seats NISSAN PICK-UP 1998 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 115 of 1659

Side and Floor Trim

CAUTION:

Wrap the tip of flat-bladed screwdriver with a cloth when removing metal clips from garnishes.

REMOVAL Ð Body side trim

Double cab model

V1Remove front and rear seats. Refer to ``SEAT'' for details, BT-30, 33.

V2Remove front and rear kicking plates.

V3Remove dash side lower finishers.

V4Remove front and rear body side welts.

V5Remove front pillar garnishes.

V6Remove center pillar garnishes.

V7Remove lock pillar garnishes.

Single cab model

V1Remove front seats. Refer to ``SEAT'' for details, BT-30.

V2Remove kicking plates.

V3Remove dash side lower finishers.

V4Remove body side welts.

V5Remove front pillar garnishes.

King cab model

V1Remove body side rear finishers.

V2Remove front seats and jump seats. Refer to ``SEAT'' for details, BT-30, 34.

V3Remove kicking plates.

V4Remove dash side lower finishers.

V5Remove front pillar garnishes.

V6Remove body side finishers.

V7Remove back panel garnish.

V8Remove rear pillar finishers.

V9Remove back panel finisher.

V10Remove body side welts.

V11Remove instrument stay cover lower center and center console. Refer to ``INSTRUMENT PANEL'' for

details, BT-12.

V12Remove accel stopper.

V13Remove rear floor trim.

V14Remove clips and accel stopper, then remove front floor trim.

