light NISSAN PICK-UP 2001 Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: PICK-UP, Model: NISSAN PICK-UP 2001Pages: 1306, PDF Size: 31.7 MB

Page 427 of 1306

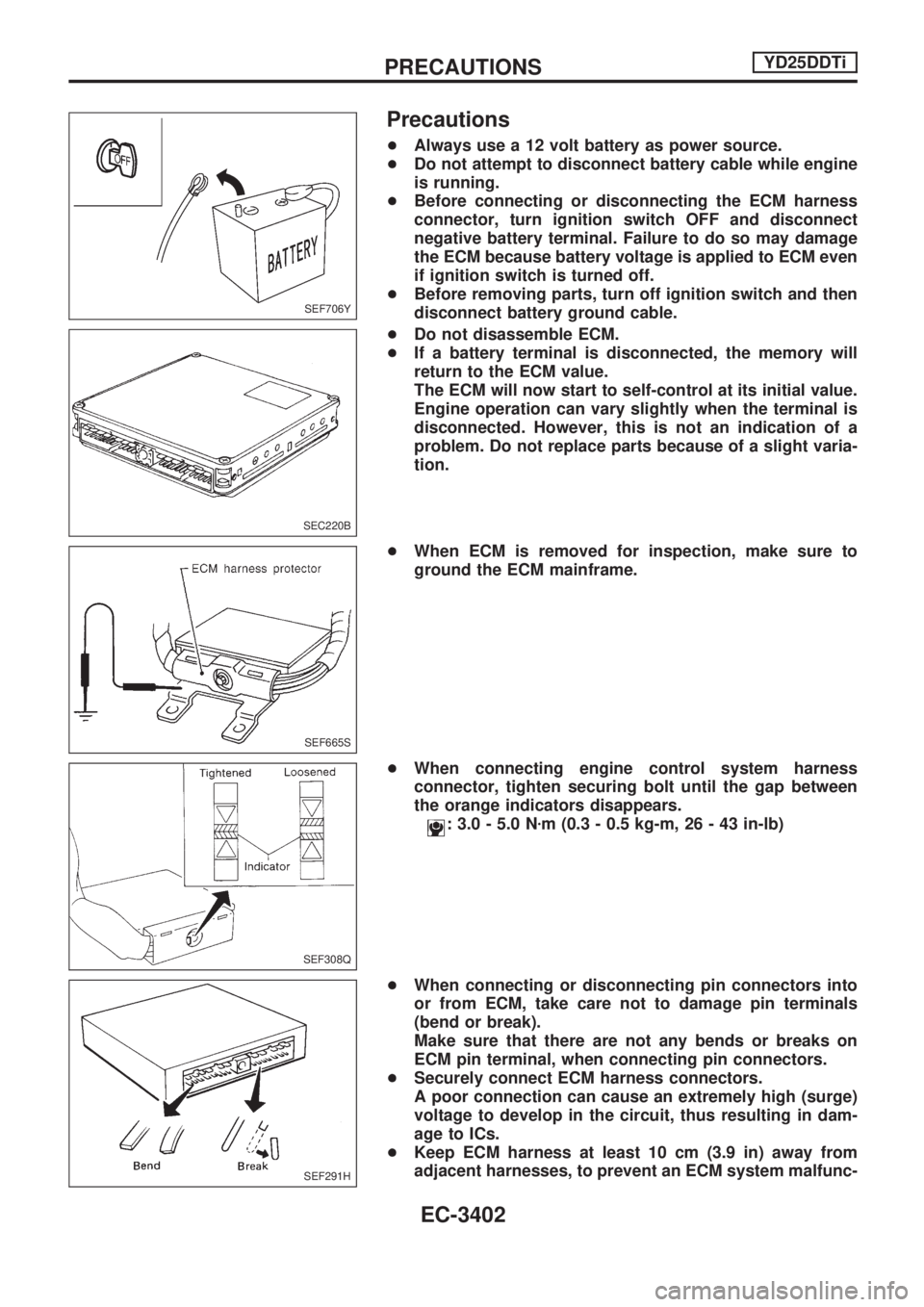

Precautions

+Always use a 12 volt battery as power source.

+Do not attempt to disconnect battery cable while engine

is running.

+Before connecting or disconnecting the ECM harness

connector, turn ignition switch OFF and disconnect

negative battery terminal. Failure to do so may damage

the ECM because battery voltage is applied to ECM even

if ignition switch is turned off.

+Before removing parts, turn off ignition switch and then

disconnect battery ground cable.

+Do not disassemble ECM.

+If a battery terminal is disconnected, the memory will

return to the ECM value.

The ECM will now start to self-control at its initial value.

Engine operation can vary slightly when the terminal is

disconnected. However, this is not an indication of a

problem. Do not replace parts because of a slight varia-

tion.

