automatic transmission fluid NISSAN PICK-UP 1998 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 812 of 1659

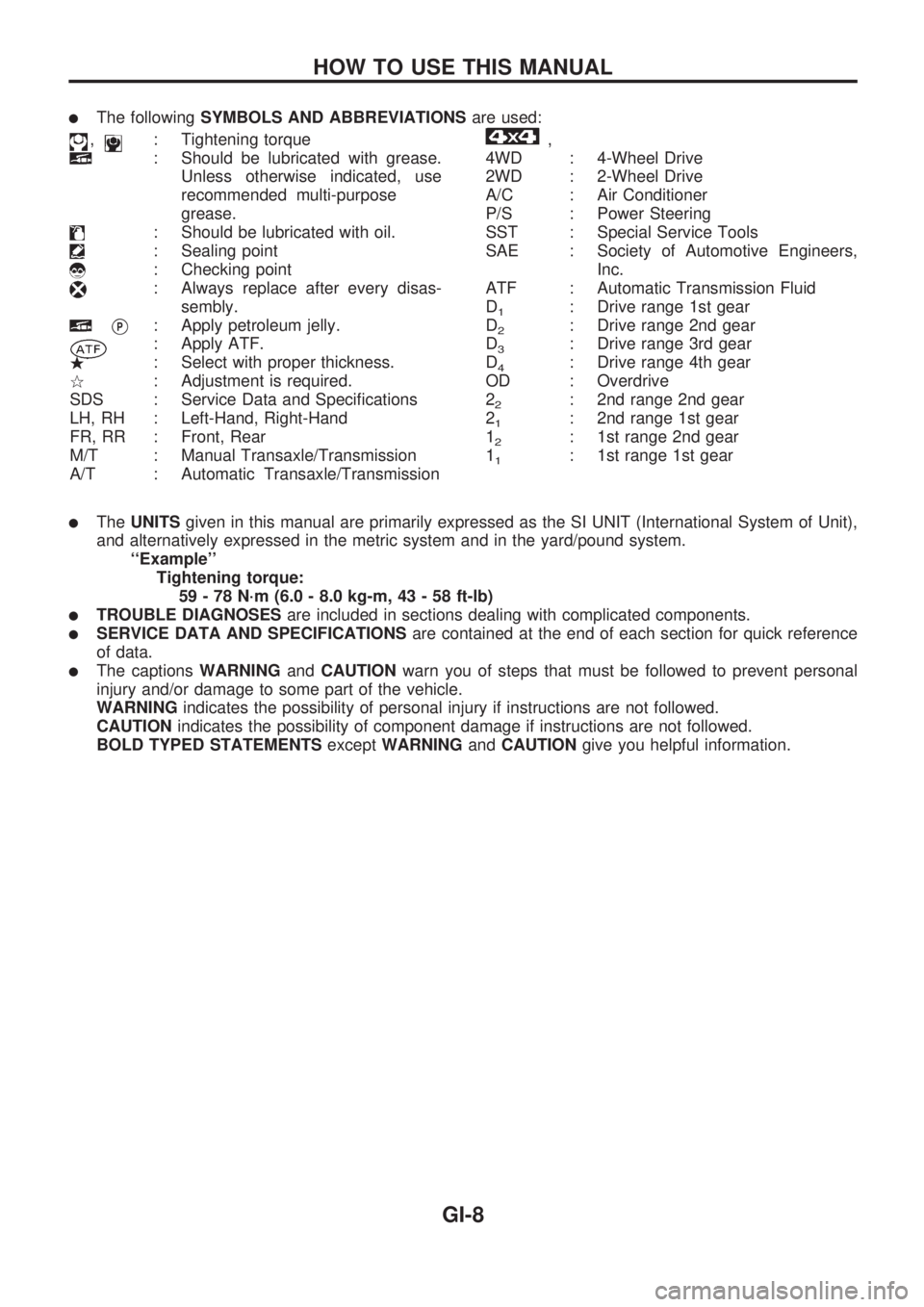

lThe followingSYMBOLS AND ABBREVIATIONSare used:

,: Tightening torque

: Should be lubricated with grease.

Unless otherwise indicated, use

recommended multi-purpose

grease.

: Should be lubricated with oil.

