towing NISSAN PICK-UP 1998 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 804 of 1659

GENERAL INFORMATION

SECTION

GI

CONTENTS

PRECAUTIONS......................................................... 1

Precautions for Supplemental Restraint

System (SRS) ``AIR BAG'' (4WD models)............. 1

Precautions for Supplemental Restraint

System (SRS) ``AIR BAG'' (2WD models)............. 1

Precautions for NATS ............................................ 2

General Precautions .............................................. 2

Precautions for Multiport Fuel Injection System

or ECCS Engine .................................................... 4

Precautions for Three Way Catalyst

(If so equipped) ...................................................... 4

Precautions for Engine Oils ................................... 4

Precautions for Fuel............................................... 5

Precautions for Air Conditioning ............................ 6

HOW TO USE THIS MANUAL.................................. 7

HOW TO READ WIRING DIAGRAMS...................... 9

Sample/Wiring Diagram - EXAMPL - .................... 9

Description ........................................................... 11

HOW TO CHECK TERMINAL................................. 18

How to Probe Connectors ................................... 18

How to Check Enlarged Contact Spring of

Terminal ............................................................... 19

Waterproof Connector Inspection ........................ 20

Terminal Lock Inspection ..................................... 20

HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT......................... 21

Work Flow ............................................................ 21HOW TO PERFORM EFFICIENT DIAGNOSIS...... 22

Incident Simulation Tests..................................... 22

Circuit Inspection ................................................. 25

HOW TO FOLLOW FLOW CHART IN

TROUBLE DIAGNOSES......................................... 31

How to Follow This Flow Chart ........................... 32

CONSULT CHECKING SYSTEM............................ 34

Function and System Application ........................ 34

Lithium Battery Replacement............................... 34

Checking Equipment ............................................ 35

Loading Procedure............................................... 36

CONSULT Data Link Connector (DLC) Circuit ... 36

IDENTIFICATION INFORMATION.......................... 37

Model Variation .................................................... 37

Identification Number ........................................... 40

Dimensions .......................................................... 44

Wheels and Tires ................................................. 46

LIFTING POINTS AND TOW TRUCK TOWING..... 47

Pantograph Jack .................................................. 47

Screw Jack........................................................... 48

Garage Jack and Safety Stand ........................... 49

2-pole Lift ............................................................. 50

Tow Truck Towing ............................................... 51

Towing Point ........................................................ 53

TIGHTENING TORQUE OF STANDARD BOLTS.. 54

SAE J1930 TERMINOLOGY LIST.......................... 55

SAE J1930 Terminology List ............................... 55

GI

Page 851 of 1659

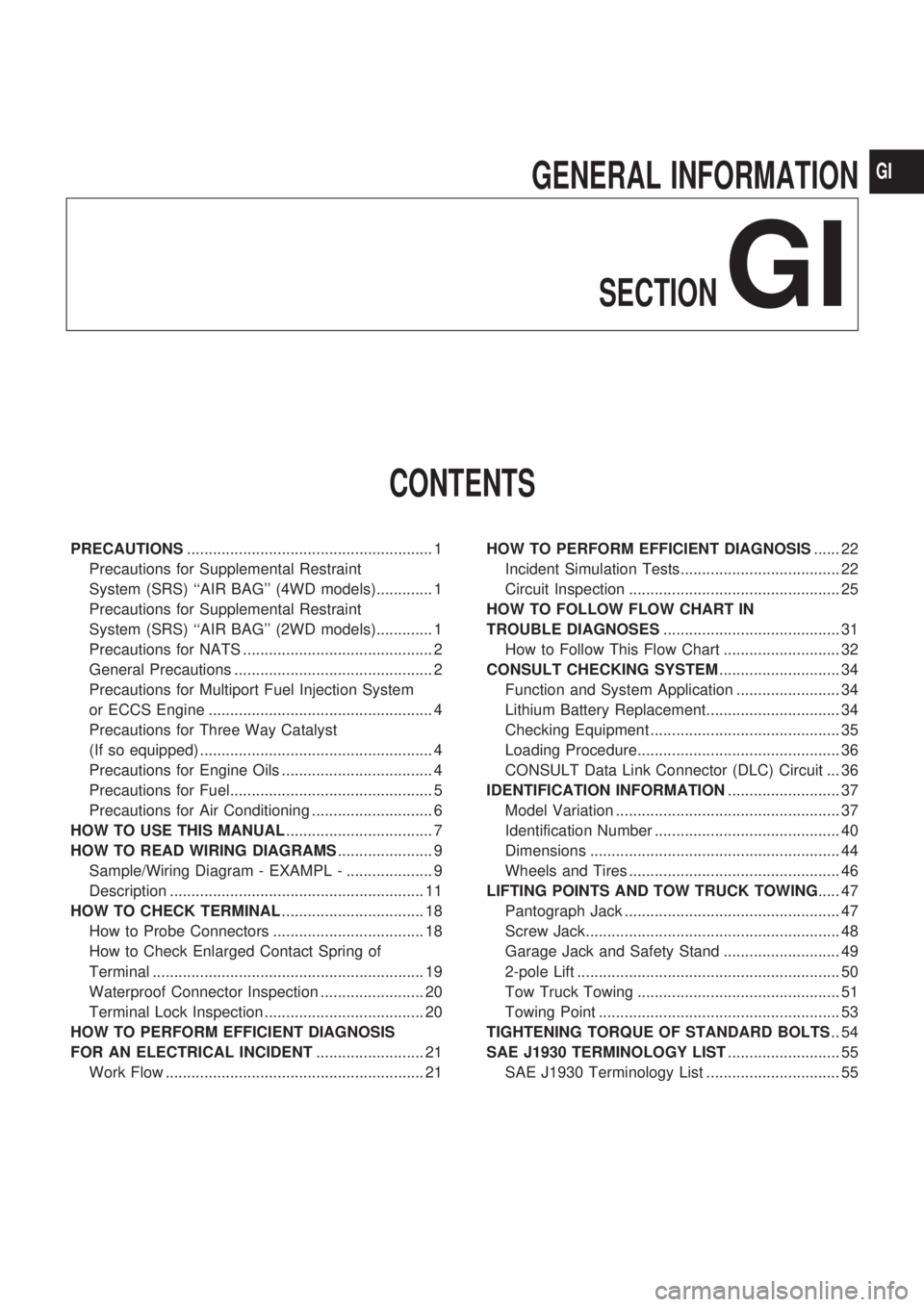

WARNING:

lNever get under the vehicle while it is supported only by the jack. Always use safety stands to

support the frame when you have to get under the vehicle.

lPlace wheel chocks at both front and back of the wheels on the ground.

