engine oil NISSAN PICK-UP 1999 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PICK-UP, Model: NISSAN PICK-UP 1999Pages: 666, PDF Size: 16.21 MB

Page 46 of 666

ENGINECONTROLSYSTEM

SECTION

EC

MODIFICATION NOTICE:

Gasoline engine

Diesel engine

lWiring diagrams have been changed.

CONTENTS

PRECAUTIONS AND PREPARATION ............... 2003

Supplemental Restraint System (SRS) ``AIR

BAG'' and ``SEAT BELT PRE-TENSIONER'' .. 2003

KA24E

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM............................................................... 2004

Circuit Diagram ................................................ 2004

TROUBLE DIAGNOSIS FOR POWER

SUPPLY ............................................................... 2005

Main Power Supply and Ground Circuit .......... 2005

TROUBLE DIAGNOSIS FOR ``CAMSHAFT

POSI SEN'' (DTC 11) ........................................... 2007

Camshaft Position Sensor (CMPS) ................. 2007

TROUBLE DIAGNOSIS FOR ``MASS AIR FLOW

SEN'' (DTC 12) .................................................... 2008

Mass Air Flow Sensor (MAFS) ........................ 2008

TROUBLE DIAGNOSIS FOR

NON-DETECTABLE ITEMS ................................ 2009

Vehicle Speed Sensor (VSS) .......................... 2009

Heated Oxygen Sensor (HO2S)

- LHD Models - ................................................ 2010

Idle Air Control Valve (IACV) - Auxiliary Air

Control (AAC) Valve ........................................ 2011 Park/Neutral Position Switch ........................... 2012

EVAP Canister Purge Control Solenoid

Valve ................................................................ 2013

Start Signal ...................................................... 2014

Fuel Pump........................................................ 2015

Power Steering Oil Pressure Switch ............... 2016

Swirl Control Valve Control Solenoid Valve .... 2017

IACV-FICD Solenoid Valve .............................. 2018

MIL & Data Link Connectors ........................... 2019

TD

QUICK-GLOW SYSTEM ...................................... 2020

Circuit Diagram ................................................ 2020

Wiring Diagram ................................................ 2021

EGR SYSTEM ...................................................... 2027

Wiring Diagram ................................................ 2027

SOLENOID TIMER .............................................. 2031

Wiring Diagram ................................................ 2031

FUEL HEATER SYSTEM .................................... 2033

Wiring Diagram ................................................ 2033

FAST IDLE CONTROL CIRCUIT ........................ 2034

Wiring Diagram ................................................ 2034

EC

Page 250 of 666

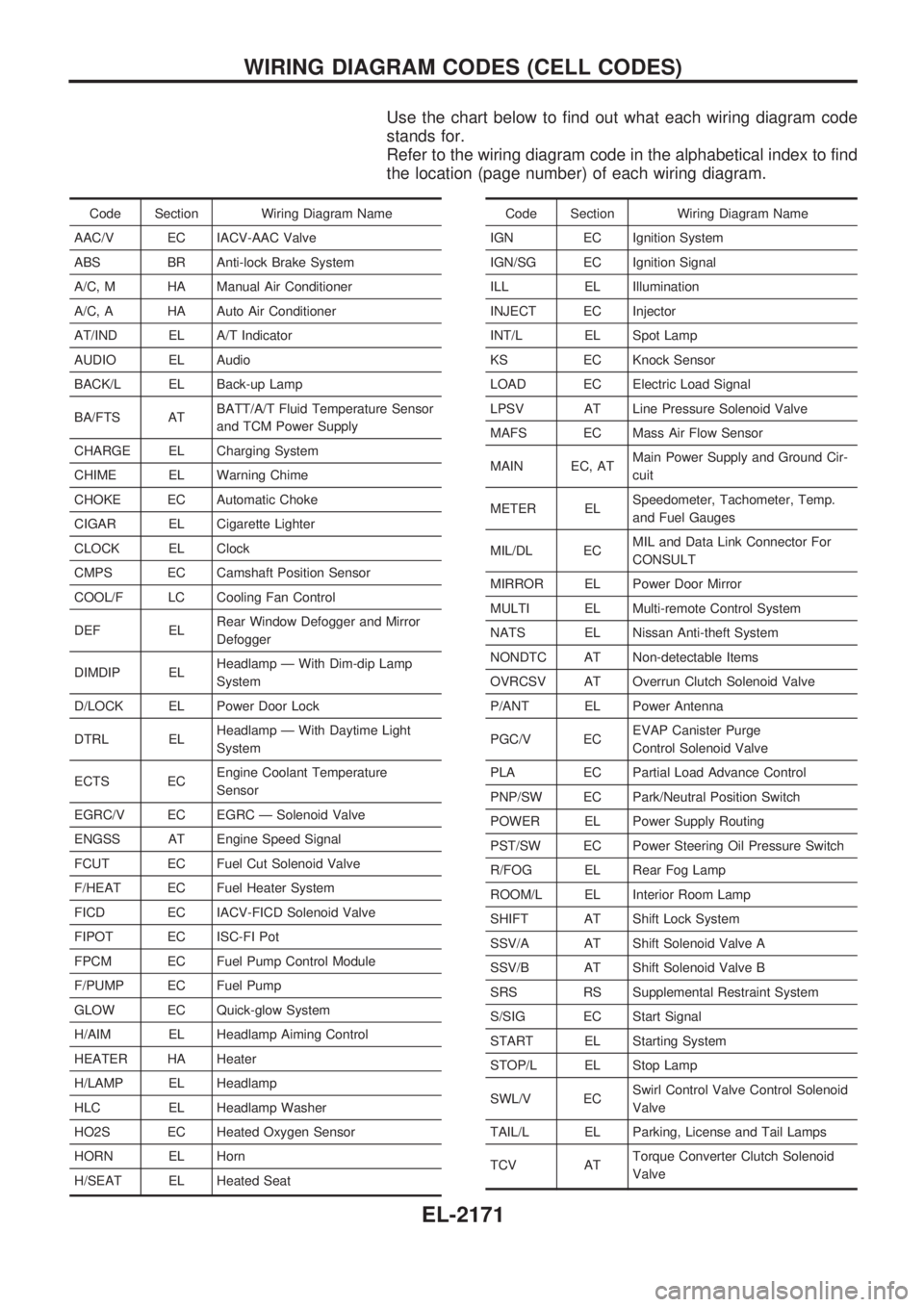

Use the chart below to find out what each wiring diagram code

stands for.

Refer to the wiring diagram code in the alphabetical index to find

the location (page number) of each wiring diagram.

