reset NISSAN PICK-UP 1998 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 166 of 1659

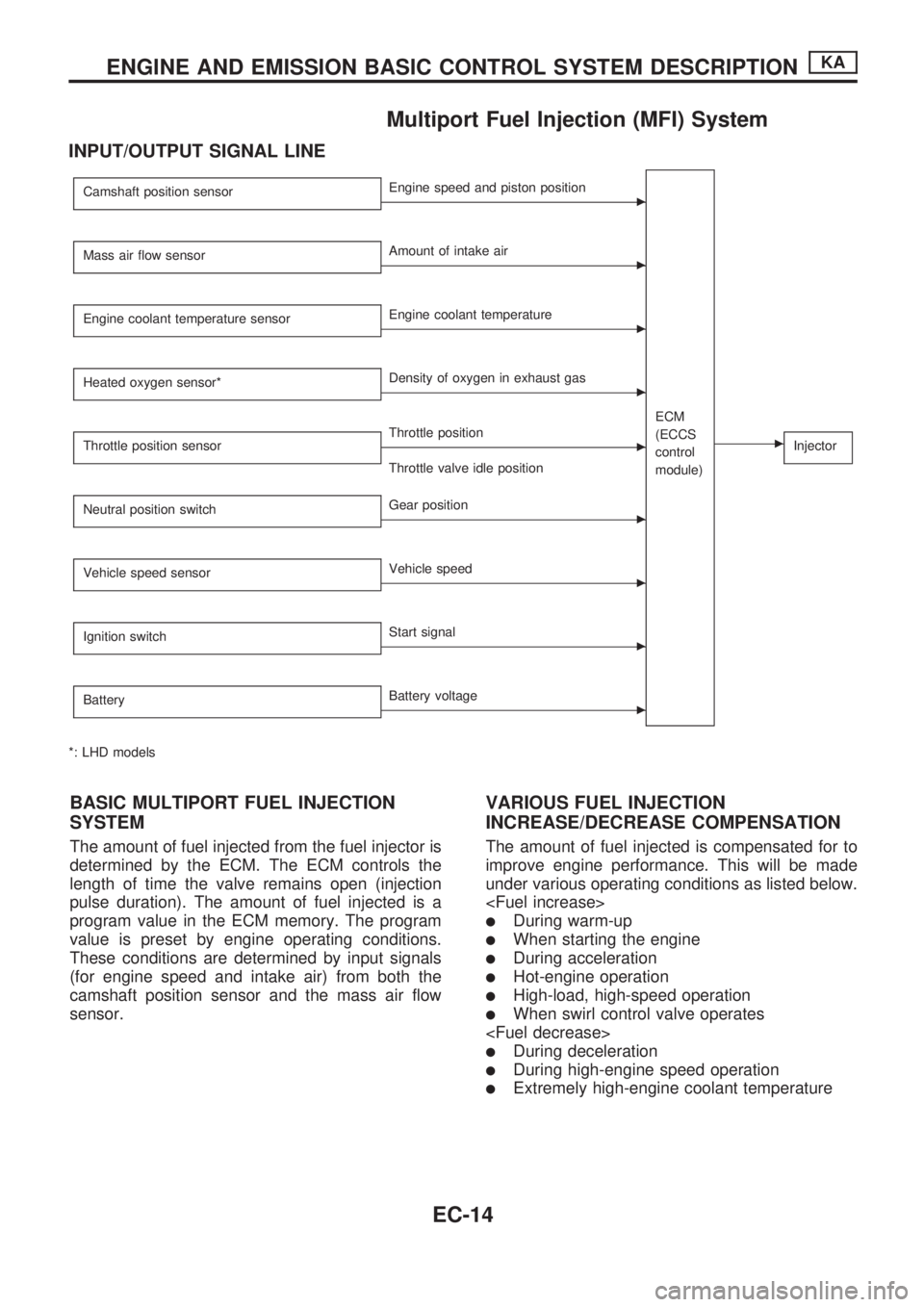

Multiport Fuel Injection (MFI) System

INPUT/OUTPUT SIGNAL LINE

Camshaft position sensorcEngine speed and piston position

ECM

(ECCS

control

module)

cInjector

Mass air flow sensorcAmount of intake air

Engine coolant temperature sensor

cEngine coolant temperature

Heated oxygen sensor*

cDensity of oxygen in exhaust gas

Throttle position sensor

cThrottle position

Throttle valve idle position

Neutral position switch

cGear position

Vehicle speed sensor

cVehicle speed

Ignition switch

cStart signal

Battery

cBattery voltage

*: LHD models

BASIC MULTIPORT FUEL INJECTION

SYSTEM

The amount of fuel injected from the fuel injector is

determined by the ECM. The ECM controls the

length of time the valve remains open (injection

pulse duration). The amount of fuel injected is a

program value in the ECM memory. The program

value is preset by engine operating conditions.

These conditions are determined by input signals

(for engine speed and intake air) from both the

camshaft position sensor and the mass air flow

sensor.

VARIOUS FUEL INJECTION

INCREASE/DECREASE COMPENSATION

The amount of fuel injected is compensated for to

improve engine performance. This will be made

under various operating conditions as listed below.