Pantograph Jack

SGI054A

LIFTING POINTS AND TOW TRUCK TOWING

GI-47

Page 852 of 1659

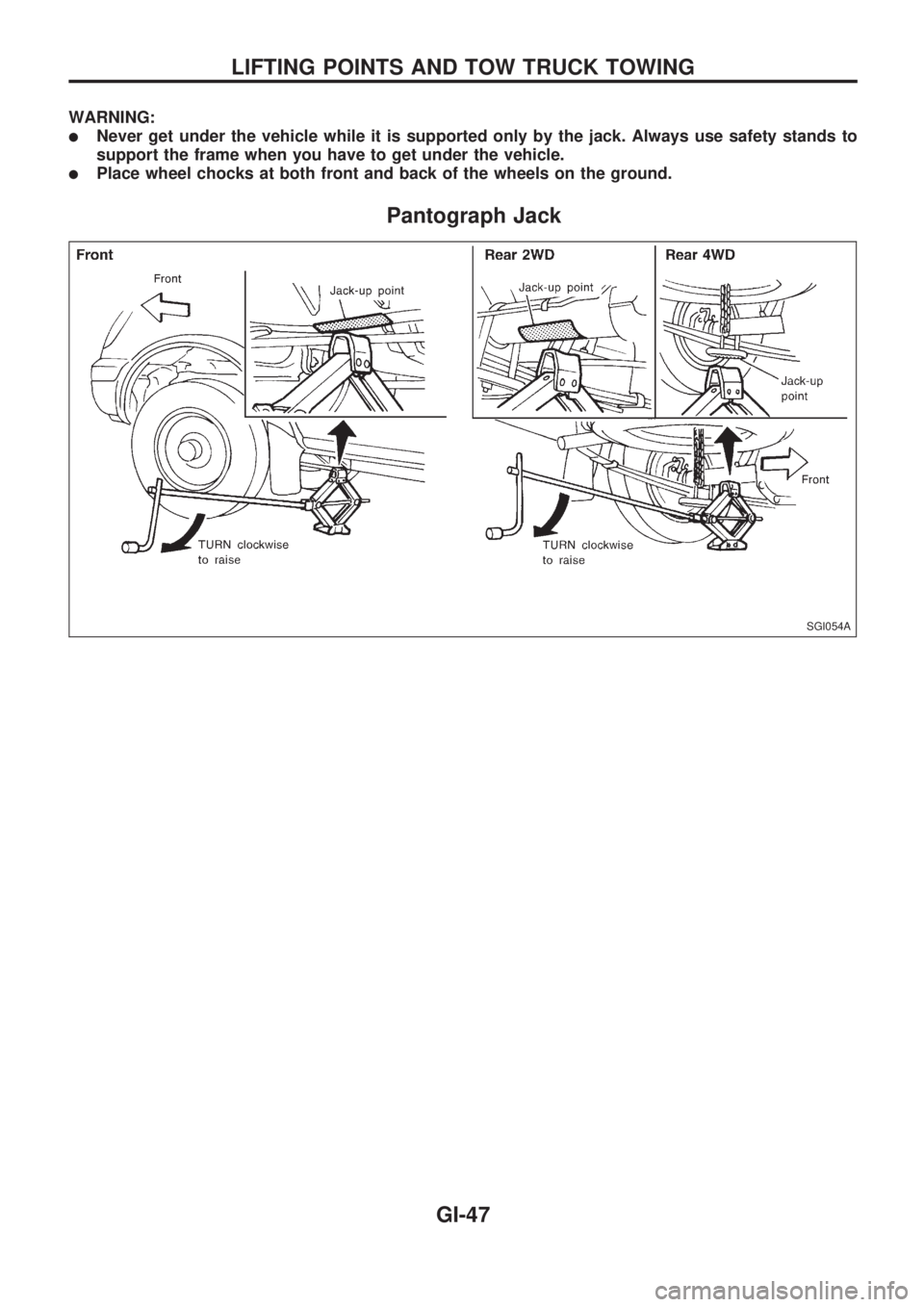

Screw Jack

SGI055A

LIFTING POINTS AND TOW TRUCK TOWING

GI-48

Page 853 of 1659

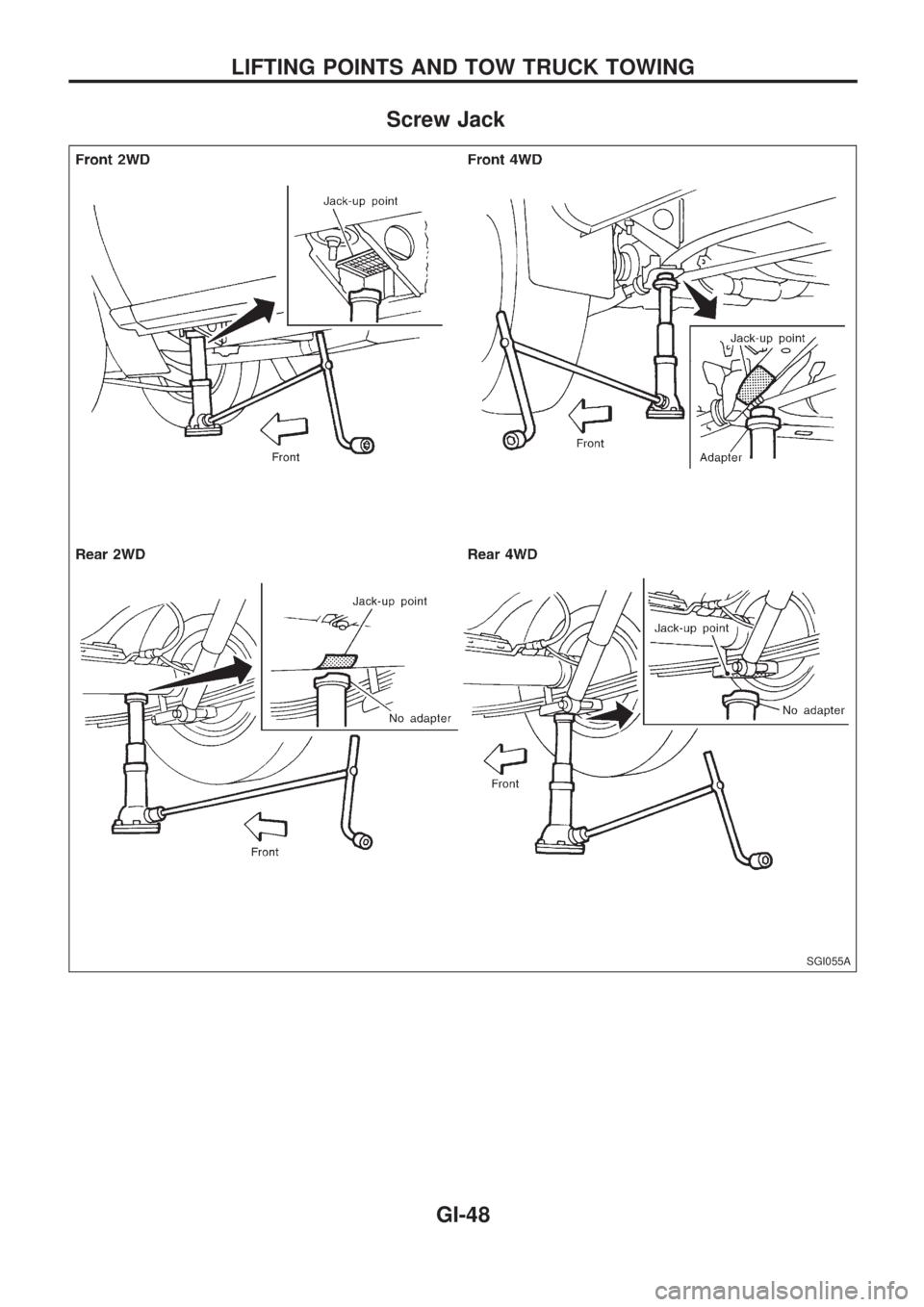

Garage Jack and Safety Stand

CAUTION:

Place a wooden or rubber block between safety stand and vehicle body when the supporting body

is flat.

