brake light NISSAN PICK-UP 1998 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 18 of 1659

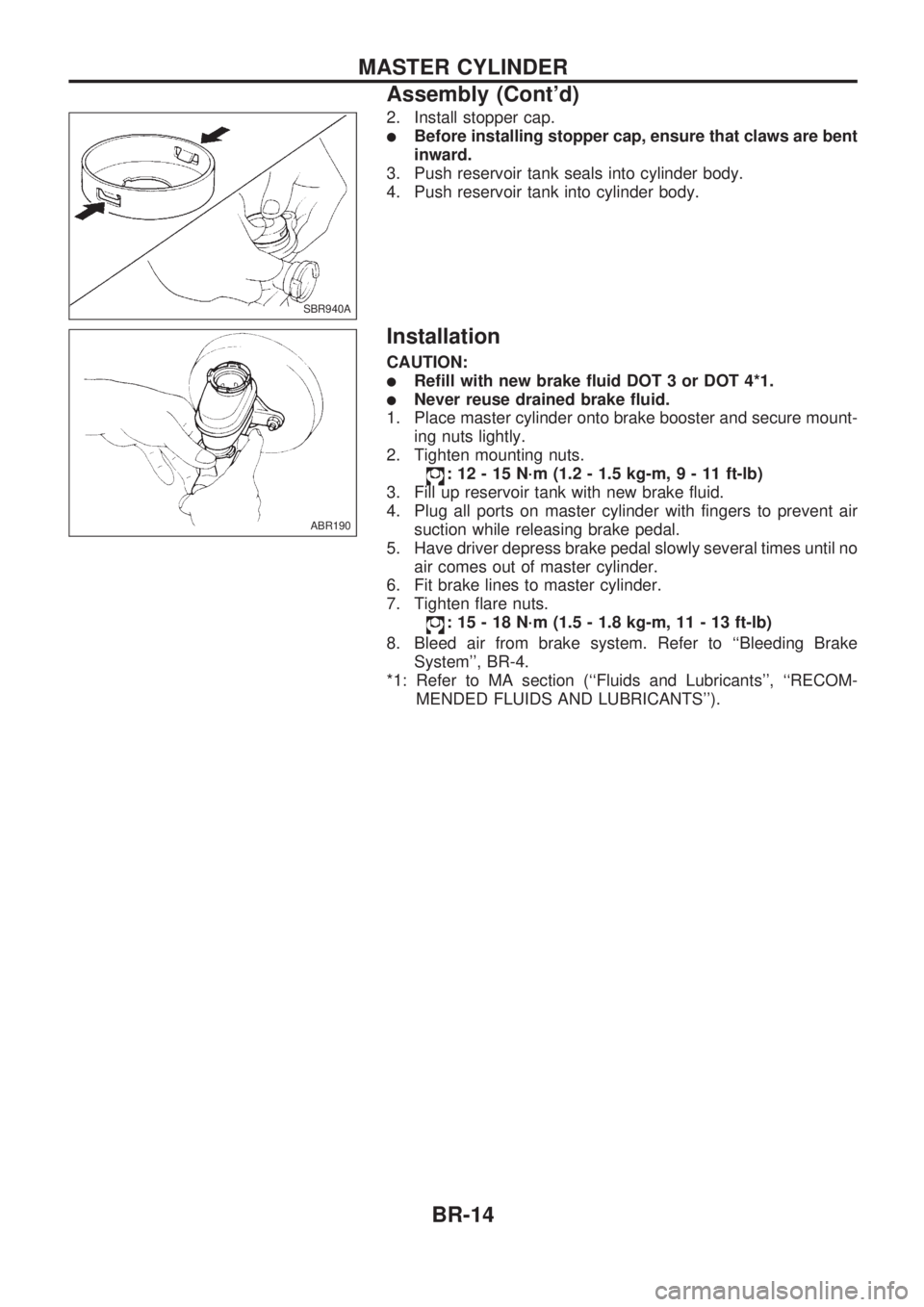

2. Install stopper cap.

lBefore installing stopper cap, ensure that claws are bent

inward.

3. Push reservoir tank seals into cylinder body.

4. Push reservoir tank into cylinder body.

Installation

CAUTION:

lRefill with new brake fluid DOT 3 or DOT 4*1.

lNever reuse drained brake fluid.

1. Place master cylinder onto brake booster and secure mount-

ing nuts lightly.

2. Tighten mounting nuts.

: 12 - 15 N´m (1.2 - 1.5 kg-m,9-11ft-lb)

3. Fill up reservoir tank with new brake fluid.

4. Plug all ports on master cylinder with fingers to prevent air

suction while releasing brake pedal.

5. Have driver depress brake pedal slowly several times until no

air comes out of master cylinder.

6. Fit brake lines to master cylinder.

7. Tighten flare nuts.

: 15 - 18 N´m (1.5 - 1.8 kg-m, 11 - 13 ft-lb)

8. Bleed air from brake system. Refer to ``Bleeding Brake

System'', BR-4.

*1: Refer to MA section (``Fluids and Lubricants'', ``RECOM-

MENDED FLUIDS AND LUBRICANTS'').

SBR940A

ABR190

MASTER CYLINDER

Assembly (Cont'd)

