differential NISSAN PICK-UP 1998 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 1 of 1659

GENERAL INFORMATIONGI

MAINTENANCEMA

ENGINE MECHANICALEM

ENGINE LUBRICATION &

COOLING SYSTEMSLC

ENGINE CONTROL SYSTEMEC

ACCELERATOR CONTROL, FUEL &

EXHAUST SYSTEMSFE

CLUTCHCL

MANUAL TRANSAXLEMT

TRANSFERTF

PROPELLER SHAFT &

DIFFERENTIAL CARRIERPD

FRONT AXLE & FRONT SUSPENSIONFA

REAR AXLE & REAR SUSPENSIONRA

BRAKE SYSTEMBR

STEERING SYSTEMST

RESTRAINT SYSTEMRS

BODY & TRIMBT

HEATER & AIR CONDITIONERHA

ELECTRICAL SYSTEMEL

ALPHABETICAL INDEXIDX

PICKUP

MODEL D22 SERIES

Edition: February 1998

Printing: May 1998 (01)

Publication No.: SM8E-0D22E0E

NISSAN EUROPE S.A.S.

1998 NISSAN EUROPE S.A.S. Printed in the Netherlands

Not to be reproduced in whole or in part without the prior written permission of Nissan Europe S.A.S., Paris, France.

QUICK REFERENCE INDEX

Page 37 of 1659

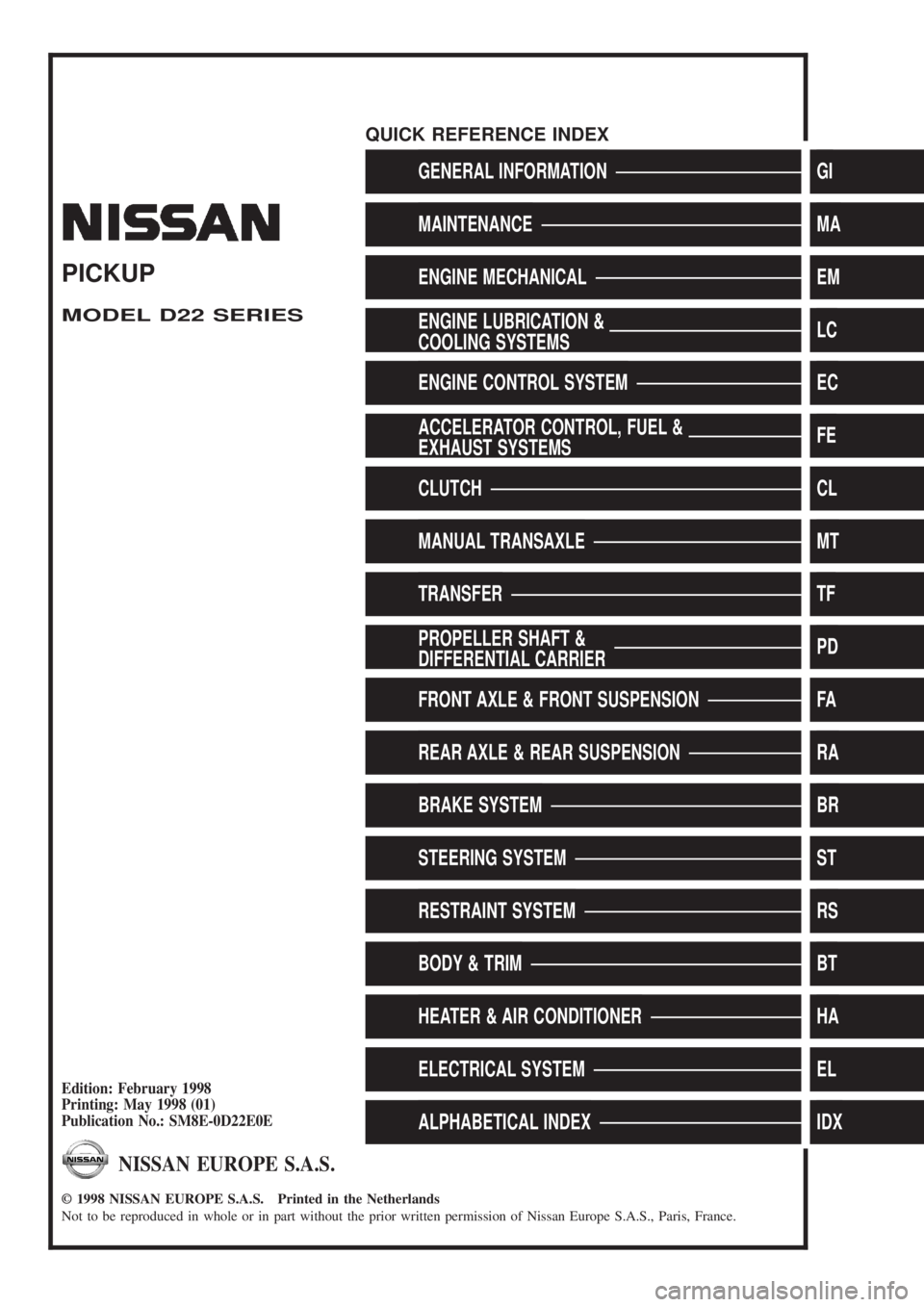

System Components

System Description

WHEEL SENSOR

The sensor unit consists of a gear-shaped sensor rotor and a

sensor element. The element contains a bar magnet around

which a coil is wound. The sensor is installed on the back of the

brake rotor and the front of the differential (2WD) or the back of

the rear brake drum (4WD). As the wheel rotates, the sensor

generates a sine-wave pattern. The frequency and voltage

increase(s) as the rotating speed increases.

CONTROL UNIT (built in ABS actuator and electric

unit)

The control unit computes the wheel rotating speed by the sig-

nal current sent from the sensor. Then it supplies a DC current

to the actuator solenoid valve. It also controls ON-OFF operation

of the valve relay and motor relay. If any electrical malfunction

should be detected in the system, the control unit causes the

warning lamp to light up. In this condition, the ABS will be deac-

tivated by the control unit, and the vehicle's brake system reverts

to normal operation. (For control unit layout, refer to ABS

ACTUATOR AND ELECTRIC UNIT, BR-34.)

