cooling NISSAN PICK-UP 1998 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 1 of 1659

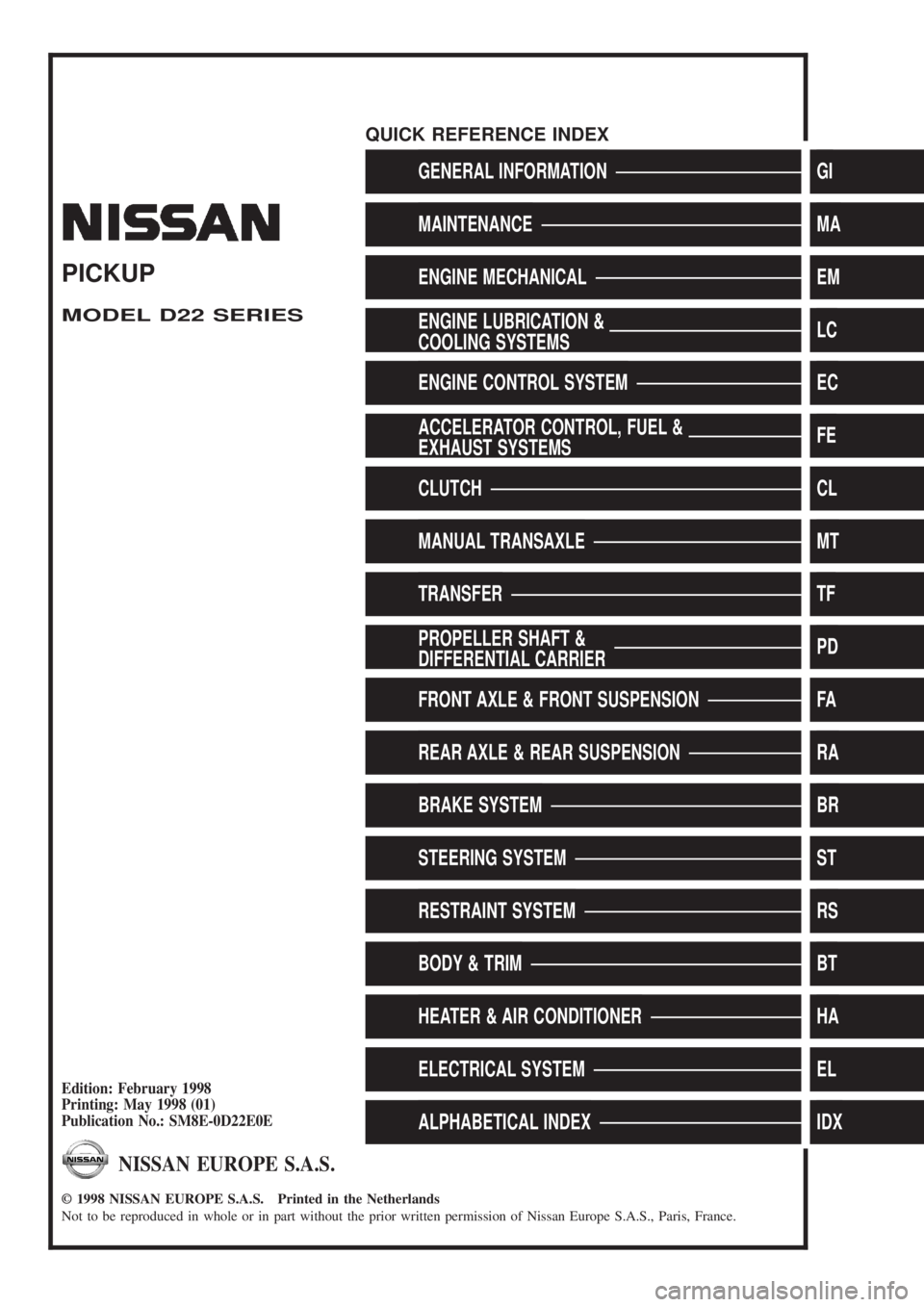

GENERAL INFORMATIONGI

MAINTENANCEMA

ENGINE MECHANICALEM

ENGINE LUBRICATION &

COOLING SYSTEMSLC

ENGINE CONTROL SYSTEMEC

ACCELERATOR CONTROL, FUEL &

EXHAUST SYSTEMSFE

CLUTCHCL

MANUAL TRANSAXLEMT

TRANSFERTF

PROPELLER SHAFT &

DIFFERENTIAL CARRIERPD

FRONT AXLE & FRONT SUSPENSIONFA

REAR AXLE & REAR SUSPENSIONRA

BRAKE SYSTEMBR

STEERING SYSTEMST

RESTRAINT SYSTEMRS

BODY & TRIMBT

HEATER & AIR CONDITIONERHA

ELECTRICAL SYSTEMEL

ALPHABETICAL INDEXIDX

PICKUP

MODEL D22 SERIES

Edition: February 1998

Printing: May 1998 (01)

Publication No.: SM8E-0D22E0E

NISSAN EUROPE S.A.S.

1998 NISSAN EUROPE S.A.S. Printed in the Netherlands

Not to be reproduced in whole or in part without the prior written permission of Nissan Europe S.A.S., Paris, France.