Code Section Wiring Diagram Name

AAC/V EC IACV-AAC Valve

ABS BR Anti-lock Brake System

A/C, M HA Manual Air Conditioner

A/C, A HA Auto Air Conditioner

AT/IND EL A/T Indicator

AUDIO EL Audio

BACK/L EL Back-up Lamp

BA/FTS ATBATT/A/T Fluid Temperature Sensor

and TCM Power Supply

CHARGE EL Charging System

CHIME EL Warning Chime

CHOKE EC Automatic Choke

CIGAR EL Cigarette Lighter

CLOCK EL Clock

CMPS EC Camshaft Position Sensor

COOL/F LC Cooling Fan Control

DEF ELRear Window Defogger and Mirror

Defogger

DIMDIP ELHeadlamp Ð With Dim-dip Lamp

System

D/LOCK EL Power Door Lock

DTRL ELHeadlamp Ð With Daytime Light

System

ECTS ECEngine Coolant Temperature

Sensor

EGRC/V EC EGRC Ð Solenoid Valve

ENGSS AT Engine Speed Signal

FCUT EC Fuel Cut Solenoid Valve

F/HEAT EC Fuel Heater System

FICD EC IACV-FICD Solenoid Valve

FIPOT EC ISC-FI Pot

FPCM EC Fuel Pump Control Module

F/PUMP EC Fuel Pump

GLOW EC Quick-glow System

H/AIM EL Headlamp Aiming Control

HEATER HA Heater

H/LAMP EL Headlamp

HLC EL Headlamp Washer

HO2S EC Heated Oxygen Sensor

HORN EL Horn

H/SEAT EL Heated SeatCode Section Wiring Diagram Name

IGN EC Ignition System

IGN/SG EC Ignition Signal

ILL EL Illumination

INJECT EC Injector

INT/L EL Spot Lamp

KS EC Knock Sensor

LOAD EC Electric Load Signal

LPSV AT Line Pressure Solenoid Valve

MAFS EC Mass Air Flow Sensor

MAIN EC, ATMain Power Supply and Ground Cir-

cuit

METER ELSpeedometer, Tachometer, Temp.

and Fuel Gauges

MIL/DL ECMIL and Data Link Connector For

CONSULT

MIRROR EL Power Door Mirror

MULTI EL Multi-remote Control System

NATS EL Nissan Anti-theft System

NONDTC AT Non-detectable Items

OVRCSV AT Overrun Clutch Solenoid Valve

P/ANT EL Power Antenna

PGC/V ECEVAP Canister Purge

Control Solenoid Valve

PLA EC Partial Load Advance Control

PNP/SW EC Park/Neutral Position Switch

POWER EL Power Supply Routing

PST/SW EC Power Steering Oil Pressure Switch

R/FOG EL Rear Fog Lamp

ROOM/L EL Interior Room Lamp

SHIFT AT Shift Lock System

SSV/A AT Shift Solenoid Valve A

SSV/B AT Shift Solenoid Valve B

SRS RS Supplemental Restraint System

S/SIG EC Start Signal

START EL Starting System

STOP/L EL Stop Lamp

SWL/V ECSwirl Control Valve Control Solenoid

Valve

TAIL/L EL Parking, License and Tail Lamps

TCV ATTorque Converter Clutch Solenoid

Valve

WIRING DIAGRAM CODES (CELL CODES)

EL-2171

Page 422 of 666

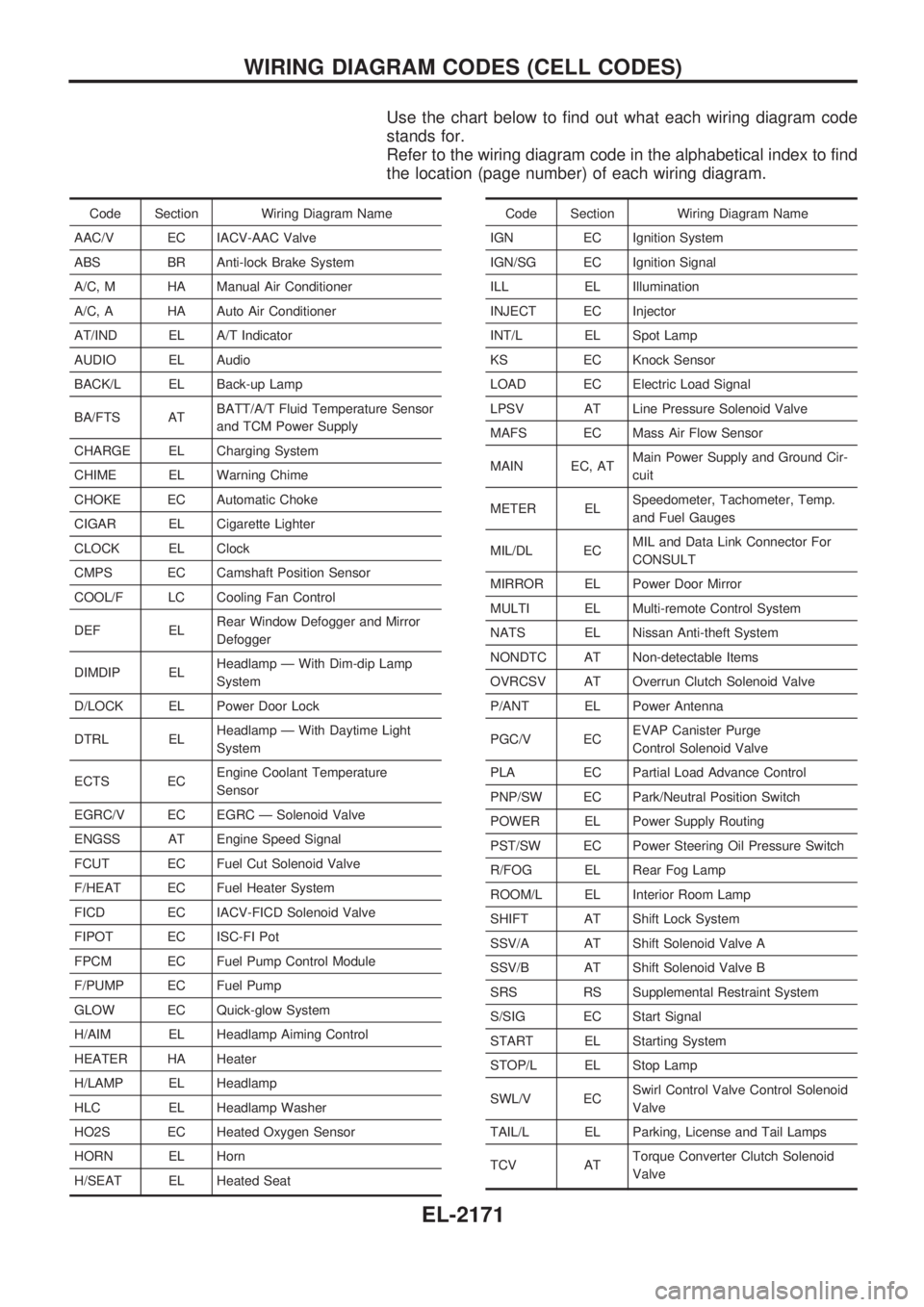

Use the chart below to find out what each wiring diagram code

stands for.

