suspension NISSAN PICK-UP 1998 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 1 of 1659

GENERAL INFORMATIONGI

MAINTENANCEMA

ENGINE MECHANICALEM

ENGINE LUBRICATION &

COOLING SYSTEMSLC

ENGINE CONTROL SYSTEMEC

ACCELERATOR CONTROL, FUEL &

EXHAUST SYSTEMSFE

CLUTCHCL

MANUAL TRANSAXLEMT

TRANSFERTF

PROPELLER SHAFT &

DIFFERENTIAL CARRIERPD

FRONT AXLE & FRONT SUSPENSIONFA

REAR AXLE & REAR SUSPENSIONRA

BRAKE SYSTEMBR

STEERING SYSTEMST

RESTRAINT SYSTEMRS

BODY & TRIMBT

HEATER & AIR CONDITIONERHA

ELECTRICAL SYSTEMEL

ALPHABETICAL INDEXIDX

PICKUP

MODEL D22 SERIES

Edition: February 1998

Printing: May 1998 (01)

Publication No.: SM8E-0D22E0E

NISSAN EUROPE S.A.S.

1998 NISSAN EUROPE S.A.S. Printed in the Netherlands

Not to be reproduced in whole or in part without the prior written permission of Nissan Europe S.A.S., Paris, France.

QUICK REFERENCE INDEX

Page 656 of 1659

Removal

1. Raise vehicle and support it with safety stands.

2. Remove engine under cover.

3. Drain engine oil.

4. Remove front final drive together with differential mounting

member. Refer to PD section (``Removal and Installation'',

``Front final drive'') Ð 4WD models only.

5. Remove front suspension member bolt (RH & LH).

6. Remove oil pan bolts.

7. Remove oil pan.

a. Insert Tool between cylinder block and oil pan.

lBe careful not to damage aluminum mating surface.

lDo not insert screwdriver, or oil pan flange will be dam-

aged.

b. Slide Tool by tapping on the side of the Tool with a hammer.

