tires NISSAN PICK-UP 1998 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 439 of 1659

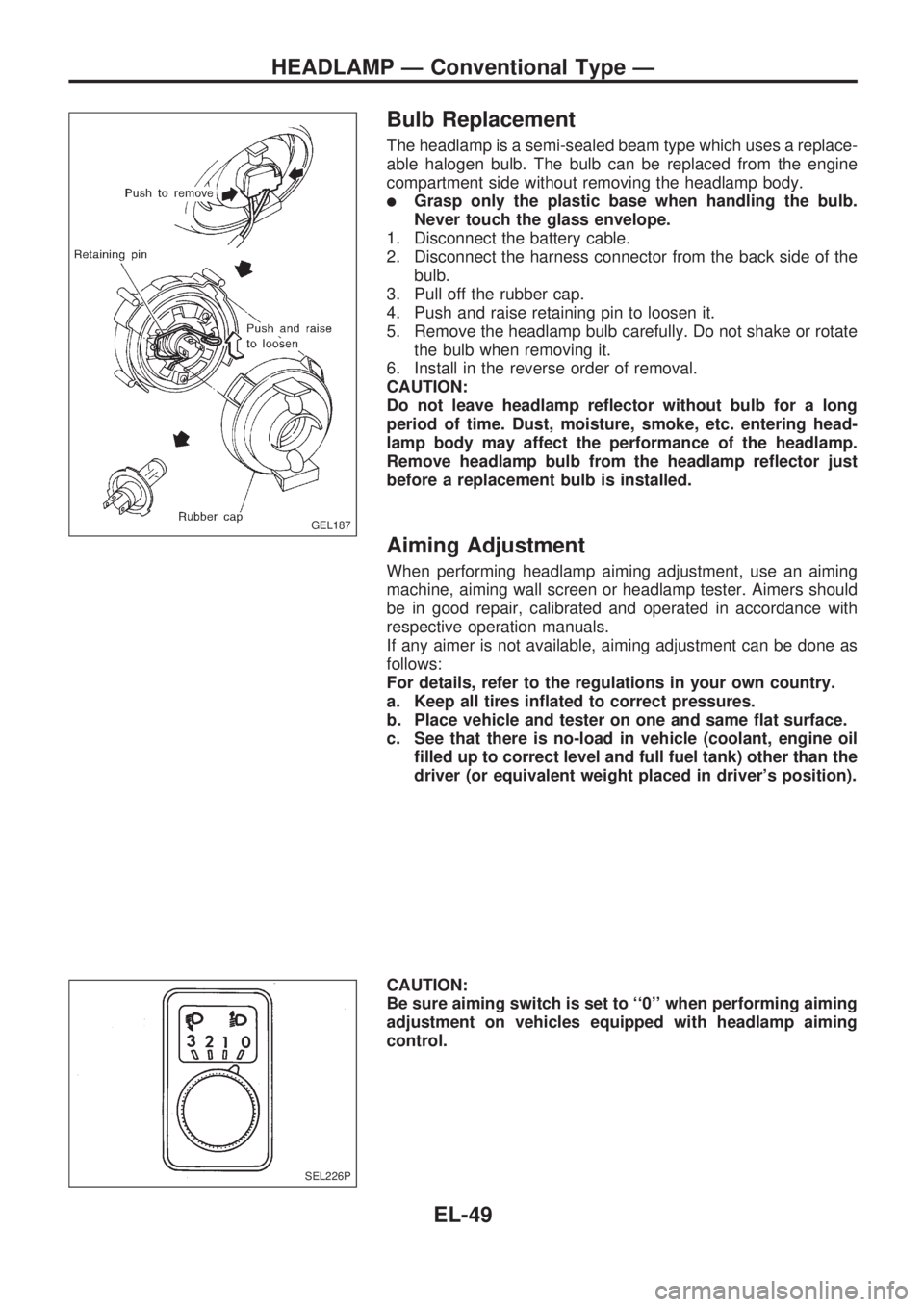

Bulb Replacement

The headlamp is a semi-sealed beam type which uses a replace-

able halogen bulb. The bulb can be replaced from the engine

compartment side without removing the headlamp body.

lGrasp only the plastic base when handling the bulb.

Never touch the glass envelope.

1. Disconnect the battery cable.

2. Disconnect the harness connector from the back side of the

bulb.

3. Pull off the rubber cap.

4. Push and raise retaining pin to loosen it.

5. Remove the headlamp bulb carefully. Do not shake or rotate

the bulb when removing it.

6. Install in the reverse order of removal.

CAUTION:

Do not leave headlamp reflector without bulb for a long

period of time. Dust, moisture, smoke, etc. entering head-

lamp body may affect the performance of the headlamp.

Remove headlamp bulb from the headlamp reflector just

before a replacement bulb is installed.

Aiming Adjustment

When performing headlamp aiming adjustment, use an aiming

machine, aiming wall screen or headlamp tester. Aimers should

be in good repair, calibrated and operated in accordance with

respective operation manuals.

If any aimer is not available, aiming adjustment can be done as

follows:

For details, refer to the regulations in your own country.

a. Keep all tires inflated to correct pressures.

b. Place vehicle and tester on one and same flat surface.

c. See that there is no-load in vehicle (coolant, engine oil

filled up to correct level and full fuel tank) other than the

driver (or equivalent weight placed in driver's position).

CAUTION:

Be sure aiming switch is set to ``0'' when performing aiming

adjustment on vehicles equipped with headlamp aiming

control.

GEL187

SEL226P

HEADLAMP Ð Conventional Type Ð

EL-49

Page 766 of 1659

Precautions

lWhen installing rubber parts, final tightening must be

carried out under unladen condition* with tires on

ground.

* Fuel, radiator coolant and engine oil full. Spare tire,

jack, hand tools and mats in designated positions.

lUse flare nut wrench when removing or installing brake

tubes.

lAfter installing removed suspension parts, check wheel

alignment and adjust if necessary.

lAlways torque brake lines when installing.

