service NISSAN PICK-UP 1998 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 2 of 1659

FOREWORD

This manual contains maintenance and repair procedures for NISSAN

PICKUP, model D22 series.

In order to assure your safety and the efficient functioning of the vehicle,

this manual should be read thoroughly. It is especially important that the

PRECAUTIONS in the GI section be completely understood before starting

any repair task.

All information in this manual is based on the latest product information

at the time of publication. The right is reserved to make changes in speci-

®cations and methods at any time without notice.

IMPORTANT SAFETY NOTICE

The proper performance of service is essential for both the safety of the

technician and the efficient functioning of the vehicle.

The service methods in this Service Manual are described in such a man-

ner that the service may be performed safely and accurately.

Service varies with the procedures used, the skills of the technician and the

tools and parts available. Accordingly, anyone using service procedures,

tools or parts which are not speci®cally recommended by NISSAN must

®rst completely satisfy himself that neither his safety nor the vehicle's

safety will be jeopardized by the service method selected.

NISSAN EUROPE S.A.S.

Service Engineering Section

Paris, France

Page 3 of 1659

BRAKE SYSTEM

SECTIONBR

CONTENTS

PRECAUTIONS AND PREPARATION..................... 1

Supplemental Restraint System (SRS) ``AIR

BAG'' (4WD models).............................................. 1

Supplemental Restraint System (SRS) ``AIR

BAG'' (2WD models).............................................. 1

Precautions for Brake System ............................... 1

Special Service Tools ............................................ 2

Commercial Service Tools ..................................... 2

CHECK AND ADJUSTMENT.................................... 3

Checking Brake Fluid Level ................................... 3

Checking Brake Line.............................................. 3

Changing Brake Fluid ............................................ 3

Bleeding Brake System ......................................... 4

BRAKE HYDRAULIC LINE....................................... 5

CONTROL VALVE..................................................... 7

Load Sensing Valve ............................................... 7

BRAKE PEDAL AND BRACKET............................ 10

Removal and Installation ..................................... 10

Inspection ............................................................. 11

Adjustment ........................................................... 11

MASTER CYLINDER............................................... 12

Removal ............................................................... 12

Disassembly ......................................................... 13

Inspection ............................................................. 13

Assembly.............................................................. 13

Installation ............................................................ 14

BRAKE BOOSTER.................................................. 15

On-vehicle Service ............................................... 15

Removal ............................................................... 15

Inspection ............................................................. 15

Installation ............................................................ 16

VACUUM HOSE...................................................... 17

Removal and Installation ..................................... 17Inspection ............................................................. 17

VACUUM PUMP...................................................... 19

Removal and Installation ..................................... 19

Inspection ............................................................. 19

FRONT DISC BRAKE............................................. 21

Pad Replacement ................................................ 21

Removal ............................................................... 22

Disassembly ......................................................... 23

Inspection - Caliper .............................................. 23

Inspection - Rotor ................................................ 23

Assembly.............................................................. 24

Installation ............................................................ 24

Brake Burnishing Procedure ................................ 24

REAR DRUM BRAKE............................................. 26

Removal ............................................................... 27

Inspection - Wheel Cylinder................................. 28

Wheel Cylinder Overhaul ..................................... 28

Inspection - Drum ................................................ 28

Inspection - Lining................................................ 28

Installation ............................................................ 28

PARKING BRAKE CONTROL................................ 30

Removal and Installation ..................................... 31

Inspection ............................................................. 31

Adjustment ........................................................... 31

ANTI-LOCK BRAKE SYSTEM................................ 32

Purpose ................................................................ 32

Operation ............................................................. 32

ABS Hydraulic Circuit .......................................... 32

System Components............................................ 33

System Description .............................................. 33

Removal and Installation ..................................... 35

TROUBLE DIAGNOSES......................................... 38

BR

Page 4 of 1659

How to Perform Trouble Diagnoses for Quick

and Accurate Repair ............................................ 38

Preliminary Check ................................................ 39

Component Parts and Harness Connector

Location................................................................ 40

Schematic/2WD Models....................................... 41

Wiring Diagram - ABS -/2WD LHD Models ......... 42

Wiring Diagram - ABS -/2WD RHD Models ........ 45

Schematic/4WD Models....................................... 48

Wiring Diagram - ABS -/4WD Models ................. 49

Self-diagnosis....................................................... 53

CONSULT ............................................................ 56

CONSULT Inspection Procedure......................... 57

Ground Circuit Check .......................................... 62

TROUBLE DIAGNOSES FOR

SELF-DIAGNOSTIC ITEMS.................................... 63

Diagnostic Procedure 1

(Wheel sensor or rotor)........................................ 63

Diagnostic Procedure 2 (ABS actuator

solenoid valve and solenoid valve relay)............. 65

Diagnostic Procedure 3 (Motor relay or motor) ... 67

Diagnostic Procedure 4 (Low voltage) ................ 69Diagnostic Procedure 5 (G sensor) ..................... 70