SGI971

LIFTING POINTS AND TOW TRUCK TOWING

GI-49

Page 854 of 1659

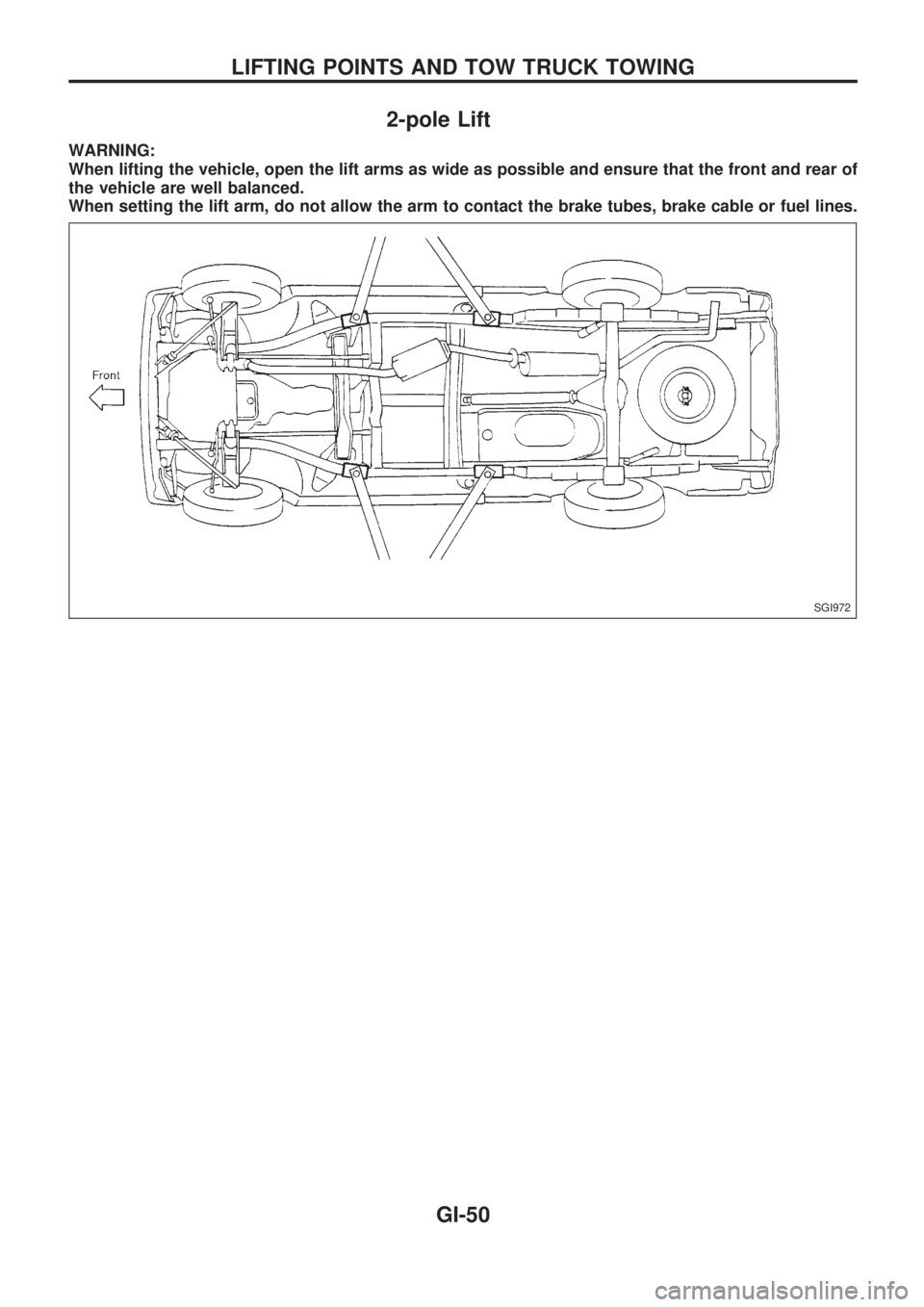

2-pole Lift

WARNING:

When lifting the vehicle, open the lift arms as wide as possible and ensure that the front and rear of

the vehicle are well balanced.

When setting the lift arm, do not allow the arm to contact the brake tubes, brake cable or fuel lines.

