fuel pressure NISSAN PICK-UP 1998 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 378 of 1659

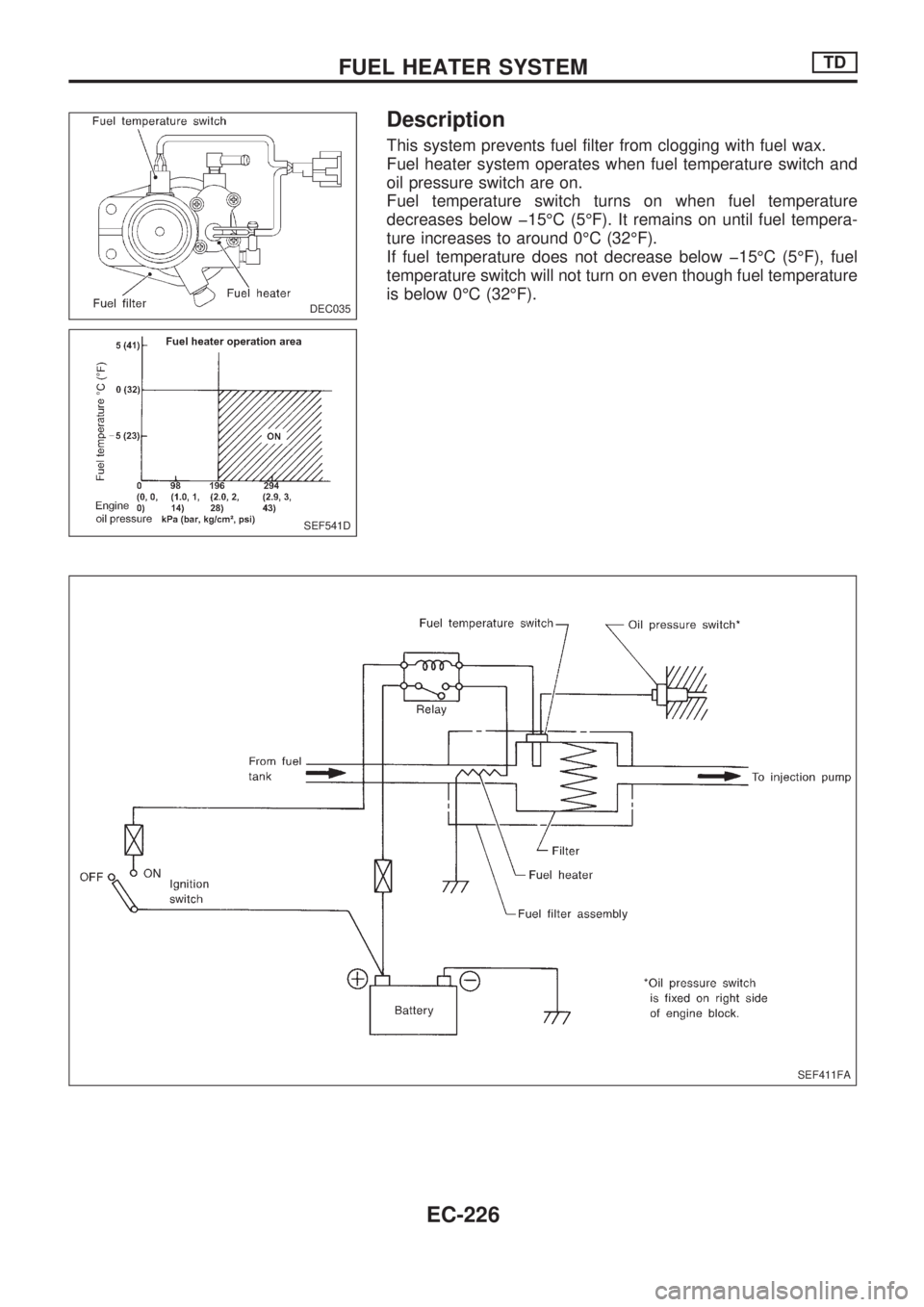

Description

This system prevents fuel filter from clogging with fuel wax.

Fuel heater system operates when fuel temperature switch and

oil pressure switch are on.

Fuel temperature switch turns on when fuel temperature

decreases below þ15ÉC (5ÉF). It remains on until fuel tempera-

ture increases to around 0ÉC (32ÉF).

If fuel temperature does not decrease below þ15ÉC (5ÉF), fuel

temperature switch will not turn on even though fuel temperature

is below 0ÉC (32ÉF).

