bulb NISSAN PICK-UP 1998 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 43 of 1659

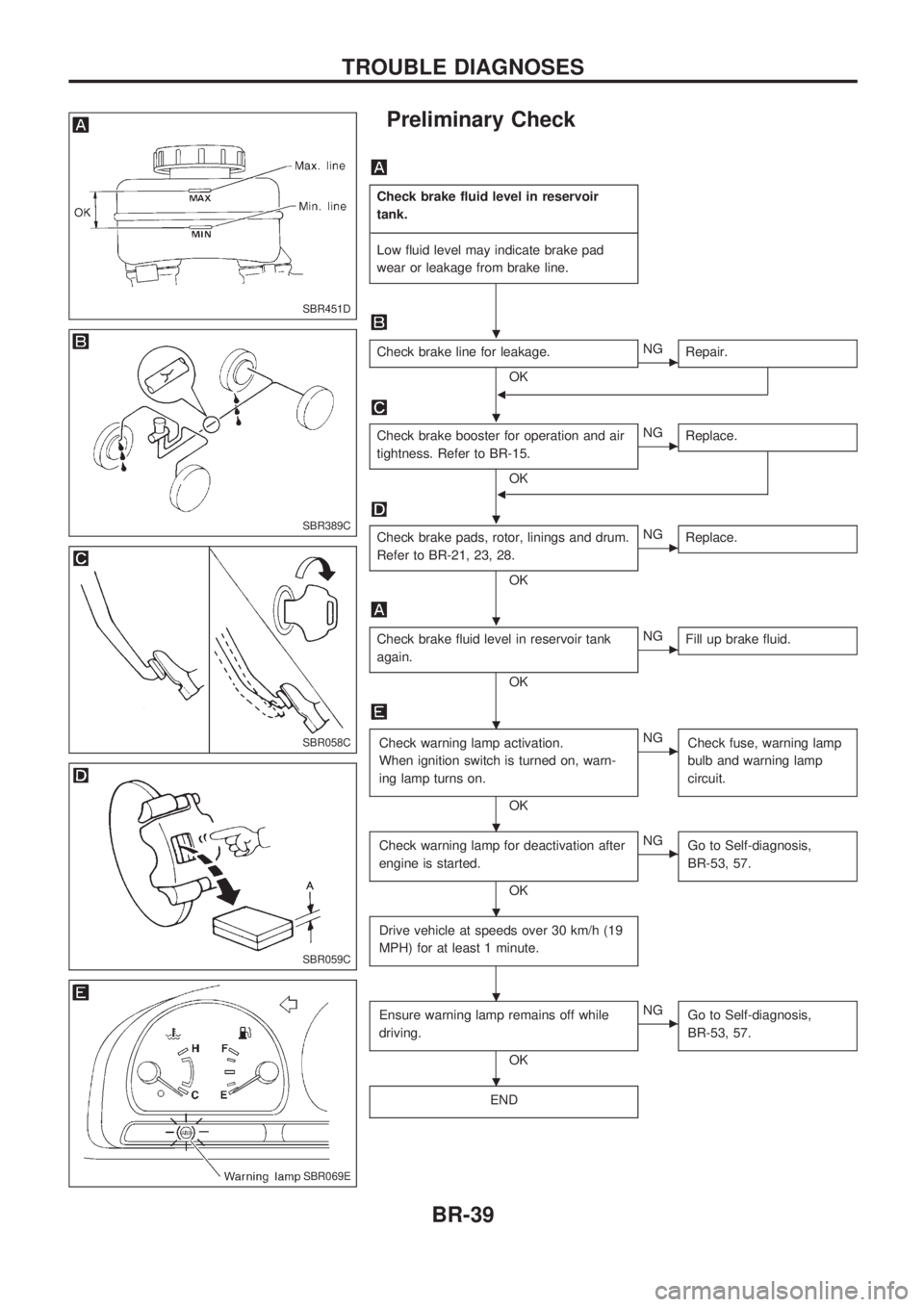

Preliminary Check

Check brake fluid level in reservoir

tank.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Low fluid level may indicate brake pad

wear or leakage from brake line.

Check brake line for leakage.

OKcNG

Repair.

b

Check brake booster for operation and air

tightness. Refer to BR-15.

OK

cNG

Replace.

b

Check brake pads, rotor, linings and drum.

Refer to BR-21, 23, 28.

OK

cNG

Replace.

Check brake fluid level in reservoir tank

again.

OK

cNG

Fill up brake fluid.

Check warning lamp activation.

When ignition switch is turned on, warn-

ing lamp turns on.

OK

cNG

Check fuse, warning lamp

bulb and warning lamp

circuit.

Check warning lamp for deactivation after

engine is started.

OK

cNG

Go to Self-diagnosis,

BR-53, 57.

Drive vehicle at speeds over 30 km/h (19

MPH) for at least 1 minute.

Ensure warning lamp remains off while

driving.

OK

cNG

Go to Self-diagnosis,

BR-53, 57.

END

SBR451D

SBR389C

SBR058C

SBR059C

SBR069E

.

.

.

.

.

.

.

.

.