Diagnostic Procedure 6 (Control unit) ................. 71

TROUBLE DIAGNOSES FOR SYMPTOMS........... 72

Diagnostic Procedure 7

(ABS works frequently.) ....................................... 72

Diagnostic Procedure 8

(Unexpected pedal action) ................................... 73

Diagnostic Procedure 9

(Long stopping distance) ..................................... 73

Diagnostic Procedure 10

(ABS does not work.)........................................... 74

Diagnostic Procedure 11

(Pedal vibration and noise) .................................. 74

Diagnostic Procedure 12 (Warning lamp does

not come on when ignition switch is turned

ON.)...................................................................... 75

Diagnostic Procedure 13 (Warning lamp stays

on when ignition switch is turned ON.)................ 77

SERVICE DATA AND SPECIFICATIONS (SDS)... 78

General Specifications ......................................... 78

Inspection and Adjustment .................................. 80

When you read wiring diagrams:

lRead GI section, ``HOW TO READ WIRING DIAGRAMS''.

lSee EL section, ``POWER SUPPLY ROUTING'' for power distribution circuit.

When you perform trouble diagnoses, read GI section, ``HOW TO FOLLOW FLOW

CHART IN TROUBLE DIAGNOSES'' and ``HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT''.

Page 5 of 1659

Supplemental Restraint System (SRS) ``AIR

BAG'' (4WD models)

The Supplemental Restraint System ``AIR BAG'', used along with a seat belt, helps to reduce the risk or

severity of injury to the driver in a frontal collision. The Supplemental Restraint System consists of air bag

module (located in the center of the steering wheel), a diagnosis sensor unit, warning lamp, wiring harness

and spiral cable. Information necessary to service the system safely is included in theRS sectionof this

Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses are covered with yellow insulation either just before the

harness connectors or for the complete harness, for easy identification.

Supplemental Restraint System (SRS) ``AIR

BAG'' (2WD models)

The Supplemental Restraint System ``AIR BAG'', used along with a seat belt, helps to reduce the risk or

severity of injury to the driver in a frontal collision. The Supplemental Restraint System consists of an air

bag module (located in the center of the steering wheel), a diagnosis sensor unit, warning lamp and spiral

cable. Information necessary to service the system safely is included in theRS sectionof this Service

Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

lDo not use electrical test equipment on any circuit related to the SRS.

Precautions for Brake System

lUse brake fluid DOT 3 or DOT 4*1.

lNever reuse drained brake fluid.

lBe careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas, wash it away with water immediately.

lTo clean master cylinder parts, disc brake caliper parts

or wheel cylinder parts, use clean brake fluid.

lNever use mineral oils such as gasoline or kerosene.

They will ruin rubber parts of the hydraulic system.

lUse flare nut wrench when removing and installing brake

tubes.

lAlways torque brake lines when installing.

WARNING:

lClean brakes with a vacuum dust collector to minimize

the hazard of airborne materials.

*1: Refer to MA section (``Fluids and Lubricants'', ``RECOM-

MENDED FLUIDS AND LUBRICANTS'').

