set clock NISSAN PICK-UP 1998 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 330 of 1659

Inspection

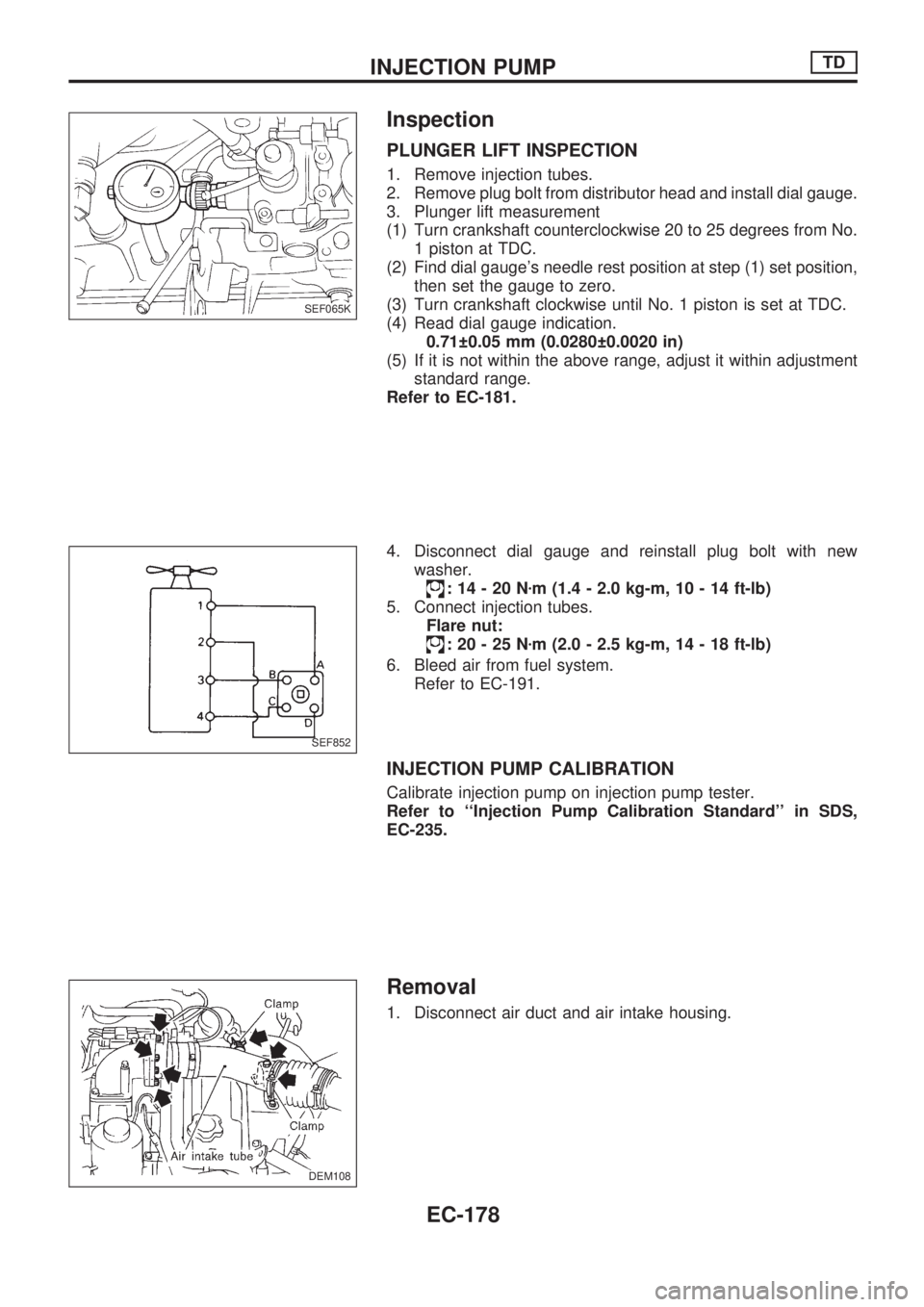

PLUNGER LIFT INSPECTION

1. Remove injection tubes.

2. Remove plug bolt from distributor head and install dial gauge.

3. Plunger lift measurement

(1) Turn crankshaft counterclockwise 20 to 25 degrees from No.

1 piston at TDC.

(2) Find dial gauge's needle rest position at step (1) set position,

then set the gauge to zero.

(3) Turn crankshaft clockwise until No. 1 piston is set at TDC.

(4) Read dial gauge indication.

