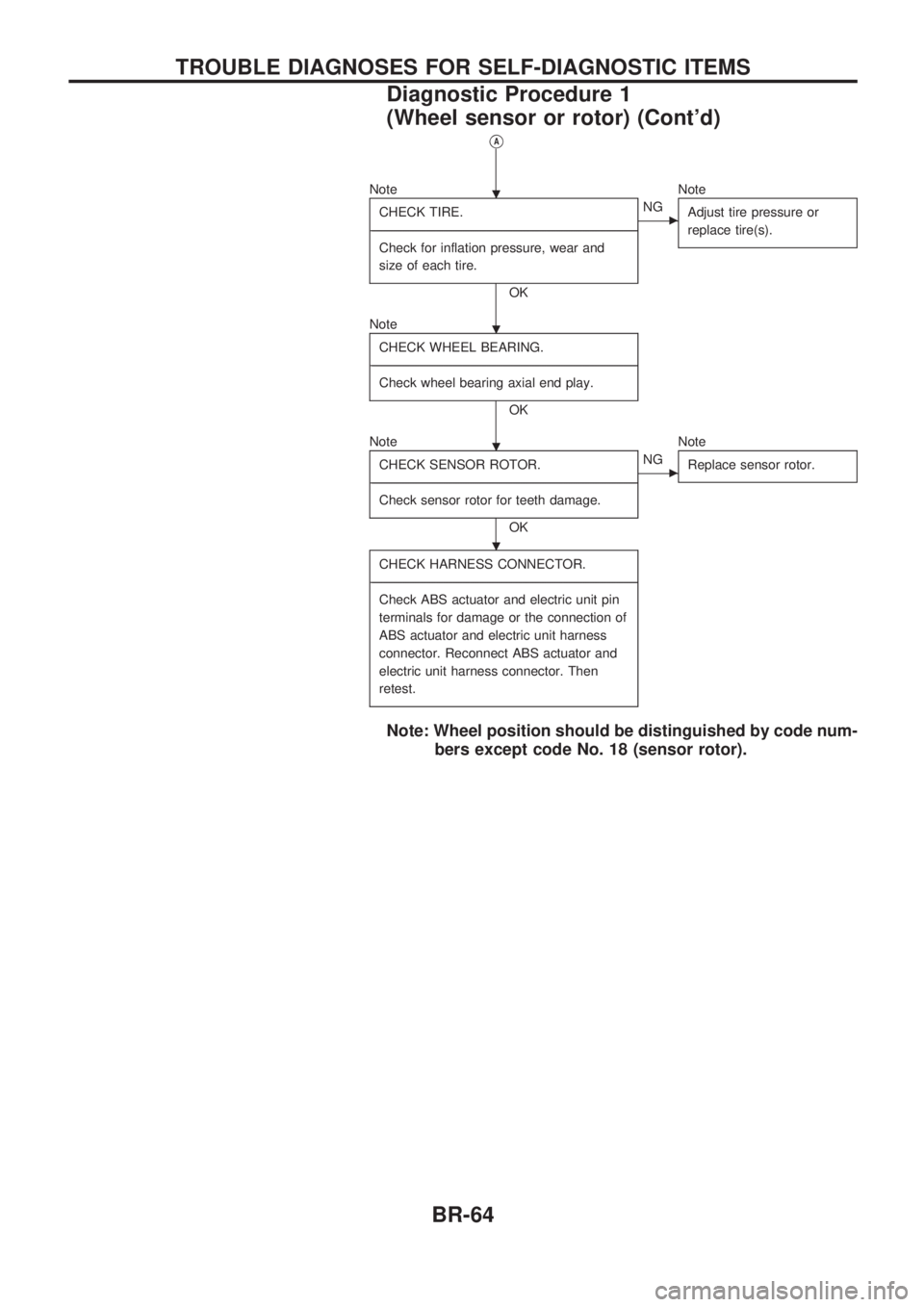

CHECK TIRE.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check for inflation pressure, wear and

size of each tire.

OK

cNGNote

Adjust tire pressure or

replace tire(s).

Note

CHECK WHEEL BEARING.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check wheel bearing axial end play.

OK

Note

CHECK SENSOR ROTOR.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check sensor rotor for teeth damage.

OK

cNGNote

Replace sensor rotor.

CHECK HARNESS CONNECTOR.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check ABS actuator and electric unit pin

terminals for damage or the connection of

ABS actuator and electric unit harness

connector. Reconnect ABS actuator and

electric unit harness connector. Then

retest.

Note: Wheel position should be distinguished by code num-

bers except code No. 18 (sensor rotor).

.

.

.

.

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMS

Diagnostic Procedure 1

(Wheel sensor or rotor) (Cont'd)