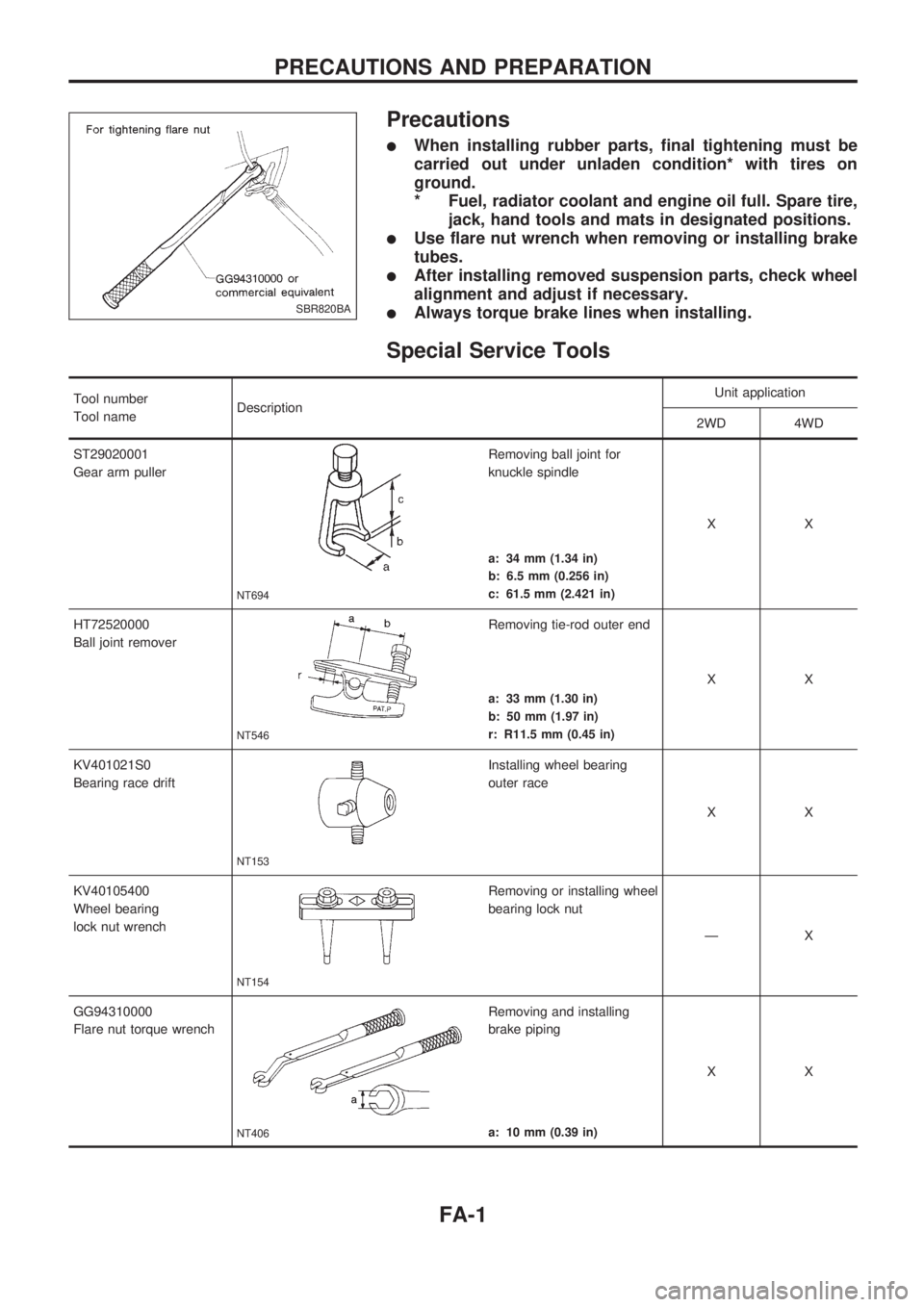

Special Service Tools

Tool number

Tool nameDescriptionUnit application

2WD 4WD

ST29020001

Gear arm puller

NT694

Removing ball joint for

knuckle spindle

XX

a: 34 mm (1.34 in)

b: 6.5 mm (0.256 in)

c: 61.5 mm (2.421 in)

HT72520000

Ball joint remover

NT546

Removing tie-rod outer end

XX

a: 33 mm (1.30 in)

b: 50 mm (1.97 in)

r: R11.5 mm (0.45 in)

KV401021S0

Bearing race drift

NT153

Installing wheel bearing

outer race

XX

KV40105400

Wheel bearing

lock nut wrench

NT154

Removing or installing wheel

bearing lock nut

ÐX

GG94310000

Flare nut torque wrench

NT406

Removing and installing

brake piping

XX

a: 10 mm (0.39 in)