: Sealing point

: Checking point

: Always replace after every disas-

sembly.

VP: Apply petroleum jelly.

: Apply ATF.

.: Select with proper thickness.

>: Adjustment is required.

SDS : Service Data and Specifications

LH, RH : Left-Hand, Right-Hand

FR, RR : Front, Rear

M/T : Manual Transaxle/Transmission

A/T : Automatic Transaxle/Transmission

,

4WD : 4-Wheel Drive

2WD : 2-Wheel Drive

A/C : Air Conditioner

P/S : Power Steering

SST : Special Service Tools

SAE : Society of Automotive Engineers,

Inc.

ATF : Automatic Transmission Fluid

D

1: Drive range 1st gear

D

2: Drive range 2nd gear

D

3: Drive range 3rd gear

D

4: Drive range 4th gear

OD : Overdrive

2

2: 2nd range 2nd gear

2

1: 2nd range 1st gear

1

2: 1st range 2nd gear

1

1: 1st range 1st gear

lTheUNITSgiven in this manual are primarily expressed as the SI UNIT (International System of Unit),

and alternatively expressed in the metric system and in the yard/pound system.

``Example''

Tightening torque:

59 - 78 N´m (6.0 - 8.0 kg-m, 43 - 58 ft-lb)

lTROUBLE DIAGNOSESare included in sections dealing with complicated components.

lSERVICE DATA AND SPECIFICATIONSare contained at the end of each section for quick reference

of data.

lThe captionsWARNINGandCAUTIONwarn you of steps that must be followed to prevent personal

injury and/or damage to some part of the vehicle.

WARNINGindicates the possibility of personal injury if instructions are not followed.

CAUTIONindicates the possibility of component damage if instructions are not followed.

BOLD TYPED STATEMENTSexceptWARNINGandCAUTIONgive you helpful information.