INTERIOR TRIM

BT-15

Page 121 of 1659

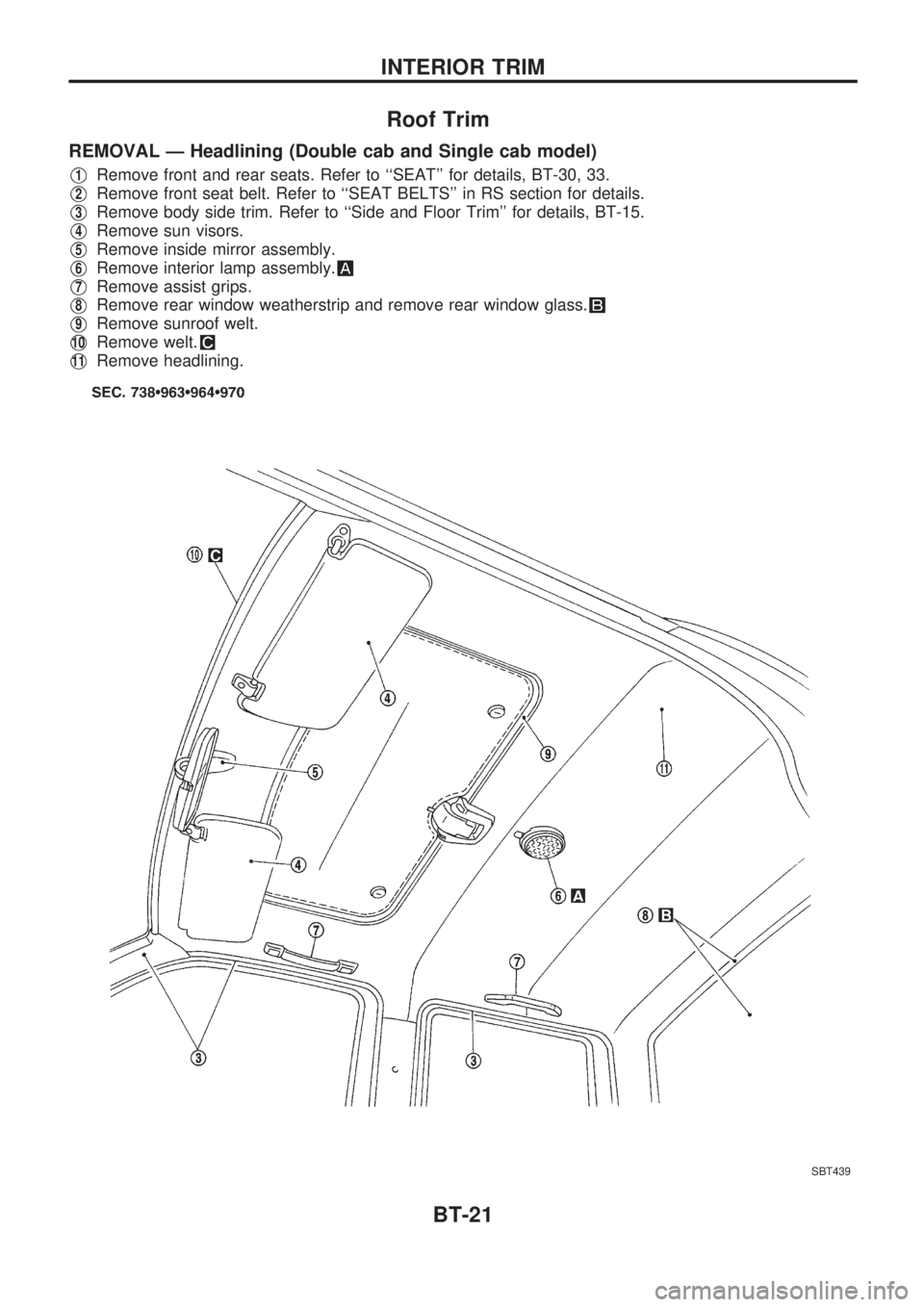

Roof Trim

REMOVAL Ð Headlining (Double cab and Single cab model)

V1Remove front and rear seats. Refer to ``SEAT'' for details, BT-30, 33.

V2Remove front seat belt. Refer to ``SEAT BELTS'' in RS section for details.

V3Remove body side trim. Refer to ``Side and Floor Trim'' for details, BT-15.

V4Remove sun visors.

V5Remove inside mirror assembly.

V6Remove interior lamp assembly.

V7Remove assist grips.

V8Remove rear window weatherstrip and remove rear window glass.

V9Remove sunroof welt.

V10Remove welt.

V11Remove headlining.

SBT439

INTERIOR TRIM

BT-21

Page 123 of 1659

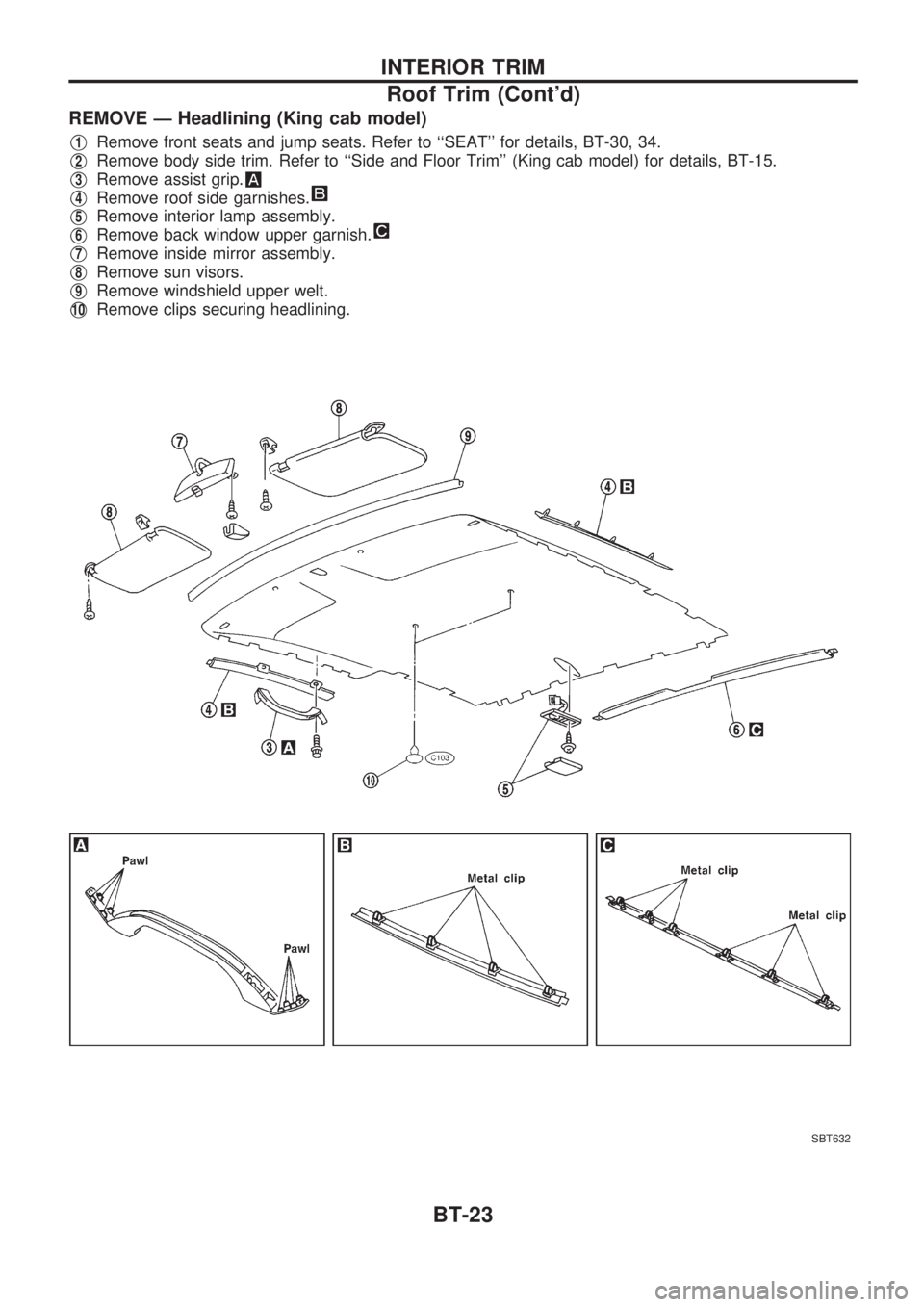

REMOVE Ð Headlining (King cab model)