SBR068E

SBR069E

ANTI-LOCK BRAKE SYSTEM

BR-33

Page 656 of 1659

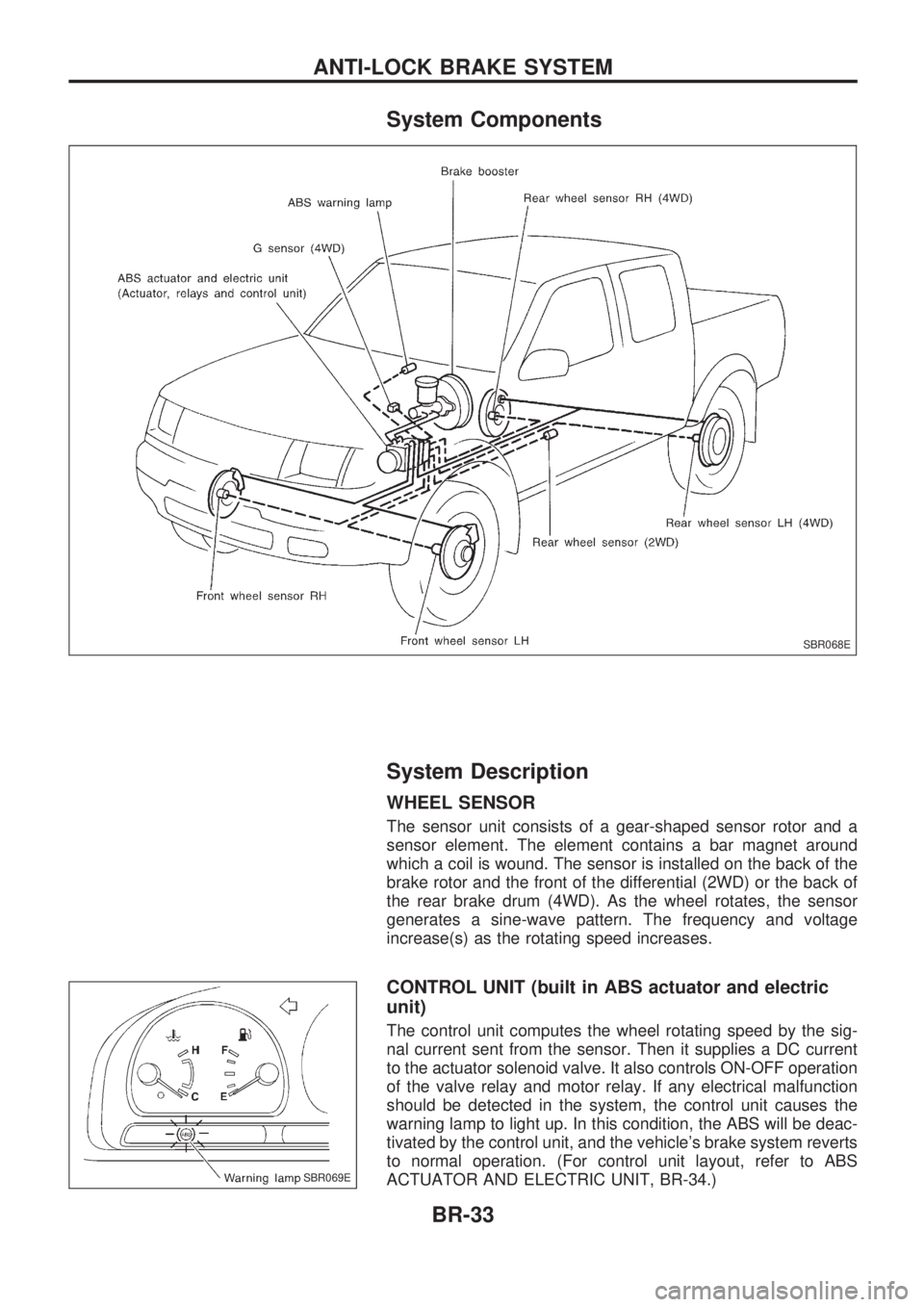

Removal

1. Raise vehicle and support it with safety stands.

2. Remove engine under cover.

3. Drain engine oil.

4. Remove front final drive together with differential mounting

member. Refer to PD section (``Removal and Installation'',

``Front final drive'') Ð 4WD models only.

5. Remove front suspension member bolt (RH & LH).

6. Remove oil pan bolts.

7. Remove oil pan.

a. Insert Tool between cylinder block and oil pan.

lBe careful not to damage aluminum mating surface.

lDo not insert screwdriver, or oil pan flange will be dam-

aged.

b. Slide Tool by tapping on the side of the Tool with a hammer.