lDuring warm-up

lWhen starting the engine

lDuring acceleration

lHot-engine operation

lHigh-load, high-speed operation

lWhen swirl control valve operates

lDuring deceleration

lDuring high-engine speed operation

lExtremely high-engine coolant temperature

ENGINE AND EMISSION BASIC CONTROL SYSTEM DESCRIPTIONKA

EC-14

Page 205 of 1659

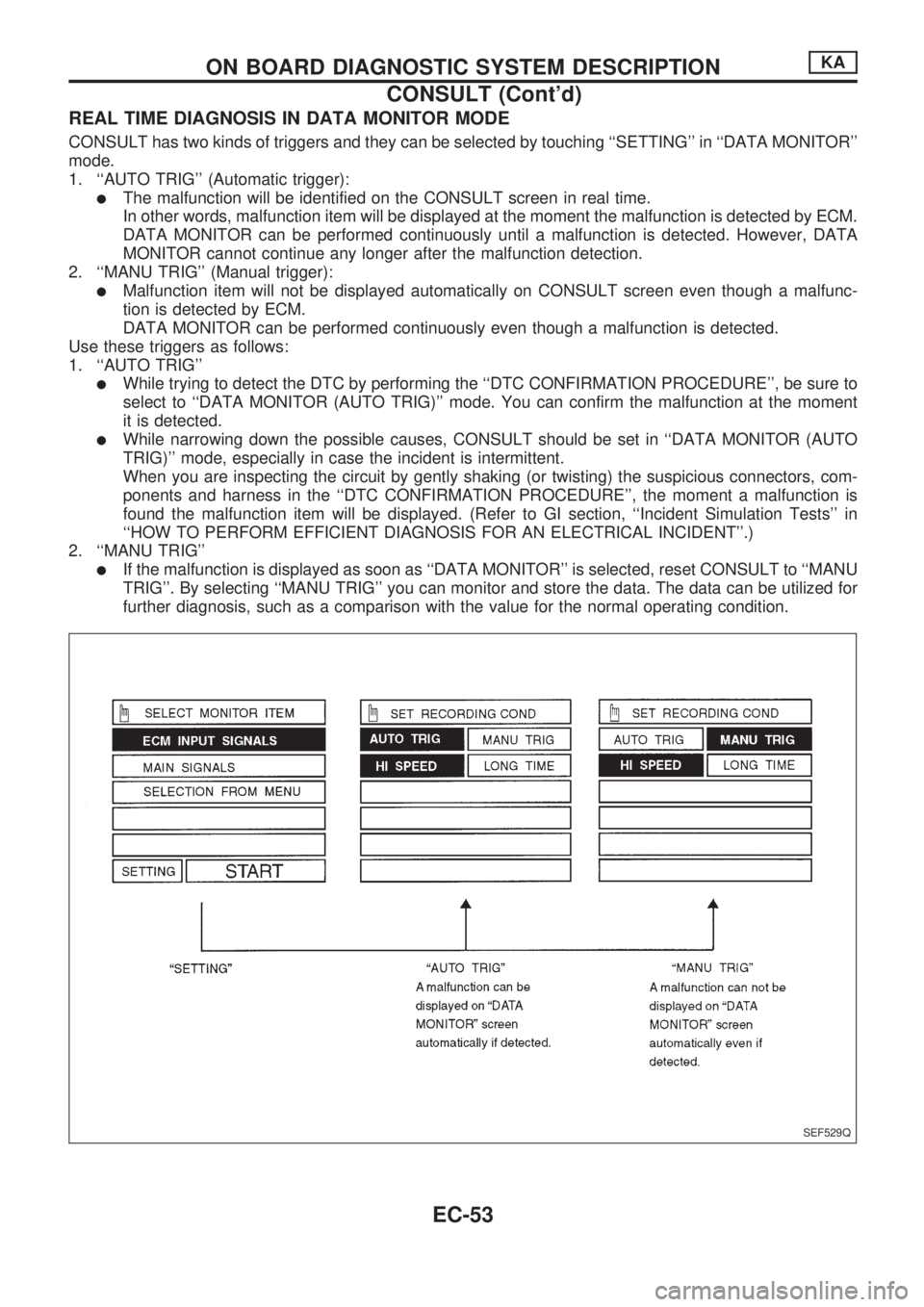

REAL TIME DIAGNOSIS IN DATA MONITOR MODE

CONSULT has two kinds of triggers and they can be selected by touching ``SETTING'' in ``DATA MONITOR''

mode.

1. ``AUTO TRIG'' (Automatic trigger):

lThe malfunction will be identified on the CONSULT screen in real time.

In other words, malfunction item will be displayed at the moment the malfunction is detected by ECM.

DATA MONITOR can be performed continuously until a malfunction is detected. However, DATA

MONITOR cannot continue any longer after the malfunction detection.

2. ``MANU TRIG'' (Manual trigger):

lMalfunction item will not be displayed automatically on CONSULT screen even though a malfunc-

tion is detected by ECM.

DATA MONITOR can be performed continuously even though a malfunction is detected.

Use these triggers as follows:

1. ``AUTO TRIG''

lWhile trying to detect the DTC by performing the ``DTC CONFIRMATION PROCEDURE'', be sure to

select to ``DATA MONITOR (AUTO TRIG)'' mode. You can confirm the malfunction at the moment

it is detected.

lWhile narrowing down the possible causes, CONSULT should be set in ``DATA MONITOR (AUTO

TRIG)'' mode, especially in case the incident is intermittent.

When you are inspecting the circuit by gently shaking (or twisting) the suspicious connectors, com-

ponents and harness in the ``DTC CONFIRMATION PROCEDURE'', the moment a malfunction is

found the malfunction item will be displayed. (Refer to GI section, ``Incident Simulation Tests'' in

``HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT''.)

2. ``MANU TRIG''

lIf the malfunction is displayed as soon as ``DATA MONITOR'' is selected, reset CONSULT to ``MANU

TRIG''. By selecting ``MANU TRIG'' you can monitor and store the data. The data can be utilized for

further diagnosis, such as a comparison with the value for the normal operating condition.

SEF529Q

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONKA

CONSULT (Cont'd)