HOW TO USE THIS MANUAL

GI-8

Page 985 of 1659

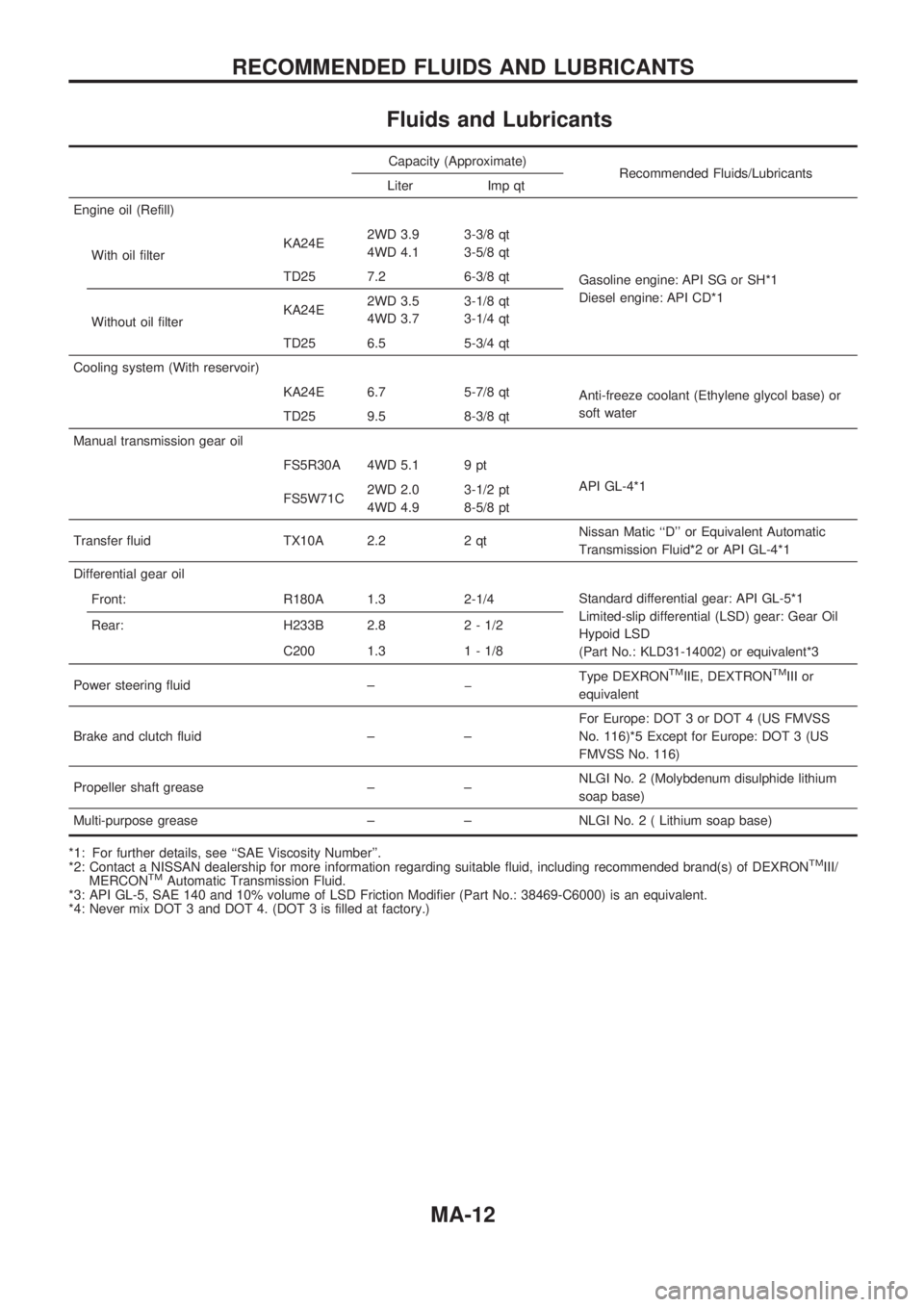

Fluids and Lubricants

Capacity (Approximate)

Recommended Fluids/Lubricants

Liter Imp qt

Engine oil (Refill)

With oil filterKA24E2WD 3.9

4WD 4.13-3/8 qt

3-5/8 qt

Gasoline engine: API SG or SH*1

Diesel engine: API CD*1 TD25 7.2 6-3/8 qt

Without oil filterKA24E2WD 3.5

4WD 3.73-1/8 qt

3-1/4 qt

TD25 6.5 5-3/4 qt

Cooling system (With reservoir)

KA24E 6.7 5-7/8 qt

Anti-freeze coolant (Ethylene glycol base) or

soft water

TD25 9.5 8-3/8 qt

Manual transmission gear oil

FS5R30A 4WD 5.1 9 pt

API GL-4*1

FS5W71C2WD 2.0

4WD 4.93-1/2 pt

8-5/8 pt

Transfer fluid TX10A 2.2 2 qtNissan Matic ``D'' or Equivalent Automatic

Transmission Fluid*2 or API GL-4*1

Differential gear oil

Front: R180A 1.3 2-1/4Standard differential gear: API GL-5*1

Limited-slip differential (LSD) gear: Gear Oil

Hypoid LSD

(Part No.: KLD31-14002) or equivalent*3 Rear: H233B 2.8 2 - 1/2

C200 1.3 1 - 1/8

Power steering fluid ± þType DEXRON

TMIIE, DEXTRONTMIII or

equivalent

Brake and clutch fluid ± ±For Europe: DOT 3 or DOT 4 (US FMVSS

No. 116)*5 Except for Europe: DOT 3 (US

FMVSS No. 116)

Propeller shaft grease ± ±NLGI No. 2 (Molybdenum disulphide lithium

soap base)

Multi-purpose grease ± ± NLGI No. 2 ( Lithium soap base)

*1: For further details, see ``SAE Viscosity Number''.

*2: Contact a NISSAN dealership for more information regarding suitable fluid, including recommended brand(s) of DEXRONTMIII/

MERCONTMAutomatic Transmission Fluid.

*3: API GL-5, SAE 140 and 10% volume of LSD Friction Modifier (Part No.: 38469-C6000) is an equivalent.

*4: Never mix DOT 3 and DOT 4. (DOT 3 is filled at factory.)