QUICK REFERENCE INDEX

Page 215 of 1659

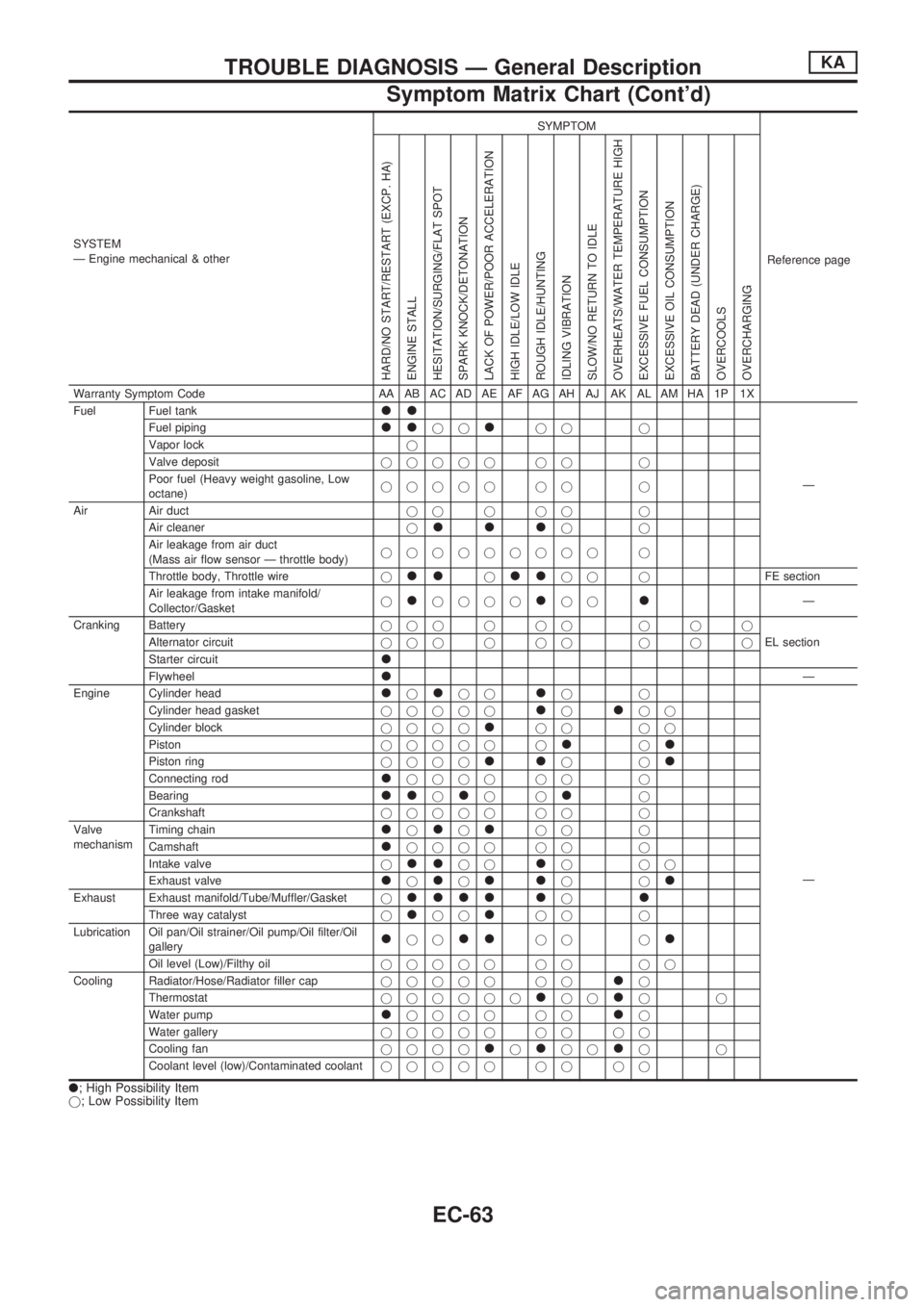

SYSTEM

Ð Engine mechanical & otherSYMPTOM

Reference page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

OVERCOOLS

OVERCHARGING

Warranty Symptom Code AA AB AC AD AE AF AG AH AJ AK AL AM HA 1P 1X

Fuel Fuel tank

ll

Ð Fuel piping

lljjljj j

Vapor lockj

Valve depositjjjjj jj j

Poor fuel (Heavy weight gasoline, Low

octane)jjjjj jj j

Air Air ductjjjjj j

Air cleanerj

llljj

Air leakage from air duct

(Mass air flow sensor Ð throttle body)jjjjjjjjj j

Throttle body, Throttle wirej

lljlljj jFE section

Air leakage from intake manifold/

Collector/Gasketj

ljjjjljjlÐ

Cranking Batteryjjjjjj jjj

EL section Alternator circuitjjjjjj jjj

Starter circuit

l

FlywheellÐ

Engine Cylinder head

ljljjljj

Ð Cylinder head gasketjjjjj

ljljj

Cylinder blockjjjj

ljj jj

Pistonjjjjj j

ljl

Piston ringjjjjlljjl

Connecting rodljjjj jj j

Bearing

lljljjlj

Crankshaftjjjjj jj j

Valve

mechanismTiming chain

ljljljj j

Camshaft

ljjjj jj j

Intake valvej

lljjljjj

Exhaust valve

ljljlljjl

Exhaust Exhaust manifold/Tube/Muffler/Gasketjllll ljl

Three way catalystjljjljj j

Lubrication Oil pan/Oil strainer/Oil pump/Oil filter/Oil

gallery

ljjlljj jl

Oil level (Low)/Filthy oiljjjjj jj jj

Cooling Radiator/Hose/Radiator filler capjjjjj jj

lj

Thermostatjjjjjj

ljjljj

Water pump

ljjjj jjlj

Water galleryjjjjj jj jj

Cooling fanjjjj

ljljjljj

Coolant level (low)/Contaminated coolantjjjjj jj jj

l; High Possibility Item

j; Low Possibility Item

TROUBLE DIAGNOSIS Ð General DescriptionKA

Symptom Matrix Chart (Cont'd)

EC-63

Page 258 of 1659

Overheat

ON BOARD DIAGNOSIS LOGIC

If the cooling fan or another component in the cooling system malfunctions, the engine coolant temperature

will rise.

When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction is

indicated.

Diagnostic trouble

code No.Malfunction is detected when ...Check Items

(Possible Cause)

28

lEngine coolant temperature reaches an abnormally

high temperature.lCooling fan

lRadiator hose

lRadiator

lRadiator cap

lWater pump

lThermostat

For more information, refer to ``MAIN 12

CAUSES OF OVERHEATING'', EC-108.

CAUTION:

When a malfunction is indicated, be sure to replace the coolant following the procedure in MA sec-

tion (``Changing Engine Coolant'', ``ENGINE MAINTENANCE''). Also, replace the engine oil.

lFill radiator with coolant up to specified level with a filling speed of 2 liters per minute like pour-

ing coolant by kettle. Be sure to use coolant with the proper mixture ratio. Refer to MA section

(``Anti-freeze Coolant Mixture Ratio'', ``RECOMMENDED FLUIDS AND LUBRICANTS'').

lAfter refilling coolant, run engine to ensure that no water-flow noise is emitted.

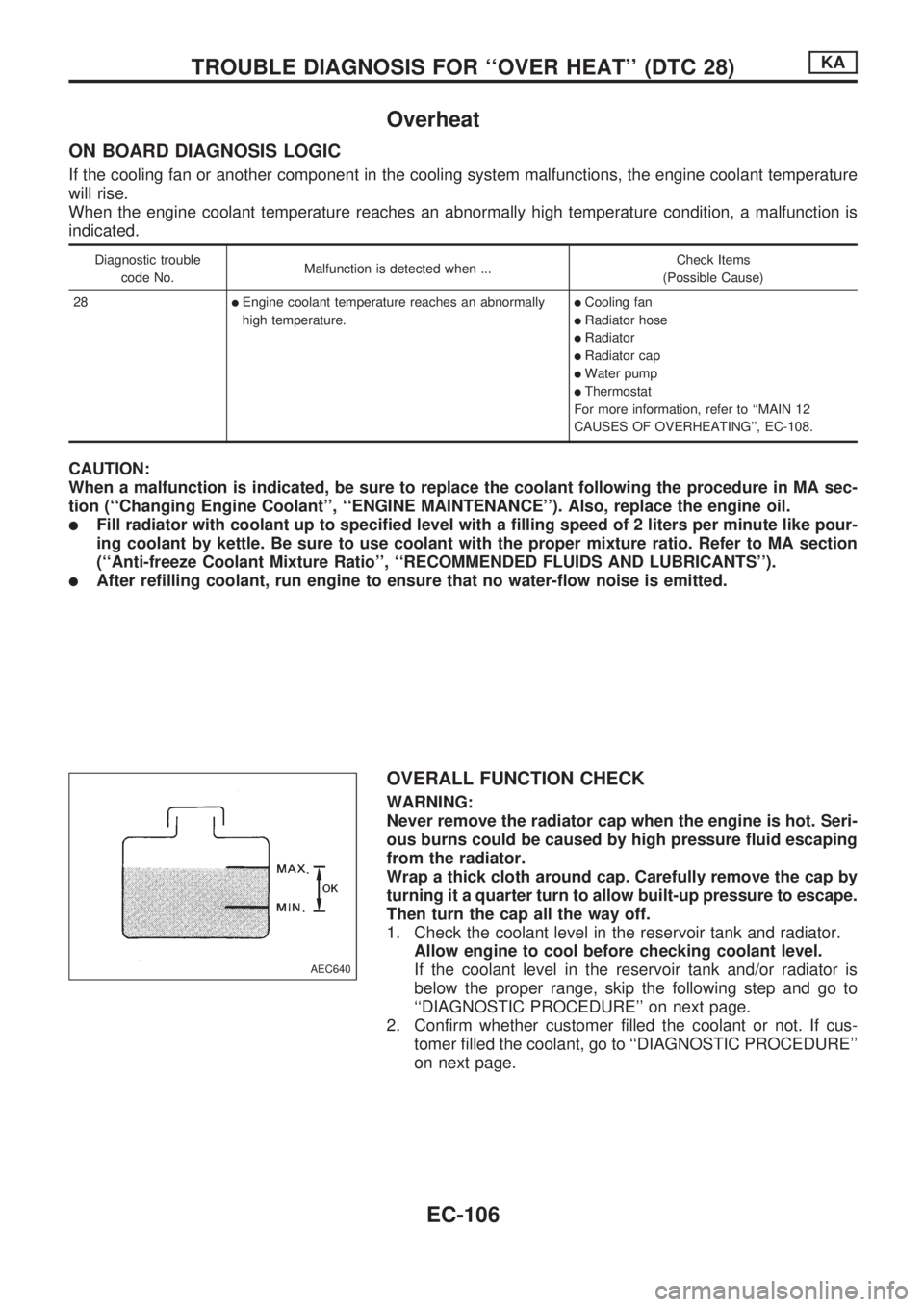

OVERALL FUNCTION CHECK

WARNING:

Never remove the radiator cap when the engine is hot. Seri-

ous burns could be caused by high pressure fluid escaping

from the radiator.