0.71 0.05 mm (0.0280 0.0020 in)

(5) If it is not within the above range, adjust it within adjustment

standard range.

Refer to EC-181.

4. Disconnect dial gauge and reinstall plug bolt with new

washer.

:14-20Nzm (1.4 - 2.0 kg-m, 10 - 14 ft-lb)

5. Connect injection tubes.

Flare nut:

:20-25Nzm (2.0 - 2.5 kg-m, 14 - 18 ft-lb)

6. Bleed air from fuel system.

Refer to EC-191.

INJECTION PUMP CALIBRATION

Calibrate injection pump on injection pump tester.

Refer to ``Injection Pump Calibration Standard'' in SDS,

EC-235.

Removal

1. Disconnect air duct and air intake housing.

SEF065K

SEF852

DEM108

.

INJECTION PUMPTD

EC-178

Page 333 of 1659

2. Install injection pump.

(1) Temporarily set injection pump so that the flange of pump is

aligned with aligning mark on front cover.

(2) Install injection drive gear over the key.

:59-69Nzm (6 - 7 kg-m, 43 - 51 ft-lb)

Coat key with grease to prevent it from falling into the front

cover. Make sure that ``Z'' marks are aligned.

(3) Install drive gear cover while applying a continuous bead of

liquid gasket.

lBe sure liquid gasket is 2.5 to 3.5 mm (0.098 to 0.138 in)

wide.

lAttach timing gear case cover to timing gear case within

5 minutes after coating.

lWait at least 30 minutes before refilling engine oil.

lUse Genuine Liquid Gasket or equivalent.

PLUNGER LIFT ADJUSTMENT

1. Loosen injection pump mounting nuts and mounting bracket

bolt.

2. Remove plug bolt from distributor head and install dial gauge.

3. Plunger lift measurement and adjustment

(1) Turn crankshaft counterclockwise 20 to 25 degrees from No.

1 piston at TDC.

(2) Find dial gauge's needle rest position at step (1) set position,

then set the gauge to zero.

(3) Turn crankshaft clockwise until No. 1 piston is set at TDC.

(4) Read dial gauge indication.

0.71 0.02 mm (0.0280 0.0008 in)

(5) If it is not within the above range, turn pump body until it

comes within standard range.

a. If indication is smaller than the specified value, turn

pump body counterclockwise.

b. If indication is larger than the specified value, turn pump

body clockwise.

4. Tighten injection pump securely.

Injection pump fixing bolt:

:20-25Nzm (2.0 - 2.5 kg-m, 14 - 18 ft-lb)

Injection pump to mounting bracket:

:30-41Nzm (3.1 - 4.2 kg-m, 22 - 30 ft-lb)

SEF337F

SEF626I

SEF065K

INJECTION PUMPTD

Installation and Adjustment (Cont'd)