SBR820BA

PRECAUTIONS AND PREPARATION

BR-1

Page 6 of 1659

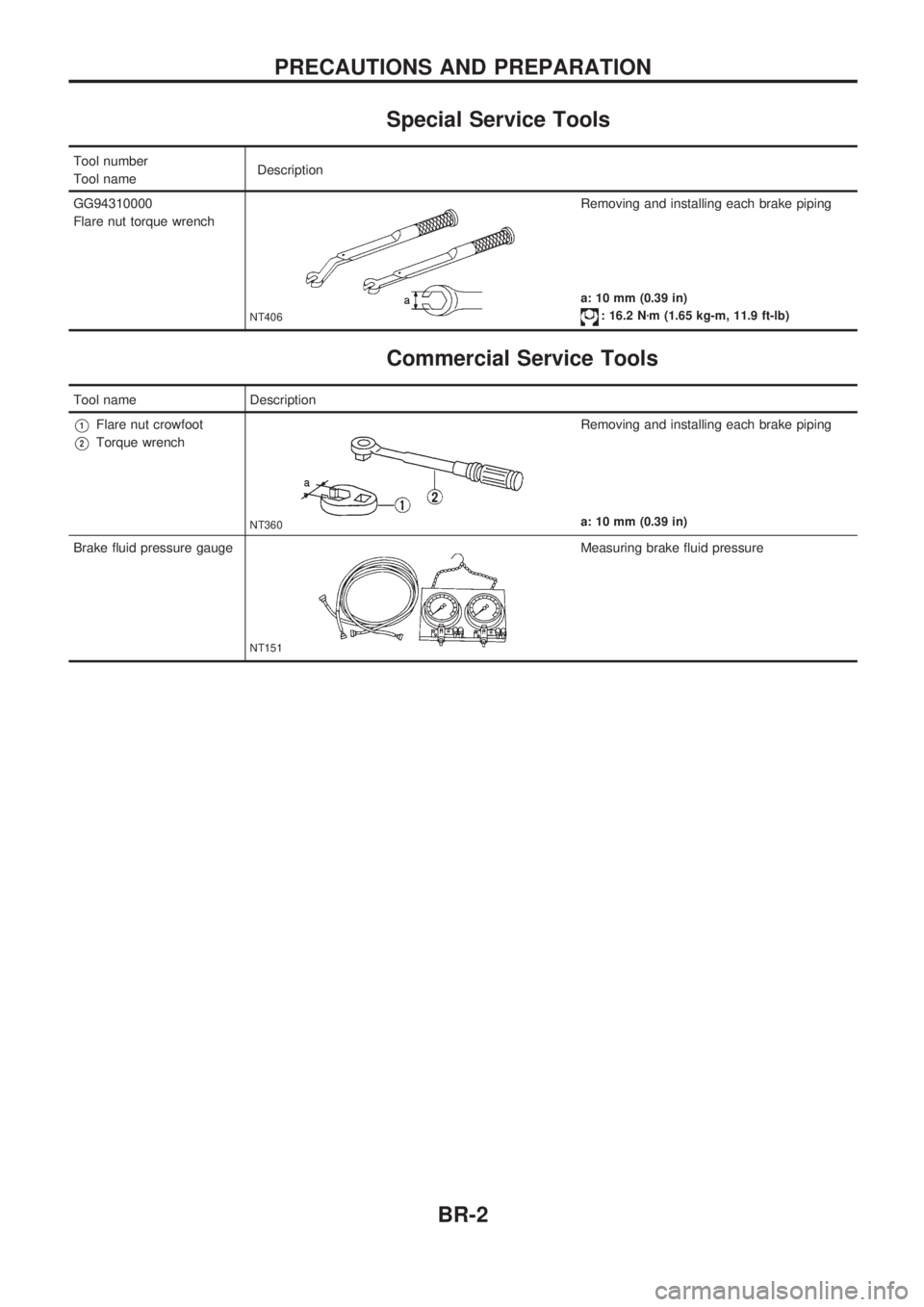

Special Service Tools

Tool number

Tool nameDescription

GG94310000

Flare nut torque wrench

NT406

Removing and installing each brake piping

a: 10 mm (0.39 in)

: 16.2 Nzm (1.65 kg-m, 11.9 ft-lb)

Commercial Service Tools

Tool name Description

V1Flare nut crowfoot

V2Torque wrench

NT360

Removing and installing each brake piping

a: 10 mm (0.39 in)