SGI972

LIFTING POINTS AND TOW TRUCK TOWING

GI-50

Page 855 of 1659

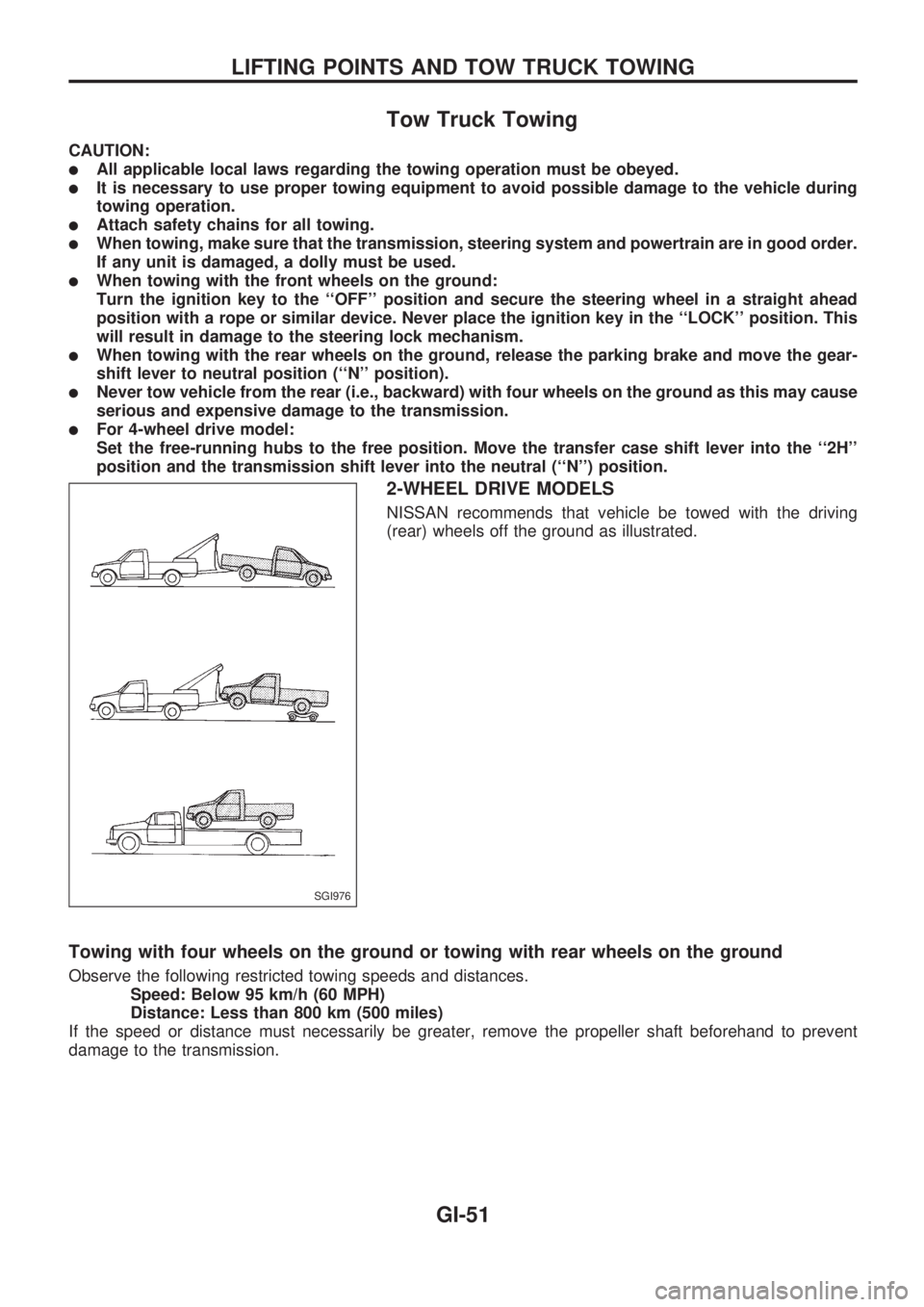

Tow Truck Towing

CAUTION:

lAll applicable local laws regarding the towing operation must be obeyed.

lIt is necessary to use proper towing equipment to avoid possible damage to the vehicle during

towing operation.

lAttach safety chains for all towing.

lWhen towing, make sure that the transmission, steering system and powertrain are in good order.

If any unit is damaged, a dolly must be used.

lWhen towing with the front wheels on the ground:

Turn the ignition key to the ``OFF'' position and secure the steering wheel in a straight ahead

position with a rope or similar device. Never place the ignition key in the ``LOCK'' position. This

will result in damage to the steering lock mechanism.

lWhen towing with the rear wheels on the ground, release the parking brake and move the gear-

shift lever to neutral position (``N'' position).

lNever tow vehicle from the rear (i.e., backward) with four wheels on the ground as this may cause

serious and expensive damage to the transmission.

lFor 4-wheel drive model:

Set the free-running hubs to the free position. Move the transfer case shift lever into the ``2H''

position and the transmission shift lever into the neutral (``N'') position.

2-WHEEL DRIVE MODELS

NISSAN recommends that vehicle be towed with the driving

(rear) wheels off the ground as illustrated.

Towing with four wheels on the ground or towing with rear wheels on the ground

Observe the following restricted towing speeds and distances.

Speed: Below 95 km/h (60 MPH)

Distance: Less than 800 km (500 miles)

If the speed or distance must necessarily be greater, remove the propeller shaft beforehand to prevent

damage to the transmission.