BR-14

Page 19 of 1659

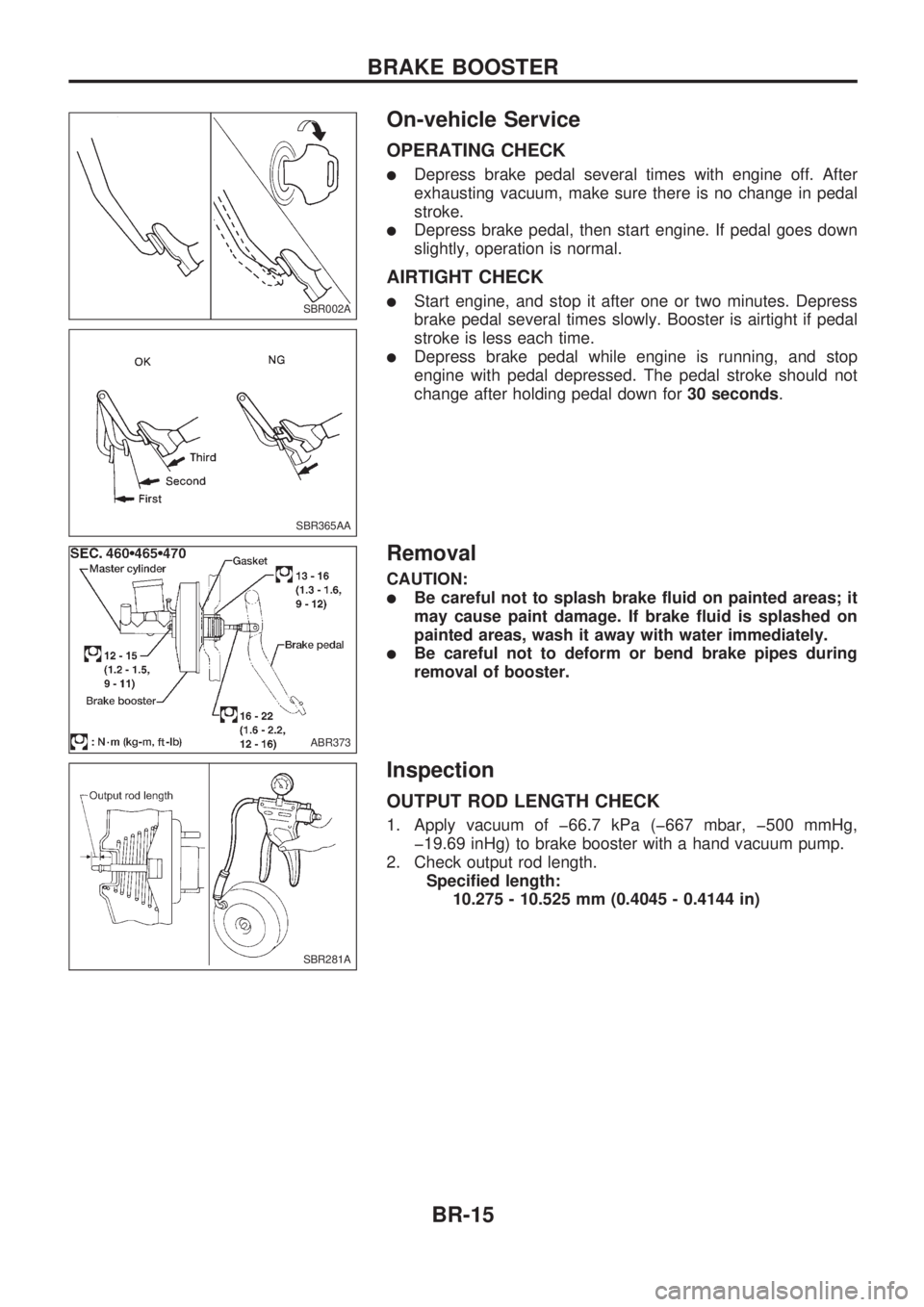

On-vehicle Service

OPERATING CHECK

lDepress brake pedal several times with engine off. After

exhausting vacuum, make sure there is no change in pedal

stroke.

lDepress brake pedal, then start engine. If pedal goes down

slightly, operation is normal.

AIRTIGHT CHECK

lStart engine, and stop it after one or two minutes. Depress

brake pedal several times slowly. Booster is airtight if pedal

stroke is less each time.

lDepress brake pedal while engine is running, and stop

engine with pedal depressed. The pedal stroke should not

change after holding pedal down for30 seconds.

Removal

CAUTION:

lBe careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas, wash it away with water immediately.

lBe careful not to deform or bend brake pipes during

removal of booster.

Inspection

OUTPUT ROD LENGTH CHECK

1. Apply vacuum of þ66.7 kPa (þ667 mbar, þ500 mmHg,

þ19.69 inHg) to brake booster with a hand vacuum pump.

2. Check output rod length.

Specified length:

10.275 - 10.525 mm (0.4045 - 0.4144 in)

SBR002A

SBR365AA

ABR373

SBR281A

BRAKE BOOSTER

BR-15

Page 20 of 1659

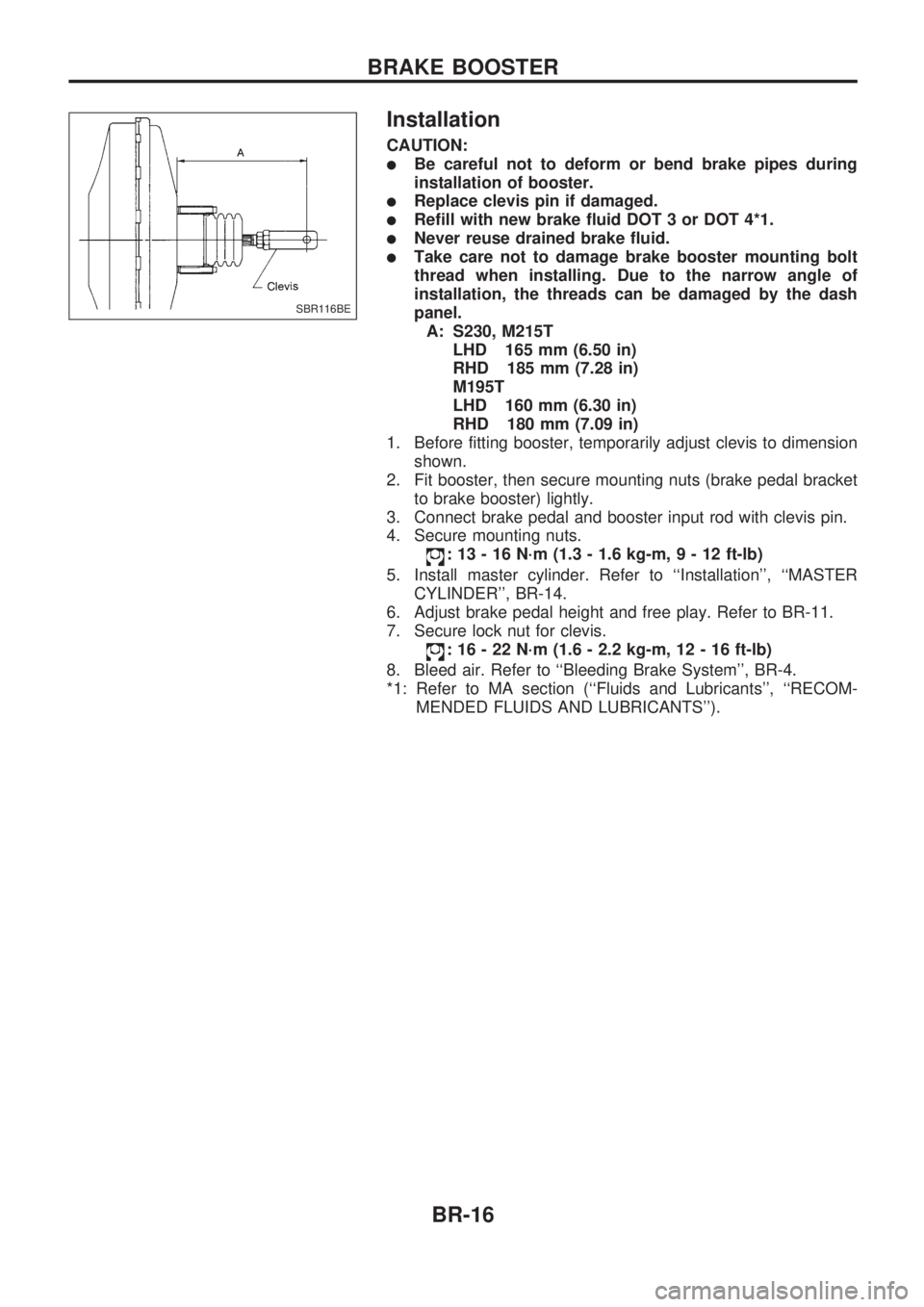

Installation

CAUTION:

lBe careful not to deform or bend brake pipes during

installation of booster.

lReplace clevis pin if damaged.

lRefill with new brake fluid DOT 3 or DOT 4*1.

lNever reuse drained brake fluid.

lTake care not to damage brake booster mounting bolt

thread when installing. Due to the narrow angle of

installation, the threads can be damaged by the dash

panel.