8. Pull out oil pan from front side.

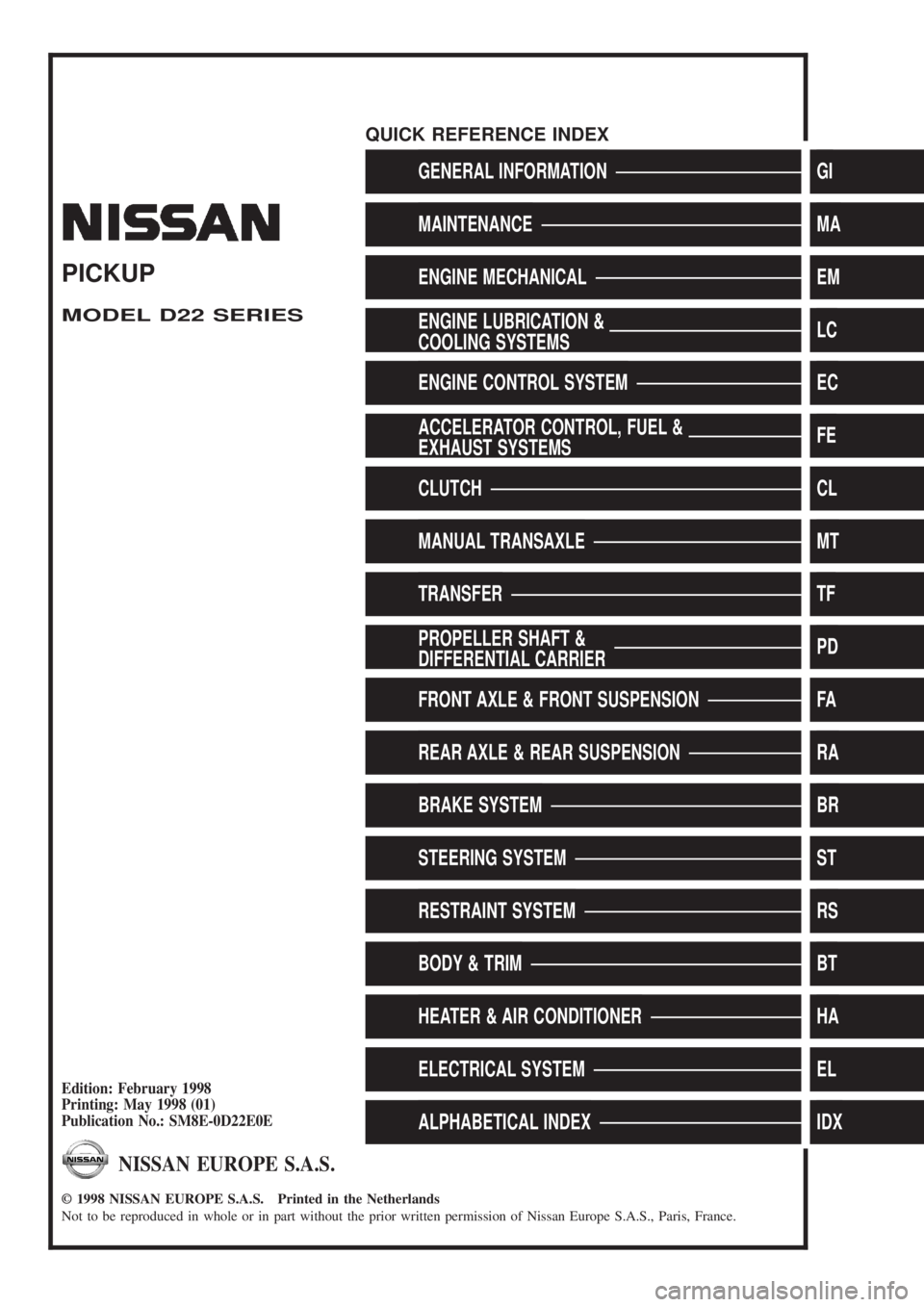

SEM566F

SEM600F

SEM567F

SEM365EA

OIL PANKA

EM-11

Page 697 of 1659

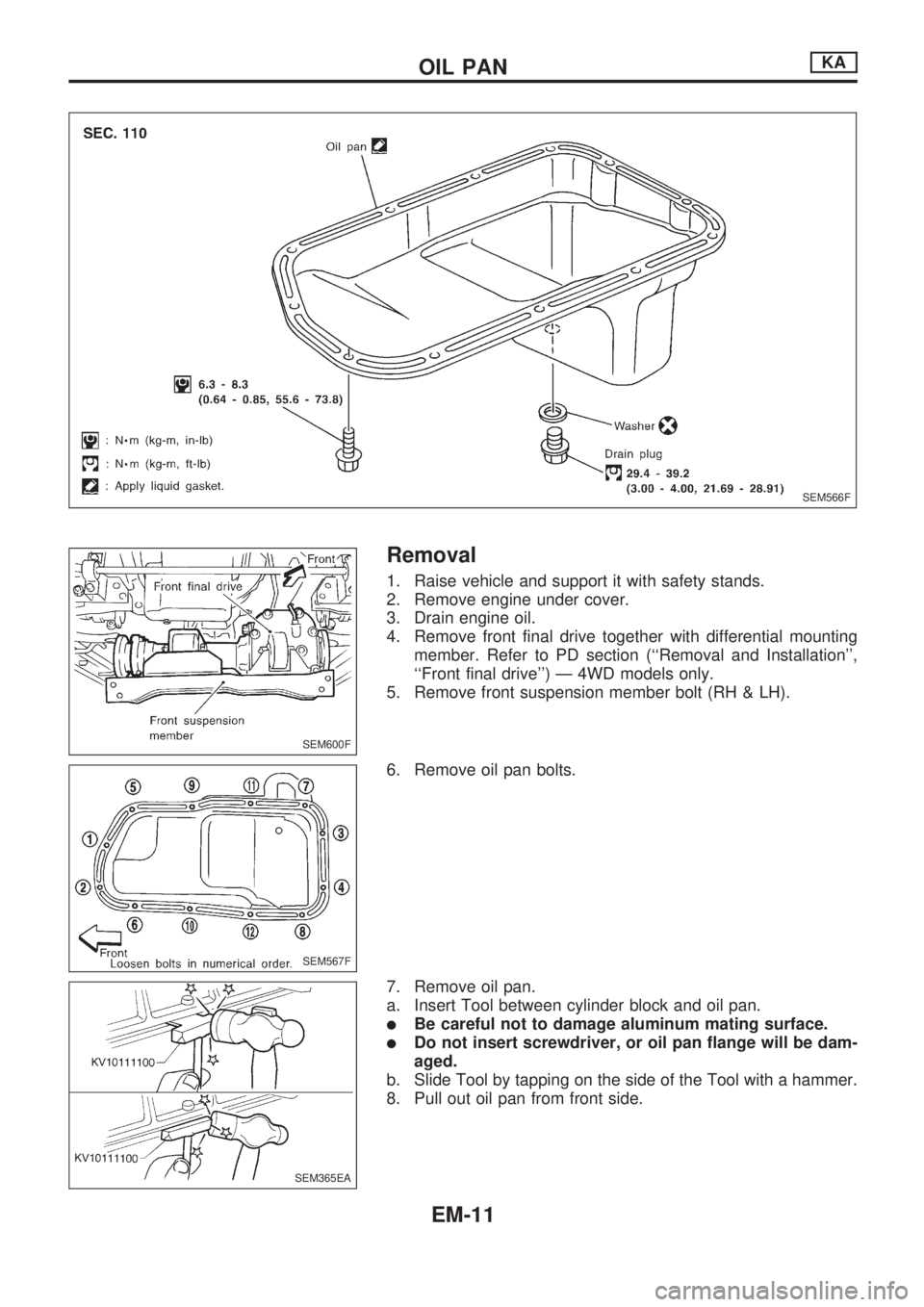

Removal

Removal order and pointsApplied model

2WD 4WD

1 Remove undercover.jj

2 Drain engine oil.jj

3Remove front propeller shaft

from front differential carrier.Ðj

4Remove front drive shaft fix-

ing bolts (RH & LH).Ðj

5Remove front suspension

crossmember.jj

6Remove differential front

mounting bolts (RH & LH)

and rear mounting bolts.Ðj

7Remove front differential car-

rier.ÐjRemoval order and pointsApplied model

2WD 4WD

8Remove front differential car-

rier mounting bracket.Ðj

9Remove transmission to rear

engine mounting bracket

nuts (RH & LH).jj

10Remove engine mounting

bolts or nuts (RH & LH).jj

11Lift up engine.

If necessary, disconnect

exhaust tube.jj

12 Remove oil pan.jj

WARNING:

lPlace vehicle on a flat and solid surface.

lPlace chocks at front and rear of rear wheels.

lYou should not remove oil pan until exhaust system and

cooling system have completely cooled off.