DEC035

SEF541D

SEF411FA

FUEL HEATER SYSTEMTD

EC-226

Page 381 of 1659

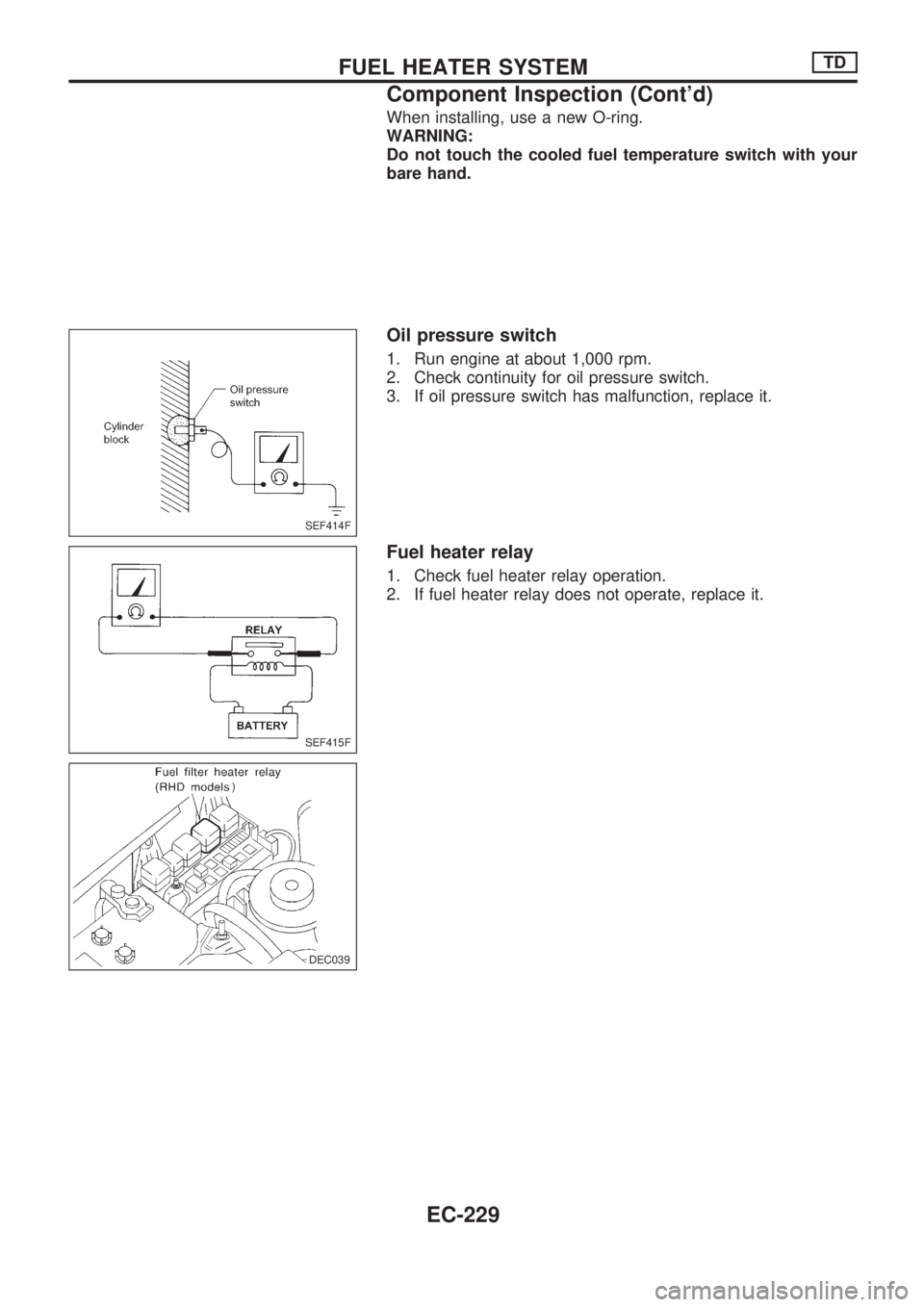

When installing, use a new O-ring.

WARNING:

Do not touch the cooled fuel temperature switch with your

bare hand.

Oil pressure switch

1. Run engine at about 1,000 rpm.

2. Check continuity for oil pressure switch.

3. If oil pressure switch has malfunction, replace it.

Fuel heater relay

1. Check fuel heater relay operation.

2. If fuel heater relay does not operate, replace it.

SEF414F

SEF415F

DEC039

.)

.DEC039

FUEL HEATER SYSTEMTD

Component Inspection (Cont'd)

EC-229

Page 384 of 1659

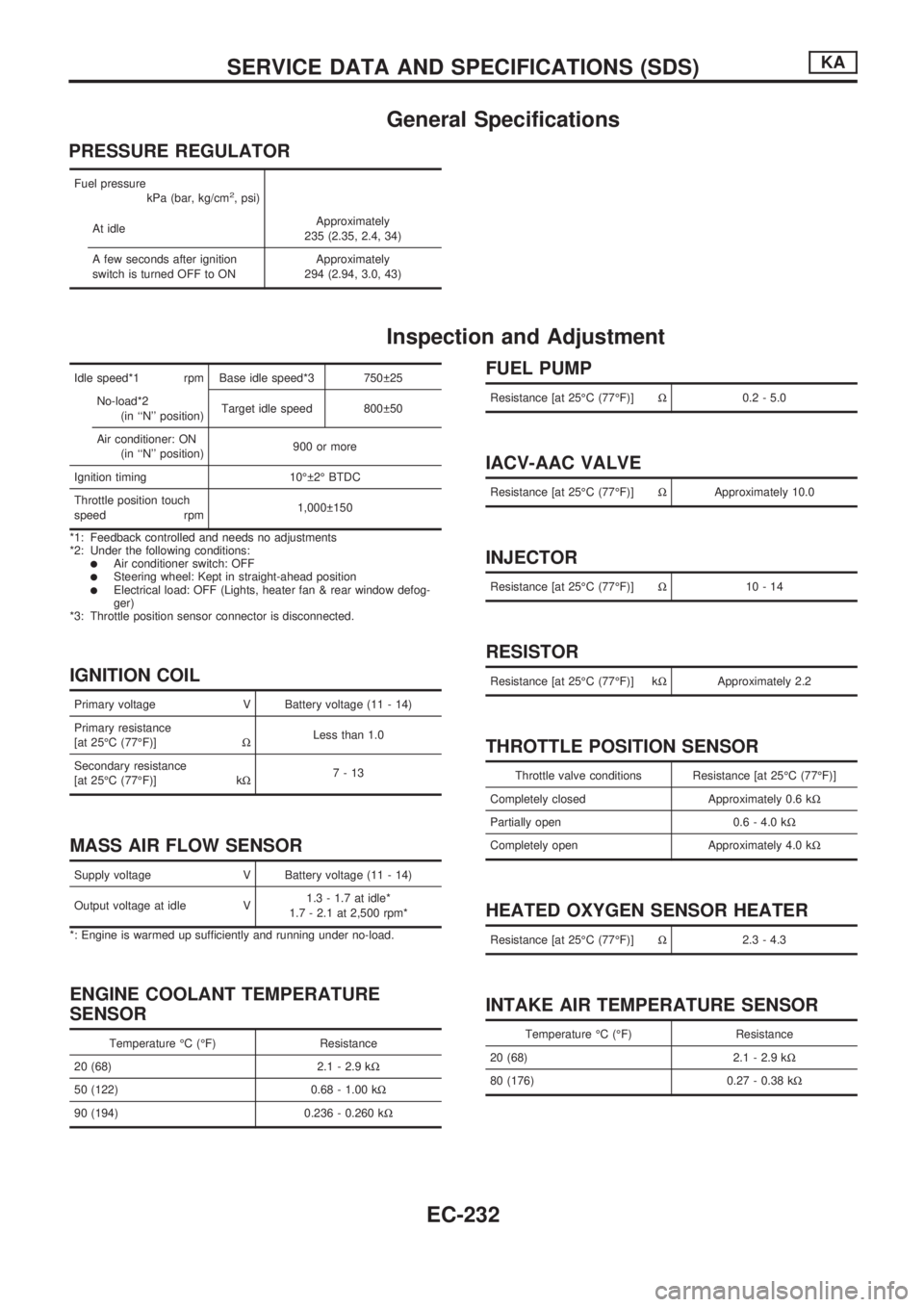

General Specifications

PRESSURE REGULATOR

Fuel pressure

kPa (bar, kg/cm2, psi)

At idleApproximately

235 (2.35, 2.4, 34)

A few seconds after ignition

switch is turned OFF to ONApproximately

294 (2.94, 3.0, 43)

Inspection and Adjustment

Idle speed*1 rpm Base idle speed*3 750 25

No-load*2

(in ``N'' position)Target idle speed 800 50

Air conditioner: ON

(in ``N'' position)900 or more

Ignition timing 10É 2É BTDC

Throttle position touch

speed rpm1,000 150

*1: Feedback controlled and needs no adjustments

*2: Under the following conditions:

lAir conditioner switch: OFFlSteering wheel: Kept in straight-ahead positionlElectrical load: OFF (Lights, heater fan & rear window defog-

ger)

*3: Throttle position sensor connector is disconnected.

IGNITION COIL

Primary voltage V Battery voltage (11 - 14)

Primary resistance

[at 25ÉC (77ÉF)]WLess than 1.0

Secondary resistance

[at 25ÉC (77ÉF)] kW7-13

MASS AIR FLOW SENSOR

Supply voltage V Battery voltage (11 - 14)

Output voltage at idle V1.3 - 1.7 at idle*

1.7 - 2.1 at 2,500 rpm*

*: Engine is warmed up sufficiently and running under no-load.