A: S230, M215T

LHD 165 mm (6.50 in)

RHD 185 mm (7.28 in)

M195T

LHD 160 mm (6.30 in)

RHD 180 mm (7.09 in)

1. Before fitting booster, temporarily adjust clevis to dimension

shown.

2. Fit booster, then secure mounting nuts (brake pedal bracket

to brake booster) lightly.

3. Connect brake pedal and booster input rod with clevis pin.

4. Secure mounting nuts.

: 13 - 16 N´m (1.3 - 1.6 kg-m,9-12ft-lb)

5. Install master cylinder. Refer to ``Installation'', ``MASTER

CYLINDER'', BR-14.

6. Adjust brake pedal height and free play. Refer to BR-11.

7. Secure lock nut for clevis.

: 16 - 22 N´m (1.6 - 2.2 kg-m, 12 - 16 ft-lb)

8. Bleed air. Refer to ``Bleeding Brake System'', BR-4.

*1: Refer to MA section (``Fluids and Lubricants'', ``RECOM-

MENDED FLUIDS AND LUBRICANTS'').

SBR116BE

BRAKE BOOSTER

BR-16

Page 37 of 1659

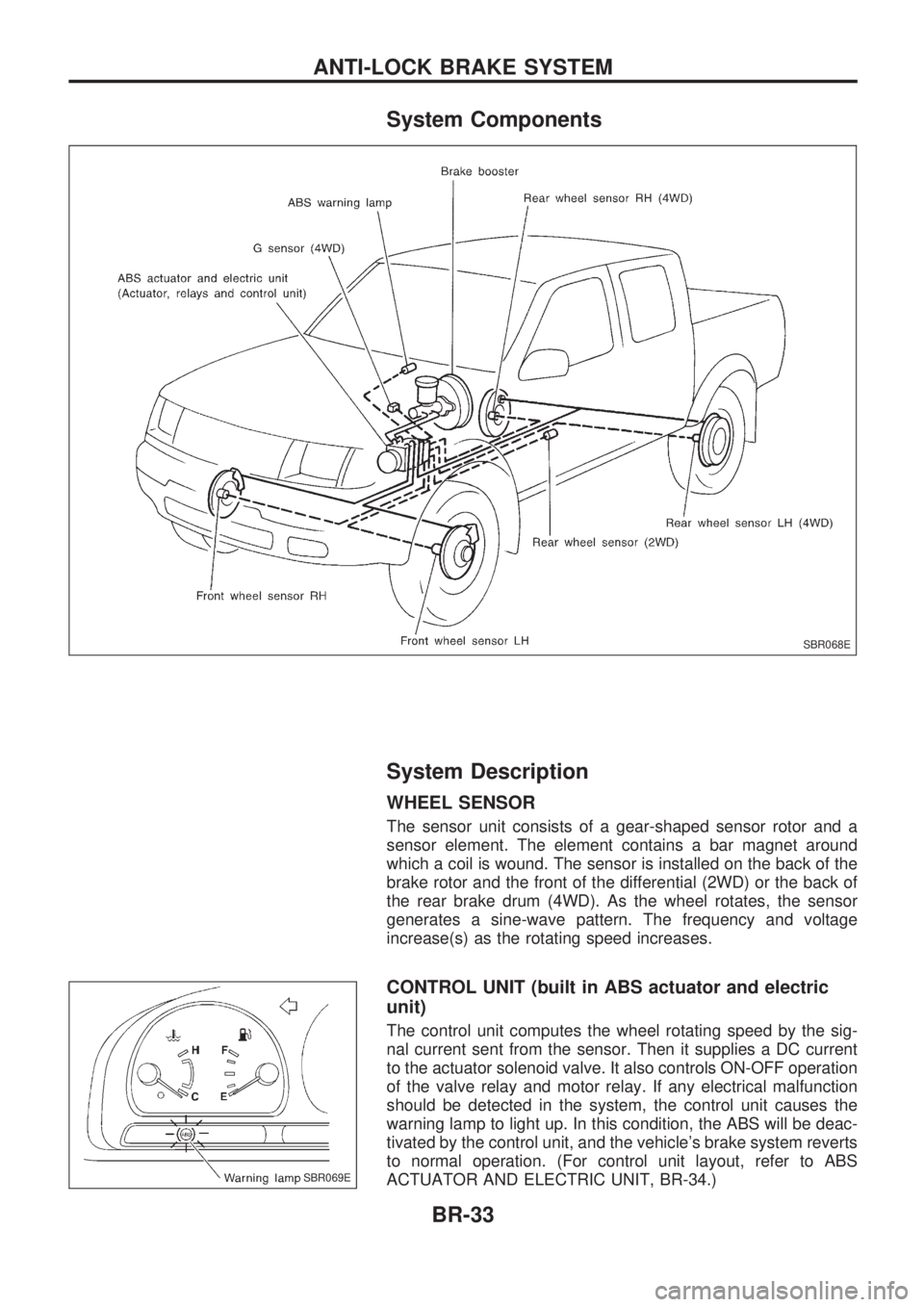

System Components

System Description

WHEEL SENSOR

The sensor unit consists of a gear-shaped sensor rotor and a

sensor element. The element contains a bar magnet around

which a coil is wound. The sensor is installed on the back of the

brake rotor and the front of the differential (2WD) or the back of

the rear brake drum (4WD). As the wheel rotates, the sensor

generates a sine-wave pattern. The frequency and voltage

increase(s) as the rotating speed increases.

CONTROL UNIT (built in ABS actuator and electric

unit)

The control unit computes the wheel rotating speed by the sig-

nal current sent from the sensor. Then it supplies a DC current

to the actuator solenoid valve. It also controls ON-OFF operation

of the valve relay and motor relay. If any electrical malfunction

should be detected in the system, the control unit causes the

warning lamp to light up. In this condition, the ABS will be deac-

tivated by the control unit, and the vehicle's brake system reverts

to normal operation. (For control unit layout, refer to ABS

ACTUATOR AND ELECTRIC UNIT, BR-34.)

