coolant capacity NISSAN PICK-UP 1998 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 985 of 1659

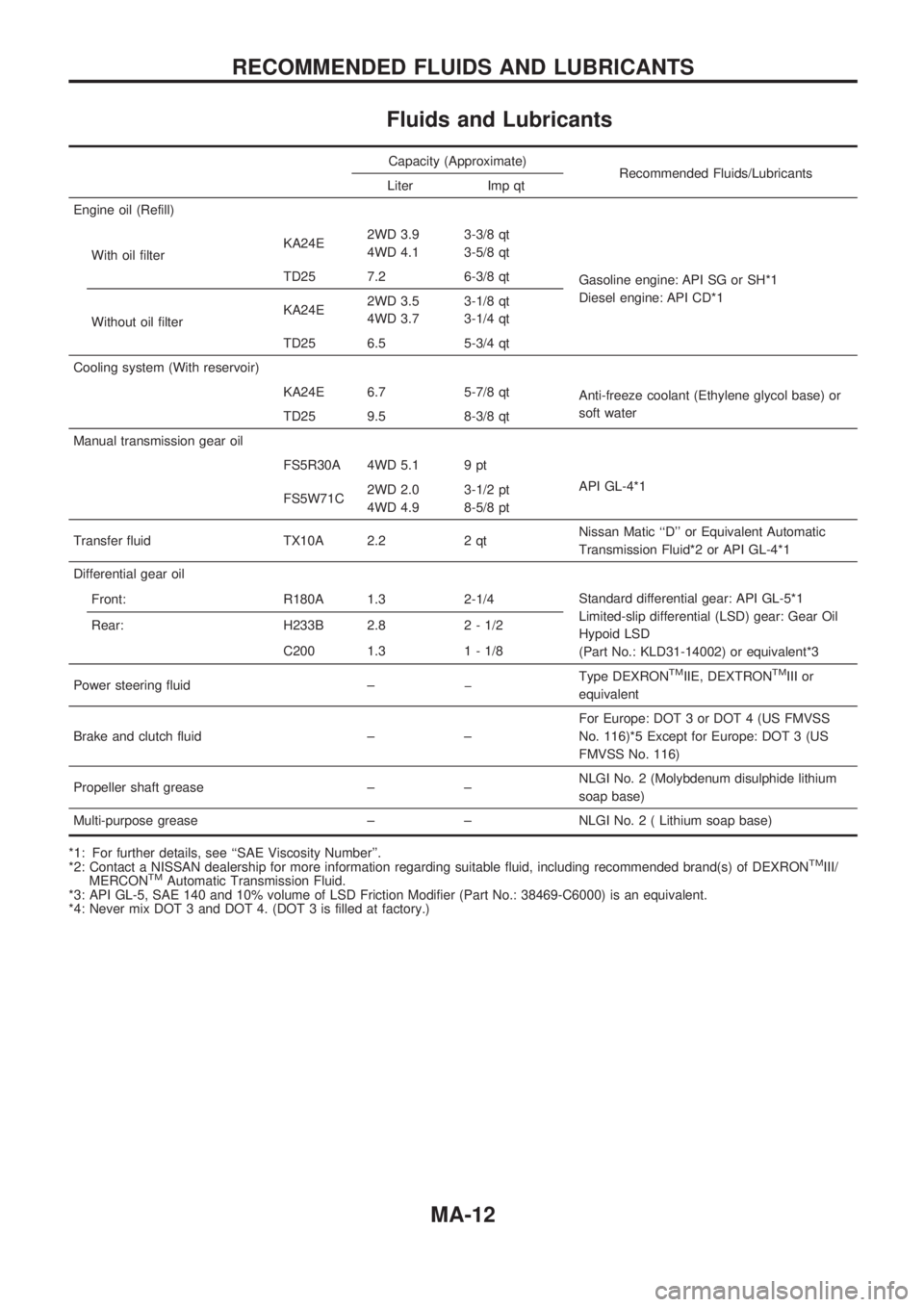

Fluids and Lubricants

Capacity (Approximate)

Recommended Fluids/Lubricants

Liter Imp qt

Engine oil (Refill)

With oil filterKA24E2WD 3.9

4WD 4.13-3/8 qt

3-5/8 qt

Gasoline engine: API SG or SH*1

Diesel engine: API CD*1 TD25 7.2 6-3/8 qt

Without oil filterKA24E2WD 3.5

4WD 3.73-1/8 qt

3-1/4 qt

TD25 6.5 5-3/4 qt

Cooling system (With reservoir)