Otherwise, you may burn yourself and/or fire may break

out in the fuel line.

lWhen removing front and/or rear engine mounting bolts

or nuts, lift up slightly engine for safety work.

CAUTION:

lIn lifting engine, be careful not to hit against adjacent

parts, especially against accelerator wire casing end,

brake tube and brake master cylinder.

lFor tightening torque, refer to EM-71, MT and PD sec-

tions.

Remove oil pan bolts in order shown.

Installation

1. Install the oil pan gasket with the coated surface facing the

cylinder block and the notch facing the rear of the engine.

2. Tighten all bolts in reverse order of removal. For tightening

torque of oil pan and correct installing direction of drain plug

washer, refer to EM-71.

DEM022

DEM023

OIL PANTD

EM-52

Page 765 of 1659

FRONT AXLE &

FRONT SUSPENSION

SECTION

FA

CONTENTS

PRECAUTIONS AND PREPARATION..................... 1

Precautions ............................................................ 1

Special Service Tools ............................................ 1

Commercial Service Tools ..................................... 2

FRONT AXLE AND FRONT SUSPENSION............. 3

ON-VEHICLE SERVICE............................................ 5

Front Axle and Front Suspension Parts ................ 5

Front Wheel Bearing .............................................. 5

Front Wheel Alignment .......................................... 7

Drive Shaft ........................................................... 11

FRONT AXLE.......................................................... 12

Manual-lock Free-running Hub - 4WD - .............. 14

Auto-lock Free-running Hub - 4WD -................... 15

Removal ............................................................... 15

Installation ............................................................ 15Wheel Hub and Rotor Disc .................................. 16

Knuckle Spindle ................................................... 18

Drive Shaft - 4WD - ............................................. 21

FRONT SUSPENSION............................................ 26

Shock Absorber ................................................... 28

Torsion Bar Spring ............................................... 28

Stabilizer Bar........................................................ 31

Upper Link............................................................ 31

Tension Rod......................................................... 33

Lower Link............................................................ 33

Upper Ball Joint and Lower Ball Joint ................. 34

SERVICE DATA AND SPECIFICATIONS (SDS)... 35

General Specifications ......................................... 35

Inspection and Adjustment .................................. 35

FA

Page 766 of 1659

Precautions

lWhen installing rubber parts, final tightening must be

carried out under unladen condition* with tires on

ground.

* Fuel, radiator coolant and engine oil full. Spare tire,

jack, hand tools and mats in designated positions.

lUse flare nut wrench when removing or installing brake

tubes.

lAfter installing removed suspension parts, check wheel

alignment and adjust if necessary.

lAlways torque brake lines when installing.