SBR068E

SBR069E

ANTI-LOCK BRAKE SYSTEM

BR-33

Page 406 of 1659

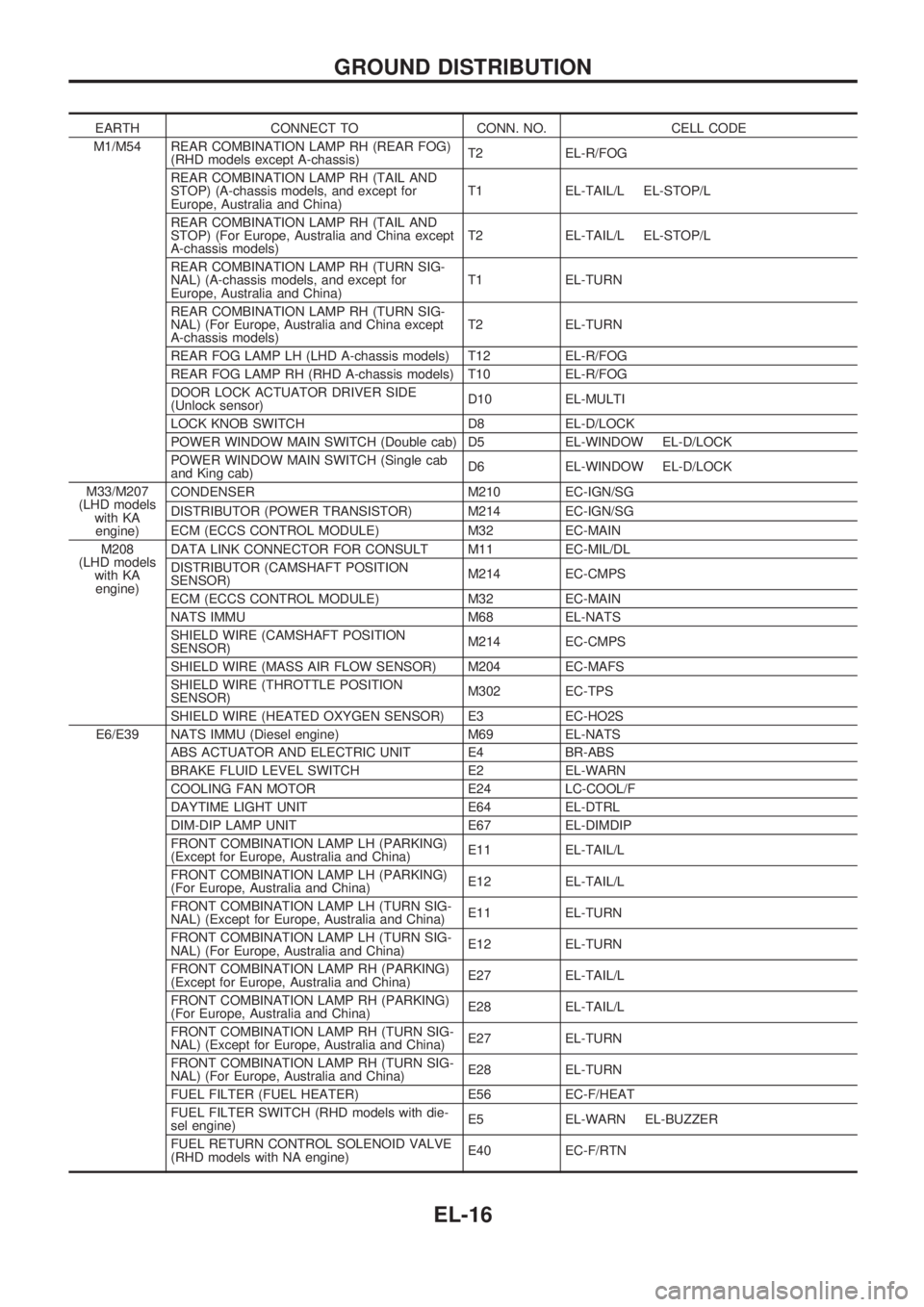

EARTH CONNECT TO CONN. NO. CELL CODE

M1/M54 REAR COMBINATION LAMP RH (REAR FOG)

(RHD models except A-chassis)T2 EL-R/FOG

REAR COMBINATION LAMP RH (TAIL AND

STOP) (A-chassis models, and except for

Europe, Australia and China)T1 EL-TAIL/L EL-STOP/L

REAR COMBINATION LAMP RH (TAIL AND

STOP) (For Europe, Australia and China except

A-chassis models)T2 EL-TAIL/L EL-STOP/L

REAR COMBINATION LAMP RH (TURN SIG-

NAL) (A-chassis models, and except for

Europe, Australia and China)T1 EL-TURN

REAR COMBINATION LAMP RH (TURN SIG-

NAL) (For Europe, Australia and China except

A-chassis models)T2 EL-TURN

REAR FOG LAMP LH (LHD A-chassis models) T12 EL-R/FOG

REAR FOG LAMP RH (RHD A-chassis models) T10 EL-R/FOG

DOOR LOCK ACTUATOR DRIVER SIDE

(Unlock sensor)D10 EL-MULTI

LOCK KNOB SWITCH D8 EL-D/LOCK

POWER WINDOW MAIN SWITCH (Double cab) D5 EL-WINDOW EL-D/LOCK

POWER WINDOW MAIN SWITCH (Single cab

and King cab)D6 EL-WINDOW EL-D/LOCK

M33/M207

(LHD models

with KA

engine)CONDENSER M210 EC-IGN/SG

DISTRIBUTOR (POWER TRANSISTOR) M214 EC-IGN/SG

ECM (ECCS CONTROL MODULE) M32 EC-MAIN

M208

(LHD models

with KA

engine)DATA LINK CONNECTOR FOR CONSULT M11 EC-MIL/DL

DISTRIBUTOR (CAMSHAFT POSITION

SENSOR)M214 EC-CMPS

ECM (ECCS CONTROL MODULE) M32 EC-MAIN

NATS IMMU M68 EL-NATS

SHIELD WIRE (CAMSHAFT POSITION

SENSOR)M214 EC-CMPS

SHIELD WIRE (MASS AIR FLOW SENSOR) M204 EC-MAFS

SHIELD WIRE (THROTTLE POSITION

SENSOR)M302 EC-TPS

SHIELD WIRE (HEATED OXYGEN SENSOR) E3 EC-HO2S

E6/E39 NATS IMMU (Diesel engine) M69 EL-NATS

ABS ACTUATOR AND ELECTRIC UNIT E4 BR-ABS

BRAKE FLUID LEVEL SWITCH E2 EL-WARN

COOLING FAN MOTOR E24 LC-COOL/F

DAYTIME LIGHT UNIT E64 EL-DTRL

DIM-DIP LAMP UNIT E67 EL-DIMDIP

FRONT COMBINATION LAMP LH (PARKING)