EC-53

Page 211 of 1659

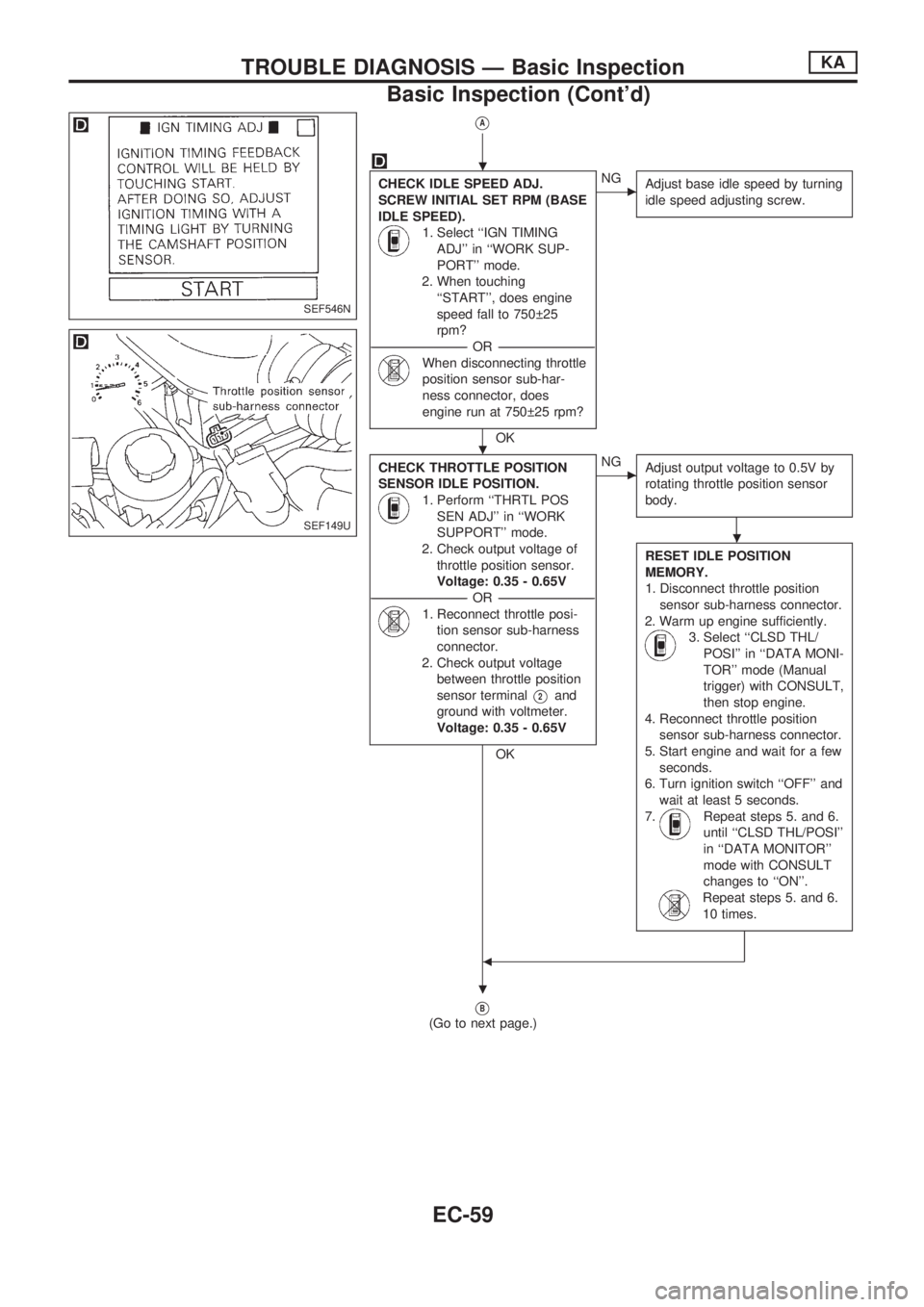

VA

CHECK IDLE SPEED ADJ.

SCREW INITIAL SET RPM (BASE

IDLE SPEED).

1. Select ``IGN TIMING

ADJ'' in ``WORK SUP-

PORT'' mode.

2. When touching

``START'', does engine

speed fall to 750 25

rpm?

-----------------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------------

When disconnecting throttle

position sensor sub-har-

ness connector, does

engine run at 750 25 rpm?

OK

cNG

Adjust base idle speed by turning

idle speed adjusting screw.

CHECK THROTTLE POSITION

SENSOR IDLE POSITION.

1. Perform ``THRTL POS

SEN ADJ'' in ``WORK

SUPPORT'' mode.

2. Check output voltage of

throttle position sensor.

Voltage: 0.35 - 0.65V

-----------------------------------------------------------------------------------------------------------OR -----------------------------------------------------------------------------------------------------------

1. Reconnect throttle posi-

tion sensor sub-harness

connector.

2. Check output voltage

between throttle position

sensor terminal

V2and

ground with voltmeter.

Voltage: 0.35 - 0.65V

OK

cNG

Adjust output voltage to 0.5V by

rotating throttle position sensor

body.

RESET IDLE POSITION

MEMORY.

1. Disconnect throttle position

sensor sub-harness connector.

2. Warm up engine sufficiently.

3. Select ``CLSD THL/

POSI'' in ``DATA MONI-

TOR'' mode (Manual

trigger) with CONSULT,

then stop engine.

4. Reconnect throttle position

sensor sub-harness connector.

5. Start engine and wait for a few

seconds.

6. Turn ignition switch ``OFF'' and

wait at least 5 seconds.

7.

Repeat steps 5. and 6.

until ``CLSD THL/POSI''

in ``DATA MONITOR''

mode with CONSULT

changes to ``ON''.

Repeat steps 5. and 6.

10 times.

b

VB

(Go to next page.)

SEF546N

SEF149U

.

.

.

.

TROUBLE DIAGNOSIS Ð Basic InspectionKA

Basic Inspection (Cont'd)

EC-59

Page 213 of 1659

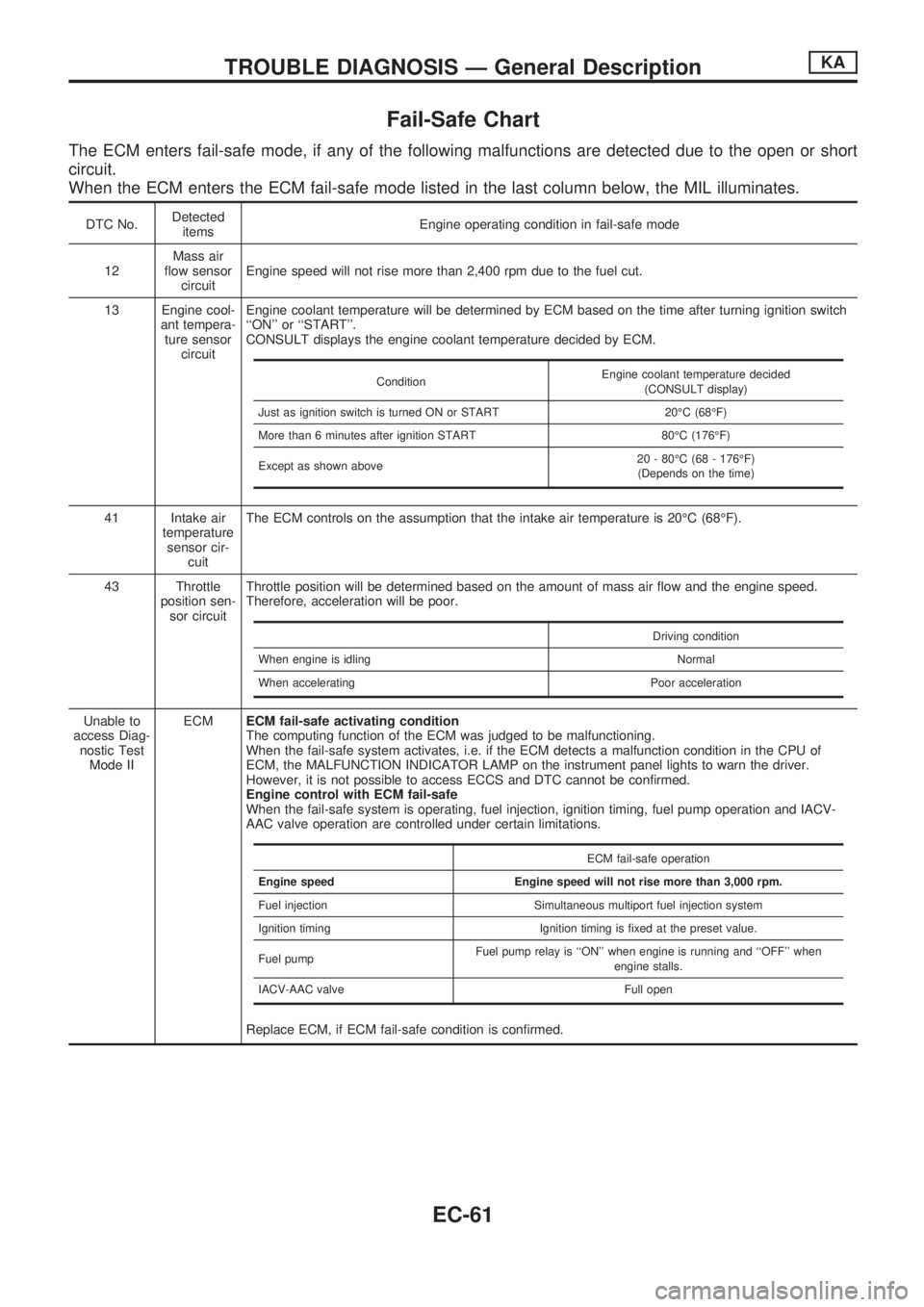

Fail-Safe Chart

The ECM enters fail-safe mode, if any of the following malfunctions are detected due to the open or short

circuit.