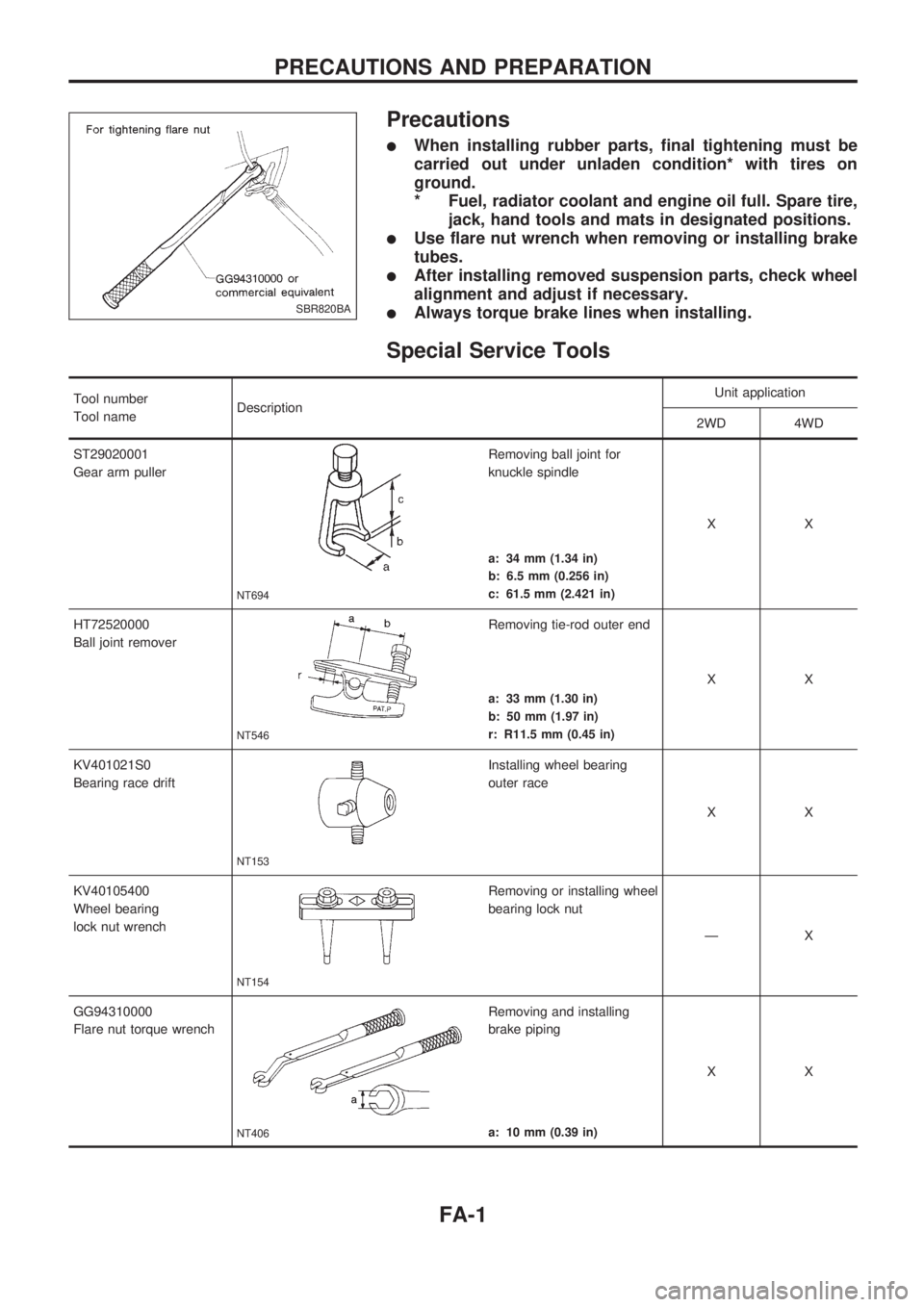

Special Service Tools

Tool number

Tool nameDescriptionUnit application

2WD 4WD

ST29020001

Gear arm puller

NT694

Removing ball joint for

knuckle spindle

XX

a: 34 mm (1.34 in)

b: 6.5 mm (0.256 in)

c: 61.5 mm (2.421 in)

HT72520000

Ball joint remover

NT546

Removing tie-rod outer end

XX

a: 33 mm (1.30 in)

b: 50 mm (1.97 in)

r: R11.5 mm (0.45 in)

KV401021S0

Bearing race drift

NT153

Installing wheel bearing

outer race

XX

KV40105400

Wheel bearing

lock nut wrench

NT154

Removing or installing wheel

bearing lock nut

ÐX

GG94310000

Flare nut torque wrench

NT406

Removing and installing

brake piping

XX

a: 10 mm (0.39 in)