ENGINE COOLANT TEMPERATURE

SENSOR

Temperature ÉC (ÉF) Resistance

20 (68) 2.1 - 2.9 kW

50 (122) 0.68 - 1.00 kW

90 (194) 0.236 - 0.260 kW

FUEL PUMP

Resistance [at 25ÉC (77ÉF)]W0.2 - 5.0

IACV-AAC VALVE

Resistance [at 25ÉC (77ÉF)]WApproximately 10.0

INJECTOR

Resistance [at 25ÉC (77ÉF)]W10-14

RESISTOR

Resistance [at 25ÉC (77ÉF)] kWApproximately 2.2

THROTTLE POSITION SENSOR

Throttle valve conditions Resistance [at 25ÉC (77ÉF)]

Completely closed Approximately 0.6 kW

Partially open 0.6 - 4.0 kW

Completely open Approximately 4.0 kW

HEATED OXYGEN SENSOR HEATER

Resistance [at 25ÉC (77ÉF)]W2.3 - 4.3

INTAKE AIR TEMPERATURE SENSOR

Temperature ÉC (ÉF) Resistance

20 (68) 2.1 - 2.9 kW

80 (176) 0.27 - 0.38 kW

SERVICE DATA AND SPECIFICATIONS (SDS)KA

EC-232

Page 386 of 1659

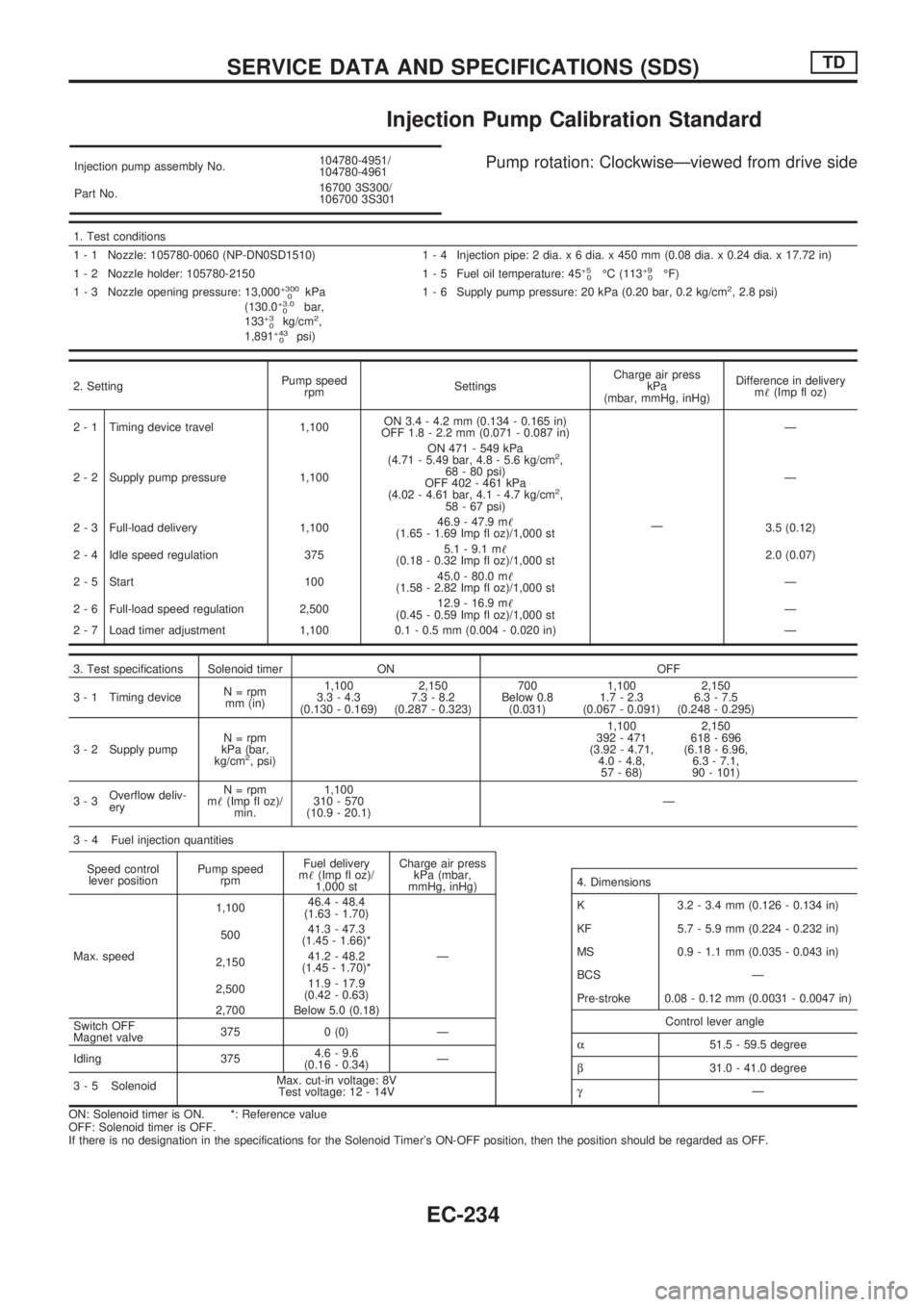

Injection Pump Calibration Standard

Injection pump assembly No.104780-4951/

104780-4961

Part No.16700 3S300/

106700 3S301Pump rotation: ClockwiseÐviewed from drive side

1. Test conditions

1 - 1 Nozzle: 105780-0060 (NP-DN0SD1510) 1 - 4 Injection pipe: 2 dia. x 6 dia. x 450 mm (0.08 dia. x 0.24 dia. x 17.72 in)

1 - 2 Nozzle holder: 105780-2150 1 - 5 Fuel oil temperature: 45

+5

0ÉC (113+9

0ÉF)

1 - 3 Nozzle opening pressure: 13,000+300

0kPa

(130.0+3.0

0bar,

133+3

0kg/cm2,

1,891+43

0psi)1 - 6 Supply pump pressure: 20 kPa (0.20 bar, 0.2 kg/cm

2, 2.8 psi)

2. SettingPump speed

rpmSettingsCharge air press

kPa

(mbar, mmHg, inHg)Difference in delivery

m!(Imp fl oz)

2 - 1 Timing device travel 1,100ON 3.4 - 4.2 mm (0.134 - 0.165 in)

OFF 1.8 - 2.2 mm (0.071 - 0.087 in)

ÐÐ

2 - 2 Supply pump pressure 1,100ON 471 - 549 kPa

(4.71 - 5.49 bar, 4.8 - 5.6 kg/cm

2,

68 - 80 psi)

OFF 402 - 461 kPa

(4.02 - 4.61 bar, 4.1 - 4.7 kg/cm

2,

58 - 67 psi)Ð

2 - 3 Full-load delivery 1,10046.9 - 47.9 m!

(1.65 - 1.69 Imp fl oz)/1,000 st3.5 (0.12)

2 - 4 Idle speed regulation 3755.1 - 9.1 m!

(0.18 - 0.32 Imp fl oz)/1,000 st2.0 (0.07)

2 - 5 Start 10045.0 - 80.0 m!

(1.58 - 2.82 Imp fl oz)/1,000 stÐ

2 - 6 Full-load speed regulation 2,50012.9 - 16.9 m!

