check engine NISSAN PICK-UP 2001 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: PICK-UP, Model: NISSAN PICK-UP 2001Pages: 1306, PDF Size: 31.7 MB

Page 60 of 1306

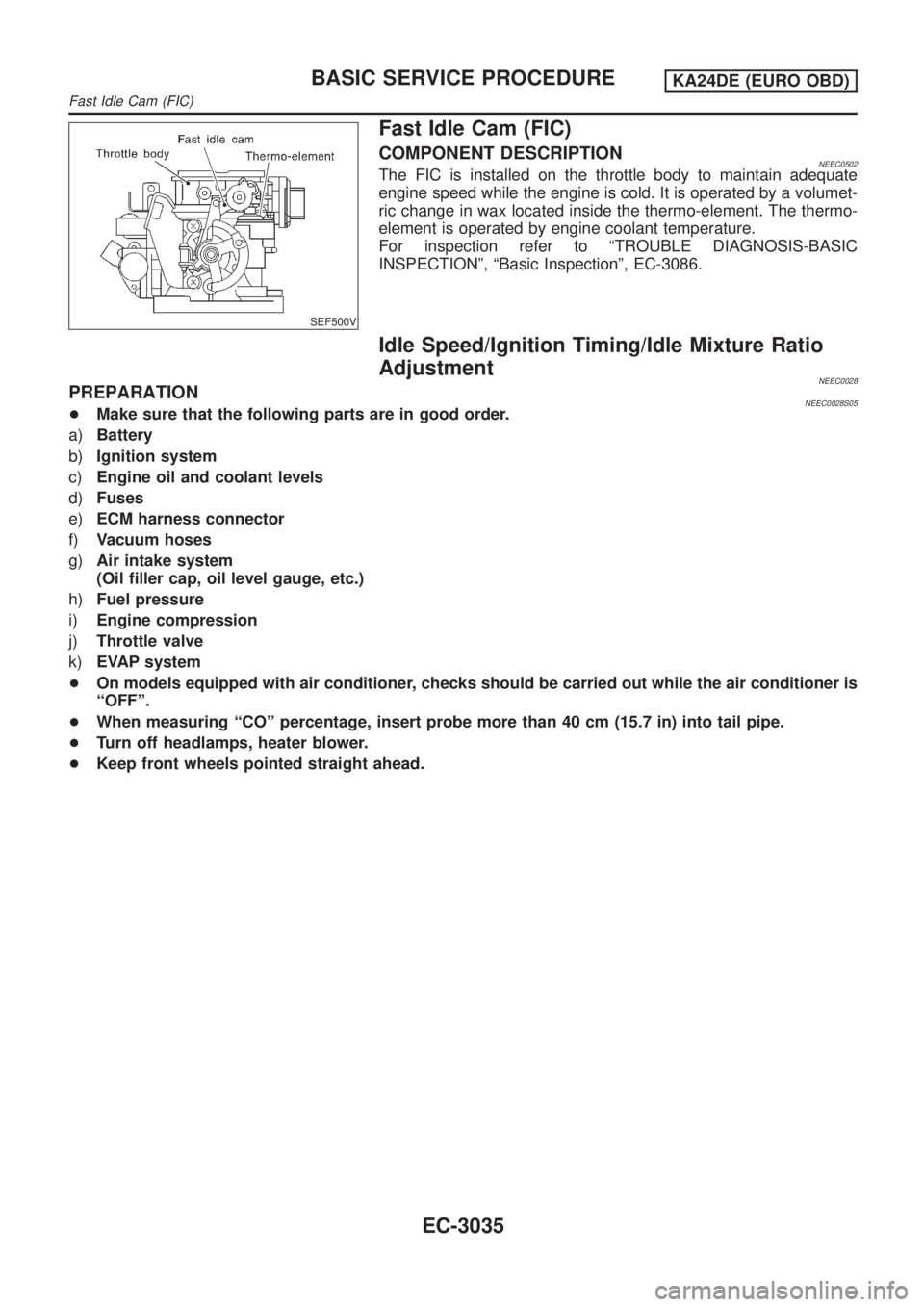

SEF500V

Fast Idle Cam (FIC)

COMPONENT DESCRIPTIONNEEC0502The FIC is installed on the throttle body to maintain adequate

engine speed while the engine is cold. It is operated by a volumet-

ric change in wax located inside the thermo-element. The thermo-

element is operated by engine coolant temperature.

For inspection refer to ªTROUBLE DIAGNOSIS-BASIC

INSPECTIONº, ªBasic Inspectionº, EC-3086.

Idle Speed/Ignition Timing/Idle Mixture Ratio

Adjustment

NEEC0028PREPARATIONNEEC0028S05+Make sure that the following parts are in good order.

a)Battery

b)Ignition system

c)Engine oil and coolant levels

d)Fuses

e)ECM harness connector

f)Vacuum hoses

g)Air intake system

(Oil filler cap, oil level gauge, etc.)

h)Fuel pressure

i)Engine compression

j)Throttle valve

k)EVAP system

+On models equipped with air conditioner, checks should be carried out while the air conditioner is

ªOFFº.

+When measuring ªCOº percentage, insert probe more than 40 cm (15.7 in) into tail pipe.

+Turn off headlamps, heater blower.

+Keep front wheels pointed straight ahead.