+When ECM is removed for inspection, make sure to

ground the ECM mainframe.

+When connecting engine control system harness

connector, tighten securing bolt until the gap between

the orange indicators disappears.

: 3.0 - 5.0 Nzm (0.3 - 0.5 kg-m, 26 - 43 in-lb)

+When connecting or disconnecting pin connectors into

or from ECM, take care not to damage pin terminals

(bend or break).

Make sure that there are not any bends or breaks on

ECM pin terminal, when connecting pin connectors.

+Securely connect ECM harness connectors.

A poor connection can cause an extremely high (surge)

voltage to develop in the circuit, thus resulting in dam-

age to ICs.

+Keep ECM harness at least 10 cm (3.9 in) away from

adjacent harnesses, to prevent an ECM system malfunc-

SEF706Y

SEC220B

SEF665S

SEF308Q

SEF291H

PRECAUTIONSYD25DDTi

EC-3402

Page 453 of 1306

DTC and MIL Detection Logic

When a malfunction is detected, the malfunction (DTC) is stored in the ECM memory.

The MIL will light up each time the ECM detects malfunction. For diagnostic items causing the MIL to light

up, refer to ªTROUBLE DIAGNOSIS Ð INDEXº, EC-3400.

Diagnostic Trouble Code (DTC)

HOW TO READ DTC

The DTC can be read by the following methods.

Without CONSULT-II

ECM displays the DTC by a set of four digit numbers with MIL illumination in the diagnostic test mode II

(Self-diagnostic results). Example: 0407, 1004, etc.

With CONSULT-II

CONSULT-II displays the DTC in ªSELF-DIAG RESULTSº mode. Examples: ªCRANK POS SEN (TDC)º, etc.