(0.45 - 0.59 Imp fl oz)/1,000 stÐ

2 - 7 Load timer adjustment 1,100 0.1 - 0.5 mm (0.004 - 0.020 in) Ð

3. Test specifications Solenoid timer ON OFF

3 - 1 Timing deviceN = rpm

mm (in)1,100

3.3 - 4.3

(0.130 - 0.169)2,150

7.3 - 8.2

(0.287 - 0.323)700

Below 0.8

(0.031)1,100

1.7 - 2.3

(0.067 - 0.091)2,150

6.3 - 7.5

(0.248 - 0.295)

3 - 2 Supply pumpN = rpm

kPa (bar,

kg/cm

2, psi)1,100

392 - 471

(3.92 - 4.71,

4.0 - 4.8,

57 - 68)2,150

618 - 696

(6.18 - 6.96,

6.3 - 7.1,

90 - 101)

3-3Overflow deliv-

eryN = rpm

m!(Imp fl oz)/

min.1,100

310 - 570

(10.9 - 20.1)Ð

3 - 4 Fuel injection quantities

Speed control

lever positionPump speed

rpmFuel delivery

m!(Imp fl oz)/

1,000 stCharge air press

kPa (mbar,

mmHg, inHg)

Max. speed1,10046.4 - 48.4

(1.63 - 1.70)

Ð 50041.3 - 47.3

(1.45 - 1.66)*

2,15041.2 - 48.2

(1.45 - 1.70)*

2,50011.9 - 17.9

(0.42 - 0.63)

2,700 Below 5.0 (0.18)

Switch OFF

Magnet valve375 0 (0) Ð

Idling 3754.6 - 9.6

(0.16 - 0.34)Ð

3 - 5 SolenoidMax. cut-in voltage: 8V

Test voltage: 12 - 14V

ON: Solenoid timer is ON. *: Reference value

OFF: Solenoid timer is OFF.

If there is no designation in the specifications for the Solenoid Timer's ON-OFF position, then the position should be regarded as OFF.

4. Dimensions

K 3.2 - 3.4 mm (0.126 - 0.134 in)

KF 5.7 - 5.9 mm (0.224 - 0.232 in)

MS 0.9 - 1.1 mm (0.035 - 0.043 in)

BCS Ð

Pre-stroke 0.08 - 0.12 mm (0.0031 - 0.0047 in)

Control lever angle

a51.5 - 59.5 degree

b31.0 - 41.0 degree

gÐ

SERVICE DATA AND SPECIFICATIONS (SDS)TD

EC-234

Page 387 of 1659

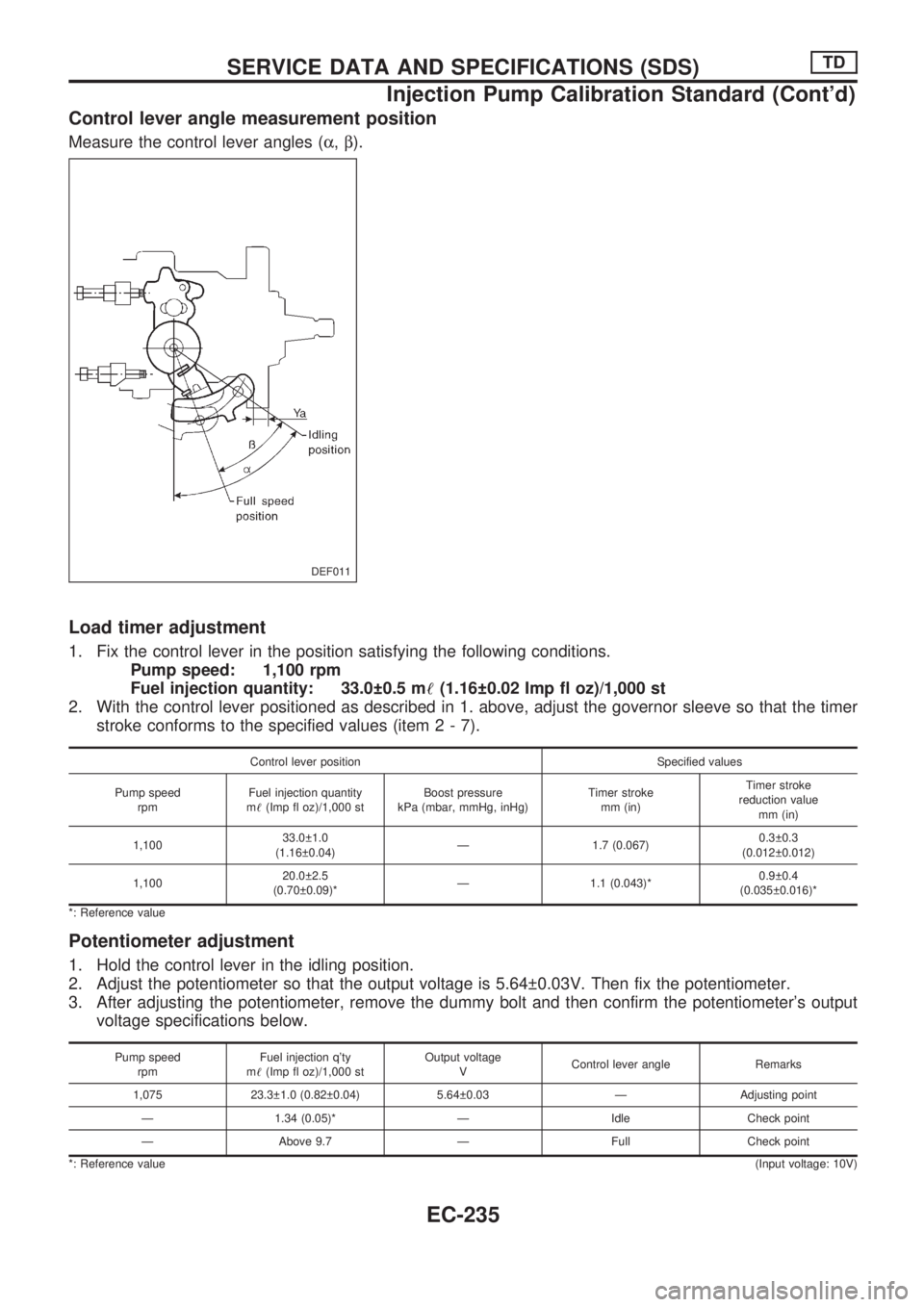

Control lever angle measurement position

Measure the control lever angles (a,b).

Load timer adjustment

1. Fix the control lever in the position satisfying the following conditions.

Pump speed: 1,100 rpm

Fuel injection quantity: 33.0 0.5 m!(1.16 0.02 Imp fl oz)/1,000 st

2. With the control lever positioned as described in 1. above, adjust the governor sleeve so that the timer

stroke conforms to the specified values (item2-7).

Control lever position Specified values

Pump speed

rpmFuel injection quantity

m!(Imp fl oz)/1,000 stBoost pressure

kPa (mbar, mmHg, inHg)Timer stroke

mm (in)Timer stroke

reduction value

mm (in)

1,10033.0 1.0

(1.16 0.04)Ð 1.7 (0.067)0.3 0.3

(0.012 0.012)

1,10020.0 2.5

(0.70 0.09)*Ð 1.1 (0.043)*0.9 0.4

(0.035 0.016)*

*: Reference value

Potentiometer adjustment

1. Hold the control lever in the idling position.

2. Adjust the potentiometer so that the output voltage is 5.64 0.03V. Then fix the potentiometer.

3. After adjusting the potentiometer, remove the dummy bolt and then confirm the potentiometer's output

voltage specifications below.

