brake sensor NISSAN PICK-UP 1998 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 5 of 1659

Supplemental Restraint System (SRS) ``AIR

BAG'' (4WD models)

The Supplemental Restraint System ``AIR BAG'', used along with a seat belt, helps to reduce the risk or

severity of injury to the driver in a frontal collision. The Supplemental Restraint System consists of air bag

module (located in the center of the steering wheel), a diagnosis sensor unit, warning lamp, wiring harness

and spiral cable. Information necessary to service the system safely is included in theRS sectionof this

Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses are covered with yellow insulation either just before the

harness connectors or for the complete harness, for easy identification.

Supplemental Restraint System (SRS) ``AIR

BAG'' (2WD models)

The Supplemental Restraint System ``AIR BAG'', used along with a seat belt, helps to reduce the risk or

severity of injury to the driver in a frontal collision. The Supplemental Restraint System consists of an air

bag module (located in the center of the steering wheel), a diagnosis sensor unit, warning lamp and spiral

cable. Information necessary to service the system safely is included in theRS sectionof this Service

Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

lDo not use electrical test equipment on any circuit related to the SRS.

Precautions for Brake System

lUse brake fluid DOT 3 or DOT 4*1.

lNever reuse drained brake fluid.

lBe careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas, wash it away with water immediately.

lTo clean master cylinder parts, disc brake caliper parts

or wheel cylinder parts, use clean brake fluid.

lNever use mineral oils such as gasoline or kerosene.

They will ruin rubber parts of the hydraulic system.

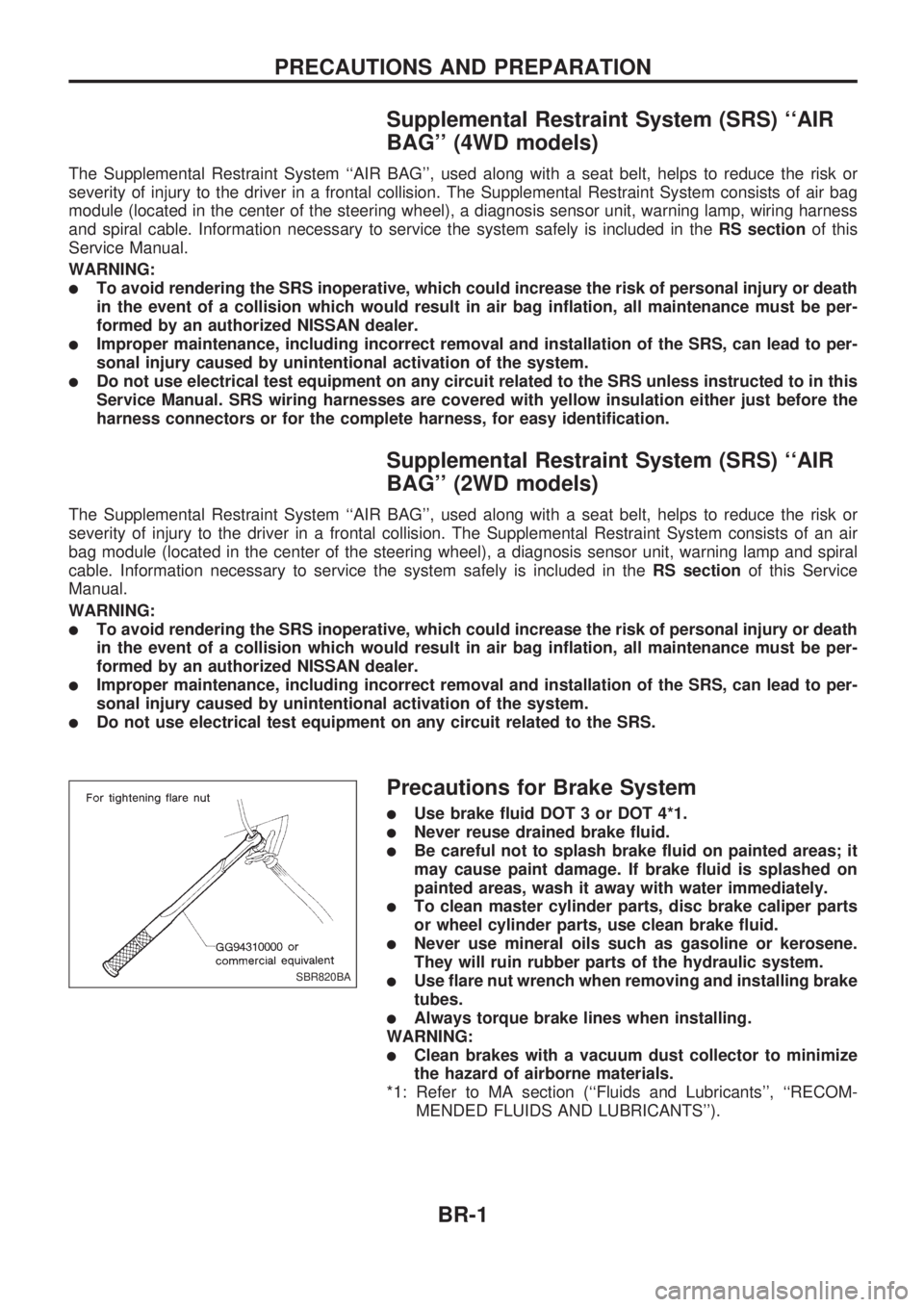

lUse flare nut wrench when removing and installing brake

tubes.

lAlways torque brake lines when installing.

WARNING:

lClean brakes with a vacuum dust collector to minimize

the hazard of airborne materials.

*1: Refer to MA section (``Fluids and Lubricants'', ``RECOM-

MENDED FLUIDS AND LUBRICANTS'').