SBR820BA

PRECAUTIONS AND PREPARATION

FA-1

Page 772 of 1659

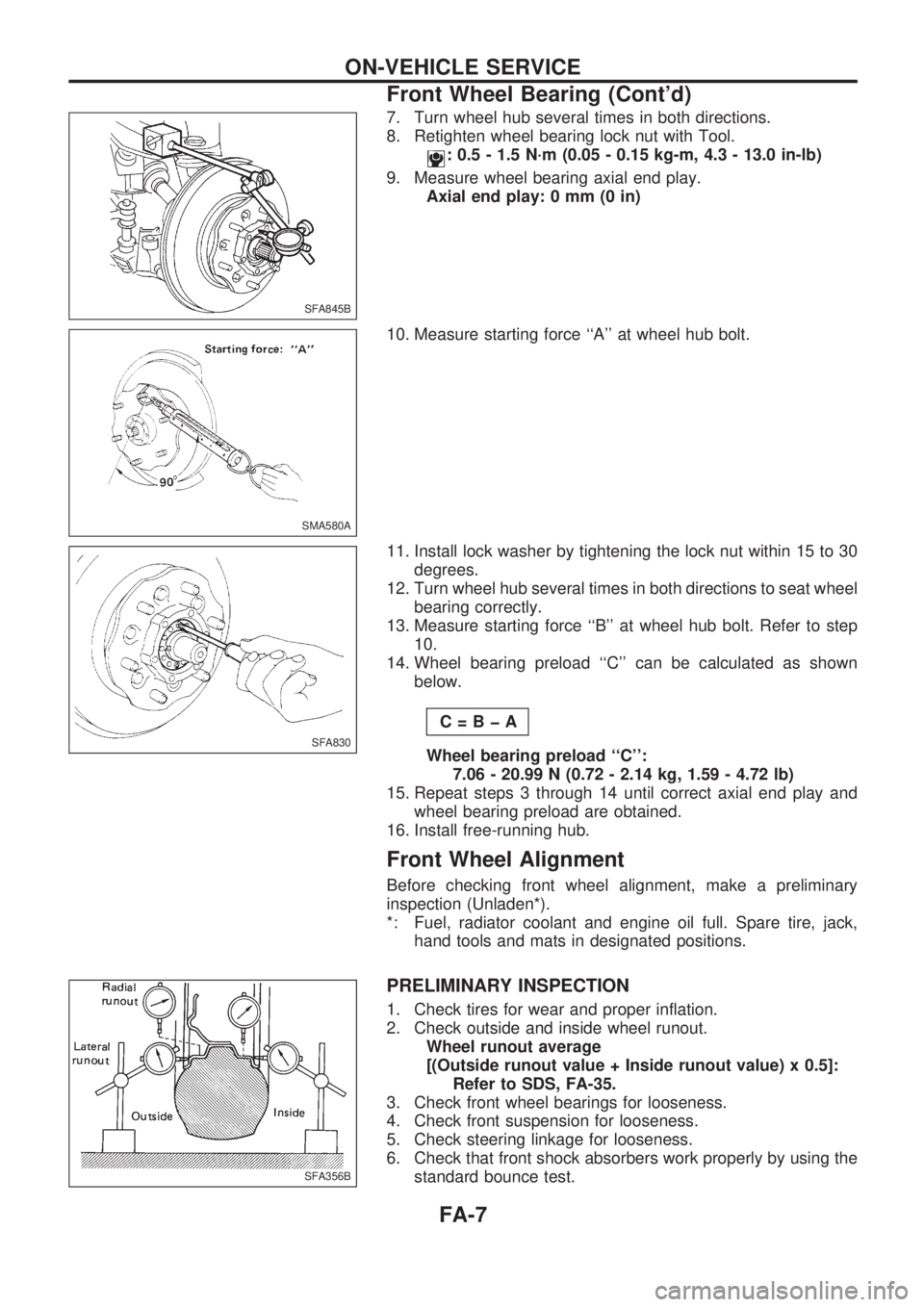

7. Turn wheel hub several times in both directions.

8. Retighten wheel bearing lock nut with Tool.

: 0.5 - 1.5 N´m (0.05 - 0.15 kg-m, 4.3 - 13.0 in-lb)

9. Measure wheel bearing axial end play.

Axial end play: 0 mm (0 in)

10. Measure starting force ``A'' at wheel hub bolt.

11. Install lock washer by tightening the lock nut within 15 to 30

degrees.

12. Turn wheel hub several times in both directions to seat wheel

bearing correctly.

13. Measure starting force ``B'' at wheel hub bolt. Refer to step

10.

14. Wheel bearing preload ``C'' can be calculated as shown

below.

C=BþA

Wheel bearing preload ``C'':

7.06 - 20.99 N (0.72 - 2.14 kg, 1.59 - 4.72 lb)

15. Repeat steps 3 through 14 until correct axial end play and

wheel bearing preload are obtained.

16. Install free-running hub.

Front Wheel Alignment

Before checking front wheel alignment, make a preliminary

inspection (Unladen*).

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

PRELIMINARY INSPECTION

1. Check tires for wear and proper inflation.

2. Check outside and inside wheel runout.

Wheel runout average

[(Outside runout value + Inside runout value) x 0.5]:

Refer to SDS, FA-35.

3. Check front wheel bearings for looseness.

4. Check front suspension for looseness.

5. Check steering linkage for looseness.

6. Check that front shock absorbers work properly by using the

standard bounce test.

SFA845B

SMA580A

SFA830

SFA356B

ON-VEHICLE SERVICE

Front Wheel Bearing (Cont'd)

FA-7

Page 775 of 1659

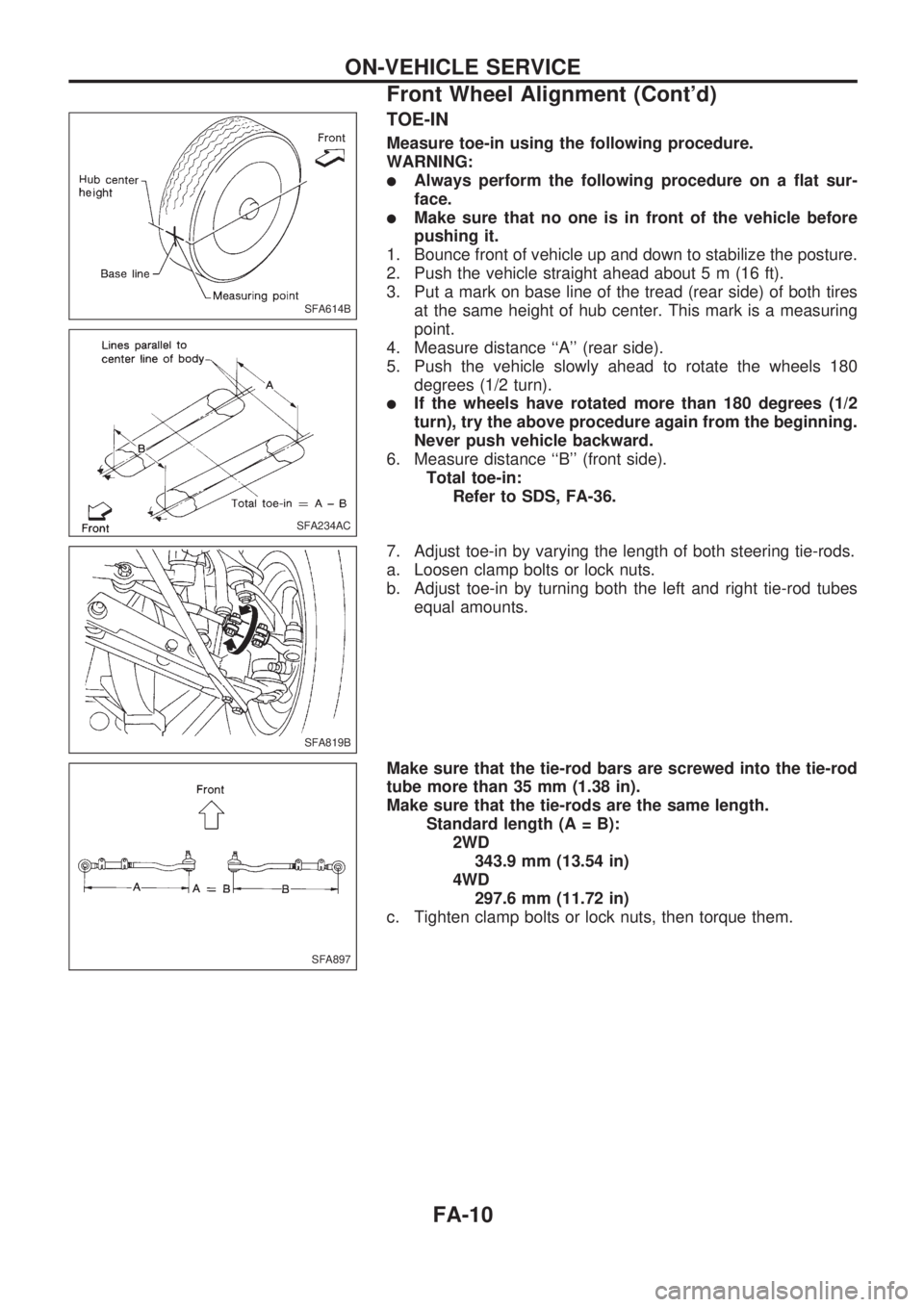

TOE-IN

Measure toe-in using the following procedure.