EC-181

Page 386 of 1659

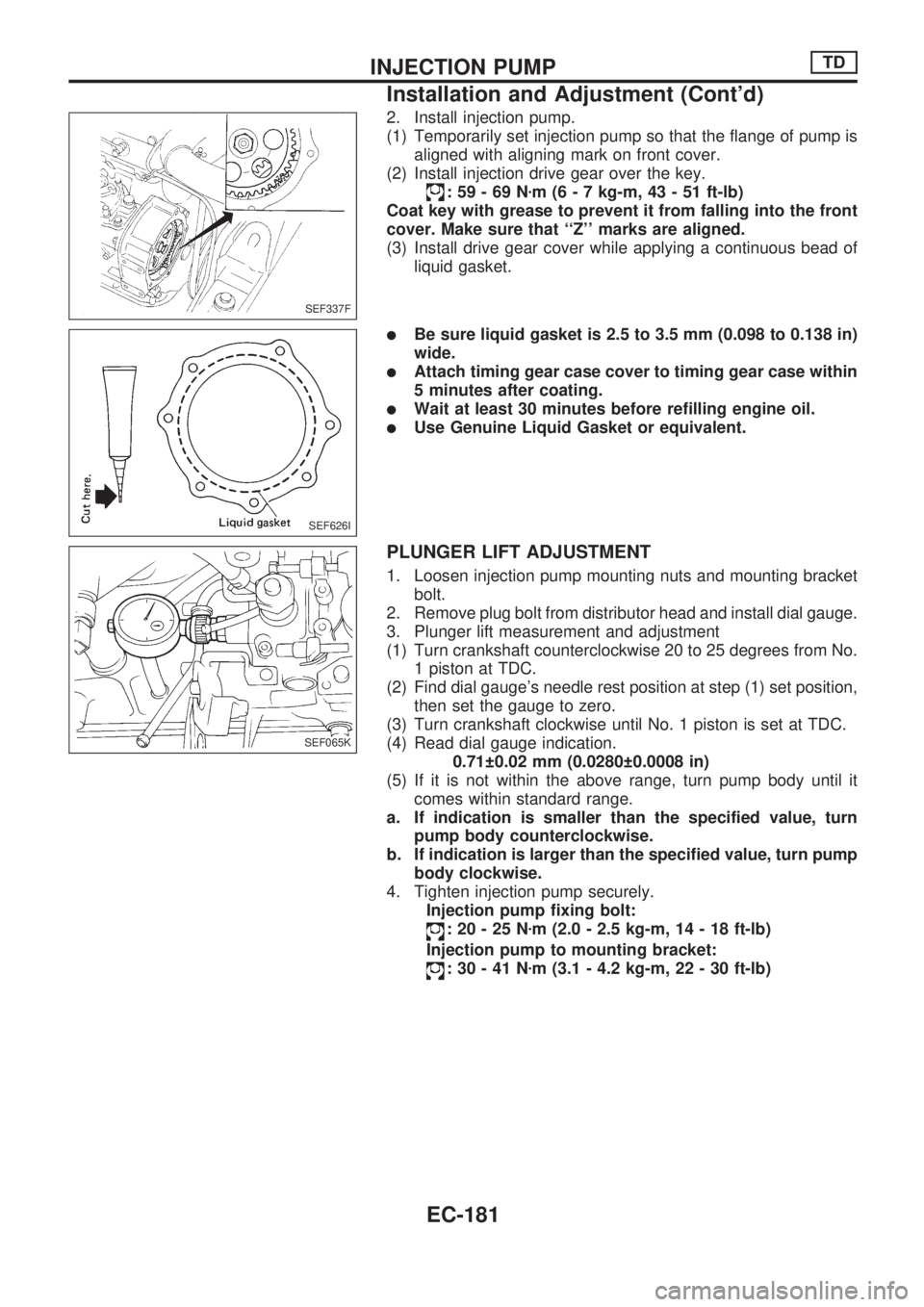

Injection Pump Calibration Standard

Injection pump assembly No.104780-4951/

104780-4961

Part No.16700 3S300/

106700 3S301Pump rotation: ClockwiseÐviewed from drive side

1. Test conditions

1 - 1 Nozzle: 105780-0060 (NP-DN0SD1510) 1 - 4 Injection pipe: 2 dia. x 6 dia. x 450 mm (0.08 dia. x 0.24 dia. x 17.72 in)

1 - 2 Nozzle holder: 105780-2150 1 - 5 Fuel oil temperature: 45

+5

0ÉC (113+9

0ÉF)

1 - 3 Nozzle opening pressure: 13,000+300

0kPa

(130.0+3.0

0bar,

133+3

0kg/cm2,

1,891+43

0psi)1 - 6 Supply pump pressure: 20 kPa (0.20 bar, 0.2 kg/cm

2, 2.8 psi)

2. SettingPump speed

rpmSettingsCharge air press

kPa

(mbar, mmHg, inHg)Difference in delivery

m!(Imp fl oz)

2 - 1 Timing device travel 1,100ON 3.4 - 4.2 mm (0.134 - 0.165 in)

OFF 1.8 - 2.2 mm (0.071 - 0.087 in)

ÐÐ

2 - 2 Supply pump pressure 1,100ON 471 - 549 kPa

(4.71 - 5.49 bar, 4.8 - 5.6 kg/cm

2,

68 - 80 psi)

OFF 402 - 461 kPa

(4.02 - 4.61 bar, 4.1 - 4.7 kg/cm

2,

58 - 67 psi)Ð

2 - 3 Full-load delivery 1,10046.9 - 47.9 m!

(1.65 - 1.69 Imp fl oz)/1,000 st3.5 (0.12)

2 - 4 Idle speed regulation 3755.1 - 9.1 m!

(0.18 - 0.32 Imp fl oz)/1,000 st2.0 (0.07)

2 - 5 Start 10045.0 - 80.0 m!

(1.58 - 2.82 Imp fl oz)/1,000 stÐ

2 - 6 Full-load speed regulation 2,50012.9 - 16.9 m!