V1Remove front seats and jump seats. Refer to ``SEAT'' for details, BT-30, 34.

V2Remove body side trim. Refer to ``Side and Floor Trim'' (King cab model) for details, BT-15.

V3Remove assist grip.

V4Remove roof side garnishes.

V5Remove interior lamp assembly.

V6Remove back window upper garnish.

V7Remove inside mirror assembly.

V8Remove sun visors.

V9Remove windshield upper welt.

V10Remove clips securing headlining.

SBT632

INTERIOR TRIM

Roof Trim (Cont'd)

BT-23

Page 676 of 1659

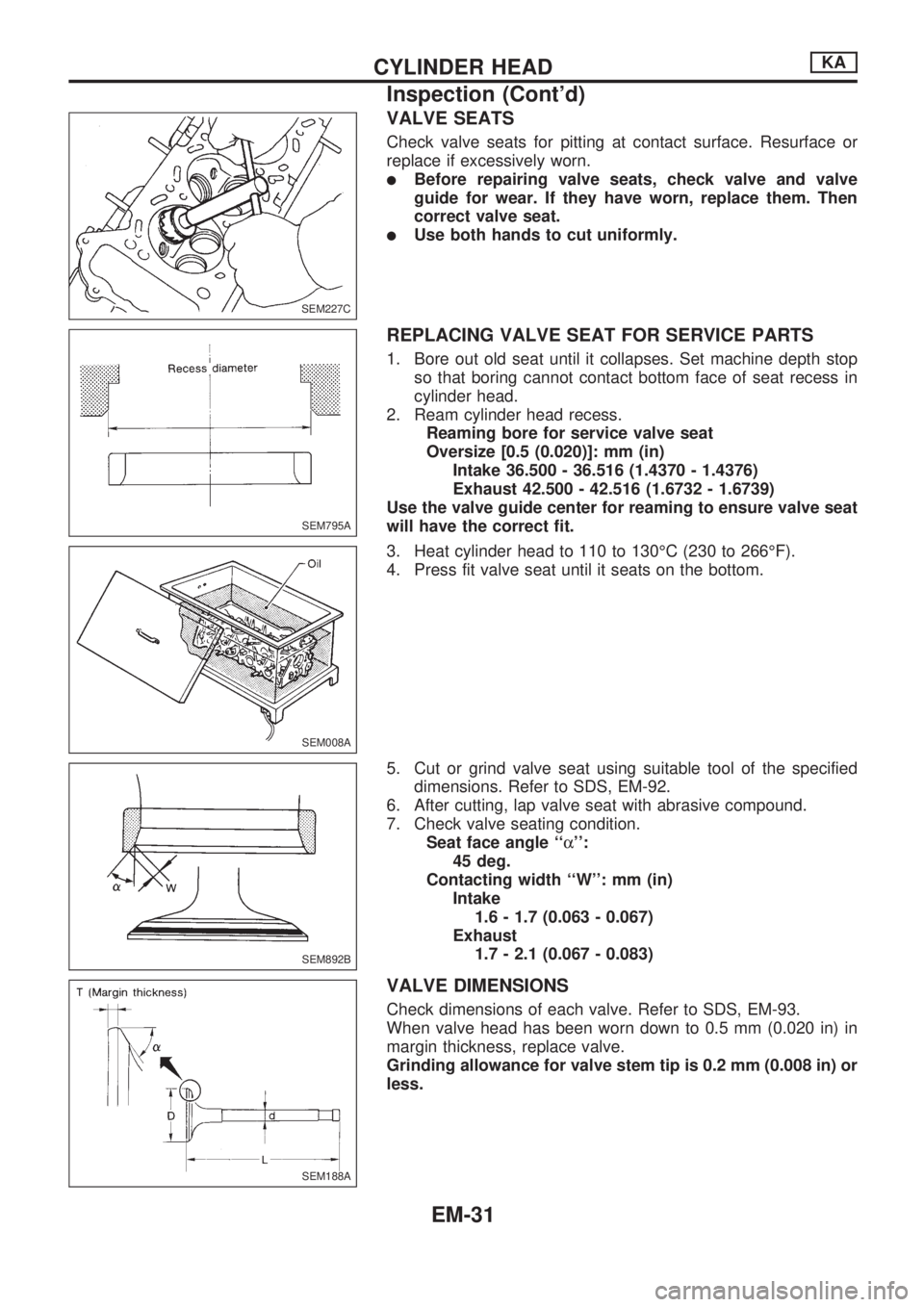

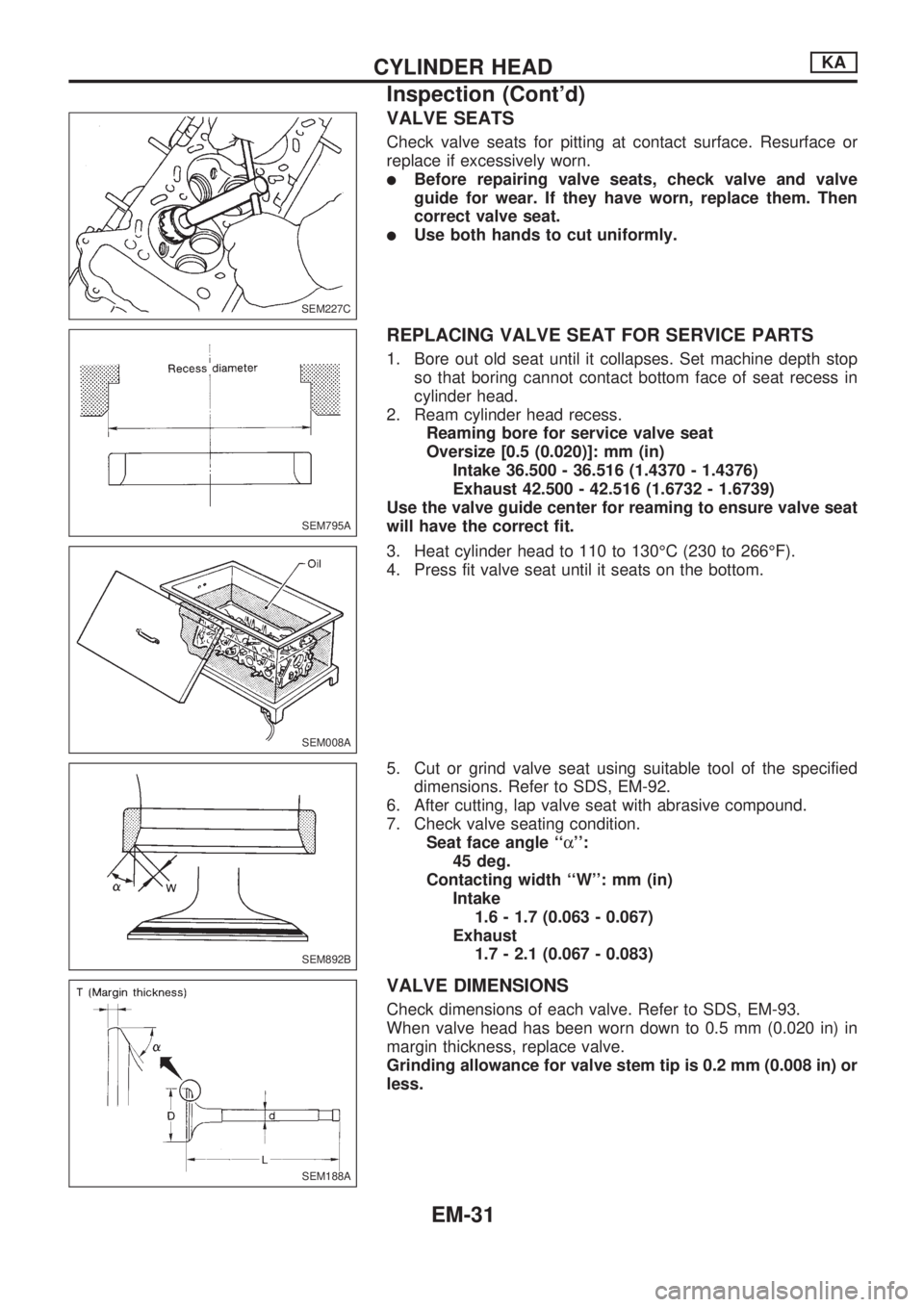

VALVE SEATS

Check valve seats for pitting at contact surface. Resurface or

replace if excessively worn.

lBefore repairing valve seats, check valve and valve

guide for wear. If they have worn, replace them. Then

correct valve seat.

lUse both hands to cut uniformly.

REPLACING VALVE SEAT FOR SERVICE PARTS

1. Bore out old seat until it collapses. Set machine depth stop

so that boring cannot contact bottom face of seat recess in

cylinder head.