Brake fluid pressure gauge

NT151

Measuring brake fluid pressure

PRECAUTIONS AND PREPARATION

BR-2

Page 19 of 1659

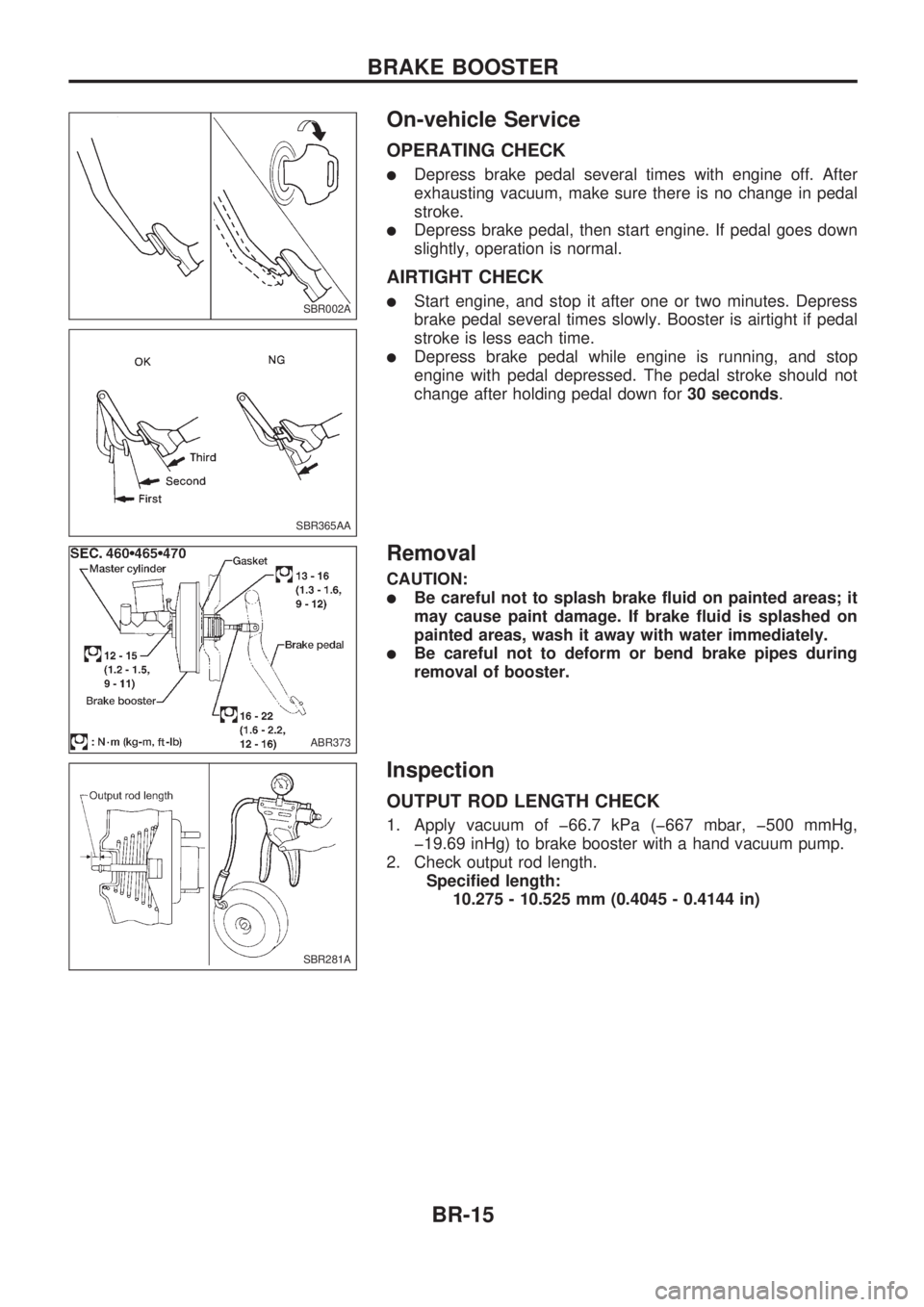

On-vehicle Service

OPERATING CHECK

lDepress brake pedal several times with engine off. After

exhausting vacuum, make sure there is no change in pedal

stroke.

lDepress brake pedal, then start engine. If pedal goes down

slightly, operation is normal.

AIRTIGHT CHECK

lStart engine, and stop it after one or two minutes. Depress

brake pedal several times slowly. Booster is airtight if pedal

stroke is less each time.

lDepress brake pedal while engine is running, and stop

engine with pedal depressed. The pedal stroke should not

change after holding pedal down for30 seconds.

Removal

CAUTION:

lBe careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas, wash it away with water immediately.

lBe careful not to deform or bend brake pipes during

removal of booster.

Inspection

OUTPUT ROD LENGTH CHECK

1. Apply vacuum of þ66.7 kPa (þ667 mbar, þ500 mmHg,

þ19.69 inHg) to brake booster with a hand vacuum pump.

2. Check output rod length.

Specified length:

10.275 - 10.525 mm (0.4045 - 0.4144 in)