BR-64

Page 690 of 1659

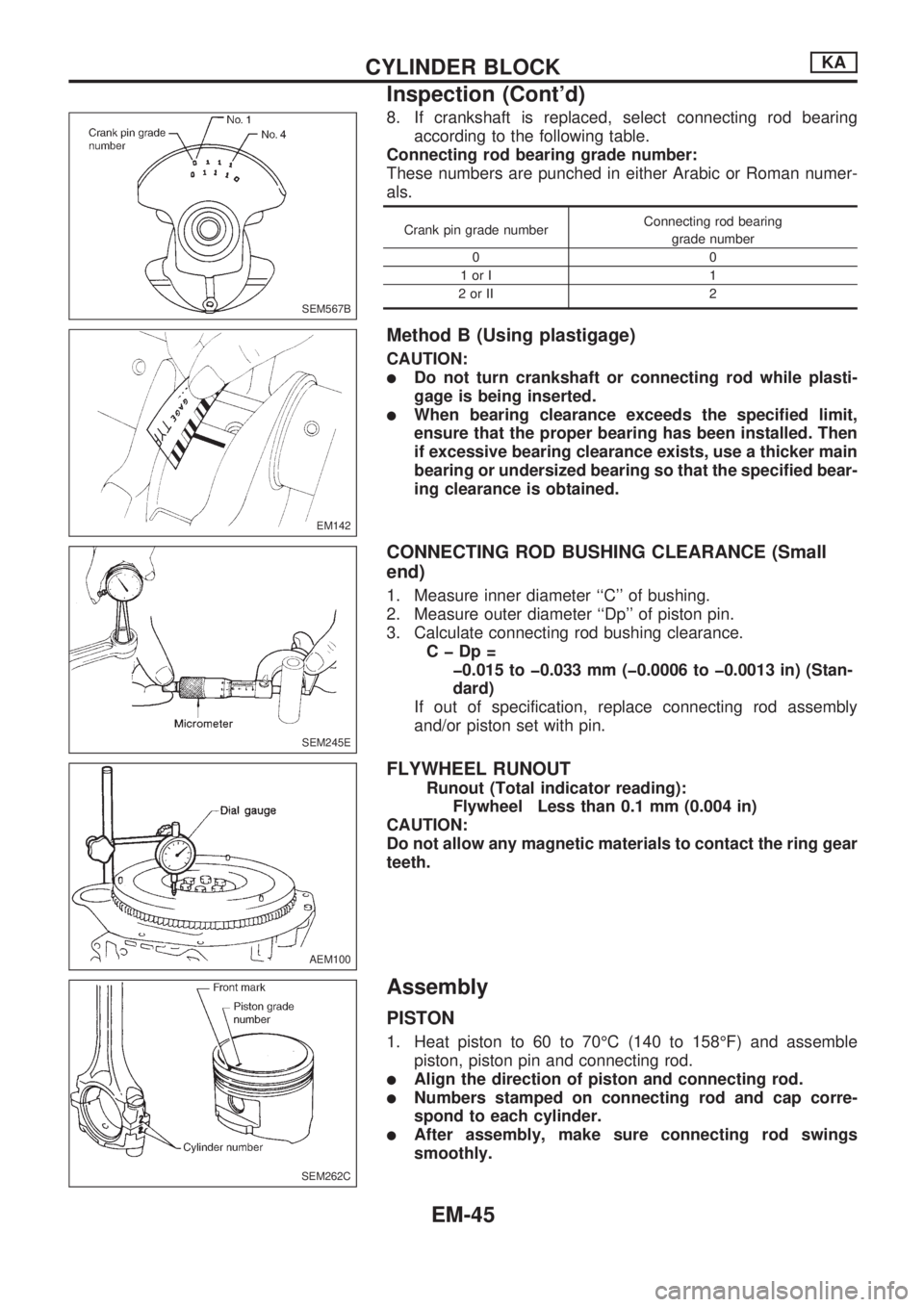

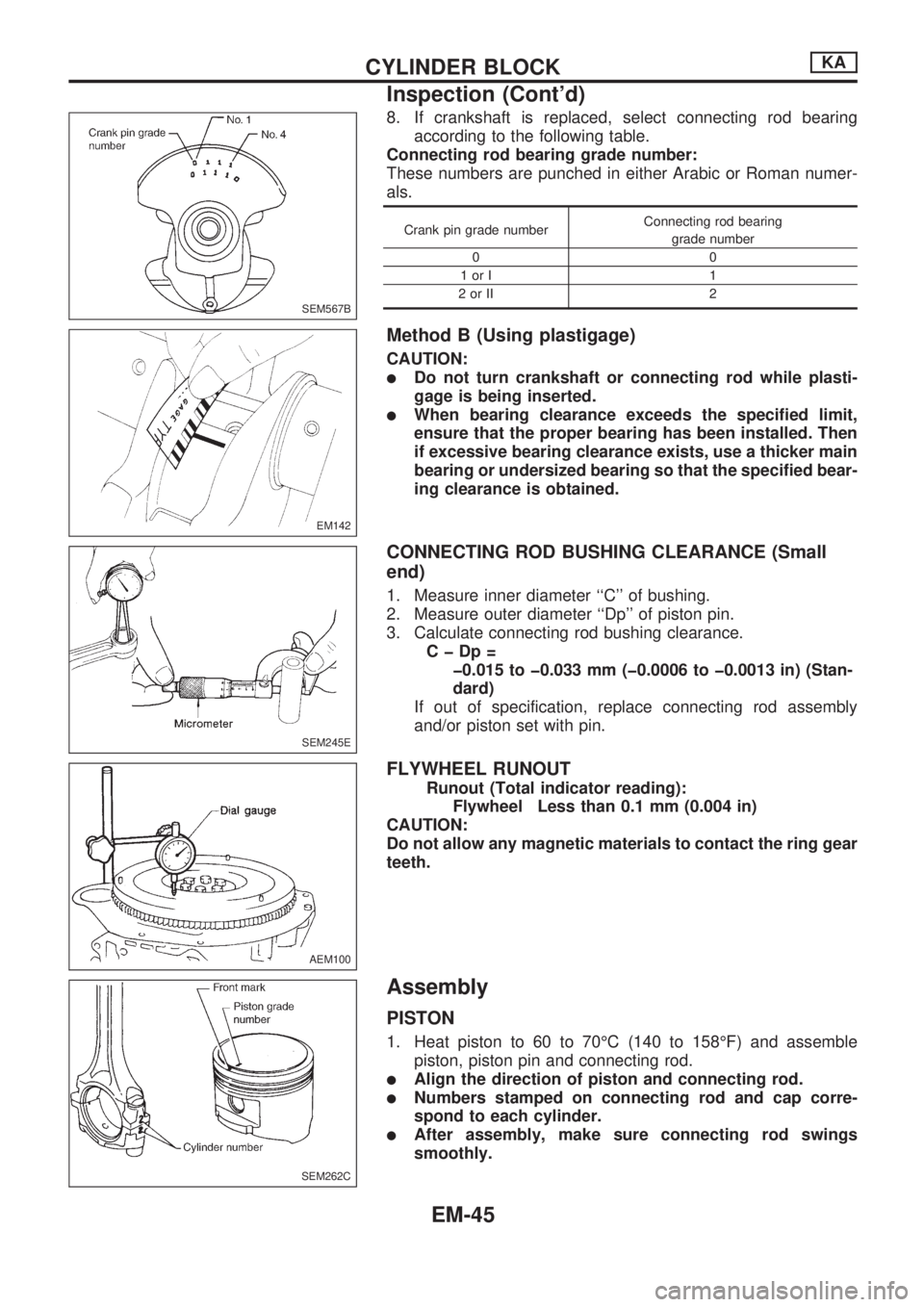

8. If crankshaft is replaced, select connecting rod bearing

according to the following table.

Connecting rod bearing grade number:

These numbers are punched in either Arabic or Roman numer-

als.

Crank pin grade numberConnecting rod bearing

grade number

00

1orI 1

2orII 2

Method B (Using plastigage)

CAUTION:

lDo not turn crankshaft or connecting rod while plasti-

gage is being inserted.

lWhen bearing clearance exceeds the specified limit,

ensure that the proper bearing has been installed. Then

if excessive bearing clearance exists, use a thicker main

bearing or undersized bearing so that the specified bear-

ing clearance is obtained.

CONNECTING ROD BUSHING CLEARANCE (Small

end)

1. Measure inner diameter ``C'' of bushing.

2. Measure outer diameter ``Dp'' of piston pin.

3. Calculate connecting rod bushing clearance.

CþDp=

þ0.015 to þ0.033 mm (þ0.0006 to þ0.0013 in) (Stan-

dard)

If out of specification, replace connecting rod assembly

and/or piston set with pin.

FLYWHEEL RUNOUT

Runout (Total indicator reading):

Flywheel Less than 0.1 mm (0.004 in)

CAUTION:

Do not allow any magnetic materials to contact the ring gear

teeth.

Assembly

PISTON

1. Heat piston to 60 to 70ÉC (140 to 158ÉF) and assemble

piston, piston pin and connecting rod.

lAlign the direction of piston and connecting rod.

lNumbers stamped on connecting rod and cap corre-

spond to each cylinder.

lAfter assembly, make sure connecting rod swings

smoothly.