WARNING:

lAlways perform the following procedure on a flat sur-

face.

lMake sure that no one is in front of the vehicle before

pushing it.

1. Bounce front of vehicle up and down to stabilize the posture.

2. Push the vehicle straight ahead about 5 m (16 ft).

3. Put a mark on base line of the tread (rear side) of both tires

at the same height of hub center. This mark is a measuring

point.

4. Measure distance ``A'' (rear side).

5. Push the vehicle slowly ahead to rotate the wheels 180

degrees (1/2 turn).

lIf the wheels have rotated more than 180 degrees (1/2

turn), try the above procedure again from the beginning.

Never push vehicle backward.

6. Measure distance ``B'' (front side).

Total toe-in:

Refer to SDS, FA-36.

7. Adjust toe-in by varying the length of both steering tie-rods.

a. Loosen clamp bolts or lock nuts.

b. Adjust toe-in by turning both the left and right tie-rod tubes

equal amounts.

Make sure that the tie-rod bars are screwed into the tie-rod

tube more than 35 mm (1.38 in).

Make sure that the tie-rods are the same length.

Standard length (A = B):

2WD

343.9 mm (13.54 in)

4WD

297.6 mm (11.72 in)

c. Tighten clamp bolts or lock nuts, then torque them.

SFA614B

SFA234AC

SFA819B

SFA897

ON-VEHICLE SERVICE

Front Wheel Alignment (Cont'd)

FA-10

Page 795 of 1659

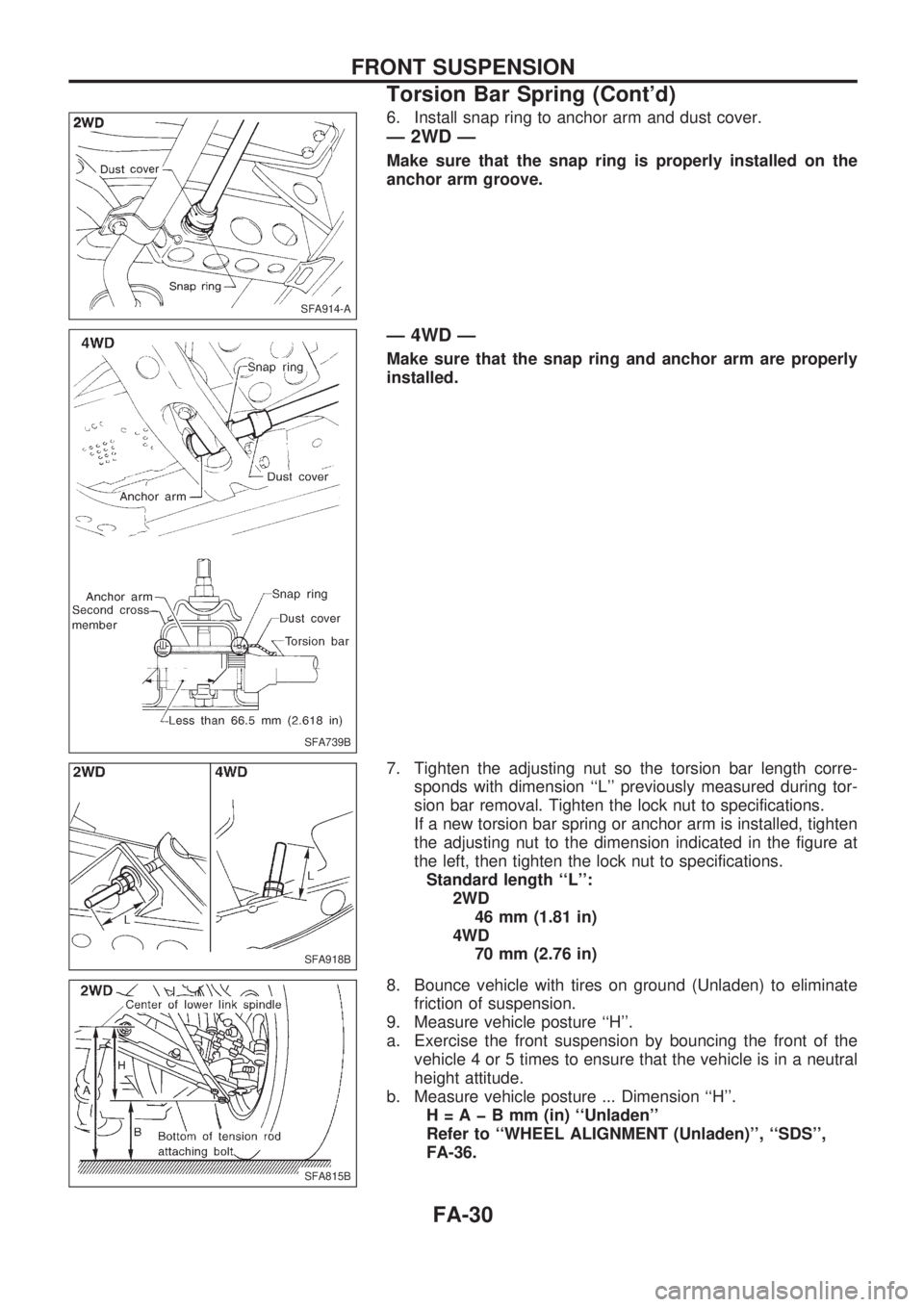

6. Install snap ring to anchor arm and dust cover.

Ð 2WD Ð

Make sure that the snap ring is properly installed on the

anchor arm groove.

Ð 4WD Ð

Make sure that the snap ring and anchor arm are properly

installed.

7. Tighten the adjusting nut so the torsion bar length corre-

sponds with dimension ``L'' previously measured during tor-

sion bar removal. Tighten the lock nut to specifications.