SBR002A

SBR365AA

ABR373

SBR281A

BRAKE BOOSTER

BR-15

Page 27 of 1659

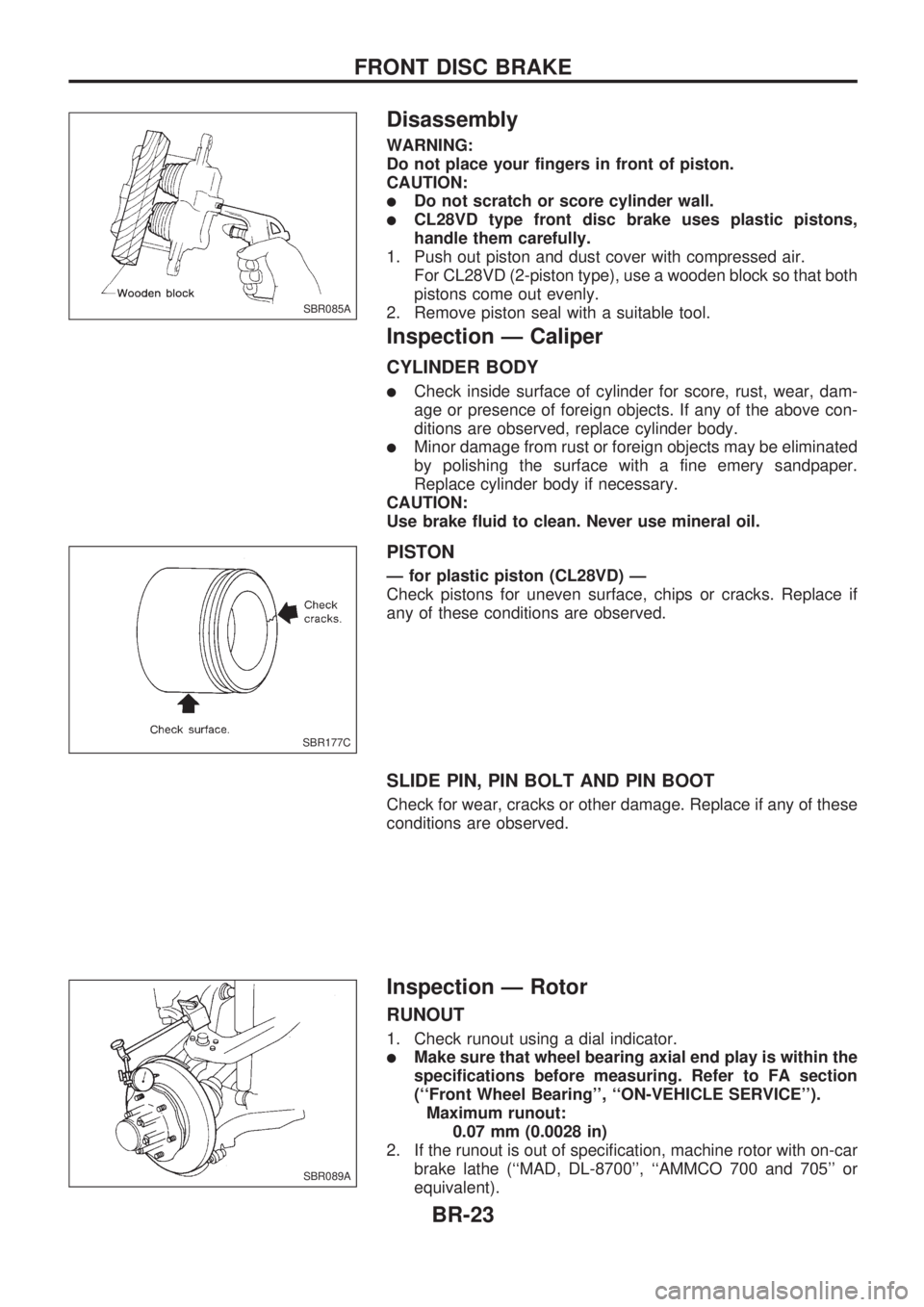

Disassembly

WARNING:

Do not place your fingers in front of piston.

CAUTION:

lDo not scratch or score cylinder wall.

lCL28VD type front disc brake uses plastic pistons,

handle them carefully.

1. Push out piston and dust cover with compressed air.

For CL28VD (2-piston type), use a wooden block so that both

pistons come out evenly.

2. Remove piston seal with a suitable tool.

Inspection Ð Caliper

CYLINDER BODY

lCheck inside surface of cylinder for score, rust, wear, dam-

age or presence of foreign objects. If any of the above con-

ditions are observed, replace cylinder body.

lMinor damage from rust or foreign objects may be eliminated

by polishing the surface with a fine emery sandpaper.

Replace cylinder body if necessary.

CAUTION:

Use brake fluid to clean. Never use mineral oil.

PISTON

Ð for plastic piston (CL28VD) Ð

Check pistons for uneven surface, chips or cracks. Replace if

any of these conditions are observed.

SLIDE PIN, PIN BOLT AND PIN BOOT

Check for wear, cracks or other damage. Replace if any of these

conditions are observed.

Inspection Ð Rotor

RUNOUT

1. Check runout using a dial indicator.

lMake sure that wheel bearing axial end play is within the

specifications before measuring. Refer to FA section

(``Front Wheel Bearing'', ``ON-VEHICLE SERVICE'').

Maximum runout:

0.07 mm (0.0028 in)

2. If the runout is out of specification, machine rotor with on-car

brake lathe (``MAD, DL-8700'', ``AMMCO 700 and 705'' or

equivalent).