SEM567B

EM142

SEM245E

AEM100

SEM262C

CYLINDER BLOCKKA

Inspection (Cont'd)

EM-45

Page 742 of 1659

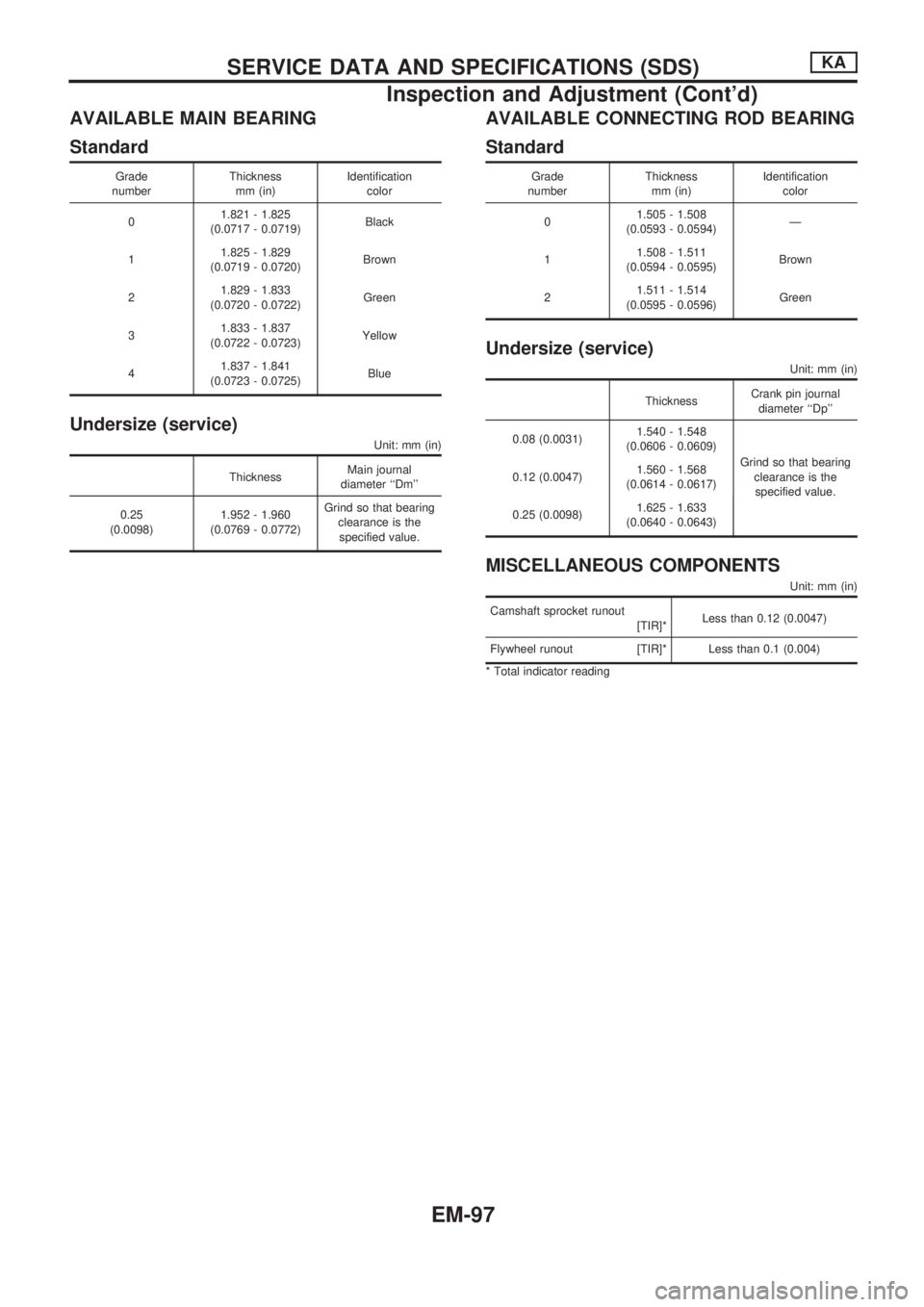

AVAILABLE MAIN BEARING

Standard

Grade

numberThickness

mm (in)Identification

color

01.821 - 1.825

(0.0717 - 0.0719)Black

11.825 - 1.829

(0.0719 - 0.0720)Brown

21.829 - 1.833

(0.0720 - 0.0722)Green

31.833 - 1.837

(0.0722 - 0.0723)Yellow

41.837 - 1.841

(0.0723 - 0.0725)Blue

Undersize (service)

Unit: mm (in)

ThicknessMain journal

diameter ``Dm''

0.25

(0.0098)1.952 - 1.960

(0.0769 - 0.0772)Grind so that bearing

clearance is the

specified value.

AVAILABLE CONNECTING ROD BEARING

Standard

Grade

numberThickness

mm (in)Identification

color

01.505 - 1.508

(0.0593 - 0.0594)Ð

11.508 - 1.511

(0.0594 - 0.0595)Brown

21.511 - 1.514

(0.0595 - 0.0596)Green

Undersize (service)

Unit: mm (in)

ThicknessCrank pin journal

diameter ``Dp''

0.08 (0.0031)1.540 - 1.548

(0.0606 - 0.0609)

Grind so that bearing

clearance is the

specified value. 0.12 (0.0047)1.560 - 1.568

(0.0614 - 0.0617)

0.25 (0.0098)1.625 - 1.633

(0.0640 - 0.0643)

MISCELLANEOUS COMPONENTS

Unit: mm (in)

Camshaft sprocket runout

[TIR]*Less than 0.12 (0.0047)

Flywheel runout [TIR]* Less than 0.1 (0.004)

* Total indicator reading

SERVICE DATA AND SPECIFICATIONS (SDS)KA

Inspection and Adjustment (Cont'd)