8. Pull out oil pan from front side.

SEM566F

SEM600F

SEM567F

SEM365EA

OIL PANKA

EM-11

Page 696 of 1659

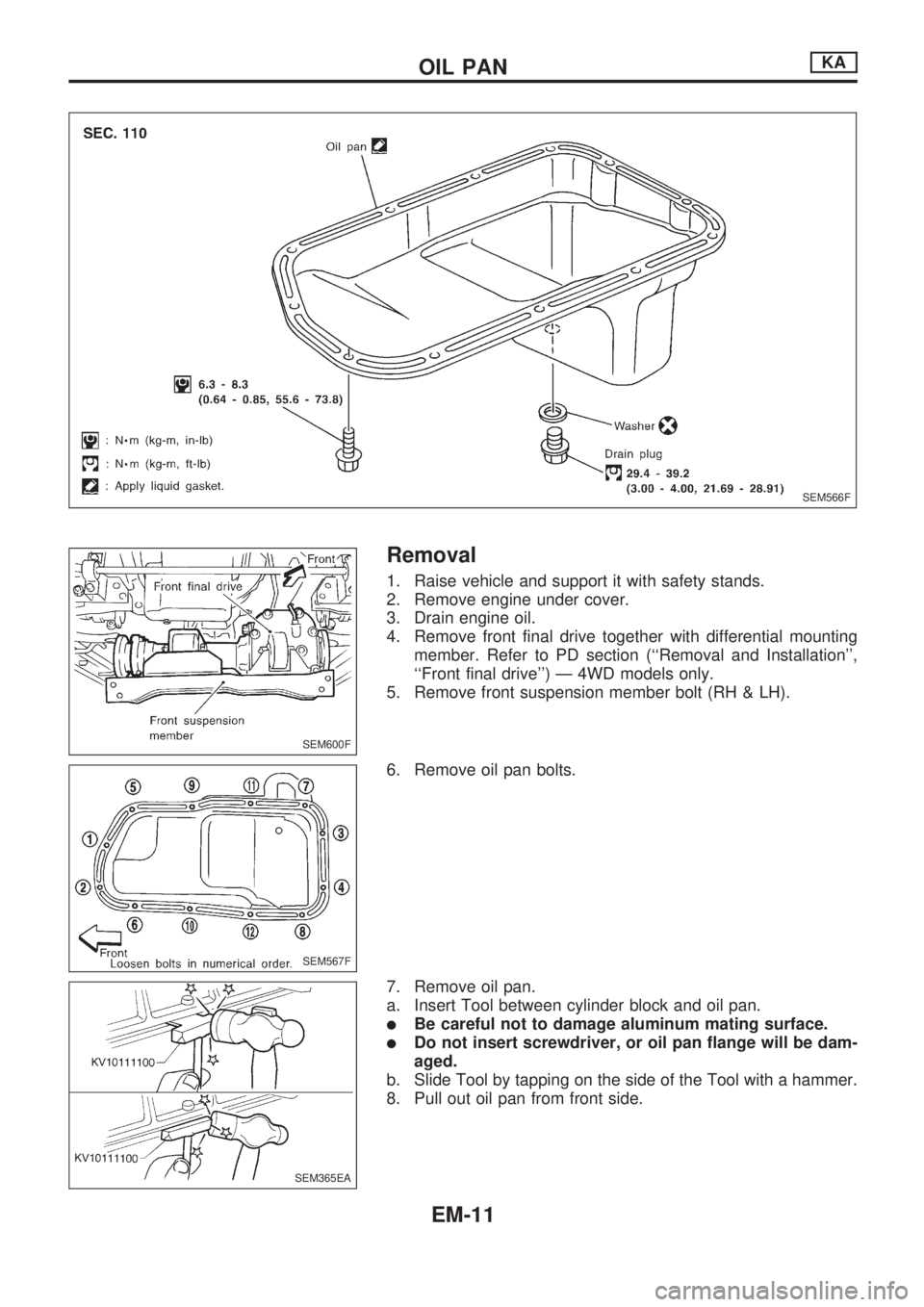

Measurement of Compression Pressure

1. Warm up engine.

2. Stop engine. Remove glow plate and glow plugs.

3. Fit compression gauge adapter to cylinder head.

Compression gauge adapter:

:15-20Nzm (1.5 - 2.0 kg-m, 11 - 14 ft-lb)

4. Disconnect fuel cut solenoid wire connector.

5. Crank engine, then read gauge indication.

lEngine compression measurement should be made as

quickly as possible.

Compression pressure:

Unit: kPa (bar, kg/cm2, psi)/200 rpm

Standard 2,942 (29.4, 30, 427)

Minimum 2,452 (24.5, 25, 356)

Differential limit between cylinders 294 (2.9, 3, 43)

6. If cylinder compression in one or more cylinders is low, pour

a small quantity of engine oil into cylinders through the glow

holes and retest compression.

lIf adding oil helps the compression pressure, chances

are that piston rings are worn or damaged.

lIf pressure stays low, valve may be sticking or seating

improperly.

lIf cylinder compression in any two adjacent cylinders is

low, and if adding oil does not help the compression,

there is leakage past the gasketed surface.

Oil and water in combustion chambers can result from

this problem.