(Except for Europe, Australia and China)E11 EL-TAIL/L

FRONT COMBINATION LAMP LH (PARKING)

(For Europe, Australia and China)E12 EL-TAIL/L

FRONT COMBINATION LAMP LH (TURN SIG-

NAL) (Except for Europe, Australia and China)E11 EL-TURN

FRONT COMBINATION LAMP LH (TURN SIG-

NAL) (For Europe, Australia and China)E12 EL-TURN

FRONT COMBINATION LAMP RH (PARKING)

(Except for Europe, Australia and China)E27 EL-TAIL/L

FRONT COMBINATION LAMP RH (PARKING)

(For Europe, Australia and China)E28 EL-TAIL/L

FRONT COMBINATION LAMP RH (TURN SIG-

NAL) (Except for Europe, Australia and China)E27 EL-TURN

FRONT COMBINATION LAMP RH (TURN SIG-

NAL) (For Europe, Australia and China)E28 EL-TURN

FUEL FILTER (FUEL HEATER) E56 EC-F/HEAT

FUEL FILTER SWITCH (RHD models with die-

sel engine)E5 EL-WARN EL-BUZZER

FUEL RETURN CONTROL SOLENOID VALVE

(RHD models with NA engine)E40 EC-F/RTN

GROUND DISTRIBUTION

EL-16

Page 643 of 1659

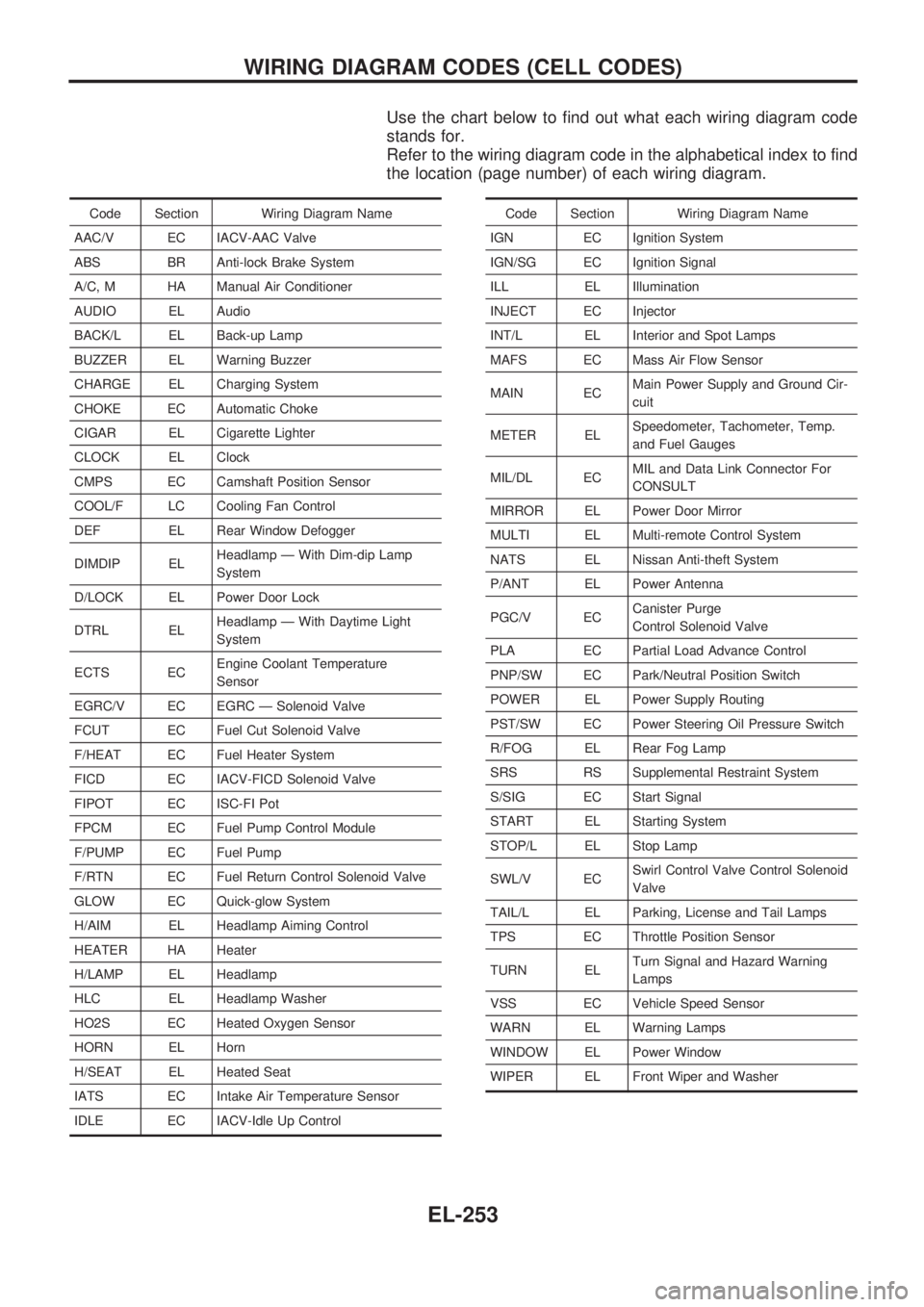

Use the chart below to find out what each wiring diagram code

stands for.

Refer to the wiring diagram code in the alphabetical index to find

the location (page number) of each wiring diagram.

Code Section Wiring Diagram Name

AAC/V EC IACV-AAC Valve

ABS BR Anti-lock Brake System

A/C, M HA Manual Air Conditioner

AUDIO EL Audio

BACK/L EL Back-up Lamp

BUZZER EL Warning Buzzer

CHARGE EL Charging System

CHOKE EC Automatic Choke

CIGAR EL Cigarette Lighter

CLOCK EL Clock

CMPS EC Camshaft Position Sensor

COOL/F LC Cooling Fan Control

DEF EL Rear Window Defogger

DIMDIP ELHeadlamp Ð With Dim-dip Lamp

System

D/LOCK EL Power Door Lock

DTRL ELHeadlamp Ð With Daytime Light

System

ECTS ECEngine Coolant Temperature

Sensor

EGRC/V EC EGRC Ð Solenoid Valve

FCUT EC Fuel Cut Solenoid Valve

F/HEAT EC Fuel Heater System

FICD EC IACV-FICD Solenoid Valve

FIPOT EC ISC-FI Pot

FPCM EC Fuel Pump Control Module

F/PUMP EC Fuel Pump

F/RTN EC Fuel Return Control Solenoid Valve

GLOW EC Quick-glow System

H/AIM EL Headlamp Aiming Control

HEATER HA Heater

H/LAMP EL Headlamp

HLC EL Headlamp Washer

HO2S EC Heated Oxygen Sensor

HORN EL Horn

H/SEAT EL Heated Seat

IATS EC Intake Air Temperature Sensor

IDLE EC IACV-Idle Up ControlCode Section Wiring Diagram Name

IGN EC Ignition System

IGN/SG EC Ignition Signal

ILL EL Illumination

INJECT EC Injector

INT/L EL Interior and Spot Lamps

MAFS EC Mass Air Flow Sensor

MAIN ECMain Power Supply and Ground Cir-

cuit

METER ELSpeedometer, Tachometer, Temp.