If a new torsion bar spring or anchor arm is installed, tighten

the adjusting nut to the dimension indicated in the figure at

the left, then tighten the lock nut to specifications.

Standard length ``L'':

2WD

46 mm (1.81 in)

4WD

70 mm (2.76 in)

8. Bounce vehicle with tires on ground (Unladen) to eliminate

friction of suspension.

9. Measure vehicle posture ``H''.

a. Exercise the front suspension by bouncing the front of the

vehicle 4 or 5 times to ensure that the vehicle is in a neutral

height attitude.

b. Measure vehicle posture ... Dimension ``H''.

H=AþBmm(in) ``Unladen''

Refer to ``WHEEL ALIGNMENT (Unladen)'', ``SDS'',

FA-36.

SFA914-A

SFA739B

SFA918B

SFA815B

FRONT SUSPENSION

Torsion Bar Spring (Cont'd)

FA-30

Page 797 of 1659

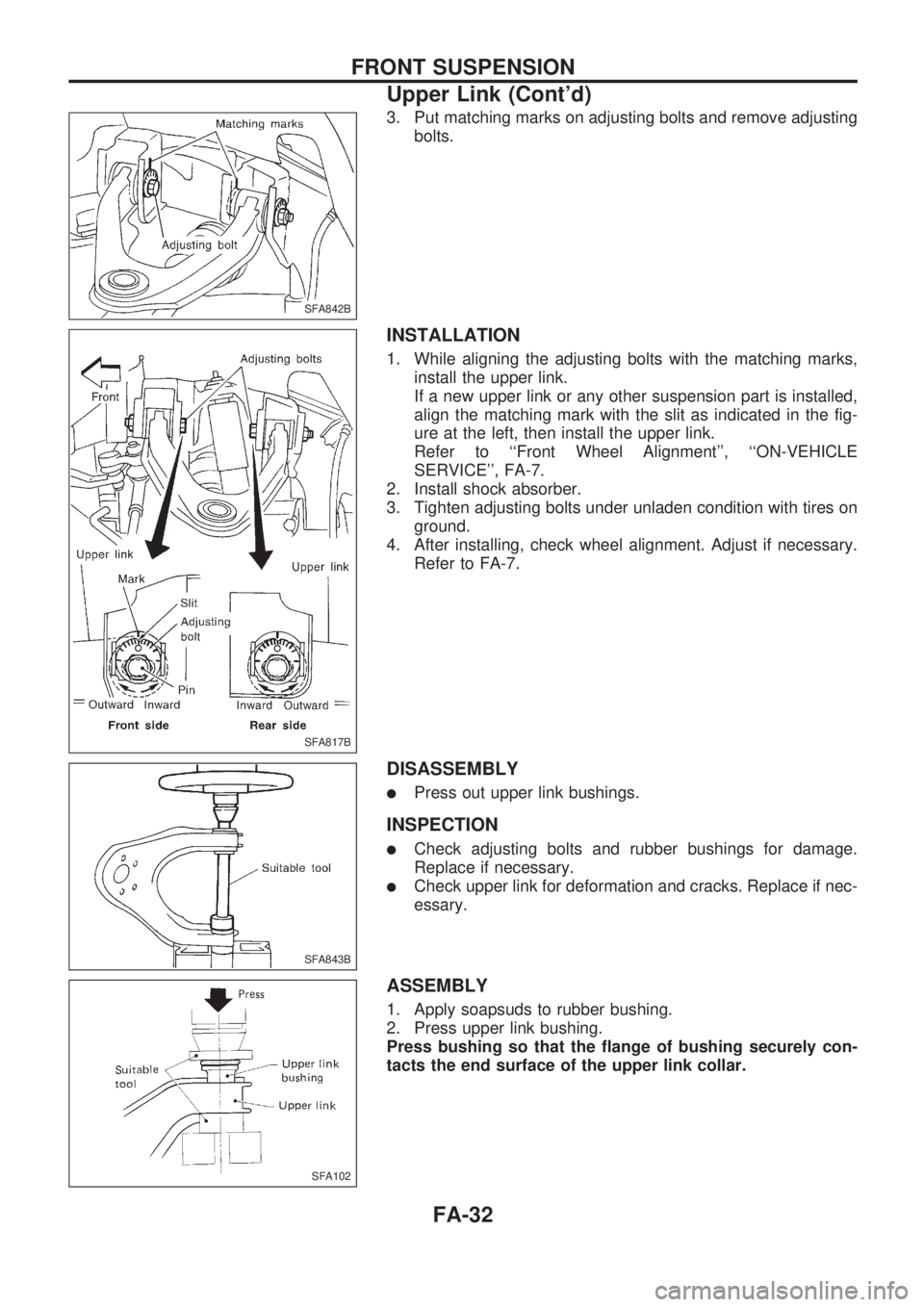

3. Put matching marks on adjusting bolts and remove adjusting

bolts.

INSTALLATION

1. While aligning the adjusting bolts with the matching marks,

install the upper link.

If a new upper link or any other suspension part is installed,

align the matching mark with the slit as indicated in the fig-

ure at the left, then install the upper link.

Refer to ``Front Wheel Alignment'', ``ON-VEHICLE

SERVICE'', FA-7.

2. Install shock absorber.

3. Tighten adjusting bolts under unladen condition with tires on

ground.

4. After installing, check wheel alignment. Adjust if necessary.

Refer to FA-7.

DISASSEMBLY

lPress out upper link bushings.

INSPECTION

lCheck adjusting bolts and rubber bushings for damage.

Replace if necessary.

lCheck upper link for deformation and cracks. Replace if nec-

essary.

ASSEMBLY

1. Apply soapsuds to rubber bushing.

2. Press upper link bushing.

Press bushing so that the flange of bushing securely con-

tacts the end surface of the upper link collar.