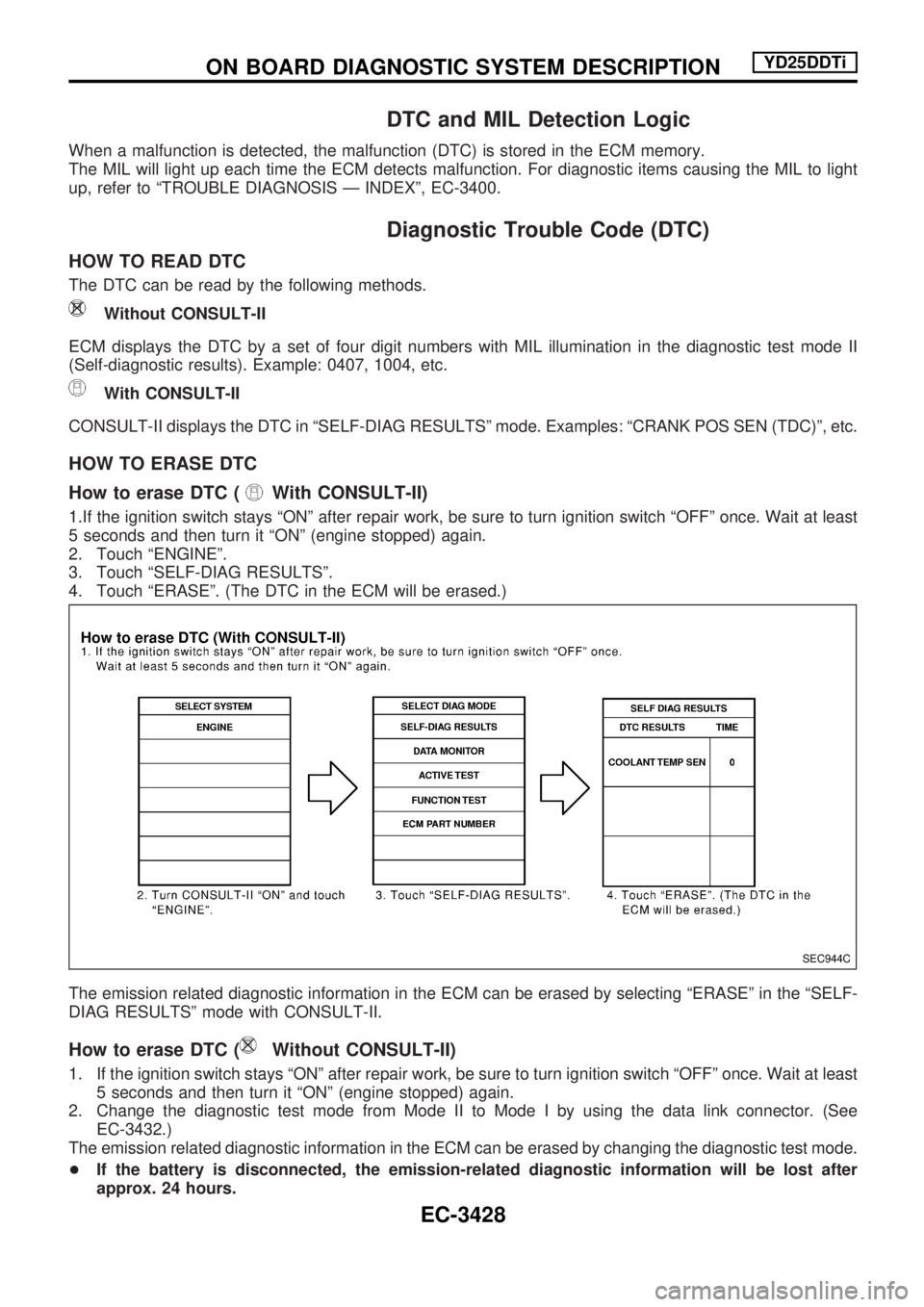

HOW TO ERASE DTC

How to erase DTC (

With CONSULT-II)

1.If the ignition switch stays ªONº after repair work, be sure to turn ignition switch ªOFFº once. Wait at least

5 seconds and then turn it ªONº (engine stopped) again.

2. Touch ªENGINEº.

3. Touch ªSELF-DIAG RESULTSº.

4. Touch ªERASEº. (The DTC in the ECM will be erased.)

The emission related diagnostic information in the ECM can be erased by selecting ªERASEº in the ªSELF-

DIAG RESULTSº mode with CONSULT-II.

How to erase DTC (Without CONSULT-II)

1. If the ignition switch stays ªONº after repair work, be sure to turn ignition switch ªOFFº once. Wait at least

5 seconds and then turn it ªONº (engine stopped) again.

2. Change the diagnostic test mode from Mode II to Mode I by using the data link connector. (See

EC-3432.)

The emission related diagnostic information in the ECM can be erased by changing the diagnostic test mode.

+If the battery is disconnected, the emission-related diagnostic information will be lost after

approx. 24 hours.

SEC944C

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONYD25DDTi

EC-3428

Page 454 of 1306

+Erasing the emission-related diagnostic information using CONSULT-II is easier and quicker than

switching the diagnostic test mode using the data link connector.

NATS (Nissan Anti-Theft System)

+If the security indicator lights up with the ignition switch

in the ªONº position or ªNATS MALFUNCTIONº is dis-

played on ªSELF-DIAG RESULTSº screen, perform self-

diagnostic results mode with CONSULT-II using NATS

program card. Refer to ªNATS (Nissan Anti-Theft Sys-

tem)º in EL section.

+Confirm no self-diagnostic results of NATS is displayed

before touching ªERASEº in ªSELF-DIAG RESULTSº

mode with CONSULT-II.

+When replacing ECM, initialization of NATS system and

registration of all NATS ignition key IDs must be carried

out with CONSULT-II using NATS program card.

Therefore, be sure to receive all keys from vehicle

owner. Regarding the procedures of NATS initialization

and NATS ignition key ID registration, refer to CON-

SULT-II operation manual, NATS.