and Fuel Gauges

MIL/DL ECMIL and Data Link Connector For

CONSULT

MIRROR EL Power Door Mirror

MULTI EL Multi-remote Control System

NATS EL Nissan Anti-theft System

P/ANT EL Power Antenna

PGC/V ECCanister Purge

Control Solenoid Valve

PLA EC Partial Load Advance Control

PNP/SW EC Park/Neutral Position Switch

POWER EL Power Supply Routing

PST/SW EC Power Steering Oil Pressure Switch

R/FOG EL Rear Fog Lamp

SRS RS Supplemental Restraint System

S/SIG EC Start Signal

START EL Starting System

STOP/L EL Stop Lamp

SWL/V ECSwirl Control Valve Control Solenoid

Valve

TAIL/L EL Parking, License and Tail Lamps

TPS EC Throttle Position Sensor

TURN ELTurn Signal and Hazard Warning

Lamps

VSS EC Vehicle Speed Sensor

WARN EL Warning Lamps

WINDOW EL Power Window

WIPER EL Front Wiper and Washer

WIRING DIAGRAM CODES (CELL CODES)

EL-253

Page 697 of 1659

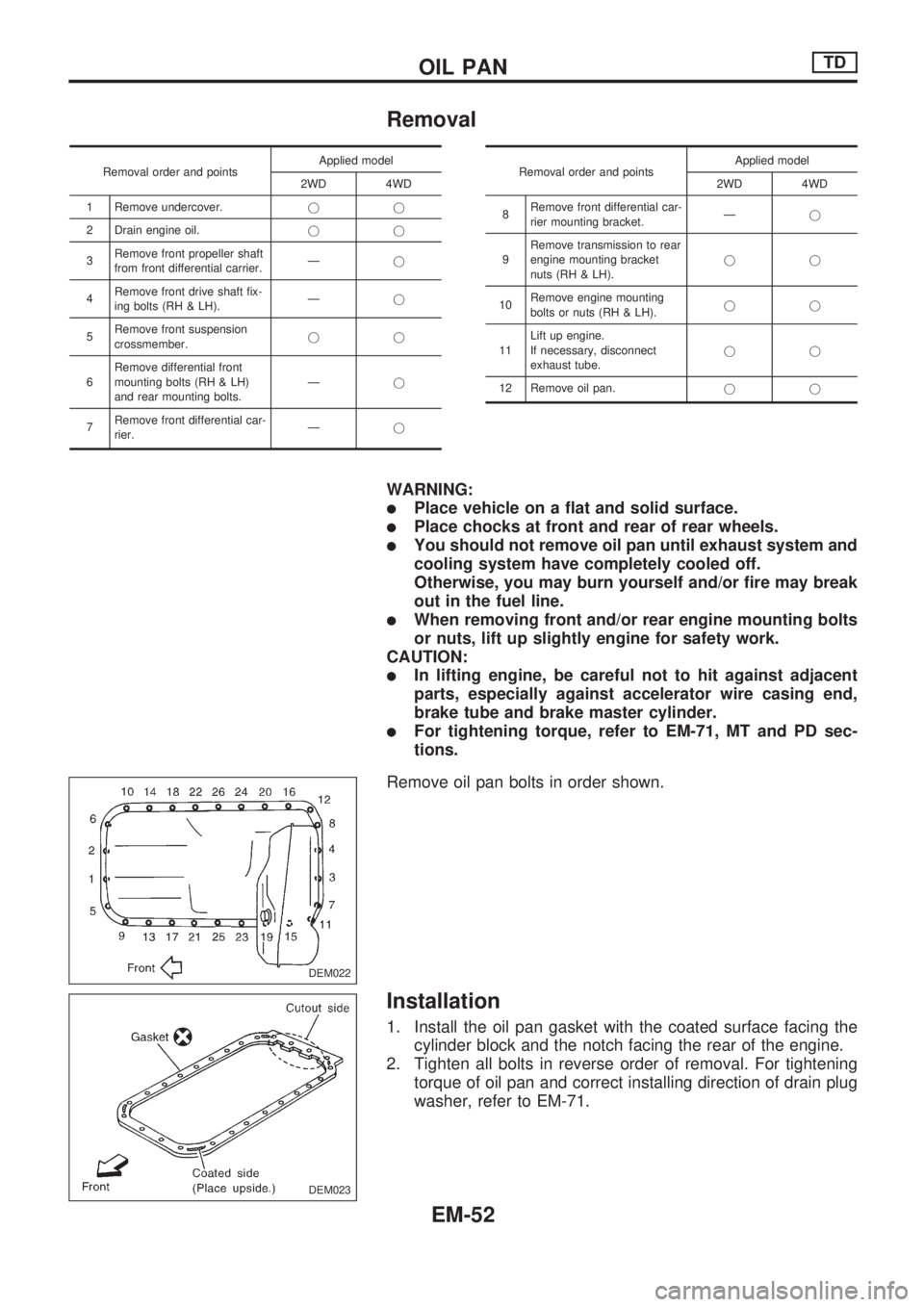

Removal

Removal order and pointsApplied model

2WD 4WD

1 Remove undercover.jj

2 Drain engine oil.jj

3Remove front propeller shaft

from front differential carrier.Ðj

4Remove front drive shaft fix-

ing bolts (RH & LH).Ðj

5Remove front suspension

crossmember.jj

6Remove differential front

mounting bolts (RH & LH)

and rear mounting bolts.Ðj

7Remove front differential car-

rier.ÐjRemoval order and pointsApplied model

2WD 4WD

8Remove front differential car-

rier mounting bracket.Ðj

9Remove transmission to rear

engine mounting bracket

nuts (RH & LH).jj

10Remove engine mounting

bolts or nuts (RH & LH).jj

11Lift up engine.

If necessary, disconnect

exhaust tube.jj

12 Remove oil pan.jj

WARNING:

lPlace vehicle on a flat and solid surface.

lPlace chocks at front and rear of rear wheels.

lYou should not remove oil pan until exhaust system and

cooling system have completely cooled off.

Otherwise, you may burn yourself and/or fire may break

out in the fuel line.

lWhen removing front and/or rear engine mounting bolts

or nuts, lift up slightly engine for safety work.