SFA842B

SFA817B

SFA843B

SFA102

FRONT SUSPENSION

Upper Link (Cont'd)

FA-32

Page 804 of 1659

GENERAL INFORMATION

SECTION

GI

CONTENTS

PRECAUTIONS......................................................... 1

Precautions for Supplemental Restraint

System (SRS) ``AIR BAG'' (4WD models)............. 1

Precautions for Supplemental Restraint

System (SRS) ``AIR BAG'' (2WD models)............. 1

Precautions for NATS ............................................ 2

General Precautions .............................................. 2

Precautions for Multiport Fuel Injection System

or ECCS Engine .................................................... 4

Precautions for Three Way Catalyst

(If so equipped) ...................................................... 4

Precautions for Engine Oils ................................... 4

Precautions for Fuel............................................... 5

Precautions for Air Conditioning ............................ 6

HOW TO USE THIS MANUAL.................................. 7

HOW TO READ WIRING DIAGRAMS...................... 9

Sample/Wiring Diagram - EXAMPL - .................... 9

Description ........................................................... 11

HOW TO CHECK TERMINAL................................. 18

How to Probe Connectors ................................... 18

How to Check Enlarged Contact Spring of

Terminal ............................................................... 19

Waterproof Connector Inspection ........................ 20

Terminal Lock Inspection ..................................... 20

HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT......................... 21

Work Flow ............................................................ 21HOW TO PERFORM EFFICIENT DIAGNOSIS...... 22

Incident Simulation Tests..................................... 22

Circuit Inspection ................................................. 25

HOW TO FOLLOW FLOW CHART IN

TROUBLE DIAGNOSES......................................... 31

How to Follow This Flow Chart ........................... 32

CONSULT CHECKING SYSTEM............................ 34

Function and System Application ........................ 34

Lithium Battery Replacement............................... 34

Checking Equipment ............................................ 35

Loading Procedure............................................... 36

CONSULT Data Link Connector (DLC) Circuit ... 36

IDENTIFICATION INFORMATION.......................... 37

Model Variation .................................................... 37

Identification Number ........................................... 40

Dimensions .......................................................... 44

Wheels and Tires ................................................. 46

LIFTING POINTS AND TOW TRUCK TOWING..... 47

Pantograph Jack .................................................. 47

Screw Jack........................................................... 48

Garage Jack and Safety Stand ........................... 49

2-pole Lift ............................................................. 50

Tow Truck Towing ............................................... 51

Towing Point ........................................................ 53

TIGHTENING TORQUE OF STANDARD BOLTS.. 54

SAE J1930 TERMINOLOGY LIST.......................... 55

SAE J1930 Terminology List ............................... 55

GI

Page 849 of 1659

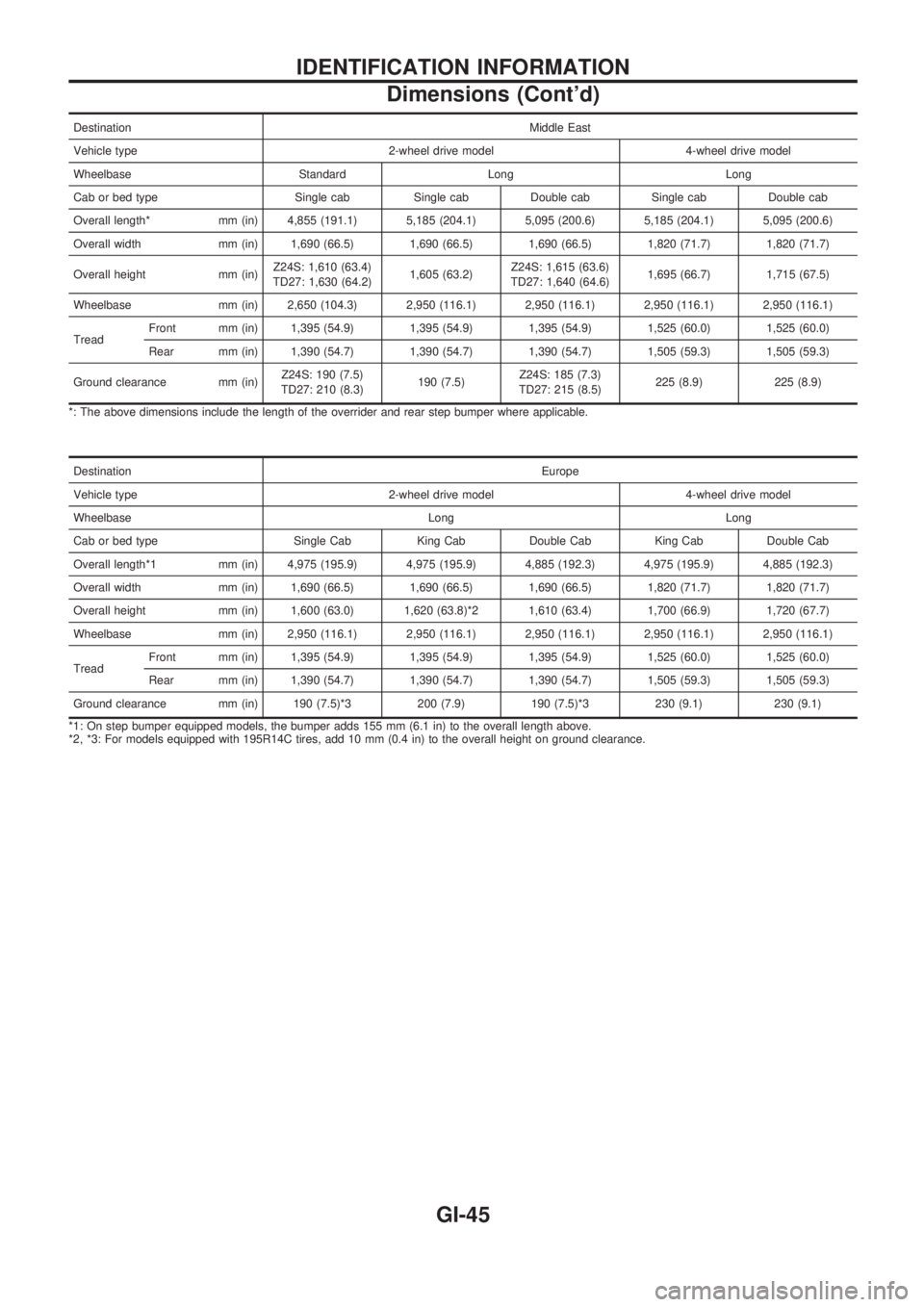

DestinationMiddle East

Vehicle type 2-wheel drive model 4-wheel drive model

Wheelbase Standard Long Long

Cab or bed type Single cab Single cab Double cab Single cab Double cab

Overall length* mm (in) 4,855 (191.1) 5,185 (204.1) 5,095 (200.6) 5,185 (204.1) 5,095 (200.6)

Overall width mm (in) 1,690 (66.5) 1,690 (66.5) 1,690 (66.5) 1,820 (71.7) 1,820 (71.7)

Overall height mm (in)Z24S: 1,610 (63.4)

TD27: 1,630 (64.2)1,605 (63.2)Z24S: 1,615 (63.6)

TD27: 1,640 (64.6)1,695 (66.7) 1,715 (67.5)

Wheelbase mm (in) 2,650 (104.3) 2,950 (116.1) 2,950 (116.1) 2,950 (116.1) 2,950 (116.1)

TreadFront mm (in) 1,395 (54.9) 1,395 (54.9) 1,395 (54.9) 1,525 (60.0) 1,525 (60.0)

Rear mm (in) 1,390 (54.7) 1,390 (54.7) 1,390 (54.7) 1,505 (59.3) 1,505 (59.3)

Ground clearance mm (in)Z24S: 190 (7.5)

TD27: 210 (8.3)190 (7.5)Z24S: 185 (7.3)

TD27: 215 (8.5)225 (8.9) 225 (8.9)

*: The above dimensions include the length of the overrider and rear step bumper where applicable.