(0.45 - 0.59 Imp fl oz)/1,000 stÐ

2 - 7 Load timer adjustment 1,100 0.1 - 0.5 mm (0.004 - 0.020 in) Ð

3. Test specifications Solenoid timer ON OFF

3 - 1 Timing deviceN = rpm

mm (in)1,100

3.3 - 4.3

(0.130 - 0.169)2,150

7.3 - 8.2

(0.287 - 0.323)700

Below 0.8

(0.031)1,100

1.7 - 2.3

(0.067 - 0.091)2,150

6.3 - 7.5

(0.248 - 0.295)

3 - 2 Supply pumpN = rpm

kPa (bar,

kg/cm

2, psi)1,100

392 - 471

(3.92 - 4.71,

4.0 - 4.8,

57 - 68)2,150

618 - 696

(6.18 - 6.96,

6.3 - 7.1,

90 - 101)

3-3Overflow deliv-

eryN = rpm

m!(Imp fl oz)/

min.1,100

310 - 570

(10.9 - 20.1)Ð

3 - 4 Fuel injection quantities

Speed control

lever positionPump speed

rpmFuel delivery

m!(Imp fl oz)/

1,000 stCharge air press

kPa (mbar,

mmHg, inHg)

Max. speed1,10046.4 - 48.4

(1.63 - 1.70)

Ð 50041.3 - 47.3

(1.45 - 1.66)*

2,15041.2 - 48.2

(1.45 - 1.70)*

2,50011.9 - 17.9

(0.42 - 0.63)

2,700 Below 5.0 (0.18)

Switch OFF

Magnet valve375 0 (0) Ð

Idling 3754.6 - 9.6

(0.16 - 0.34)Ð

3 - 5 SolenoidMax. cut-in voltage: 8V

Test voltage: 12 - 14V

ON: Solenoid timer is ON. *: Reference value

OFF: Solenoid timer is OFF.

If there is no designation in the specifications for the Solenoid Timer's ON-OFF position, then the position should be regarded as OFF.

4. Dimensions

K 3.2 - 3.4 mm (0.126 - 0.134 in)

KF 5.7 - 5.9 mm (0.224 - 0.232 in)

MS 0.9 - 1.1 mm (0.035 - 0.043 in)

BCS Ð

Pre-stroke 0.08 - 0.12 mm (0.0031 - 0.0047 in)