When the ECM enters the ECM fail-safe mode listed in the last column below, the MIL illuminates.

DTC No.Detected

itemsEngine operating condition in fail-safe mode

12Mass air

flow sensor

circuitEngine speed will not rise more than 2,400 rpm due to the fuel cut.

13 Engine cool-

ant tempera-

ture sensor

circuitEngine coolant temperature will be determined by ECM based on the time after turning ignition switch

``ON'' or ``START''.

CONSULT displays the engine coolant temperature decided by ECM.

41 Intake air

temperature

sensor cir-

cuitThe ECM controls on the assumption that the intake air temperature is 20ÉC (68ÉF).

43 Throttle

position sen-

sor circuitThrottle position will be determined based on the amount of mass air flow and the engine speed.

Therefore, acceleration will be poor.

Unable to

access Diag-

nostic Test

Mode IIECMECM fail-safe activating condition

The computing function of the ECM was judged to be malfunctioning.

When the fail-safe system activates, i.e. if the ECM detects a malfunction condition in the CPU of

ECM, the MALFUNCTION INDICATOR LAMP on the instrument panel lights to warn the driver.

However, it is not possible to access ECCS and DTC cannot be confirmed.

Engine control with ECM fail-safe

When the fail-safe system is operating, fuel injection, ignition timing, fuel pump operation and IACV-

AAC valve operation are controlled under certain limitations.

Replace ECM, if ECM fail-safe condition is confirmed.

ConditionEngine coolant temperature decided

(CONSULT display)

Just as ignition switch is turned ON or START 20ÉC (68ÉF)

More than 6 minutes after ignition START 80ÉC (176ÉF)

Except as shown above20 - 80ÉC (68 - 176ÉF)

(Depends on the time)

Driving condition

When engine is idling Normal

When accelerating Poor acceleration

ECM fail-safe operation

Engine speed Engine speed will not rise more than 3,000 rpm.

Fuel injection Simultaneous multiport fuel injection system

Ignition timing Ignition timing is fixed at the preset value.

Fuel pumpFuel pump relay is ``ON'' when engine is running and ``OFF'' when

engine stalls.

IACV-AAC valve Full open

TROUBLE DIAGNOSIS Ð General DescriptionKA

EC-61

Page 322 of 1659

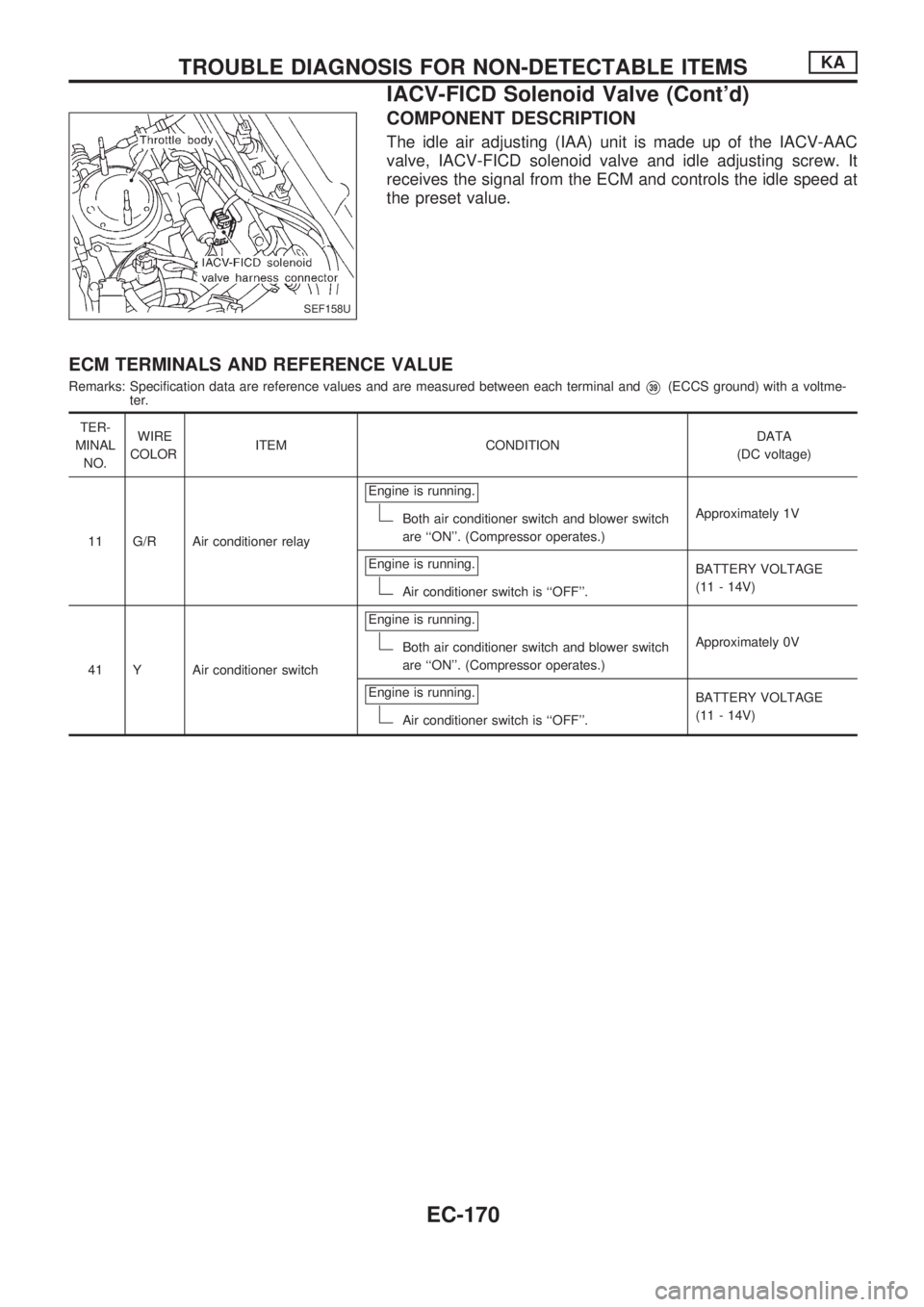

COMPONENT DESCRIPTION

The idle air adjusting (IAA) unit is made up of the IACV-AAC

valve, IACV-FICD solenoid valve and idle adjusting screw. It

receives the signal from the ECM and controls the idle speed at

the preset value.