DestinationEurope

Vehicle type 2-wheel drive model 4-wheel drive model

Wheelbase Long Long

Cab or bed type Single Cab King Cab Double Cab King Cab Double Cab

Overall length*1 mm (in) 4,975 (195.9) 4,975 (195.9) 4,885 (192.3) 4,975 (195.9) 4,885 (192.3)

Overall width mm (in) 1,690 (66.5) 1,690 (66.5) 1,690 (66.5) 1,820 (71.7) 1,820 (71.7)

Overall height mm (in) 1,600 (63.0) 1,620 (63.8)*2 1,610 (63.4) 1,700 (66.9) 1,720 (67.7)

Wheelbase mm (in) 2,950 (116.1) 2,950 (116.1) 2,950 (116.1) 2,950 (116.1) 2,950 (116.1)

TreadFront mm (in) 1,395 (54.9) 1,395 (54.9) 1,395 (54.9) 1,525 (60.0) 1,525 (60.0)

Rear mm (in) 1,390 (54.7) 1,390 (54.7) 1,390 (54.7) 1,505 (59.3) 1,505 (59.3)

Ground clearance mm (in) 190 (7.5)*3 200 (7.9) 190 (7.5)*3 230 (9.1) 230 (9.1)

*1: On step bumper equipped models, the bumper adds 155 mm (6.1 in) to the overall length above.

*2, *3: For models equipped with 195R14C tires, add 10 mm (0.4 in) to the overall height on ground clearance.

IDENTIFICATION INFORMATION

Dimensions (Cont'd)

GI-45

Page 850 of 1659

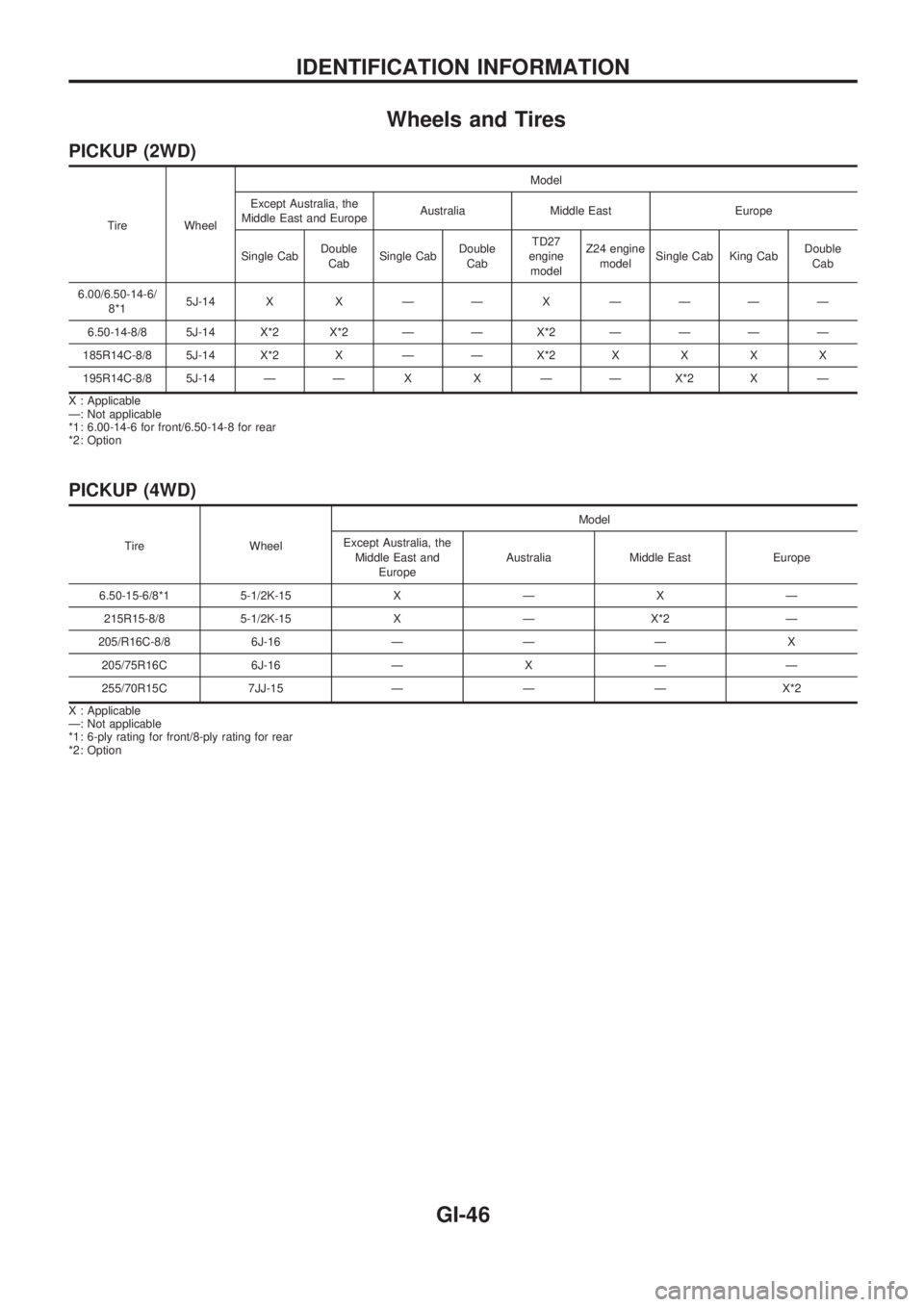

Wheels and Tires

PICKUP (2WD)