Pump speed

rpmFuel injection q'ty

m!(Imp fl oz)/1,000 stOutput voltage

VControl lever angle Remarks

1,075 23.3 1.0 (0.82 0.04) 5.64 0.03 Ð Adjusting point

Ð 1.34 (0.05)* Ð Idle Check point

Ð Above 9.7 Ð Full Check point

*: Reference value(Input voltage: 10V)

DEF011

SERVICE DATA AND SPECIFICATIONS (SDS)TD

Injection Pump Calibration Standard (Cont'd)

EC-235

Page 439 of 1659

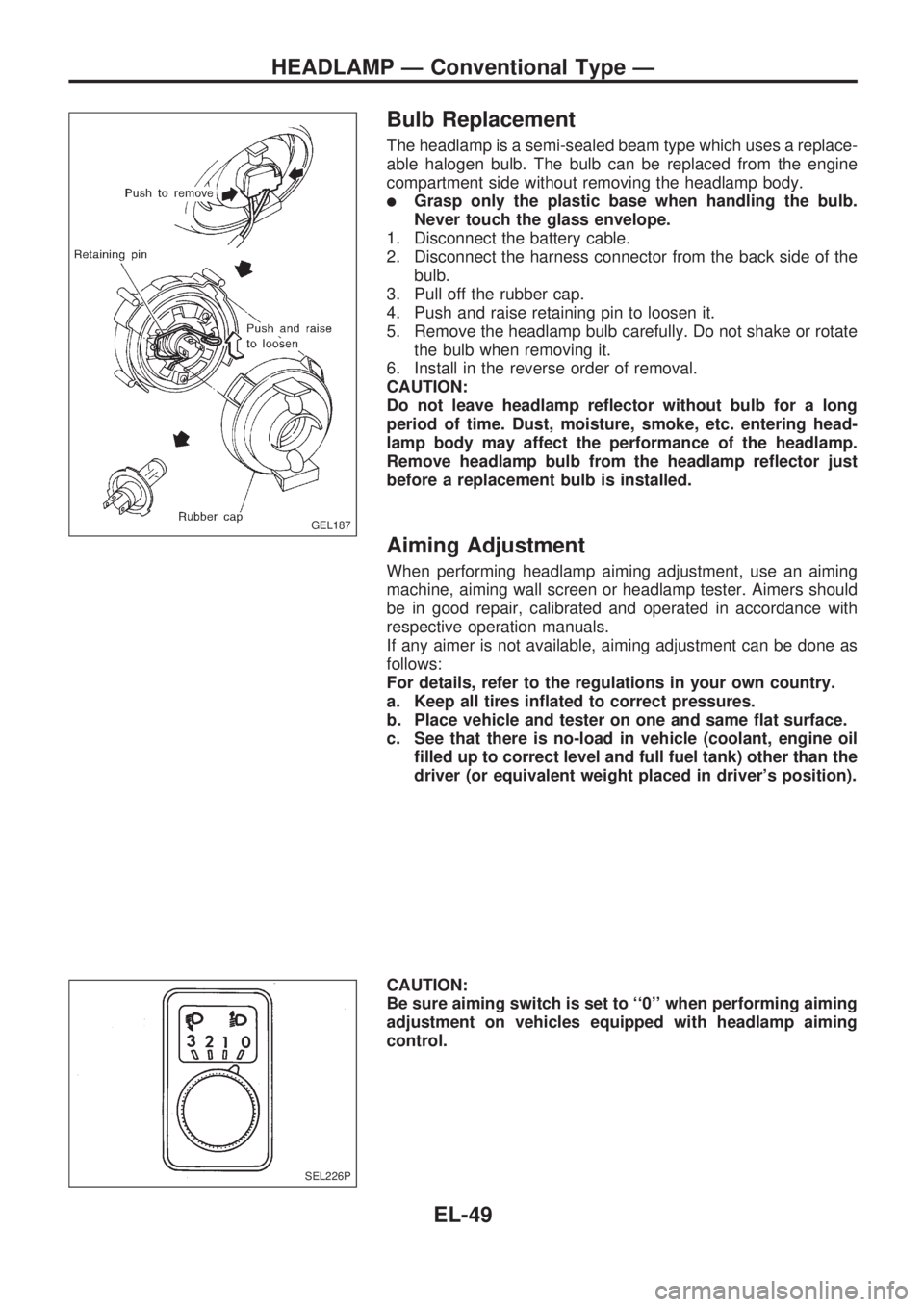

Bulb Replacement

The headlamp is a semi-sealed beam type which uses a replace-

able halogen bulb. The bulb can be replaced from the engine

compartment side without removing the headlamp body.

lGrasp only the plastic base when handling the bulb.

Never touch the glass envelope.

1. Disconnect the battery cable.

2. Disconnect the harness connector from the back side of the

bulb.

3. Pull off the rubber cap.

4. Push and raise retaining pin to loosen it.

5. Remove the headlamp bulb carefully. Do not shake or rotate

the bulb when removing it.

6. Install in the reverse order of removal.

CAUTION:

Do not leave headlamp reflector without bulb for a long

period of time. Dust, moisture, smoke, etc. entering head-

lamp body may affect the performance of the headlamp.

Remove headlamp bulb from the headlamp reflector just

before a replacement bulb is installed.

Aiming Adjustment

When performing headlamp aiming adjustment, use an aiming

machine, aiming wall screen or headlamp tester. Aimers should

be in good repair, calibrated and operated in accordance with

respective operation manuals.

If any aimer is not available, aiming adjustment can be done as

follows:

For details, refer to the regulations in your own country.

a. Keep all tires inflated to correct pressures.

b. Place vehicle and tester on one and same flat surface.

c. See that there is no-load in vehicle (coolant, engine oil

filled up to correct level and full fuel tank) other than the

driver (or equivalent weight placed in driver's position).

CAUTION:

Be sure aiming switch is set to ``0'' when performing aiming

adjustment on vehicles equipped with headlamp aiming

control.