SGI976

LIFTING POINTS AND TOW TRUCK TOWING

GI-51

Page 856 of 1659

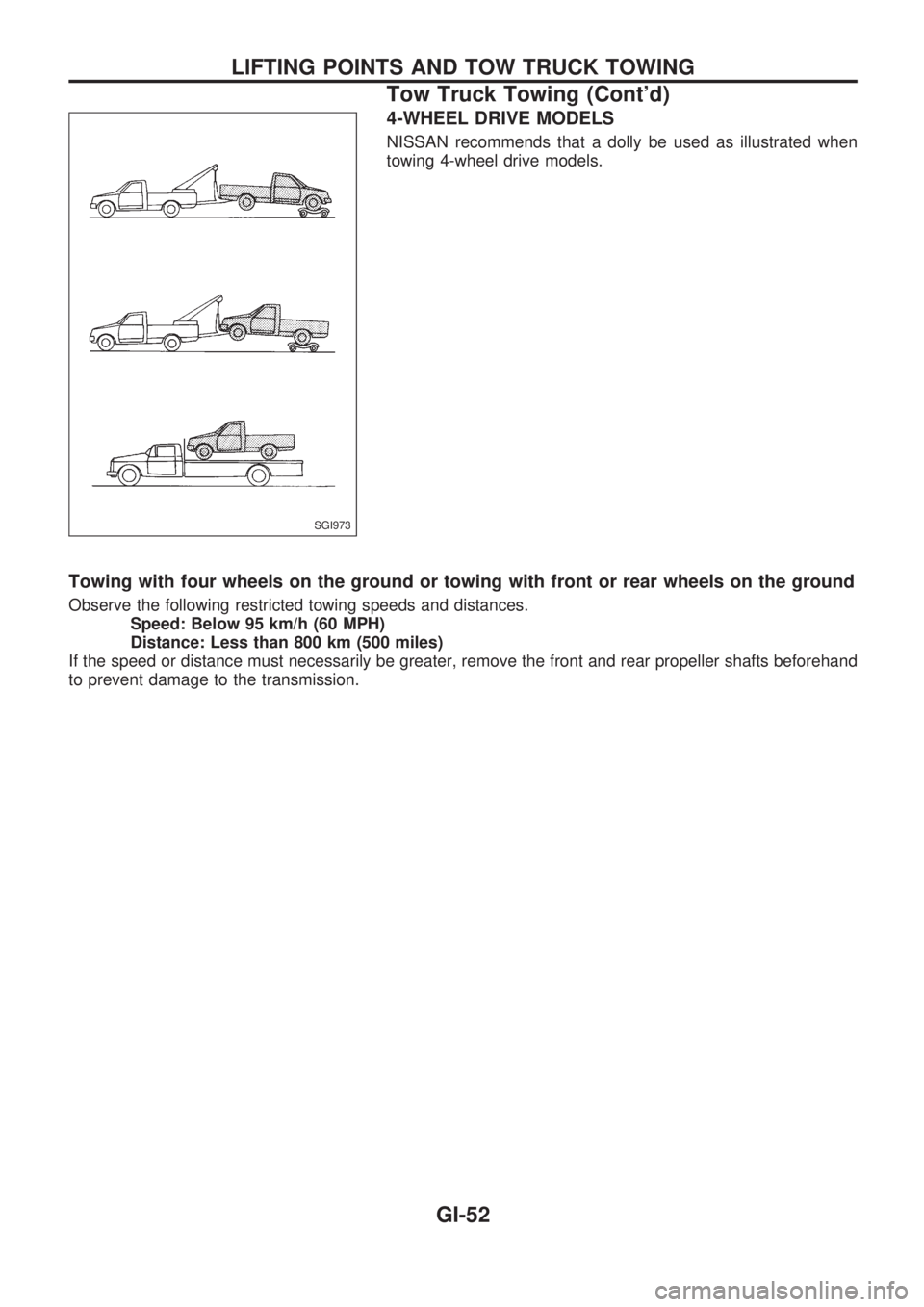

4-WHEEL DRIVE MODELS

NISSAN recommends that a dolly be used as illustrated when

towing 4-wheel drive models.

Towing with four wheels on the ground or towing with front or rear wheels on the ground

Observe the following restricted towing speeds and distances.

Speed: Below 95 km/h (60 MPH)

Distance: Less than 800 km (500 miles)

If the speed or distance must necessarily be greater, remove the front and rear propeller shafts beforehand

to prevent damage to the transmission.

SGI973

LIFTING POINTS AND TOW TRUCK TOWING

Tow Truck Towing (Cont'd)

GI-52

Page 857 of 1659

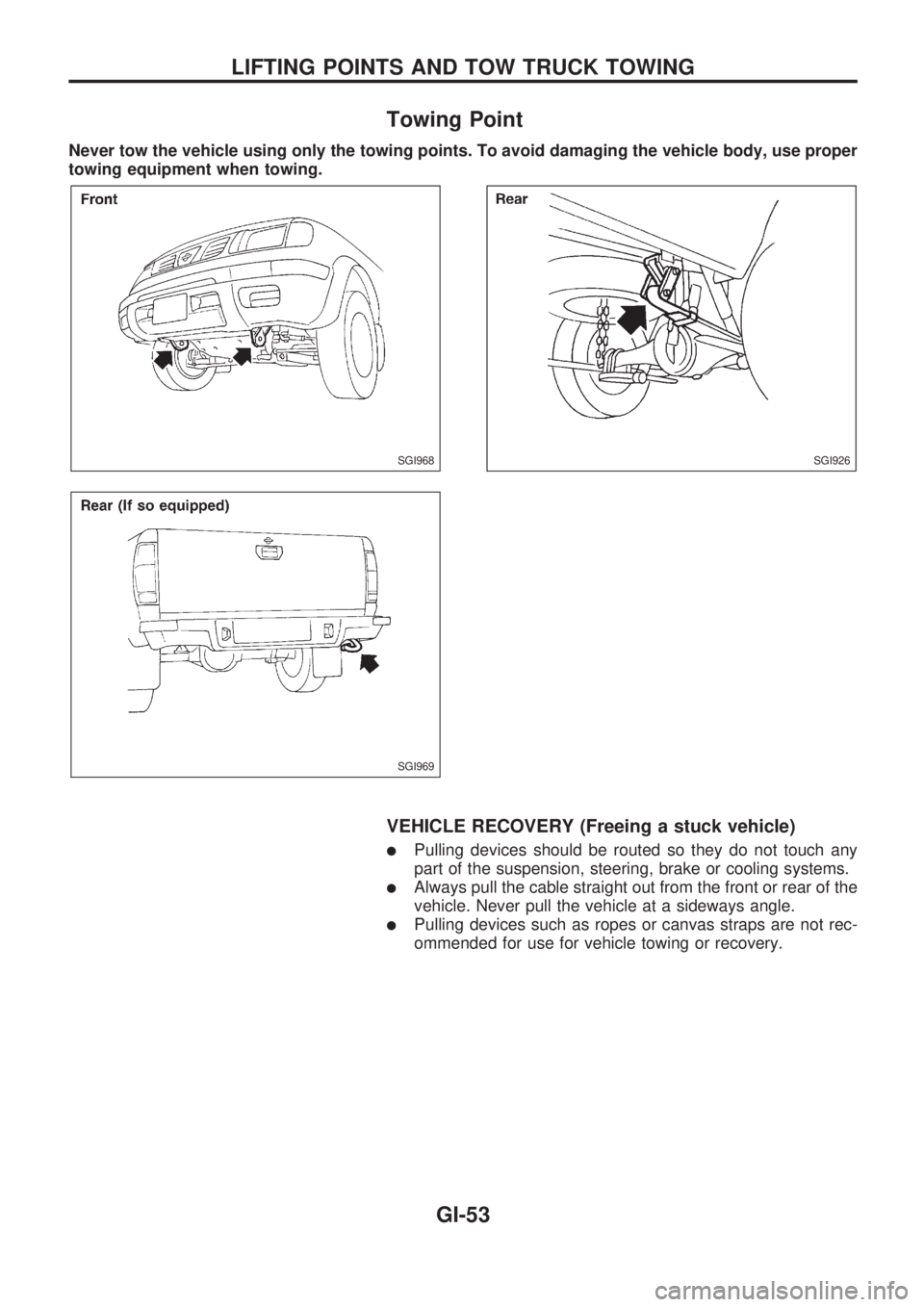

Towing Point

Never tow the vehicle using only the towing points. To avoid damaging the vehicle body, use proper

towing equipment when towing.