BASIC SERVICE PROCEDUREKA24DE (EURO OBD)

Fast Idle Cam (FIC)

EC-3035

Page 62 of 1306

INSPECTION PROCEDURE=NEEC0028S02

1 INSPECTION START

1. Visually check the following:

+Air cleaner clogging

+Hoses and duct for leaks

+Electrical connectors

+Gasket (intake manifold, cylinder head, exhaust system)

+Throttle valve and throttle position sensor operation

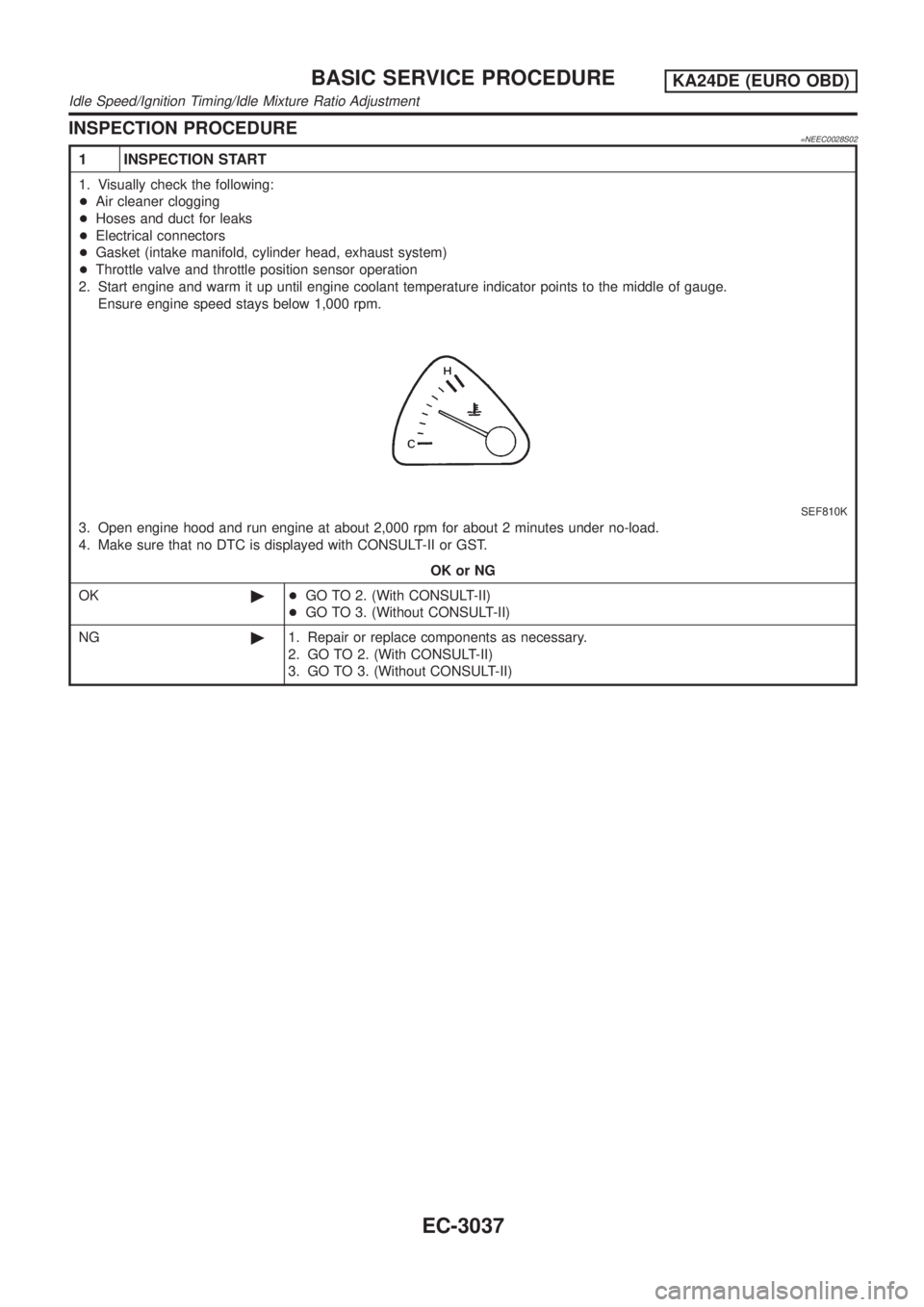

2. Start engine and warm it up until engine coolant temperature indicator points to the middle of gauge.

Ensure engine speed stays below 1,000 rpm.

SEF810K

3. Open engine hood and run engine at about 2,000 rpm for about 2 minutes under no-load.

4. Make sure that no DTC is displayed with CONSULT-II or GST.

OK or NG

OK©+GO TO 2. (With CONSULT-II)

+GO TO 3. (Without CONSULT-II)

NG©1. Repair or replace components as necessary.

2. GO TO 2. (With CONSULT-II)

3. GO TO 3. (Without CONSULT-II)

BASIC SERVICE PROCEDUREKA24DE (EURO OBD)