DEM019.DEM019

DEM020

DEM058

COMPRESSION PRESSURETD

EM-51

Page 697 of 1659

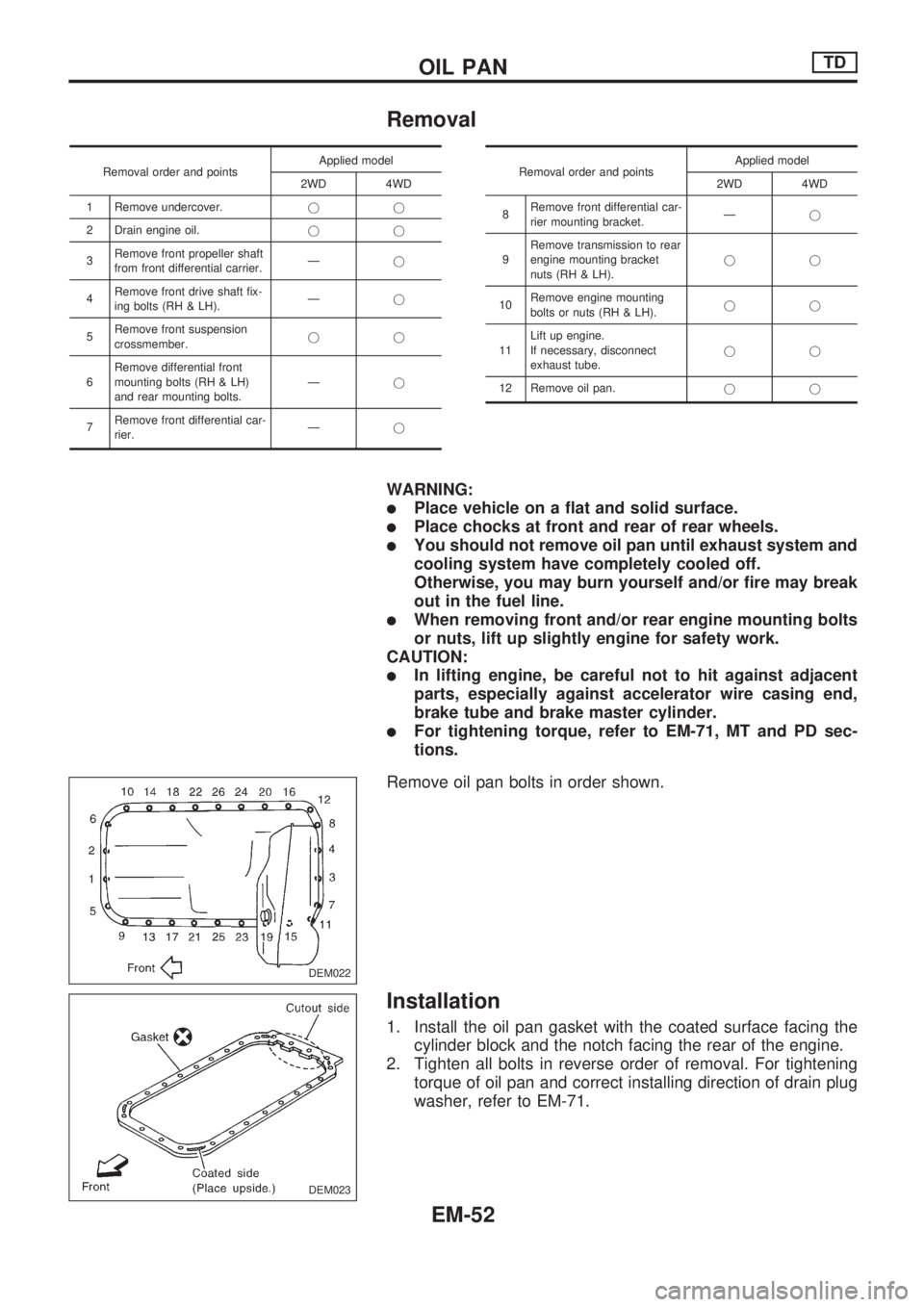

Removal

Removal order and pointsApplied model

2WD 4WD

1 Remove undercover.jj

2 Drain engine oil.jj

3Remove front propeller shaft

from front differential carrier.Ðj

4Remove front drive shaft fix-

ing bolts (RH & LH).Ðj

5Remove front suspension

crossmember.jj

6Remove differential front

mounting bolts (RH & LH)

and rear mounting bolts.Ðj

7Remove front differential car-

rier.ÐjRemoval order and pointsApplied model

2WD 4WD

8Remove front differential car-

rier mounting bracket.Ðj

9Remove transmission to rear

engine mounting bracket

nuts (RH & LH).jj

10Remove engine mounting

bolts or nuts (RH & LH).jj

11Lift up engine.

If necessary, disconnect

exhaust tube.jj

12 Remove oil pan.jj

WARNING:

lPlace vehicle on a flat and solid surface.

lPlace chocks at front and rear of rear wheels.

lYou should not remove oil pan until exhaust system and

cooling system have completely cooled off.

Otherwise, you may burn yourself and/or fire may break

out in the fuel line.

lWhen removing front and/or rear engine mounting bolts

or nuts, lift up slightly engine for safety work.

CAUTION:

lIn lifting engine, be careful not to hit against adjacent

parts, especially against accelerator wire casing end,

brake tube and brake master cylinder.

lFor tightening torque, refer to EM-71, MT and PD sec-

tions.

Remove oil pan bolts in order shown.

Installation

1. Install the oil pan gasket with the coated surface facing the

cylinder block and the notch facing the rear of the engine.

2. Tighten all bolts in reverse order of removal. For tightening

torque of oil pan and correct installing direction of drain plug

washer, refer to EM-71.

DEM022

DEM023

OIL PANTD

EM-52

Page 736 of 1659

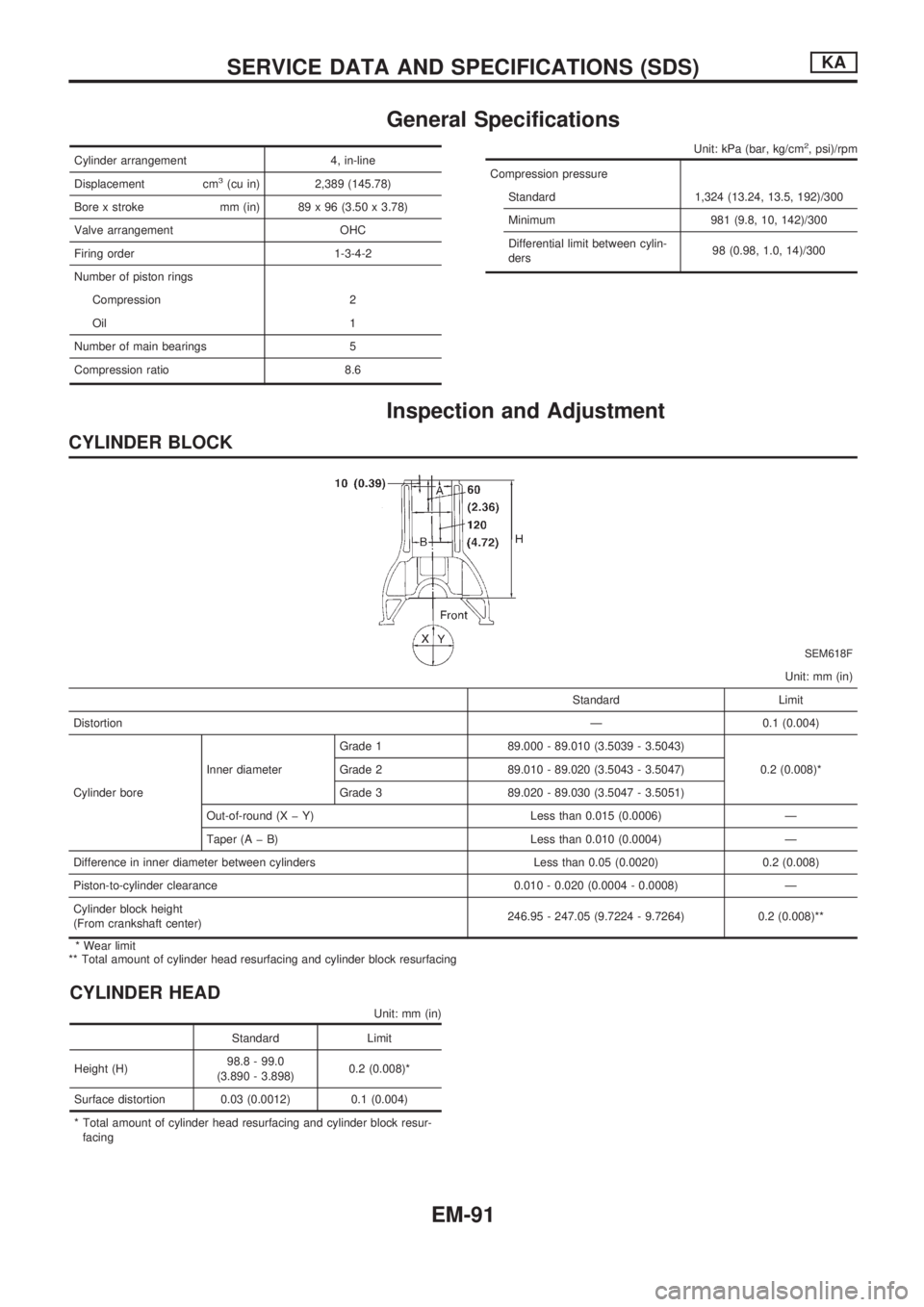

General Specifications

Cylinder arrangement 4, in-line

Displacement cm

3(cu in) 2,389 (145.78)