EM-97

Page 751 of 1659

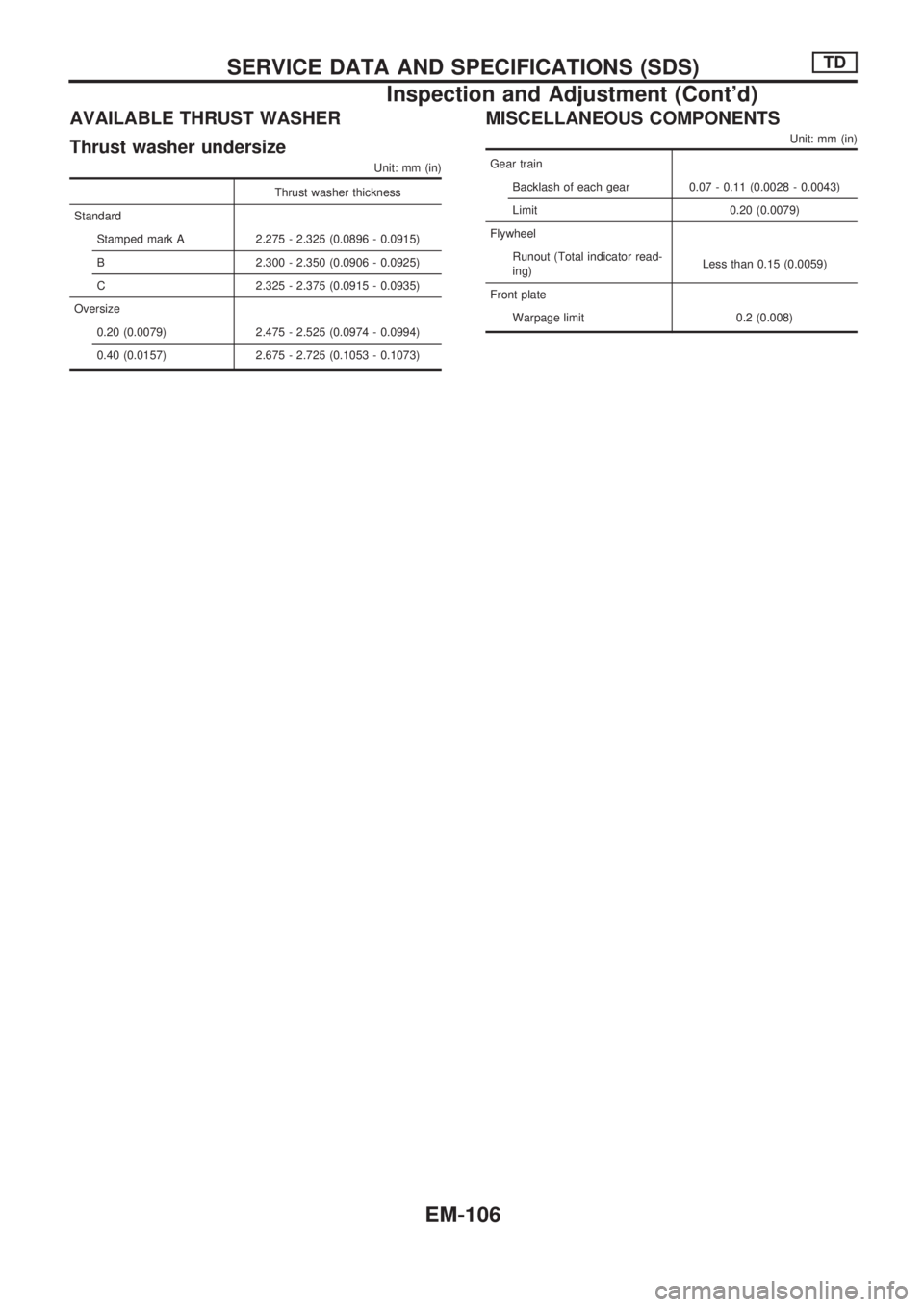

AVAILABLE THRUST WASHER

Thrust washer undersize

Unit: mm (in)

Thrust washer thickness

Standard

Stamped mark A 2.275 - 2.325 (0.0896 - 0.0915)

B 2.300 - 2.350 (0.0906 - 0.0925)

C 2.325 - 2.375 (0.0915 - 0.0935)

Oversize

0.20 (0.0079) 2.475 - 2.525 (0.0974 - 0.0994)

0.40 (0.0157) 2.675 - 2.725 (0.1053 - 0.1073)

MISCELLANEOUS COMPONENTS

Unit: mm (in)

Gear train

Backlash of each gear 0.07 - 0.11 (0.0028 - 0.0043)

Limit 0.20 (0.0079)

Flywheel

Runout (Total indicator read-

ing)Less than 0.15 (0.0059)

Front plate

Warpage limit 0.2 (0.008)

SERVICE DATA AND SPECIFICATIONS (SDS)TD

Inspection and Adjustment (Cont'd)