Refer to the wiring diagram code in the alphabetical index to find

the location (page number) of each wiring diagram.

Code Section Wiring Diagram Name

AAC/V EC IACV-AAC Valve

ABS BR Anti-lock Brake System

A/C, M HA Manual Air Conditioner

A/C, A HA Auto Air Conditioner

AT/IND EL A/T Indicator

AUDIO EL Audio

BACK/L EL Back-up Lamp

BA/FTS ATBATT/A/T Fluid Temperature Sensor

and TCM Power Supply

CHARGE EL Charging System

CHIME EL Warning Chime

CHOKE EC Automatic Choke

CIGAR EL Cigarette Lighter

CLOCK EL Clock

CMPS EC Camshaft Position Sensor

COOL/F LC Cooling Fan Control

DEF ELRear Window Defogger and Mirror

Defogger

DIMDIP ELHeadlamp Ð With Dim-dip Lamp

System

D/LOCK EL Power Door Lock

DTRL ELHeadlamp Ð With Daytime Light

System

ECTS ECEngine Coolant Temperature

Sensor

EGRC/V EC EGRC Ð Solenoid Valve

ENGSS AT Engine Speed Signal

FCUT EC Fuel Cut Solenoid Valve

F/HEAT EC Fuel Heater System

FICD EC IACV-FICD Solenoid Valve

FIPOT EC ISC-FI Pot

FPCM EC Fuel Pump Control Module

F/PUMP EC Fuel Pump

GLOW EC Quick-glow System

H/AIM EL Headlamp Aiming Control

HEATER HA Heater

H/LAMP EL Headlamp

HLC EL Headlamp Washer

HO2S EC Heated Oxygen Sensor

HORN EL Horn

H/SEAT EL Heated SeatCode Section Wiring Diagram Name

IGN EC Ignition System

IGN/SG EC Ignition Signal

ILL EL Illumination

INJECT EC Injector

INT/L EL Spot Lamp

KS EC Knock Sensor

LOAD EC Electric Load Signal

LPSV AT Line Pressure Solenoid Valve

MAFS EC Mass Air Flow Sensor

MAIN EC, ATMain Power Supply and Ground Cir-

cuit

METER ELSpeedometer, Tachometer, Temp.

and Fuel Gauges

MIL/DL ECMIL and Data Link Connector For

CONSULT

MIRROR EL Power Door Mirror

MULTI EL Multi-remote Control System

NATS EL Nissan Anti-theft System

NONDTC AT Non-detectable Items

OVRCSV AT Overrun Clutch Solenoid Valve

P/ANT EL Power Antenna

PGC/V ECEVAP Canister Purge

Control Solenoid Valve

PLA EC Partial Load Advance Control

PNP/SW EC Park/Neutral Position Switch

POWER EL Power Supply Routing

PST/SW EC Power Steering Oil Pressure Switch

R/FOG EL Rear Fog Lamp

ROOM/L EL Interior Room Lamp

SHIFT AT Shift Lock System

SSV/A AT Shift Solenoid Valve A

SSV/B AT Shift Solenoid Valve B

SRS RS Supplemental Restraint System

S/SIG EC Start Signal

START EL Starting System

STOP/L EL Stop Lamp

SWL/V ECSwirl Control Valve Control Solenoid

Valve

TAIL/L EL Parking, License and Tail Lamps

TCV ATTorque Converter Clutch Solenoid

Valve

WIRING DIAGRAM CODES (CELL CODES)