Bore x stroke mm (in) 89 x 96 (3.50 x 3.78)

Valve arrangement OHC

Firing order 1-3-4-2

Number of piston rings

Compression 2

Oil 1

Number of main bearings 5

Compression ratio 8.6

Unit: kPa (bar, kg/cm2, psi)/rpm

Compression pressure

Standard 1,324 (13.24, 13.5, 192)/300

Minimum 981 (9.8, 10, 142)/300

Differential limit between cylin-

ders98 (0.98, 1.0, 14)/300

Inspection and Adjustment

CYLINDER BLOCK

SEM618F

Unit: mm (in)

Standard Limit

DistortionÐ 0.1 (0.004)

Cylinder boreInner diameterGrade 1 89.000 - 89.010 (3.5039 - 3.5043)

0.2 (0.008)* Grade 2 89.010 - 89.020 (3.5043 - 3.5047)

Grade 3 89.020 - 89.030 (3.5047 - 3.5051)

Out-of-round (X þ Y) Less than 0.015 (0.0006) Ð

Taper (A þ B) Less than 0.010 (0.0004) Ð

Difference in inner diameter between cylinders Less than 0.05 (0.0020) 0.2 (0.008)

Piston-to-cylinder clearance 0.010 - 0.020 (0.0004 - 0.0008) Ð

Cylinder block height

(From crankshaft center)246.95 - 247.05 (9.7224 - 9.7264) 0.2 (0.008)**

* Wear limit

** Total amount of cylinder head resurfacing and cylinder block resurfacing

CYLINDER HEAD

Unit: mm (in)

Standard Limit

Height (H)98.8 - 99.0

(3.890 - 3.898)0.2 (0.008)*

Surface distortion 0.03 (0.0012) 0.1 (0.004)

* Total amount of cylinder head resurfacing and cylinder block resur-

facing

SERVICE DATA AND SPECIFICATIONS (SDS)KA

EM-91

Page 743 of 1659

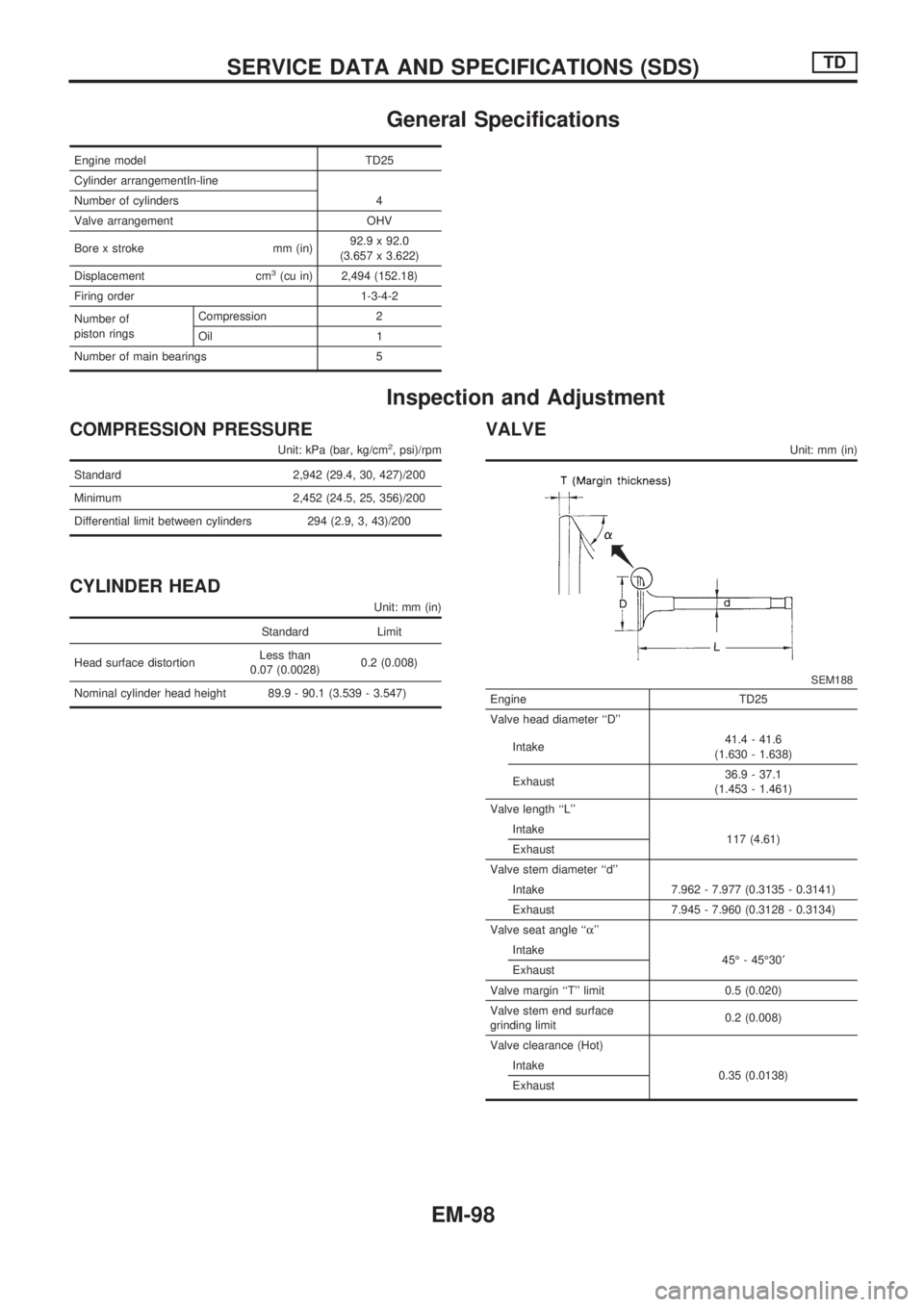

General Specifications

Engine model TD25

Cylinder arrangementIn-line

Number of cylinders 4

Valve arrangement OHV

Bore x stroke mm (in)92.9 x 92.0

(3.657 x 3.622)