TROUBLE DIAGNOSES

BR-39

Page 59 of 1659

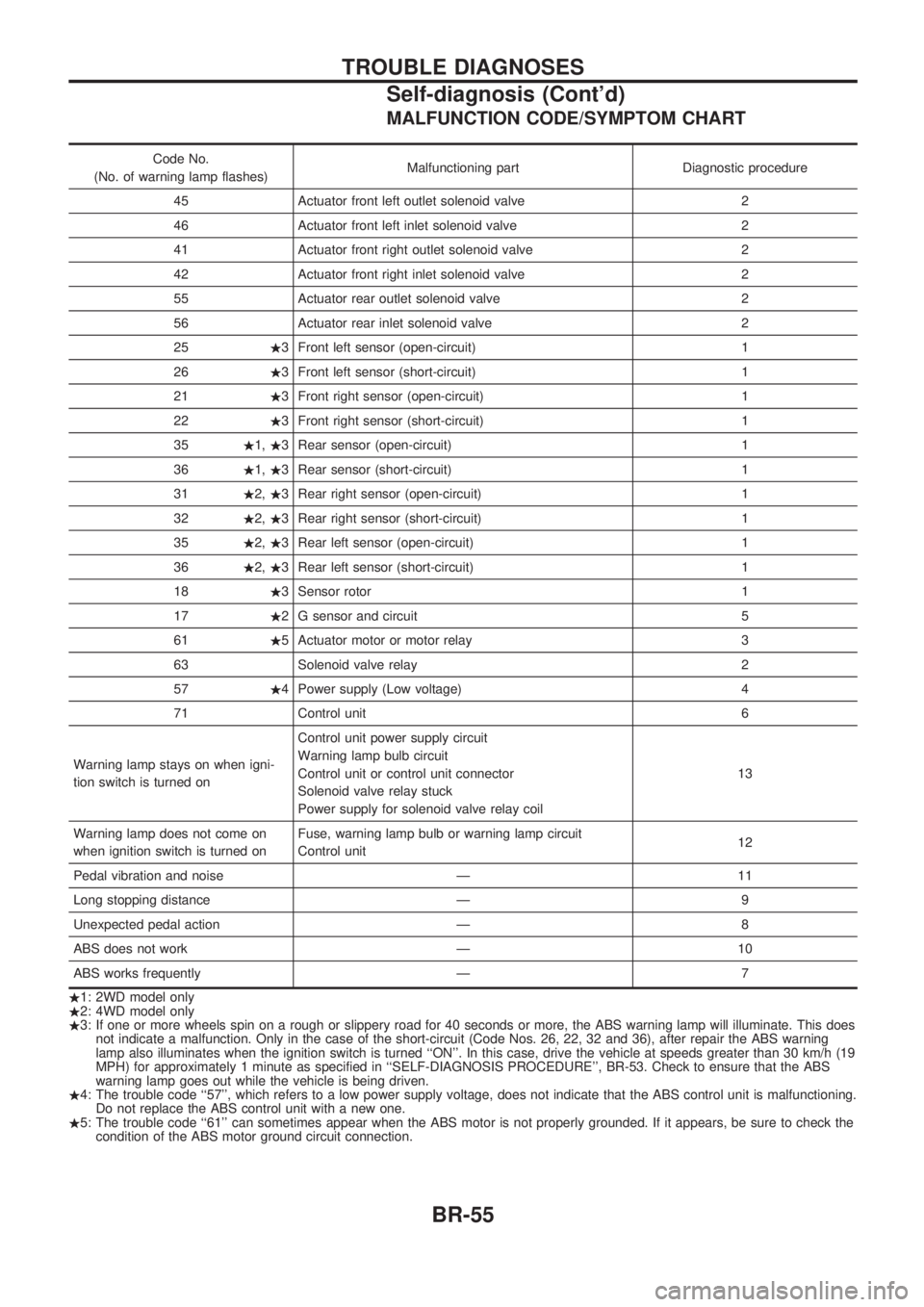

MALFUNCTION CODE/SYMPTOM CHART

Code No.

(No. of warning lamp flashes)Malfunctioning part Diagnostic procedure

45 Actuator front left outlet solenoid valve 2

46 Actuator front left inlet solenoid valve 2

41 Actuator front right outlet solenoid valve 2

42 Actuator front right inlet solenoid valve 2

55 Actuator rear outlet solenoid valve 2

56 Actuator rear inlet solenoid valve 2

25.3 Front left sensor (open-circuit) 1

26.3 Front left sensor (short-circuit) 1

21.3 Front right sensor (open-circuit) 1

22.3 Front right sensor (short-circuit) 1

35.1,.3 Rear sensor (open-circuit) 1

36.1,.3 Rear sensor (short-circuit) 1

31.2,.3 Rear right sensor (open-circuit) 1

32.2,.3 Rear right sensor (short-circuit) 1

35.2,.3 Rear left sensor (open-circuit) 1

36.2,.3 Rear left sensor (short-circuit) 1

18.3 Sensor rotor 1

17.2 G sensor and circuit 5

61.5 Actuator motor or motor relay 3

63 Solenoid valve relay 2

57.4 Power supply (Low voltage) 4

71 Control unit 6

Warning lamp stays on when igni-

tion switch is turned onControl unit power supply circuit

Warning lamp bulb circuit

Control unit or control unit connector

Solenoid valve relay stuck

Power supply for solenoid valve relay coil13

Warning lamp does not come on

when ignition switch is turned onFuse, warning lamp bulb or warning lamp circuit

Control unit12

Pedal vibration and noise Ð 11

Long stopping distance Ð 9

Unexpected pedal action Ð 8

ABS does not work Ð 10

ABS works frequently Ð 7

.1: 2WD model only

.2: 4WD model only

.3: If one or more wheels spin on a rough or slippery road for 40 seconds or more, the ABS warning lamp will illuminate. This does

not indicate a malfunction. Only in the case of the short-circuit (Code Nos. 26, 22, 32 and 36), after repair the ABS warning

lamp also illuminates when the ignition switch is turned ``ON''. In this case, drive the vehicle at speeds greater than 30 km/h (19

MPH) for approximately 1 minute as specified in ``SELF-DIAGNOSIS PROCEDURE'', BR-53. Check to ensure that the ABS

warning lamp goes out while the vehicle is being driven.

.4: The trouble code ``57'', which refers to a low power supply voltage, does not indicate that the ABS control unit is malfunctioning.

Do not replace the ABS control unit with a new one.

.5: The trouble code ``61'' can sometimes appear when the ABS motor is not properly grounded. If it appears, be sure to check the

condition of the ABS motor ground circuit connection.

TROUBLE DIAGNOSES

Self-diagnosis (Cont'd)