2. Ream cylinder head recess.

Reaming bore for service valve seat

Oversize [0.5 (0.020)]: mm (in)

Intake 36.500 - 36.516 (1.4370 - 1.4376)

Exhaust 42.500 - 42.516 (1.6732 - 1.6739)

Use the valve guide center for reaming to ensure valve seat

will have the correct fit.

3. Heat cylinder head to 110 to 130ÉC (230 to 266ÉF).

4. Press fit valve seat until it seats on the bottom.

5. Cut or grind valve seat using suitable tool of the specified

dimensions. Refer to SDS, EM-92.

6. After cutting, lap valve seat with abrasive compound.

7. Check valve seating condition.

Seat face angle ``a'':

45 deg.

Contacting width ``W'': mm (in)

Intake

1.6 - 1.7 (0.063 - 0.067)

Exhaust

1.7 - 2.1 (0.067 - 0.083)

VALVE DIMENSIONS

Check dimensions of each valve. Refer to SDS, EM-93.

When valve head has been worn down to 0.5 mm (0.020 in) in

margin thickness, replace valve.

Grinding allowance for valve stem tip is 0.2 mm (0.008 in) or

less.

SEM227C

SEM795A

SEM008A

SEM892B

SEM188A

CYLINDER HEADKA

Inspection (Cont'd)

EM-31

Page 702 of 1659

![NISSAN PICK-UP 1998 Repair Manual Valve guide inner diameter:

8.000 - 8.015 mm (0.3150 - 0.3156 in)

VALVE GUIDE REPLACEMENT

1. Drive out valve guide with a press [under a 20 kN (2 ton, 2.2

US ton, 2.0 Imp ton) pressure] or hammer, and NISSAN PICK-UP 1998 Repair Manual Valve guide inner diameter:

8.000 - 8.015 mm (0.3150 - 0.3156 in)

VALVE GUIDE REPLACEMENT

1. Drive out valve guide with a press [under a 20 kN (2 ton, 2.2

US ton, 2.0 Imp ton) pressure] or hammer, and](/img/5/57374/w960_57374-701.png)

Valve guide inner diameter:

8.000 - 8.015 mm (0.3150 - 0.3156 in)

VALVE GUIDE REPLACEMENT

1. Drive out valve guide with a press [under a 20 kN (2 ton, 2.2

US ton, 2.0 Imp ton) pressure] or hammer, and suitable tool.

2. Press service valve guide onto cylinder head using suitable

tool until the guide projects out 15.8 to 16.2 mm (0.622 to

0.638 in).

3. Ream valve guide.

Finished size:

8.000 - 8.015 mm (0.3150 - 0.3156 in)

VALVE SEATS

Check valve for any evidence of pitting at valve contact surface,

and reseat or replace if worn out excessively.

lWhen repairing valve seats, check valve and valve guide

for wear beforehand. If worn, replace them. Then correct

valve seat.

lThe cutting should be done with both hands for uniform

cutting.

SEM649B

SEM628B

SEM629BA

SEM630B

SEM024-A

CYLINDER HEADTD

Inspection (Cont'd)