Displacement cm

3(cu in) 2,494 (152.18)

Firing order 1-3-4-2

Number of

piston ringsCompression 2

Oil 1

Number of main bearings 5

Inspection and Adjustment

COMPRESSION PRESSURE

Unit: kPa (bar, kg/cm2, psi)/rpm

Standard 2,942 (29.4, 30, 427)/200

Minimum 2,452 (24.5, 25, 356)/200

Differential limit between cylinders 294 (2.9, 3, 43)/200

CYLINDER HEAD

Unit: mm (in)

Standard Limit

Head surface distortionLess than

0.07 (0.0028)0.2 (0.008)

Nominal cylinder head height 89.9 - 90.1 (3.539 - 3.547)

VALVE

Unit: mm (in)

SEM188

Engine TD25

Valve head diameter ``D''

Intake41.4 - 41.6

(1.630 - 1.638)

Exhaust36.9 - 37.1

(1.453 - 1.461)

Valve length ``L''

Intake

117 (4.61)

Exhaust

Valve stem diameter ``d''

Intake 7.962 - 7.977 (0.3135 - 0.3141)

Exhaust 7.945 - 7.960 (0.3128 - 0.3134)

Valve seat angle ``a''

Intake

45É - 45É30¢

Exhaust

Valve margin ``T'' limit 0.5 (0.020)

Valve stem end surface

grinding limit0.2 (0.008)

Valve clearance (Hot)

Intake

0.35 (0.0138)

Exhaust

SERVICE DATA AND SPECIFICATIONS (SDS)TD

EM-98

Page 841 of 1659

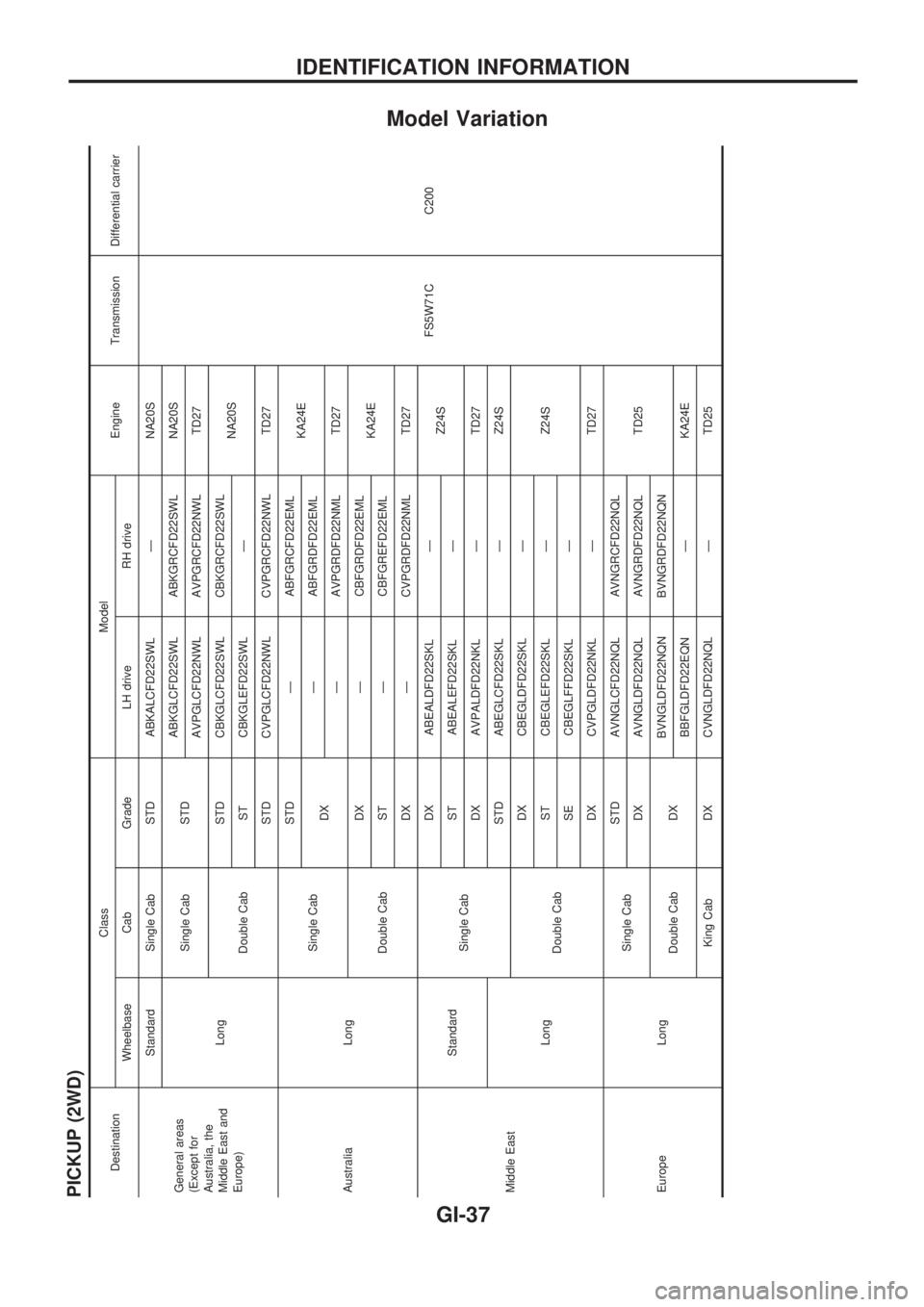

Model Variation

PICKUP (2WD)