CAUTION:

lIn lifting engine, be careful not to hit against adjacent

parts, especially against accelerator wire casing end,

brake tube and brake master cylinder.

lFor tightening torque, refer to EM-71, MT and PD sec-

tions.

Remove oil pan bolts in order shown.

Installation

1. Install the oil pan gasket with the coated surface facing the

cylinder block and the notch facing the rear of the engine.

2. Tighten all bolts in reverse order of removal. For tightening

torque of oil pan and correct installing direction of drain plug

washer, refer to EM-71.

DEM022

DEM023

OIL PANTD

EM-52

Page 864 of 1659

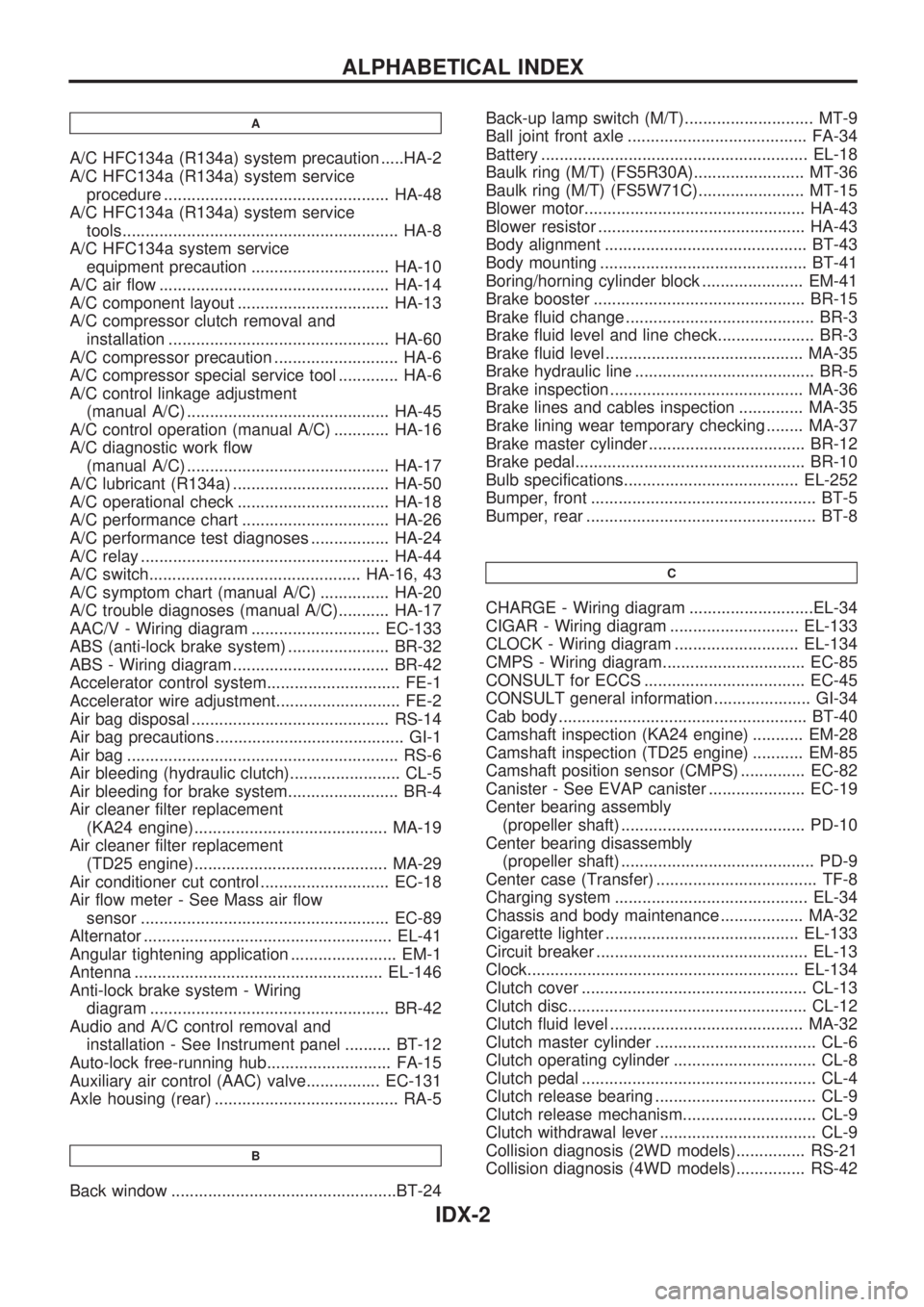

A

A/C HFC134a (R134a) system precaution .....HA-2

A/C HFC134a (R134a) system service

procedure ................................................. HA-48

A/C HFC134a (R134a) system service

tools............................................................ HA-8

A/C HFC134a system service

equipment precaution .............................. HA-10

A/C air flow .................................................. HA-14

A/C component layout ................................. HA-13

A/C compressor clutch removal and

installation ................................................ HA-60

A/C compressor precaution ........................... HA-6

A/C compressor special service tool ............. HA-6

A/C control linkage adjustment

(manual A/C) ............................................ HA-45

A/C control operation (manual A/C) ............ HA-16

A/C diagnostic work flow

(manual A/C) ............................................ HA-17

A/C lubricant (R134a) .................................. HA-50

A/C operational check ................................. HA-18

A/C performance chart ................................ HA-26

A/C performance test diagnoses ................. HA-24

A/C relay ...................................................... HA-44

A/C switch.............................................. HA-16, 43

A/C symptom chart (manual A/C) ............... HA-20

A/C trouble diagnoses (manual A/C)........... HA-17

AAC/V - Wiring diagram ............................ EC-133

ABS (anti-lock brake system) ...................... BR-32

ABS - Wiring diagram .................................. BR-42

Accelerator control system............................. FE-1

Accelerator wire adjustment........................... FE-2

Air bag disposal ........................................... RS-14

Air bag precautions ......................................... GI-1

Air bag ........................................................... RS-6

Air bleeding (hydraulic clutch)........................ CL-5

Air bleeding for brake system........................ BR-4

Air cleaner filter replacement

(KA24 engine).......................................... MA-19

Air cleaner filter replacement

(TD25 engine).......................................... MA-29

Air conditioner cut control ............................ EC-18

Air flow meter - See Mass air flow

sensor ...................................................... EC-89

Alternator ...................................................... EL-41

Angular tightening application ....................... EM-1

Antenna ...................................................... EL-146

Anti-lock brake system - Wiring

diagram .................................................... BR-42

Audio and A/C control removal and

installation - See Instrument panel .......... BT-12

Auto-lock free-running hub........................... FA-15

Auxiliary air control (AAC) valve................ EC-131

Axle housing (rear) ........................................ RA-5

B

Back window .................................................BT-24Back-up lamp switch (M/T)............................ MT-9