ECM TERMINALS AND REFERENCE VALUE

Remarks: Specification data are reference values and are measured between each terminal andV39(ECCS ground) with a voltme-

ter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC voltage)

11 G/R Air conditioner relayEngine is running.

Both air conditioner switch and blower switch

are ``ON''. (Compressor operates.)Approximately 1V

Engine is running.

Air conditioner switch is ``OFF''.BATTERY VOLTAGE

(11 - 14V)

41 Y Air conditioner switchEngine is running.

Both air conditioner switch and blower switch

are ``ON''. (Compressor operates.)Approximately 0V

Engine is running.

Air conditioner switch is ``OFF''.BATTERY VOLTAGE

(11 - 14V)

SEF158U

TROUBLE DIAGNOSIS FOR NON-DETECTABLE ITEMSKA

IACV-FICD Solenoid Valve (Cont'd)

EC-170

Page 532 of 1659

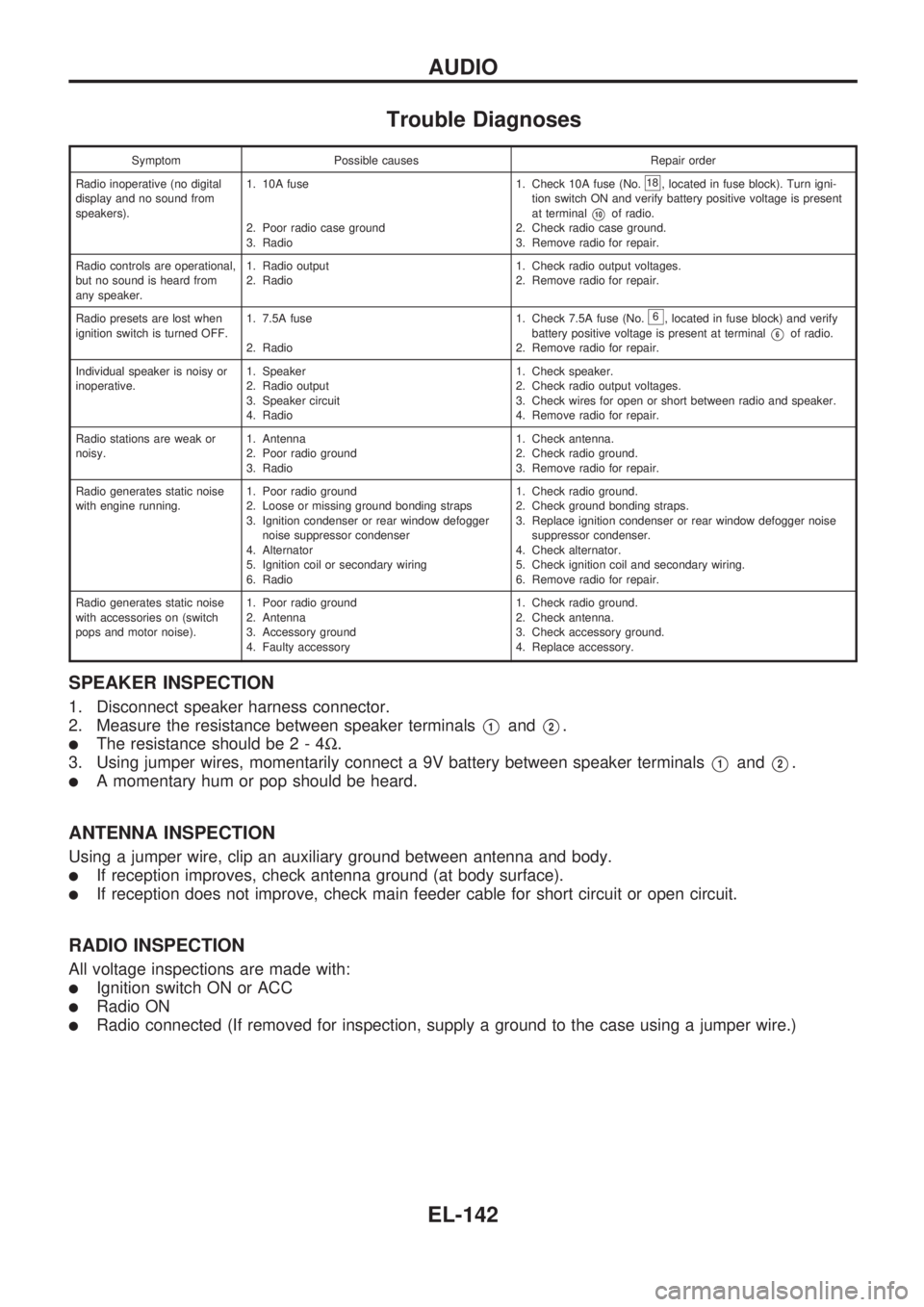

Trouble Diagnoses

Symptom Possible causes Repair order

Radio inoperative (no digital

display and no sound from

speakers).1. 10A fuse

2. Poor radio case ground

3. Radio1. Check 10A fuse (No.

18, located in fuse block). Turn igni-

tion switch ON and verify battery positive voltage is present

at terminal

V10of radio.

2. Check radio case ground.

3. Remove radio for repair.

Radio controls are operational,

but no sound is heard from

any speaker.1. Radio output

2. Radio1. Check radio output voltages.

2. Remove radio for repair.

Radio presets are lost when

ignition switch is turned OFF.1. 7.5A fuse

2. Radio1. Check 7.5A fuse (No.

6, located in fuse block) and verify

battery positive voltage is present at terminal

V6of radio.

2. Remove radio for repair.

Individual speaker is noisy or

inoperative.1. Speaker

2. Radio output

3. Speaker circuit

4. Radio1. Check speaker.

2. Check radio output voltages.

3. Check wires for open or short between radio and speaker.

4. Remove radio for repair.

Radio stations are weak or

noisy.1. Antenna

2. Poor radio ground

3. Radio1. Check antenna.

2. Check radio ground.

3. Remove radio for repair.

Radio generates static noise

with engine running.1. Poor radio ground

2. Loose or missing ground bonding straps

3. Ignition condenser or rear window defogger

noise suppressor condenser

4. Alternator

5. Ignition coil or secondary wiring

6. Radio1. Check radio ground.

2. Check ground bonding straps.

3. Replace ignition condenser or rear window defogger noise

suppressor condenser.

4. Check alternator.

5. Check ignition coil and secondary wiring.

6. Remove radio for repair.

Radio generates static noise

with accessories on (switch

pops and motor noise).1. Poor radio ground

2. Antenna

3. Accessory ground

4. Faulty accessory1. Check radio ground.

2. Check antenna.

3. Check accessory ground.

4. Replace accessory.

SPEAKER INSPECTION

1. Disconnect speaker harness connector.

2. Measure the resistance between speaker terminals

V1andV2.

lThe resistance should be2-4W.