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment

EC-3037

Page 63 of 1306

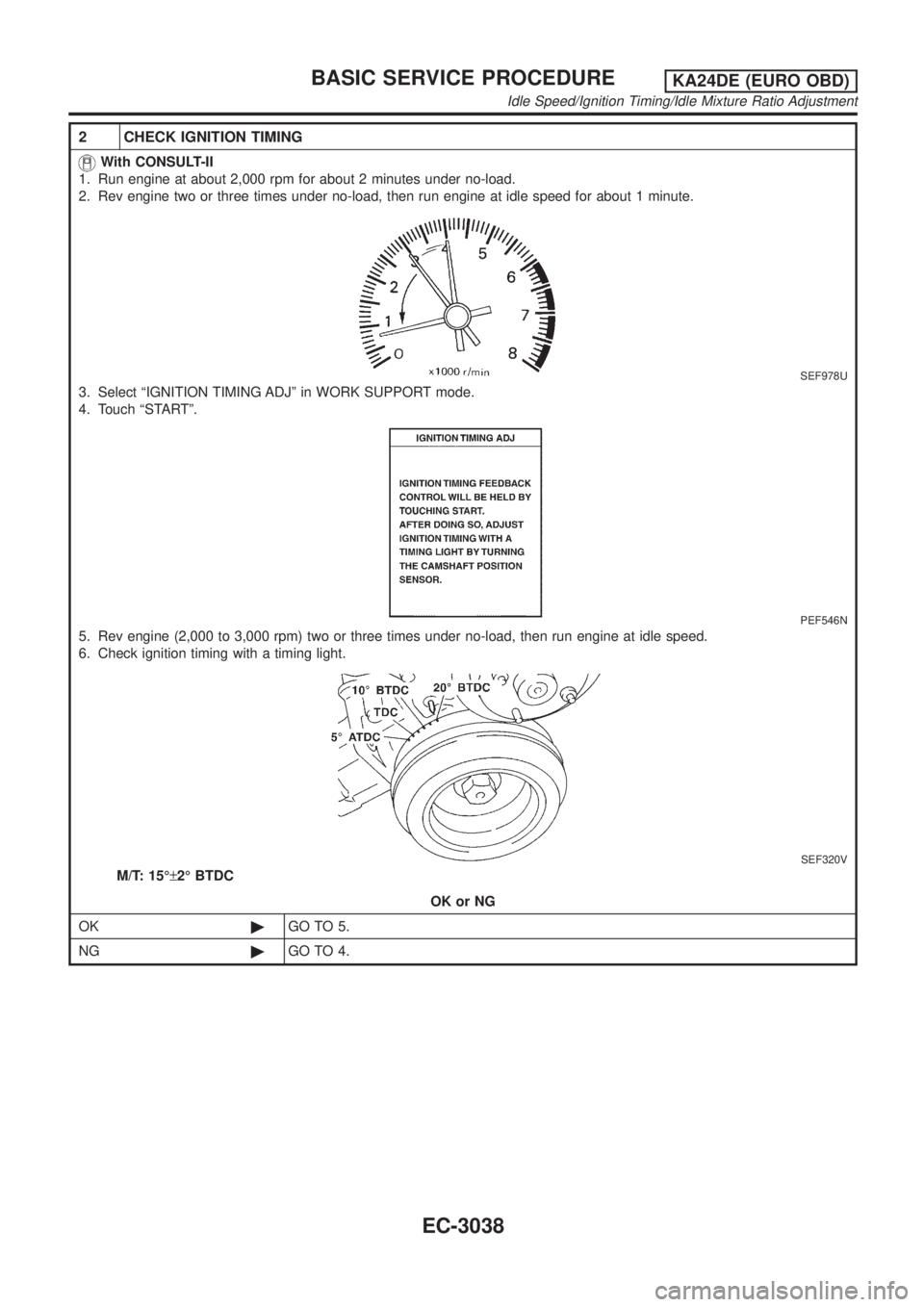

2 CHECK IGNITION TIMING

With CONSULT-II

1. Run engine at about 2,000 rpm for about 2 minutes under no-load.

2. Rev engine two or three times under no-load, then run engine at idle speed for about 1 minute.

SEF978U

3. Select ªIGNITION TIMING ADJº in WORK SUPPORT mode.

4. Touch ªSTARTº.

PEF546N

5. Rev engine (2,000 to 3,000 rpm) two or three times under no-load, then run engine at idle speed.

6. Check ignition timing with a timing light.

SEF320V

M/T: 15ɱ2É BTDC

OK or NG

OK©GO TO 5.

NG©GO TO 4.

BASIC SERVICE PROCEDUREKA24DE (EURO OBD)