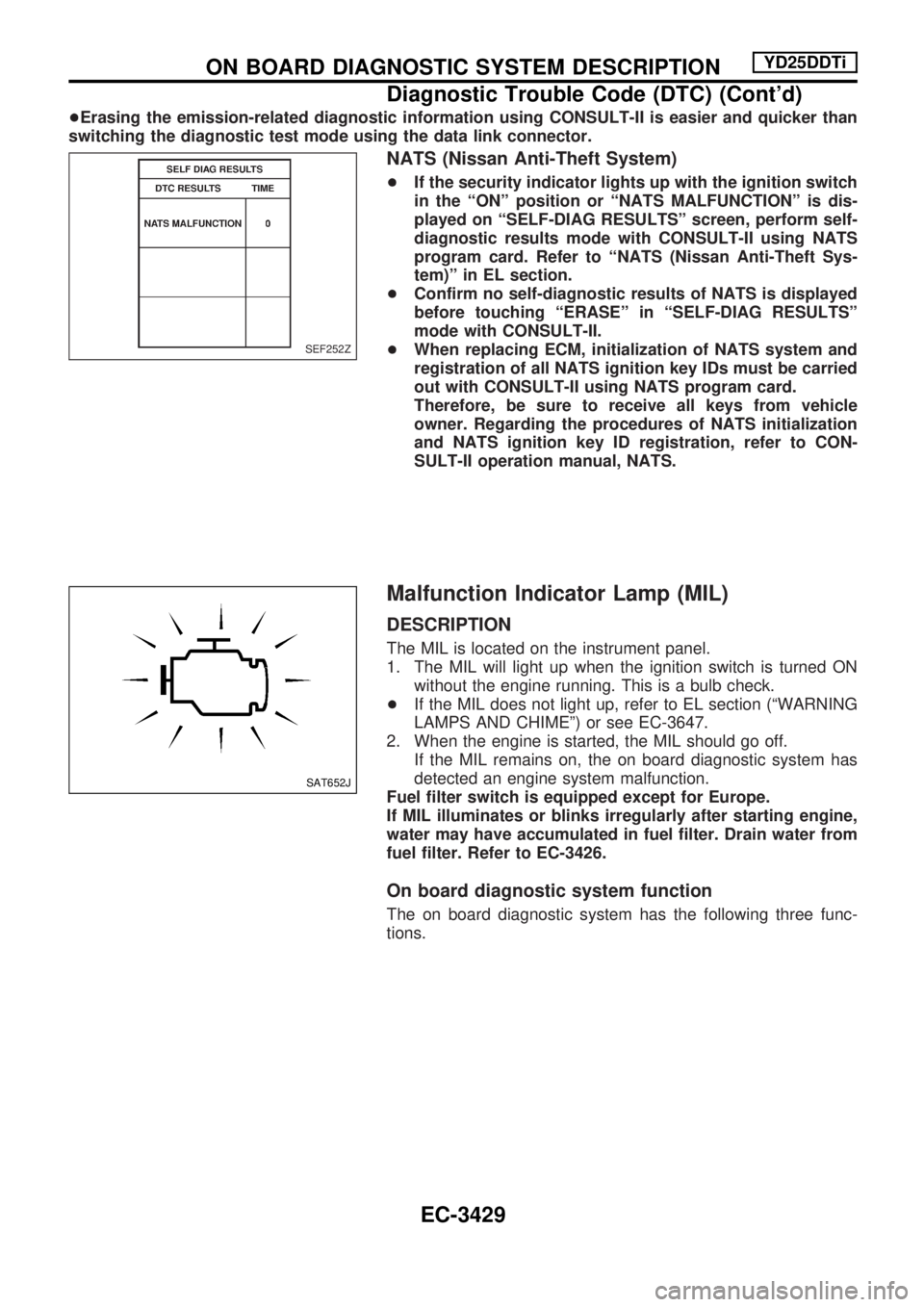

Malfunction Indicator Lamp (MIL)

DESCRIPTION

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned ON

without the engine running. This is a bulb check.

+If the MIL does not light up, refer to EL section (ªWARNING

LAMPS AND CHIMEº) or see EC-3647.

2. When the engine is started, the MIL should go off.

If the MIL remains on, the on board diagnostic system has

detected an engine system malfunction.

Fuel filter switch is equipped except for Europe.

If MIL illuminates or blinks irregularly after starting engine,

water may have accumulated in fuel filter. Drain water from

fuel filter. Refer to EC-3426.

On board diagnostic system function

The on board diagnostic system has the following three func-

tions.

SEF252Z

SAT652J

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONYD25DDTi

Diagnostic Trouble Code (DTC) (Cont'd)