VEHICLE RECOVERY (Freeing a stuck vehicle)

lPulling devices should be routed so they do not touch any

part of the suspension, steering, brake or cooling systems.

lAlways pull the cable straight out from the front or rear of the

vehicle. Never pull the vehicle at a sideways angle.

lPulling devices such as ropes or canvas straps are not rec-

ommended for use for vehicle towing or recovery.

SGI968

SGI969

SGI926

LIFTING POINTS AND TOW TRUCK TOWING

GI-53

Page 870 of 1659

Throttle body ................................................. EM-9

Throttle position sensor (TPS)................... EC-113

Throwout bearing - See Clutch release

bearing........................................................ CL-9

Tie-rod .......................................................... ST-37

Tie-rod ball joints.......................................... ST-37

Tightening torque of standard bolts .............. GI-54

Timing chain ................................................ EM-13

Timing gear ................................................. EM-89

Tire rotation ................................................. MA-35

Tire size ........................................................ GI-46

Tooth contact (R180A) ................................ PD-26

Tooth contact (C200) ................................... PD-49

Tooth contact (H233B) ................................ PD-70

Torsion bar spring ........................................ FA-28

Tow truck towing ........................................... GI-51

Towing point.................................................. GI-53

Transfer case ................................................. TF-8

Transfer oil replacement ............................. MA-33

Transfer serial number.................................. GI-43

Transmission case (M/T) (FS5R30A).......... MT-35

Transmission case (M/T) (FS5W71C)......... MT-14

Transmission serial number.......................... GI-43

Tread - FR&RR (Dimensions) ...................... GI-44

Trim .............................................................. BT-15

Triple pressure switch ........................... HA-12, 44

Turn signal lamp........................................... EL-74

Two-pole lift................................................... GI-50

U

Under body ....................................................BT-46

Upper link (front susp.) ................................ FA-31

V

VSS - Wiring diagram .................................EC-119

Vacuum hose (brake system) .......................BR-17

Vacuum hose drawing (ECCS).....................EC-12

Vacuum pump ...............................................BR-19

Valve clearance adjustment .........................MA-23

Valve clearance ............................................EM-31

Valve guide (KA24 engine) ......................... EM-29Valve guide (TD25 engine) ..........................EM-56