SBR820BA

PRECAUTIONS AND PREPARATION

BR-1

Page 13 of 1659

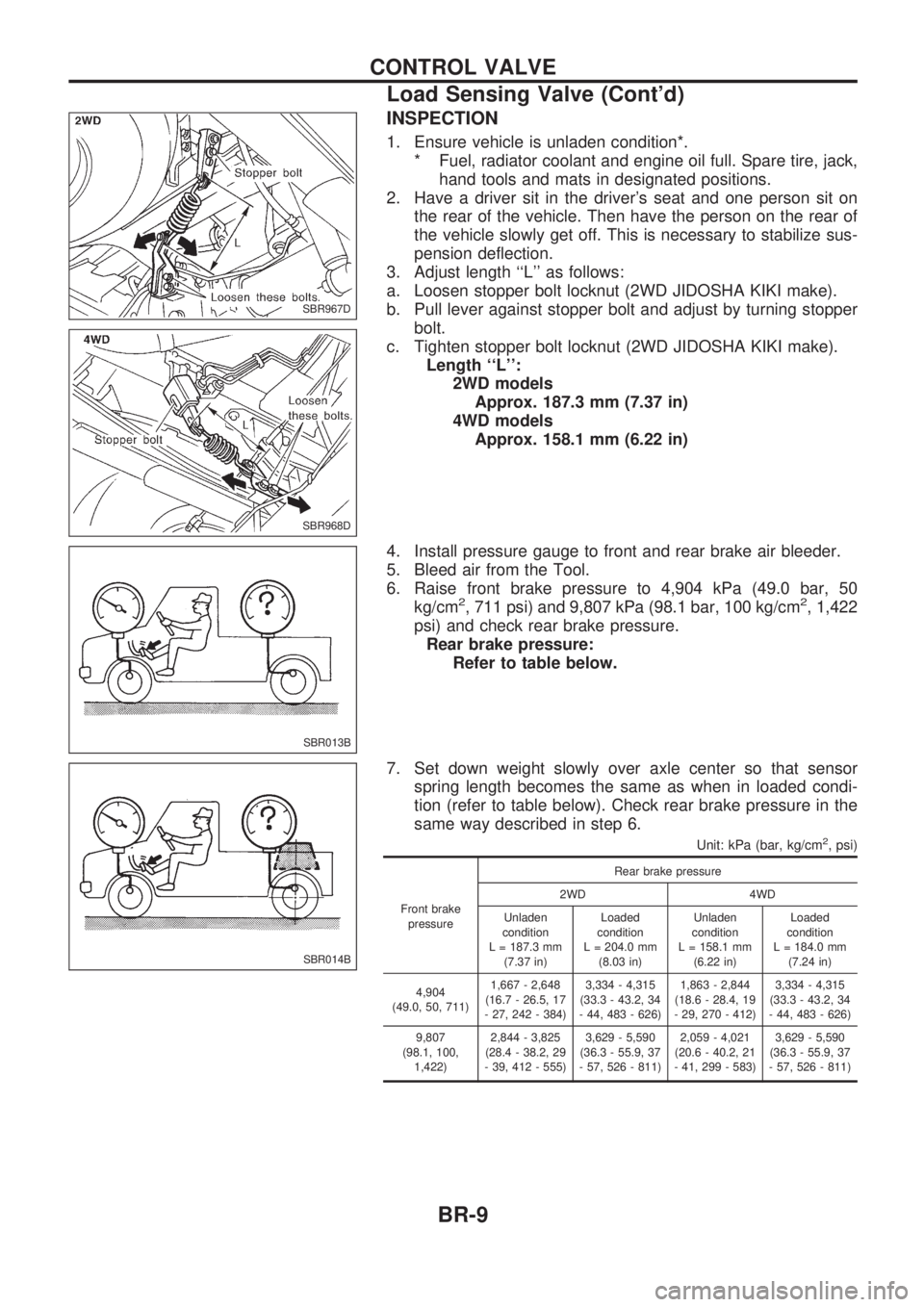

INSPECTION

1. Ensure vehicle is unladen condition*.

* Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

2. Have a driver sit in the driver's seat and one person sit on

the rear of the vehicle. Then have the person on the rear of

the vehicle slowly get off. This is necessary to stabilize sus-

pension deflection.

3. Adjust length ``L'' as follows:

a. Loosen stopper bolt locknut (2WD JIDOSHA KIKI make).

b. Pull lever against stopper bolt and adjust by turning stopper

bolt.

c. Tighten stopper bolt locknut (2WD JIDOSHA KIKI make).

Length ``L'':

2WD models

Approx. 187.3 mm (7.37 in)

4WD models

Approx. 158.1 mm (6.22 in)

4. Install pressure gauge to front and rear brake air bleeder.

5. Bleed air from the Tool.

6. Raise front brake pressure to 4,904 kPa (49.0 bar, 50

kg/cm

2, 711 psi) and 9,807 kPa (98.1 bar, 100 kg/cm2, 1,422

psi) and check rear brake pressure.

Rear brake pressure:

Refer to table below.

7. Set down weight slowly over axle center so that sensor

spring length becomes the same as when in loaded condi-

tion (refer to table below). Check rear brake pressure in the

same way described in step 6.

Unit: kPa (bar, kg/cm2, psi)

Front brake

pressureRear brake pressure

2WD 4WD

Unladen

condition

L = 187.3 mm

(7.37 in)Loaded

condition

L = 204.0 mm

(8.03 in)Unladen

condition

L = 158.1 mm

(6.22 in)Loaded

condition

L = 184.0 mm

(7.24 in)

4,904

(49.0, 50, 711)1,667 - 2,648

(16.7 - 26.5, 17

- 27, 242 - 384)3,334 - 4,315

(33.3 - 43.2, 34

- 44, 483 - 626)1,863 - 2,844

(18.6 - 28.4, 19

- 29, 270 - 412)3,334 - 4,315

(33.3 - 43.2, 34

- 44, 483 - 626)

9,807

(98.1, 100,

1,422)2,844 - 3,825

(28.4 - 38.2, 29

- 39, 412 - 555)3,629 - 5,590

(36.3 - 55.9, 37

- 57, 526 - 811)2,059 - 4,021

(20.6 - 40.2, 21

- 41, 299 - 583)3,629 - 5,590

(36.3 - 55.9, 37

- 57, 526 - 811)