EM-57

Page 703 of 1659

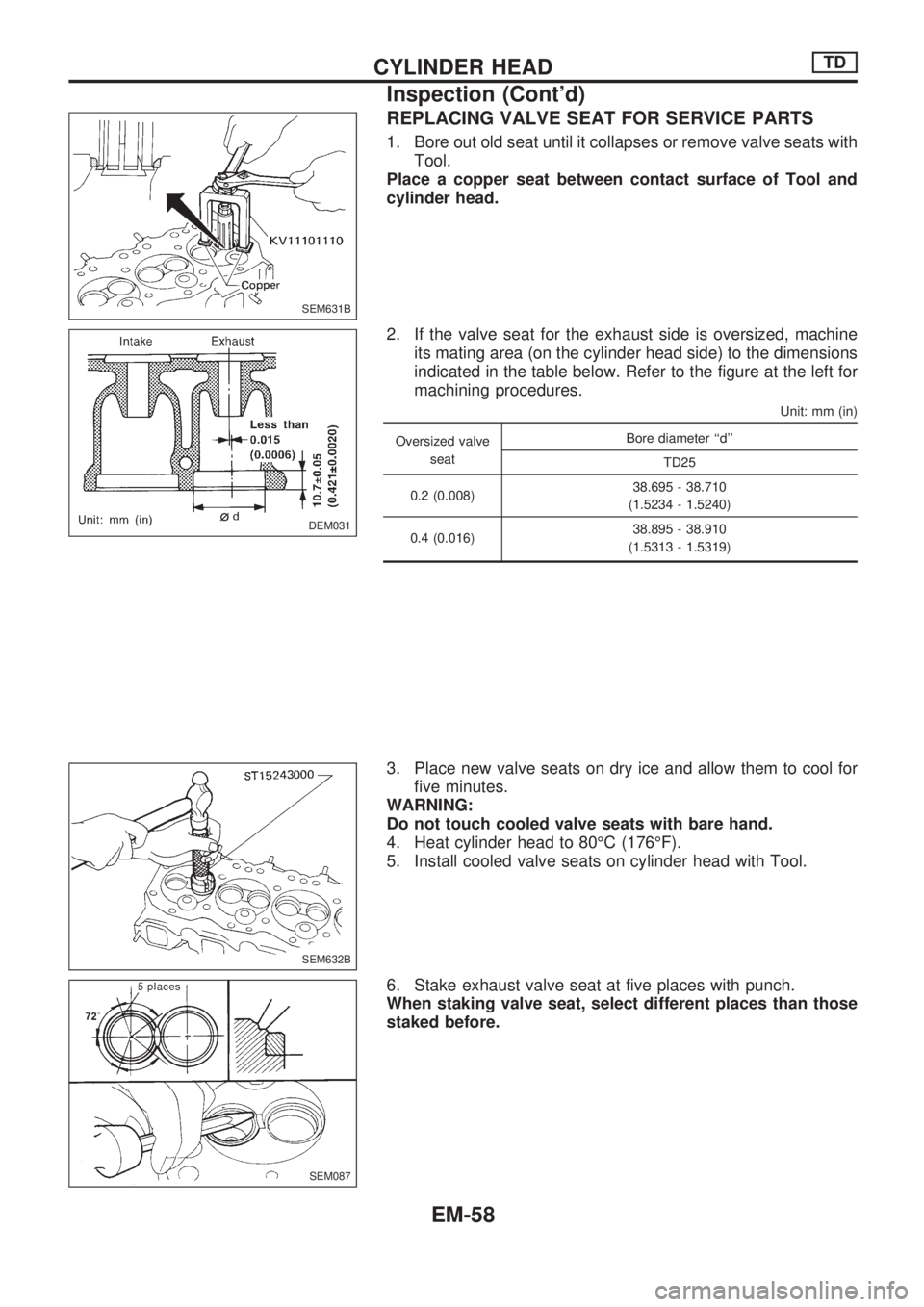

REPLACING VALVE SEAT FOR SERVICE PARTS

1. Bore out old seat until it collapses or remove valve seats with

Tool.

Place a copper seat between contact surface of Tool and

cylinder head.

2. If the valve seat for the exhaust side is oversized, machine

its mating area (on the cylinder head side) to the dimensions

indicated in the table below. Refer to the figure at the left for

machining procedures.

Unit: mm (in)

Oversized valve

seatBore diameter ``d''

TD25

0.2 (0.008)38.695 - 38.710

(1.5234 - 1.5240)

0.4 (0.016)38.895 - 38.910

(1.5313 - 1.5319)

3. Place new valve seats on dry ice and allow them to cool for

five minutes.

WARNING:

Do not touch cooled valve seats with bare hand.

4. Heat cylinder head to 80ÉC (176ÉF).

5. Install cooled valve seats on cylinder head with Tool.

6. Stake exhaust valve seat at five places with punch.

When staking valve seat, select different places than those

staked before.

SEM631B

DEM031

SEM632B

SEM087

CYLINDER HEADTD

Inspection (Cont'd)