KA24E 6.7 5-7/8 qt

Anti-freeze coolant (Ethylene glycol base) or

soft water

TD25 9.5 8-3/8 qt

Manual transmission gear oil

FS5R30A 4WD 5.1 9 pt

API GL-4*1

FS5W71C2WD 2.0

4WD 4.93-1/2 pt

8-5/8 pt

Transfer fluid TX10A 2.2 2 qtNissan Matic ``D'' or Equivalent Automatic

Transmission Fluid*2 or API GL-4*1

Differential gear oil

Front: R180A 1.3 2-1/4Standard differential gear: API GL-5*1

Limited-slip differential (LSD) gear: Gear Oil

Hypoid LSD

(Part No.: KLD31-14002) or equivalent*3 Rear: H233B 2.8 2 - 1/2

C200 1.3 1 - 1/8

Power steering fluid ± þType DEXRON

TMIIE, DEXTRONTMIII or

equivalent

Brake and clutch fluid ± ±For Europe: DOT 3 or DOT 4 (US FMVSS

No. 116)*5 Except for Europe: DOT 3 (US

FMVSS No. 116)

Propeller shaft grease ± ±NLGI No. 2 (Molybdenum disulphide lithium

soap base)

Multi-purpose grease ± ± NLGI No. 2 ( Lithium soap base)

*1: For further details, see ``SAE Viscosity Number''.

*2: Contact a NISSAN dealership for more information regarding suitable fluid, including recommended brand(s) of DEXRONTMIII/

MERCONTMAutomatic Transmission Fluid.

*3: API GL-5, SAE 140 and 10% volume of LSD Friction Modifier (Part No.: 38469-C6000) is an equivalent.

*4: Never mix DOT 3 and DOT 4. (DOT 3 is filled at factory.)