EM-106

Page 869 of 1659

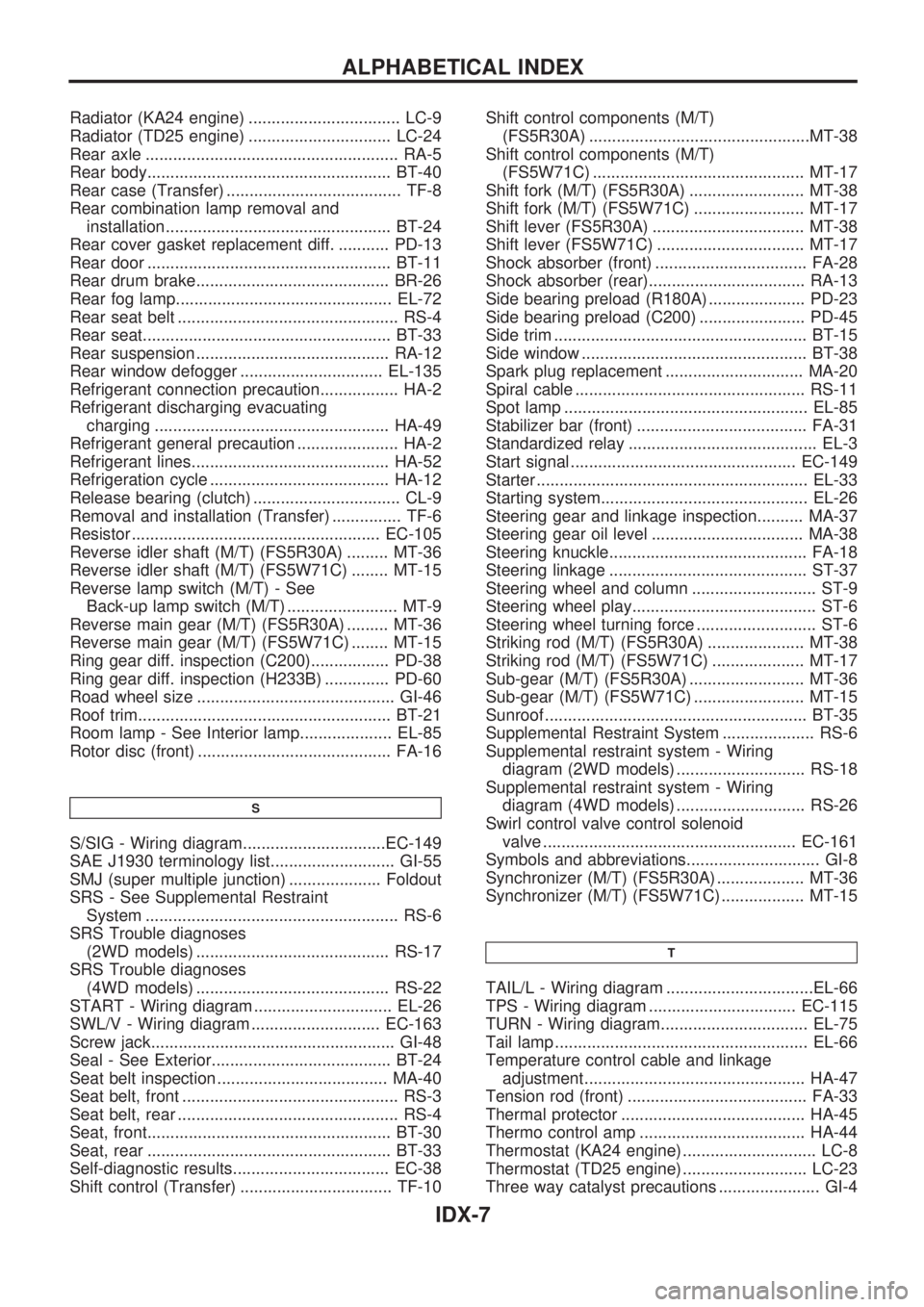

Radiator (KA24 engine) ................................. LC-9

Radiator (TD25 engine) ............................... LC-24

Rear axle ....................................................... RA-5

Rear body..................................................... BT-40

Rear case (Transfer) ...................................... TF-8

Rear combination lamp removal and

installation................................................. BT-24

Rear cover gasket replacement diff. ........... PD-13

Rear door ..................................................... BT-11

Rear drum brake.......................................... BR-26

Rear fog lamp............................................... EL-72

Rear seat belt ................................................ RS-4

Rear seat...................................................... BT-33

Rear suspension .......................................... RA-12

Rear window defogger ............................... EL-135

Refrigerant connection precaution................. HA-2

Refrigerant discharging evacuating

charging ................................................... HA-49

Refrigerant general precaution ...................... HA-2

Refrigerant lines........................................... HA-52

Refrigeration cycle ....................................... HA-12

Release bearing (clutch) ................................ CL-9

Removal and installation (Transfer) ............... TF-6

Resistor ...................................................... EC-105

Reverse idler shaft (M/T) (FS5R30A) ......... MT-36

Reverse idler shaft (M/T) (FS5W71C) ........ MT-15

Reverse lamp switch (M/T) - See

Back-up lamp switch (M/T) ........................ MT-9

Reverse main gear (M/T) (FS5R30A) ......... MT-36

Reverse main gear (M/T) (FS5W71C) ........ MT-15

Ring gear diff. inspection (C200)................. PD-38

Ring gear diff. inspection (H233B) .............. PD-60

Road wheel size ........................................... GI-46

Roof trim....................................................... BT-21

Room lamp - See Interior lamp.................... EL-85

Rotor disc (front) .......................................... FA-16

S

S/SIG - Wiring diagram...............................EC-149

SAE J1930 terminology list........................... GI-55

SMJ (super multiple junction) .................... Foldout

SRS - See Supplemental Restraint

System ....................................................... RS-6

SRS Trouble diagnoses

(2WD models) .......................................... RS-17

SRS Trouble diagnoses

(4WD models) .......................................... RS-22

START - Wiring diagram .............................. EL-26

SWL/V - Wiring diagram ............................ EC-163

Screw jack..................................................... GI-48

Seal - See Exterior....................................... BT-24

Seat belt inspection ..................................... MA-40

Seat belt, front ............................................... RS-3

Seat belt, rear ................................................ RS-4

Seat, front..................................................... BT-30

Seat, rear ..................................................... BT-33

Self-diagnostic results.................................. EC-38

Shift control (Transfer) ................................. TF-10Shift control components (M/T)

(FS5R30A) ................................................MT-38

Shift control components (M/T)