Wrap a thick cloth around cap. Carefully remove the cap by

turning it a quarter turn to allow built-up pressure to escape.

Then turn the cap all the way off.

1. Check the coolant level in the reservoir tank and radiator.

Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is

below the proper range, skip the following step and go to

``DIAGNOSTIC PROCEDURE'' on next page.

2. Confirm whether customer filled the coolant or not. If cus-

tomer filled the coolant, go to ``DIAGNOSTIC PROCEDURE''

on next page.

AEC640

TROUBLE DIAGNOSIS FOR ``OVER HEAT'' (DTC 28)KA

EC-106

Page 259 of 1659

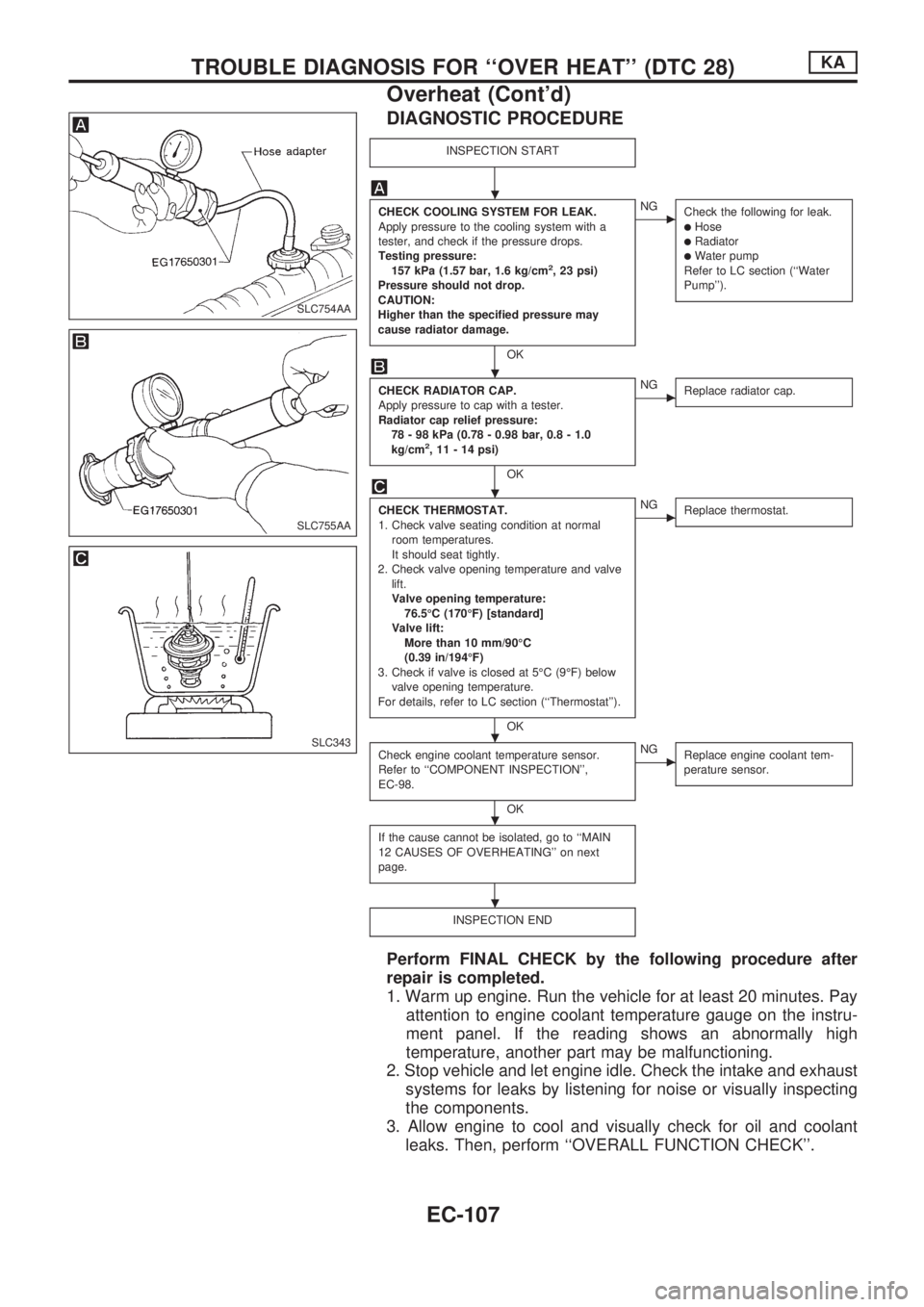

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK COOLING SYSTEM FOR LEAK.

Apply pressure to the cooling system with a

tester, and check if the pressure drops.

Testing pressure:

157 kPa (1.57 bar, 1.6 kg/cm

2, 23 psi)

Pressure should not drop.

CAUTION:

Higher than the specified pressure may

cause radiator damage.

OK

cNG

Check the following for leak.

lHoselRadiatorlWater pump

Refer to LC section (``Water

Pump'').

CHECK RADIATOR CAP.

Apply pressure to cap with a tester.

Radiator cap relief pressure:

78 - 98 kPa (0.78 - 0.98 bar, 0.8 - 1.0

kg/cm

2, 11 - 14 psi)

OK

cNG

Replace radiator cap.

CHECK THERMOSTAT.

1. Check valve seating condition at normal

room temperatures.

It should seat tightly.

2. Check valve opening temperature and valve

lift.

Valve opening temperature:

76.5ÉC (170ÉF) [standard]

Valve lift:

More than 10 mm/90ÉC

(0.39 in/194ÉF)

3. Check if valve is closed at 5ÉC (9ÉF) below

valve opening temperature.

For details, refer to LC section (``Thermostat'').

OK

cNG

Replace thermostat.

Check engine coolant temperature sensor.

Refer to ``COMPONENT INSPECTION'',

EC-98.

OK

cNG

Replace engine coolant tem-

perature sensor.

If the cause cannot be isolated, go to ``MAIN

12 CAUSES OF OVERHEATING'' on next

page.

INSPECTION END

Perform FINAL CHECK by the following procedure after

repair is completed.

1. Warm up engine. Run the vehicle for at least 20 minutes. Pay

attention to engine coolant temperature gauge on the instru-

ment panel. If the reading shows an abnormally high

temperature, another part may be malfunctioning.

2. Stop vehicle and let engine idle. Check the intake and exhaust

systems for leaks by listening for noise or visually inspecting

the components.

3. Allow engine to cool and visually check for oil and coolant

leaks. Then, perform ``OVERALL FUNCTION CHECK''.