Control lever angle

a51.5 - 59.5 degree

b31.0 - 41.0 degree

gÐ

SERVICE DATA AND SPECIFICATIONS (SDS)TD

EC-234

Page 662 of 1659

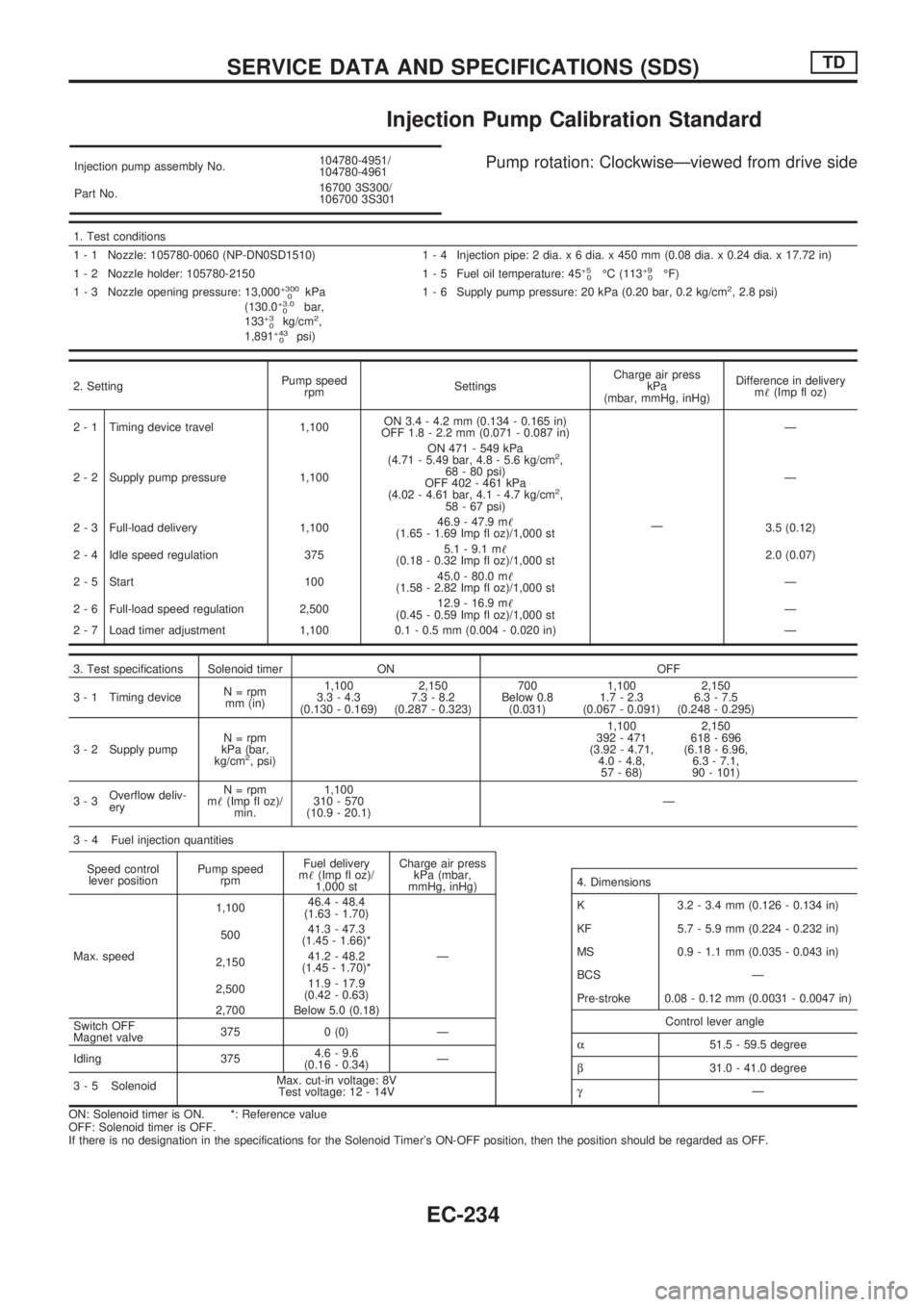

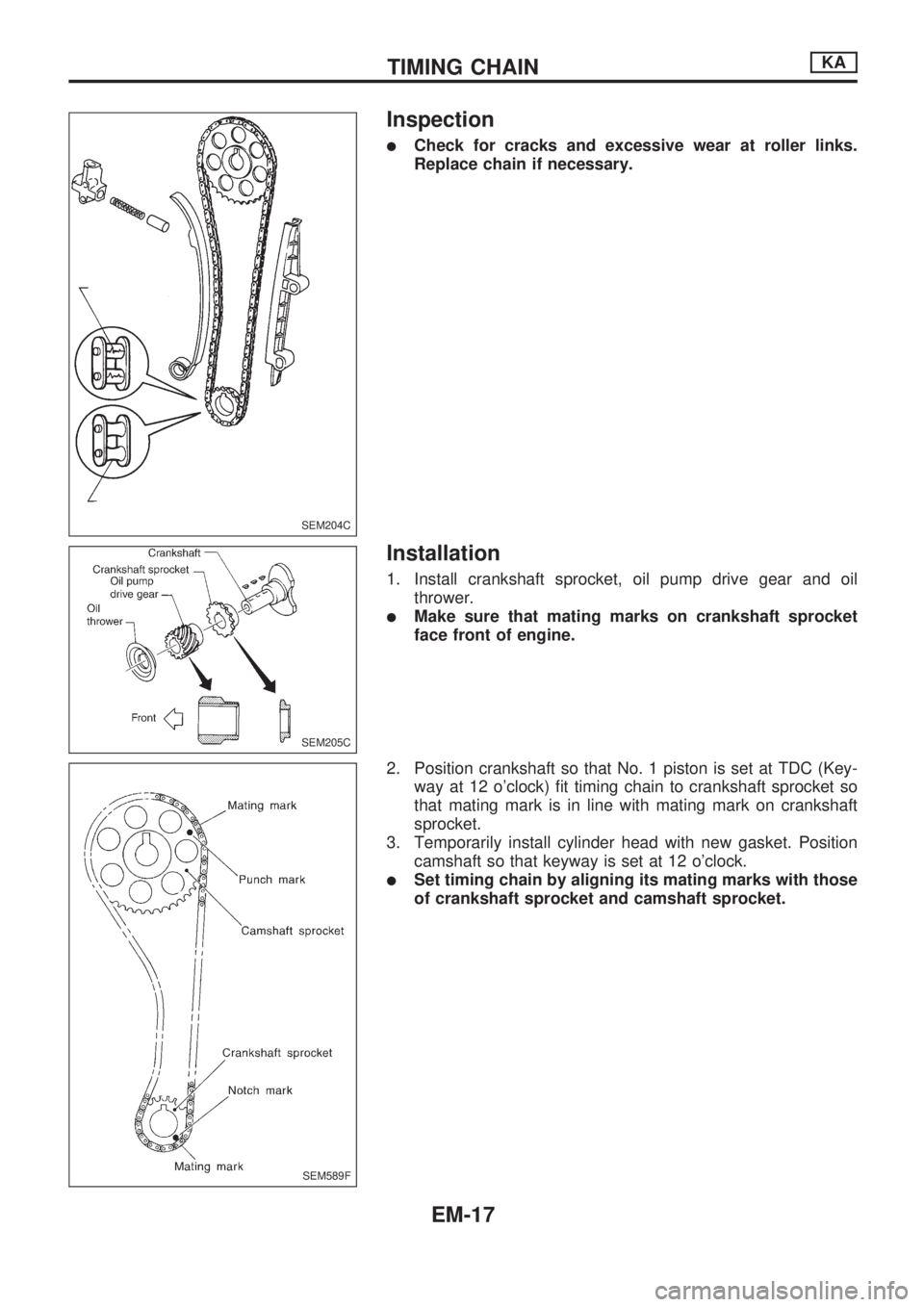

Inspection

lCheck for cracks and excessive wear at roller links.

Replace chain if necessary.

Installation

1. Install crankshaft sprocket, oil pump drive gear and oil

thrower.

lMake sure that mating marks on crankshaft sprocket

face front of engine.

2. Position crankshaft so that No. 1 piston is set at TDC (Key-

way at 12 o'clock) fit timing chain to crankshaft sprocket so

that mating mark is in line with mating mark on crankshaft

sprocket.

3. Temporarily install cylinder head with new gasket. Position

camshaft so that keyway is set at 12 o'clock.

lSet timing chain by aligning its mating marks with those

of crankshaft sprocket and camshaft sprocket.