EC-3429

Page 455 of 1306

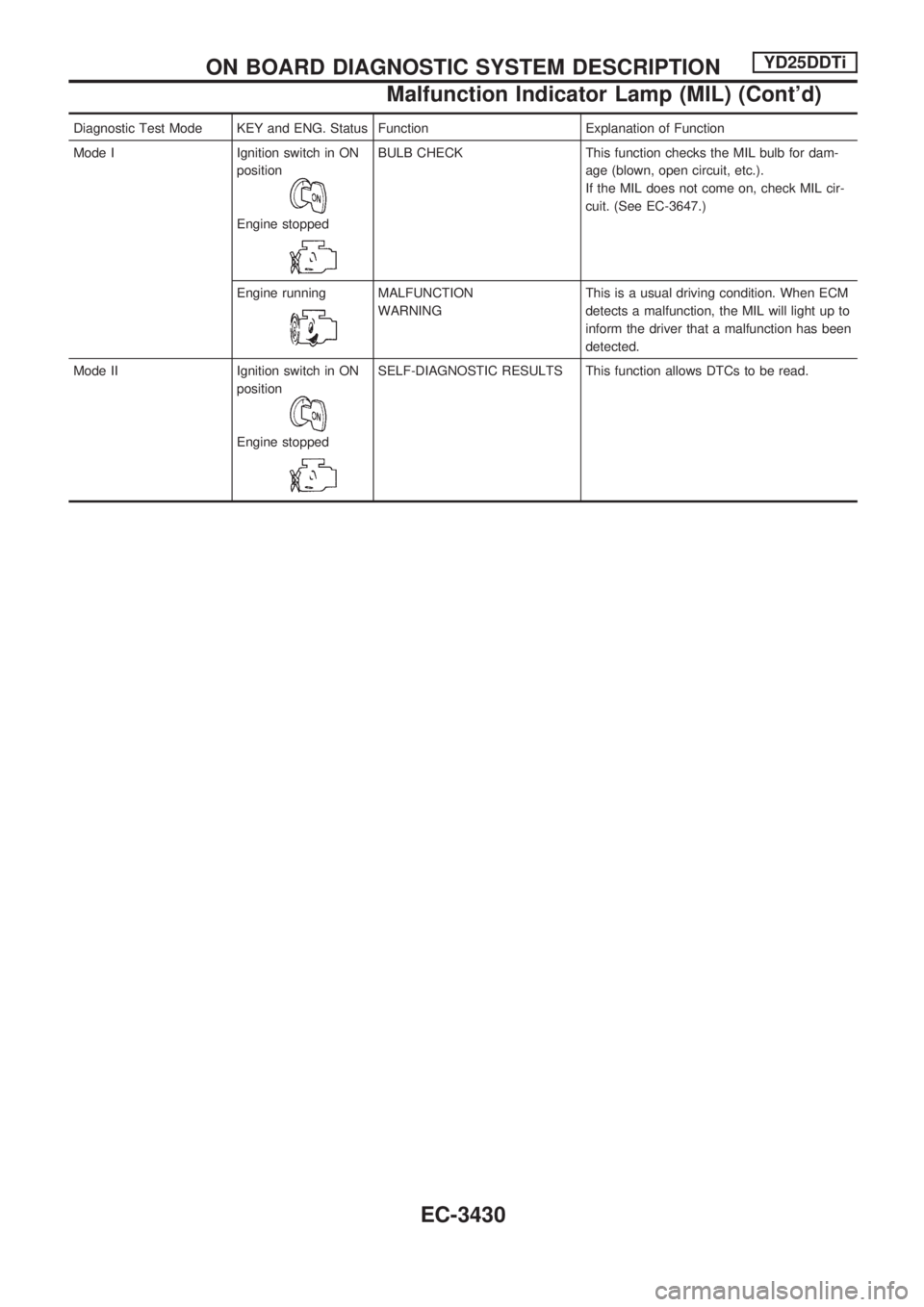

Diagnostic Test Mode KEY and ENG. Status Function Explanation of Function

Mode I Ignition switch in ON

position

Engine stopped

BULB CHECK This function checks the MIL bulb for dam-

age (blown, open circuit, etc.).

If the MIL does not come on, check MIL cir-

cuit. (See EC-3647.)

Engine running

MALFUNCTION

WARNINGThis is a usual driving condition. When ECM

detects a malfunction, the MIL will light up to

inform the driver that a malfunction has been

detected.

Mode II Ignition switch in ON

position

Engine stopped

SELF-DIAGNOSTIC RESULTS This function allows DTCs to be read.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONYD25DDTi

Malfunction Indicator Lamp (MIL) (Cont'd)