SBR967D

SBR968D

SBR013B

SBR014B

CONTROL VALVE

Load Sensing Valve (Cont'd)

BR-9

Page 37 of 1659

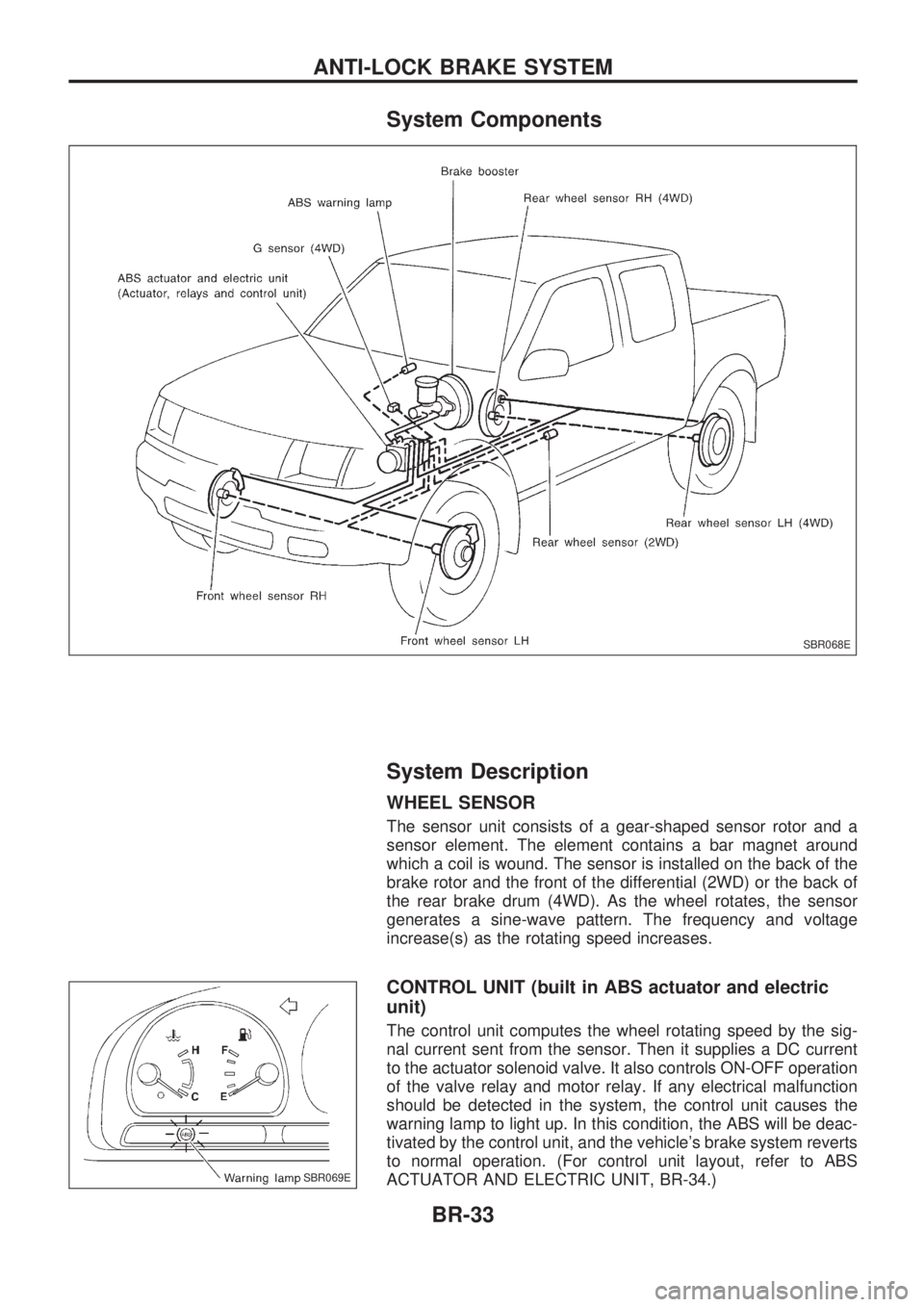

System Components

System Description

WHEEL SENSOR

The sensor unit consists of a gear-shaped sensor rotor and a

sensor element. The element contains a bar magnet around

which a coil is wound. The sensor is installed on the back of the

brake rotor and the front of the differential (2WD) or the back of

the rear brake drum (4WD). As the wheel rotates, the sensor

generates a sine-wave pattern. The frequency and voltage

increase(s) as the rotating speed increases.

CONTROL UNIT (built in ABS actuator and electric

unit)

The control unit computes the wheel rotating speed by the sig-

nal current sent from the sensor. Then it supplies a DC current

to the actuator solenoid valve. It also controls ON-OFF operation

of the valve relay and motor relay. If any electrical malfunction

should be detected in the system, the control unit causes the

warning lamp to light up. In this condition, the ABS will be deac-

tivated by the control unit, and the vehicle's brake system reverts

to normal operation. (For control unit layout, refer to ABS

ACTUATOR AND ELECTRIC UNIT, BR-34.)