SLC754AA

SLC755AA

SLC343

.

.

.

.

.

.

TROUBLE DIAGNOSIS FOR ``OVER HEAT'' (DTC 28)KA

Overheat (Cont'd)

EC-107

Page 260 of 1659

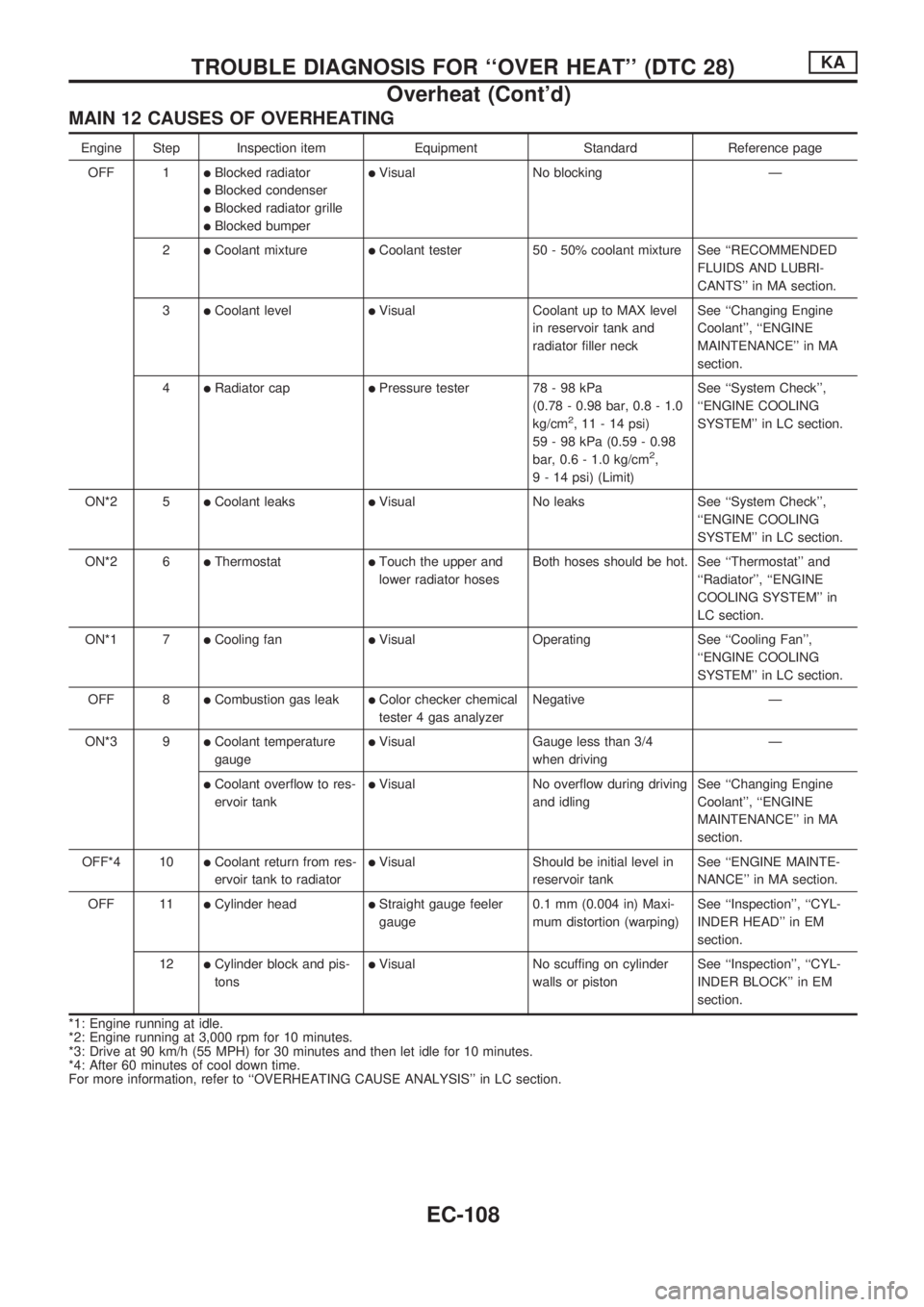

MAIN 12 CAUSES OF OVERHEATING

Engine Step Inspection item Equipment Standard Reference page

OFF 1

lBlocked radiator

lBlocked condenser

lBlocked radiator grille

lBlocked bumper

lVisual No blocking Ð

2

lCoolant mixturelCoolant tester 50 - 50% coolant mixture See ``RECOMMENDED

FLUIDS AND LUBRI-

CANTS'' in MA section.

3

lCoolant levellVisual Coolant up to MAX level

in reservoir tank and

radiator filler neckSee ``Changing Engine

Coolant'', ``ENGINE

MAINTENANCE'' in MA

section.

4

lRadiator caplPressure tester 78 - 98 kPa

(0.78 - 0.98 bar, 0.8 - 1.0

kg/cm

2, 11 - 14 psi)

59 - 98 kPa (0.59 - 0.98

bar, 0.6 - 1.0 kg/cm

2,

9 - 14 psi) (Limit)See ``System Check'',

``ENGINE COOLING

SYSTEM'' in LC section.

ON*2 5

lCoolant leakslVisual No leaks See ``System Check'',

``ENGINE COOLING

SYSTEM'' in LC section.

ON*2 6

lThermostatlTouch the upper and

lower radiator hosesBoth hoses should be hot. See ``Thermostat'' and

``Radiator'', ``ENGINE

COOLING SYSTEM'' in

LC section.

ON*1 7

lCooling fanlVisual Operating See ``Cooling Fan'',

``ENGINE COOLING

SYSTEM'' in LC section.

OFF 8

lCombustion gas leaklColor checker chemical

tester 4 gas analyzerNegative Ð

ON*3 9

lCoolant temperature

gaugelVisual Gauge less than 3/4

when drivingÐ

lCoolant overflow to res-

ervoir tanklVisual No overflow during driving

and idlingSee ``Changing Engine

Coolant'', ``ENGINE

MAINTENANCE'' in MA

section.

OFF*4 10

lCoolant return from res-

ervoir tank to radiatorlVisual Should be initial level in

reservoir tankSee ``ENGINE MAINTE-

NANCE'' in MA section.

OFF 11

lCylinder headlStraight gauge feeler

gauge0.1 mm (0.004 in) Maxi-

mum distortion (warping)See ``Inspection'', ``CYL-

INDER HEAD'' in EM

section.

12

lCylinder block and pis-

tonslVisual No scuffing on cylinder

walls or pistonSee ``Inspection'', ``CYL-

INDER BLOCK'' in EM

section.

*1: Engine running at idle.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

For more information, refer to ``OVERHEATING CAUSE ANALYSIS'' in LC section.

