fuse NISSAN PICK-UP 1998 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 43 of 1659

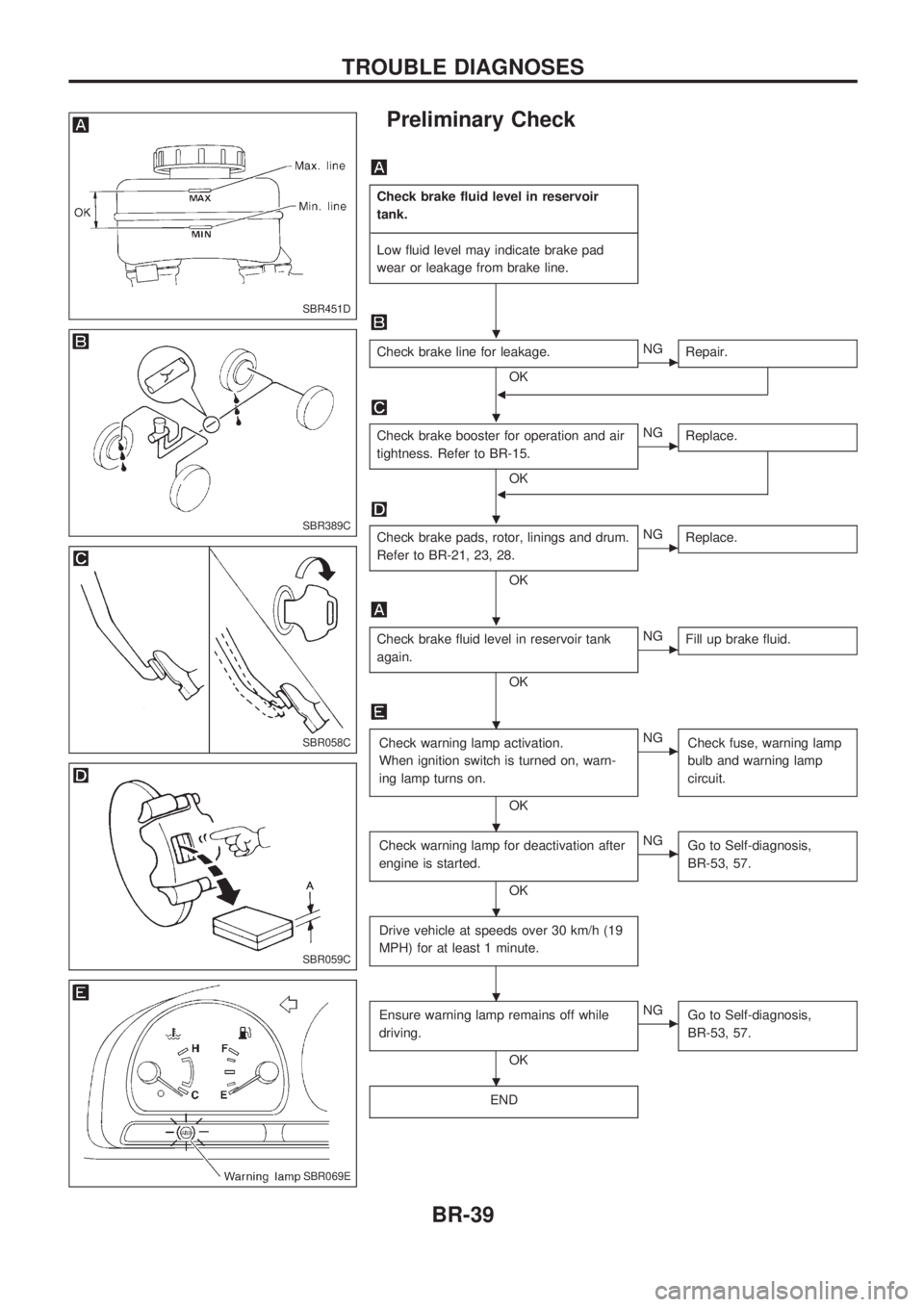

Preliminary Check

Check brake fluid level in reservoir

tank.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Low fluid level may indicate brake pad

wear or leakage from brake line.

Check brake line for leakage.

OKcNG

Repair.

b

Check brake booster for operation and air

tightness. Refer to BR-15.

OK

cNG

Replace.

b

Check brake pads, rotor, linings and drum.

Refer to BR-21, 23, 28.

OK

cNG

Replace.

Check brake fluid level in reservoir tank

again.

OK

cNG

Fill up brake fluid.

Check warning lamp activation.

When ignition switch is turned on, warn-

ing lamp turns on.

OK

cNG

Check fuse, warning lamp

bulb and warning lamp

circuit.

Check warning lamp for deactivation after

engine is started.

OK

cNG

Go to Self-diagnosis,

BR-53, 57.

Drive vehicle at speeds over 30 km/h (19

MPH) for at least 1 minute.

Ensure warning lamp remains off while

driving.

OK

cNG

Go to Self-diagnosis,

BR-53, 57.

END

SBR451D

SBR389C

SBR058C

SBR059C

SBR069E

.

.

.

.

.

.

.

.

.