EL-2171

Page 429 of 666

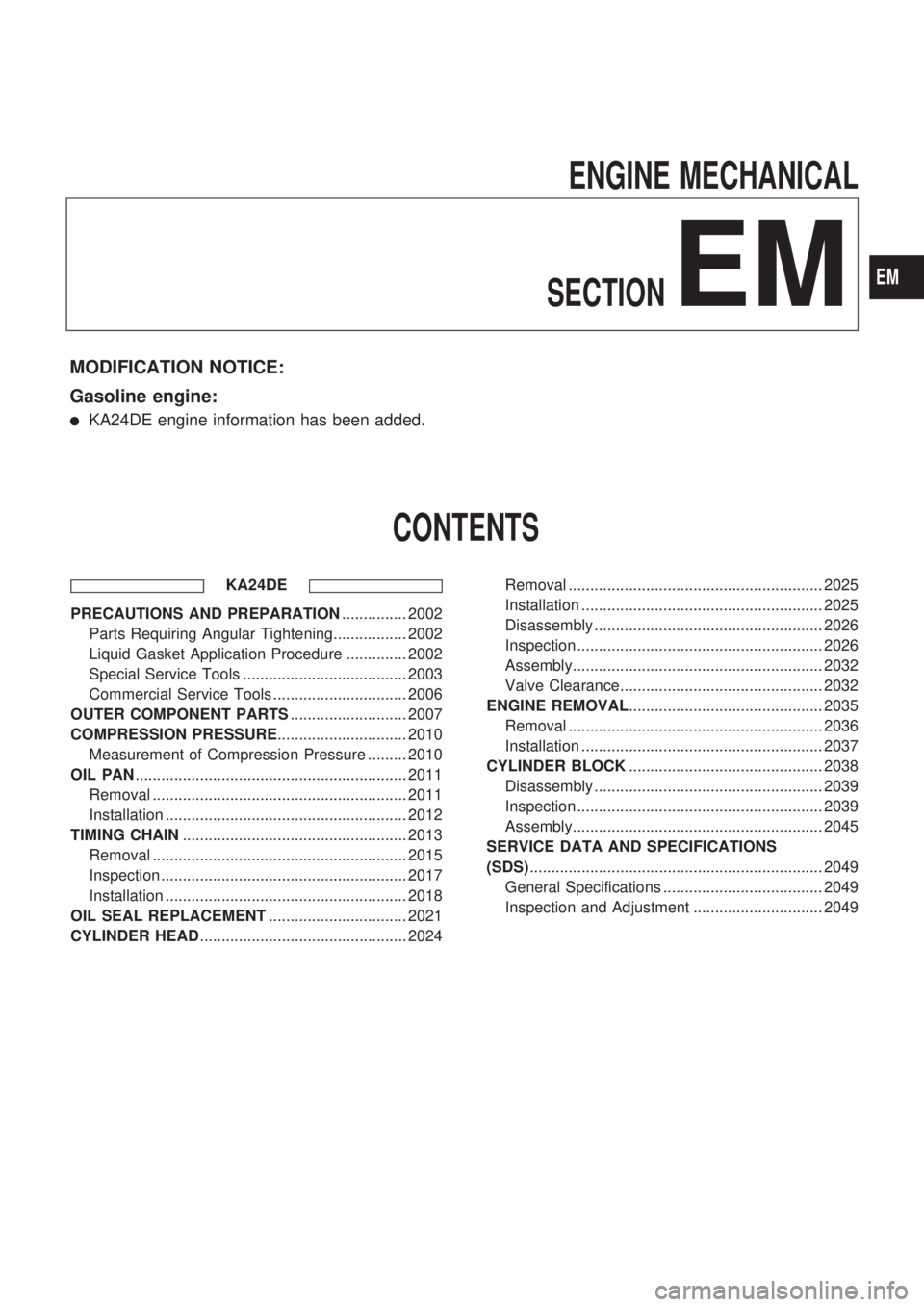

ENGINE MECHANICAL

SECTION

EM

MODIFICATION NOTICE:

Gasoline engine:

lKA24DE engine information has been added.

CONTENTS

KA24DE

PRECAUTIONS AND PREPARATION............... 2002

Parts Requiring Angular Tightening................. 2002

Liquid Gasket Application Procedure .............. 2002

Special Service Tools ...................................... 2003

Commercial Service Tools ............................... 2006

OUTER COMPONENT PARTS........................... 2007

COMPRESSION PRESSURE.............................. 2010

Measurement of Compression Pressure ......... 2010

OIL PAN............................................................... 2011

Removal ........................................................... 2011

Installation ........................................................ 2012

TIMING CHAIN.................................................... 2013

Removal ........................................................... 2015

Inspection ......................................................... 2017

Installation ........................................................ 2018

OIL SEAL REPLACEMENT................................ 2021

CYLINDER HEAD................................................ 2024Removal ........................................................... 2025

Installation ........................................................ 2025

Disassembly ..................................................... 2026

Inspection ......................................................... 2026

Assembly.......................................................... 2032

Valve Clearance............................................... 2032

ENGINE REMOVAL............................................. 2035

Removal ........................................................... 2036

Installation ........................................................ 2037

CYLINDER BLOCK............................................. 2038

Disassembly ..................................................... 2039

Inspection ......................................................... 2039

Assembly.......................................................... 2045

SERVICE DATA AND SPECIFICATIONS

(SDS).................................................................... 2049

General Specifications ..................................... 2049

Inspection and Adjustment .............................. 2049

EM

Page 430 of 666

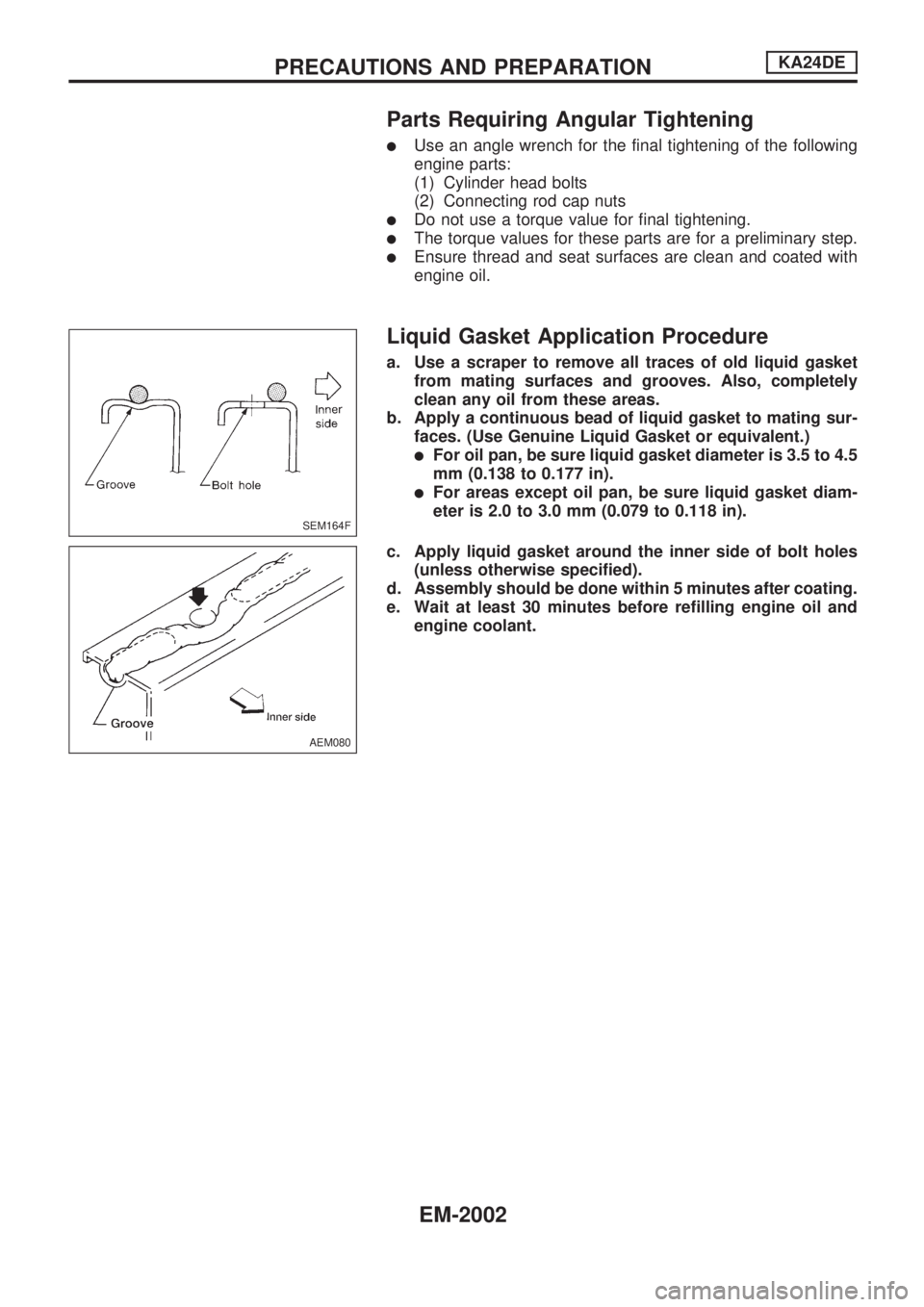

Parts Requiring Angular Tightening

lUse an angle wrench for the final tightening of the following

engine parts:

(1) Cylinder head bolts

(2) Connecting rod cap nuts

lDo not use a torque value for final tightening.

lThe torque values for these parts are for a preliminary step.

lEnsure thread and seat surfaces are clean and coated with

engine oil.