SEM204C

SEM205C

SEM589F

TIMING CHAINKA

EM-17

Page 679 of 1659

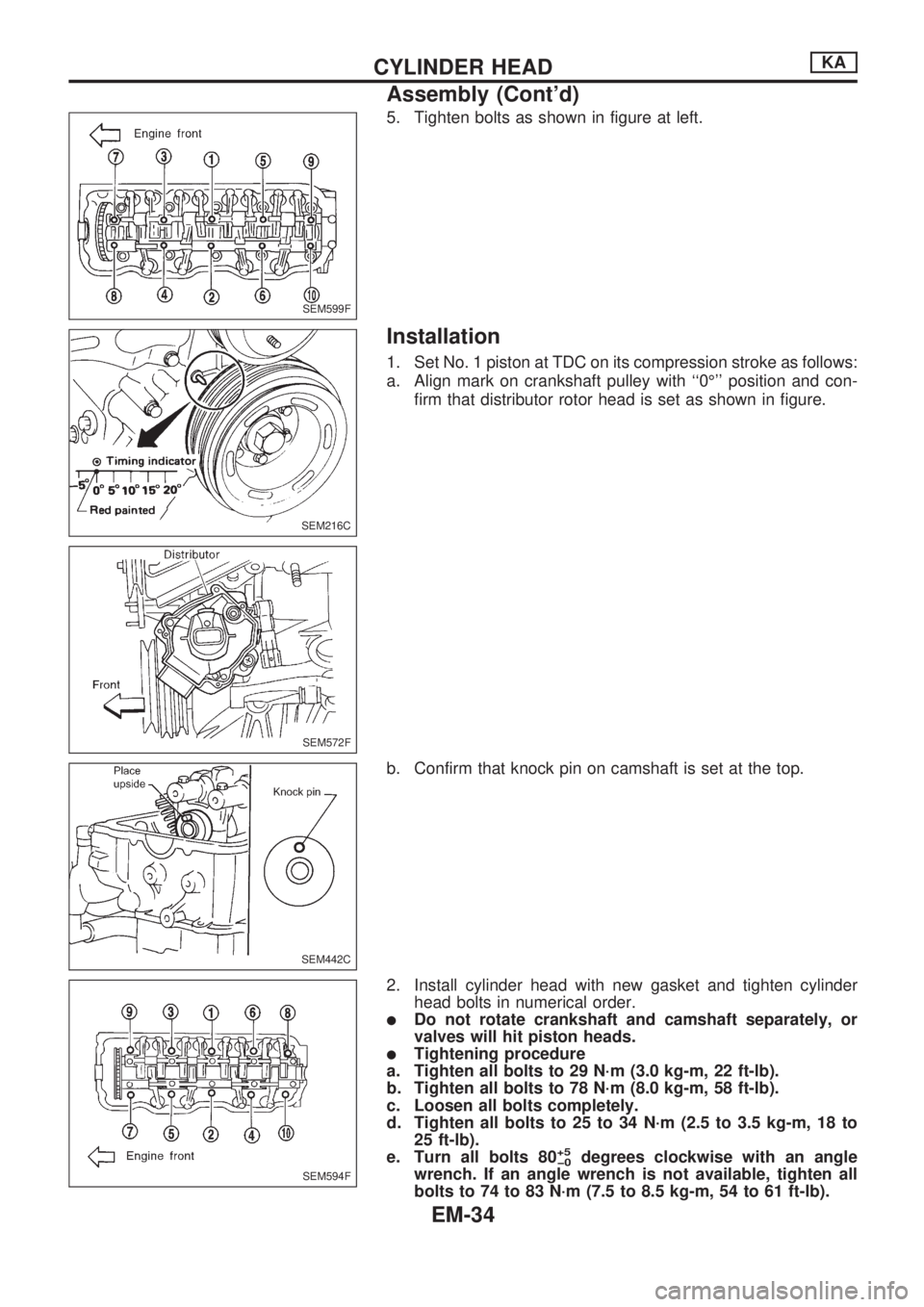

5. Tighten bolts as shown in figure at left.

Installation

1. Set No. 1 piston at TDC on its compression stroke as follows:

a. Align mark on crankshaft pulley with ``0É'' position and con-

firm that distributor rotor head is set as shown in figure.

b. Confirm that knock pin on camshaft is set at the top.

2. Install cylinder head with new gasket and tighten cylinder

head bolts in numerical order.

lDo not rotate crankshaft and camshaft separately, or

valves will hit piston heads.

lTightening procedure

a. Tighten all bolts to 29 N´m (3.0 kg-m, 22 ft-lb).

b. Tighten all bolts to 78 N´m (8.0 kg-m, 58 ft-lb).

c. Loosen all bolts completely.

d. Tighten all bolts to 25 to 34 N´m (2.5 to 3.5 kg-m, 18 to

25 ft-lb).

e. Turn all bolts 80

+5

þ0degrees clockwise with an angle

wrench. If an angle wrench is not available, tighten all

bolts to 74 to 83 N´m (7.5 to 8.5 kg-m, 54 to 61 ft-lb).

SEM599F

SEM216C

SEM572F

SEM442C

SEM594F

CYLINDER HEADKA

Assembly (Cont'd)

EM-34

Page 1570 of 1659

Inspection

lCheck for cracks and excessive wear at roller links.

Replace chain if necessary.

Installation

1. Install crankshaft sprocket, oil pump drive gear and oil

thrower.

lMake sure that mating marks on crankshaft sprocket

face front of engine.

2. Position crankshaft so that No. 1 piston is set at TDC (Key-

way at 12 o'clock) fit timing chain to crankshaft sprocket so

that mating mark is in line with mating mark on crankshaft

sprocket.

3. Temporarily install cylinder head with new gasket. Position

camshaft so that keyway is set at 12 o'clock.

lSet timing chain by aligning its mating marks with those

of crankshaft sprocket and camshaft sprocket.