TROUBLE DIAGNOSES

BR-39

Page 59 of 1659

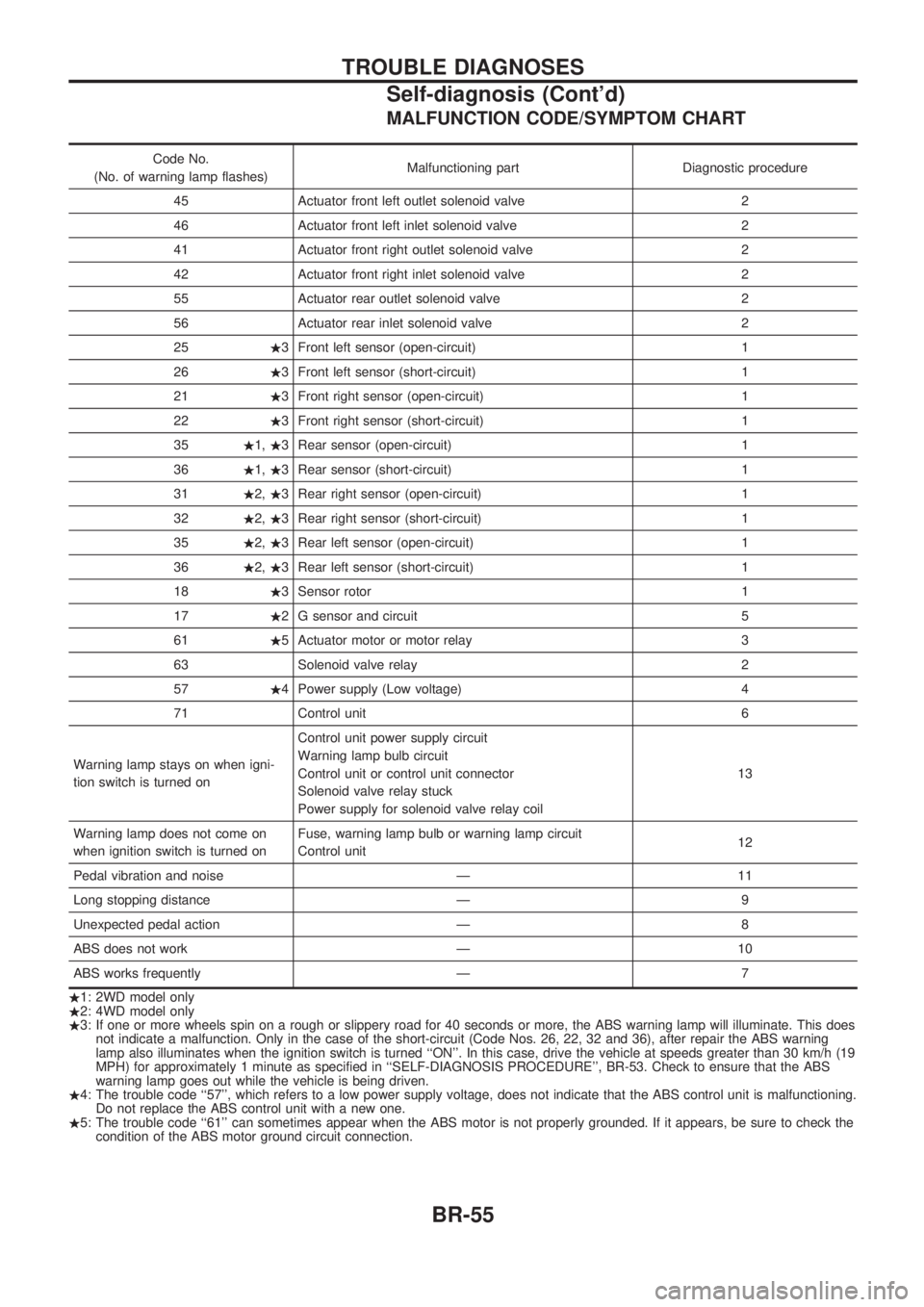

MALFUNCTION CODE/SYMPTOM CHART

Code No.

(No. of warning lamp flashes)Malfunctioning part Diagnostic procedure

45 Actuator front left outlet solenoid valve 2

46 Actuator front left inlet solenoid valve 2

41 Actuator front right outlet solenoid valve 2

42 Actuator front right inlet solenoid valve 2

55 Actuator rear outlet solenoid valve 2

56 Actuator rear inlet solenoid valve 2

25.3 Front left sensor (open-circuit) 1

26.3 Front left sensor (short-circuit) 1

21.3 Front right sensor (open-circuit) 1

22.3 Front right sensor (short-circuit) 1

35.1,.3 Rear sensor (open-circuit) 1

36.1,.3 Rear sensor (short-circuit) 1

31.2,.3 Rear right sensor (open-circuit) 1

32.2,.3 Rear right sensor (short-circuit) 1

35.2,.3 Rear left sensor (open-circuit) 1

36.2,.3 Rear left sensor (short-circuit) 1

18.3 Sensor rotor 1

17.2 G sensor and circuit 5

61.5 Actuator motor or motor relay 3

63 Solenoid valve relay 2

57.4 Power supply (Low voltage) 4

71 Control unit 6

Warning lamp stays on when igni-

tion switch is turned onControl unit power supply circuit

Warning lamp bulb circuit

Control unit or control unit connector

Solenoid valve relay stuck

Power supply for solenoid valve relay coil13

Warning lamp does not come on

when ignition switch is turned onFuse, warning lamp bulb or warning lamp circuit

Control unit12

Pedal vibration and noise Ð 11

Long stopping distance Ð 9

Unexpected pedal action Ð 8

ABS does not work Ð 10

ABS works frequently Ð 7

.1: 2WD model only

.2: 4WD model only

.3: If one or more wheels spin on a rough or slippery road for 40 seconds or more, the ABS warning lamp will illuminate. This does

not indicate a malfunction. Only in the case of the short-circuit (Code Nos. 26, 22, 32 and 36), after repair the ABS warning

lamp also illuminates when the ignition switch is turned ``ON''. In this case, drive the vehicle at speeds greater than 30 km/h (19

MPH) for approximately 1 minute as specified in ``SELF-DIAGNOSIS PROCEDURE'', BR-53. Check to ensure that the ABS

warning lamp goes out while the vehicle is being driven.

.4: The trouble code ``57'', which refers to a low power supply voltage, does not indicate that the ABS control unit is malfunctioning.

Do not replace the ABS control unit with a new one.

.5: The trouble code ``61'' can sometimes appear when the ABS motor is not properly grounded. If it appears, be sure to check the

condition of the ABS motor ground circuit connection.

TROUBLE DIAGNOSES

Self-diagnosis (Cont'd)