SBR068E

SBR069E

ANTI-LOCK BRAKE SYSTEM

BR-33

Page 38 of 1659

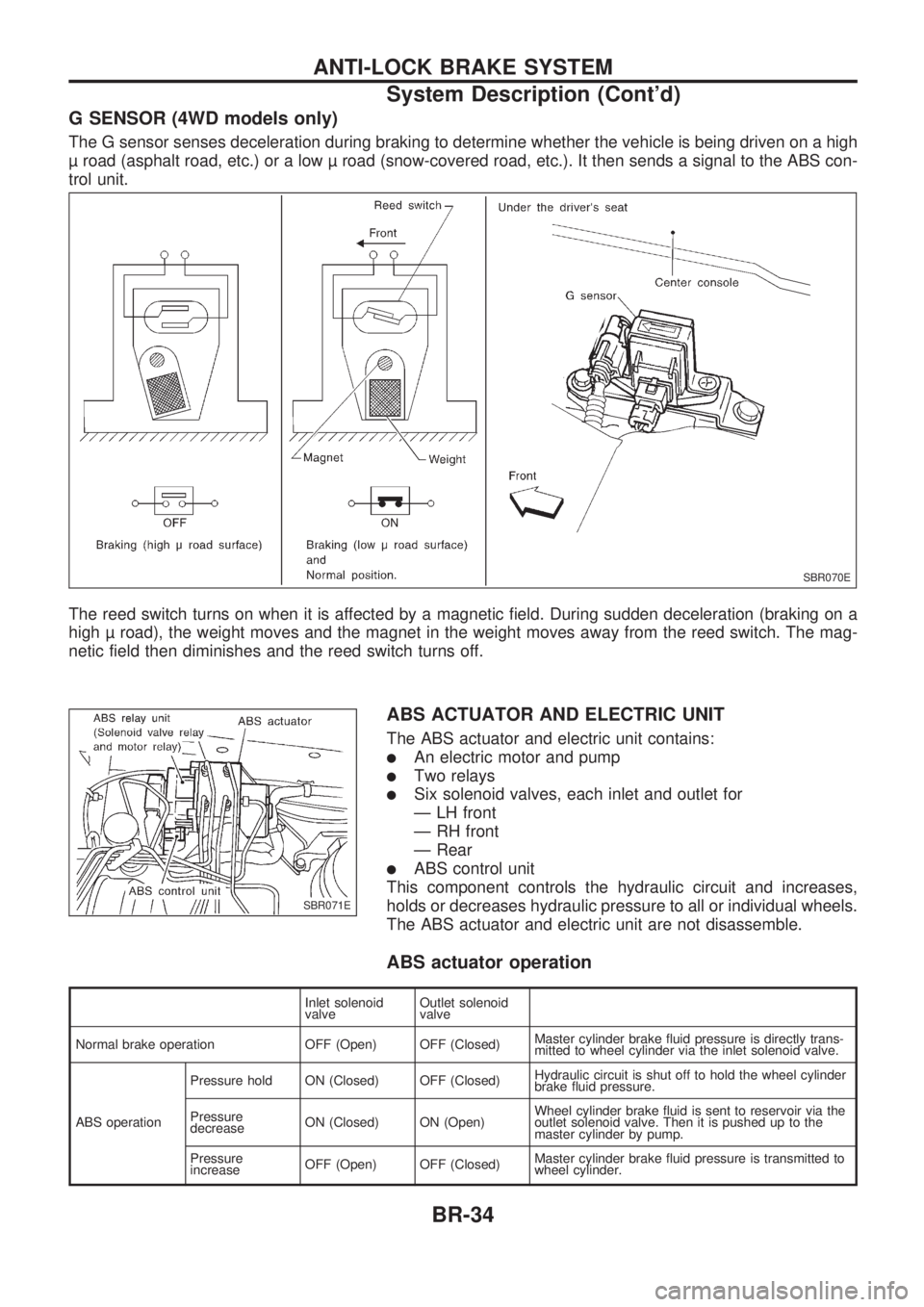

G SENSOR (4WD models only)

The G sensor senses deceleration during braking to determine whether the vehicle is being driven on a high

road (asphalt road, etc.) or a low road (snow-covered road, etc.). It then sends a signal to the ABS con-

trol unit.

The reed switch turns on when it is affected by a magnetic field. During sudden deceleration (braking on a

high road), the weight moves and the magnet in the weight moves away from the reed switch. The mag-

netic field then diminishes and the reed switch turns off.

ABS ACTUATOR AND ELECTRIC UNIT

The ABS actuator and electric unit contains:

lAn electric motor and pump

lTwo relays

lSix solenoid valves, each inlet and outlet for

Ð LH front

Ð RH front

Ð Rear

lABS control unit

This component controls the hydraulic circuit and increases,

holds or decreases hydraulic pressure to all or individual wheels.

The ABS actuator and electric unit are not disassemble.

ABS actuator operation

Inlet solenoid

valveOutlet solenoid

valve

Normal brake operation OFF (Open) OFF (Closed)Master cylinder brake fluid pressure is directly trans-

mitted to wheel cylinder via the inlet solenoid valve.

ABS operationPressure hold ON (Closed) OFF (Closed)Hydraulic circuit is shut off to hold the wheel cylinder

brake fluid pressure.

Pressure

decreaseON (Closed) ON (Open)Wheel cylinder brake fluid is sent to reservoir via the

outlet solenoid valve. Then it is pushed up to the

master cylinder by pump.

Pressure

increaseOFF (Open) OFF (Closed)Master cylinder brake fluid pressure is transmitted to

wheel cylinder.

SBR070E

SBR071E

ANTI-LOCK BRAKE SYSTEM

System Description (Cont'd)