RECOMMENDED FLUIDS AND LUBRICANTS

MA-12

Page 1006 of 1659

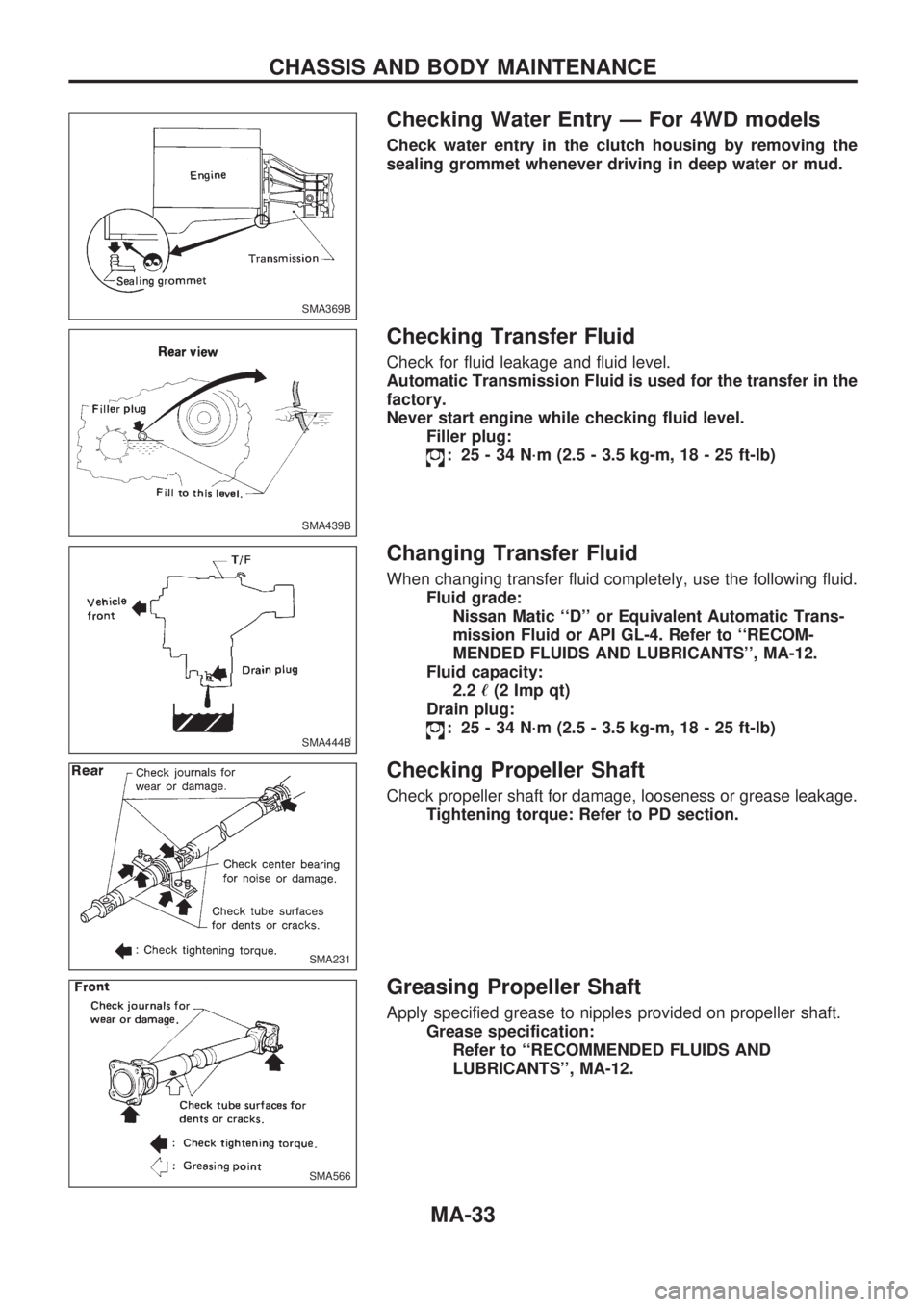

Checking Water Entry Ð For 4WD models

Check water entry in the clutch housing by removing the

sealing grommet whenever driving in deep water or mud.

Checking Transfer Fluid

Check for fluid leakage and fluid level.

Automatic Transmission Fluid is used for the transfer in the

factory.

Never start engine while checking fluid level.

Filler plug:

: 25 - 34 N´m (2.5 - 3.5 kg-m, 18 - 25 ft-lb)

Changing Transfer Fluid

When changing transfer fluid completely, use the following fluid.