BR-55

Page 69 of 1659

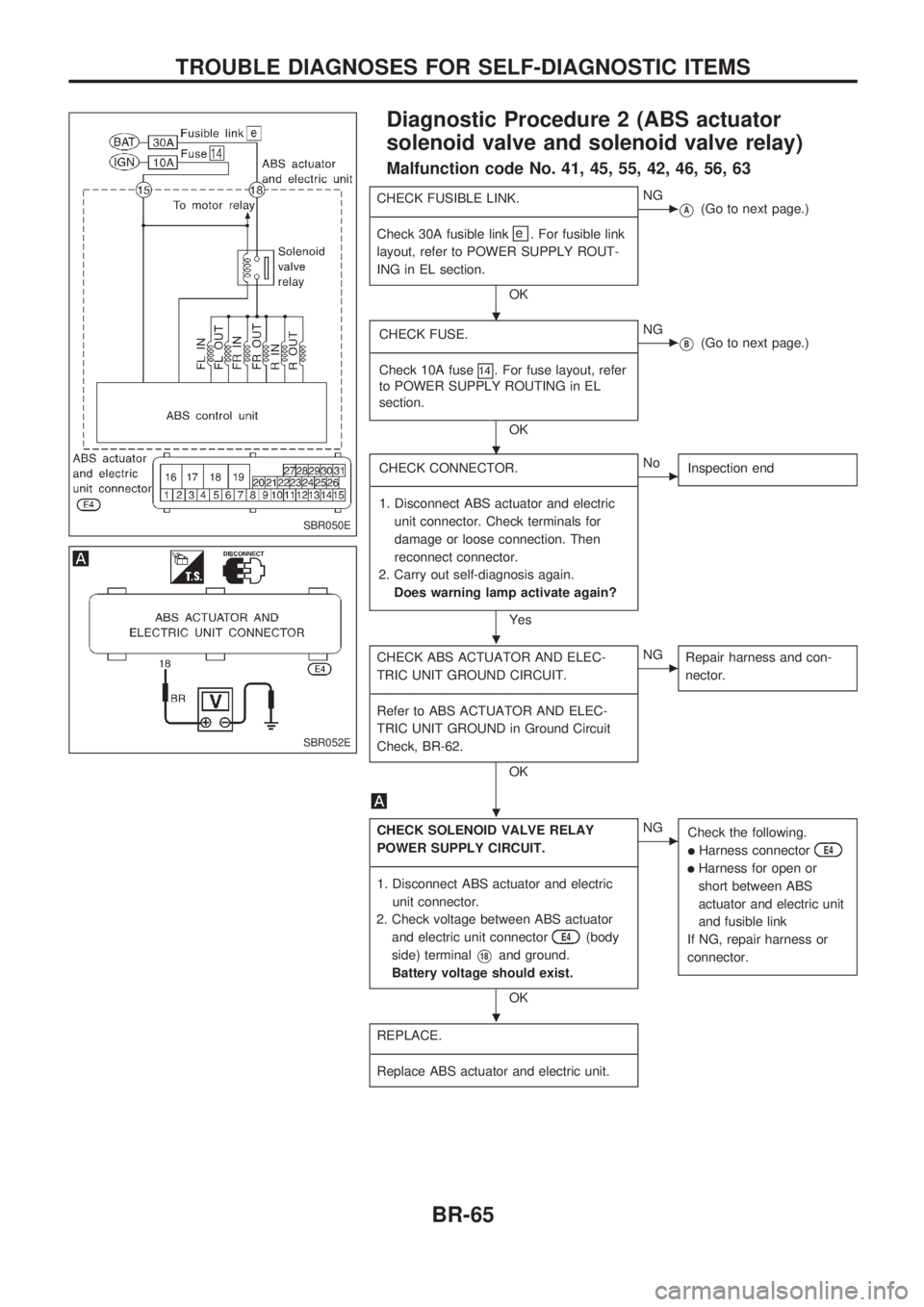

Diagnostic Procedure 2 (ABS actuator

solenoid valve and solenoid valve relay)

Malfunction code No. 41, 45, 55, 42, 46, 56, 63

CHECK FUSIBLE LINK.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check 30A fusible link

e

. For fusible link

layout, refer to POWER SUPPLY ROUT-

ING in EL section.

OK

cNG

VA(Go to next page.)

CHECK FUSE.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check 10A fuse

14. For fuse layout, refer

to POWER SUPPLY ROUTING in EL

section.

OK

cNG

VB(Go to next page.)

CHECK CONNECTOR.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Disconnect ABS actuator and electric

unit connector. Check terminals for

damage or loose connection. Then

reconnect connector.

2. Carry out self-diagnosis again.

Does warning lamp activate again?

Yes

cNo

Inspection end

CHECK ABS ACTUATOR AND ELEC-

TRIC UNIT GROUND CIRCUIT.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Refer to ABS ACTUATOR AND ELEC-

TRIC UNIT GROUND in Ground Circuit

Check, BR-62.

OK

cNG

Repair harness and con-

nector.

CHECK SOLENOID VALVE RELAY

POWER SUPPLY CIRCUIT.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Disconnect ABS actuator and electric

unit connector.

2. Check voltage between ABS actuator

and electric unit connector

E4(body

side) terminal

V18and ground.

Battery voltage should exist.

OK

cNG

Check the following.

lHarness connectorE4

lHarness for open or

short between ABS

actuator and electric unit

and fusible link

If NG, repair harness or

connector.

REPLACE.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Replace ABS actuator and electric unit.

SBR050E

SBR052E

.

.

.

.

.

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMS

BR-65

Page 70 of 1659

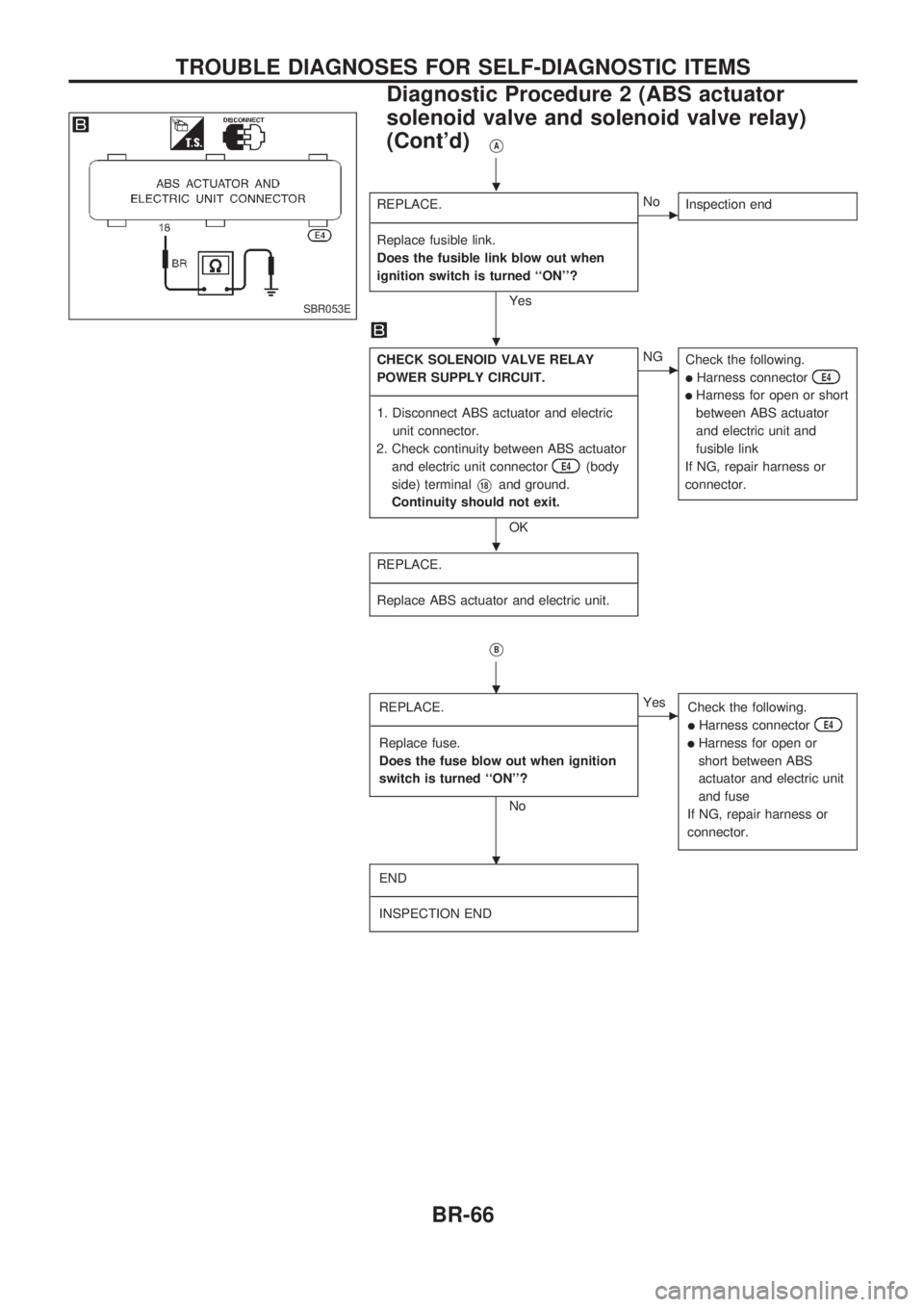

VA

REPLACE.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Replace fusible link.