TROUBLE DIAGNOSIS FOR ``OVER HEAT'' (DTC 28)KA

Overheat (Cont'd)

EC-108

Page 390 of 1659

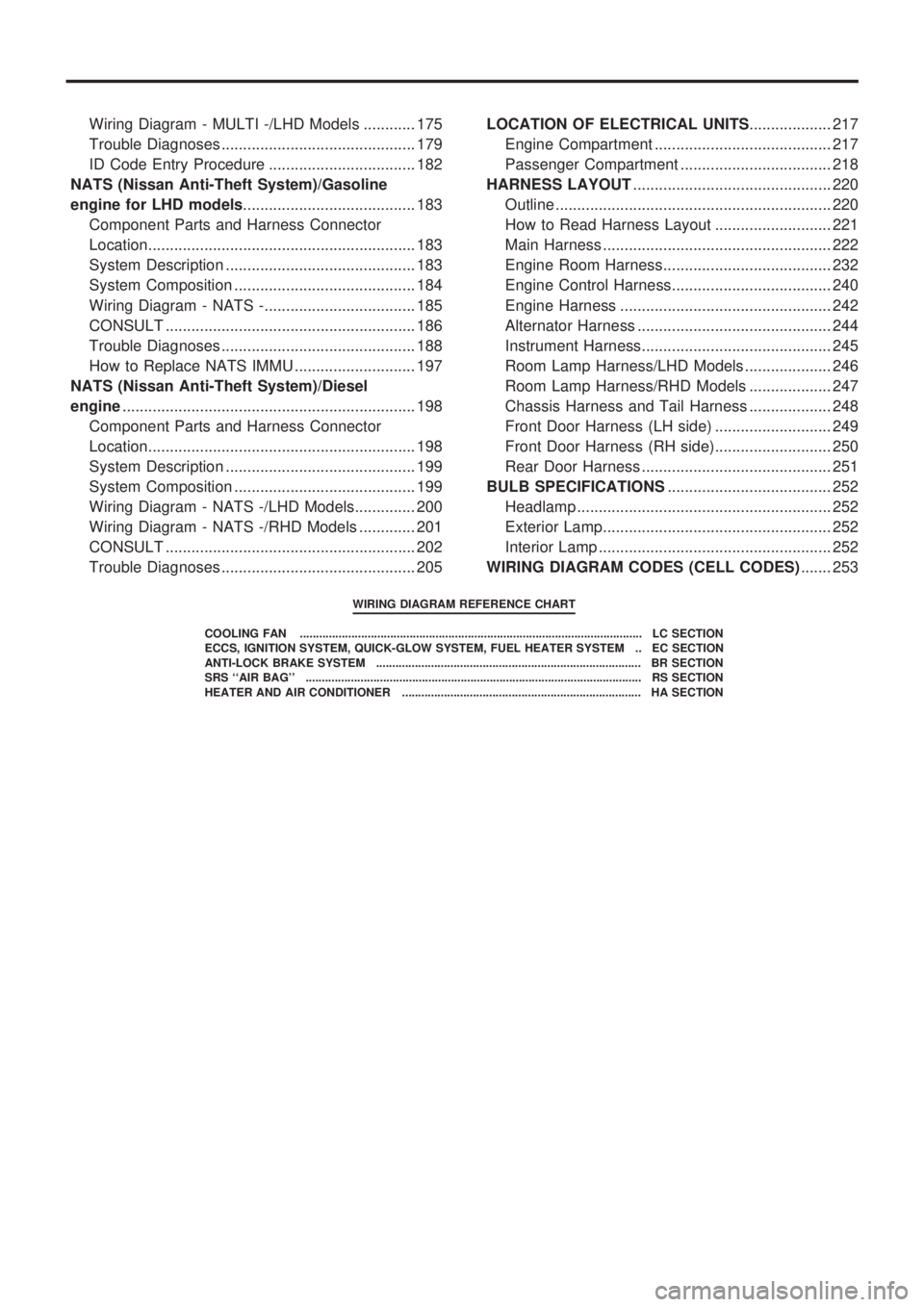

Wiring Diagram - MULTI -/LHD Models ............ 175

Trouble Diagnoses ............................................. 179

ID Code Entry Procedure .................................. 182

NATS (Nissan Anti-Theft System)/Gasoline

engine for LHD models........................................ 183

Component Parts and Harness Connector

Location.............................................................. 183

System Description ............................................ 183

System Composition .......................................... 184

Wiring Diagram - NATS -................................... 185

CONSULT .......................................................... 186

Trouble Diagnoses ............................................. 188

How to Replace NATS IMMU ............................ 197

NATS (Nissan Anti-Theft System)/Diesel

engine.................................................................... 198

Component Parts and Harness Connector

Location.............................................................. 198

System Description ............................................ 199

System Composition .......................................... 199

Wiring Diagram - NATS -/LHD Models.............. 200

Wiring Diagram - NATS -/RHD Models ............. 201

CONSULT .......................................................... 202

Trouble Diagnoses ............................................. 205LOCATION OF ELECTRICAL UNITS................... 217

Engine Compartment ......................................... 217

Passenger Compartment ................................... 218

HARNESS LAYOUT.............................................. 220

Outline ................................................................ 220

How to Read Harness Layout ........................... 221

Main Harness ..................................................... 222

Engine Room Harness....................................... 232

Engine Control Harness..................................... 240

Engine Harness ................................................. 242

Alternator Harness ............................................. 244

Instrument Harness............................................ 245

Room Lamp Harness/LHD Models .................... 246

Room Lamp Harness/RHD Models ................... 247

Chassis Harness and Tail Harness ................... 248

Front Door Harness (LH side) ........................... 249

Front Door Harness (RH side)........................... 250

Rear Door Harness ............................................ 251

BULB SPECIFICATIONS...................................... 252

Headlamp ........................................................... 252

Exterior Lamp..................................................... 252

Interior Lamp ...................................................... 252

WIRING DIAGRAM CODES (CELL CODES)....... 253

WIRING DIAGRAM REFERENCE CHART

COOLING FAN .......................................................................................................... LC SECTION

ECCS, IGNITION SYSTEM, QUICK-GLOW SYSTEM, FUEL HEATER SYSTEM .. EC SECTION

ANTI-LOCK BRAKE SYSTEM .................................................................................. BR SECTION

SRS ``AIR BAG'' ........................................................................................................ RS SECTION