SBR820BA

PRECAUTIONS AND PREPARATION

FA-1

Page 768 of 1659

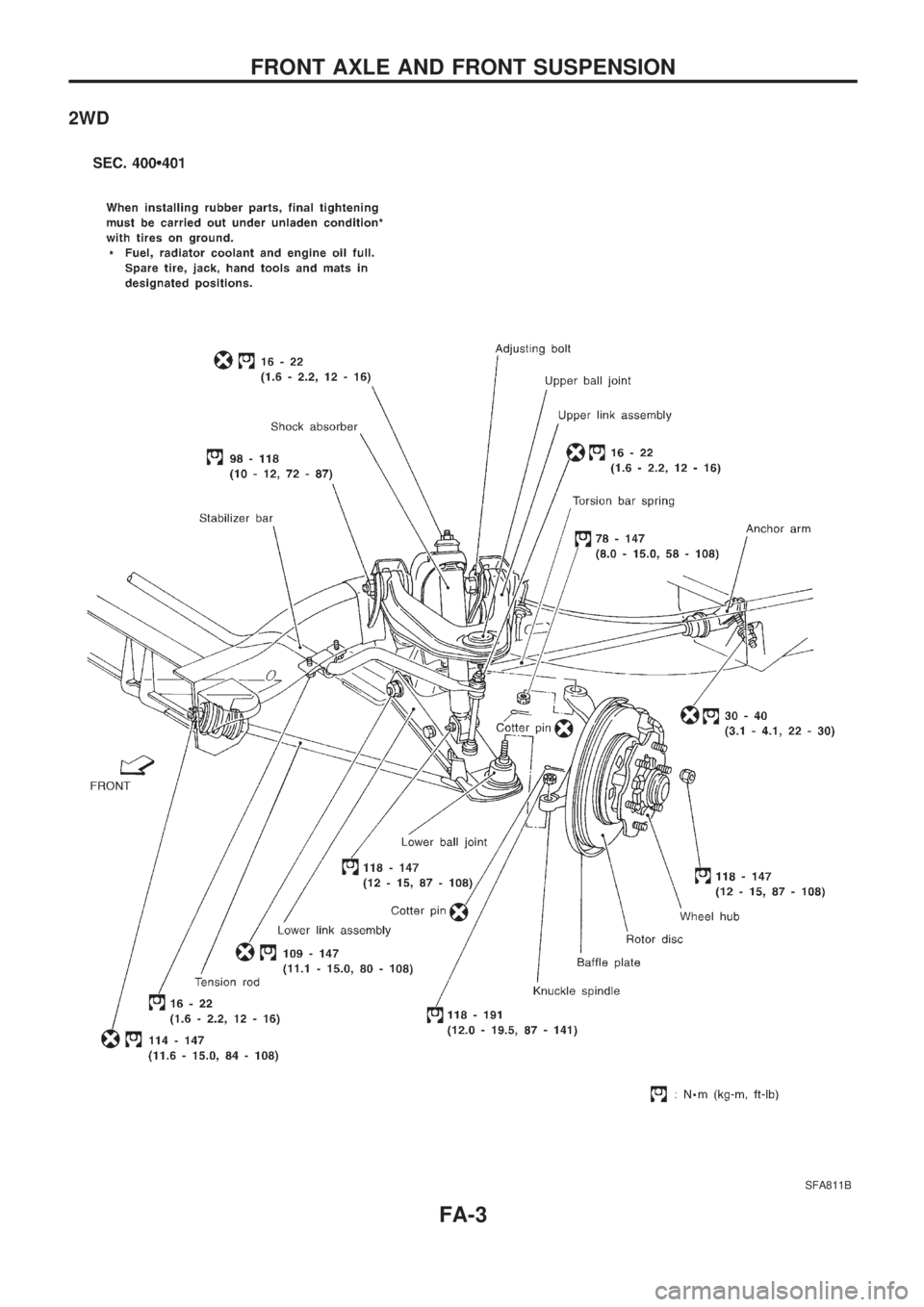

2WD

SFA811B

FRONT AXLE AND FRONT SUSPENSION

FA-3

Page 769 of 1659

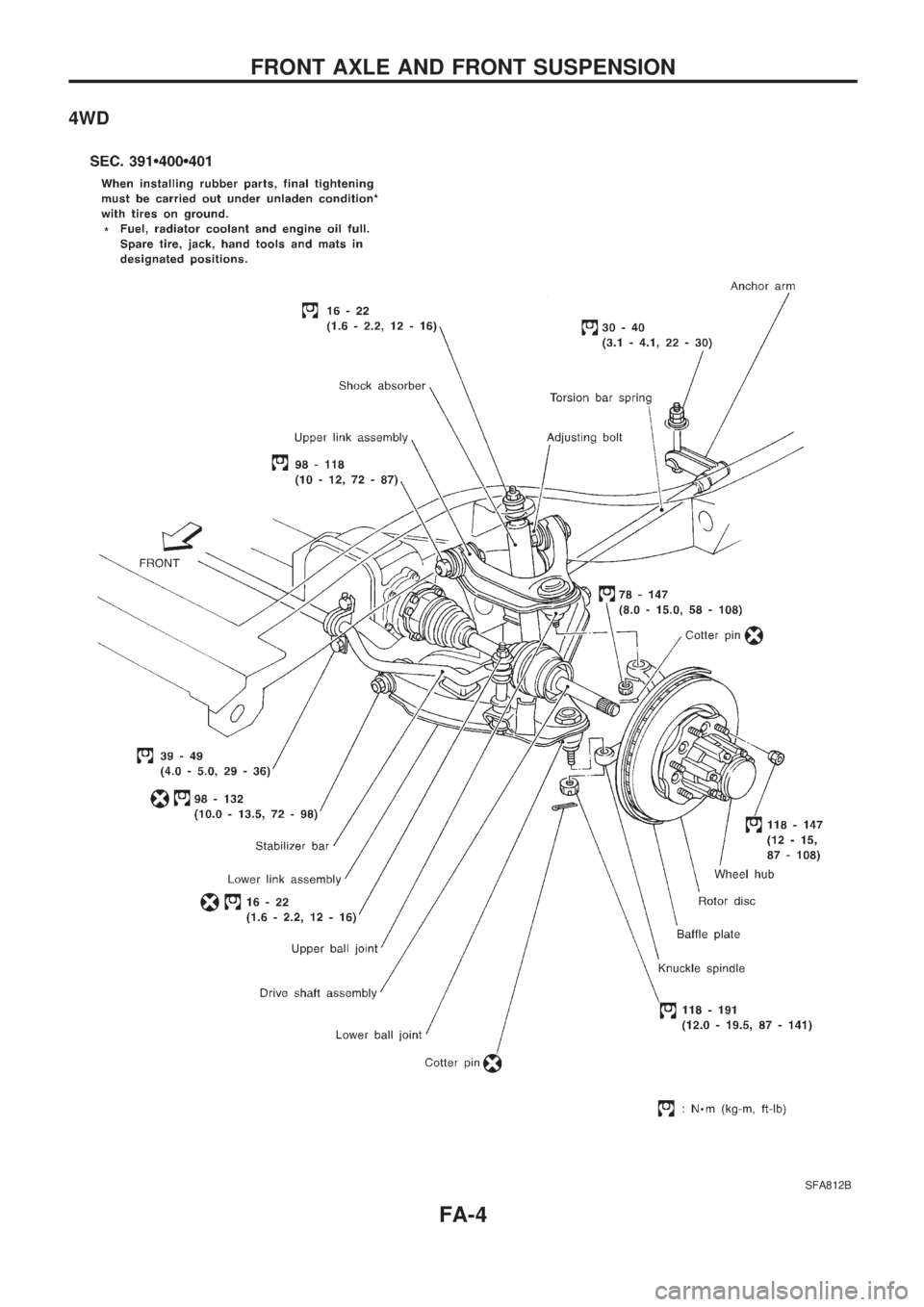

4WD

SFA812B

FRONT AXLE AND FRONT SUSPENSION

FA-4

Page 770 of 1659

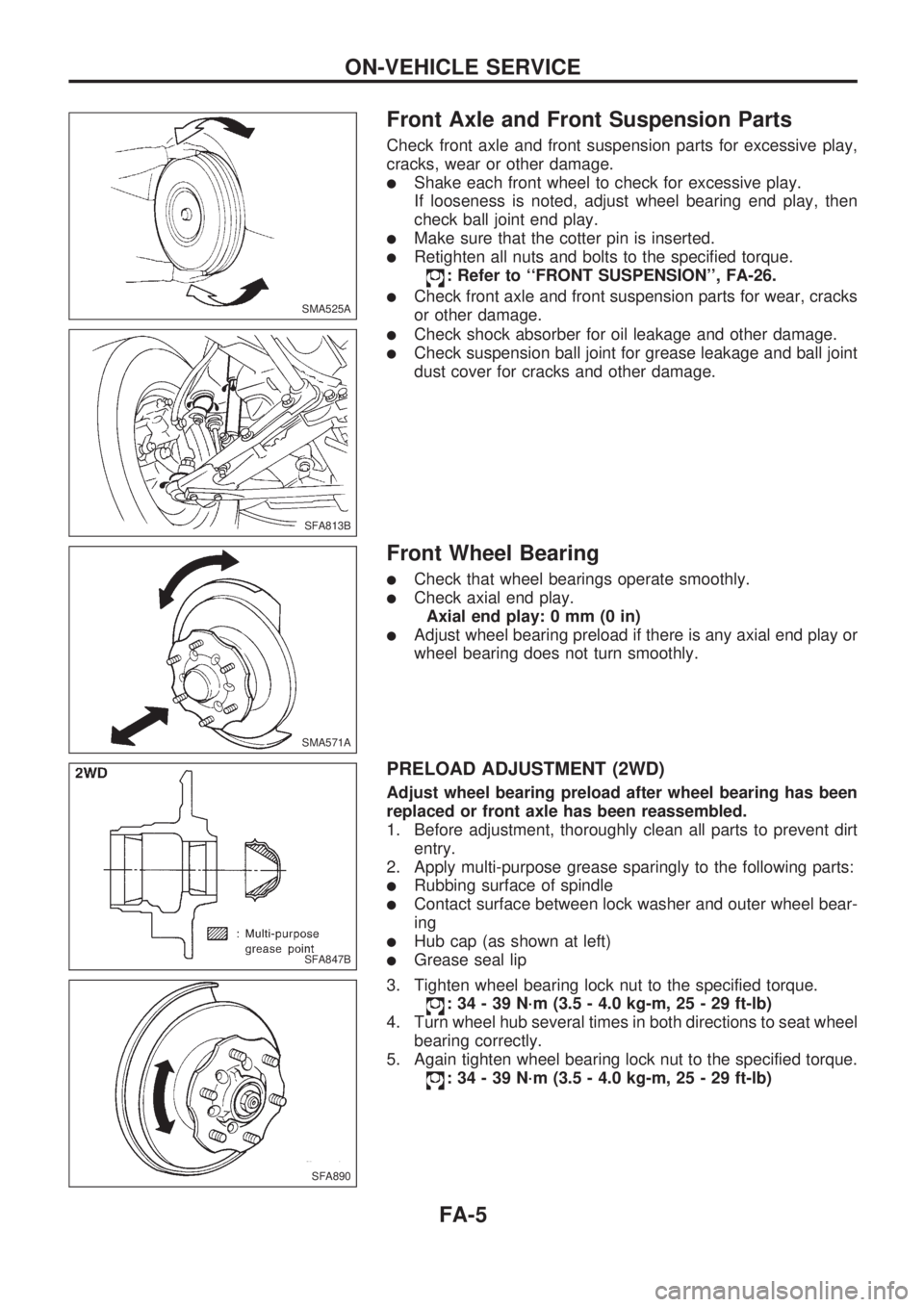

Front Axle and Front Suspension Parts

Check front axle and front suspension parts for excessive play,

cracks, wear or other damage.

lShake each front wheel to check for excessive play.

If looseness is noted, adjust wheel bearing end play, then

check ball joint end play.

lMake sure that the cotter pin is inserted.

lRetighten all nuts and bolts to the specified torque.

: Refer to ``FRONT SUSPENSION'', FA-26.

lCheck front axle and front suspension parts for wear, cracks

or other damage.

lCheck shock absorber for oil leakage and other damage.

lCheck suspension ball joint for grease leakage and ball joint

dust cover for cracks and other damage.

Front Wheel Bearing

lCheck that wheel bearings operate smoothly.

lCheck axial end play.

Axial end play: 0 mm (0 in)

lAdjust wheel bearing preload if there is any axial end play or

wheel bearing does not turn smoothly.

PRELOAD ADJUSTMENT (2WD)

Adjust wheel bearing preload after wheel bearing has been

replaced or front axle has been reassembled.

1. Before adjustment, thoroughly clean all parts to prevent dirt

entry.

2. Apply multi-purpose grease sparingly to the following parts:

lRubbing surface of spindle

lContact surface between lock washer and outer wheel bear-

ing

lHub cap (as shown at left)

lGrease seal lip

3. Tighten wheel bearing lock nut to the specified torque.

: 34 - 39 N´m (3.5 - 4.0 kg-m, 25 - 29 ft-lb)

4. Turn wheel hub several times in both directions to seat wheel

bearing correctly.