(FS5W71C) .............................................. MT-17

Shift fork (M/T) (FS5R30A) ......................... MT-38

Shift fork (M/T) (FS5W71C) ........................ MT-17

Shift lever (FS5R30A) ................................. MT-38

Shift lever (FS5W71C) ................................ MT-17

Shock absorber (front) ................................. FA-28

Shock absorber (rear).................................. RA-13

Side bearing preload (R180A) ..................... PD-23

Side bearing preload (C200) ....................... PD-45

Side trim ....................................................... BT-15

Side window ................................................. BT-38

Spark plug replacement .............................. MA-20

Spiral cable .................................................. RS-11

Spot lamp ..................................................... EL-85

Stabilizer bar (front) ..................................... FA-31

Standardized relay ......................................... EL-3

Start signal ................................................. EC-149

Starter ........................................................... EL-33

Starting system............................................. EL-26

Steering gear and linkage inspection.......... MA-37

Steering gear oil level ................................. MA-38

Steering knuckle........................................... FA-18

Steering linkage ........................................... ST-37

Steering wheel and column ........................... ST-9

Steering wheel play........................................ ST-6

Steering wheel turning force .......................... ST-6

Striking rod (M/T) (FS5R30A) ..................... MT-38

Striking rod (M/T) (FS5W71C) .................... MT-17

Sub-gear (M/T) (FS5R30A) ......................... MT-36

Sub-gear (M/T) (FS5W71C) ........................ MT-15

Sunroof ......................................................... BT-35

Supplemental Restraint System .................... RS-6

Supplemental restraint system - Wiring

diagram (2WD models) ............................ RS-18

Supplemental restraint system - Wiring

diagram (4WD models) ............................ RS-26

Swirl control valve control solenoid

valve ....................................................... EC-161

Symbols and abbreviations............................. GI-8

Synchronizer (M/T) (FS5R30A) ................... MT-36

Synchronizer (M/T) (FS5W71C) .................. MT-15

T

TAIL/L - Wiring diagram ................................EL-66

TPS - Wiring diagram ................................ EC-115

TURN - Wiring diagram................................ EL-75

Tail lamp ....................................................... EL-66

Temperature control cable and linkage

adjustment................................................ HA-47

Tension rod (front) ....................................... FA-33

Thermal protector ........................................ HA-45

Thermo control amp .................................... HA-44

Thermostat (KA24 engine) ............................. LC-8

Thermostat (TD25 engine) ........................... LC-23

Three way catalyst precautions ...................... GI-4

ALPHABETICAL INDEX

IDX-7

Page 870 of 1659

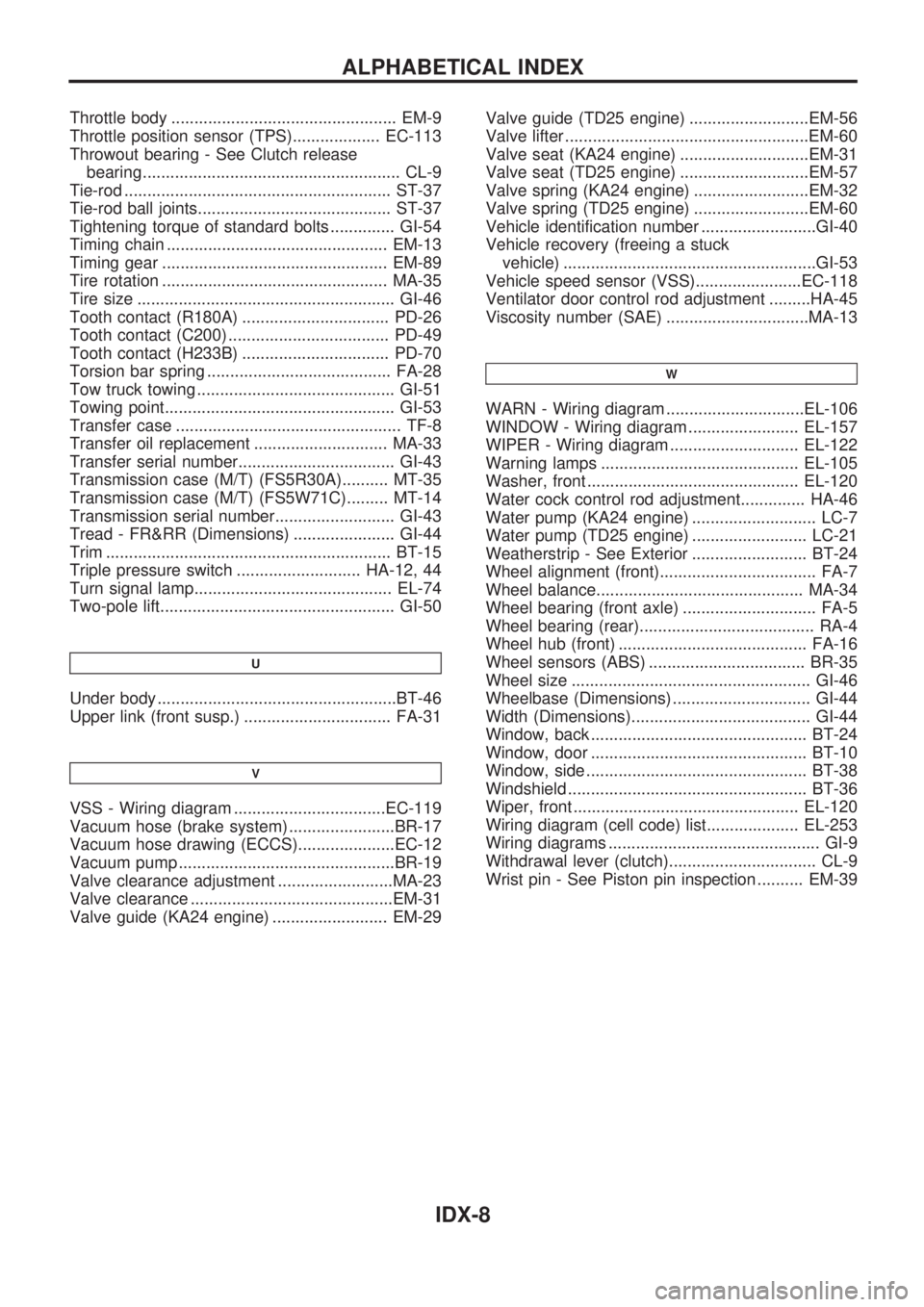

Throttle body ................................................. EM-9

Throttle position sensor (TPS)................... EC-113

Throwout bearing - See Clutch release

bearing........................................................ CL-9

Tie-rod .......................................................... ST-37

Tie-rod ball joints.......................................... ST-37

Tightening torque of standard bolts .............. GI-54

Timing chain ................................................ EM-13

Timing gear ................................................. EM-89

Tire rotation ................................................. MA-35

Tire size ........................................................ GI-46

Tooth contact (R180A) ................................ PD-26

Tooth contact (C200) ................................... PD-49

Tooth contact (H233B) ................................ PD-70

Torsion bar spring ........................................ FA-28

Tow truck towing ........................................... GI-51

Towing point.................................................. GI-53

Transfer case ................................................. TF-8

Transfer oil replacement ............................. MA-33

Transfer serial number.................................. GI-43

Transmission case (M/T) (FS5R30A).......... MT-35

Transmission case (M/T) (FS5W71C)......... MT-14

Transmission serial number.......................... GI-43

Tread - FR&RR (Dimensions) ...................... GI-44

Trim .............................................................. BT-15

Triple pressure switch ........................... HA-12, 44

Turn signal lamp........................................... EL-74

Two-pole lift................................................... GI-50

U

Under body ....................................................BT-46

Upper link (front susp.) ................................ FA-31

V

VSS - Wiring diagram .................................EC-119

Vacuum hose (brake system) .......................BR-17

Vacuum hose drawing (ECCS).....................EC-12

Vacuum pump ...............................................BR-19

Valve clearance adjustment .........................MA-23

Valve clearance ............................................EM-31

Valve guide (KA24 engine) ......................... EM-29Valve guide (TD25 engine) ..........................EM-56

Valve lifter .....................................................EM-60

Valve seat (KA24 engine) ............................EM-31

Valve seat (TD25 engine) ............................EM-57

Valve spring (KA24 engine) .........................EM-32

Valve spring (TD25 engine) .........................EM-60

Vehicle identification number .........................GI-40

Vehicle recovery (freeing a stuck

vehicle) .......................................................GI-53

Vehicle speed sensor (VSS).......................EC-118

Ventilator door control rod adjustment .........HA-45

Viscosity number (SAE) ...............................MA-13

W

WARN - Wiring diagram ..............................EL-106

WINDOW - Wiring diagram ........................ EL-157

WIPER - Wiring diagram ............................ EL-122

Warning lamps ........................................... EL-105

Washer, front .............................................. EL-120

Water cock control rod adjustment.............. HA-46

Water pump (KA24 engine) ........................... LC-7

Water pump (TD25 engine) ......................... LC-21

Weatherstrip - See Exterior ......................... BT-24

Wheel alignment (front).................................. FA-7

Wheel balance............................................. MA-34

Wheel bearing (front axle) ............................. FA-5

Wheel bearing (rear)...................................... RA-4

Wheel hub (front) ......................................... FA-16

Wheel sensors (ABS) .................................. BR-35

Wheel size .................................................... GI-46

Wheelbase (Dimensions) .............................. GI-44

Width (Dimensions)....................................... GI-44

Window, back ............................................... BT-24

Window, door ............................................... BT-10

Window, side ................................................ BT-38

Windshield .................................................... BT-36

Wiper, front ................................................. EL-120

Wiring diagram (cell code) list.................... EL-253

Wiring diagrams .............................................. GI-9

Withdrawal lever (clutch)................................ CL-9

Wrist pin - See Piston pin inspection .......... EM-39

ALPHABETICAL INDEX

IDX-8

Page 970 of 1659

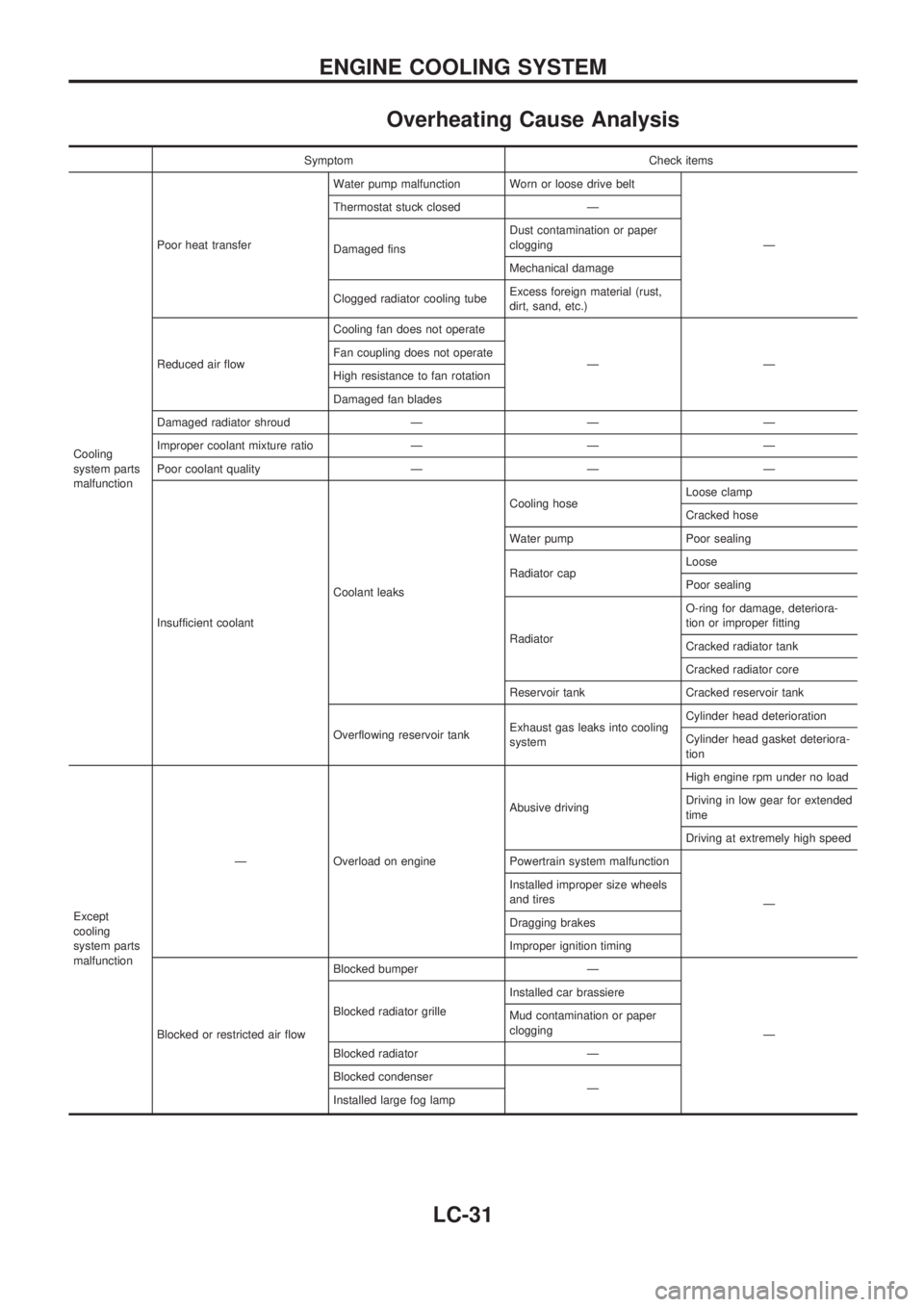

Overheating Cause Analysis

Symptom Check items

Cooling

system parts

malfunctionPoor heat transferWater pump malfunction Worn or loose drive belt

Ð Thermostat stuck closed Ð

Damaged finsDust contamination or paper

clogging

Mechanical damage

Clogged radiator cooling tubeExcess foreign material (rust,

dirt, sand, etc.)