Does the fusible link blow out when

ignition switch is turned ``ON''?

Yes

cNo

Inspection end

CHECK SOLENOID VALVE RELAY

POWER SUPPLY CIRCUIT.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Disconnect ABS actuator and electric

unit connector.

2. Check continuity between ABS actuator

and electric unit connector

E4(body

side) terminal

V18and ground.

Continuity should not exit.

OK

cNG

Check the following.

lHarness connectorE4

lHarness for open or short

between ABS actuator

and electric unit and

fusible link

If NG, repair harness or

connector.

REPLACE.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Replace ABS actuator and electric unit.

VB

REPLACE.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Replace fuse.

Does the fuse blow out when ignition

switch is turned ``ON''?

No

cYes

Check the following.

lHarness connectorE4

lHarness for open or

short between ABS

actuator and electric unit

and fuse

If NG, repair harness or

connector.

END

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

INSPECTION END

SBR053E

.

.

.

.

.

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMS

Diagnostic Procedure 2 (ABS actuator

solenoid valve and solenoid valve relay)

(Cont'd)

BR-66

Page 73 of 1659

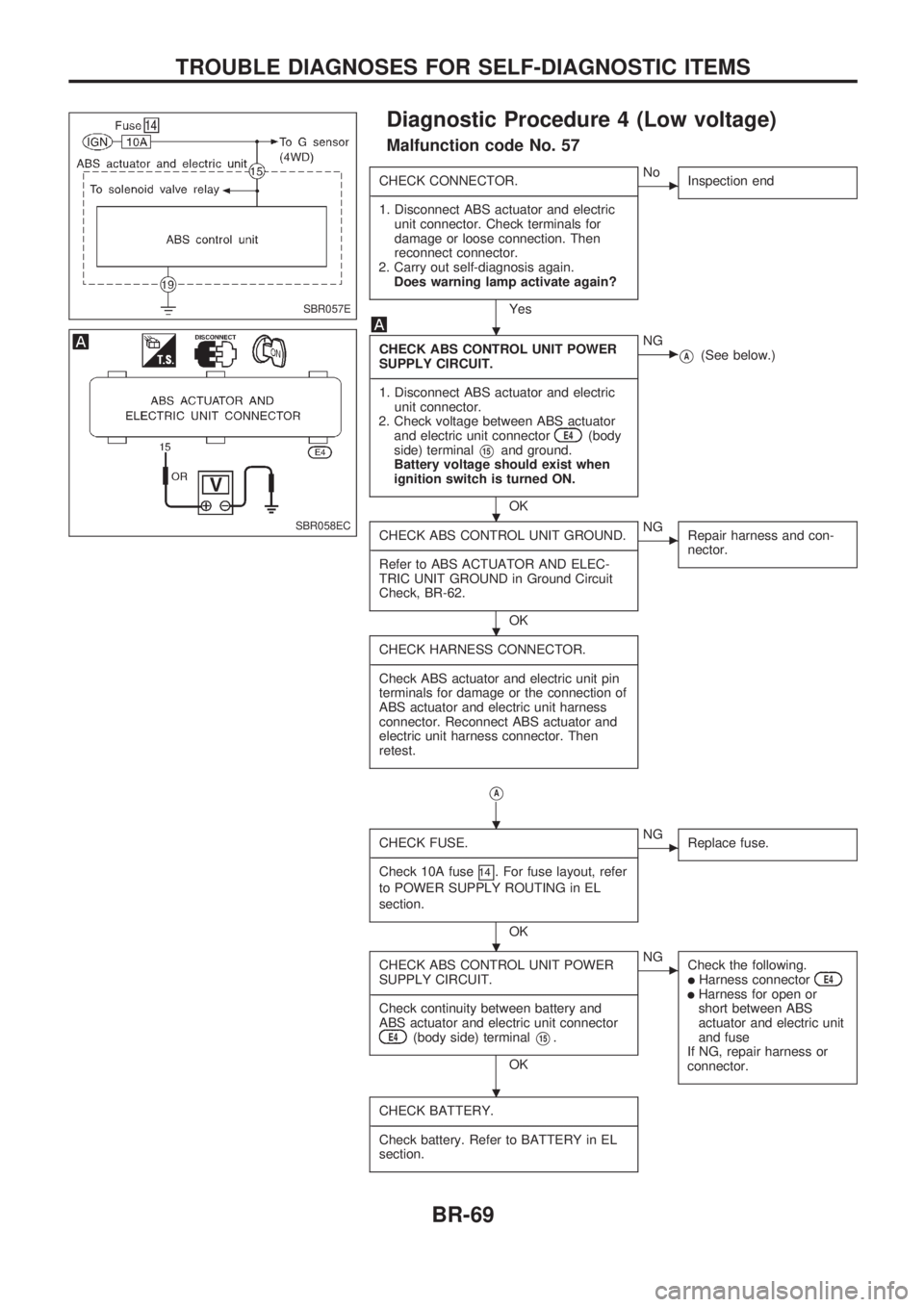

Diagnostic Procedure 4 (Low voltage)

Malfunction code No. 57

CHECK CONNECTOR.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Disconnect ABS actuator and electric

unit connector. Check terminals for

damage or loose connection. Then

reconnect connector.

2. Carry out self-diagnosis again.

Does warning lamp activate again?

Yes

cNo

Inspection end

CHECK ABS CONTROL UNIT POWER

SUPPLY CIRCUIT.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Disconnect ABS actuator and electric

unit connector.

2. Check voltage between ABS actuator

and electric unit connector

E4(body

side) terminal

V15and ground.

Battery voltage should exist when

ignition switch is turned ON.

OK

cNG

VA(See below.)

CHECK ABS CONTROL UNIT GROUND.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Refer to ABS ACTUATOR AND ELEC-

TRIC UNIT GROUND in Ground Circuit

Check, BR-62.

OK

cNG

Repair harness and con-

nector.

CHECK HARNESS CONNECTOR.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check ABS actuator and electric unit pin

terminals for damage or the connection of

ABS actuator and electric unit harness

connector. Reconnect ABS actuator and

electric unit harness connector. Then

retest.

VA

CHECK FUSE.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check 10A fuse

14. For fuse layout, refer

to POWER SUPPLY ROUTING in EL

section.

OK

cNG

Replace fuse.

CHECK ABS CONTROL UNIT POWER

SUPPLY CIRCUIT.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check continuity between battery and

ABS actuator and electric unit connector

E4(body side) terminalV15.