BR-55

Page 190 of 1659

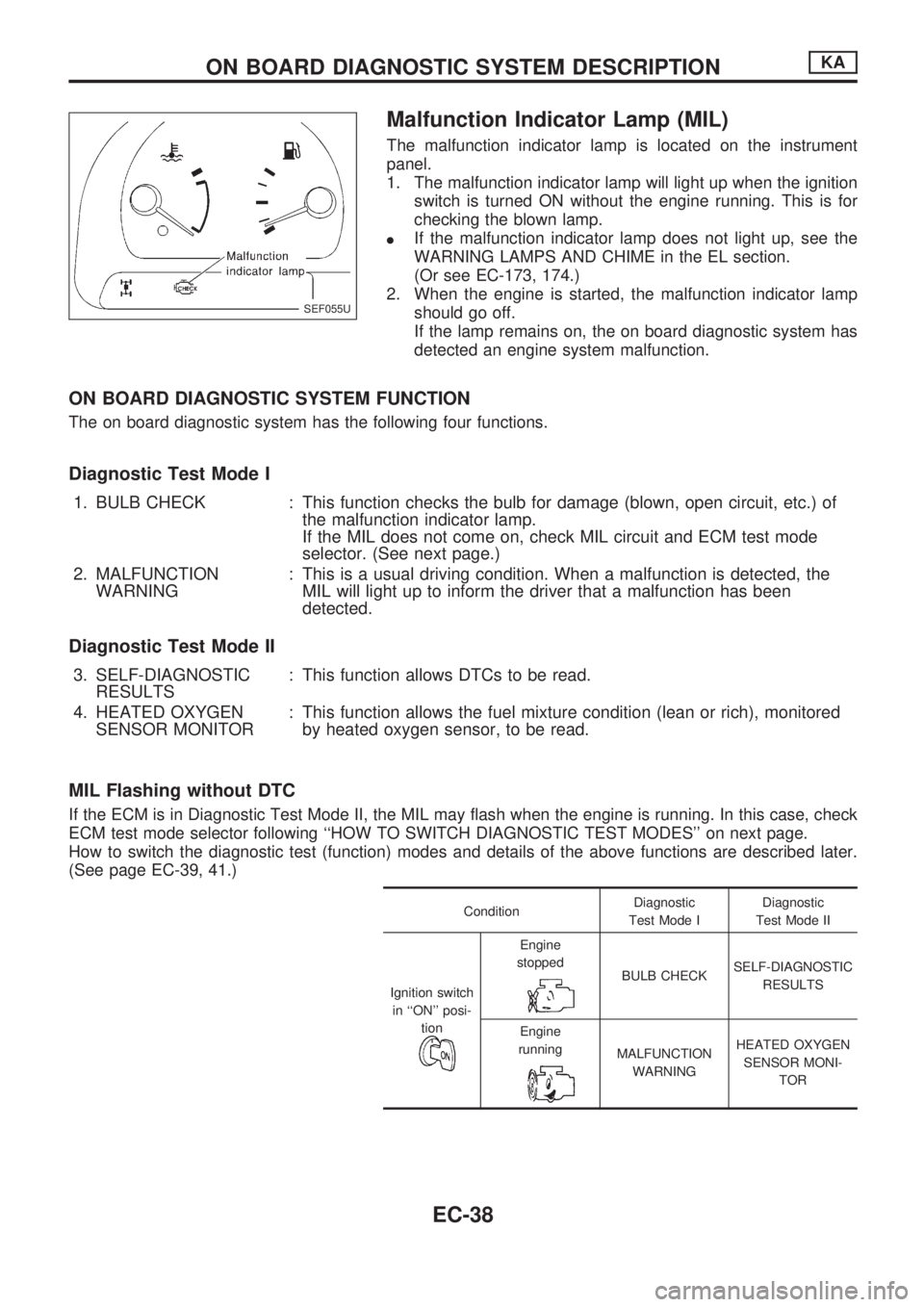

Malfunction Indicator Lamp (MIL)

The malfunction indicator lamp is located on the instrument

panel.

1. The malfunction indicator lamp will light up when the ignition

switch is turned ON without the engine running. This is for

checking the blown lamp.

lIf the malfunction indicator lamp does not light up, see the

WARNING LAMPS AND CHIME in the EL section.

(Or see EC-173, 174.)

2. When the engine is started, the malfunction indicator lamp

should go off.

If the lamp remains on, the on board diagnostic system has

detected an engine system malfunction.

ON BOARD DIAGNOSTIC SYSTEM FUNCTION

The on board diagnostic system has the following four functions.

Diagnostic Test Mode I

1. BULB CHECK : This function checks the bulb for damage (blown, open circuit, etc.) of

the malfunction indicator lamp.

If the MIL does not come on, check MIL circuit and ECM test mode

selector. (See next page.)

2. MALFUNCTION

WARNING: This is a usual driving condition. When a malfunction is detected, the

MIL will light up to inform the driver that a malfunction has been

detected.

Diagnostic Test Mode II

3. SELF-DIAGNOSTIC

RESULTS: This function allows DTCs to be read.

4. HEATED OXYGEN

SENSOR MONITOR: This function allows the fuel mixture condition (lean or rich), monitored

by heated oxygen sensor, to be read.

MIL Flashing without DTC

If the ECM is in Diagnostic Test Mode II, the MIL may flash when the engine is running. In this case, check

ECM test mode selector following ``HOW TO SWITCH DIAGNOSTIC TEST MODES'' on next page.

How to switch the diagnostic test (function) modes and details of the above functions are described later.

(See page EC-39, 41.)