Tire WheelModel

Except Australia, the

Middle East and EuropeAustralia Middle East Europe

Single CabDouble

CabSingle CabDouble

CabTD27

engine

modelZ24 engine

modelSingle Cab King CabDouble

Cab

6.00/6.50-14-6/

8*15J-14 X X Ð Ð XÐÐÐÐ

6.50-14-8/8 5J-14 X*2 X*2 Ð Ð X*2ÐÐÐÐ

185R14C-8/8 5J-14 X*2 X Ð Ð X*2XXXX

195R14C-8/8 5J-14 Ð Ð X X Ð Ð X*2 X Ð

X : Applicable

Ð: Not applicable

*1 : 6.00-14-6 for front/6.50-14-8 for rear

*2 : Option

PICKUP (4WD)

Tire WheelModel

Except Australia, the

Middle East and

EuropeAustralia Middle East Europe

6.50-15-6/8*1 5-1/2K-15 X Ð X Ð

215R15-8/8 5-1/2K-15 X Ð X*2 Ð

205/R16C-8/8 6J-16 Ð Ð Ð X

205/75R16C 6J-16 Ð X Ð Ð

255/70R15C 7JJ-15 Ð Ð Ð X*2

X : Applicable

Ð: Not applicable

*1 : 6-ply rating for front/8-ply rating for rear

*2 : Option

IDENTIFICATION INFORMATION

GI-46

Page 970 of 1659

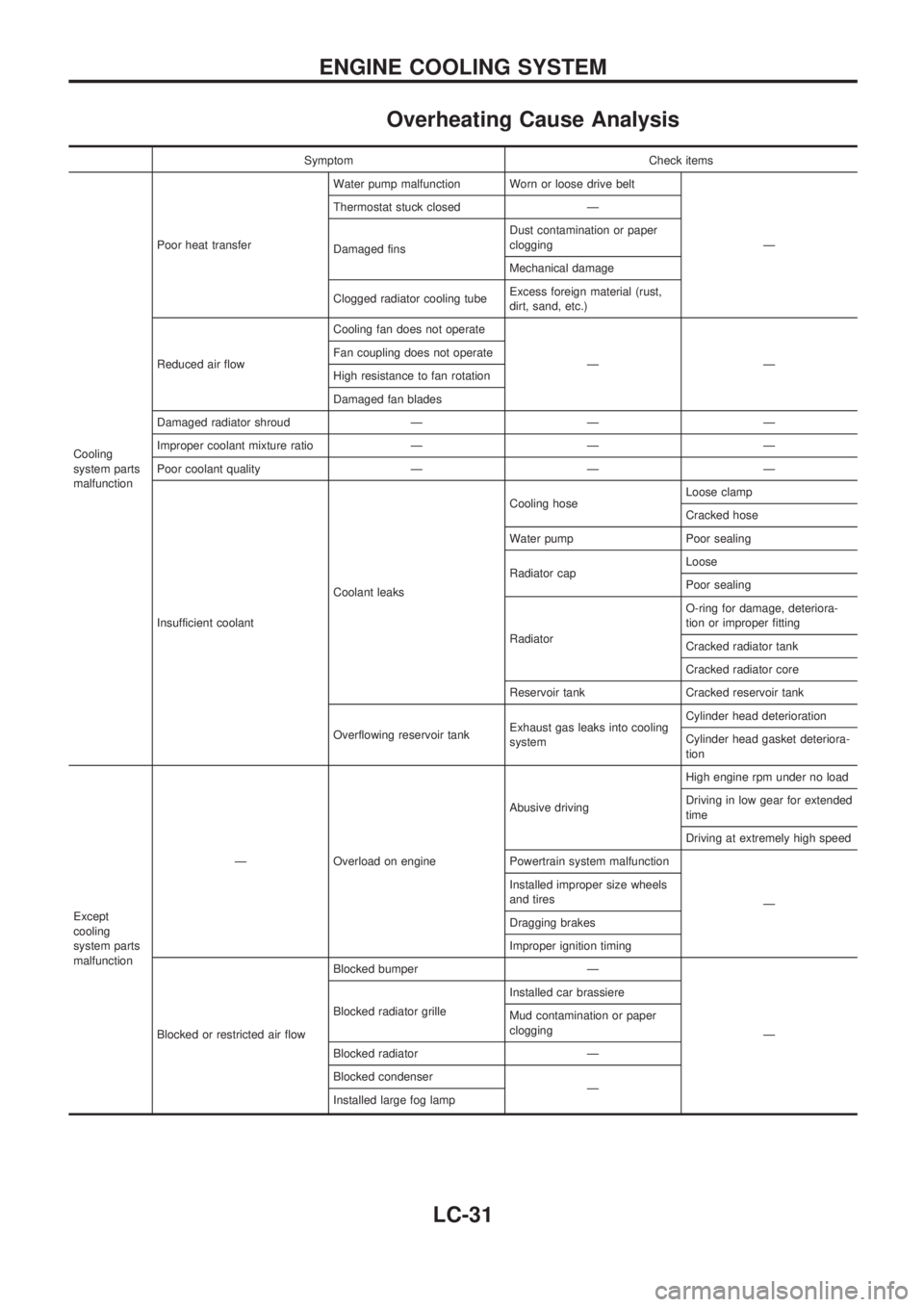

Overheating Cause Analysis

Symptom Check items

Cooling

system parts

malfunctionPoor heat transferWater pump malfunction Worn or loose drive belt

Ð Thermostat stuck closed Ð

Damaged finsDust contamination or paper

clogging

Mechanical damage

Clogged radiator cooling tubeExcess foreign material (rust,

dirt, sand, etc.)

Reduced air flowCooling fan does not operate

ÐÐ Fan coupling does not operate

High resistance to fan rotation

Damaged fan blades

Damaged radiator shroud Ð Ð Ð

Improper coolant mixture ratio Ð Ð Ð

Poor coolant quality Ð Ð Ð

Insufficient coolantCoolant leaksCooling hoseLoose clamp

Cracked hose

Water pump Poor sealing

Radiator capLoose

Poor sealing

RadiatorO-ring for damage, deteriora-

tion or improper fitting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir tankExhaust gas leaks into cooling

systemCylinder head deterioration

Cylinder head gasket deteriora-

tion

Except

cooling

system parts

malfunctionÐ Overload on engineAbusive drivingHigh engine rpm under no load

Driving in low gear for extended

time

Driving at extremely high speed

Powertrain system malfunction

Ð Installed improper size wheels

and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air flowBlocked bumper Ð

Ð Blocked radiator grilleInstalled car brassiere

Mud contamination or paper

clogging

Blocked radiator Ð

Blocked condenser

Ð

Installed large fog lamp

ENGINE COOLING SYSTEM

LC-31