OK

cNG

Check the following.

lHarness connectorE4lHarness for open or

short between ABS

actuator and electric unit

and fuse

If NG, repair harness or

connector.

CHECK BATTERY.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check battery. Refer to BATTERY in EL

section.

SBR057E

SBR058EC

.

.

.

.

.

.

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMS

BR-69

Page 74 of 1659

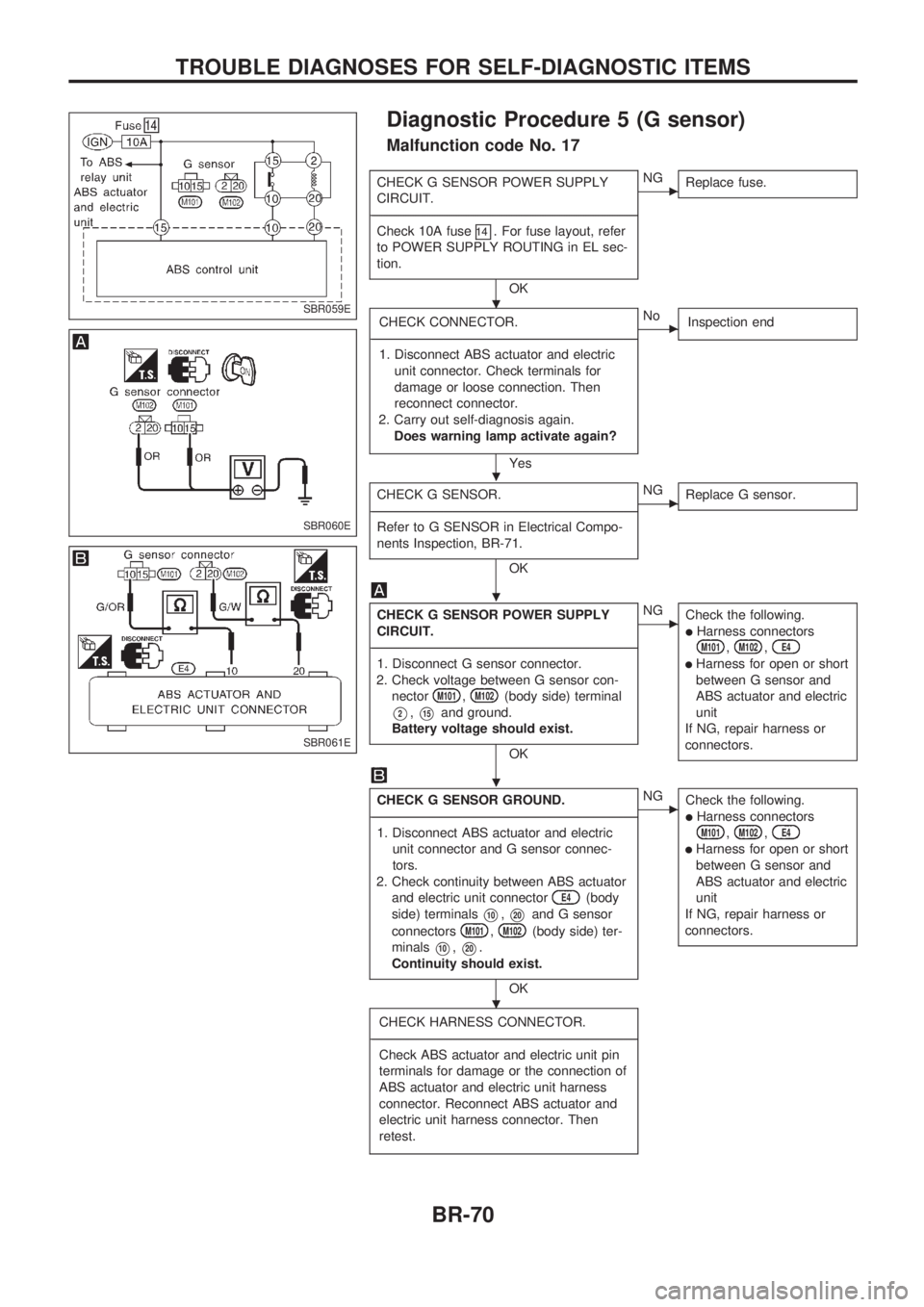

Diagnostic Procedure 5 (G sensor)

Malfunction code No. 17

CHECK G SENSOR POWER SUPPLY

CIRCUIT.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check 10A fuse

14. For fuse layout, refer

to POWER SUPPLY ROUTING in EL sec-

tion.

OK

cNG

Replace fuse.

CHECK CONNECTOR.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Disconnect ABS actuator and electric

unit connector. Check terminals for

damage or loose connection. Then

reconnect connector.

2. Carry out self-diagnosis again.

Does warning lamp activate again?

Yes

cNo

Inspection end

CHECK G SENSOR.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Refer to G SENSOR in Electrical Compo-

nents Inspection, BR-71.

OK

cNG

Replace G sensor.

CHECK G SENSOR POWER SUPPLY

CIRCUIT.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Disconnect G sensor connector.

2. Check voltage between G sensor con-

nector

M101,M102(body side) terminal

V2,V15and ground.

Battery voltage should exist.

OK

cNG

Check the following.

lHarness connectorsM101,M102,E4

lHarness for open or short

between G sensor and

ABS actuator and electric

unit

If NG, repair harness or

connectors.

CHECK G SENSOR GROUND.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Disconnect ABS actuator and electric

unit connector and G sensor connec-

tors.

2. Check continuity between ABS actuator

and electric unit connector

E4(body

side) terminals

V10,V20and G sensor

connectors

M101,M102(body side) ter-

minals

V10,V20.

Continuity should exist.

OK

cNG

Check the following.

lHarness connectorsM101,M102,E4

lHarness for open or short

between G sensor and

ABS actuator and electric

unit

If NG, repair harness or

connectors.

CHECK HARNESS CONNECTOR.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check ABS actuator and electric unit pin

terminals for damage or the connection of

ABS actuator and electric unit harness

connector. Reconnect ABS actuator and

electric unit harness connector. Then

retest.

SBR059E

SBR060E

SBR061E

.

.

.

.

.

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMS

BR-70

Page 79 of 1659

Note: ABS may operate and cause vibration under any of the

following conditions.

lApplying brake gradually when shifting or operating

clutch.

lLow friction (slippery) road.

lHigh speed cornering.

lDriving over bumps and pot holes.

lEngine speed is over 5,000 rpm with vehicle stopped.