5. Again tighten wheel bearing lock nut to the specified torque.

: 34 - 39 N´m (3.5 - 4.0 kg-m, 25 - 29 ft-lb)

SMA525A

SFA813B

SMA571A

SFA847B

SFA890

ON-VEHICLE SERVICE

FA-5

Page 772 of 1659

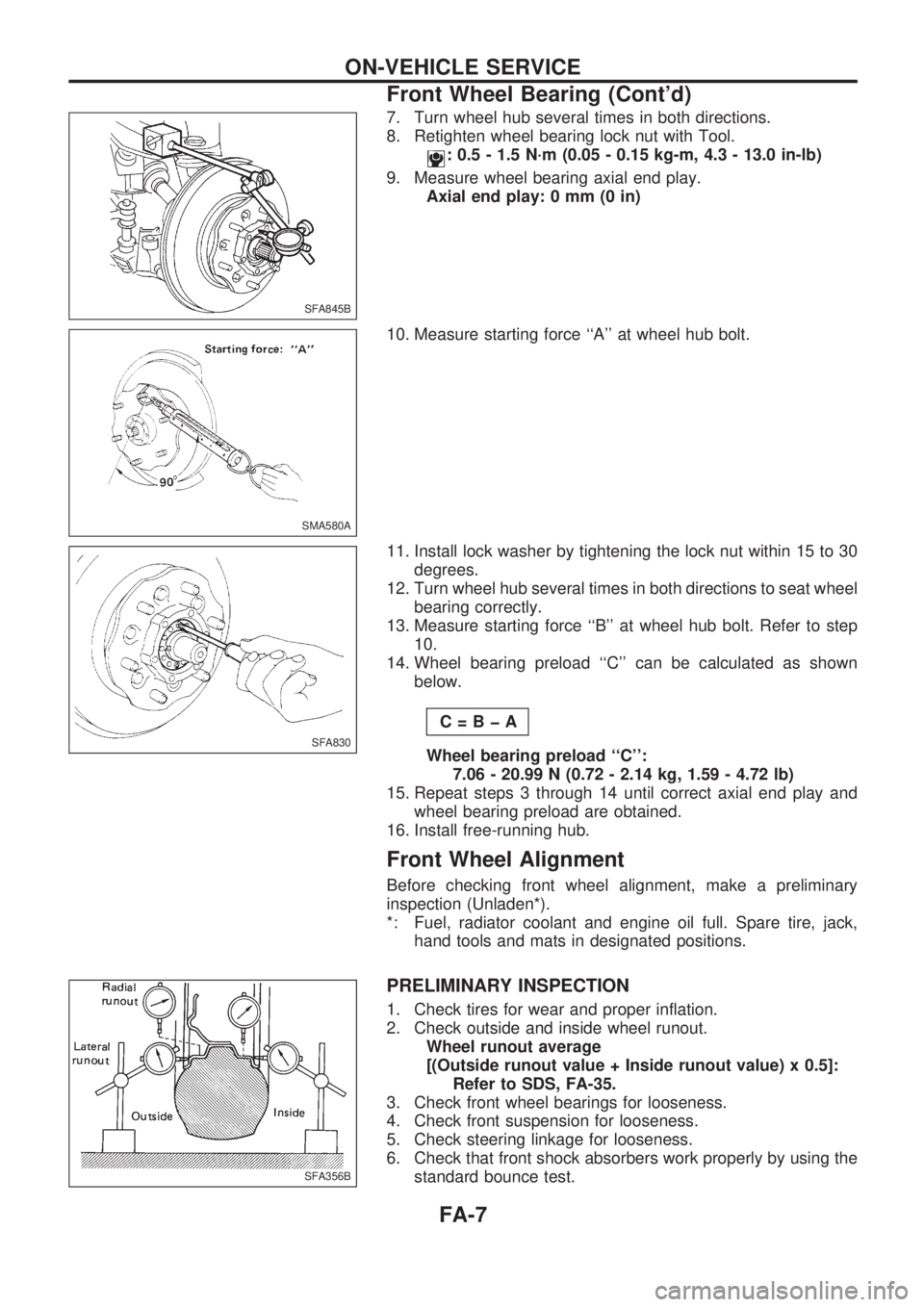

7. Turn wheel hub several times in both directions.

8. Retighten wheel bearing lock nut with Tool.

: 0.5 - 1.5 N´m (0.05 - 0.15 kg-m, 4.3 - 13.0 in-lb)

9. Measure wheel bearing axial end play.

Axial end play: 0 mm (0 in)

10. Measure starting force ``A'' at wheel hub bolt.

11. Install lock washer by tightening the lock nut within 15 to 30

degrees.

12. Turn wheel hub several times in both directions to seat wheel

bearing correctly.

13. Measure starting force ``B'' at wheel hub bolt. Refer to step

10.

14. Wheel bearing preload ``C'' can be calculated as shown

below.

C=BþA

Wheel bearing preload ``C'':

7.06 - 20.99 N (0.72 - 2.14 kg, 1.59 - 4.72 lb)

15. Repeat steps 3 through 14 until correct axial end play and

wheel bearing preload are obtained.

16. Install free-running hub.

Front Wheel Alignment

Before checking front wheel alignment, make a preliminary

inspection (Unladen*).

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

PRELIMINARY INSPECTION

1. Check tires for wear and proper inflation.

2. Check outside and inside wheel runout.

Wheel runout average

[(Outside runout value + Inside runout value) x 0.5]:

Refer to SDS, FA-35.

3. Check front wheel bearings for looseness.

4. Check front suspension for looseness.

5. Check steering linkage for looseness.

6. Check that front shock absorbers work properly by using the

standard bounce test.