Valve lifter .....................................................EM-60

Valve seat (KA24 engine) ............................EM-31

Valve seat (TD25 engine) ............................EM-57

Valve spring (KA24 engine) .........................EM-32

Valve spring (TD25 engine) .........................EM-60

Vehicle identification number .........................GI-40

Vehicle recovery (freeing a stuck

vehicle) .......................................................GI-53

Vehicle speed sensor (VSS).......................EC-118

Ventilator door control rod adjustment .........HA-45

Viscosity number (SAE) ...............................MA-13

W

WARN - Wiring diagram ..............................EL-106

WINDOW - Wiring diagram ........................ EL-157

WIPER - Wiring diagram ............................ EL-122

Warning lamps ........................................... EL-105

Washer, front .............................................. EL-120

Water cock control rod adjustment.............. HA-46

Water pump (KA24 engine) ........................... LC-7

Water pump (TD25 engine) ......................... LC-21

Weatherstrip - See Exterior ......................... BT-24

Wheel alignment (front).................................. FA-7

Wheel balance............................................. MA-34

Wheel bearing (front axle) ............................. FA-5

Wheel bearing (rear)...................................... RA-4

Wheel hub (front) ......................................... FA-16

Wheel sensors (ABS) .................................. BR-35

Wheel size .................................................... GI-46

Wheelbase (Dimensions) .............................. GI-44

Width (Dimensions)....................................... GI-44

Window, back ............................................... BT-24

Window, door ............................................... BT-10

Window, side ................................................ BT-38

Windshield .................................................... BT-36

Wiper, front ................................................. EL-120

Wiring diagram (cell code) list.................... EL-253

Wiring diagrams .............................................. GI-9

Withdrawal lever (clutch)................................ CL-9

Wrist pin - See Piston pin inspection .......... EM-39

ALPHABETICAL INDEX

IDX-8

Page 983 of 1659

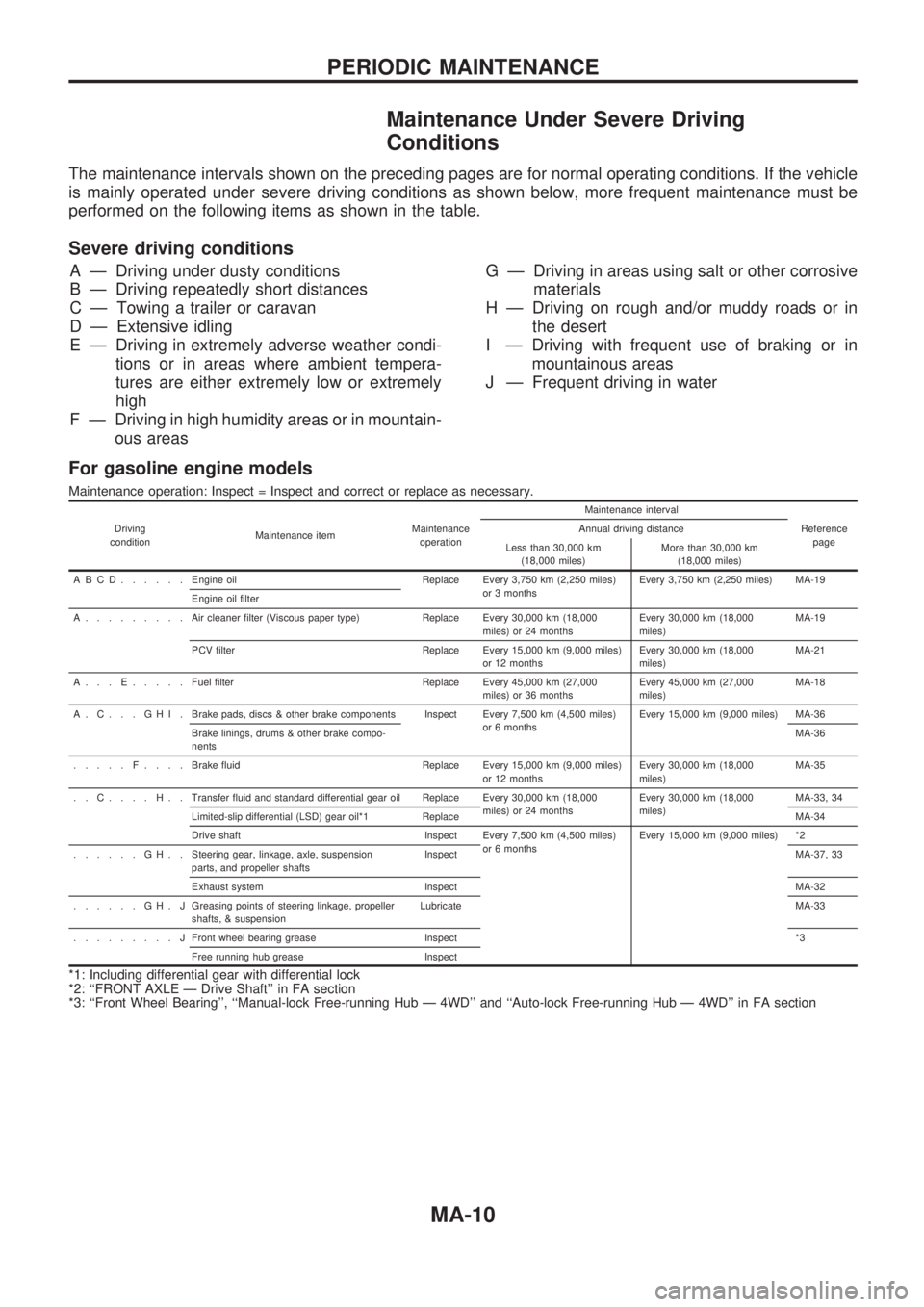

Maintenance Under Severe Driving

Conditions

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle

is mainly operated under severe driving conditions as shown below, more frequent maintenance must be