EC-3430

Page 458 of 1306

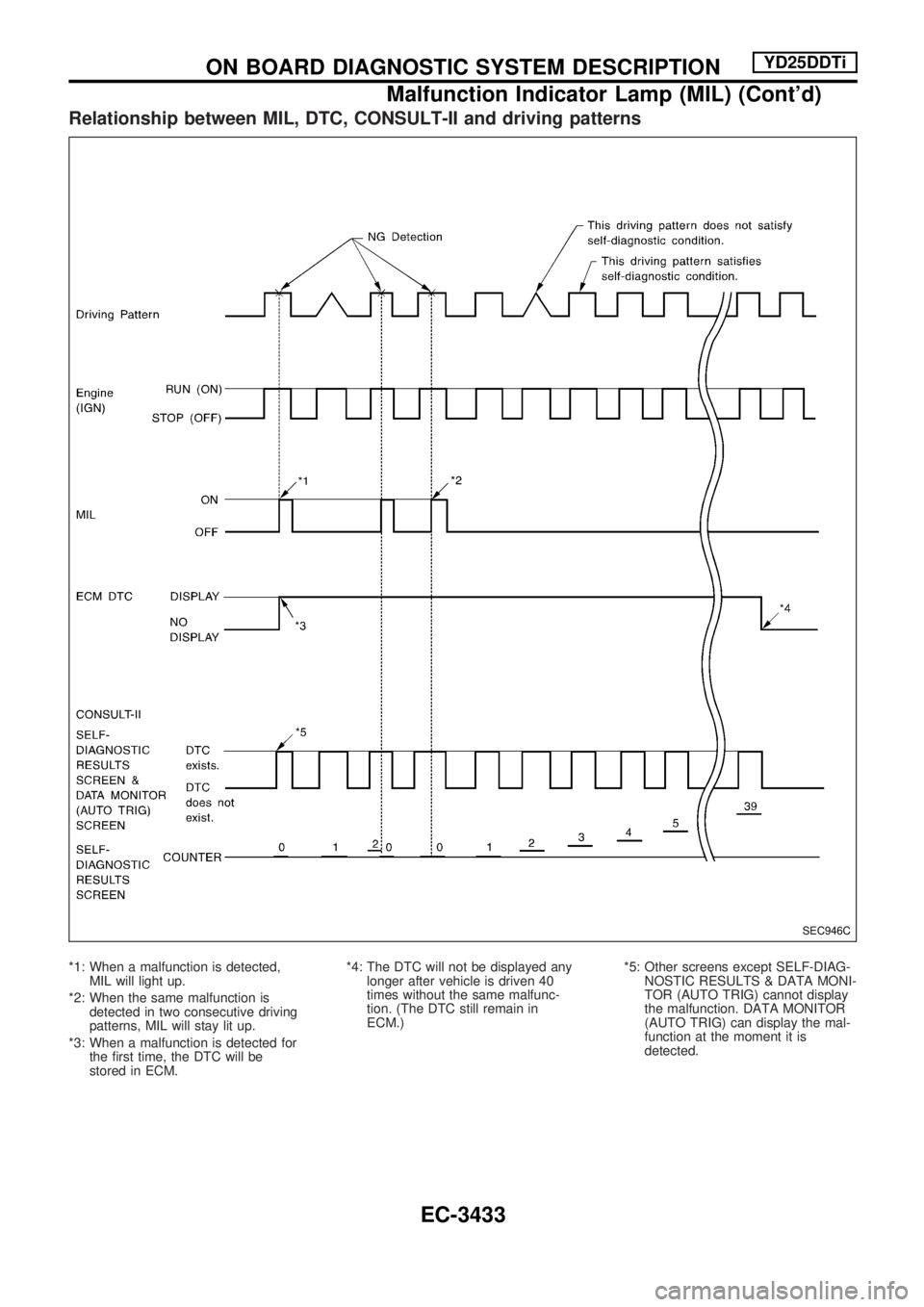

Relationship between MIL, DTC, CONSULT-II and driving patterns

*1: When a malfunction is detected,

MIL will light up.

*2: When the same malfunction is

detected in two consecutive driving

patterns, MIL will stay lit up.

*3: When a malfunction is detected for

the first time, the DTC will be

stored in ECM.*4: The DTC will not be displayed any

longer after vehicle is driven 40

times without the same malfunc-

tion. (The DTC still remain in

ECM.)*5: Other screens except SELF-DIAG-

NOSTIC RESULTS & DATA MONI-

TOR (AUTO TRIG) cannot display

the malfunction. DATA MONITOR

(AUTO TRIG) can display the mal-

function at the moment it is

detected.

SEC946C

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONYD25DDTi

Malfunction Indicator Lamp (MIL) (Cont'd)