GEL187

SEL226P

HEADLAMP Ð Conventional Type Ð

EL-49

Page 506 of 1659

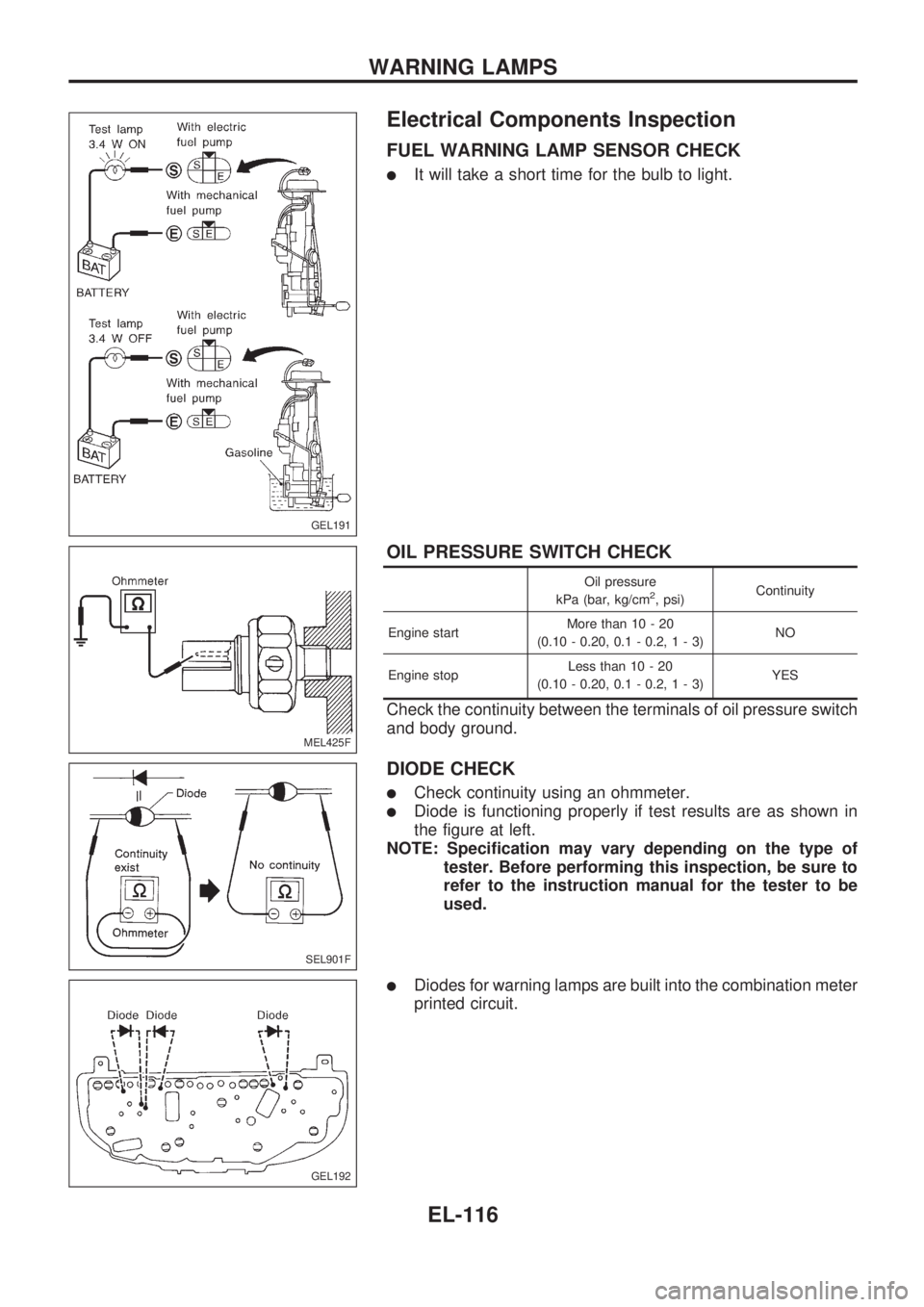

Electrical Components Inspection

FUEL WARNING LAMP SENSOR CHECK

lIt will take a short time for the bulb to light.

OIL PRESSURE SWITCH CHECK

Oil pressure

kPa (bar, kg/cm2, psi)Continuity

Engine startMore than 10 - 20

(0.10 - 0.20, 0.1 - 0.2,1-3)NO

Engine stopLess than 10 - 20

(0.10 - 0.20, 0.1 - 0.2,1-3)YES

Check the continuity between the terminals of oil pressure switch

and body ground.

DIODE CHECK

lCheck continuity using an ohmmeter.

lDiode is functioning properly if test results are as shown in

the figure at left.

NOTE: Specification may vary depending on the type of

tester. Before performing this inspection, be sure to

refer to the instruction manual for the tester to be

used.

lDiodes for warning lamps are built into the combination meter

printed circuit.

GEL191

MEL425F

SEL901F

GEL192

WARNING LAMPS

EL-116

Page 643 of 1659

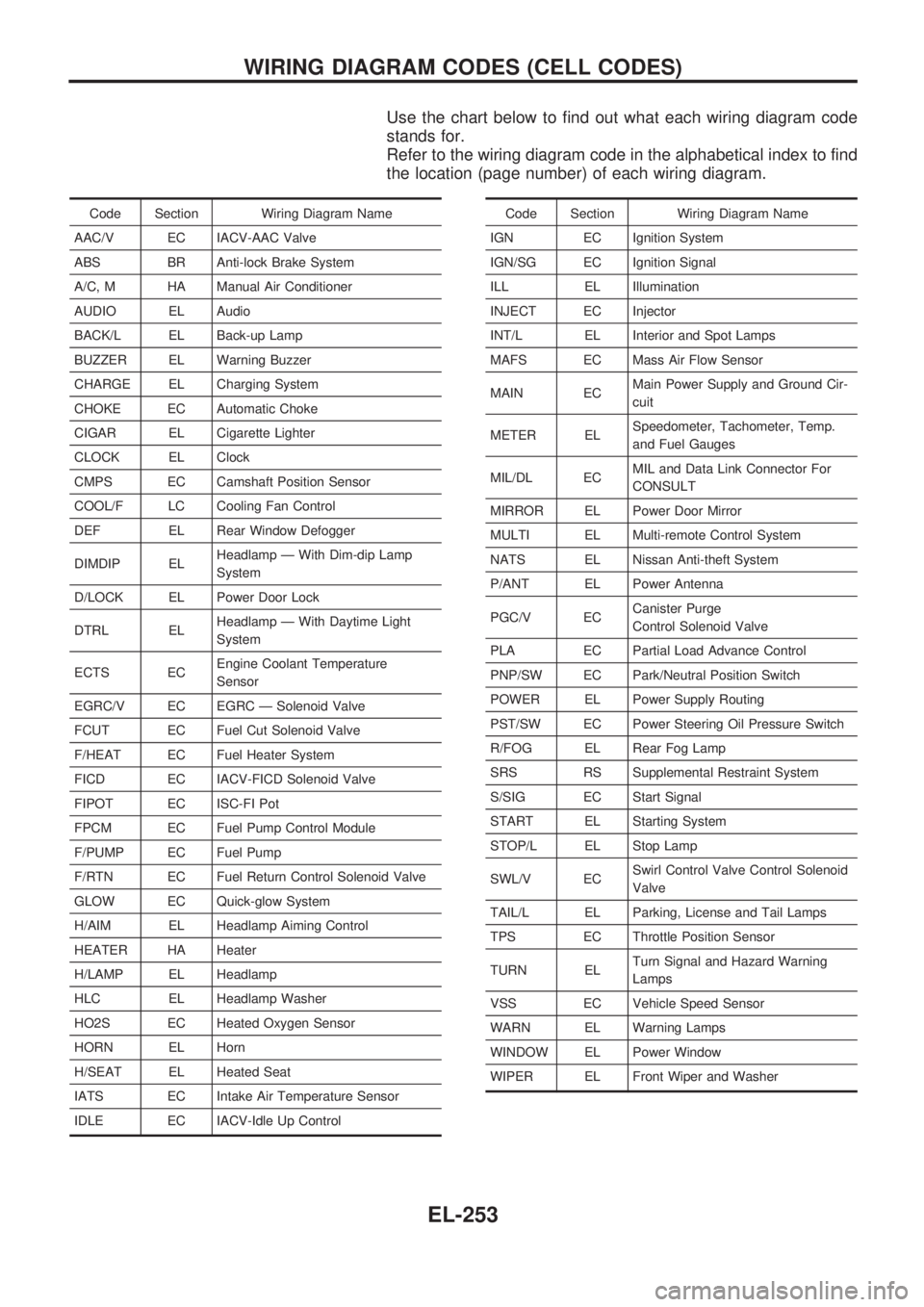

Use the chart below to find out what each wiring diagram code

stands for.