BR-34

Page 39 of 1659

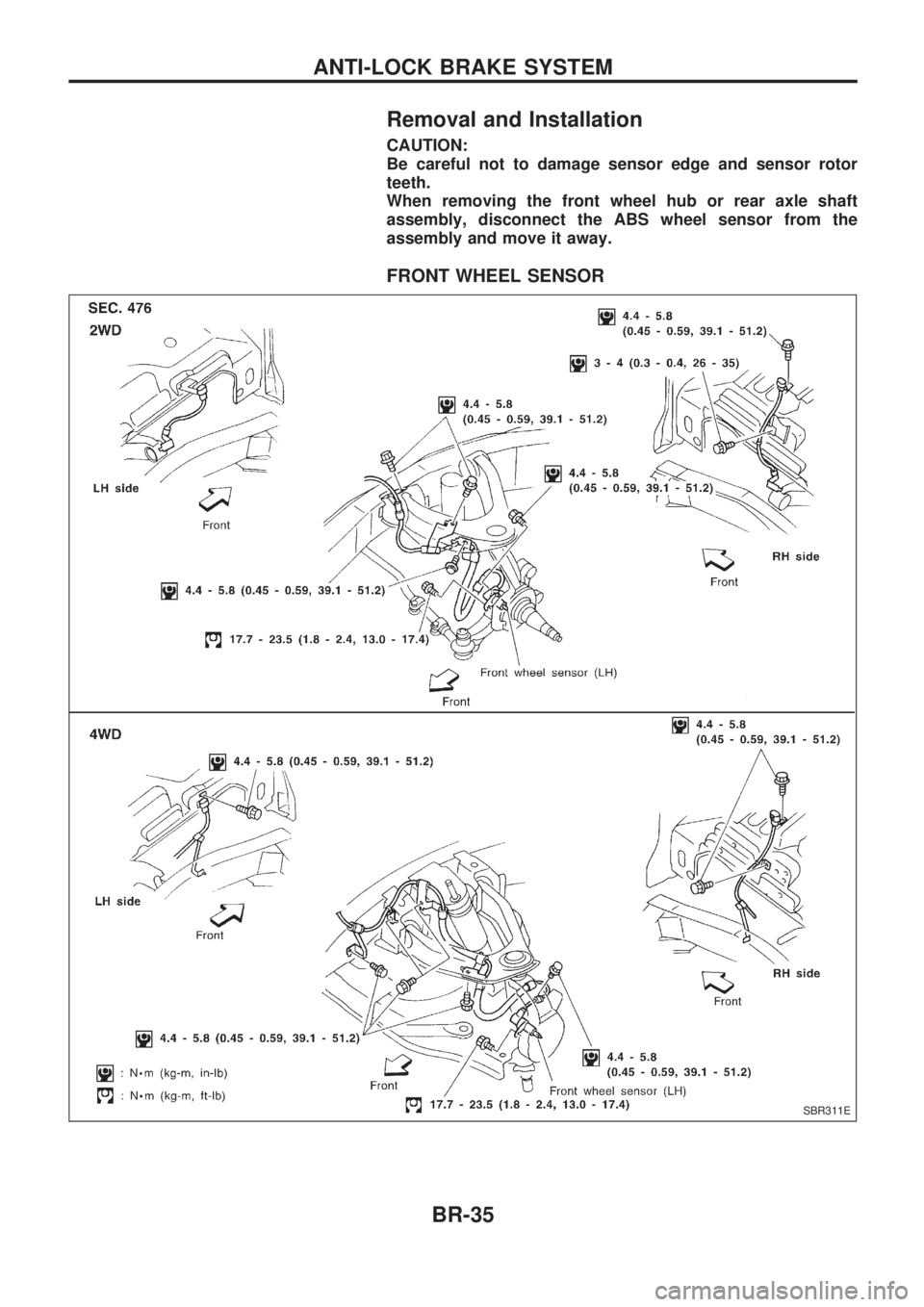

Removal and Installation

CAUTION:

Be careful not to damage sensor edge and sensor rotor

teeth.

When removing the front wheel hub or rear axle shaft

assembly, disconnect the ABS wheel sensor from the

assembly and move it away.