EC-3433

Page 485 of 1306

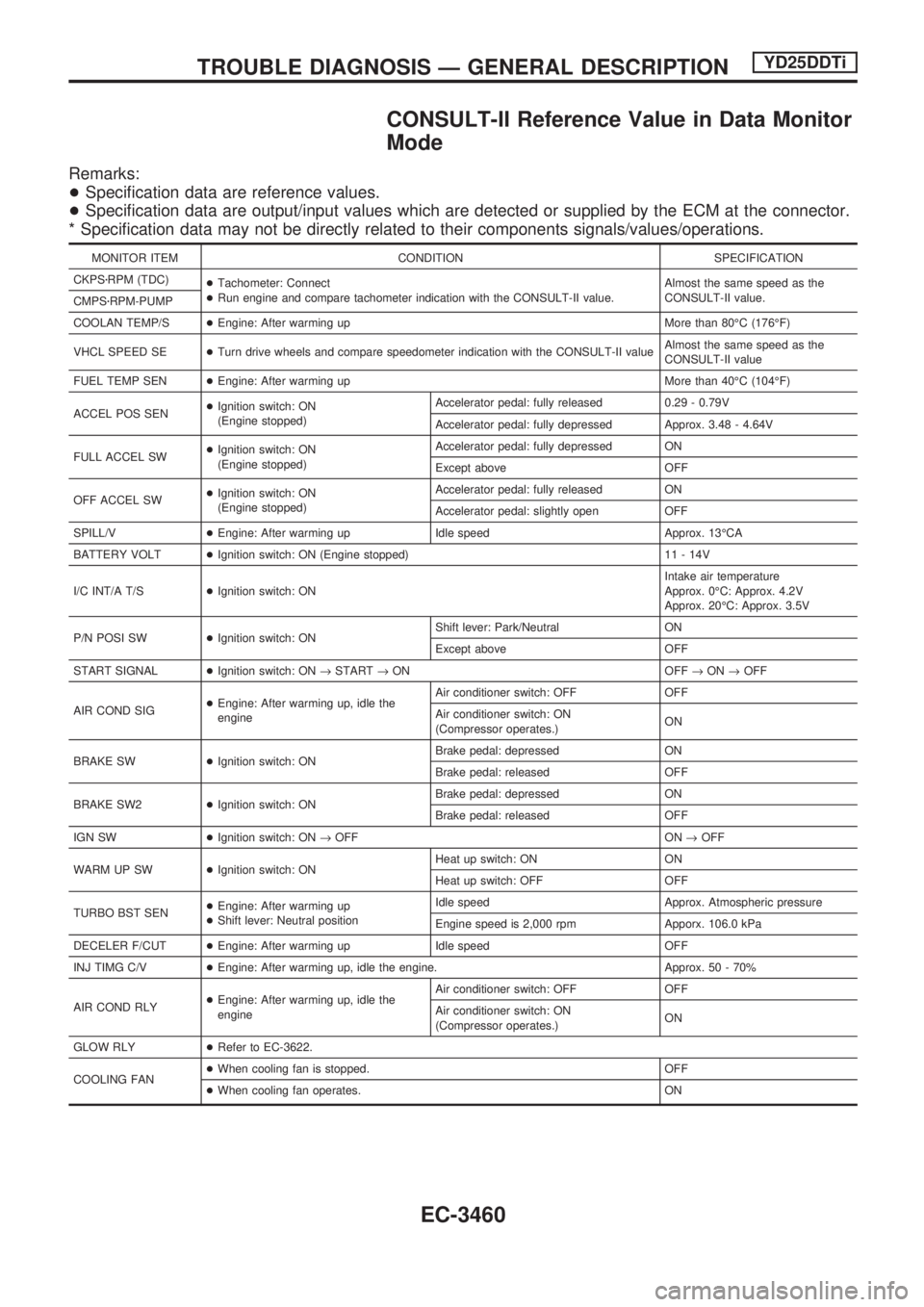

CONSULT-II Reference Value in Data Monitor

Mode

Remarks:

+Specification data are reference values.

+Specification data are output/input values which are detected or supplied by the ECM at the connector.

* Specification data may not be directly related to their components signals/values/operations.

MONITOR ITEM CONDITION SPECIFICATION

CKPSzRPM (TDC)

+Tachometer: Connect

+Run engine and compare tachometer indication with the CONSULT-II value.Almost the same speed as the

CONSULT-II value.

CMPSzRPM-PUMP

COOLAN TEMP/S+Engine: After warming up More than 80ÉC (176ÉF)

VHCL SPEED SE+Turn drive wheels and compare speedometer indication with the CONSULT-II valueAlmost the same speed as the

CONSULT-II value

FUEL TEMP SEN+Engine: After warming up More than 40ÉC (104ÉF)

ACCEL POS SEN+Ignition switch: ON

(Engine stopped)Accelerator pedal: fully released 0.29 - 0.79V

Accelerator pedal: fully depressed Approx. 3.48 - 4.64V

FULL ACCEL SW+Ignition switch: ON

(Engine stopped)Accelerator pedal: fully depressed ON

Except above OFF

OFF ACCEL SW+Ignition switch: ON

(Engine stopped)Accelerator pedal: fully released ON

Accelerator pedal: slightly open OFF

SPILL/V+Engine: After warming up Idle speed Approx. 13ÉCA

BATTERY VOLT+Ignition switch: ON (Engine stopped) 11 - 14V

I/C INT/A T/S+Ignition switch: ONIntake air temperature

Approx. 0ÉC: Approx. 4.2V

Approx. 20ÉC: Approx. 3.5V

P/N POSI SW+Ignition switch: ONShift lever: Park/Neutral ON

Except above OFF

START SIGNAL+Ignition switch: ON®START®ON OFF®ON®OFF

AIR COND SIG+Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)ON

BRAKE SW+Ignition switch: ONBrake pedal: depressed ON

Brake pedal: released OFF

BRAKE SW2+Ignition switch: ONBrake pedal: depressed ON

Brake pedal: released OFF

IGN SW+Ignition switch: ON®OFF ON®OFF

WARM UP SW+Ignition switch: ONHeat up switch: ON ON

Heat up switch: OFF OFF

TURBO BST SEN+Engine: After warming up

+Shift lever: Neutral positionIdle speed Approx. Atmospheric pressure

Engine speed is 2,000 rpm Apporx. 106.0 kPa

DECELER F/CUT+Engine: After warming up Idle speed OFF

INJ TIMG C/V+Engine: After warming up, idle the engine. Approx. 50 - 70%

AIR COND RLY+Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)ON

GLOW RLY+Refer to EC-3622.