3. Using jumper wires, momentarily connect a 9V battery between speaker terminals

V1andV2.

lA momentary hum or pop should be heard.

ANTENNA INSPECTION

Using a jumper wire, clip an auxiliary ground between antenna and body.

lIf reception improves, check antenna ground (at body surface).

lIf reception does not improve, check main feeder cable for short circuit or open circuit.

RADIO INSPECTION

All voltage inspections are made with:

lIgnition switch ON or ACC

lRadio ON

lRadio connected (If removed for inspection, supply a ground to the case using a jumper wire.)

AUDIO

EL-142

Page 533 of 1659

CATS (Code) System/For Europe RHD

NOTE:

lThis system is used for code indicator-equipped radios on all models.

lThe Europe LHD model with KA24E engine has a NATS-linked anti-theft function with radio as

optional equipment that renders the code system inoperable.

DESCRIPTION

By using a personal 4-digit code known only to the vehicle owner, the possibility of the audio unit being sto-

len is effectively reduced, because without the code the unit can not be activated. When in normal use, the

unit is unlocked and accessible in the usual way.

If however, someone attempts to remove the unit or the battery cable is disconnected, the anti-theft system

activates and the unit ``locks''. The only way it can be unlocked is by entering a personal code number known

only by the owner.

UNLOCKING THE UNIT (How to enter a personal code number)

lIf the battery supply to the vehicle is interrupted by accident for some reason, the unit will lock.

To unlock the unit, proceed as follows:

1. Press the power/volume control knob to turn the unit on.

2. ``CODE IN'' is displayed.

3. Input your personal code by pressing the preset buttons (1 to 4).

4. Press the

button.

5. If the entered code number is correct, the radio turns on.

When the code is incorrect

1. If the entered code is incorrect, the unit becomes inoperable for 10 seconds for the first three attempts,

then the code input mode is automatically set (``CODE IN'' is displayed).

2. If the code is incorrect the fourth time, the unit becomes inoperable for 60 minutes and ``

'' is dis-

played. After 60 minutes, the code input mode is automatically set (``CODE IN'' is displayed).

NOTE:

If the above is repeated 17 times, the unit will lock and ``LOCKED'' is displayed.

3. After ``LOCKED'' is displayed, radio can be returned to the code input mode only within three attempts

as follows. (Only three attempts are allowed to unlock the unit.)

a. Press the power/volume control knob while pushing both the MOD and TA switches.

b. The unit then returns to the code input mode.

CAUTION:

If the third attempt is unsuccessful, the unit will lock permanently.

AUDIO

EL-143

Page 534 of 1659

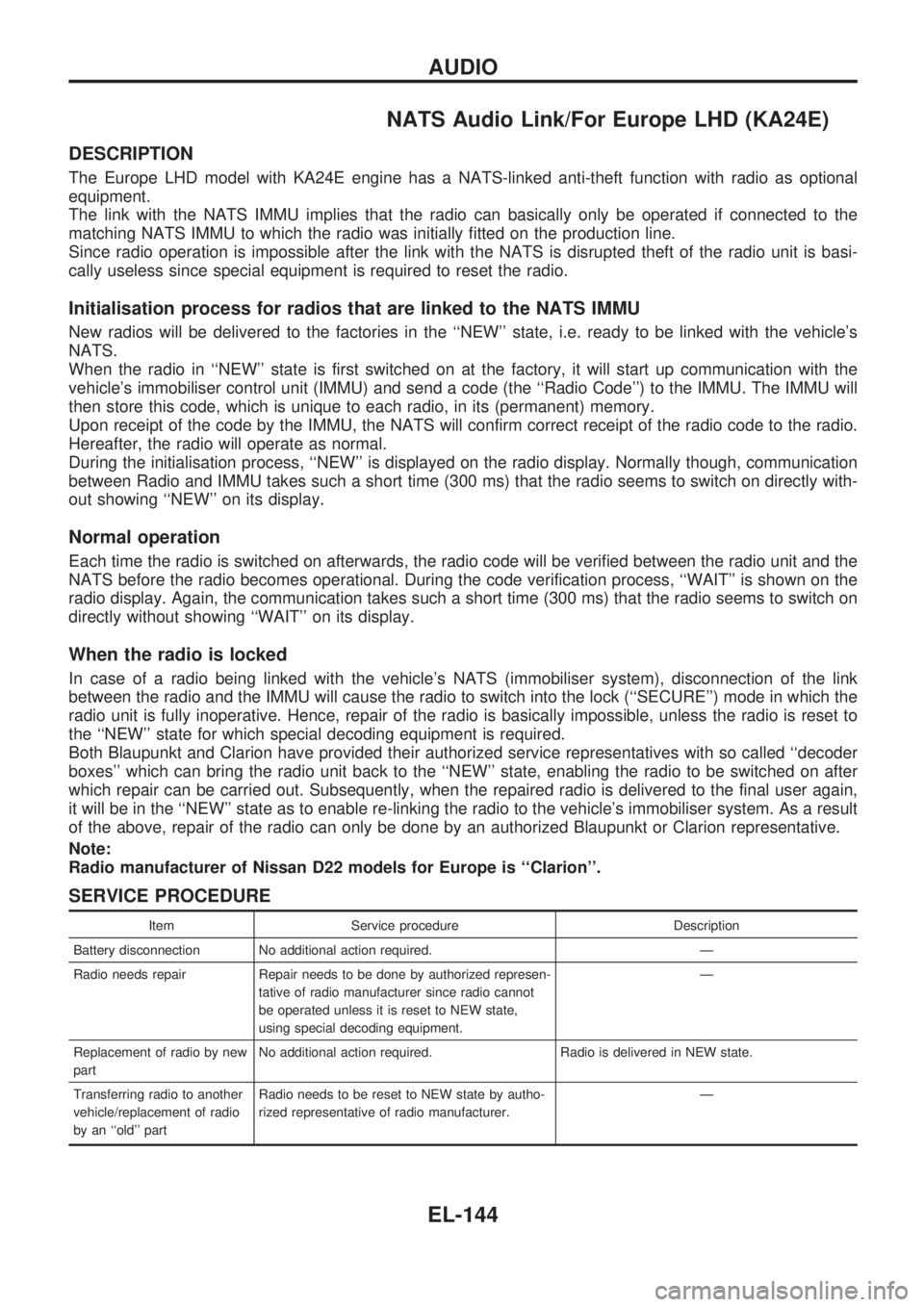

NATS Audio Link/For Europe LHD (KA24E)

DESCRIPTION

The Europe LHD model with KA24E engine has a NATS-linked anti-theft function with radio as optional

equipment.

The link with the NATS IMMU implies that the radio can basically only be operated if connected to the

matching NATS IMMU to which the radio was initially fitted on the production line.

Since radio operation is impossible after the link with the NATS is disrupted theft of the radio unit is basi-

cally useless since special equipment is required to reset the radio.