SFA845B

SMA580A

SFA830

SFA356B

ON-VEHICLE SERVICE

Front Wheel Bearing (Cont'd)

FA-7

Page 773 of 1659

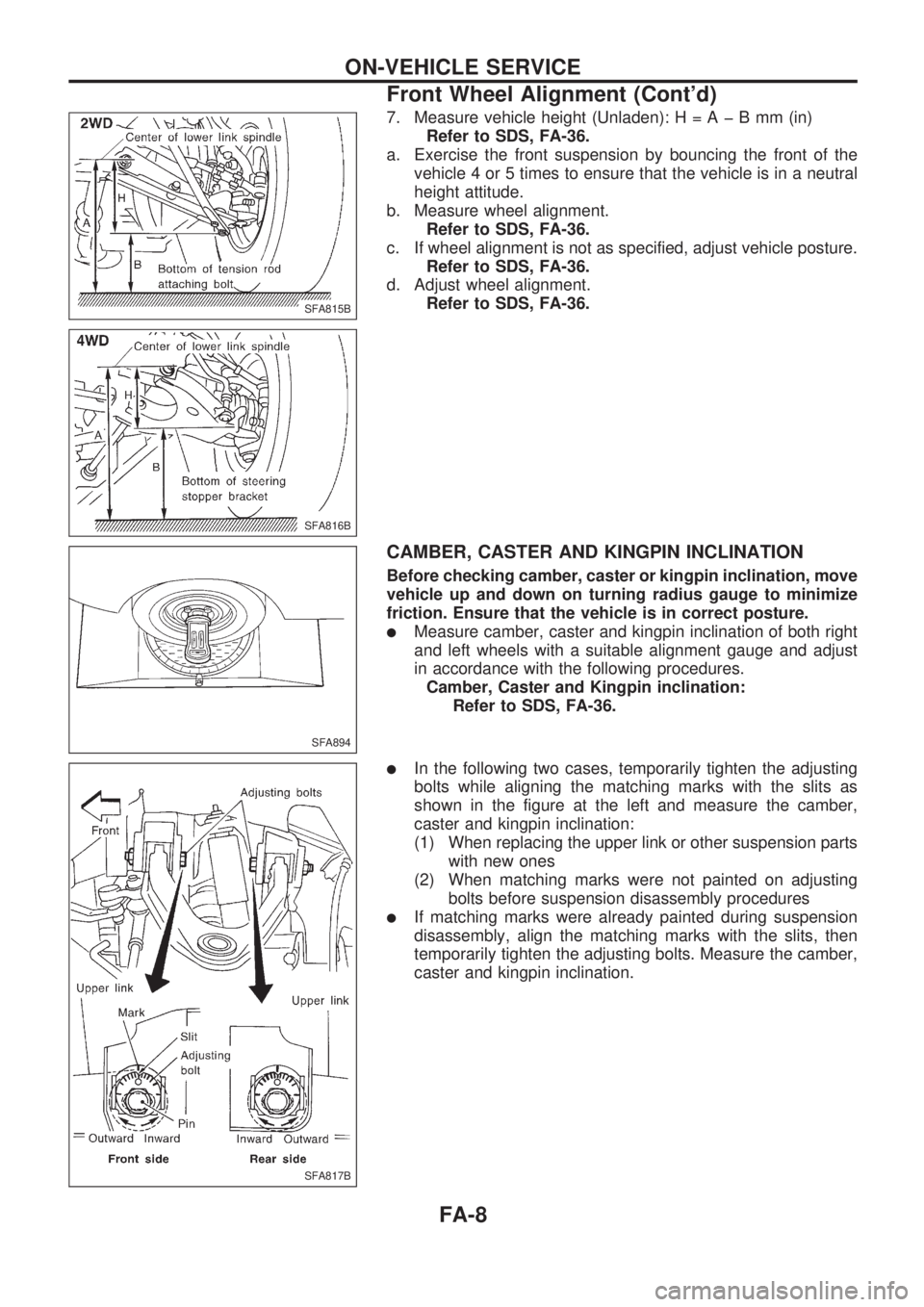

7. Measure vehicle height (Unladen):H=AþBmm(in)

Refer to SDS, FA-36.

a. Exercise the front suspension by bouncing the front of the

vehicle 4 or 5 times to ensure that the vehicle is in a neutral

height attitude.

b. Measure wheel alignment.

Refer to SDS, FA-36.

c. If wheel alignment is not as specified, adjust vehicle posture.

Refer to SDS, FA-36.

d. Adjust wheel alignment.

Refer to SDS, FA-36.

CAMBER, CASTER AND KINGPIN INCLINATION

Before checking camber, caster or kingpin inclination, move

vehicle up and down on turning radius gauge to minimize

friction. Ensure that the vehicle is in correct posture.

lMeasure camber, caster and kingpin inclination of both right

and left wheels with a suitable alignment gauge and adjust

in accordance with the following procedures.

Camber, Caster and Kingpin inclination:

Refer to SDS, FA-36.

lIn the following two cases, temporarily tighten the adjusting

bolts while aligning the matching marks with the slits as

shown in the figure at the left and measure the camber,

caster and kingpin inclination:

(1) When replacing the upper link or other suspension parts

with new ones

(2) When matching marks were not painted on adjusting

bolts before suspension disassembly procedures

lIf matching marks were already painted during suspension

disassembly, align the matching marks with the slits, then

temporarily tighten the adjusting bolts. Measure the camber,

caster and kingpin inclination.

SFA815B

SFA816B

SFA894

SFA817B

ON-VEHICLE SERVICE

Front Wheel Alignment (Cont'd)

FA-8