Reduced air flowCooling fan does not operate

ÐÐ Fan coupling does not operate

High resistance to fan rotation

Damaged fan blades

Damaged radiator shroud Ð Ð Ð

Improper coolant mixture ratio Ð Ð Ð

Poor coolant quality Ð Ð Ð

Insufficient coolantCoolant leaksCooling hoseLoose clamp

Cracked hose

Water pump Poor sealing

Radiator capLoose

Poor sealing

RadiatorO-ring for damage, deteriora-

tion or improper fitting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir tankExhaust gas leaks into cooling

systemCylinder head deterioration

Cylinder head gasket deteriora-

tion

Except

cooling

system parts

malfunctionÐ Overload on engineAbusive drivingHigh engine rpm under no load

Driving in low gear for extended

time

Driving at extremely high speed

Powertrain system malfunction

Ð Installed improper size wheels

and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air flowBlocked bumper Ð

Ð Blocked radiator grilleInstalled car brassiere

Mud contamination or paper

clogging

Blocked radiator Ð

Blocked condenser

Ð

Installed large fog lamp

ENGINE COOLING SYSTEM

LC-31

Page 1169 of 1659

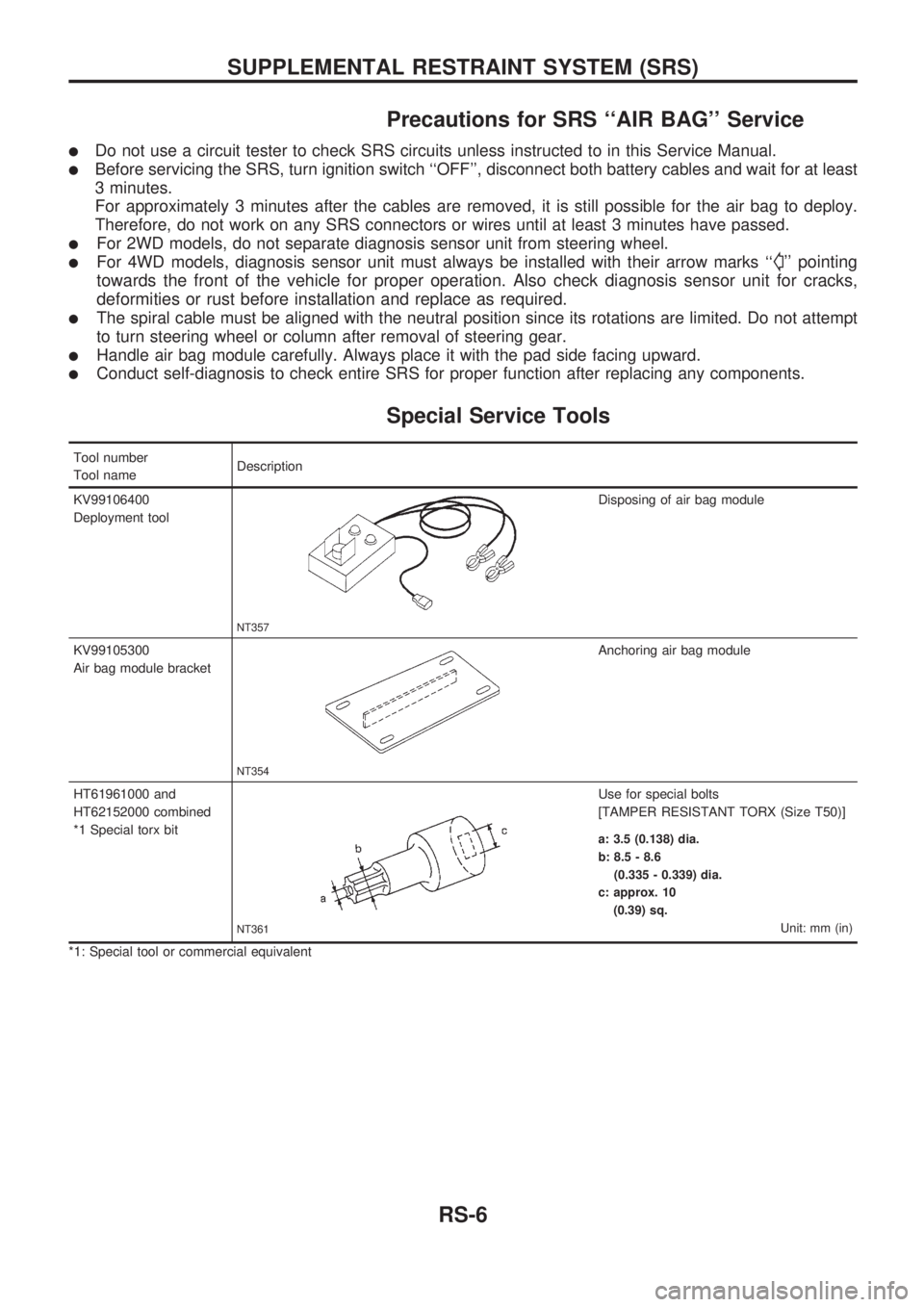

Precautions for SRS ``AIR BAG'' Service

lDo not use a circuit tester to check SRS circuits unless instructed to in this Service Manual.

lBefore servicing the SRS, turn ignition switch ``OFF'', disconnect both battery cables and wait for at least

3 minutes.

For approximately 3 minutes after the cables are removed, it is still possible for the air bag to deploy.

Therefore, do not work on any SRS connectors or wires until at least 3 minutes have passed.

lFor 2WD models, do not separate diagnosis sensor unit from steering wheel.

lFor 4WD models, diagnosis sensor unit must always be installed with their arrow marks ``S'' pointing

towards the front of the vehicle for proper operation. Also check diagnosis sensor unit for cracks,

deformities or rust before installation and replace as required.

lThe spiral cable must be aligned with the neutral position since its rotations are limited. Do not attempt

to turn steering wheel or column after removal of steering gear.

lHandle air bag module carefully. Always place it with the pad side facing upward.

lConduct self-diagnosis to check entire SRS for proper function after replacing any components.

Special Service Tools

Tool number

Tool nameDescription

KV99106400

Deployment tool

NT357

Disposing of air bag module

KV99105300

Air bag module bracket

NT354

Anchoring air bag module

HT61961000 and

HT62152000 combined

*1 Special torx bit

NT361

Use for special bolts

[TAMPER RESISTANT TORX (Size T50)]

a: 3.5 (0.138) dia.

b: 8.5 - 8.6

(0.335 - 0.339) dia.

c: approx. 10

(0.39) sq.