EM-58

Page 782 of 1659

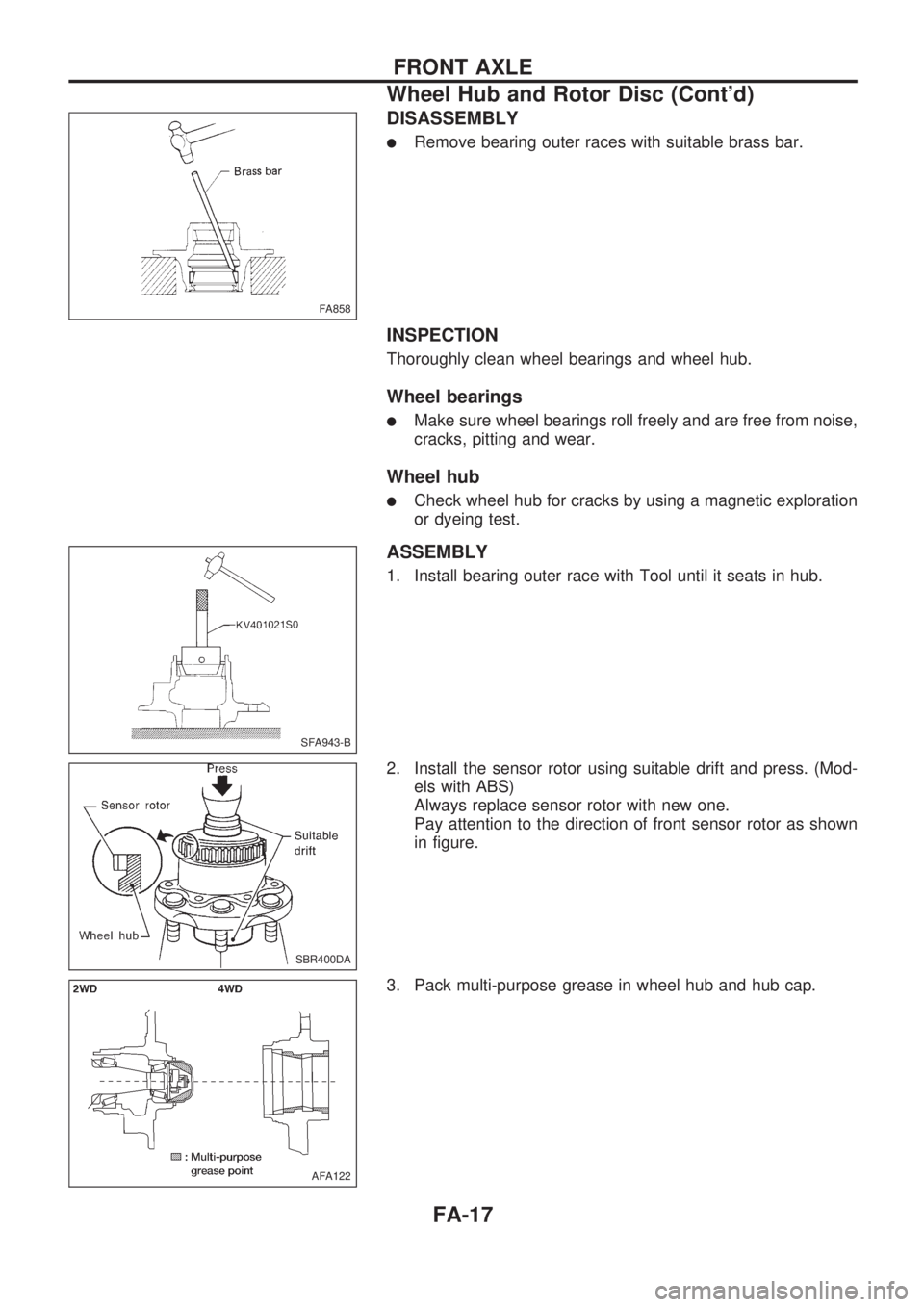

DISASSEMBLY

lRemove bearing outer races with suitable brass bar.

INSPECTION

Thoroughly clean wheel bearings and wheel hub.

Wheel bearings

lMake sure wheel bearings roll freely and are free from noise,

cracks, pitting and wear.

Wheel hub

lCheck wheel hub for cracks by using a magnetic exploration

or dyeing test.

ASSEMBLY

1. Install bearing outer race with Tool until it seats in hub.

2. Install the sensor rotor using suitable drift and press. (Mod-

els with ABS)

Always replace sensor rotor with new one.

Pay attention to the direction of front sensor rotor as shown

in figure.

3. Pack multi-purpose grease in wheel hub and hub cap.

FA858

SFA943-B

SBR400DA

AFA122

FRONT AXLE

Wheel Hub and Rotor Disc (Cont'd)

FA-17

Page 976 of 1659

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD Ð engine off

hRadiator coolant level and coolant hose con-

nections for leaks

hBattery fluid level, specific gravity and condi-

tions of battery terminals

hDrive belts tension

hFuel filter for water or dusts, and fuel lines and

connections for leaks

hEngine oil level and oil leaks

hClutch and brake reservoir fluid level and fluid

lines for leaks

hWindshield and rear window washer and head-

lamp cleaner reservoir fluid level

hPower steering reservoir fluid level and hose

connections for leaks

ON INSIDE AND OUTSIDE

hRemove front spring/strut spacer (If applicable)

hOperation of all instruments, gauges, lights and

accessories

hOperation of horn(s), wiper and washer

hSteering lock for operation

hCheck air conditioner for gas leaks

hFront and rear seats, and seat belts for opera-

tion

hAll moldings, trims and fittings for fit and align-

ment

hAll windows for operation and alignment

hHood, trunk lid, door panels for fit and align-

ment

hLatches, keys and locks for operation

hWeatherstrips for adhesion and fit

hHeadlamp aiming

hTighten wheel nuts (Inc. inner nuts if appli-

cable)

hTire pressure (Inc. spare tire)

hCheck front wheels for toe-in

hInstall clock/voltmeter/room lamp fuse (If appli-

cable)