SBR085A

SBR177C

SBR089A

FRONT DISC BRAKE

BR-23

Page 76 of 1659

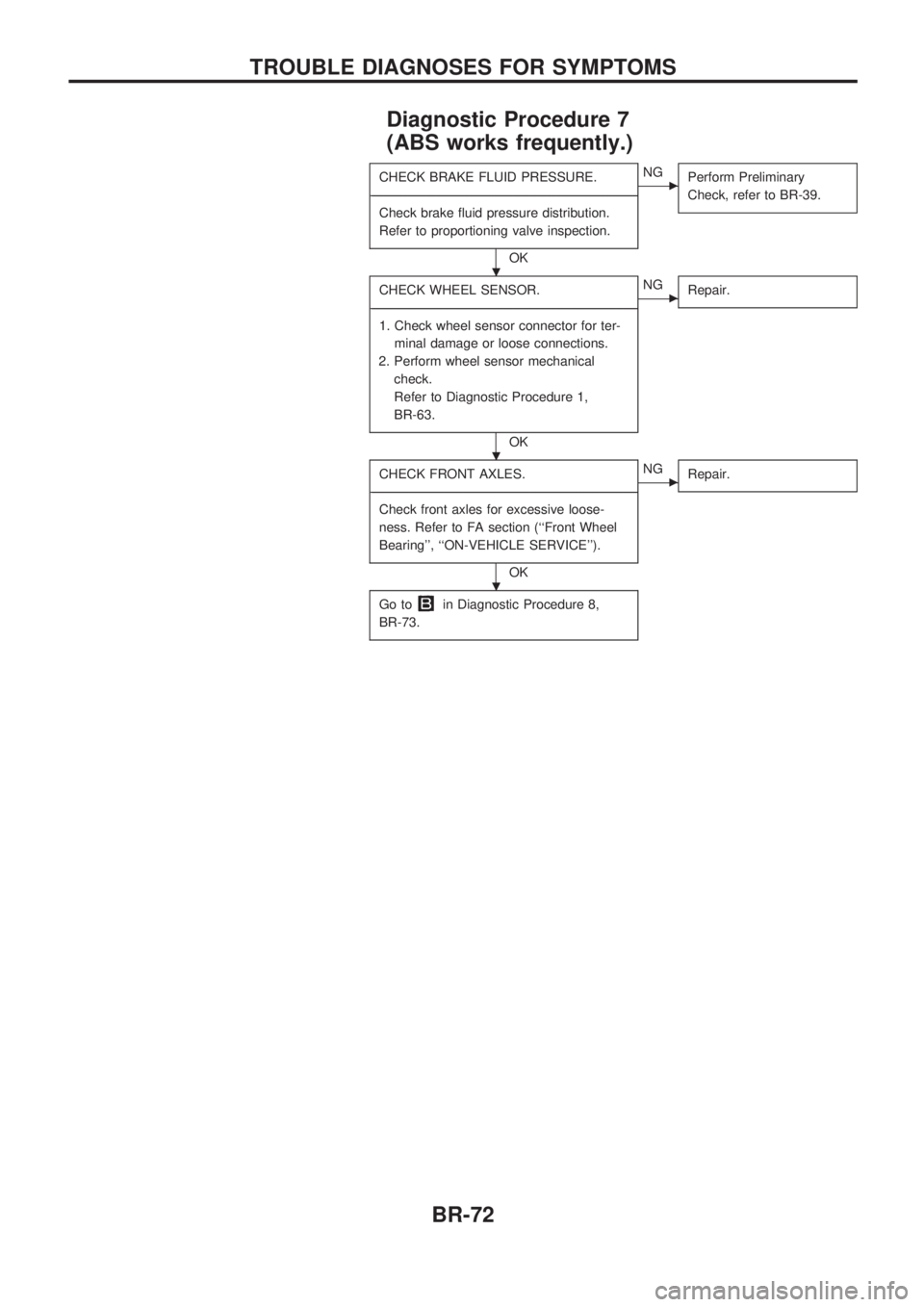

Diagnostic Procedure 7

(ABS works frequently.)

CHECK BRAKE FLUID PRESSURE.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check brake fluid pressure distribution.

Refer to proportioning valve inspection.

OK

cNG

Perform Preliminary

Check, refer to BR-39.

CHECK WHEEL SENSOR.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Check wheel sensor connector for ter-

minal damage or loose connections.

2. Perform wheel sensor mechanical

check.

Refer to Diagnostic Procedure 1,

BR-63.

OK

cNG

Repair.

CHECK FRONT AXLES.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check front axles for excessive loose-

ness. Refer to FA section (``Front Wheel

Bearing'', ``ON-VEHICLE SERVICE'').

OK

cNG

Repair.

Go toin Diagnostic Procedure 8,

BR-73.

.

.

.