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment

EC-3038

Page 64 of 1306

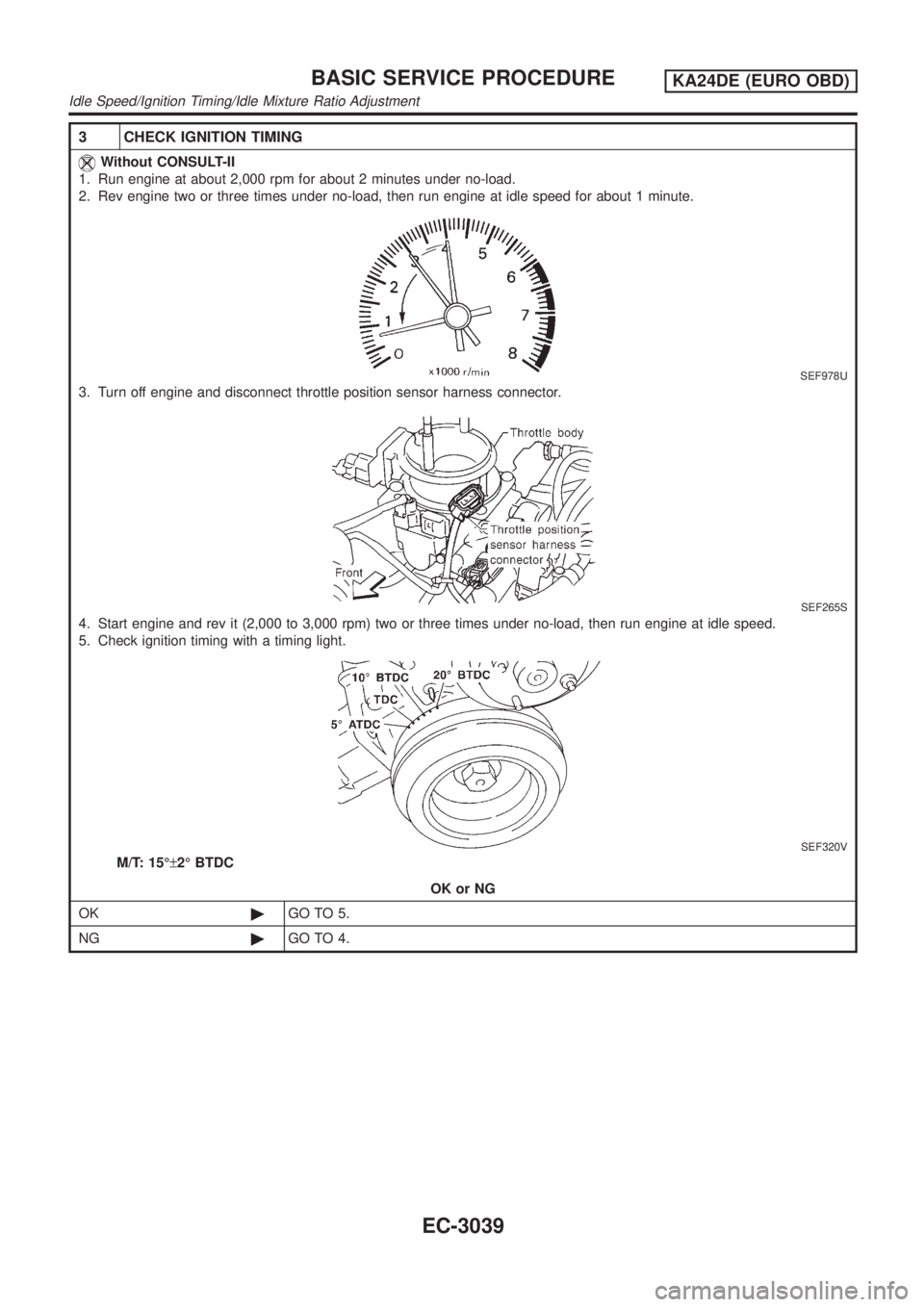

3 CHECK IGNITION TIMING

Without CONSULT-II

1. Run engine at about 2,000 rpm for about 2 minutes under no-load.

2. Rev engine two or three times under no-load, then run engine at idle speed for about 1 minute.

SEF978U

3. Turn off engine and disconnect throttle position sensor harness connector.

SEF265S

4. Start engine and rev it (2,000 to 3,000 rpm) two or three times under no-load, then run engine at idle speed.

5. Check ignition timing with a timing light.

SEF320V

M/T: 15ɱ2É BTDC

OK or NG

OK©GO TO 5.

NG©GO TO 4.

BASIC SERVICE PROCEDUREKA24DE (EURO OBD)

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment

EC-3039

Page 65 of 1306

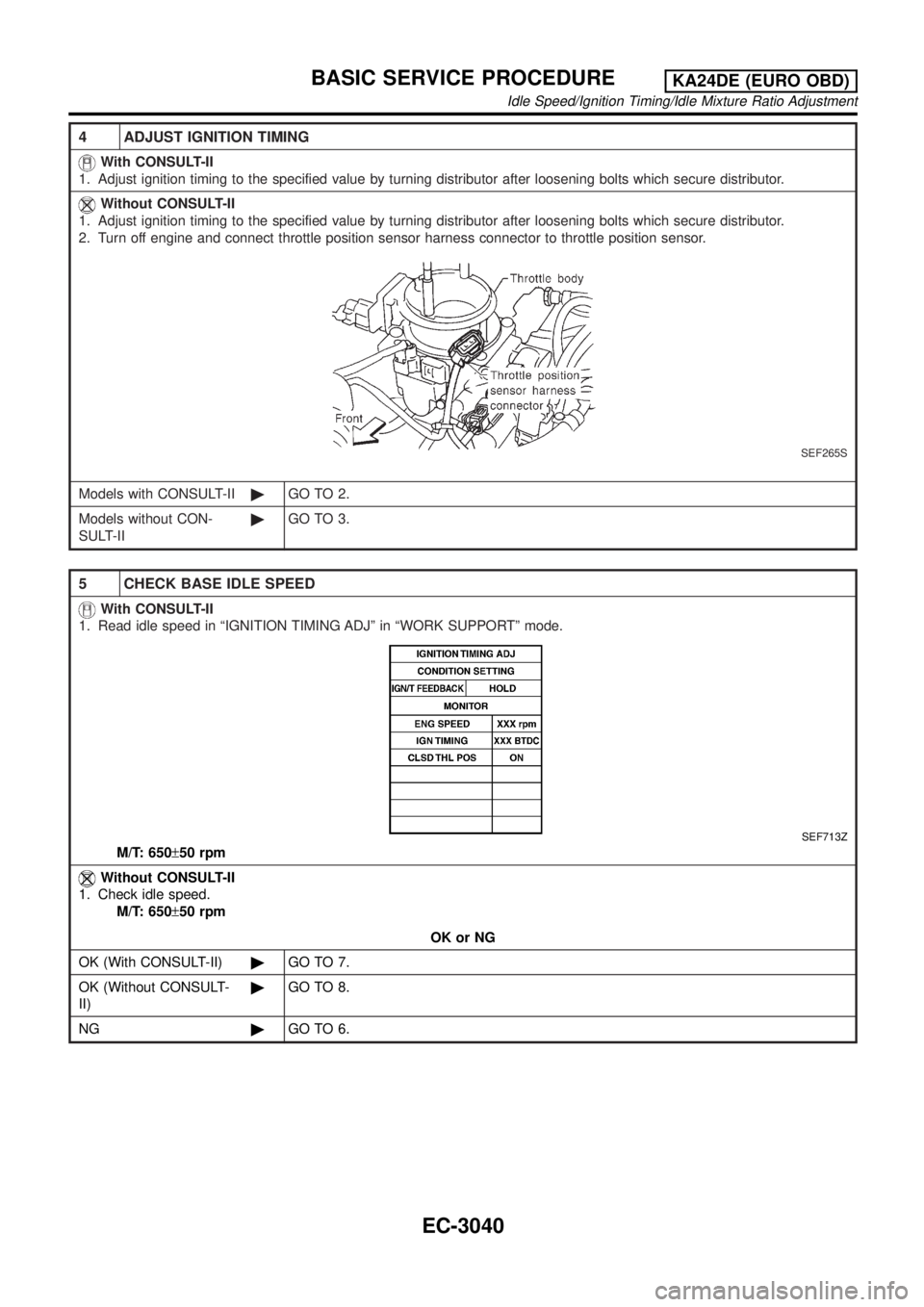

4 ADJUST IGNITION TIMING

With CONSULT-II

1. Adjust ignition timing to the specified value by turning distributor after loosening bolts which secure distributor.

Without CONSULT-II

1. Adjust ignition timing to the specified value by turning distributor after loosening bolts which secure distributor.

2. Turn off engine and connect throttle position sensor harness connector to throttle position sensor.

SEF265S

Models with CONSULT-II©GO TO 2.

Models without CON-

SULT-II©GO TO 3.

5 CHECK BASE IDLE SPEED

With CONSULT-II

1. Read idle speed in ªIGNITION TIMING ADJº in ªWORK SUPPORTº mode.

SEF713Z

M/T: 650±50 rpm

Without CONSULT-II

1. Check idle speed.

M/T: 650±50 rpm

OK or NG

OK (With CONSULT-II)©GO TO 7.