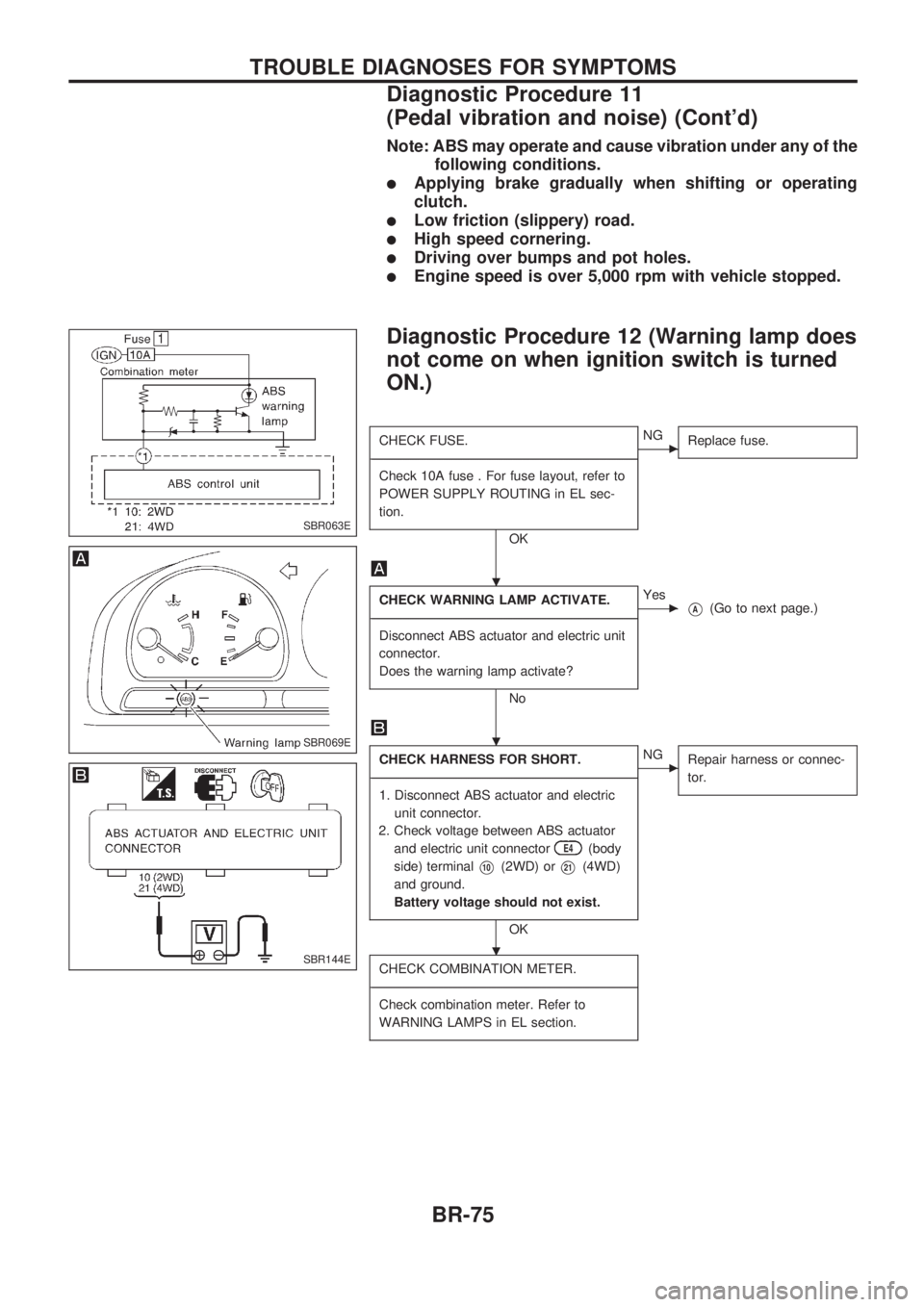

Diagnostic Procedure 12 (Warning lamp does

not come on when ignition switch is turned

ON.)

CHECK FUSE.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check 10A fuse . For fuse layout, refer to

POWER SUPPLY ROUTING in EL sec-

tion.

OK

cNG

Replace fuse.

CHECK WARNING LAMP ACTIVATE.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Disconnect ABS actuator and electric unit

connector.

Does the warning lamp activate?

No

cYes

VA(Go to next page.)

CHECK HARNESS FOR SHORT.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Disconnect ABS actuator and electric

unit connector.

2. Check voltage between ABS actuator

and electric unit connector

E4(body

side) terminal

V10(2WD) orV21(4WD)

and ground.

Battery voltage should not exist.

OK

cNG

Repair harness or connec-

tor.

CHECK COMBINATION METER.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check combination meter. Refer to

WARNING LAMPS in EL section.

SBR063E

SBR069E

SBR144E

.

.

.

TROUBLE DIAGNOSES FOR SYMPTOMS

Diagnostic Procedure 11

(Pedal vibration and noise) (Cont'd)