Liquid Gasket Application Procedure

a. Use a scraper to remove all traces of old liquid gasket

from mating surfaces and grooves. Also, completely

clean any oil from these areas.

b. Apply a continuous bead of liquid gasket to mating sur-

faces. (Use Genuine Liquid Gasket or equivalent.)

lFor oil pan, be sure liquid gasket diameter is 3.5 to 4.5

mm (0.138 to 0.177 in).

lFor areas except oil pan, be sure liquid gasket diam-

eter is 2.0 to 3.0 mm (0.079 to 0.118 in).

c. Apply liquid gasket around the inner side of bolt holes

(unless otherwise specified).

d. Assembly should be done within 5 minutes after coating.

e. Wait at least 30 minutes before refilling engine oil and

engine coolant.

SEM164F

AEM080

PRECAUTIONS AND PREPARATIONKA24DE

EM-2002

Page 438 of 666

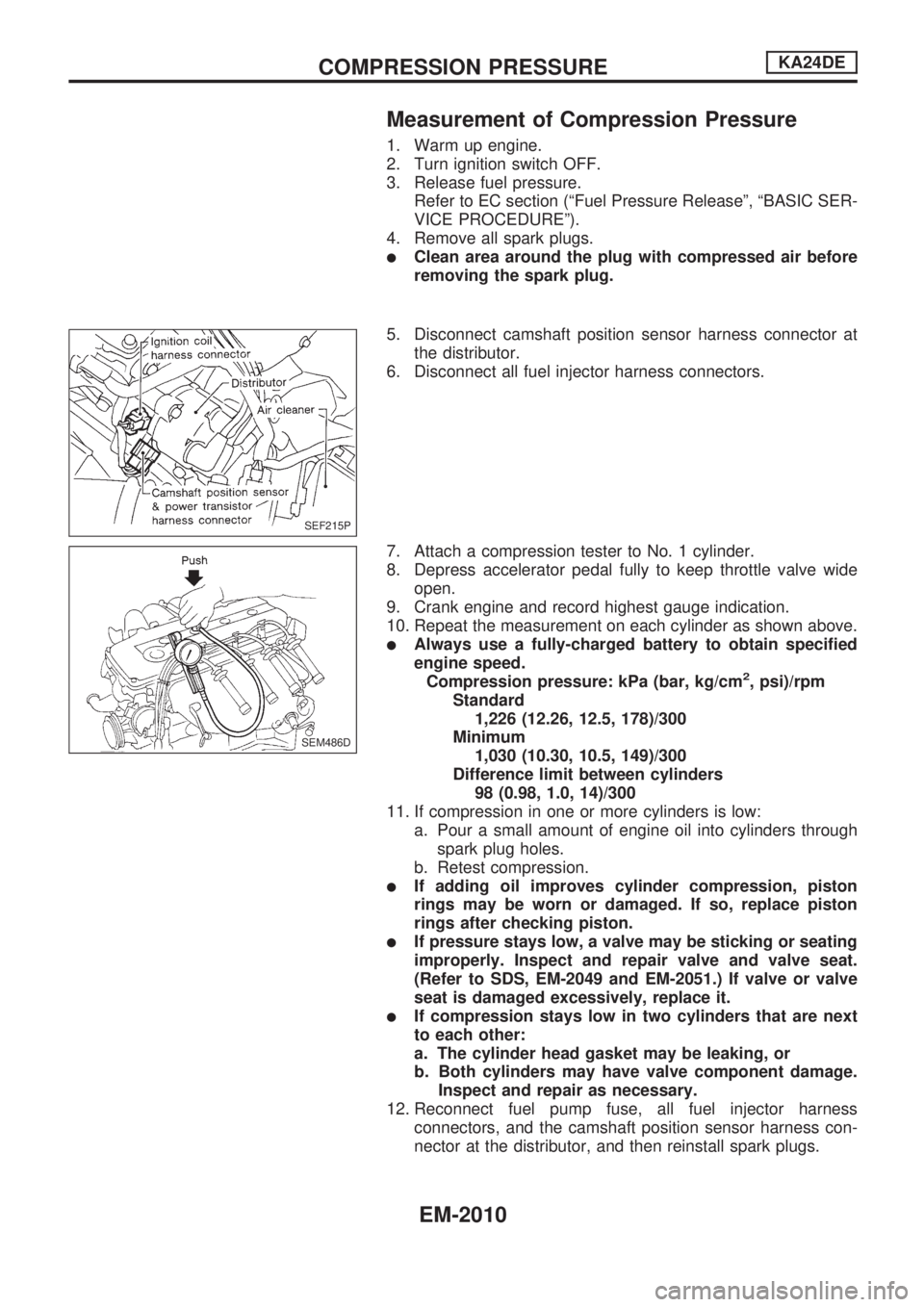

Measurement of Compression Pressure

1. Warm up engine.

2. Turn ignition switch OFF.

3. Release fuel pressure.

Refer to EC section (ªFuel Pressure Releaseº, ªBASIC SER-

VICE PROCEDUREº).

4. Remove all spark plugs.

lClean area around the plug with compressed air before

removing the spark plug.

5. Disconnect camshaft position sensor harness connector at

the distributor.

6. Disconnect all fuel injector harness connectors.

7. Attach a compression tester to No. 1 cylinder.

8. Depress accelerator pedal fully to keep throttle valve wide

open.

9. Crank engine and record highest gauge indication.

10. Repeat the measurement on each cylinder as shown above.

lAlways use a fully-charged battery to obtain specified

engine speed.

Compression pressure: kPa (bar, kg/cm

2, psi)/rpm

Standard

1,226 (12.26, 12.5, 178)/300

Minimum

1,030 (10.30, 10.5, 149)/300

Difference limit between cylinders

98 (0.98, 1.0, 14)/300

11. If compression in one or more cylinders is low:

a. Pour a small amount of engine oil into cylinders through

spark plug holes.

b. Retest compression.

lIf adding oil improves cylinder compression, piston

rings may be worn or damaged. If so, replace piston

rings after checking piston.

lIf pressure stays low, a valve may be sticking or seating

improperly. Inspect and repair valve and valve seat.

(Refer to SDS, EM-2049 and EM-2051.) If valve or valve

seat is damaged excessively, replace it.

lIf compression stays low in two cylinders that are next

to each other:

a. The cylinder head gasket may be leaking, or

b. Both cylinders may have valve component damage.