ConditionDiagnostic

Test Mode IDiagnostic

Test Mode II

Ignition switch

in ``ON'' posi-

tion

Engine

stopped

BULB CHECKSELF-DIAGNOSTIC

RESULTS

Engine

running

MALFUNCTION

WARNINGHEATED OXYGEN

SENSOR MONI-

TOR

SEF055U

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONKA

EC-38

Page 191 of 1659

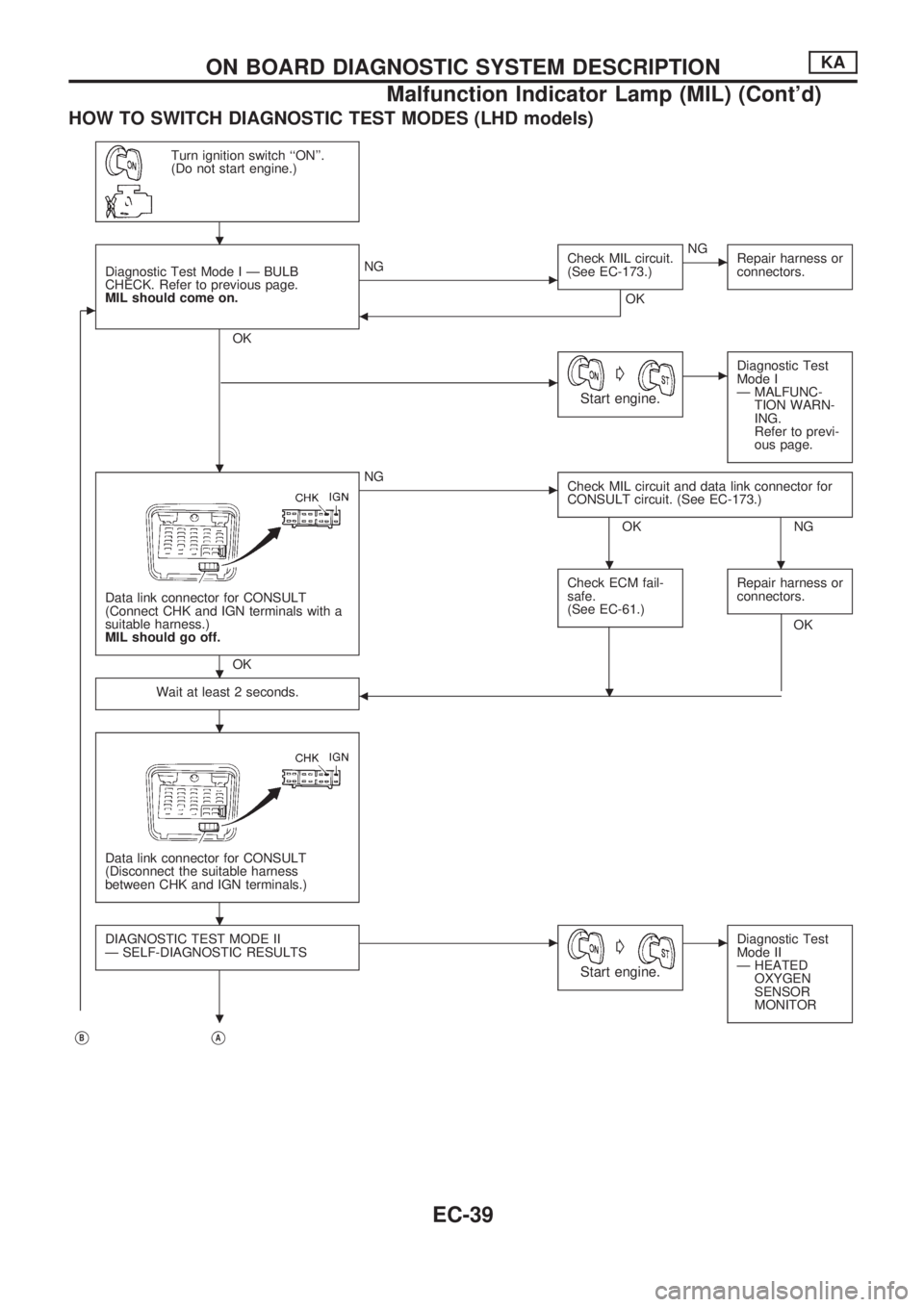

HOW TO SWITCH DIAGNOSTIC TEST MODES (LHD models)

Turn ignition switch ``ON''.

(Do not start engine.)

c

Diagnostic Test Mode I Ð BULB

CHECK. Refer to previous page.

MIL should come on.

OK

cNGCheck MIL circuit.

(See EC-173.)

OK

cNG

Repair harness or

connectors.

b

cG

Start engine.

cDiagnostic Test

Mode I

Ð MALFUNC-

TION WARN-

ING.

Refer to previ-

ous page.

Data link connector for CONSULT

(Connect CHK and IGN terminals with a

suitable harness.)

MIL should go off.

OK

cNG

Check MIL circuit and data link connector for

CONSULT circuit. (See EC-173.)

OK NG

Check ECM fail-

safe.

(See EC-61.)

Repair harness or

connectors.

OK

Wait at least 2 seconds.

b

Data link connector for CONSULT

(Disconnect the suitable harness

between CHK and IGN terminals.)

DIAGNOSTIC TEST MODE II

Ð SELF-DIAGNOSTIC RESULTScG

Start engine.

cDiagnostic Test

Mode II

Ð HEATED

OXYGEN

SENSOR

MONITOR

VBVA

.

.

..

.

.

.

.

.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONKA

Malfunction Indicator Lamp (MIL) (Cont'd)