TROUBLE DIAGNOSES FOR SYMPTOMS

BR-72

Page 82 of 1659

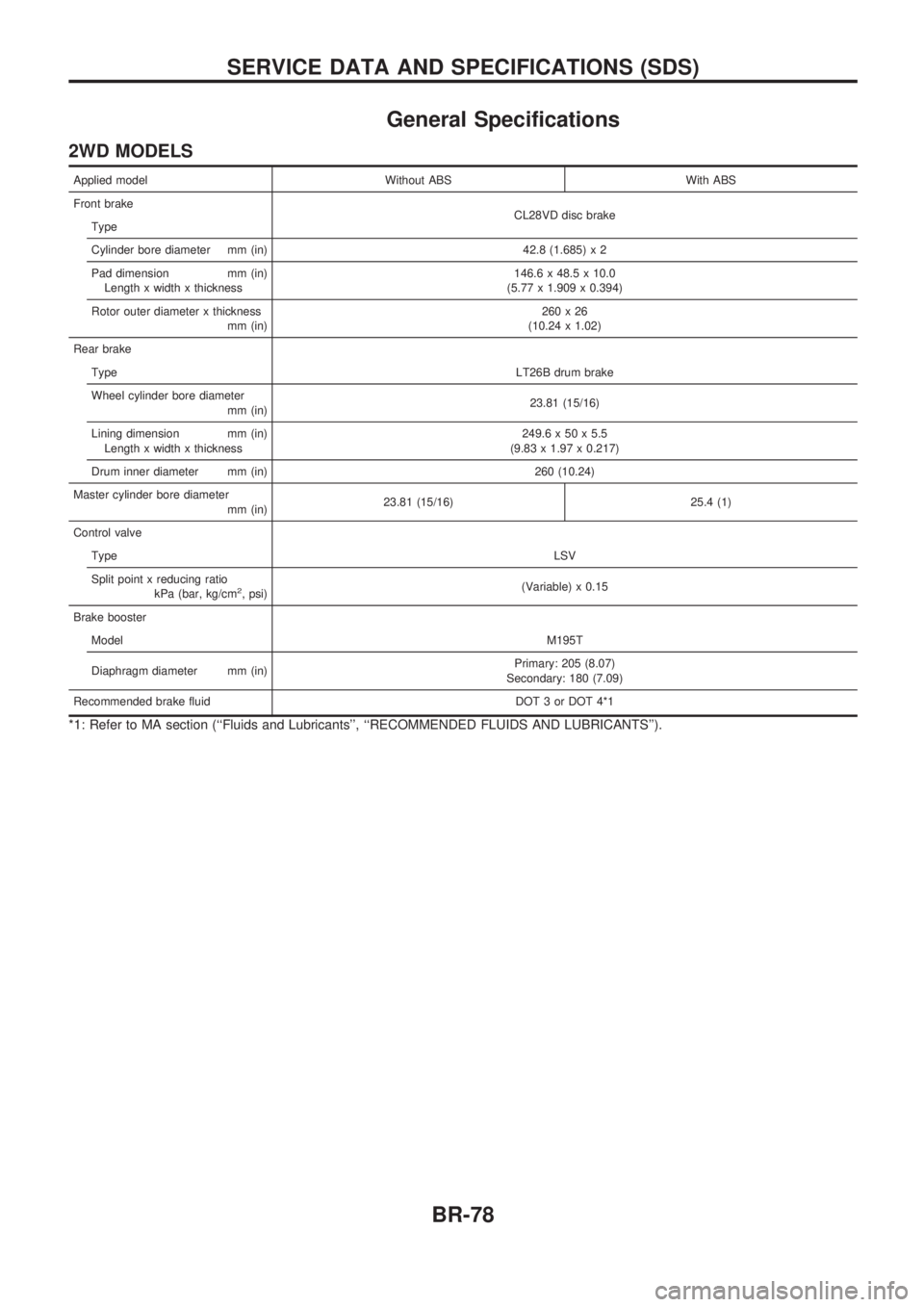

General Specifications

2WD MODELS

Applied model Without ABS With ABS

Front brake

CL28VD disc brake

Type

Cylinder bore diameter mm (in) 42.8 (1.685) x 2

Pad dimension mm (in)

Length x width x thickness146.6 x 48.5 x 10.0

(5.77 x 1.909 x 0.394)

Rotor outer diameter x thickness

mm (in)260x26

(10.24 x 1.02)

Rear brake

TypeLT26B drum brake

Wheel cylinder bore diameter

mm (in)23.81 (15/16)

Lining dimension mm (in)

Length x width x thickness249.6 x 50 x 5.5

(9.83 x 1.97 x 0.217)

Drum inner diameter mm (in) 260 (10.24)

Master cylinder bore diameter

mm (in)23.81 (15/16) 25.4 (1)

Control valve

TypeLSV

Split point x reducing ratio

kPa (bar, kg/cm

2, psi)(Variable) x 0.15

Brake booster

ModelM195T

Diaphragm diameter mm (in)Primary: 205 (8.07)

Secondary: 180 (7.09)

Recommended brake fluid DOT 3 or DOT 4*1

*1: Refer to MA section (``Fluids and Lubricants'', ``RECOMMENDED FLUIDS AND LUBRICANTS'').