performed on the following items as shown in the table.

Severe driving conditions

A Ð Driving under dusty conditions

B Ð Driving repeatedly short distances

C Ð Towing a trailer or caravan

D Ð Extensive idling

E Ð Driving in extremely adverse weather condi-

tions or in areas where ambient tempera-

tures are either extremely low or extremely

high

F Ð Driving in high humidity areas or in mountain-

ous areasG Ð Driving in areas using salt or other corrosive

materials

H Ð Driving on rough and/or muddy roads or in

the desert

I Ð Driving with frequent use of braking or in

mountainous areas

J Ð Frequent driving in water

For gasoline engine models

Maintenance operation: Inspect = Inspect and correct or replace as necessary.

Driving

conditionMaintenance itemMaintenance

operationMaintenance interval

Reference

page Annual driving distance

Less than 30,000 km

(18,000 miles)More than 30,000 km

(18,000 miles)

ABCD......Engine oil Replace Every 3,750 km (2,250 miles)

or 3 monthsEvery 3,750 km (2,250 miles) MA-19

Engine oil filter

A.........Aircleaner filter (Viscous paper type) Replace Every 30,000 km (18,000

miles) or 24 monthsEvery 30,000 km (18,000

miles)MA-19

PCV filter Replace Every 15,000 km (9,000 miles)

or 12 monthsEvery 30,000 km (18,000

miles)MA-21

A...E.....Fuel filter Replace Every 45,000 km (27,000

miles) or 36 monthsEvery 45,000 km (27,000

miles)MA-18

A.C...GHI.Brake pads, discs & other brake components Inspect Every 7,500 km (4,500 miles)

or 6 monthsEvery 15,000 km (9,000 miles) MA-36

Brake linings, drums & other brake compo-

nentsMA-36

.....F....Brake fluid Replace Every 15,000 km (9,000 miles)

or 12 monthsEvery 30,000 km (18,000

miles)MA-35

..C....H..Transfer fluid and standard differential gear oil Replace Every 30,000 km (18,000

miles) or 24 monthsEvery 30,000 km (18,000

miles)MA-33, 34

Limited-slip differential (LSD) gear oil*1 ReplaceMA-34

Drive shaft Inspect Every 7,500 km (4,500 miles)

or 6 monthsEvery 15,000 km (9,000 miles) *2

......GH..Steering gear, linkage, axle, suspension

parts, and propeller shaftsInspectMA-37, 33

Exhaust system InspectMA-32

......GH.JGreasing points of steering linkage, propeller

shafts, & suspensionLubricateMA-33

.........JFront wheel bearing grease Inspect*3

Free running hub grease Inspect

*1: Including differential gear with differential lock

*2: ``FRONT AXLE Ð Drive Shaft'' in FA section

*3: ``Front Wheel Bearing'', ``Manual-lock Free-running Hub Ð 4WD'' and ``Auto-lock Free-running Hub Ð 4WD'' in FA section

PERIODIC MAINTENANCE

MA-10