Fluid grade:

Nissan Matic ``D'' or Equivalent Automatic Trans-

mission Fluid or API GL-4. Refer to ``RECOM-

MENDED FLUIDS AND LUBRICANTS'', MA-12.

Fluid capacity:

2.2ø(2 Imp qt)

Drain plug:

: 25 - 34 N´m (2.5 - 3.5 kg-m, 18 - 25 ft-lb)

Checking Propeller Shaft

Check propeller shaft for damage, looseness or grease leakage.

Tightening torque: Refer to PD section.

Greasing Propeller Shaft

Apply specified grease to nipples provided on propeller shaft.

Grease specification:

Refer to ``RECOMMENDED FLUIDS AND

LUBRICANTS'', MA-12.

SMA369B

SMA439B

SMA444B

SMA231

SMA566

CHASSIS AND BODY MAINTENANCE

MA-33

Page 1010 of 1659

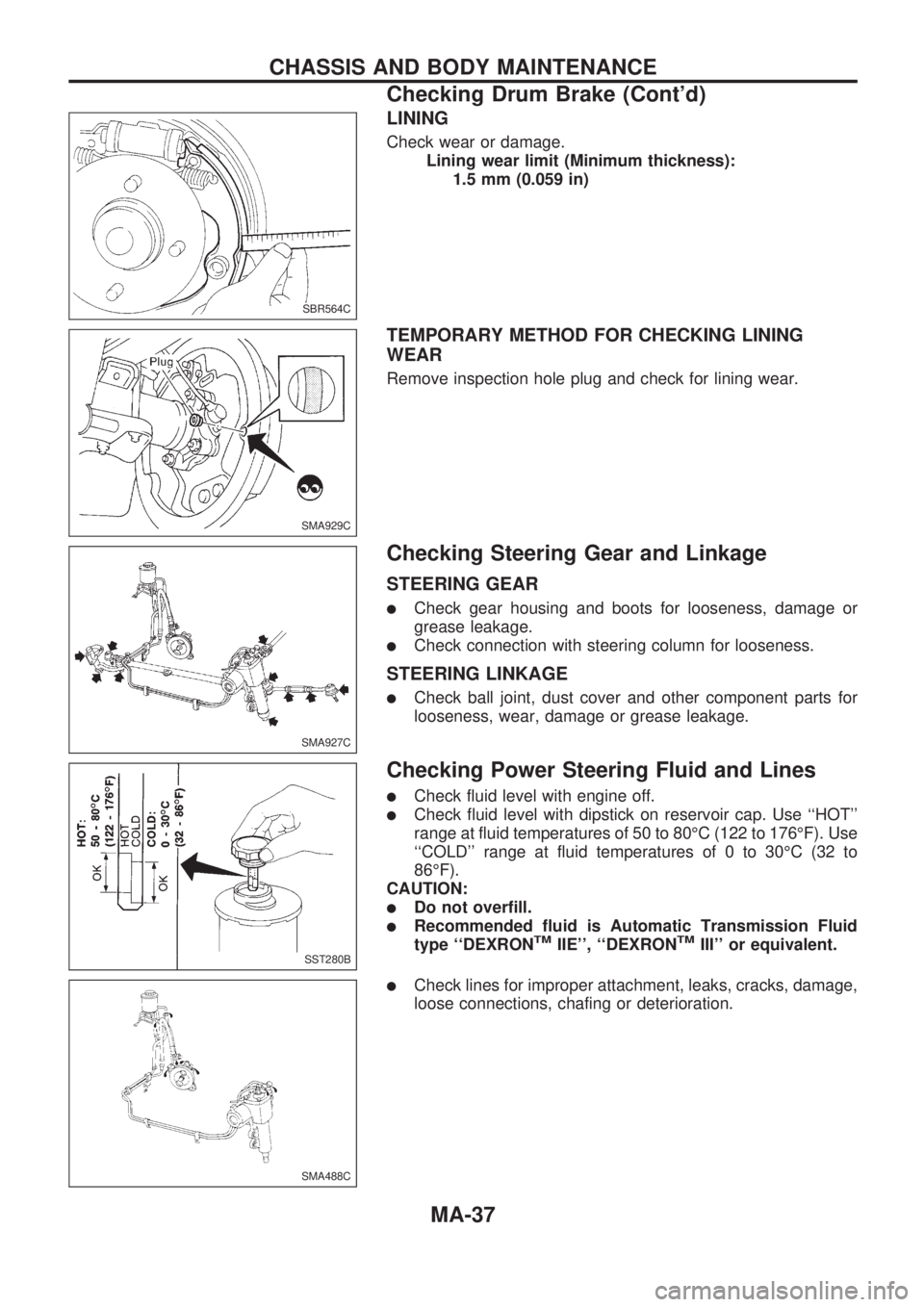

LINING

Check wear or damage.