Inspect and repair as necessary.

12. Reconnect fuel pump fuse, all fuel injector harness

connectors, and the camshaft position sensor harness con-

nector at the distributor, and then reinstall spark plugs.

SEF215P

SEM486D

COMPRESSION PRESSUREKA24DE

EM-2010

Page 439 of 666

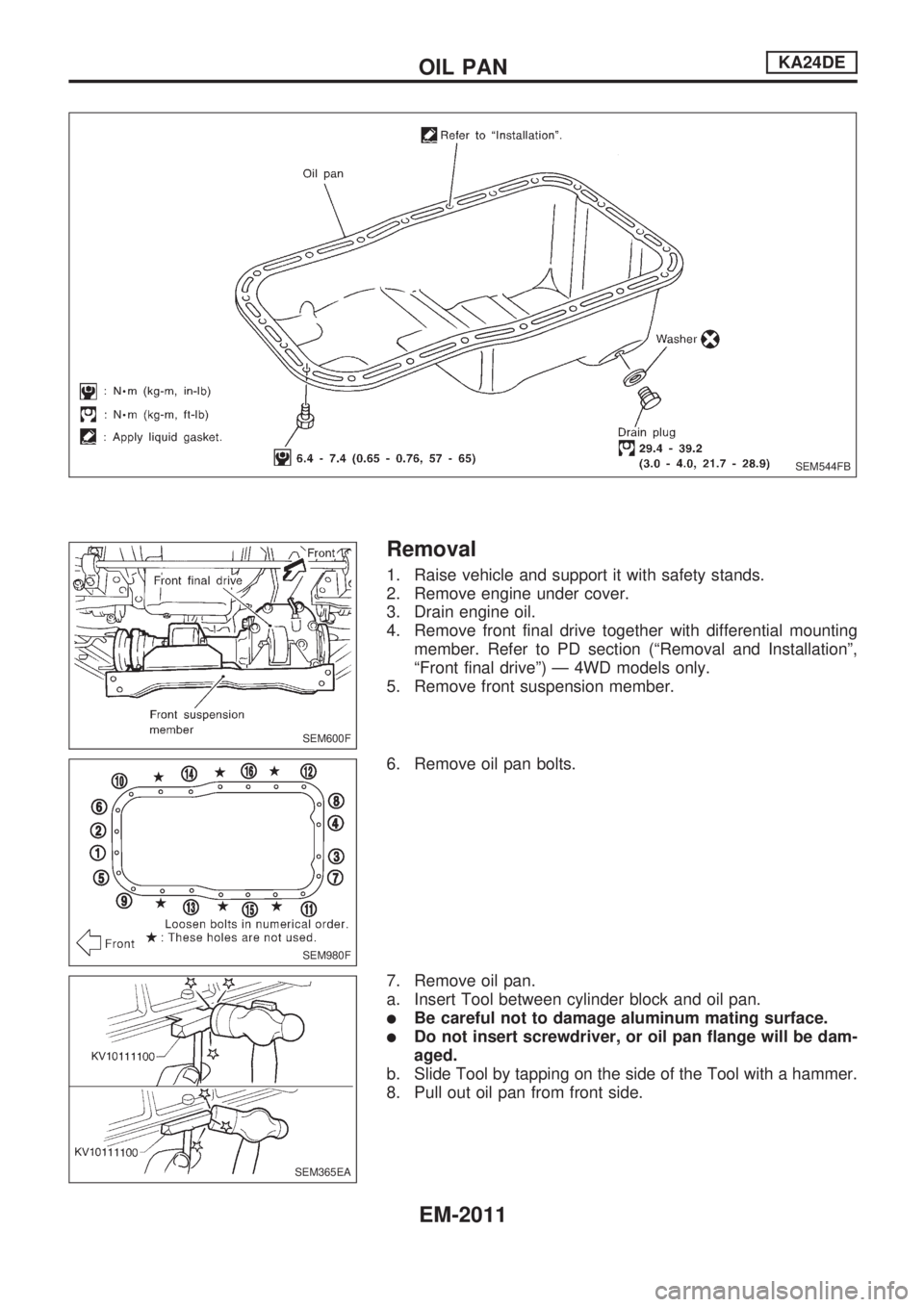

Removal

1. Raise vehicle and support it with safety stands.

2. Remove engine under cover.

3. Drain engine oil.

4. Remove front final drive together with differential mounting

member. Refer to PD section (ªRemoval and Installationº,

ªFront final driveº) Ð 4WD models only.

5. Remove front suspension member.

6. Remove oil pan bolts.

7. Remove oil pan.

a. Insert Tool between cylinder block and oil pan.

lBe careful not to damage aluminum mating surface.

lDo not insert screwdriver, or oil pan flange will be dam-

aged.

b. Slide Tool by tapping on the side of the Tool with a hammer.