RECOMMENDED FLUIDS AND LUBRICANTS

MA-12

Page 990 of 1659

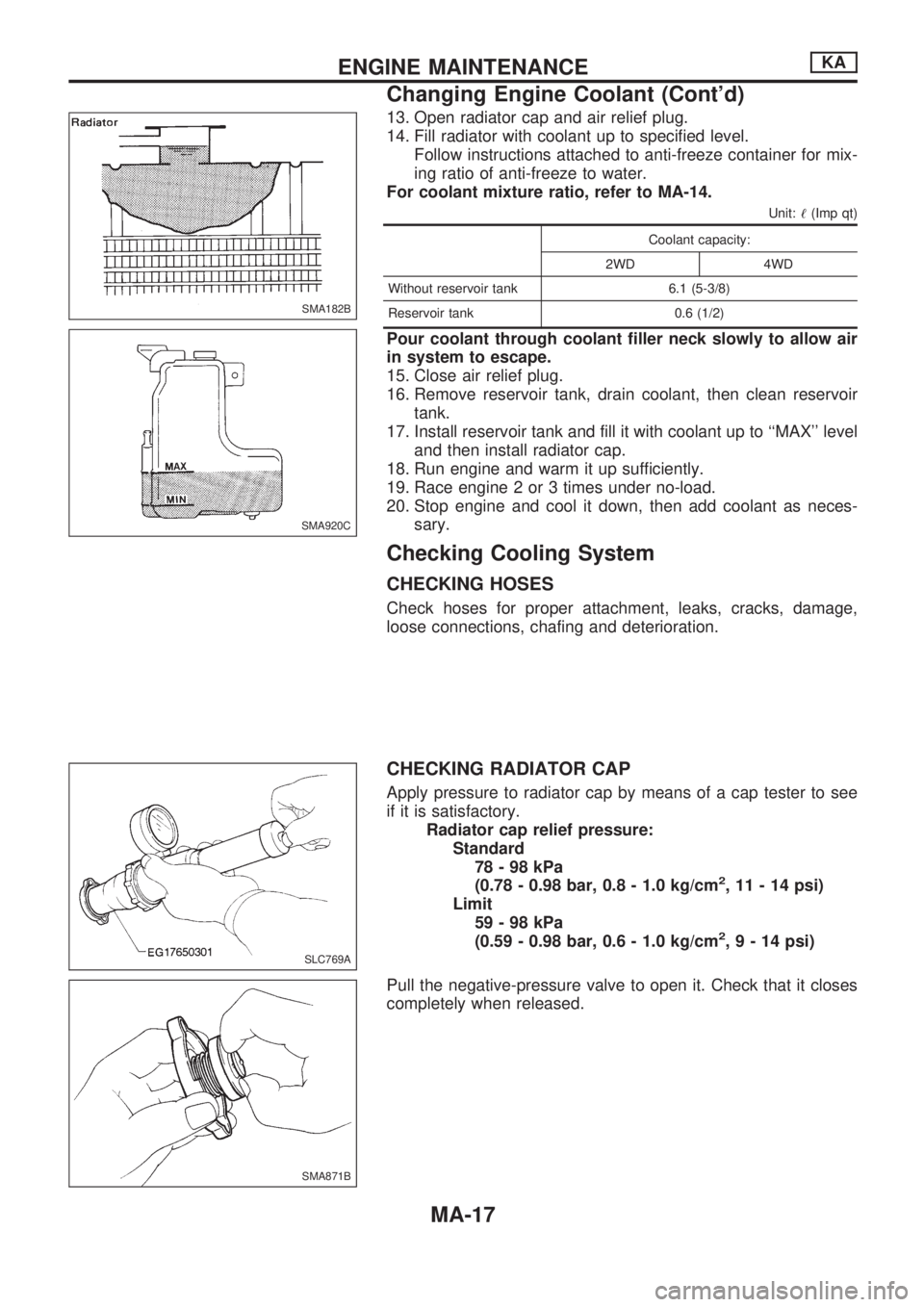

13. Open radiator cap and air relief plug.

14. Fill radiator with coolant up to specified level.

Follow instructions attached to anti-freeze container for mix-

ing ratio of anti-freeze to water.

For coolant mixture ratio, refer to MA-14.

Unit:!(Imp qt)

Coolant capacity:

2WD 4WD

Without reservoir tank 6.1 (5-3/8)

Reservoir tank 0.6 (1/2)

Pour coolant through coolant filler neck slowly to allow air

in system to escape.

15. Close air relief plug.

16. Remove reservoir tank, drain coolant, then clean reservoir

tank.

17. Install reservoir tank and fill it with coolant up to ``MAX'' level

and then install radiator cap.

18. Run engine and warm it up sufficiently.

19. Race engine 2 or 3 times under no-load.

20. Stop engine and cool it down, then add coolant as neces-

sary.

Checking Cooling System

CHECKING HOSES

Check hoses for proper attachment, leaks, cracks, damage,

loose connections, chafing and deterioration.

CHECKING RADIATOR CAP

Apply pressure to radiator cap by means of a cap tester to see

if it is satisfactory.

Radiator cap relief pressure:

Standard

78-98kPa

(0.78 - 0.98 bar, 0.8 - 1.0 kg/cm

2, 11 - 14 psi)

Limit

59-98kPa

(0.59 - 0.98 bar, 0.6 - 1.0 kg/cm

2,9-14psi)

Pull the negative-pressure valve to open it. Check that it closes

completely when released.

SMA182B

SMA920C

SLC769A

SMA871B

ENGINE MAINTENANCEKA

Changing Engine Coolant (Cont'd)