UNDER BODY

hManual transmission/transaxle gear oil, trans-

fer fluid and differential gear oil level

hBrake and fuel lines and oil/fluid reservoirs for

leaks

hTighten bolts and nuts of steering linkage and

gear box, suspension, propeller shafts and

drive shafts

ROAD TEST

hClutch operation

hParking brake operation

hService brake operation

hSteering control and returnability

hEngine performance

hSqueaks and rattles

ENGINE OPERATING AND HOT

hAdjust idle mixture and speed (and ignition tim-

ing*1)

hEngine idling and stop knob operation (Diesel

only)

FINAL INSPECTION

hInstall necessary parts (outside mirror, wheel

covers, seat belts, mat, carpet or mud flaps)

hInspect for interior and exterior metal and paint

damage

hCheck for spare tire, jack, tools (wheel chock),

and literature

hWash, clean interior and exterior

*1: Not required on models with a direct ignition system

h

X: Not applicable to this model.

PRE-DELIVERY INSPECTION ITEMS

MA-3

Page 1584 of 1659

VALVE SEATS

Check valve seats for pitting at contact surface. Resurface or

replace if excessively worn.

lBefore repairing valve seats, check valve and valve

guide for wear. If they have worn, replace them. Then

correct valve seat.

lUse both hands to cut uniformly.

REPLACING VALVE SEAT FOR SERVICE PARTS

1. Bore out old seat until it collapses. Set machine depth stop

so that boring cannot contact bottom face of seat recess in

cylinder head.

2. Ream cylinder head recess.

Reaming bore for service valve seat

Oversize [0.5 (0.020)]: mm (in)

Intake 36.500 - 36.516 (1.4370 - 1.4376)

Exhaust 42.500 - 42.516 (1.6732 - 1.6739)

Use the valve guide center for reaming to ensure valve seat

will have the correct fit.

3. Heat cylinder head to 110 to 130ÉC (230 to 266ÉF).

4. Press fit valve seat until it seats on the bottom.

5. Cut or grind valve seat using suitable tool of the specified

dimensions. Refer to SDS, EM-92.

6. After cutting, lap valve seat with abrasive compound.

7. Check valve seating condition.

Seat face angle ``a'':

45 deg.

Contacting width ``W'': mm (in)

Intake

1.6 - 1.7 (0.063 - 0.067)

Exhaust

1.7 - 2.1 (0.067 - 0.083)

VALVE DIMENSIONS

Check dimensions of each valve. Refer to SDS, EM-93.

When valve head has been worn down to 0.5 mm (0.020 in) in

margin thickness, replace valve.

Grinding allowance for valve stem tip is 0.2 mm (0.008 in) or

less.

SEM227C

SEM795A

SEM008A

SEM892B

SEM188A

CYLINDER HEADKA

Inspection (Cont'd)

EM-31

Page 1610 of 1659

![NISSAN PICK-UP 1998 Repair Manual Valve guide inner diameter:

8.000 - 8.015 mm (0.3150 - 0.3156 in)

VALVE GUIDE REPLACEMENT

1. Drive out valve guide with a press [under a 20 kN (2 ton, 2.2

US ton, 2.0 Imp ton) pressure] or hammer, and NISSAN PICK-UP 1998 Repair Manual Valve guide inner diameter:

8.000 - 8.015 mm (0.3150 - 0.3156 in)

VALVE GUIDE REPLACEMENT

1. Drive out valve guide with a press [under a 20 kN (2 ton, 2.2

US ton, 2.0 Imp ton) pressure] or hammer, and](/img/5/57374/w960_57374-1609.png)

Valve guide inner diameter:

8.000 - 8.015 mm (0.3150 - 0.3156 in)

VALVE GUIDE REPLACEMENT

1. Drive out valve guide with a press [under a 20 kN (2 ton, 2.2

US ton, 2.0 Imp ton) pressure] or hammer, and suitable tool.

2. Press service valve guide onto cylinder head using suitable

tool until the guide projects out 15.8 to 16.2 mm (0.622 to

0.638 in).

3. Ream valve guide.

Finished size:

8.000 - 8.015 mm (0.3150 - 0.3156 in)

VALVE SEATS

Check valve for any evidence of pitting at valve contact surface,

and reseat or replace if worn out excessively.

lWhen repairing valve seats, check valve and valve guide

for wear beforehand. If worn, replace them. Then correct

valve seat.

lThe cutting should be done with both hands for uniform

cutting.

SEM649B

SEM628B

SEM629BA

SEM630B

SEM024-A

CYLINDER HEADTD

Inspection (Cont'd)

EM-57