HEATER AND AIR CONDITIONER .......................................................................... HA SECTION

Page 406 of 1659

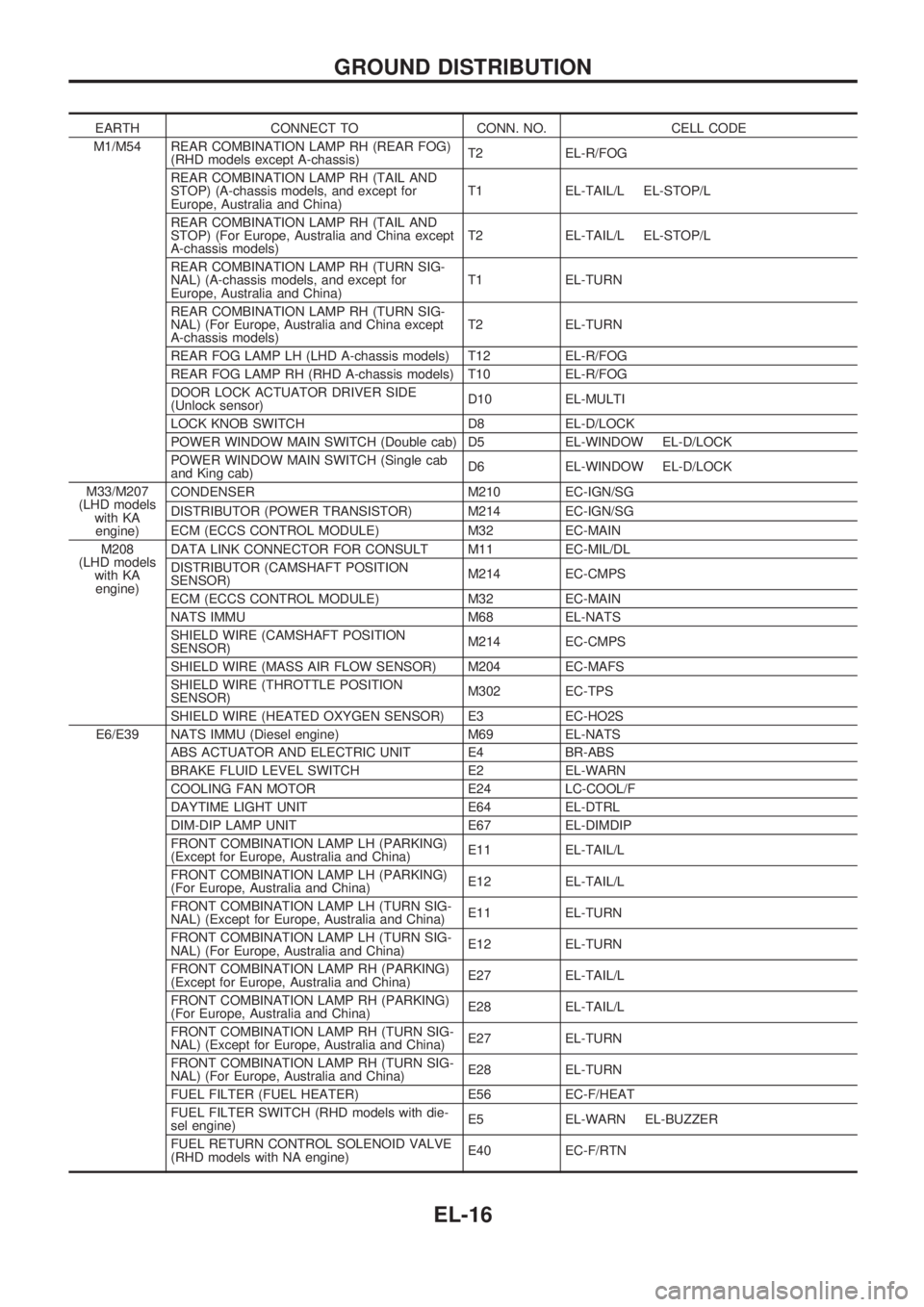

EARTH CONNECT TO CONN. NO. CELL CODE

M1/M54 REAR COMBINATION LAMP RH (REAR FOG)

(RHD models except A-chassis)T2 EL-R/FOG

REAR COMBINATION LAMP RH (TAIL AND

STOP) (A-chassis models, and except for

Europe, Australia and China)T1 EL-TAIL/L EL-STOP/L

REAR COMBINATION LAMP RH (TAIL AND

STOP) (For Europe, Australia and China except

A-chassis models)T2 EL-TAIL/L EL-STOP/L

REAR COMBINATION LAMP RH (TURN SIG-

NAL) (A-chassis models, and except for

Europe, Australia and China)T1 EL-TURN

REAR COMBINATION LAMP RH (TURN SIG-

NAL) (For Europe, Australia and China except

A-chassis models)T2 EL-TURN

REAR FOG LAMP LH (LHD A-chassis models) T12 EL-R/FOG

REAR FOG LAMP RH (RHD A-chassis models) T10 EL-R/FOG

DOOR LOCK ACTUATOR DRIVER SIDE

(Unlock sensor)D10 EL-MULTI

LOCK KNOB SWITCH D8 EL-D/LOCK

POWER WINDOW MAIN SWITCH (Double cab) D5 EL-WINDOW EL-D/LOCK

POWER WINDOW MAIN SWITCH (Single cab

and King cab)D6 EL-WINDOW EL-D/LOCK

M33/M207

(LHD models

with KA

engine)CONDENSER M210 EC-IGN/SG

DISTRIBUTOR (POWER TRANSISTOR) M214 EC-IGN/SG

ECM (ECCS CONTROL MODULE) M32 EC-MAIN

M208

(LHD models

with KA

engine)DATA LINK CONNECTOR FOR CONSULT M11 EC-MIL/DL

DISTRIBUTOR (CAMSHAFT POSITION

SENSOR)M214 EC-CMPS

ECM (ECCS CONTROL MODULE) M32 EC-MAIN

NATS IMMU M68 EL-NATS

SHIELD WIRE (CAMSHAFT POSITION

SENSOR)M214 EC-CMPS

SHIELD WIRE (MASS AIR FLOW SENSOR) M204 EC-MAFS

SHIELD WIRE (THROTTLE POSITION

SENSOR)M302 EC-TPS

SHIELD WIRE (HEATED OXYGEN SENSOR) E3 EC-HO2S

E6/E39 NATS IMMU (Diesel engine) M69 EL-NATS

ABS ACTUATOR AND ELECTRIC UNIT E4 BR-ABS

BRAKE FLUID LEVEL SWITCH E2 EL-WARN

COOLING FAN MOTOR E24 LC-COOL/F

DAYTIME LIGHT UNIT E64 EL-DTRL

DIM-DIP LAMP UNIT E67 EL-DIMDIP

FRONT COMBINATION LAMP LH (PARKING)

(Except for Europe, Australia and China)E11 EL-TAIL/L

FRONT COMBINATION LAMP LH (PARKING)

(For Europe, Australia and China)E12 EL-TAIL/L

FRONT COMBINATION LAMP LH (TURN SIG-

NAL) (Except for Europe, Australia and China)E11 EL-TURN

FRONT COMBINATION LAMP LH (TURN SIG-

NAL) (For Europe, Australia and China)E12 EL-TURN

FRONT COMBINATION LAMP RH (PARKING)

(Except for Europe, Australia and China)E27 EL-TAIL/L

FRONT COMBINATION LAMP RH (PARKING)