Lining wear limit (Minimum thickness):

1.5 mm (0.059 in)

TEMPORARY METHOD FOR CHECKING LINING

WEAR

Remove inspection hole plug and check for lining wear.

Checking Steering Gear and Linkage

STEERING GEAR

lCheck gear housing and boots for looseness, damage or

grease leakage.

lCheck connection with steering column for looseness.

STEERING LINKAGE

lCheck ball joint, dust cover and other component parts for

looseness, wear, damage or grease leakage.

Checking Power Steering Fluid and Lines

lCheck fluid level with engine off.

lCheck fluid level with dipstick on reservoir cap. Use ``HOT''

range at fluid temperatures of 50 to 80ÉC (122 to 176ÉF). Use

``COLD'' range at fluid temperatures of 0 to 30ÉC (32 to

86ÉF).

CAUTION:

lDo not overfill.

lRecommended fluid is Automatic Transmission Fluid

type ``DEXRONTMIIE'', ``DEXRONTMIII'' or equivalent.

lCheck lines for improper attachment, leaks, cracks, damage,

loose connections, chafing or deterioration.

SBR564C

SMA929C

SMA927C

SST280B

SMA488C

CHASSIS AND BODY MAINTENANCE

Checking Drum Brake (Cont'd)

MA-37

Page 1223 of 1659

Supplemental Restraint System (SRS) ``AIR

BAG'' (4WD models)

The Supplemental Restraint System ``Air Bag'', used along with a seat belt, helps to reduce the risk or

severity of injury to the driver in a frontal collision. The Supplemental Restraint System consists of an air

bag module (located in the center of the steering wheel), a diagnosis sensor unit, warning lamp, wiring har-

ness and spiral cable. Information necessary to service the system safely is included in theRS sectionof

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses are covered with yellow insulation either just before the

harness connectors or for the complete harness, for easy identification.

Supplemental Restraint System (SRS) ``AIR

BAG'' (2WD models)

The Supplemental Restraint System ``Air Bag'', used along with a seat belt, helps to reduce the risk or

severity of injury to the driver in a frontal collision. The Supplemental Restraint System consists of an air

bag module (located in the center of the steering wheel), a diagnosis sensor unit, warning lamp and spiral

cable. Information necessary to service the system safely is included in theRS sectionof this Service

Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

lDo not use electrical test equipment on any circuit related to the SRS.

Precautions for Steering System

lBefore disassembly, thoroughly clean the outside of the unit.

lDisassembly should be done in a clean work area. It is important to prevent the internal parts

from becoming contaminated by dirt or other foreign matter.

lFor easier and proper assembly, place disassembled parts in order on a parts rack.

lUse nylon cloths or paper towels to clean the parts; common shop rags can leave lint that might

interfere with their operation.

lBefore inspection or reassembly, carefully clean all parts with a general purpose, non-flammable

solvent.

lBefore assembly, apply a coat of recommended ATF* to hydraulic parts. Petroleum jelly may be

applied to O-rings and seals. Do not use any grease.

lReplace all gaskets, seals and O-rings. Avoid damaging O-rings, seals and gaskets during instal-

lation. Perform functional tests whenever designated.

*: Automatic Transmission Fluid type DEXRON

TMII E, DEXRONTMIII, or equivalent.