MA-17

Page 999 of 1659

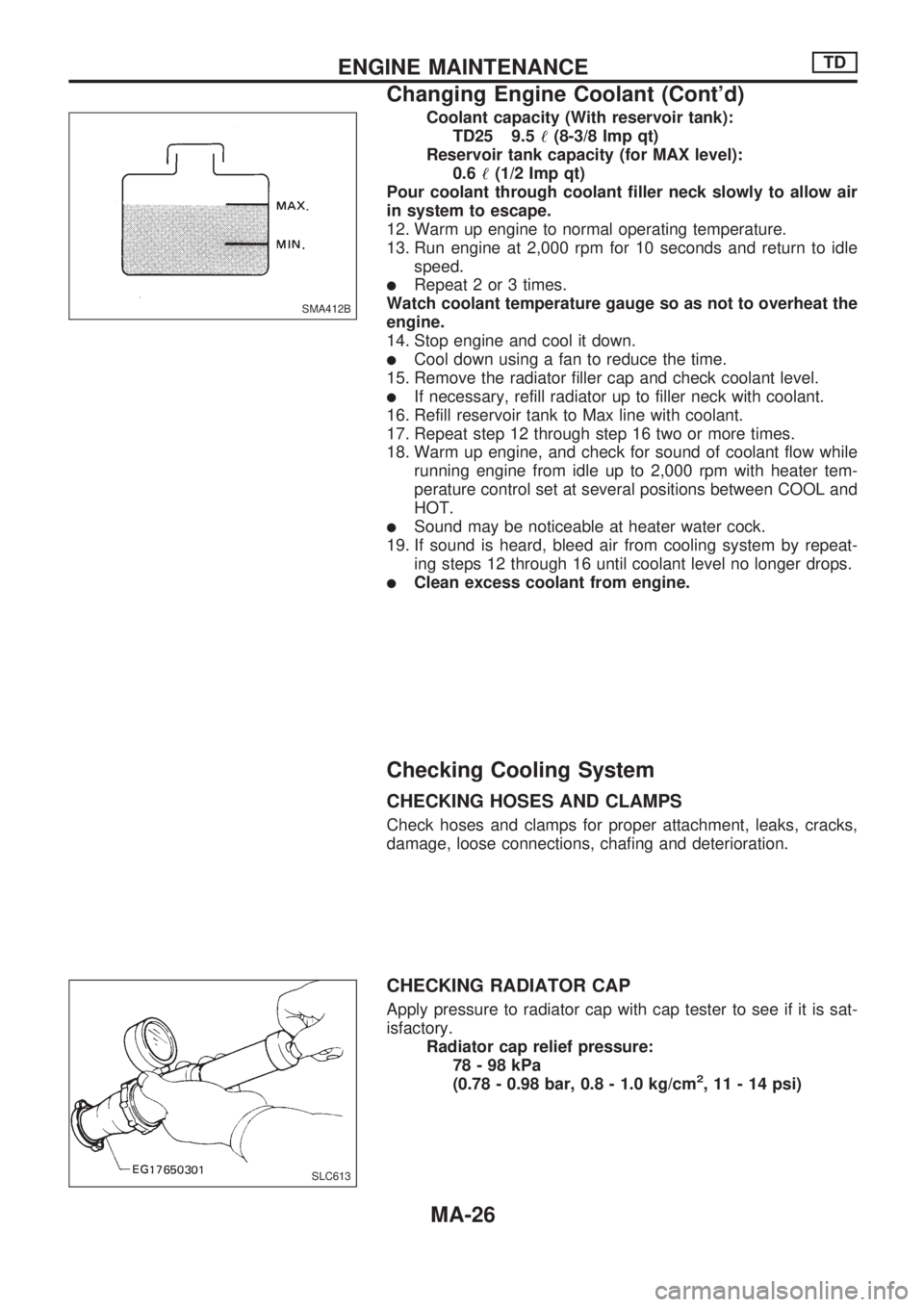

Coolant capacity (With reservoir tank):

TD25 9.5!(8-3/8 Imp qt)

Reservoir tank capacity (for MAX level):

0.6!(1/2 Imp qt)

Pour coolant through coolant filler neck slowly to allow air

in system to escape.

12. Warm up engine to normal operating temperature.

13. Run engine at 2,000 rpm for 10 seconds and return to idle

speed.

lRepeat 2 or 3 times.

Watch coolant temperature gauge so as not to overheat the

engine.

14. Stop engine and cool it down.

lCool down using a fan to reduce the time.

15. Remove the radiator filler cap and check coolant level.

lIf necessary, refill radiator up to filler neck with coolant.

16. Refill reservoir tank to Max line with coolant.

17. Repeat step 12 through step 16 two or more times.

18. Warm up engine, and check for sound of coolant flow while

running engine from idle up to 2,000 rpm with heater tem-

perature control set at several positions between COOL and

HOT.

lSound may be noticeable at heater water cock.

19. If sound is heard, bleed air from cooling system by repeat-

ing steps 12 through 16 until coolant level no longer drops.

lClean excess coolant from engine.

Checking Cooling System

CHECKING HOSES AND CLAMPS

Check hoses and clamps for proper attachment, leaks, cracks,

damage, loose connections, chafing and deterioration.

CHECKING RADIATOR CAP

Apply pressure to radiator cap with cap tester to see if it is sat-

isfactory.

Radiator cap relief pressure:

78-98kPa

(0.78 - 0.98 bar, 0.8 - 1.0 kg/cm

2, 11 - 14 psi)

SMA412B

SLC613

ENGINE MAINTENANCETD

Changing Engine Coolant (Cont'd)

MA-26