BR-75

Page 81 of 1659

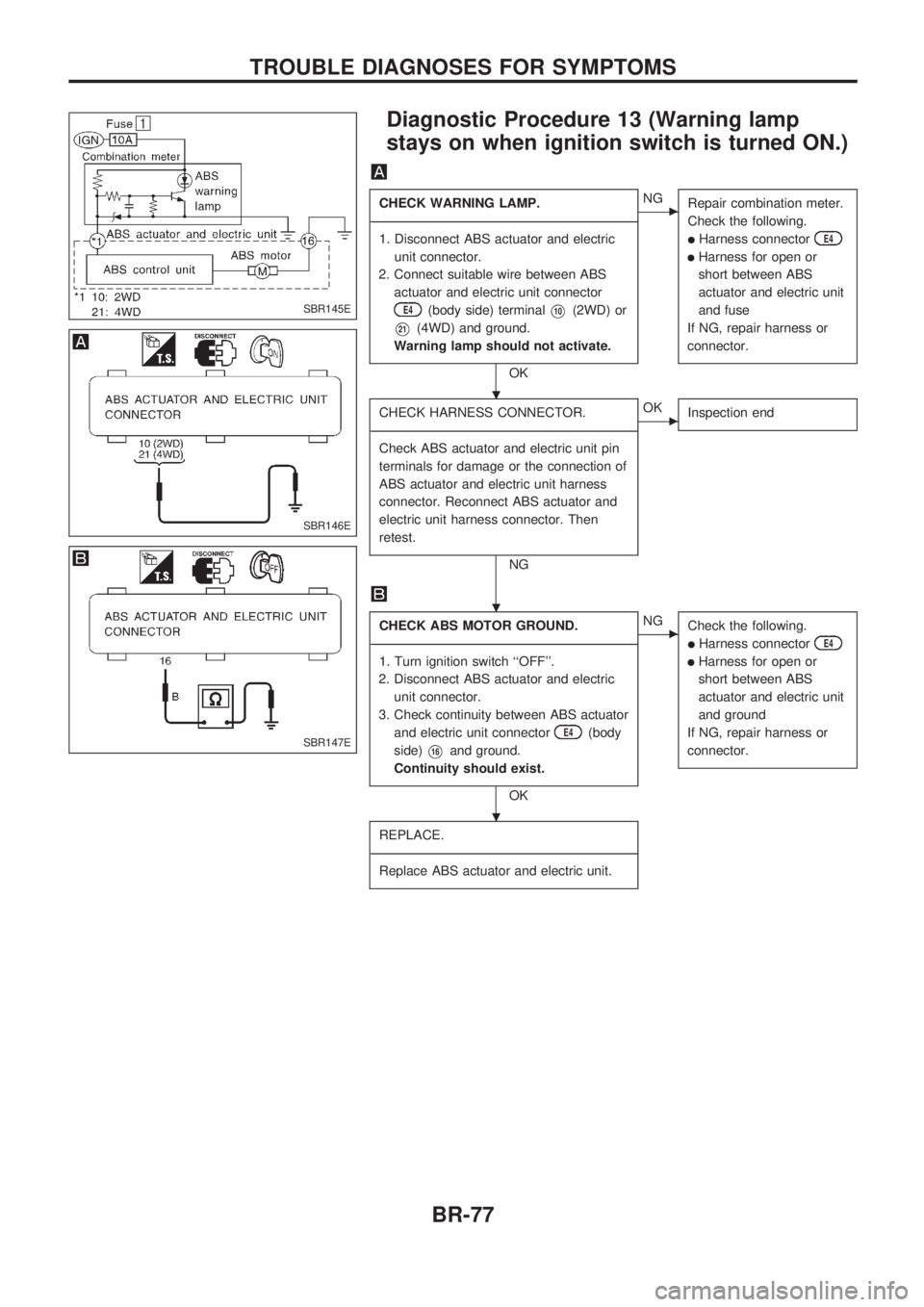

Diagnostic Procedure 13 (Warning lamp

stays on when ignition switch is turned ON.)

CHECK WARNING LAMP.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Disconnect ABS actuator and electric

unit connector.

2. Connect suitable wire between ABS

actuator and electric unit connector

E4(body side) terminalV10(2WD) or

V21(4WD) and ground.

Warning lamp should not activate.

OK

cNG

Repair combination meter.

Check the following.

lHarness connectorE4

lHarness for open or

short between ABS

actuator and electric unit

and fuse

If NG, repair harness or

connector.

CHECK HARNESS CONNECTOR.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check ABS actuator and electric unit pin

terminals for damage or the connection of

ABS actuator and electric unit harness

connector. Reconnect ABS actuator and

electric unit harness connector. Then

retest.

NG

cOK

Inspection end

CHECK ABS MOTOR GROUND.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch ``OFF''.

2. Disconnect ABS actuator and electric

unit connector.

3. Check continuity between ABS actuator

and electric unit connector

E4(body

side)

V16and ground.

Continuity should exist.

OK

cNG

Check the following.

lHarness connectorE4

lHarness for open or

short between ABS

actuator and electric unit

and ground

If NG, repair harness or

connector.

REPLACE.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Replace ABS actuator and electric unit.

SBR145E

SBR146E

SBR147E

.

.

.

TROUBLE DIAGNOSES FOR SYMPTOMS

BR-77

Page 174 of 1659

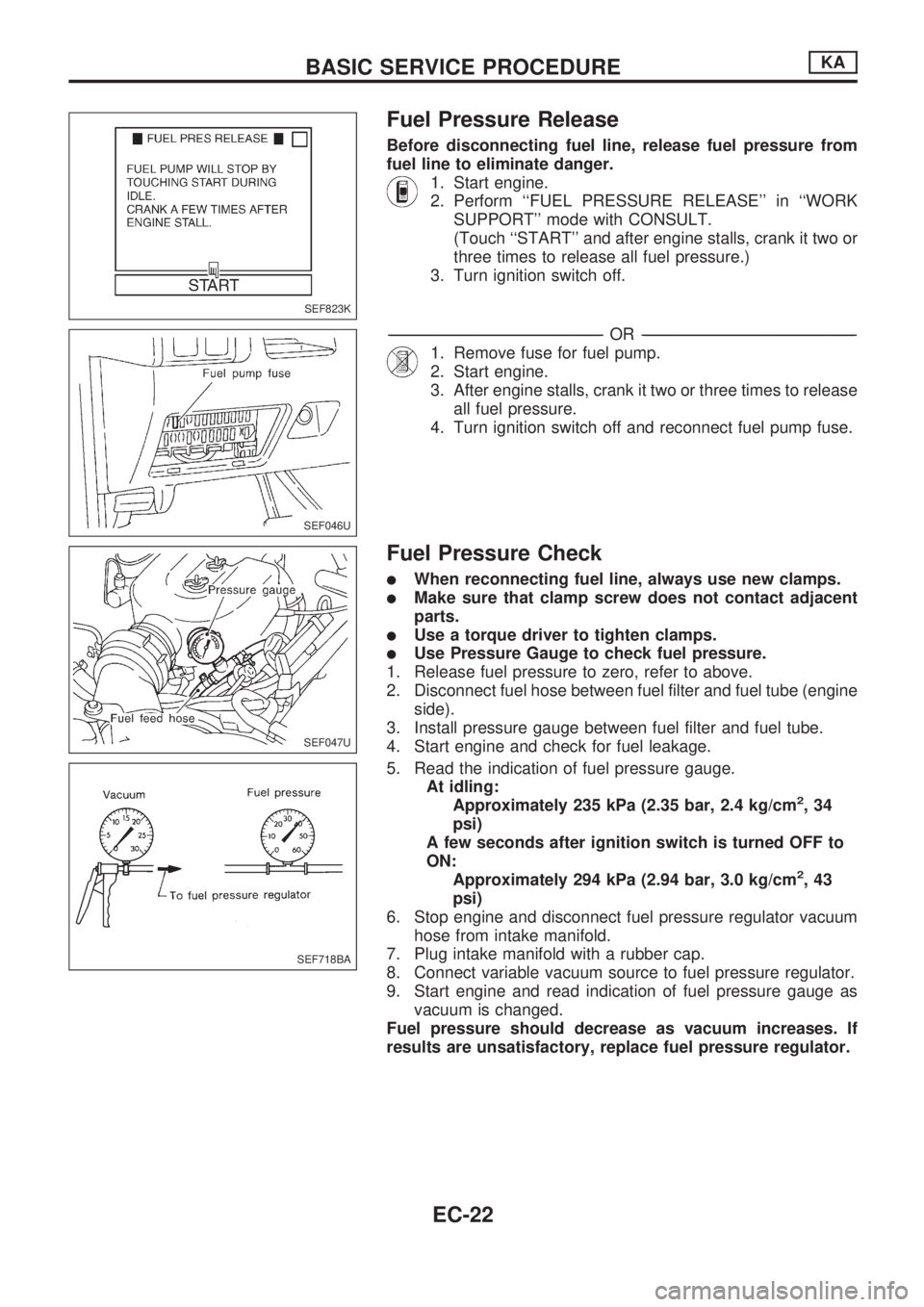

Fuel Pressure Release

Before disconnecting fuel line, release fuel pressure from

fuel line to eliminate danger.

1. Start engine.

2. Perform ``FUEL PRESSURE RELEASE'' in ``WORK

SUPPORT'' mode with CONSULT.