8. Pull out oil pan from front side.

SEM544FB

SEM600F

SEM980F

SEM365EA

OIL PANKA24DE

EM-2011

Page 440 of 666

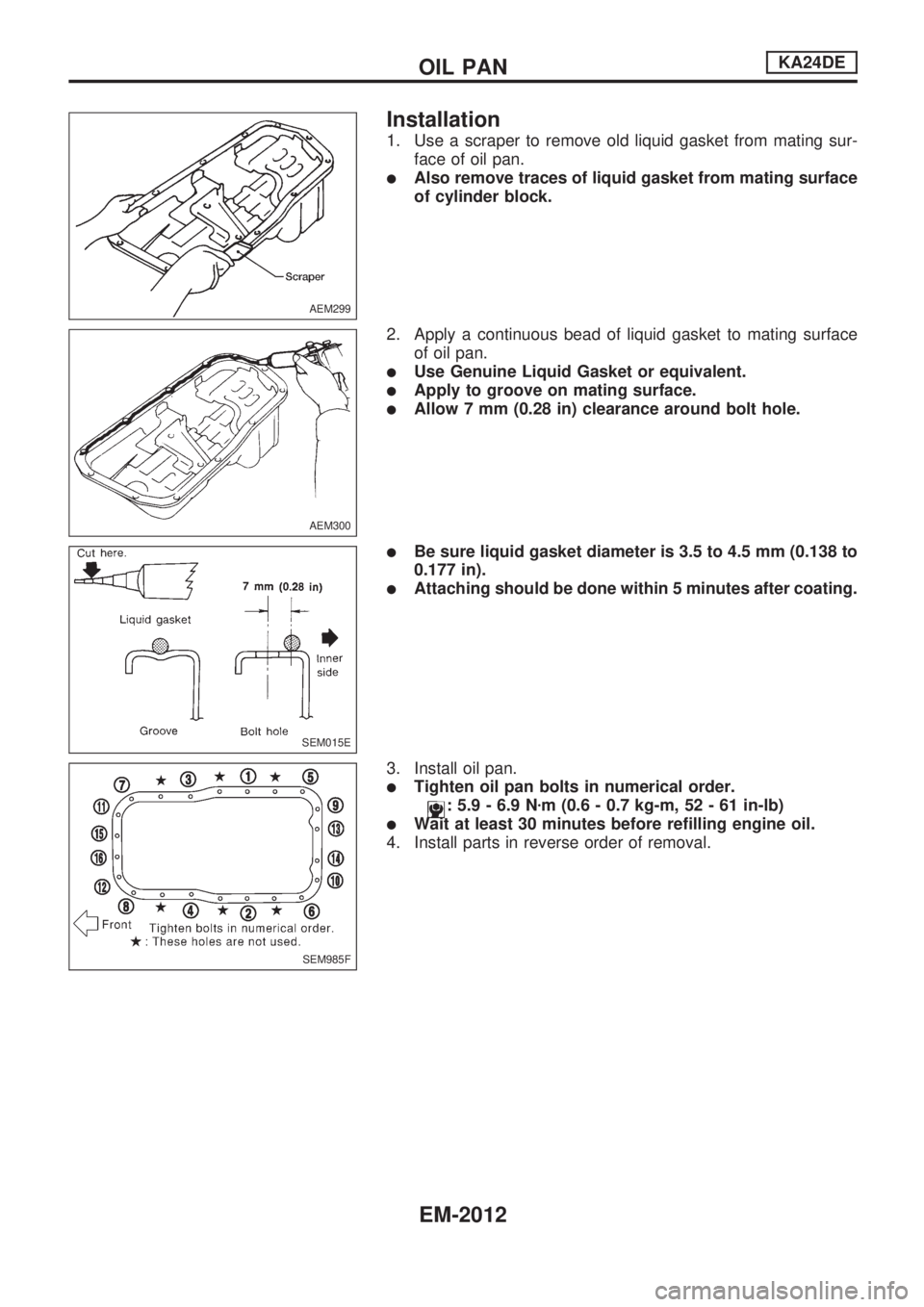

Installation

1. Use a scraper to remove old liquid gasket from mating sur-

face of oil pan.

lAlso remove traces of liquid gasket from mating surface

of cylinder block.

2. Apply a continuous bead of liquid gasket to mating surface

of oil pan.

lUse Genuine Liquid Gasket or equivalent.

lApply to groove on mating surface.

lAllow 7 mm (0.28 in) clearance around bolt hole.

lBe sure liquid gasket diameter is 3.5 to 4.5 mm (0.138 to

0.177 in).

lAttaching should be done within 5 minutes after coating.

3. Install oil pan.

lTighten oil pan bolts in numerical order.

: 5.9 - 6.9 Nzm (0.6 - 0.7 kg-m, 52 - 61 in-lb)

lWait at least 30 minutes before refilling engine oil.

4. Install parts in reverse order of removal.

AEM299

AEM300

SEM015E

SEM985F

OIL PANKA24DE

EM-2012

Page 443 of 666

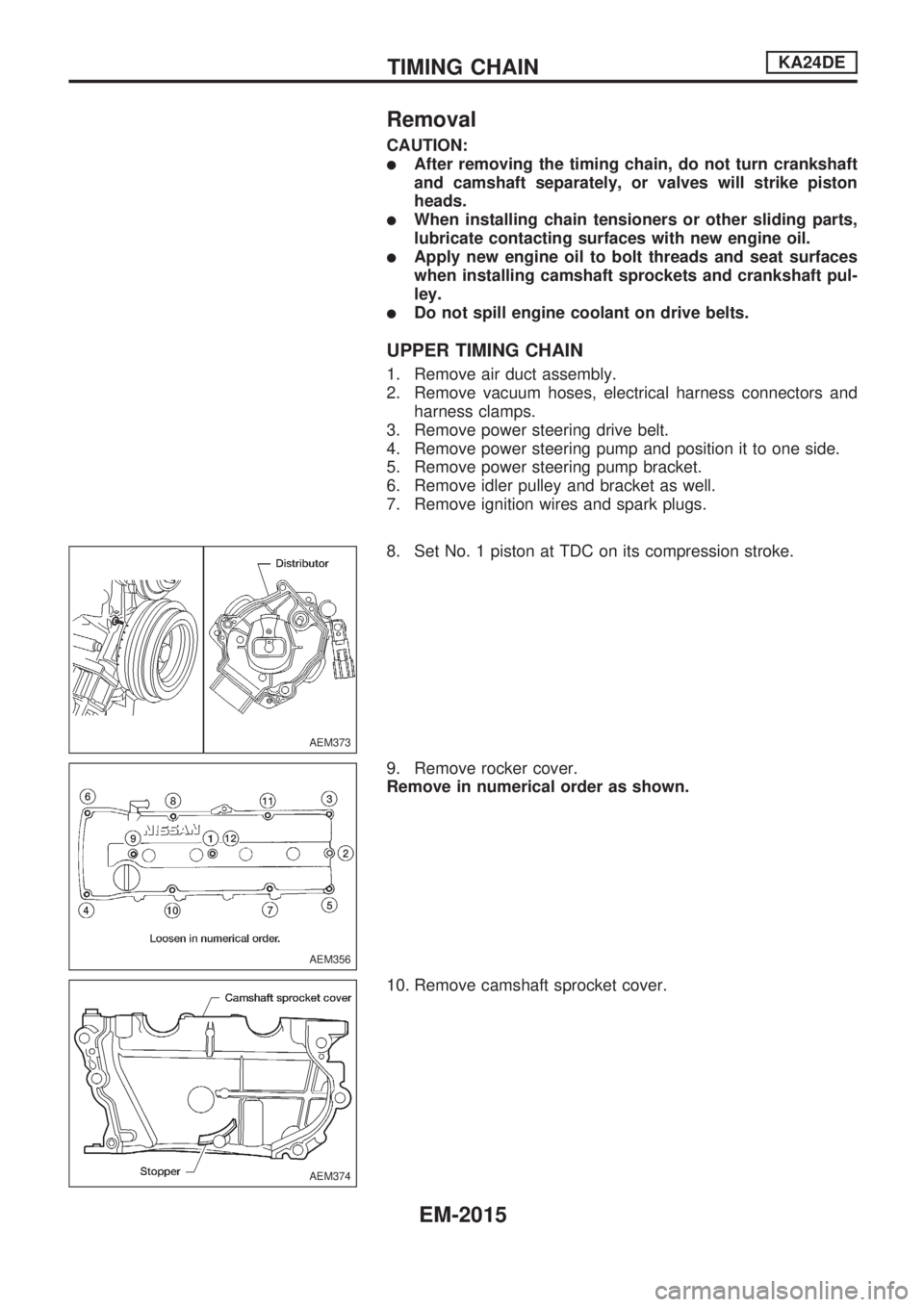

Removal

CAUTION:

lAfter removing the timing chain, do not turn crankshaft

and camshaft separately, or valves will strike piston

heads.

lWhen installing chain tensioners or other sliding parts,

lubricate contacting surfaces with new engine oil.

lApply new engine oil to bolt threads and seat surfaces

when installing camshaft sprockets and crankshaft pul-

ley.

lDo not spill engine coolant on drive belts.