EC-39

Page 193 of 1659

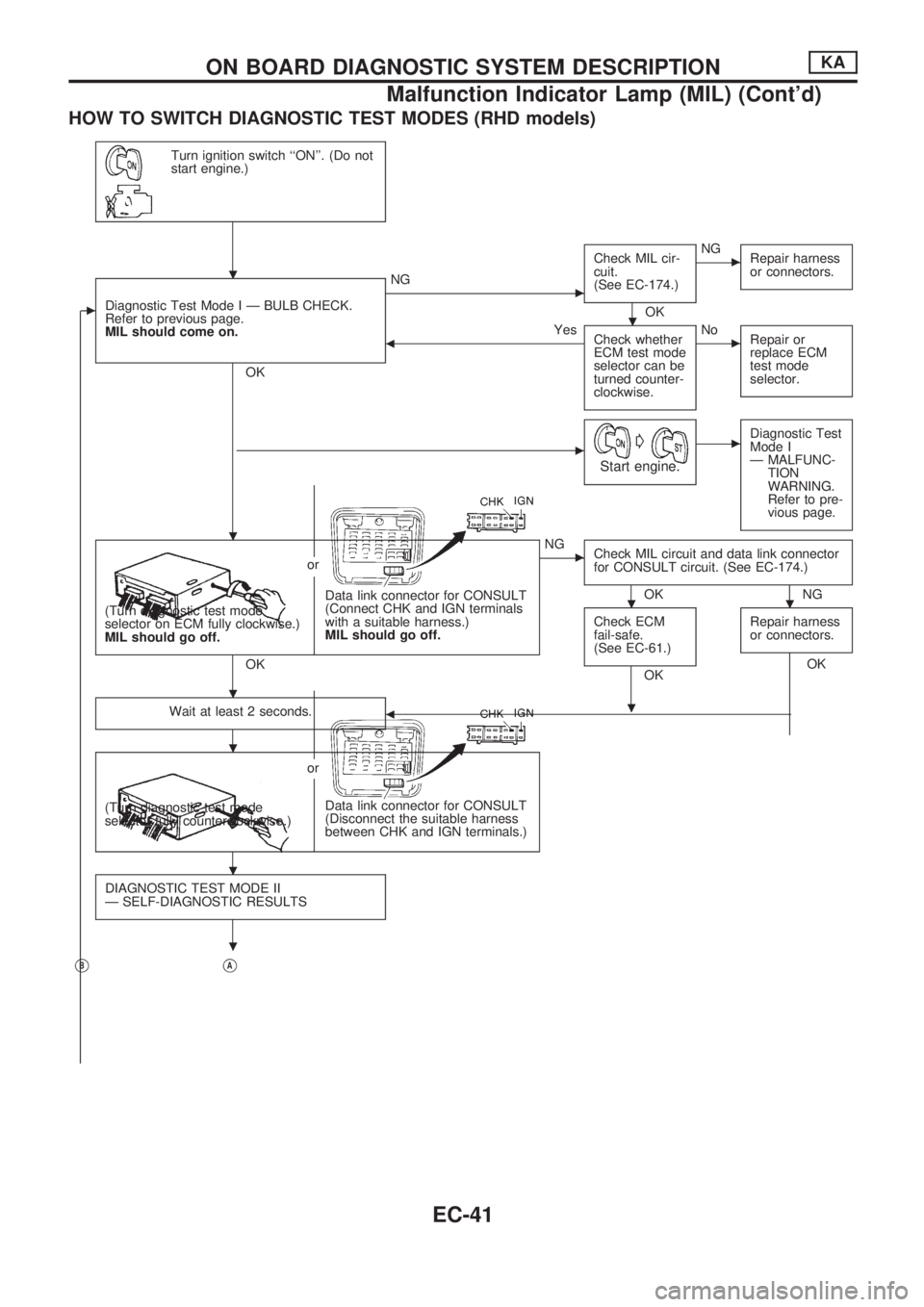

HOW TO SWITCH DIAGNOSTIC TEST MODES (RHD models)

Turn ignition switch ``ON''. (Do not

start engine.)

cDiagnostic Test Mode I Ð BULB CHECK.

Refer to previous page.

MIL should come on.

OK

cNGCheck MIL cir-

cuit.

(See EC-174.)

OK

cNG

Repair harness

or connectors.

bYes

Check whether

ECM test mode

selector can be

turned counter-

clockwise.cNo

Repair or

replace ECM

test mode

selector.

cG

Start engine.

cDiagnostic Test

Mode I

Ð MALFUNC-

TION

WARNING.

Refer to pre-

vious page.

Data link connector for CONSULT

(Connect CHK and IGN terminals

with a suitable harness.)

MIL should go off. (Turn diagnostic test mode

selector on ECM fully clockwise.)

MIL should go off.or

OK

cNG

Check MIL circuit and data link connector

for CONSULT circuit. (See EC-174.)

OK NG

Check ECM

fail-safe.

(See EC-61.)

OKRepair harness

or connectors.OK

Wait at least 2 seconds.

b

Data link connector for CONSULT

(Disconnect the suitable harness

between CHK and IGN terminals.) (Turn diagnostic test mode

selector fully counterclockwise.)or

DIAGNOSTIC TEST MODE II

Ð SELF-DIAGNOSTIC RESULTS

VBVA

.

.

.

..

.

.

.

.

.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONKA

Malfunction Indicator Lamp (MIL) (Cont'd)

EC-41

Page 195 of 1659

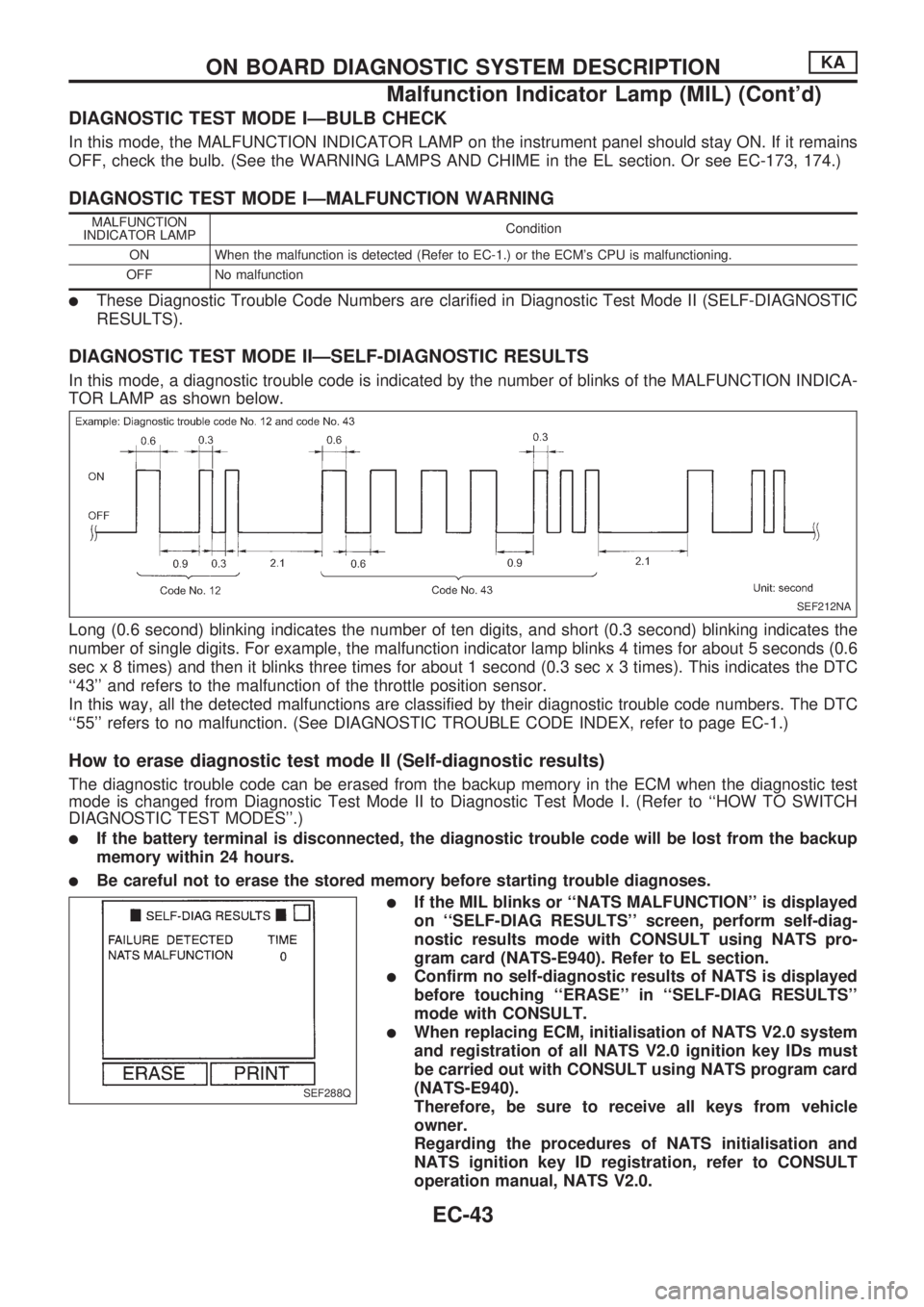

DIAGNOSTIC TEST MODE IÐBULB CHECK

In this mode, the MALFUNCTION INDICATOR LAMP on the instrument panel should stay ON. If it remains

OFF, check the bulb. (See the WARNING LAMPS AND CHIME in the EL section. Or see EC-173, 174.)