(Touch ``START'' and after engine stalls, crank it two or

three times to release all fuel pressure.)

3. Turn ignition switch off.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Remove fuse for fuel pump.

2. Start engine.

3. After engine stalls, crank it two or three times to release

all fuel pressure.

4. Turn ignition switch off and reconnect fuel pump fuse.

Fuel Pressure Check

lWhen reconnecting fuel line, always use new clamps.

lMake sure that clamp screw does not contact adjacent

parts.

lUse a torque driver to tighten clamps.

lUse Pressure Gauge to check fuel pressure.

1. Release fuel pressure to zero, refer to above.

2. Disconnect fuel hose between fuel filter and fuel tube (engine

side).

3. Install pressure gauge between fuel filter and fuel tube.

4. Start engine and check for fuel leakage.

5. Read the indication of fuel pressure gauge.

At idling:

Approximately 235 kPa (2.35 bar, 2.4 kg/cm

2,34

psi)

A few seconds after ignition switch is turned OFF to

ON:

Approximately 294 kPa (2.94 bar, 3.0 kg/cm

2,43

psi)

6. Stop engine and disconnect fuel pressure regulator vacuum

hose from intake manifold.

7. Plug intake manifold with a rubber cap.

8. Connect variable vacuum source to fuel pressure regulator.

9. Start engine and read indication of fuel pressure gauge as

vacuum is changed.

Fuel pressure should decrease as vacuum increases. If

results are unsatisfactory, replace fuel pressure regulator.

SEF823K

SEF046U

SEF047U

SEF718BA

BASIC SERVICE PROCEDUREKA

EC-22

Page 177 of 1659

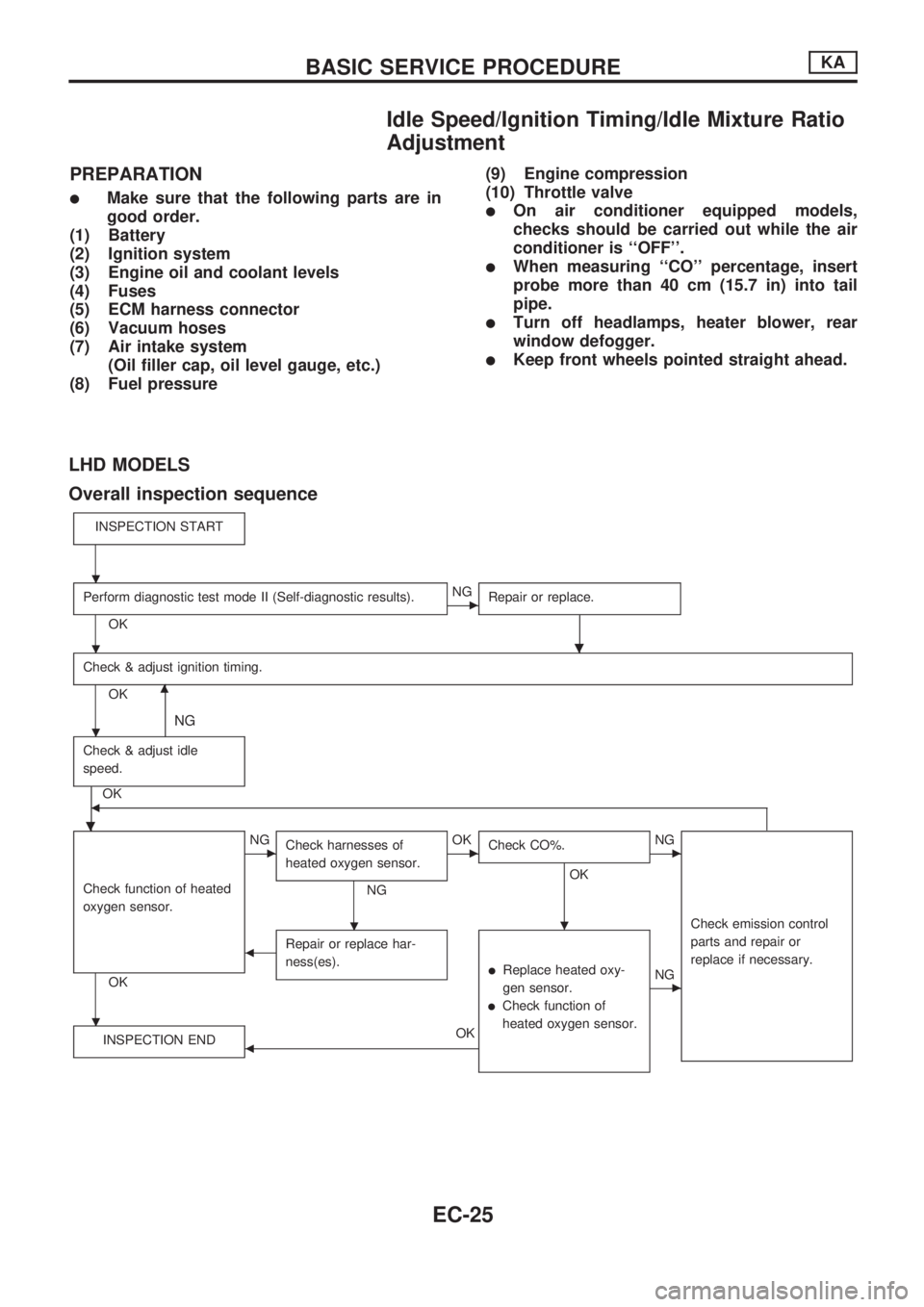

Idle Speed/Ignition Timing/Idle Mixture Ratio

Adjustment

PREPARATION

lMake sure that the following parts are in

good order.

(1) Battery

(2) Ignition system

(3) Engine oil and coolant levels

(4) Fuses

(5) ECM harness connector

(6) Vacuum hoses

(7) Air intake system

(Oil filler cap, oil level gauge, etc.)

(8) Fuel pressure(9) Engine compression

(10) Throttle valvelOn air conditioner equipped models,

checks should be carried out while the air

conditioner is ``OFF''.

lWhen measuring ``CO'' percentage, insert

probe more than 40 cm (15.7 in) into tail

pipe.

lTurn off headlamps, heater blower, rear

window defogger.

lKeep front wheels pointed straight ahead.

LHD MODELS

Overall inspection sequence

INSPECTION START

Perform diagnostic test mode II (Self-diagnostic results).

OK

cNG

Repair or replace.

.

Check & adjust ignition timing.

OKm

NG

Check & adjust idle

speed.

.

OKb

Check function of heated

oxygen sensor.

OK

cNG

Check harnesses of

heated oxygen sensor.

NG

cOK

Check CO%.

OK

.

cNG

Check emission control

parts and repair or

replace if necessary.

bRepair or replace har-

ness(es).

lReplace heated oxy-

gen sensor.

lCheck function of

heated oxygen sensor.

cNG

INSPECTION END

bOK

.

.

.

.

.

BASIC SERVICE PROCEDUREKA

EC-25