UPPER TIMING CHAIN

1. Remove air duct assembly.

2. Remove vacuum hoses, electrical harness connectors and

harness clamps.

3. Remove power steering drive belt.

4. Remove power steering pump and position it to one side.

5. Remove power steering pump bracket.

6. Remove idler pulley and bracket as well.

7. Remove ignition wires and spark plugs.

8. Set No. 1 piston at TDC on its compression stroke.

9. Remove rocker cover.

Remove in numerical order as shown.

10. Remove camshaft sprocket cover.

AEM373

AEM356

AEM374

TIMING CHAINKA24DE

EM-2015

Page 444 of 666

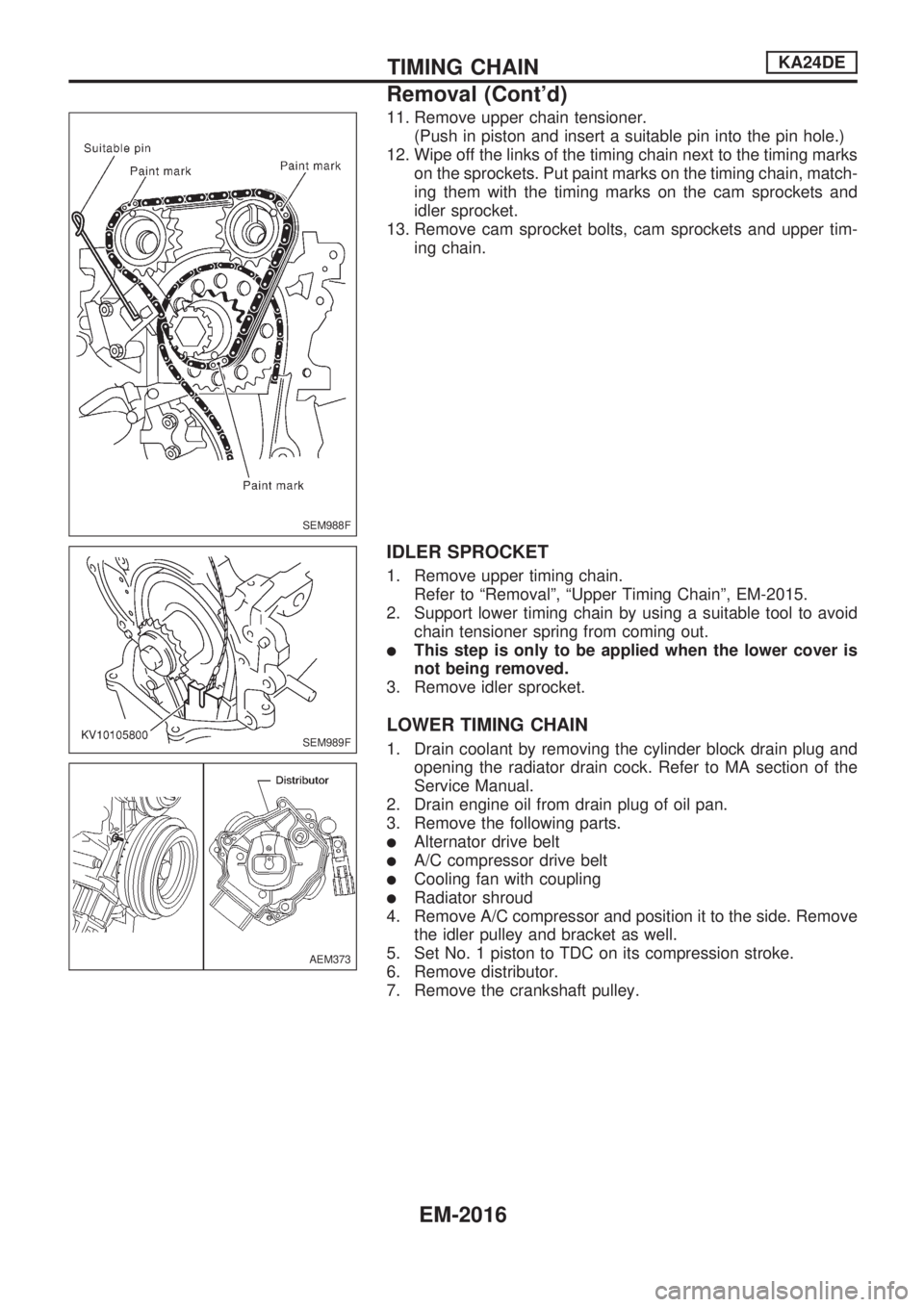

11. Remove upper chain tensioner.

(Push in piston and insert a suitable pin into the pin hole.)

12. Wipe off the links of the timing chain next to the timing marks

on the sprockets. Put paint marks on the timing chain, match-

ing them with the timing marks on the cam sprockets and

idler sprocket.

13. Remove cam sprocket bolts, cam sprockets and upper tim-

ing chain.

IDLER SPROCKET

1. Remove upper timing chain.

Refer to ªRemovalº, ªUpper Timing Chainº, EM-2015.

2. Support lower timing chain by using a suitable tool to avoid

chain tensioner spring from coming out.

lThis step is only to be applied when the lower cover is

not being removed.

3. Remove idler sprocket.

LOWER TIMING CHAIN

1. Drain coolant by removing the cylinder block drain plug and

opening the radiator drain cock. Refer to MA section of the

Service Manual.

2. Drain engine oil from drain plug of oil pan.

3. Remove the following parts.

lAlternator drive belt

lA/C compressor drive belt

lCooling fan with coupling

lRadiator shroud

4. Remove A/C compressor and position it to the side. Remove

the idler pulley and bracket as well.

5. Set No. 1 piston to TDC on its compression stroke.

6. Remove distributor.

7. Remove the crankshaft pulley.

SEM988F

SEM989F

AEM373

TIMING CHAINKA24DE

Removal (Cont'd)

EM-2016