DIAGNOSTIC TEST MODE IÐMALFUNCTION WARNING

MALFUNCTION

INDICATOR LAMPCondition

ON When the malfunction is detected (Refer to EC-1.) or the ECM's CPU is malfunctioning.

OFF No malfunction

lThese Diagnostic Trouble Code Numbers are clarified in Diagnostic Test Mode II (SELF-DIAGNOSTIC

RESULTS).

DIAGNOSTIC TEST MODE IIÐSELF-DIAGNOSTIC RESULTS

In this mode, a diagnostic trouble code is indicated by the number of blinks of the MALFUNCTION INDICA-

TOR LAMP as shown below.

Long (0.6 second) blinking indicates the number of ten digits, and short (0.3 second) blinking indicates the

number of single digits. For example, the malfunction indicator lamp blinks 4 times for about 5 seconds (0.6

sec x 8 times) and then it blinks three times for about 1 second (0.3 sec x 3 times). This indicates the DTC

``43'' and refers to the malfunction of the throttle position sensor.

In this way, all the detected malfunctions are classified by their diagnostic trouble code numbers. The DTC

``55'' refers to no malfunction. (See DIAGNOSTIC TROUBLE CODE INDEX, refer to page EC-1.)

How to erase diagnostic test mode II (Self-diagnostic results)

The diagnostic trouble code can be erased from the backup memory in the ECM when the diagnostic test

mode is changed from Diagnostic Test Mode II to Diagnostic Test Mode I. (Refer to ``HOW TO SWITCH

DIAGNOSTIC TEST MODES''.)

lIf the battery terminal is disconnected, the diagnostic trouble code will be lost from the backup

memory within 24 hours.

lBe careful not to erase the stored memory before starting trouble diagnoses.

lIf the MIL blinks or ``NATS MALFUNCTION'' is displayed

on ``SELF-DIAG RESULTS'' screen, perform self-diag-

nostic results mode with CONSULT using NATS pro-

gram card (NATS-E940). Refer to EL section.

lConfirm no self-diagnostic results of NATS is displayed

before touching ``ERASE'' in ``SELF-DIAG RESULTS''

mode with CONSULT.

lWhen replacing ECM, initialisation of NATS V2.0 system

and registration of all NATS V2.0 ignition key IDs must

be carried out with CONSULT using NATS program card

(NATS-E940).

Therefore, be sure to receive all keys from vehicle

owner.

Regarding the procedures of NATS initialisation and

NATS ignition key ID registration, refer to CONSULT

operation manual, NATS V2.0.

SEF212NA

SEF288Q

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONKA

Malfunction Indicator Lamp (MIL) (Cont'd)

EC-43

Page 388 of 1659

ELECTRICAL SYSTEM

SECTION

EL

When you read wiring diagrams:

lRead GI section, ``HOW TO READ WIRING DIAGRAMS''.

When you perform trouble diagnoses, read GI section, ``HOW TO FOLLOW FLOW CHART IN

TROUBLE DIAGNOSES'' and ``HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRI-

CAL INCIDENT''.

CONTENTS

PRECAUTIONS......................................................... 1

Supplemental Restraint System (SRS) ``AIR

BAG'' (4WD models).............................................. 1

Supplemental Restraint System (SRS) ``AIR

BAG'' (2WD models).............................................. 1

HARNESS CONNECTOR.......................................... 2

Description ............................................................. 2

STANDARDIZED RELAY.......................................... 3

Description ............................................................. 3

POWER SUPPLY ROUTING..................................... 5

Schematic .............................................................. 5

Wiring Diagram - POWER -................................... 6

Fuse ..................................................................... 13

Fusible Link .......................................................... 13

Circuit Breaker Inspection.................................... 13

GROUND DISTRIBUTION....................................... 14

BATTERY................................................................. 18

How to Handle Battery......................................... 18

Battery Test and Charging Chart......................... 21

Service Data and Specifications (SDS) ............... 25

STARTING SYSTEM............................................... 26

Wiring Diagram - START - .................................. 26

Trouble Diagnoses ............................................... 27

Construction ......................................................... 28

Removal and Installation ..................................... 30

Inspection ............................................................. 30

Assembly.............................................................. 32

Service Data and Specifications (SDS) ............... 33

CHARGING SYSTEM.............................................. 34

Wiring Diagram - CHARGE -/Gasoline Engine ... 34

Wiring Diagram - CHARGE -/Diesel Engine ....... 35Trouble Diagnoses ............................................... 36

Construction ......................................................... 38

Removal and Installation ..................................... 39

Disassembly ......................................................... 39

Inspection ............................................................. 39

Assembly.............................................................. 40

Service Data and Specifications (SDS) ............... 41

COMBINATION SWITCH........................................ 42

Check ................................................................... 42

Replacement ........................................................ 43

HEADLAMP - Conventional Type -....................... 44

Wiring Diagram - H/LAMP -/LHD Models ............ 44

Wiring Diagram - H/LAMP -/RHD Models ........... 46

Trouble Diagnoses ............................................... 48

Bulb Replacement................................................ 49

Aiming Adjustment ............................................... 49

Low Beam ............................................................ 50

HEADLAMP - Daytime Light System -................. 51

System Description .............................................. 51

Schematic ............................................................ 53

Wiring Diagram - DTRL - ..................................... 54

Trouble Diagnoses ............................................... 57

Bulb Replacement................................................ 57

Aiming Adjustment ............................................... 57

HEADLAMP - Dim-dip Lamp System -................. 58

System Description .............................................. 58

Schematic ............................................................ 58

Wiring Diagram - DIMDIP -.................................. 59

Trouble Diagnoses ............................................... 62

Bulb Replacement................................................ 62

Aiming Adjustment ............................................... 62

EL

Page 390 of 1659

Wiring Diagram - MULTI -/LHD Models ............ 175

Trouble Diagnoses ............................................. 179

ID Code Entry Procedure .................................. 182

NATS (Nissan Anti-Theft System)/Gasoline

engine for LHD models........................................ 183

Component Parts and Harness Connector

Location.............................................................. 183

System Description ............................................ 183

System Composition .......................................... 184

Wiring Diagram - NATS -................................... 185

CONSULT .......................................................... 186

Trouble Diagnoses ............................................. 188

How to Replace NATS IMMU ............................ 197

NATS (Nissan Anti-Theft System)/Diesel

engine.................................................................... 198

Component Parts and Harness Connector

Location.............................................................. 198

System Description ............................................ 199

System Composition .......................................... 199

Wiring Diagram - NATS -/LHD Models.............. 200

Wiring Diagram - NATS -/RHD Models ............. 201

CONSULT .......................................................... 202

Trouble Diagnoses ............................................. 205LOCATION OF ELECTRICAL UNITS................... 217