FRONT WHEEL SENSOR

SBR311E

ANTI-LOCK BRAKE SYSTEM

BR-35

Page 40 of 1659

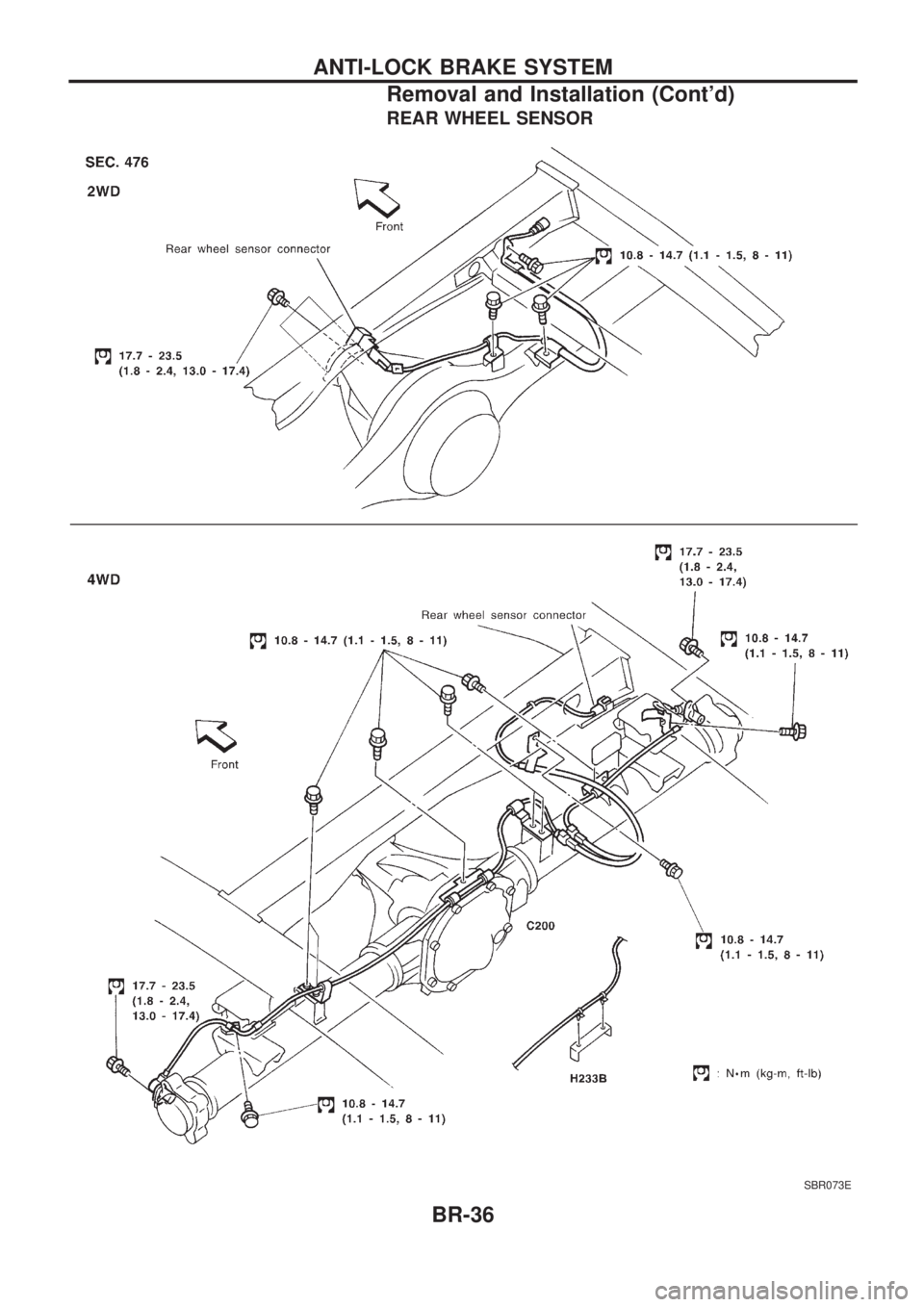

REAR WHEEL SENSOR

SBR073E

ANTI-LOCK BRAKE SYSTEM

Removal and Installation (Cont'd)

BR-36

Page 41 of 1659

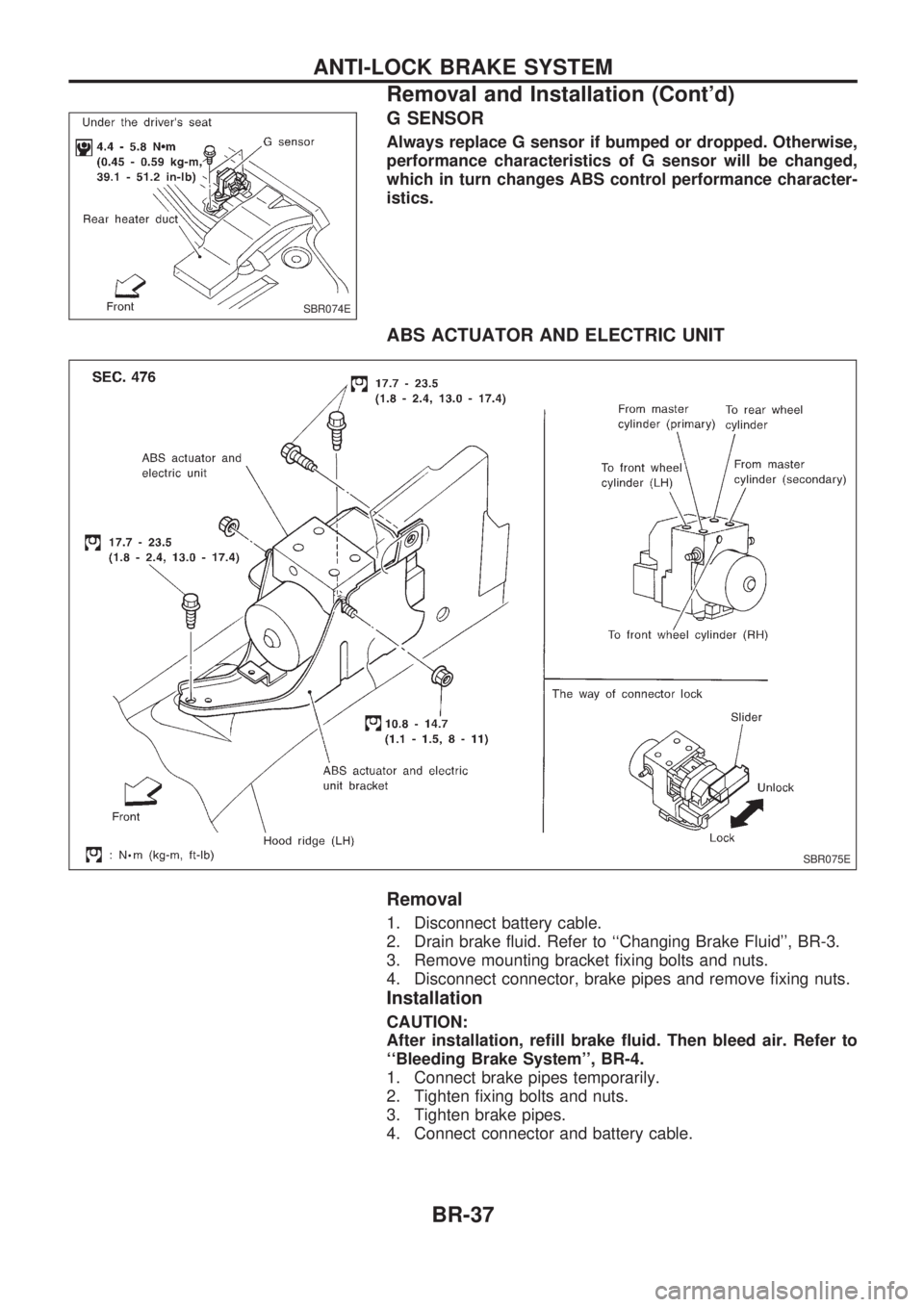

G SENSOR

Always replace G sensor if bumped or dropped. Otherwise,

performance characteristics of G sensor will be changed,

which in turn changes ABS control performance character-

istics.

ABS ACTUATOR AND ELECTRIC UNIT

Removal

1. Disconnect battery cable.

2. Drain brake fluid. Refer to ``Changing Brake Fluid'', BR-3.

3. Remove mounting bracket fixing bolts and nuts.

4. Disconnect connector, brake pipes and remove fixing nuts.

Installation

CAUTION:

After installation, refill brake fluid. Then bleed air. Refer to

``Bleeding Brake System'', BR-4.

1. Connect brake pipes temporarily.

2. Tighten fixing bolts and nuts.

3. Tighten brake pipes.

4. Connect connector and battery cable.

SBR074E

SBR075E

ANTI-LOCK BRAKE SYSTEM

Removal and Installation (Cont'd)

BR-37

Page 42 of 1659

How to Perform Trouble Diagnoses for Quick

and Accurate Repair

INTRODUCTION

The ABS system has an electronic control unit to control major

functions. The control unit accepts input signals from sensors

and instantly drives the actuators. It is essential that both kinds

of signals are proper and stable. It is also important to check for

conventional problems: such as air leaks in booster lines, lack of

brake fluid, or other problems with the brake system.