OK (Without CONSULT-

II)©GO TO 8.

NG©GO TO 6.

BASIC SERVICE PROCEDUREKA24DE (EURO OBD)

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment

EC-3040

Page 66 of 1306

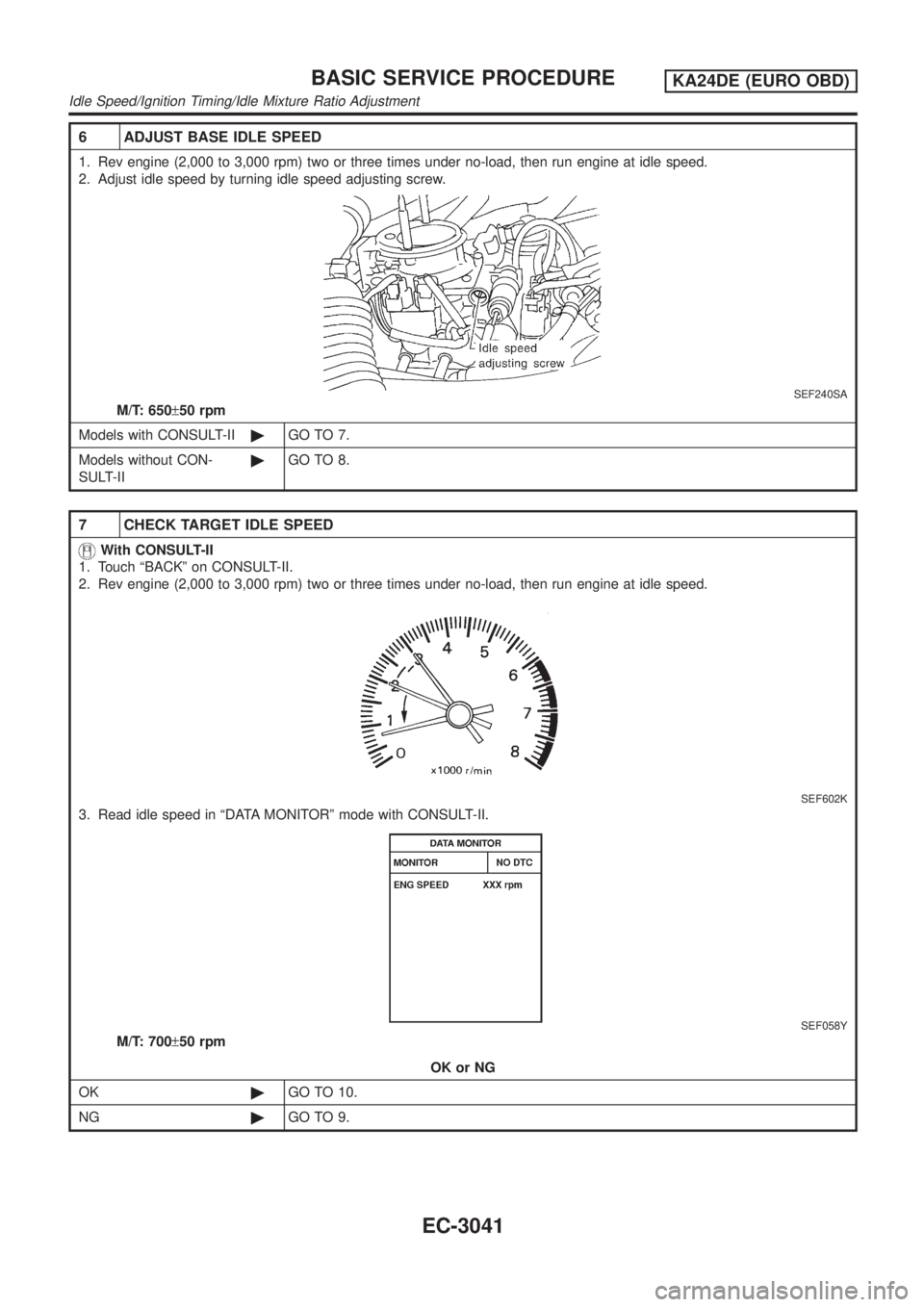

6 ADJUST BASE IDLE SPEED

1. Rev engine (2,000 to 3,000 rpm) two or three times under no-load, then run engine at idle speed.

2. Adjust idle speed by turning idle speed adjusting screw.

SEF240SA

M/T: 650±50 rpm

Models with CONSULT-II©GO TO 7.

Models without CON-

SULT-II©GO TO 8.

7 CHECK TARGET IDLE SPEED

With CONSULT-II

1. Touch ªBACKº on CONSULT-II.

2. Rev engine (2,000 to 3,000 rpm) two or three times under no-load, then run engine at idle speed.

SEF602K

3. Read idle speed in ªDATA MONITORº mode with CONSULT-II.

SEF058Y

M/T: 700±50 rpm

OK or NG

OK©GO TO 10.

NG©GO TO 9.

BASIC SERVICE PROCEDUREKA24DE (EURO OBD)