SEM204C

SEM205C

SEM589F

TIMING CHAINKA

EM-17

Page 1587 of 1659

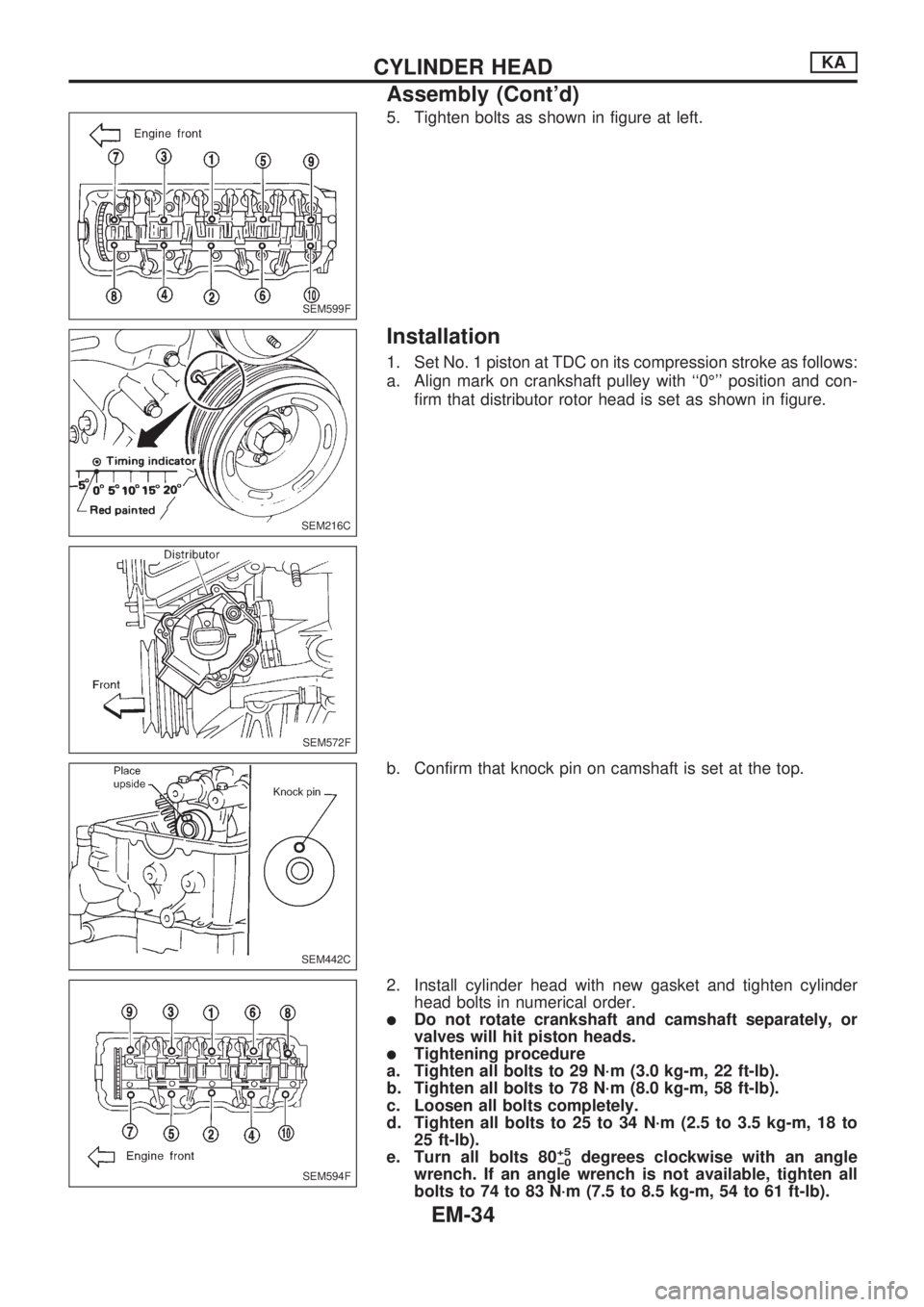

5. Tighten bolts as shown in figure at left.

Installation

1. Set No. 1 piston at TDC on its compression stroke as follows:

a. Align mark on crankshaft pulley with ``0É'' position and con-

firm that distributor rotor head is set as shown in figure.

b. Confirm that knock pin on camshaft is set at the top.

2. Install cylinder head with new gasket and tighten cylinder

head bolts in numerical order.

lDo not rotate crankshaft and camshaft separately, or

valves will hit piston heads.

lTightening procedure

a. Tighten all bolts to 29 N´m (3.0 kg-m, 22 ft-lb).

b. Tighten all bolts to 78 N´m (8.0 kg-m, 58 ft-lb).

c. Loosen all bolts completely.

d. Tighten all bolts to 25 to 34 N´m (2.5 to 3.5 kg-m, 18 to

25 ft-lb).

e. Turn all bolts 80

+5

þ0degrees clockwise with an angle

wrench. If an angle wrench is not available, tighten all

bolts to 74 to 83 N´m (7.5 to 8.5 kg-m, 54 to 61 ft-lb).

SEM599F

SEM216C

SEM572F

SEM442C

SEM594F

CYLINDER HEADKA

Assembly (Cont'd)

EM-34