Ball joint front axle ....................................... FA-34

Battery .......................................................... EL-18

Baulk ring (M/T) (FS5R30A)........................ MT-36

Baulk ring (M/T) (FS5W71C)....................... MT-15

Blower motor................................................ HA-43

Blower resistor ............................................. HA-43

Body alignment ............................................ BT-43

Body mounting ............................................. BT-41

Boring/horning cylinder block ...................... EM-41

Brake booster .............................................. BR-15

Brake fluid change ......................................... BR-3

Brake fluid level and line check..................... BR-3

Brake fluid level ........................................... MA-35

Brake hydraulic line ....................................... BR-5

Brake inspection .......................................... MA-36

Brake lines and cables inspection .............. MA-35

Brake lining wear temporary checking ........ MA-37

Brake master cylinder .................................. BR-12

Brake pedal.................................................. BR-10

Bulb specifications...................................... EL-252

Bumper, front ................................................. BT-5

Bumper, rear .................................................. BT-8

C

CHARGE - Wiring diagram ...........................EL-34

CIGAR - Wiring diagram ............................ EL-133

CLOCK - Wiring diagram ........................... EL-134

CMPS - Wiring diagram............................... EC-85

CONSULT for ECCS ................................... EC-45

CONSULT general information ..................... GI-34

Cab body ...................................................... BT-40

Camshaft inspection (KA24 engine) ........... EM-28

Camshaft inspection (TD25 engine) ........... EM-85

Camshaft position sensor (CMPS) .............. EC-82

Canister - See EVAP canister ..................... EC-19

Center bearing assembly

(propeller shaft) ........................................ PD-10

Center bearing disassembly

(propeller shaft) .......................................... PD-9

Center case (Transfer) ................................... TF-8

Charging system .......................................... EL-34

Chassis and body maintenance .................. MA-32

Cigarette lighter .......................................... EL-133

Circuit breaker .............................................. EL-13

Clock........................................................... EL-134

Clutch cover ................................................. CL-13

Clutch disc.................................................... CL-12

Clutch fluid level .......................................... MA-32

Clutch master cylinder ................................... CL-6

Clutch operating cylinder ............................... CL-8

Clutch pedal ................................................... CL-4

Clutch release bearing ................................... CL-9

Clutch release mechanism............................. CL-9

Clutch withdrawal lever .................................. CL-9

Collision diagnosis (2WD models)............... RS-21

Collision diagnosis (4WD models)............... RS-42

ALPHABETICAL INDEX

IDX-2

Page 976 of 1659

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD Ð engine off

hRadiator coolant level and coolant hose con-

nections for leaks

hBattery fluid level, specific gravity and condi-

tions of battery terminals

hDrive belts tension

hFuel filter for water or dusts, and fuel lines and

connections for leaks

hEngine oil level and oil leaks

hClutch and brake reservoir fluid level and fluid

lines for leaks

hWindshield and rear window washer and head-

lamp cleaner reservoir fluid level

hPower steering reservoir fluid level and hose

connections for leaks

ON INSIDE AND OUTSIDE

hRemove front spring/strut spacer (If applicable)

hOperation of all instruments, gauges, lights and

accessories

hOperation of horn(s), wiper and washer

hSteering lock for operation

hCheck air conditioner for gas leaks

hFront and rear seats, and seat belts for opera-

tion

hAll moldings, trims and fittings for fit and align-

ment

hAll windows for operation and alignment

hHood, trunk lid, door panels for fit and align-

ment

hLatches, keys and locks for operation

hWeatherstrips for adhesion and fit

hHeadlamp aiming

hTighten wheel nuts (Inc. inner nuts if appli-

cable)

hTire pressure (Inc. spare tire)

hCheck front wheels for toe-in

hInstall clock/voltmeter/room lamp fuse (If appli-

cable)

UNDER BODY

hManual transmission/transaxle gear oil, trans-

fer fluid and differential gear oil level

hBrake and fuel lines and oil/fluid reservoirs for

leaks

hTighten bolts and nuts of steering linkage and

gear box, suspension, propeller shafts and

drive shafts

ROAD TEST

hClutch operation

hParking brake operation

hService brake operation

hSteering control and returnability

hEngine performance

hSqueaks and rattles

ENGINE OPERATING AND HOT

hAdjust idle mixture and speed (and ignition tim-

ing*1)

hEngine idling and stop knob operation (Diesel

only)

FINAL INSPECTION

hInstall necessary parts (outside mirror, wheel

covers, seat belts, mat, carpet or mud flaps)

hInspect for interior and exterior metal and paint

damage

hCheck for spare tire, jack, tools (wheel chock),

and literature

hWash, clean interior and exterior

*1: Not required on models with a direct ignition system

h

X: Not applicable to this model.

PRE-DELIVERY INSPECTION ITEMS

MA-3

Page 977 of 1659

General maintenance includes those items which should be checked during the normal day-to-day opera-

tion of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can per-

form the checks and inspections themselves or they can have their NISSAN dealers do them.

Item Reference pages

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise

specified.

TiresCheck the pressure with a gauge periodically when at a service station, including the

spare, and adjust to the specified pressure if necessary. Check carefully for damage, cuts or

excessive wear.Ð

Windshield wiper bladesCheck for cracks or wear if they do not wipe properly. Ð

Doors and engine hoodCheck that all doors, the engine hood, the trunk lid and back door

operate properly. Also ensure that all latches lock securely. Lubricate hinges, latches, rollers and

links if necessary. Make sure that the secondary latch keeps the hood from opening when the

primary latch is released.

When driving in areas using road salt or other corrosive materials, check for lubrication fre-

quently.MA-39

Tire rotationTires should be rotated every 10,000 km (6,000 miles) for 2WD models and every

5,000 km (3,000 miles) for 4WD models.MA-35

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when per-

forming periodic maintenance, cleaning the vehicle, etc.

LightsMake sure that the headlights, stop lights, tail lights, turn signal lights, and other lights

are all operating properly and installed securely. Also check headlight aim.Ð

Warning lights and chimesMake sure that all warning lights and chimes are operating prop-

erly.Ð

Steering wheelCheck for change in the steering conditions, such as excessive free play, hard

steering or strange noises.

Free play: Less than 35 mm (1.38 in)Ð

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly, and are installed securely. Check the belt webbing for

cuts, fraying, wear or damage.MA-40

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the

engine oil or refuel.

Windshield washer fluidCheck that there is adequate fluid in the tank. Ð

Engine coolant levelCheck the coolant level when the engine is cold. MA-16, 25

Engine oil levelCheck the level after parking the vehicle on a level spot and turning off the

engine.MA-19, 24

Brake and clutch fluid levelMake sure that the brake and clutch fluid levels are between the

``MAX'' and ``MIN'' lines on the reservoir.MA-32, 35

BatteryCheck the fluid level in each cell. It should be between the ``MAX'' and ``MIN'' lines. Ð

GENERAL MAINTENANCE

MA-4