It is much more difficult to diagnose a problem that occurs inter-

mittently rather than continuously. Most intermittent problems are

caused by poor electric connections or faulty wiring. In this case,

careful checking of suspicious circuits may help prevent the

replacement of good parts.

A visual check only may not find the cause of the problems, so

a road test should be performed.

Before undertaking actual checks, take a few minutes to talk with

a customer who approaches with a ABS complaint. The cus-

tomer is a very good source of information on such problems;

especially intermittent ones. Through the talks with the customer,

find out what symptoms are present and under what conditions

they occur.

Start your diagnosis by looking for ``conventional'' problems first.

This is one of the best ways to troubleshoot brake problems on

an ABS controlled vehicle.

SEF233G

SEF234G

TROUBLE DIAGNOSES

BR-38

Page 65 of 1659

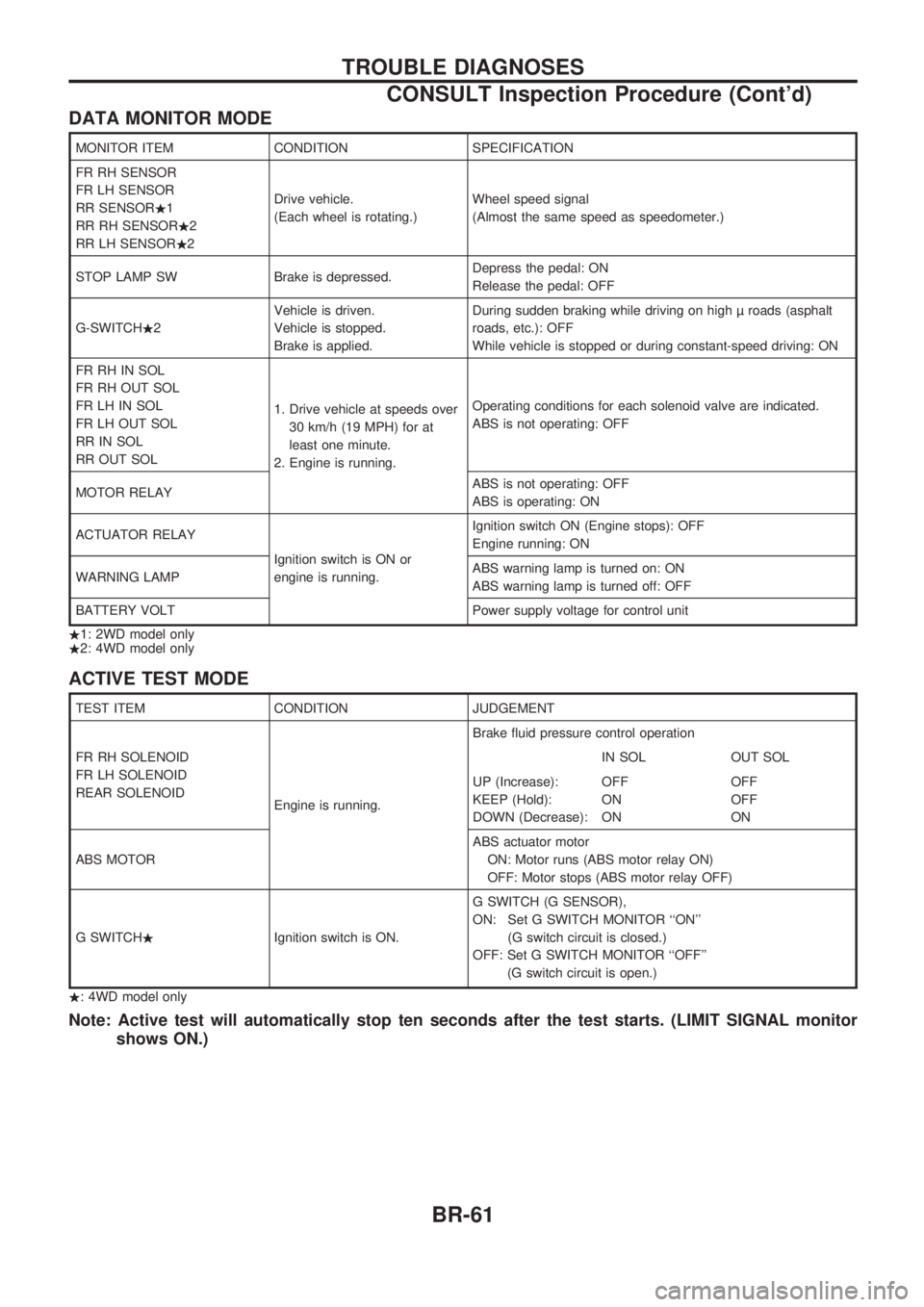

DATA MONITOR MODE

MONITOR ITEM CONDITION SPECIFICATION

FR RH SENSOR

FR LH SENSOR

RR SENSOR.1

RR RH SENSOR.2

RR LH SENSOR.2Drive vehicle.

(Each wheel is rotating.)Wheel speed signal

(Almost the same speed as speedometer.)

STOP LAMP SW Brake is depressed.Depress the pedal: ON

Release the pedal: OFF

G-SWITCH.2Vehicle is driven.

Vehicle is stopped.

Brake is applied.During sudden braking while driving on high roads (asphalt

roads, etc.): OFF

While vehicle is stopped or during constant-speed driving: ON

FR RH IN SOL

FR RH OUT SOL

FR LH IN SOL

FR LH OUT SOL

RR IN SOL

RR OUT SOL1. Drive vehicle at speeds over

30 km/h (19 MPH) for at

least one minute.