Refer to the wiring diagram code in the alphabetical index to find

the location (page number) of each wiring diagram.

Code Section Wiring Diagram Name

AAC/V EC IACV-AAC Valve

ABS BR Anti-lock Brake System

A/C, M HA Manual Air Conditioner

AUDIO EL Audio

BACK/L EL Back-up Lamp

BUZZER EL Warning Buzzer

CHARGE EL Charging System

CHOKE EC Automatic Choke

CIGAR EL Cigarette Lighter

CLOCK EL Clock

CMPS EC Camshaft Position Sensor

COOL/F LC Cooling Fan Control

DEF EL Rear Window Defogger

DIMDIP ELHeadlamp Ð With Dim-dip Lamp

System

D/LOCK EL Power Door Lock

DTRL ELHeadlamp Ð With Daytime Light

System

ECTS ECEngine Coolant Temperature

Sensor

EGRC/V EC EGRC Ð Solenoid Valve

FCUT EC Fuel Cut Solenoid Valve

F/HEAT EC Fuel Heater System

FICD EC IACV-FICD Solenoid Valve

FIPOT EC ISC-FI Pot

FPCM EC Fuel Pump Control Module

F/PUMP EC Fuel Pump

F/RTN EC Fuel Return Control Solenoid Valve

GLOW EC Quick-glow System

H/AIM EL Headlamp Aiming Control

HEATER HA Heater

H/LAMP EL Headlamp

HLC EL Headlamp Washer

HO2S EC Heated Oxygen Sensor

HORN EL Horn

H/SEAT EL Heated Seat

IATS EC Intake Air Temperature Sensor

IDLE EC IACV-Idle Up ControlCode Section Wiring Diagram Name

IGN EC Ignition System

IGN/SG EC Ignition Signal

ILL EL Illumination

INJECT EC Injector

INT/L EL Interior and Spot Lamps

MAFS EC Mass Air Flow Sensor

MAIN ECMain Power Supply and Ground Cir-

cuit

METER ELSpeedometer, Tachometer, Temp.

and Fuel Gauges

MIL/DL ECMIL and Data Link Connector For

CONSULT

MIRROR EL Power Door Mirror

MULTI EL Multi-remote Control System

NATS EL Nissan Anti-theft System

P/ANT EL Power Antenna

PGC/V ECCanister Purge

Control Solenoid Valve

PLA EC Partial Load Advance Control

PNP/SW EC Park/Neutral Position Switch

POWER EL Power Supply Routing

PST/SW EC Power Steering Oil Pressure Switch

R/FOG EL Rear Fog Lamp

SRS RS Supplemental Restraint System

S/SIG EC Start Signal

START EL Starting System

STOP/L EL Stop Lamp

SWL/V ECSwirl Control Valve Control Solenoid

Valve

TAIL/L EL Parking, License and Tail Lamps

TPS EC Throttle Position Sensor

TURN ELTurn Signal and Hazard Warning

Lamps

VSS EC Vehicle Speed Sensor

WARN EL Warning Lamps

WINDOW EL Power Window

WIPER EL Front Wiper and Washer

WIRING DIAGRAM CODES (CELL CODES)

EL-253

Page 655 of 1659

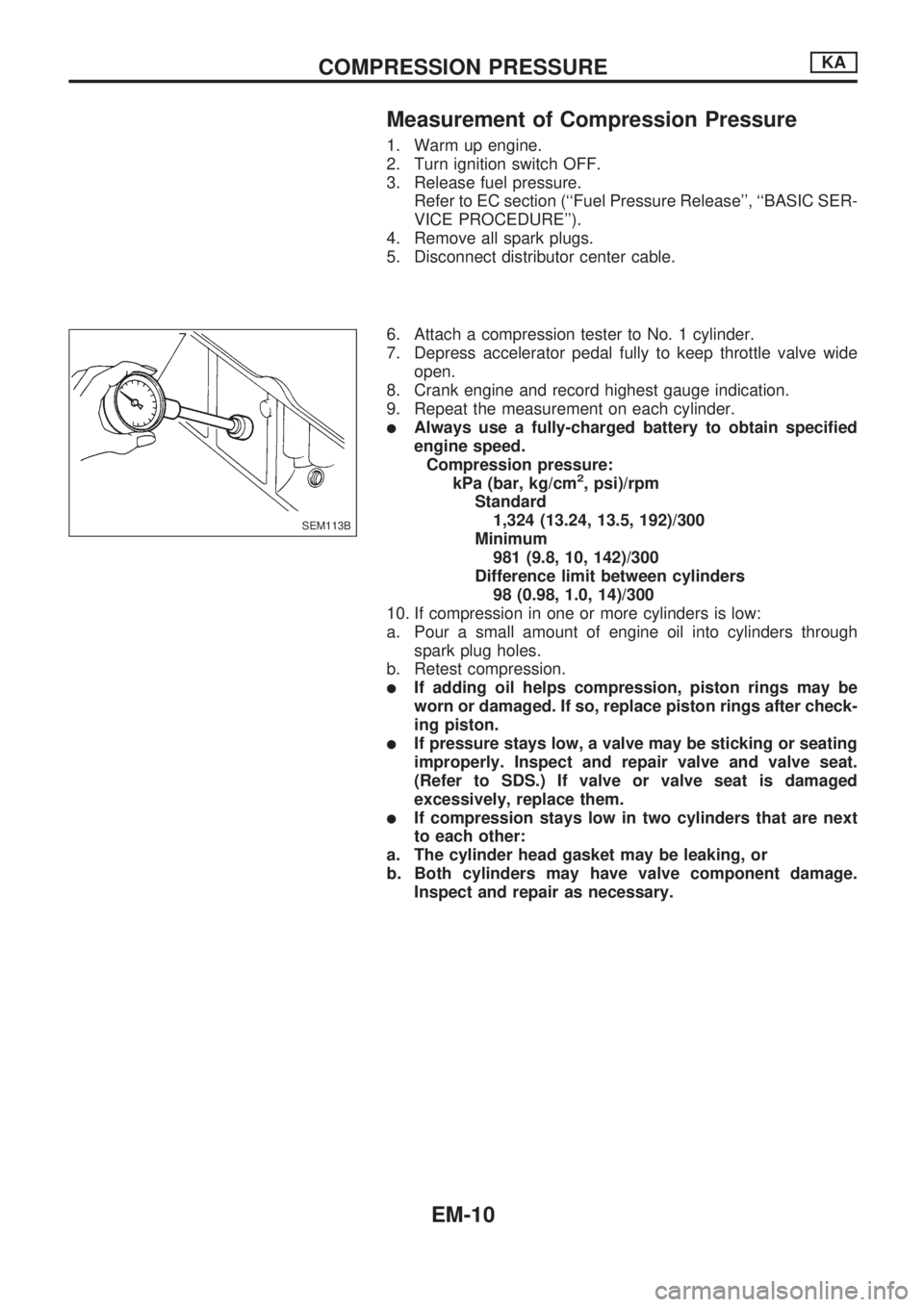

Measurement of Compression Pressure

1. Warm up engine.

2. Turn ignition switch OFF.

3. Release fuel pressure.

Refer to EC section (``Fuel Pressure Release'', ``BASIC SER-

VICE PROCEDURE'').