PRECAUTIONS AND PREPARATION

ST-1

Page 1226 of 1659

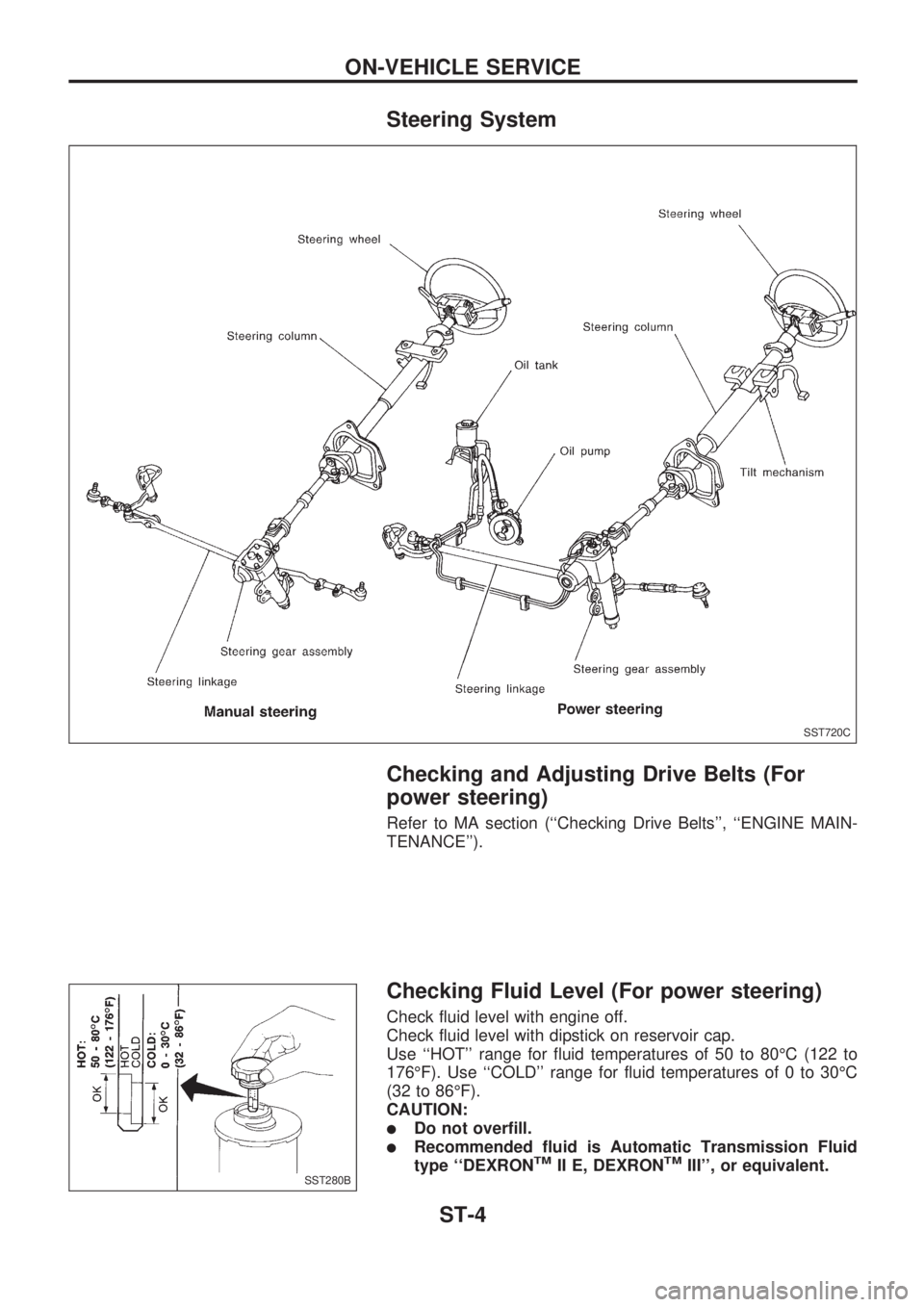

Steering System

Checking and Adjusting Drive Belts (For

power steering)

Refer to MA section (``Checking Drive Belts'', ``ENGINE MAIN-

TENANCE'').

Checking Fluid Level (For power steering)

Check fluid level with engine off.

Check fluid level with dipstick on reservoir cap.

Use ``HOT'' range for fluid temperatures of 50 to 80ÉC (122 to

176ÉF). Use ``COLD'' range for fluid temperatures of 0 to 30ÉC

(32 to 86ÉF).

CAUTION:

lDo not overfill.

lRecommended fluid is Automatic Transmission Fluid

type ``DEXRONTMII E, DEXRONTMIII'', or equivalent.

SST720C

SST280B

ON-VEHICLE SERVICE

ST-4