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment

EC-3041

Page 67 of 1306

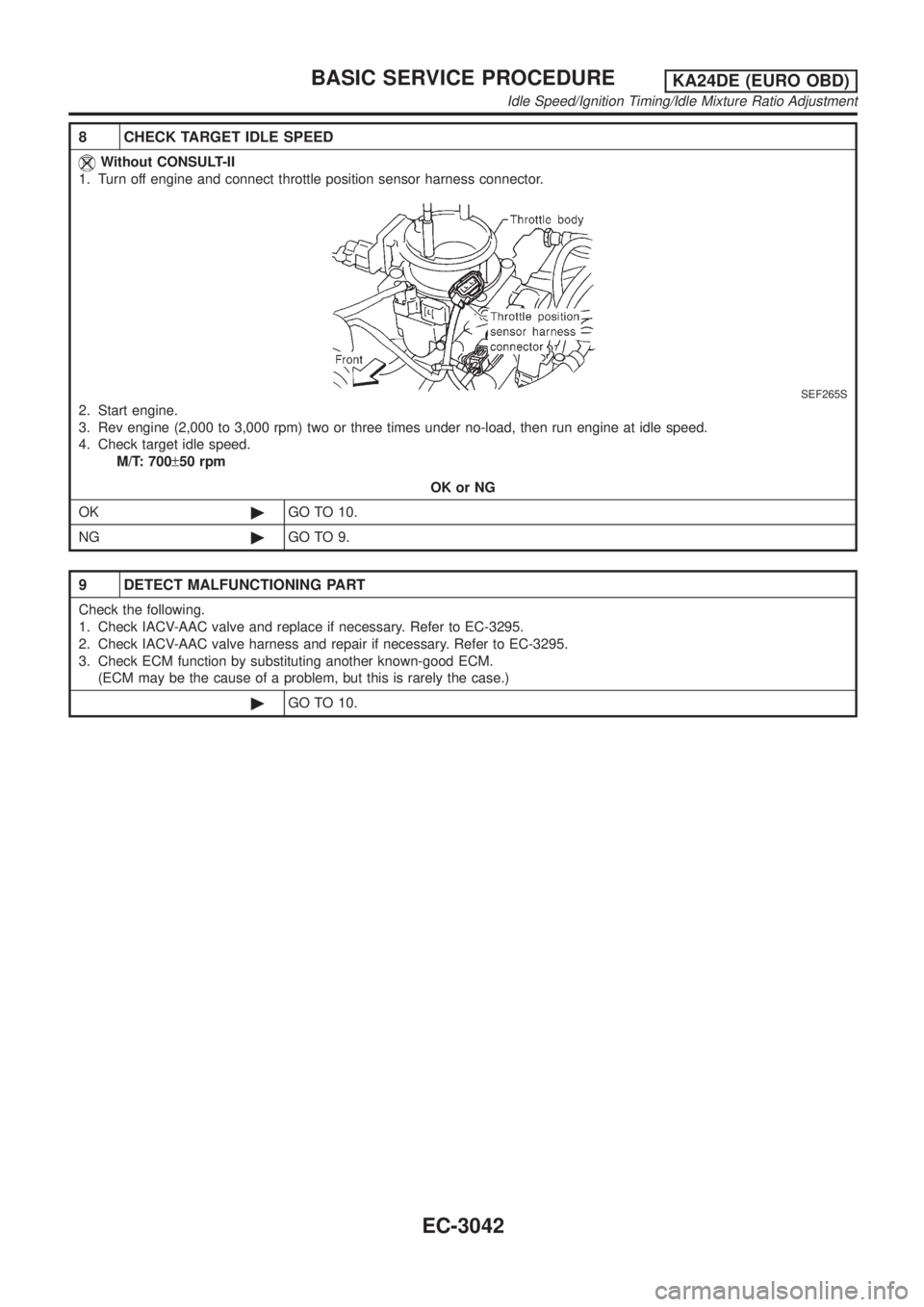

8 CHECK TARGET IDLE SPEED

Without CONSULT-II

1. Turn off engine and connect throttle position sensor harness connector.

SEF265S

2. Start engine.

3. Rev engine (2,000 to 3,000 rpm) two or three times under no-load, then run engine at idle speed.

4. Check target idle speed.

M/T: 700±50 rpm

OK or NG

OK©GO TO 10.

NG©GO TO 9.

9 DETECT MALFUNCTIONING PART

Check the following.

1. Check IACV-AAC valve and replace if necessary. Refer to EC-3295.

2. Check IACV-AAC valve harness and repair if necessary. Refer to EC-3295.

3. Check ECM function by substituting another known-good ECM.

(ECM may be the cause of a problem, but this is rarely the case.)

©GO TO 10.

BASIC SERVICE PROCEDUREKA24DE (EURO OBD)