Unit: mm (in)

*1: Special tool or commercial equivalent

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

RS-6

Page 1175 of 1659

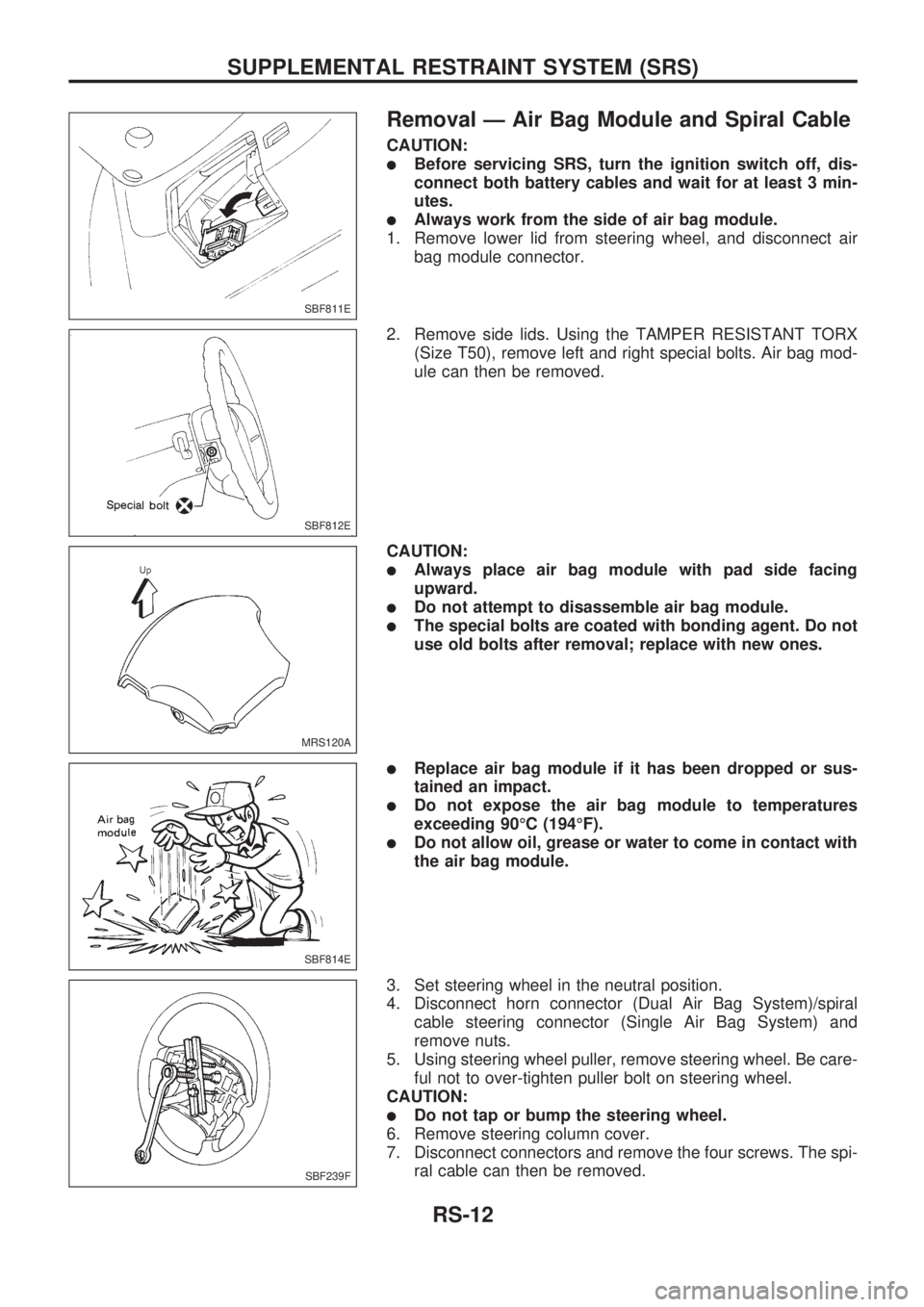

Removal Ð Air Bag Module and Spiral Cable

CAUTION:

lBefore servicing SRS, turn the ignition switch off, dis-

connect both battery cables and wait for at least 3 min-

utes.

lAlways work from the side of air bag module.

1. Remove lower lid from steering wheel, and disconnect air

bag module connector.

2. Remove side lids. Using the TAMPER RESISTANT TORX

(Size T50), remove left and right special bolts. Air bag mod-

ule can then be removed.

CAUTION:

lAlways place air bag module with pad side facing

upward.

lDo not attempt to disassemble air bag module.

lThe special bolts are coated with bonding agent. Do not

use old bolts after removal; replace with new ones.

lReplace air bag module if it has been dropped or sus-

tained an impact.

lDo not expose the air bag module to temperatures

exceeding 90ÉC (194ÉF).

lDo not allow oil, grease or water to come in contact with

the air bag module.

3. Set steering wheel in the neutral position.

4. Disconnect horn connector (Dual Air Bag System)/spiral

cable steering connector (Single Air Bag System) and

remove nuts.

5. Using steering wheel puller, remove steering wheel. Be care-

ful not to over-tighten puller bolt on steering wheel.

CAUTION:

lDo not tap or bump the steering wheel.

6. Remove steering column cover.

7. Disconnect connectors and remove the four screws. The spi-

ral cable can then be removed.

SBF811E

SBF812E

MRS120A

SBF814E

SBF239F

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

RS-12

Page 1598 of 1659

8. If crankshaft is replaced, select connecting rod bearing

according to the following table.

Connecting rod bearing grade number:

These numbers are punched in either Arabic or Roman numer-

als.

Crank pin grade numberConnecting rod bearing

grade number

00

1orI 1

2orII 2

Method B (Using plastigage)

CAUTION:

lDo not turn crankshaft or connecting rod while plasti-

gage is being inserted.

lWhen bearing clearance exceeds the specified limit,

ensure that the proper bearing has been installed. Then

if excessive bearing clearance exists, use a thicker main

bearing or undersized bearing so that the specified bear-

ing clearance is obtained.

CONNECTING ROD BUSHING CLEARANCE (Small

end)

1. Measure inner diameter ``C'' of bushing.

2. Measure outer diameter ``Dp'' of piston pin.

3. Calculate connecting rod bushing clearance.

CþDp=

þ0.015 to þ0.033 mm (þ0.0006 to þ0.0013 in) (Stan-

dard)

If out of specification, replace connecting rod assembly

and/or piston set with pin.

FLYWHEEL RUNOUT

Runout (Total indicator reading):

Flywheel Less than 0.1 mm (0.004 in)

CAUTION:

Do not allow any magnetic materials to contact the ring gear

teeth.

Assembly

PISTON

1. Heat piston to 60 to 70ÉC (140 to 158ÉF) and assemble

piston, piston pin and connecting rod.

lAlign the direction of piston and connecting rod.

lNumbers stamped on connecting rod and cap corre-

spond to each cylinder.

lAfter assembly, make sure connecting rod swings

smoothly.

SEM567B

EM142

SEM245E

AEM100

SEM262C

CYLINDER BLOCKKA

Inspection (Cont'd)

EM-45