DestinationClass Model

Engine Transmission Differential carrier

Wheelbase Cab Grade LH drive RH drive

General areas

(Except for

Australia, the

Middle East and

Europe)Standard Single Cab STD ABKALCFD22SWL Ð NA20S

FS5W71C C200 LongSingle Cab STDABKGLCFD22SWL ABKGRCFD22SWL NA20S

AVPGLCFD22NWL AVPGRCFD22NWL TD27

Double CabSTD CBKGLCFD22SWL CBKGRCFD22SWL

NA20S

ST CBKGLEFD22SWL Ð

STD CVPGLCFD22NWL CVPGRCFD22NWL TD27

Australia LongSingle CabSTD Ð ABFGRCFD22EML

KA24E

DXÐ ABFGRDFD22EML

Ð AVPGRDFD22NML TD27

Double CabDX Ð CBFGRDFD22EML

KA24E

ST Ð CBFGREFD22EML

DX Ð CVPGRDFD22NML TD27

Middle EastStandard

Single CabDX ABEALDFD22SKL Ð

Z24S

ST ABEALEFD22SKL Ð

DX AVPALDFD22NKL Ð TD27

LongSTD ABEGLCFD22SKL Ð Z24S

Double CabDX CBEGLDFD22SKL Ð

Z24S ST CBEGLEFD22SKL Ð

SE CBEGLFFD22SKL Ð

DX CVPGLDFD22NKL Ð TD27

Europe LongSingle CabSTD AVNGLCFD22NQL AVNGRCFD22NQL

TD25 DX AVNGLDFD22NQL AVNGRDFD22NQL

Double Cab DXBVNGLDFD22NQN BVNGRDFD22NQN

BBFGLDFD22EQN Ð KA24E

King Cab DX CVNGLDFD22NQL Ð TD25

IDENTIFICATION INFORMATION

GI-37

Page 842 of 1659

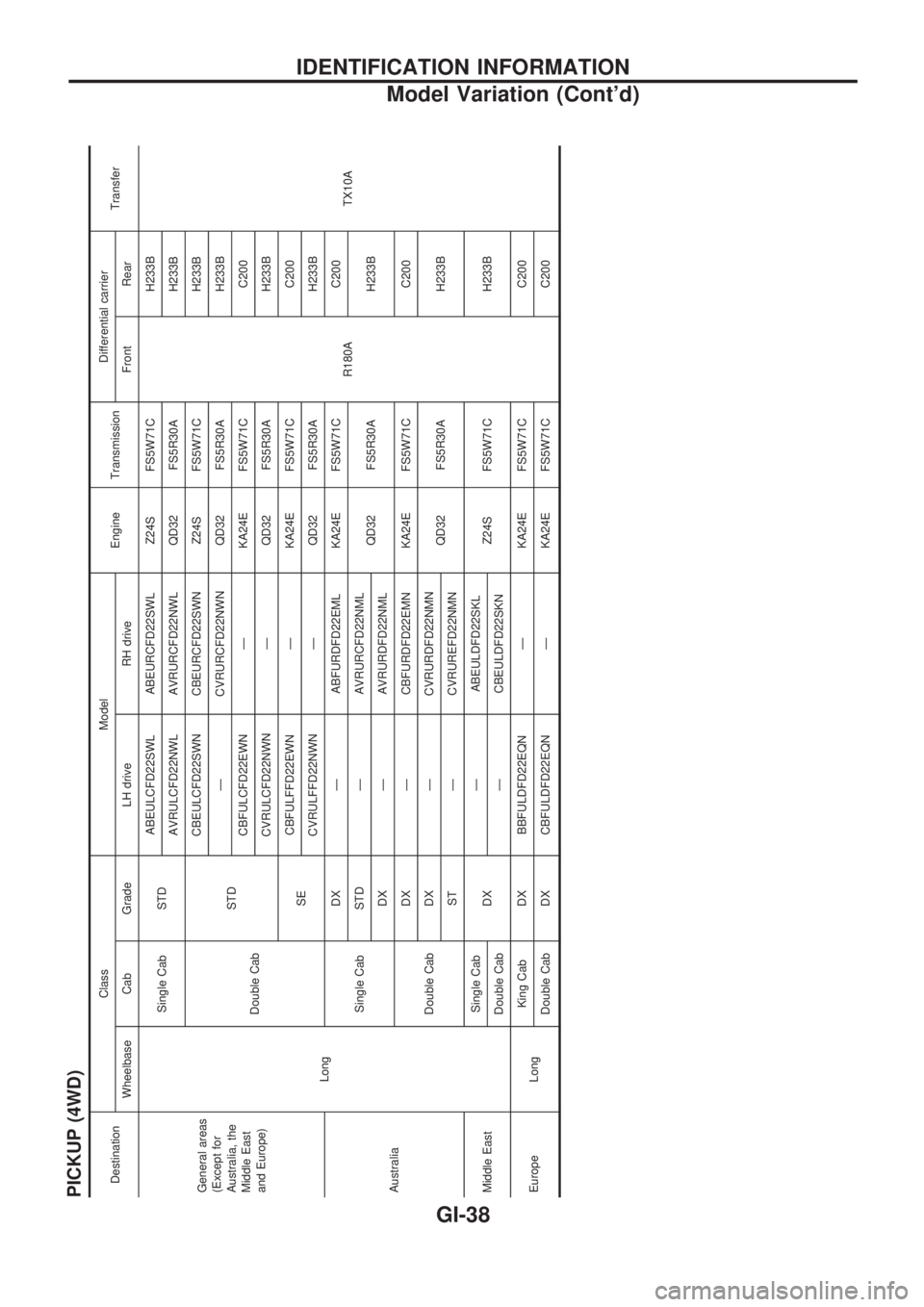

PICKUP (4WD)DestinationClass Model

Engine TransmissionDifferential carrier

Transfer

Wheelbase Cab Grade LH drive RH drive Front Rear

General areas

(Except for

Australia, the

Middle East

and Europe)

LongSingle Cab STDABEULCFD22SWL ABEURCFD22SWL Z24S FS5W71C

R180AH233B

TX10A AVRULCFD22NWL AVRURCFD22NWL QD32 FS5R30A H233B

Double CabSTDCBEULCFD22SWN CBEURCFD22SWN Z24S FS5W71C H233B

Ð CVRURCFD22NWN QD32 FS5R30A H233B

CBFULCFD22EWN Ð KA24E FS5W71C C200

CVRULCFD22NWN Ð QD32 FS5R30A H233B

SECBFULFFD22EWN Ð KA24E FS5W71C C200

CVRULFFD22NWN Ð QD32 FS5R30A H233B

AustraliaSingle CabDX Ð ABFURDFD22EML KA24E FS5W71C C200

STD Ð AVRURCFD22NML

QD32 FS5R30A H233B

DX Ð AVRURDFD22NML

Double CabDX Ð CBFURDFD22EMN KA24E FS5W71C C200

DX Ð CVRURDFD22NMN

QD32 FS5R30A H233B

ST Ð CVRUREFD22NMN

Middle EastSingle Cab

DXÐ ABEULDFD22SKL

Z24S FS5W71C H233B

Double Cab Ð CBEULDFD22SKN

Europe LongKing Cab DX BBFULDFD22EQN Ð KA24E FS5W71C C200

Double Cab DX CBFULDFD22EQN Ð KA24E FS5W71C C200

IDENTIFICATION INFORMATION

Model Variation (Cont'd)