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment

EC-3042

Page 68 of 1306

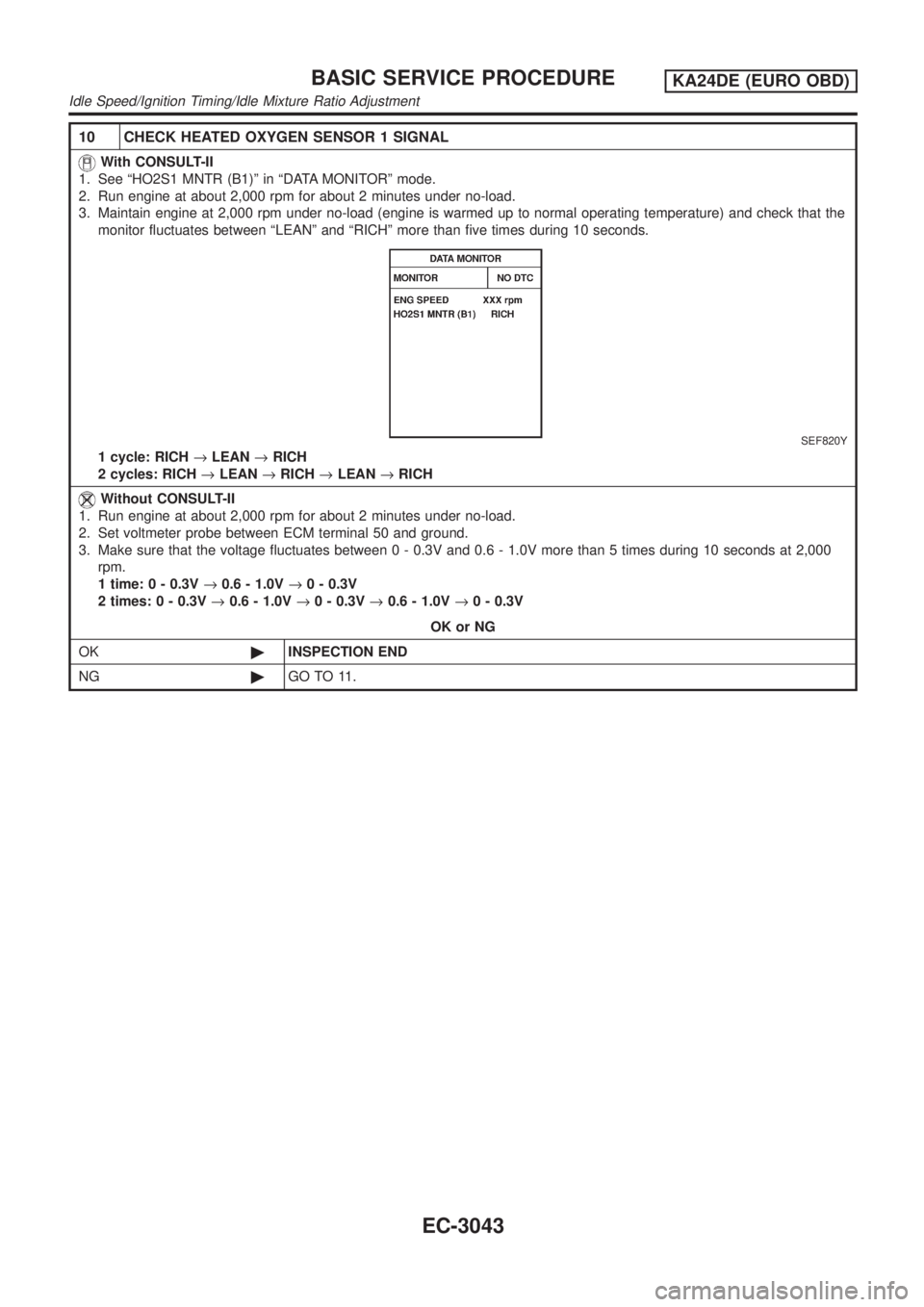

10 CHECK HEATED OXYGEN SENSOR 1 SIGNAL

With CONSULT-II

1. See ªHO2S1 MNTR (B1)º in ªDATA MONITORº mode.

2. Run engine at about 2,000 rpm for about 2 minutes under no-load.

3. Maintain engine at 2,000 rpm under no-load (engine is warmed up to normal operating temperature) and check that the

monitor fluctuates between ªLEANº and ªRICHº more than five times during 10 seconds.

SEF820Y

1 cycle: RICH®LEAN®RICH

2 cycles: RICH®LEAN®RICH®LEAN®RICH

Without CONSULT-II

1. Run engine at about 2,000 rpm for about 2 minutes under no-load.

2. Set voltmeter probe between ECM terminal 50 and ground.

3. Make sure that the voltage fluctuates between 0 - 0.3V and 0.6 - 1.0V more than 5 times during 10 seconds at 2,000

rpm.

1 time: 0 - 0.3V®0.6 - 1.0V®0 - 0.3V

2 times: 0 - 0.3V®0.6 - 1.0V®0 - 0.3V®0.6 - 1.0V®0 - 0.3V

OK or NG

OK©INSPECTION END

NG©GO TO 11.

BASIC SERVICE PROCEDUREKA24DE (EURO OBD)