Engine Compartment ......................................... 217

Passenger Compartment ................................... 218

HARNESS LAYOUT.............................................. 220

Outline ................................................................ 220

How to Read Harness Layout ........................... 221

Main Harness ..................................................... 222

Engine Room Harness....................................... 232

Engine Control Harness..................................... 240

Engine Harness ................................................. 242

Alternator Harness ............................................. 244

Instrument Harness............................................ 245

Room Lamp Harness/LHD Models .................... 246

Room Lamp Harness/RHD Models ................... 247

Chassis Harness and Tail Harness ................... 248

Front Door Harness (LH side) ........................... 249

Front Door Harness (RH side)........................... 250

Rear Door Harness ............................................ 251

BULB SPECIFICATIONS...................................... 252

Headlamp ........................................................... 252

Exterior Lamp..................................................... 252

Interior Lamp ...................................................... 252

WIRING DIAGRAM CODES (CELL CODES)....... 253

WIRING DIAGRAM REFERENCE CHART

COOLING FAN .......................................................................................................... LC SECTION

ECCS, IGNITION SYSTEM, QUICK-GLOW SYSTEM, FUEL HEATER SYSTEM .. EC SECTION

ANTI-LOCK BRAKE SYSTEM .................................................................................. BR SECTION

SRS ``AIR BAG'' ........................................................................................................ RS SECTION

HEATER AND AIR CONDITIONER .......................................................................... HA SECTION

Page 426 of 1659

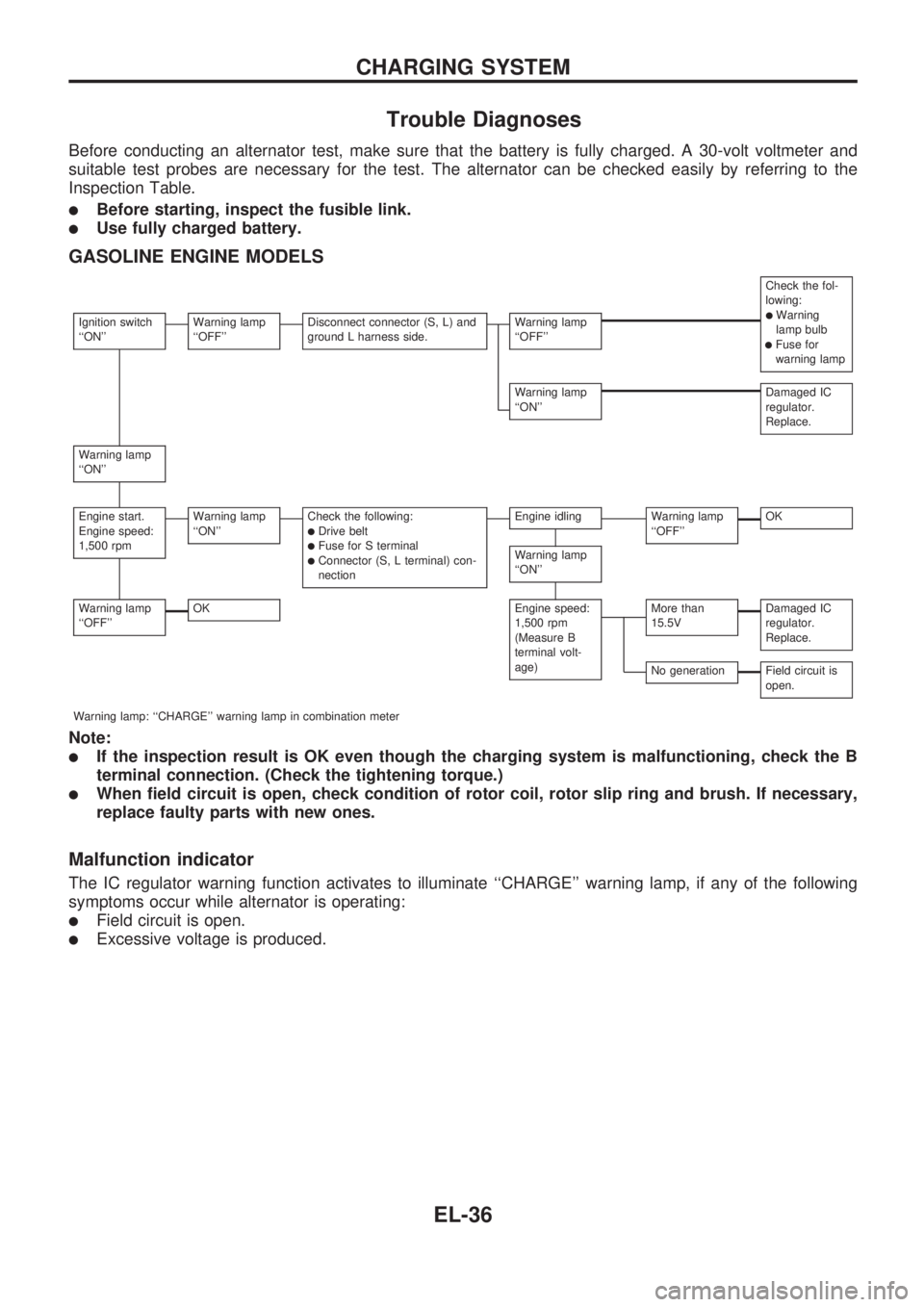

Trouble Diagnoses

Before conducting an alternator test, make sure that the battery is fully charged. A 30-volt voltmeter and

suitable test probes are necessary for the test. The alternator can be checked easily by referring to the

Inspection Table.

lBefore starting, inspect the fusible link.

lUse fully charged battery.