SERVICE DATA AND SPECIFICATIONS (SDS)

BR-78

Page 83 of 1659

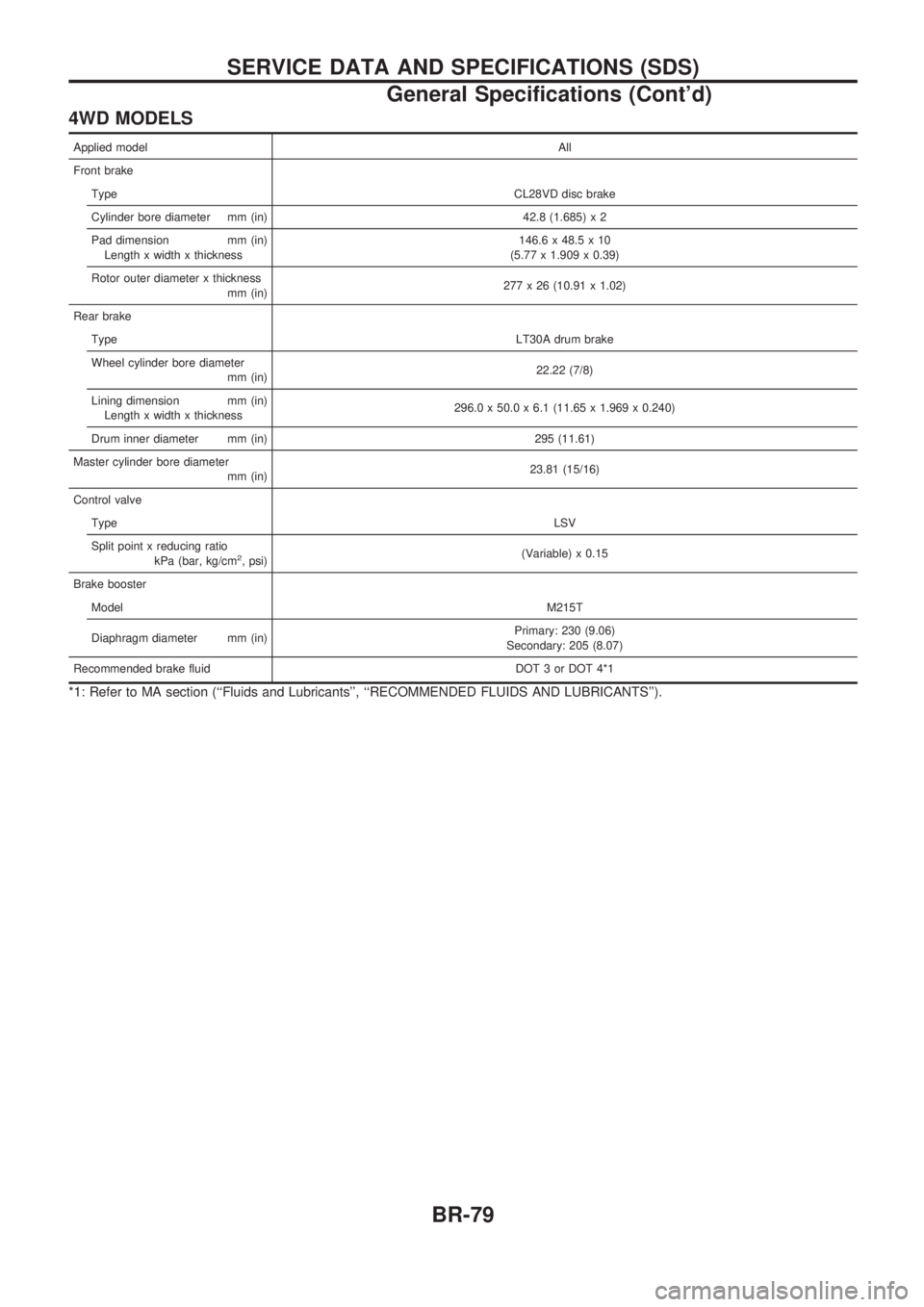

4WD MODELS

Applied modelAll

Front brake

TypeCL28VD disc brake

Cylinder bore diameter mm (in) 42.8 (1.685) x 2

Pad dimension mm (in)

Length x width x thickness146.6 x 48.5 x 10

(5.77 x 1.909 x 0.39)

Rotor outer diameter x thickness

mm (in)277 x 26 (10.91 x 1.02)

Rear brake

TypeLT30A drum brake

Wheel cylinder bore diameter

mm (in)22.22 (7/8)

Lining dimension mm (in)

Length x width x thickness296.0 x 50.0 x 6.1 (11.65 x 1.969 x 0.240)

Drum inner diameter mm (in) 295 (11.61)

Master cylinder bore diameter

mm (in)23.81 (15/16)

Control valve

TypeLSV

Split point x reducing ratio

kPa (bar, kg/cm

2, psi)(Variable) x 0.15

Brake booster

ModelM215T

Diaphragm diameter mm (in)Primary: 230 (9.06)

Secondary: 205 (8.07)

Recommended brake fluid DOT 3 or DOT 4*1

*1: Refer to MA section (``Fluids and Lubricants'', ``RECOMMENDED FLUIDS AND LUBRICANTS'').

SERVICE DATA AND SPECIFICATIONS (SDS)

General Specifications (Cont'd)

BR-79