4. Remove all spark plugs.

5. Disconnect distributor center cable.

6. Attach a compression tester to No. 1 cylinder.

7. Depress accelerator pedal fully to keep throttle valve wide

open.

8. Crank engine and record highest gauge indication.

9. Repeat the measurement on each cylinder.

lAlways use a fully-charged battery to obtain specified

engine speed.

Compression pressure:

kPa (bar, kg/cm

2, psi)/rpm

Standard

1,324 (13.24, 13.5, 192)/300

Minimum

981 (9.8, 10, 142)/300

Difference limit between cylinders

98 (0.98, 1.0, 14)/300

10. If compression in one or more cylinders is low:

a. Pour a small amount of engine oil into cylinders through

spark plug holes.

b. Retest compression.

lIf adding oil helps compression, piston rings may be

worn or damaged. If so, replace piston rings after check-

ing piston.

lIf pressure stays low, a valve may be sticking or seating

improperly. Inspect and repair valve and valve seat.

(Refer to SDS.) If valve or valve seat is damaged

excessively, replace them.

lIf compression stays low in two cylinders that are next

to each other:

a. The cylinder head gasket may be leaking, or

b. Both cylinders may have valve component damage.

Inspect and repair as necessary.

SEM113B

COMPRESSION PRESSUREKA

EM-10

Page 670 of 1659

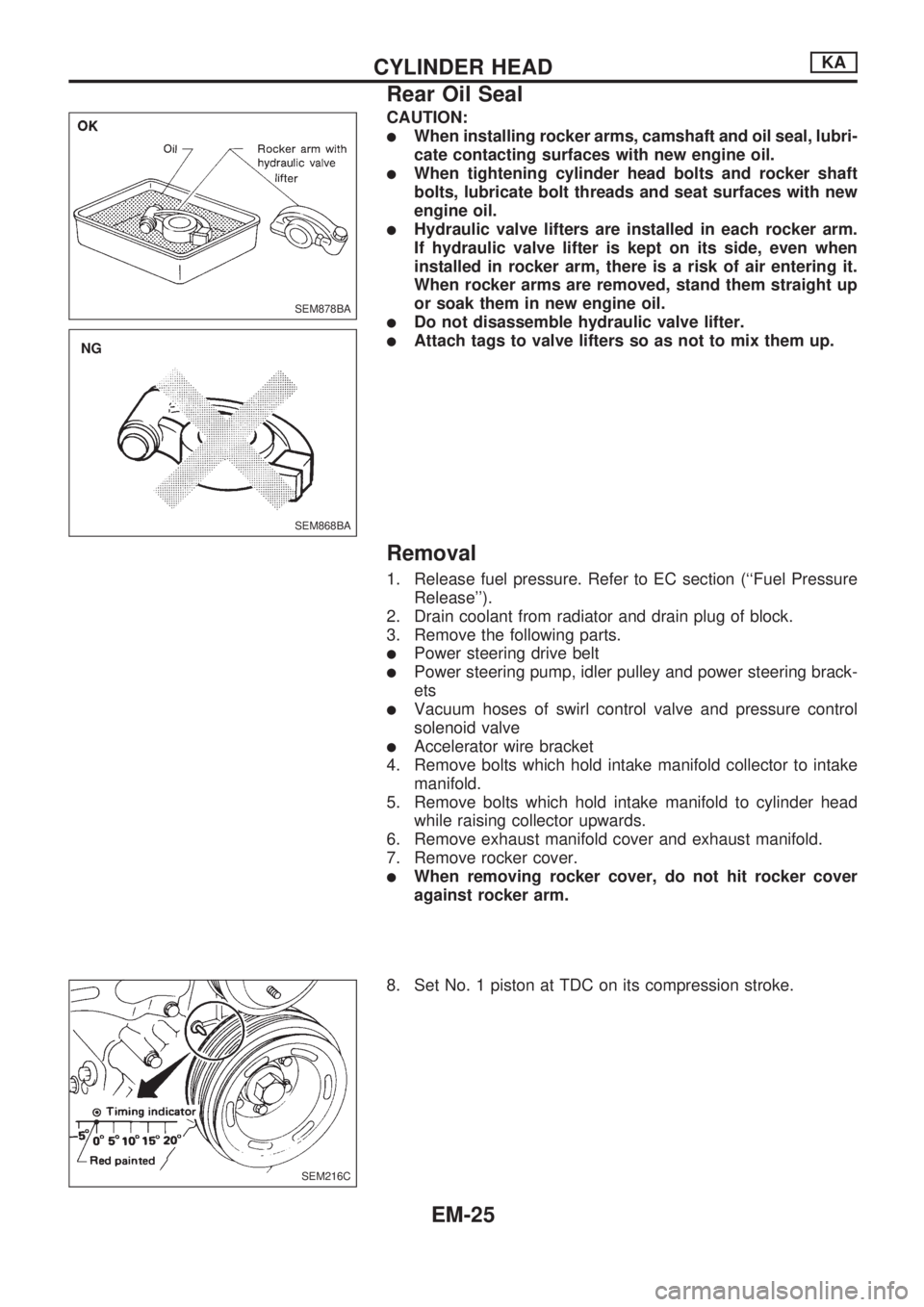

CAUTION:

lWhen installing rocker arms, camshaft and oil seal, lubri-

cate contacting surfaces with new engine oil.

lWhen tightening cylinder head bolts and rocker shaft

bolts, lubricate bolt threads and seat surfaces with new

engine oil.

lHydraulic valve lifters are installed in each rocker arm.

If hydraulic valve lifter is kept on its side, even when

installed in rocker arm, there is a risk of air entering it.

When rocker arms are removed, stand them straight up

or soak them in new engine oil.

lDo not disassemble hydraulic valve lifter.

lAttach tags to valve lifters so as not to mix them up.

Removal

1. Release fuel pressure. Refer to EC section (``Fuel Pressure

Release'').

2. Drain coolant from radiator and drain plug of block.

3. Remove the following parts.

lPower steering drive belt

lPower steering pump, idler pulley and power steering brack-

ets

lVacuum hoses of swirl control valve and pressure control

solenoid valve

lAccelerator wire bracket

4. Remove bolts which hold intake manifold collector to intake

manifold.

5. Remove bolts which hold intake manifold to cylinder head

while raising collector upwards.

6. Remove exhaust manifold cover and exhaust manifold.

7. Remove rocker cover.

lWhen removing rocker cover, do not hit rocker cover

against rocker arm.

8. Set No. 1 piston at TDC on its compression stroke.

SEM878BA

SEM868BA

.NG

SEM216C

CYLINDER HEADKA

Rear Oil Seal

EM-25