Initialisation process for radios that are linked to the NATS IMMU

New radios will be delivered to the factories in the ``NEW'' state, i.e. ready to be linked with the vehicle's

NATS.

When the radio in ``NEW'' state is first switched on at the factory, it will start up communication with the

vehicle's immobiliser control unit (IMMU) and send a code (the ``Radio Code'') to the IMMU. The IMMU will

then store this code, which is unique to each radio, in its (permanent) memory.

Upon receipt of the code by the IMMU, the NATS will confirm correct receipt of the radio code to the radio.

Hereafter, the radio will operate as normal.

During the initialisation process, ``NEW'' is displayed on the radio display. Normally though, communication

between Radio and IMMU takes such a short time (300 ms) that the radio seems to switch on directly with-

out showing ``NEW'' on its display.

Normal operation

Each time the radio is switched on afterwards, the radio code will be verified between the radio unit and the

NATS before the radio becomes operational. During the code verification process, ``WAIT'' is shown on the

radio display. Again, the communication takes such a short time (300 ms) that the radio seems to switch on

directly without showing ``WAIT'' on its display.

When the radio is locked

In case of a radio being linked with the vehicle's NATS (immobiliser system), disconnection of the link

between the radio and the IMMU will cause the radio to switch into the lock (``SECURE'') mode in which the

radio unit is fully inoperative. Hence, repair of the radio is basically impossible, unless the radio is reset to

the ``NEW'' state for which special decoding equipment is required.

Both Blaupunkt and Clarion have provided their authorized service representatives with so called ``decoder

boxes'' which can bring the radio unit back to the ``NEW'' state, enabling the radio to be switched on after

which repair can be carried out. Subsequently, when the repaired radio is delivered to the final user again,

it will be in the ``NEW'' state as to enable re-linking the radio to the vehicle's immobiliser system. As a result

of the above, repair of the radio can only be done by an authorized Blaupunkt or Clarion representative.

Note:

Radio manufacturer of Nissan D22 models for Europe is ``Clarion''.

SERVICE PROCEDURE

Item Service procedure Description

Battery disconnection No additional action required. Ð

Radio needs repair Repair needs to be done by authorized represen-

tative of radio manufacturer since radio cannot

be operated unless it is reset to NEW state,

using special decoding equipment.Ð

Replacement of radio by new

partNo additional action required. Radio is delivered in NEW state.

Transferring radio to another

vehicle/replacement of radio

by an ``old'' partRadio needs to be reset to NEW state by autho-

rized representative of radio manufacturer.Ð

AUDIO

EL-144

Page 535 of 1659

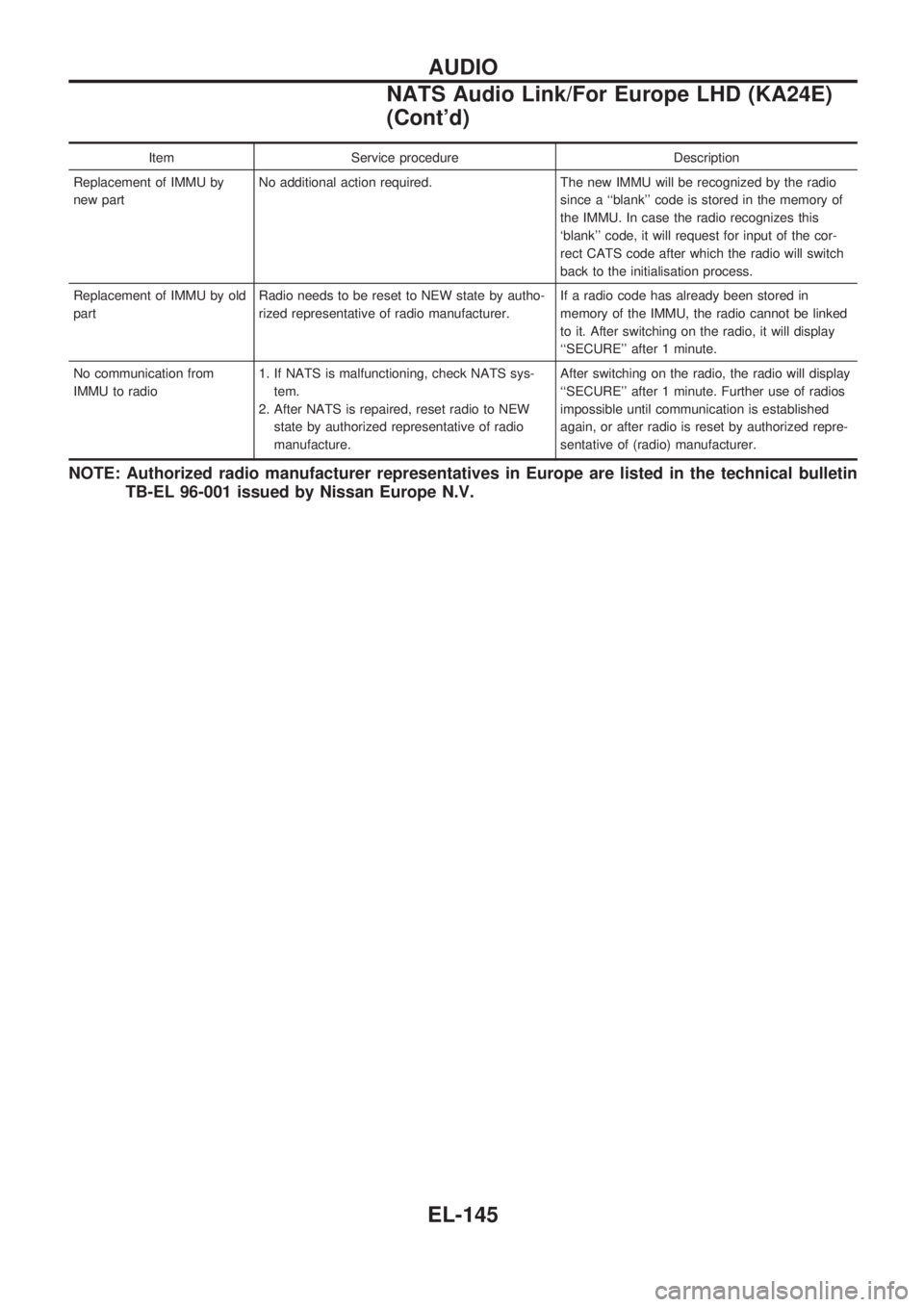

Item Service procedure Description

Replacement of IMMU by

new partNo additional action required. The new IMMU will be recognized by the radio

since a ``blank'' code is stored in the memory of

the IMMU. In case the radio recognizes this

`blank'' code, it will request for input of the cor-

rect CATS code after which the radio will switch

back to the initialisation process.

Replacement of IMMU by old

partRadio needs to be reset to NEW state by autho-

rized representative of radio manufacturer.If a radio code has already been stored in

memory of the IMMU, the radio cannot be linked

to it. After switching on the radio, it will display

``SECURE'' after 1 minute.