2. Engine is running.Operating conditions for each solenoid valve are indicated.

ABS is not operating: OFF

MOTOR RELAYABS is not operating: OFF

ABS is operating: ON

ACTUATOR RELAY

Ignition switch is ON or

engine is running.Ignition switch ON (Engine stops): OFF

Engine running: ON

WARNING LAMPABS warning lamp is turned on: ON

ABS warning lamp is turned off: OFF

BATTERY VOLT Power supply voltage for control unit

.1: 2WD model only

.2: 4WD model only

ACTIVE TEST MODE

TEST ITEM CONDITION JUDGEMENT

FR RH SOLENOID

FR LH SOLENOID

REAR SOLENOID

Engine is running.Brake fluid pressure control operation

IN SOL OUT SOL

UP (Increase):

KEEP (Hold):

DOWN (Decrease):OFF

ON

ONOFF

OFF

ON

ABS MOTORABS actuator motor

ON: Motor runs (ABS motor relay ON)

OFF: Motor stops (ABS motor relay OFF)

G SWITCH.Ignition switch is ON.G SWITCH (G SENSOR),

ON: Set G SWITCH MONITOR ``ON''

(G switch circuit is closed.)

OFF: Set G SWITCH MONITOR ``OFF''

(G switch circuit is open.)

.: 4WD model only

Note: Active test will automatically stop ten seconds after the test starts. (LIMIT SIGNAL monitor

shows ON.)

TROUBLE DIAGNOSES

CONSULT Inspection Procedure (Cont'd)

BR-61

Page 76 of 1659

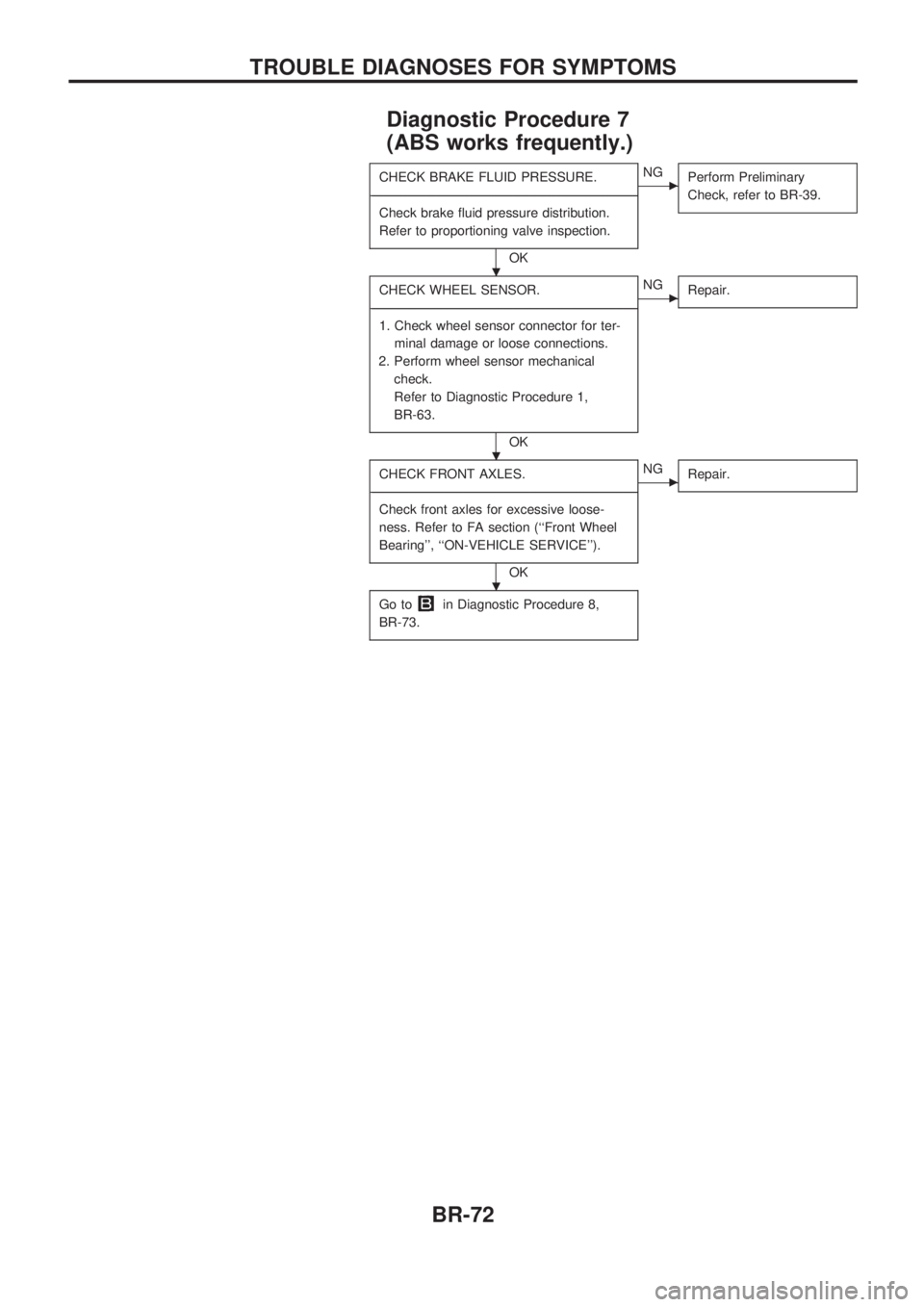

Diagnostic Procedure 7

(ABS works frequently.)

CHECK BRAKE FLUID PRESSURE.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check brake fluid pressure distribution.

Refer to proportioning valve inspection.

OK

cNG

Perform Preliminary

Check, refer to BR-39.

CHECK WHEEL SENSOR.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Check wheel sensor connector for ter-

minal damage or loose connections.

2. Perform wheel sensor mechanical

check.

Refer to Diagnostic Procedure 1,

BR-63.

OK

cNG

Repair.

CHECK FRONT AXLES.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check front axles for excessive loose-

ness. Refer to FA section (``Front Wheel

Bearing'', ``ON-VEHICLE SERVICE'').

OK

cNG

Repair.

Go toin Diagnostic Procedure 8,

BR-73.

.

.

.

TROUBLE DIAGNOSES FOR SYMPTOMS

BR-72