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment

EC-3043

Page 69 of 1306

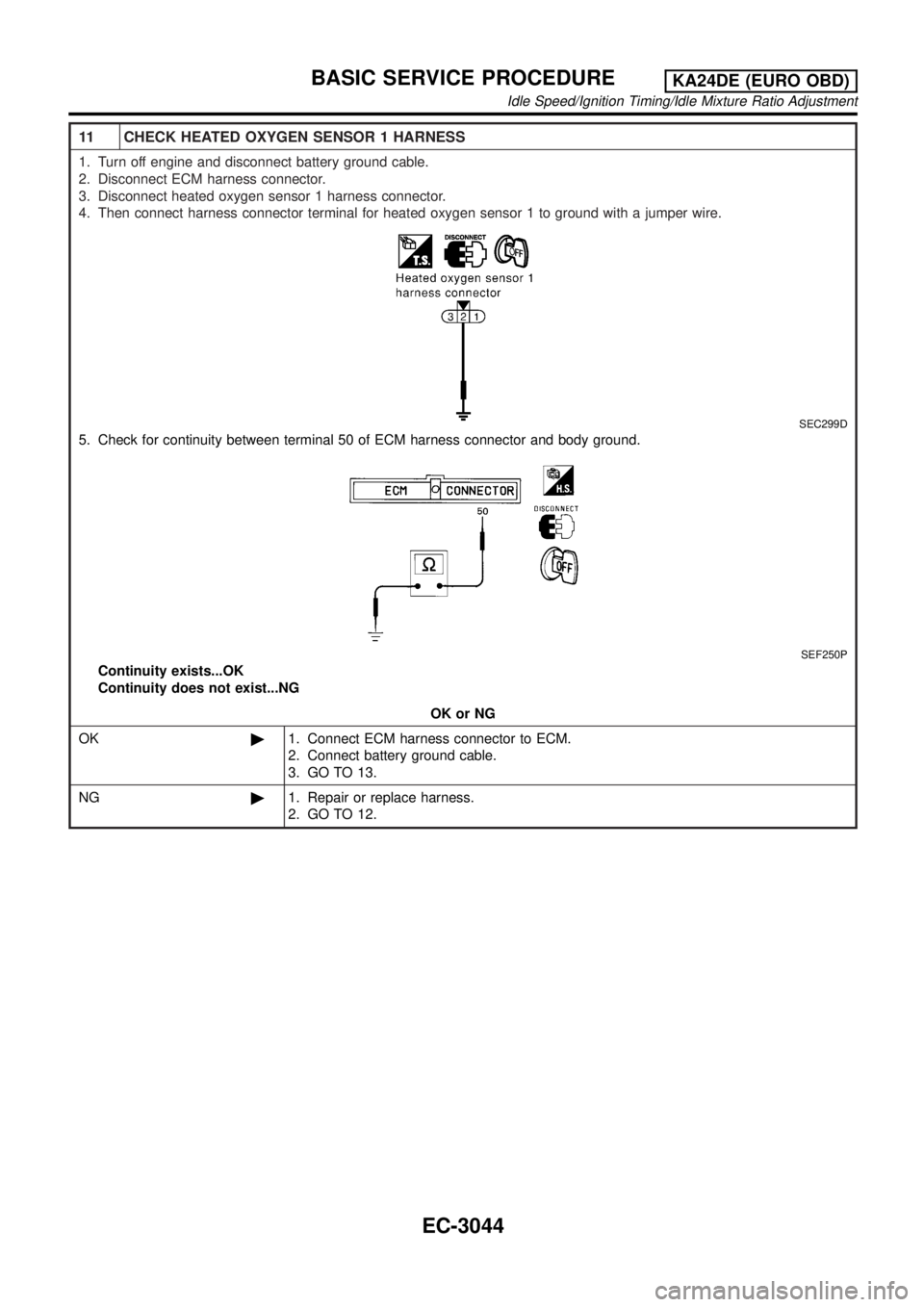

11 CHECK HEATED OXYGEN SENSOR 1 HARNESS

1. Turn off engine and disconnect battery ground cable.

2. Disconnect ECM harness connector.

3. Disconnect heated oxygen sensor 1 harness connector.

4. Then connect harness connector terminal for heated oxygen sensor 1 to ground with a jumper wire.

SEC299D

5. Check for continuity between terminal 50 of ECM harness connector and body ground.

SEF250P

Continuity exists...OK

Continuity does not exist...NG

OK or NG

OK©1. Connect ECM harness connector to ECM.

2. Connect battery ground cable.

3. GO TO 13.

NG©1. Repair or replace harness.

2. GO TO 12.

BASIC SERVICE PROCEDUREKA24DE (EURO OBD)

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment

EC-3044

Page 71 of 1306

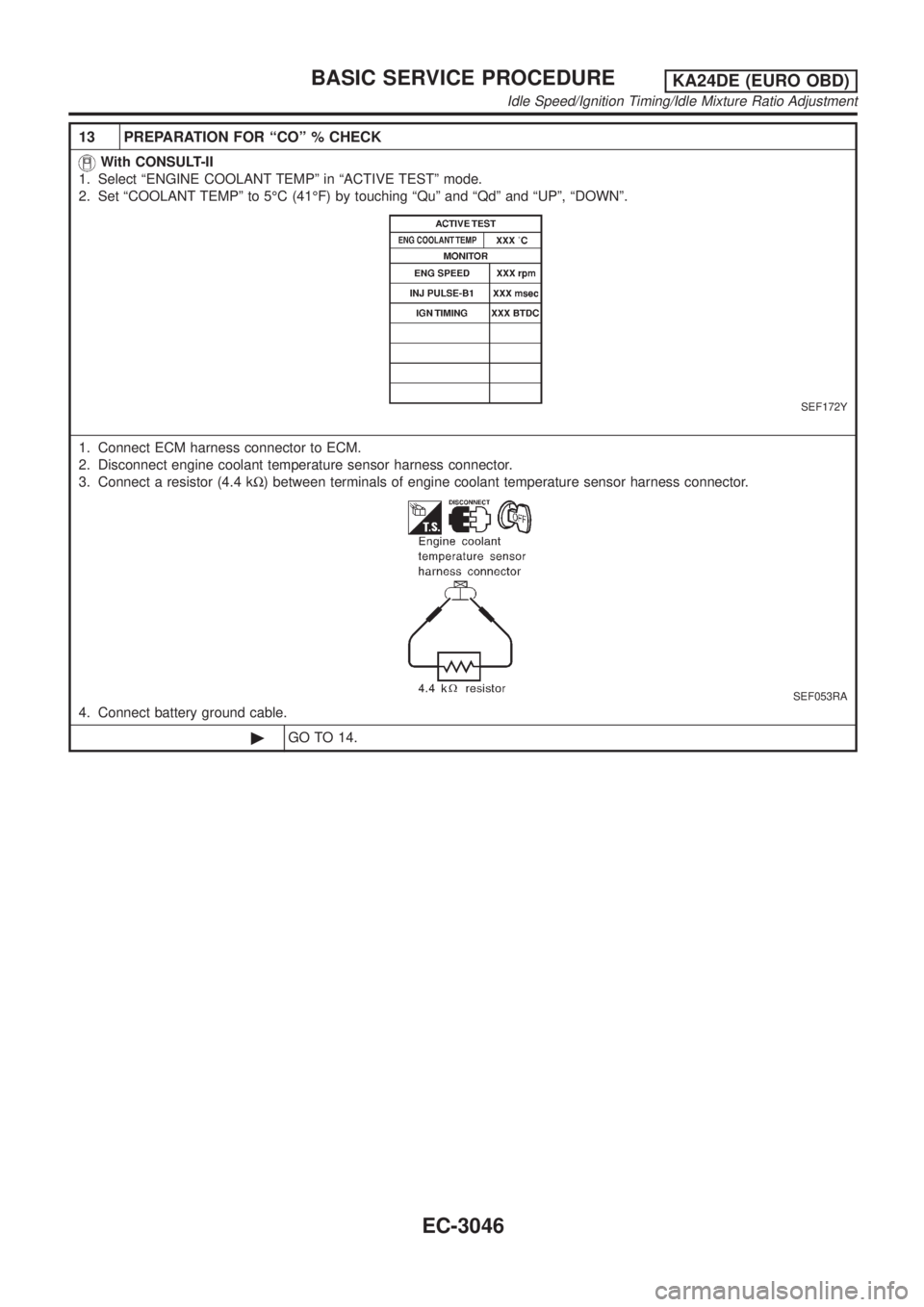

13 PREPARATION FOR ªCOº % CHECK

With CONSULT-II

1. Select ªENGINE COOLANT TEMPº in ªACTIVE TESTº mode.

2. Set ªCOOLANT TEMPº to 5ÉC (41ÉF) by touching ªQuº and ªQdº and ªUPº, ªDOWNº.

SEF172Y

1. Connect ECM harness connector to ECM.

2. Disconnect engine coolant temperature sensor harness connector.

3. Connect a resistor (4.4 kW) between terminals of engine coolant temperature sensor harness connector.

SEF053RA

4. Connect battery ground cable.

©GO TO 14.

BASIC SERVICE PROCEDUREKA24DE (EURO OBD)

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment

EC-3046