No communication from

IMMU to radio1. If NATS is malfunctioning, check NATS sys-

tem.

2. After NATS is repaired, reset radio to NEW

state by authorized representative of radio

manufacture.After switching on the radio, the radio will display

``SECURE'' after 1 minute. Further use of radios

impossible until communication is established

again, or after radio is reset by authorized repre-

sentative of (radio) manufacturer.

NOTE: Authorized radio manufacturer representatives in Europe are listed in the technical bulletin

TB-EL 96-001 issued by Nissan Europe N.V.

AUDIO

NATS Audio Link/For Europe LHD (KA24E)

(Cont'd)

EL-145

Page 1185 of 1659

Trouble Diagnoses Introduction

CAUTION:

lDo not use a circuit tester to check SRS harness connectors unless instructed to in this Service

Manual. SRS wiring harnesses can be identified with yellow harness protector or yellow insula-

tion tape before the harness connectors.

lDo not attempt to repair, splice or modify the SRS wiring harness. If the harness is damaged,

replace it with a new one.

lKeep ground portion clean.

DIAGNOSIS FUNCTION

The SRS self-diagnosis results can be read by using ``AIR BAG'' warning lamp and/or CONSULT. The

reading of these results is accomplished using one of two modes Ð ``User mode'' and ``Diagnosis mode''.

The User mode is exclusively prepared for the customer (driver). This mode warns the driver of a system

malfunction through the operation of the ``AIR BAG'' warning lamp.

The Diagnosis mode allows the technician to locate and inspect the malfunctioning part.

The mode applications for the ``AIR BAG'' warning lamp and CONSULT are as follows:

User mode Diagnosis mode Display type

``AIR BAG'' warning lamp X X ON-OFF operation

CONSULT Ð X Monitoring

DIAGNOSIS MODE FOR CONSULT

l``SELF-DIAG [CURRENT]''

A current Self-diagnosis result (also indicated by the warning lamp flashes in the Diagnosis mode) is

displayed on the CONSULT screen in real time. This refers to a malfunctioning part requiring repairs.

l``SELF-DIAG [PAST]''

Diagnosis results previously stored in the memory (also indicated by the warning lamp flashes in the

Diagnosis mode) are displayed on the CONSULT screen. The stored results are not erased until memory

erasing is executed.

l``TROUBLE DIAG RECORD''

With TROUBLE DIAG RECORD, diagnosis results previously erased by a reset operation can be dis-

played on the CONSULT screen.

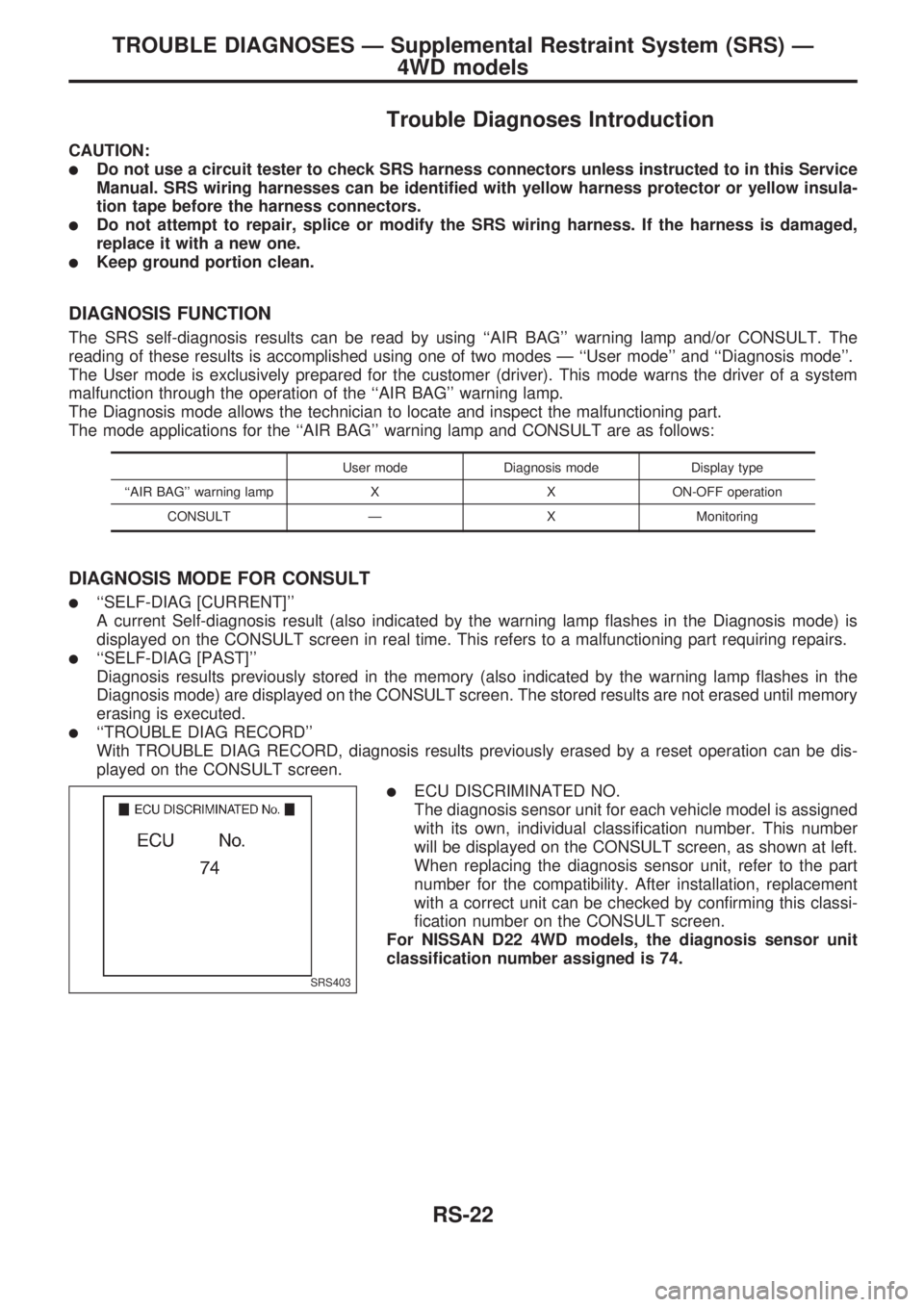

lECU DISCRIMINATED NO.

The diagnosis sensor unit for each vehicle model is assigned

with its own, individual classification number. This number

will be displayed on the CONSULT screen, as shown at left.

When replacing the diagnosis sensor unit, refer to the part

number for the compatibility. After installation, replacement

with a correct unit can be checked by confirming this classi-

fication number on the CONSULT screen.

For NISSAN D22 4WD models, the diagnosis sensor unit

classification number assigned is 74.

SRS403

TROUBLE DIAGNOSES Ð Supplemental Restraint System (SRS) Ð

4WD models

RS-22