GI-38

Page 860 of 1659

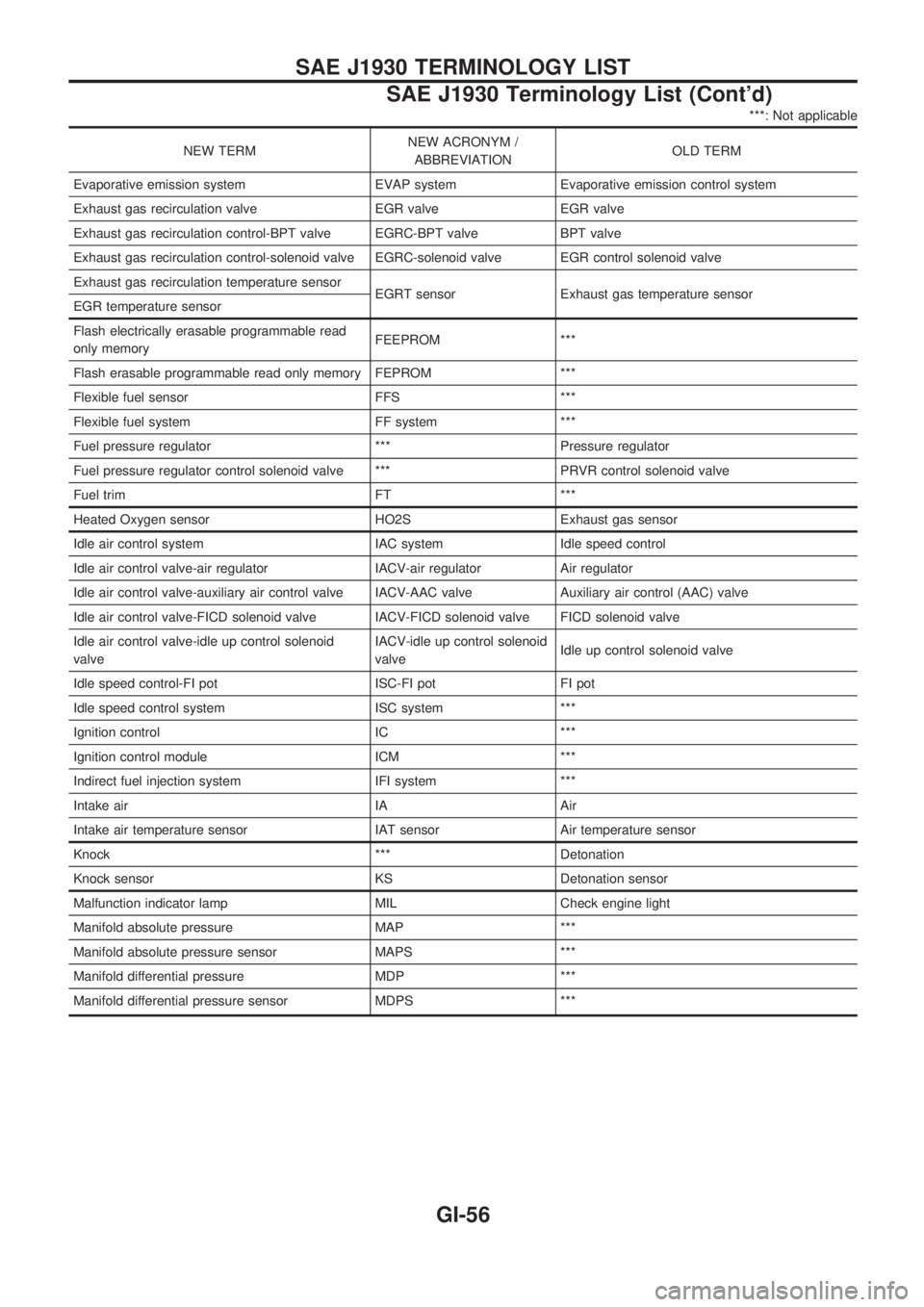

***: Not applicable

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Evaporative emission system EVAP system Evaporative emission control system

Exhaust gas recirculation valve EGR valve EGR valve

Exhaust gas recirculation control-BPT valve EGRC-BPT valve BPT valve

Exhaust gas recirculation control-solenoid valve EGRC-solenoid valve EGR control solenoid valve

Exhaust gas recirculation temperature sensor

EGRT sensor Exhaust gas temperature sensor

EGR temperature sensor

Flash electrically erasable programmable read

only memoryFEEPROM ***

Flash erasable programmable read only memory FEPROM ***

Flexible fuel sensor FFS ***

Flexible fuel system FF system ***

Fuel pressure regulator *** Pressure regulator

Fuel pressure regulator control solenoid valve *** PRVR control solenoid valve

Fuel trim FT ***

Heated Oxygen sensor HO2S Exhaust gas sensor

Idle air control system IAC system Idle speed control

Idle air control valve-air regulator IACV-air regulator Air regulator

Idle air control valve-auxiliary air control valve IACV-AAC valve Auxiliary air control (AAC) valve

Idle air control valve-FICD solenoid valve IACV-FICD solenoid valve FICD solenoid valve

Idle air control valve-idle up control solenoid

valveIACV-idle up control solenoid

valveIdle up control solenoid valve

Idle speed control-FI pot ISC-FI pot FI pot

Idle speed control system ISC system ***

Ignition control IC ***

Ignition control module ICM ***

Indirect fuel injection system IFI system ***

Intake air IA Air

Intake air temperature sensor IAT sensor Air temperature sensor

Knock *** Detonation

Knock sensor KS Detonation sensor

Malfunction indicator lamp MIL Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

SAE J1930 TERMINOLOGY LIST

SAE J1930 Terminology List (Cont'd)

GI-56