(For Europe, Australia and China)E28 EL-TAIL/L

FRONT COMBINATION LAMP RH (TURN SIG-

NAL) (Except for Europe, Australia and China)E27 EL-TURN

FRONT COMBINATION LAMP RH (TURN SIG-

NAL) (For Europe, Australia and China)E28 EL-TURN

FUEL FILTER (FUEL HEATER) E56 EC-F/HEAT

FUEL FILTER SWITCH (RHD models with die-

sel engine)E5 EL-WARN EL-BUZZER

FUEL RETURN CONTROL SOLENOID VALVE

(RHD models with NA engine)E40 EC-F/RTN

GROUND DISTRIBUTION

EL-16

Page 643 of 1659

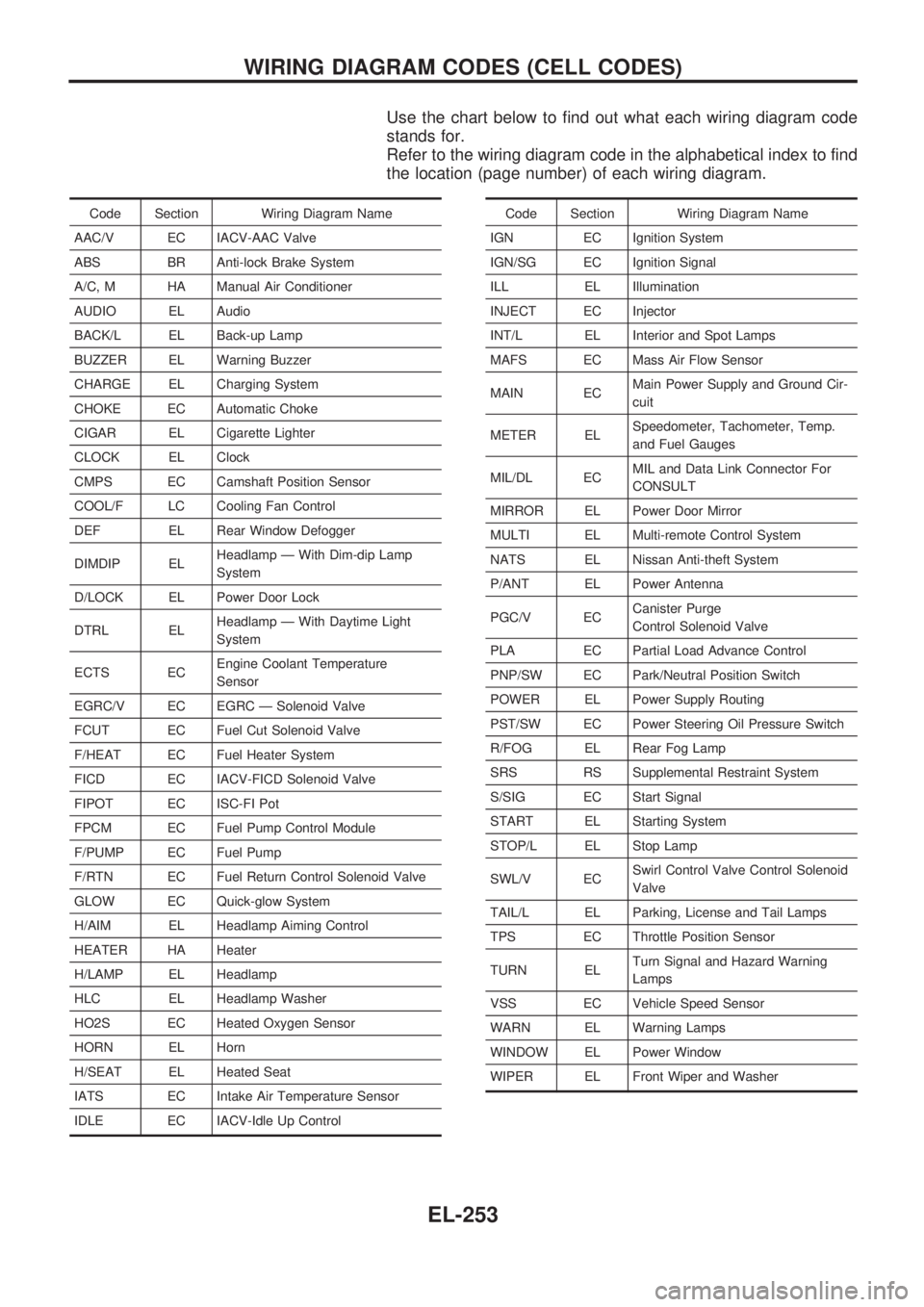

Use the chart below to find out what each wiring diagram code

stands for.

Refer to the wiring diagram code in the alphabetical index to find

the location (page number) of each wiring diagram.

Code Section Wiring Diagram Name

AAC/V EC IACV-AAC Valve

ABS BR Anti-lock Brake System

A/C, M HA Manual Air Conditioner

AUDIO EL Audio

BACK/L EL Back-up Lamp

BUZZER EL Warning Buzzer

CHARGE EL Charging System

CHOKE EC Automatic Choke

CIGAR EL Cigarette Lighter

CLOCK EL Clock

CMPS EC Camshaft Position Sensor

COOL/F LC Cooling Fan Control

DEF EL Rear Window Defogger

DIMDIP ELHeadlamp Ð With Dim-dip Lamp

System

D/LOCK EL Power Door Lock

DTRL ELHeadlamp Ð With Daytime Light

System

ECTS ECEngine Coolant Temperature

Sensor

EGRC/V EC EGRC Ð Solenoid Valve

FCUT EC Fuel Cut Solenoid Valve

F/HEAT EC Fuel Heater System

FICD EC IACV-FICD Solenoid Valve

FIPOT EC ISC-FI Pot

FPCM EC Fuel Pump Control Module

F/PUMP EC Fuel Pump

F/RTN EC Fuel Return Control Solenoid Valve

GLOW EC Quick-glow System

H/AIM EL Headlamp Aiming Control

HEATER HA Heater

H/LAMP EL Headlamp

HLC EL Headlamp Washer

HO2S EC Heated Oxygen Sensor

HORN EL Horn

H/SEAT EL Heated Seat

IATS EC Intake Air Temperature Sensor

IDLE EC IACV-Idle Up ControlCode Section Wiring Diagram Name

IGN EC Ignition System

IGN/SG EC Ignition Signal

ILL EL Illumination

INJECT EC Injector

INT/L EL Interior and Spot Lamps

MAFS EC Mass Air Flow Sensor

MAIN ECMain Power Supply and Ground Cir-

cuit

METER ELSpeedometer, Tachometer, Temp.

and Fuel Gauges

MIL/DL ECMIL and Data Link Connector For

CONSULT

MIRROR EL Power Door Mirror

MULTI EL Multi-remote Control System

NATS EL Nissan Anti-theft System

P/ANT EL Power Antenna

PGC/V ECCanister Purge

Control Solenoid Valve

PLA EC Partial Load Advance Control

PNP/SW EC Park/Neutral Position Switch

POWER EL Power Supply Routing

PST/SW EC Power Steering Oil Pressure Switch

R/FOG EL Rear Fog Lamp

SRS RS Supplemental Restraint System

S/SIG EC Start Signal

START EL Starting System

STOP/L EL Stop Lamp

SWL/V ECSwirl Control Valve Control Solenoid

Valve

TAIL/L EL Parking, License and Tail Lamps

TPS EC Throttle Position Sensor

TURN ELTurn Signal and Hazard Warning

Lamps

VSS EC Vehicle Speed Sensor

WARN EL Warning Lamps

WINDOW EL Power Window

WIPER EL Front Wiper and Washer

WIRING DIAGRAM CODES (CELL CODES)