GASOLINE ENGINE MODELS

Check the fol-

lowing:

lWarning

lamp bulb

lFuse for

warning lamp

Ignition switch

``ON''Warning lamp

``OFF''Disconnect connector (S, L) and

ground L harness side.Warning lamp

``OFF''

Warning lamp

``ON''Damaged IC

regulator.

Replace.

Warning lamp

``ON''

Engine start.

Engine speed:

1,500 rpmWarning lamp

``ON''Check the following:lDrive beltlFuse for S terminallConnector (S, L terminal) con-

nection

Engine idlingWarning lamp

``OFF''OK

Warning lamp

``ON''

Warning lamp

``OFF''OKEngine speed:

1,500 rpm

(Measure B

terminal volt-

age)More than

15.5VDamaged IC

regulator.

Replace.

No generationField circuit is

open.

Warning lamp: ``CHARGE'' warning lamp in combination meter

Note:

lIf the inspection result is OK even though the charging system is malfunctioning, check the B

terminal connection. (Check the tightening torque.)

lWhen field circuit is open, check condition of rotor coil, rotor slip ring and brush. If necessary,

replace faulty parts with new ones.

Malfunction indicator

The IC regulator warning function activates to illuminate ``CHARGE'' warning lamp, if any of the following

symptoms occur while alternator is operating:

lField circuit is open.

lExcessive voltage is produced.

CHARGING SYSTEM

EL-36

Page 427 of 1659

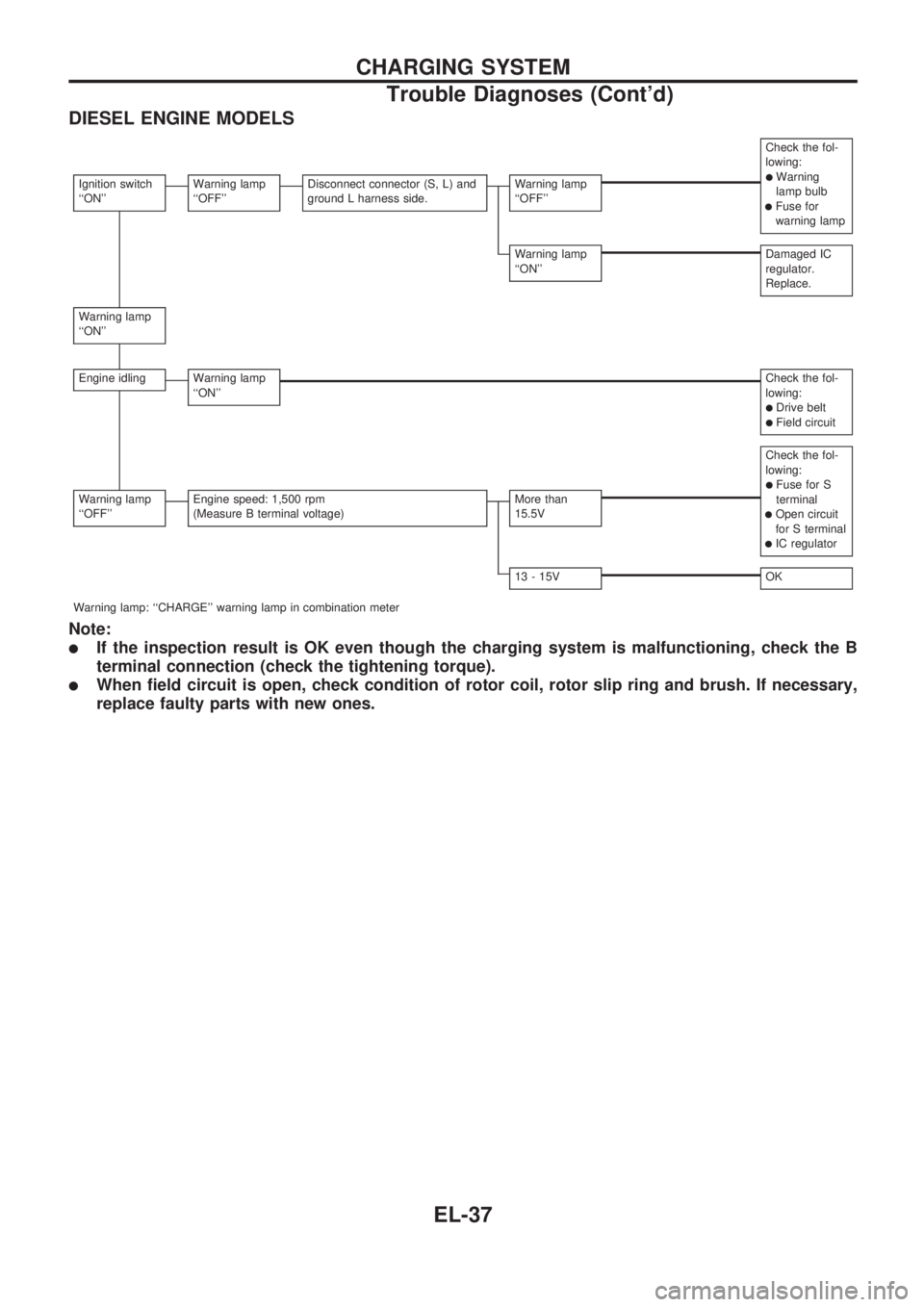

DIESEL ENGINE MODELS

Check the fol-

lowing:

lWarning

lamp bulb

lFuse for

warning lamp

Ignition switch

``ON''Warning lamp

``OFF''Disconnect connector (S, L) and

ground L harness side.Warning lamp

``OFF''

Warning lamp

``ON''Damaged IC

regulator.

Replace.

Warning lamp

``ON''

Engine idlingWarning lamp

``ON''Check the fol-

lowing:

lDrive beltlField circuit

Check the fol-

lowing:

lFuse for S

terminal

lOpen circuit

for S terminal

lIC regulator

Warning lamp

``OFF''Engine speed: 1,500 rpm

(Measure B terminal voltage)More than

15.5V

13 - 15VOK

Warning lamp: ``CHARGE'' warning lamp in combination meter

Note:

lIf the inspection result is OK even though the charging system is malfunctioning, check the B

terminal connection (check the tightening torque).

lWhen field circuit is open, check condition of rotor coil, rotor slip ring and brush. If necessary,

replace faulty parts with new ones.

CHARGING SYSTEM

Trouble Diagnoses (Cont'd)

EL-37