EL-253

Page 658 of 1659

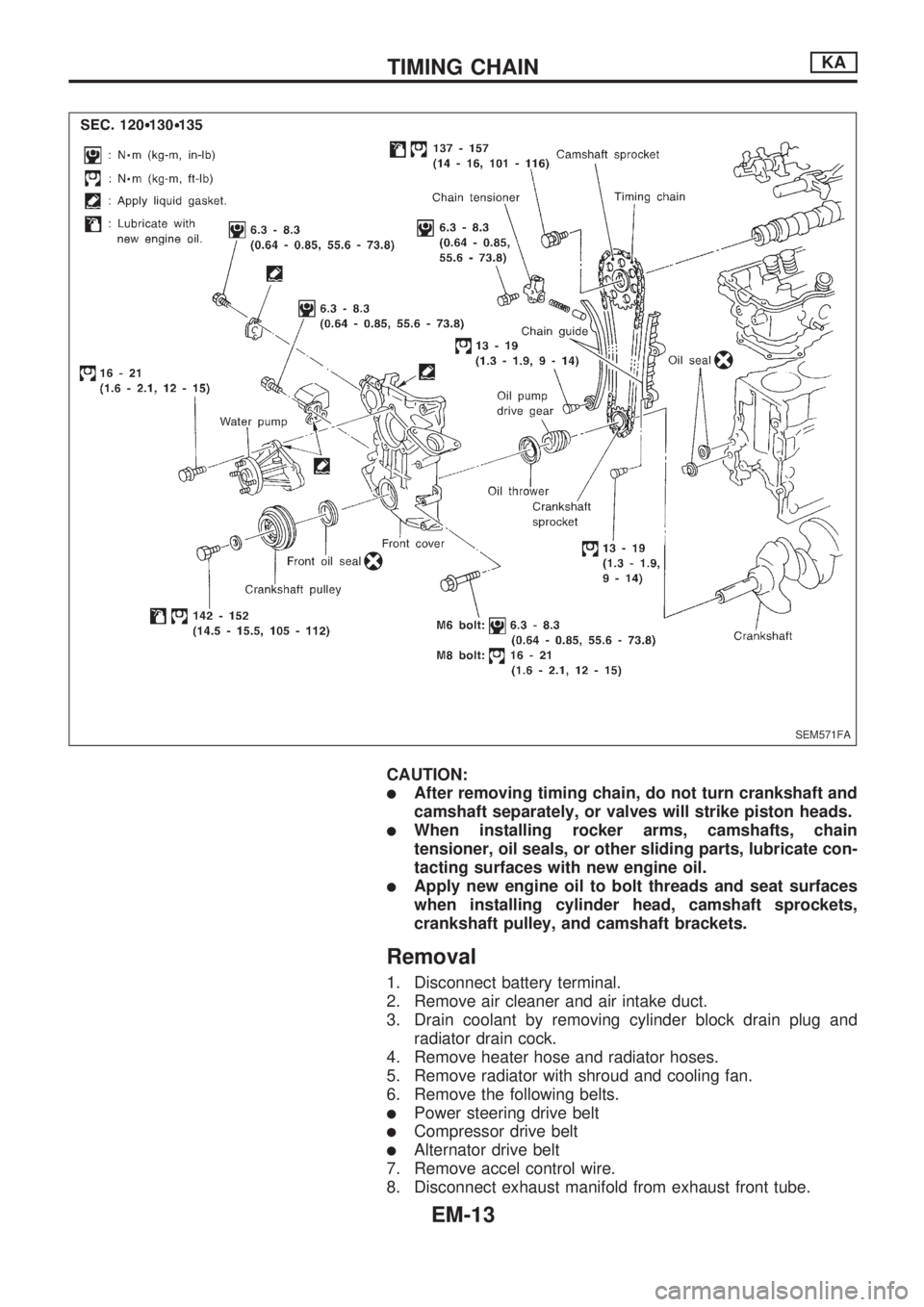

CAUTION:

lAfter removing timing chain, do not turn crankshaft and

camshaft separately, or valves will strike piston heads.

lWhen installing rocker arms, camshafts, chain

tensioner, oil seals, or other sliding parts, lubricate con-

tacting surfaces with new engine oil.

lApply new engine oil to bolt threads and seat surfaces

when installing cylinder head, camshaft sprockets,

crankshaft pulley, and camshaft brackets.

Removal

1. Disconnect battery terminal.

2. Remove air cleaner and air intake duct.

3. Drain coolant by removing cylinder block drain plug and

radiator drain cock.

4. Remove heater hose and radiator hoses.

5. Remove radiator with shroud and cooling fan.

6. Remove the following belts.

lPower steering drive belt

lCompressor drive belt

lAlternator drive belt

7. Remove accel control wire.

8. Disconnect exhaust manifold from exhaust front tube.

SEM571FA

TIMING CHAINKA

EM-13

Page 682 of 1659

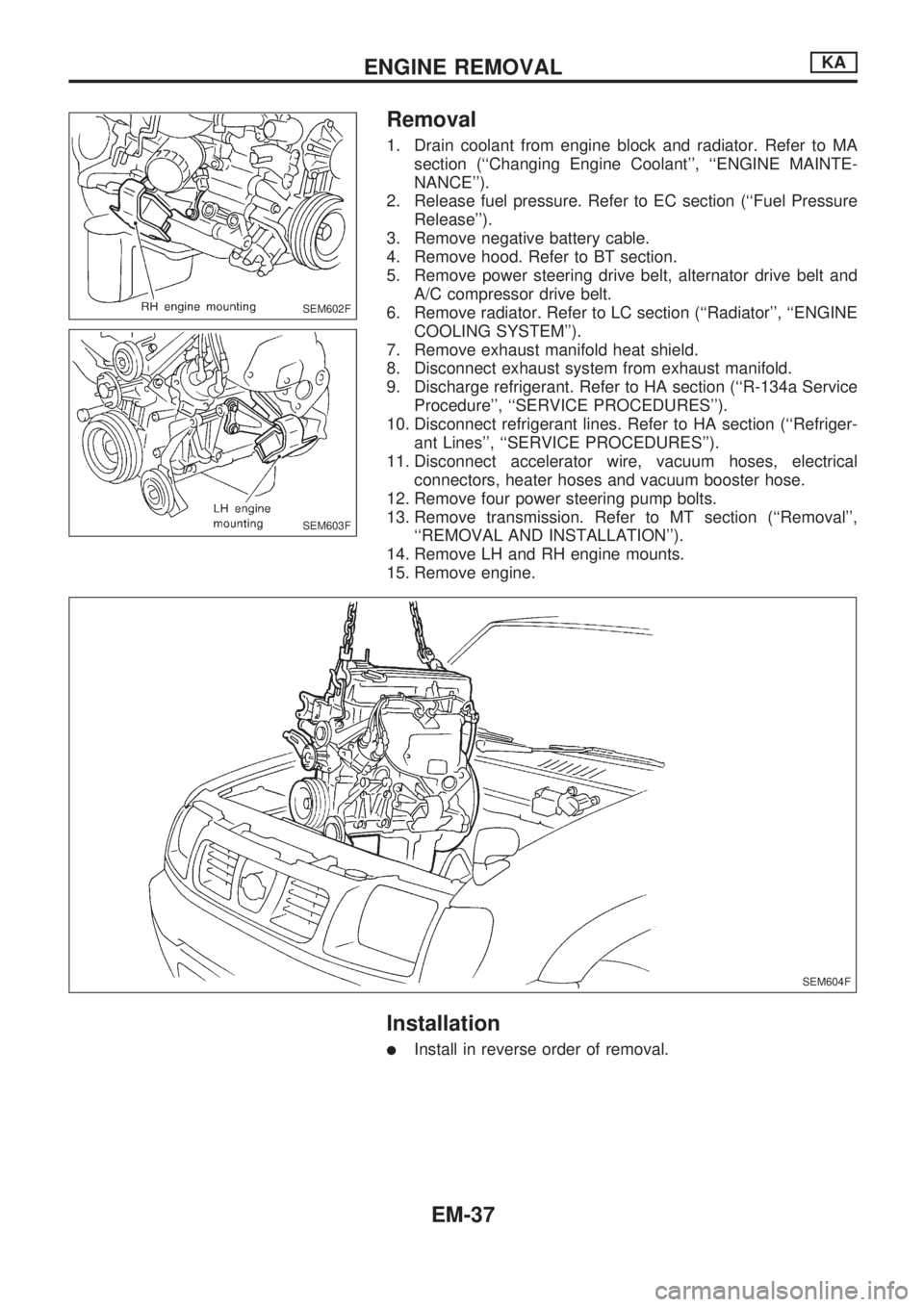

Removal

1. Drain coolant from engine block and radiator. Refer to MA

section (``Changing Engine Coolant'', ``ENGINE MAINTE-

NANCE'').

2. Release fuel pressure. Refer to EC section (``Fuel Pressure

Release'').

3. Remove negative battery cable.

4. Remove hood. Refer to BT section.

5. Remove power steering drive belt, alternator drive belt and

A/C compressor drive belt.

6. Remove radiator. Refer to LC section (``Radiator'', ``ENGINE

COOLING SYSTEM'').

7. Remove exhaust manifold heat shield.

8. Disconnect exhaust system from exhaust manifold.

9. Discharge refrigerant. Refer to HA section (``R-134a Service

Procedure'', ``SERVICE PROCEDURES'').

10. Disconnect refrigerant lines. Refer to HA section (``Refriger-

ant Lines'', ``SERVICE PROCEDURES'').

11. Disconnect accelerator wire, vacuum hoses, electrical

connectors, heater hoses and vacuum booster hose.

12. Remove four power steering pump bolts.

13. Remove transmission. Refer to MT section (``Removal'',

``REMOVAL AND INSTALLATION'').

14. Remove LH and RH engine mounts.

15. Remove engine.

Installation

lInstall in reverse order of removal.

SEM602F

SEM603F

SEM604F

ENGINE REMOVALKA

EM-37