COOLING FAN+When cooling fan is stopped. OFF

+When cooling fan operates. ON

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONYD25DDTi

EC-3460

Page 540 of 1306

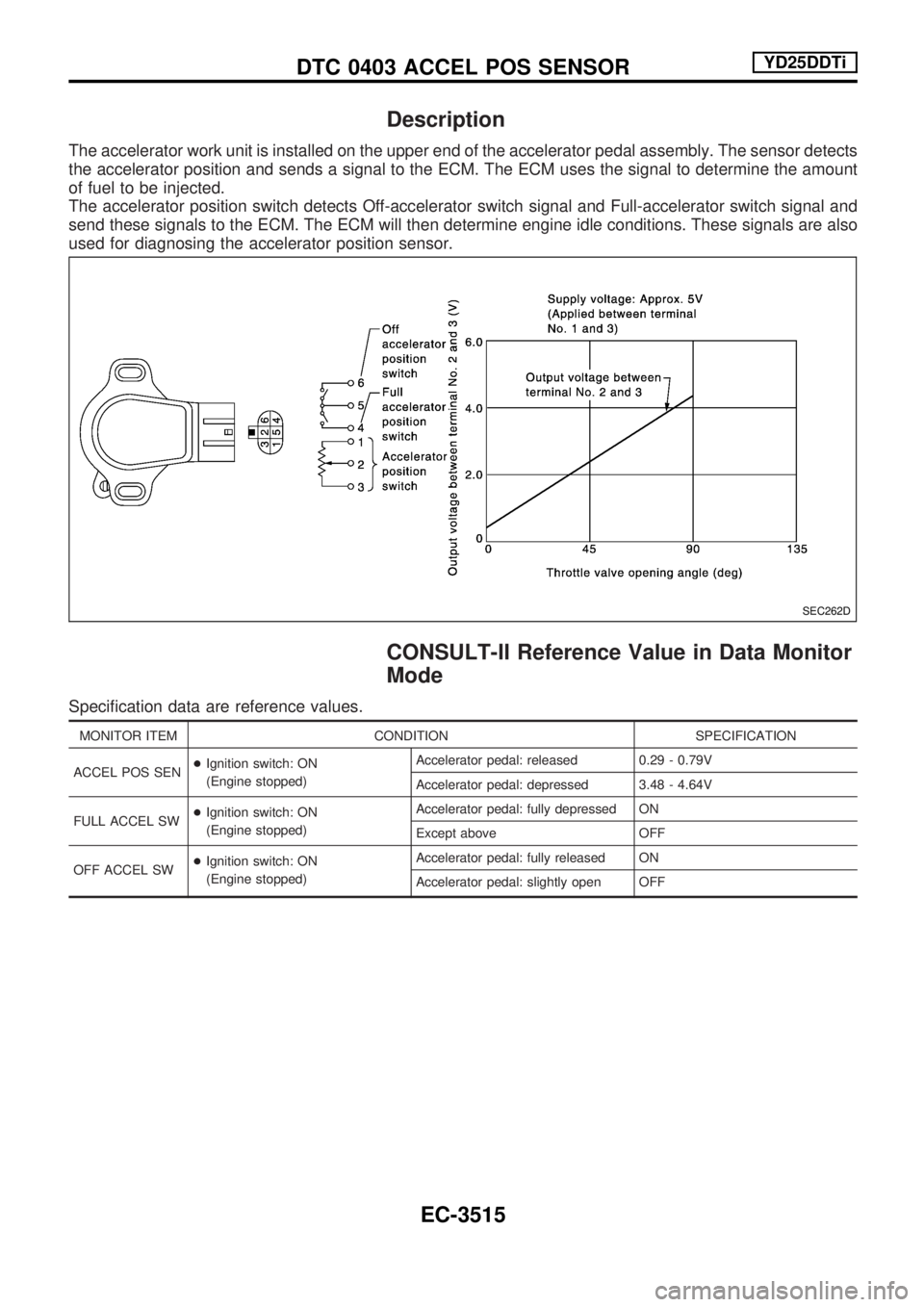

Description

The accelerator work unit is installed on the upper end of the accelerator pedal assembly. The sensor detects

the accelerator position and sends a signal to the ECM. The ECM uses the signal to determine the amount

of fuel to be injected.

The accelerator position switch detects Off-accelerator switch signal and Full-accelerator switch signal and

send these signals to the ECM. The ECM will then determine engine idle conditions. These signals are also

used for diagnosing the accelerator position sensor.

CONSULT-II Reference Value in Data Monitor

Mode

Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

ACCEL POS SEN+Ignition switch: ON

(Engine stopped)Accelerator pedal: released 0.29 - 0.79V

Accelerator pedal: depressed 3.48 - 4.64V

FULL ACCEL SW+Ignition switch: ON

(Engine stopped)Accelerator pedal: fully depressed ON

Except above OFF

OFF ACCEL SW+Ignition switch: ON

(Engine stopped)Accelerator pedal: fully released ON

Accelerator pedal: slightly open OFF

SEC262D

DTC 0403 ACCEL POS SENSORYD25DDTi

EC-3515

Page 676 of 1306

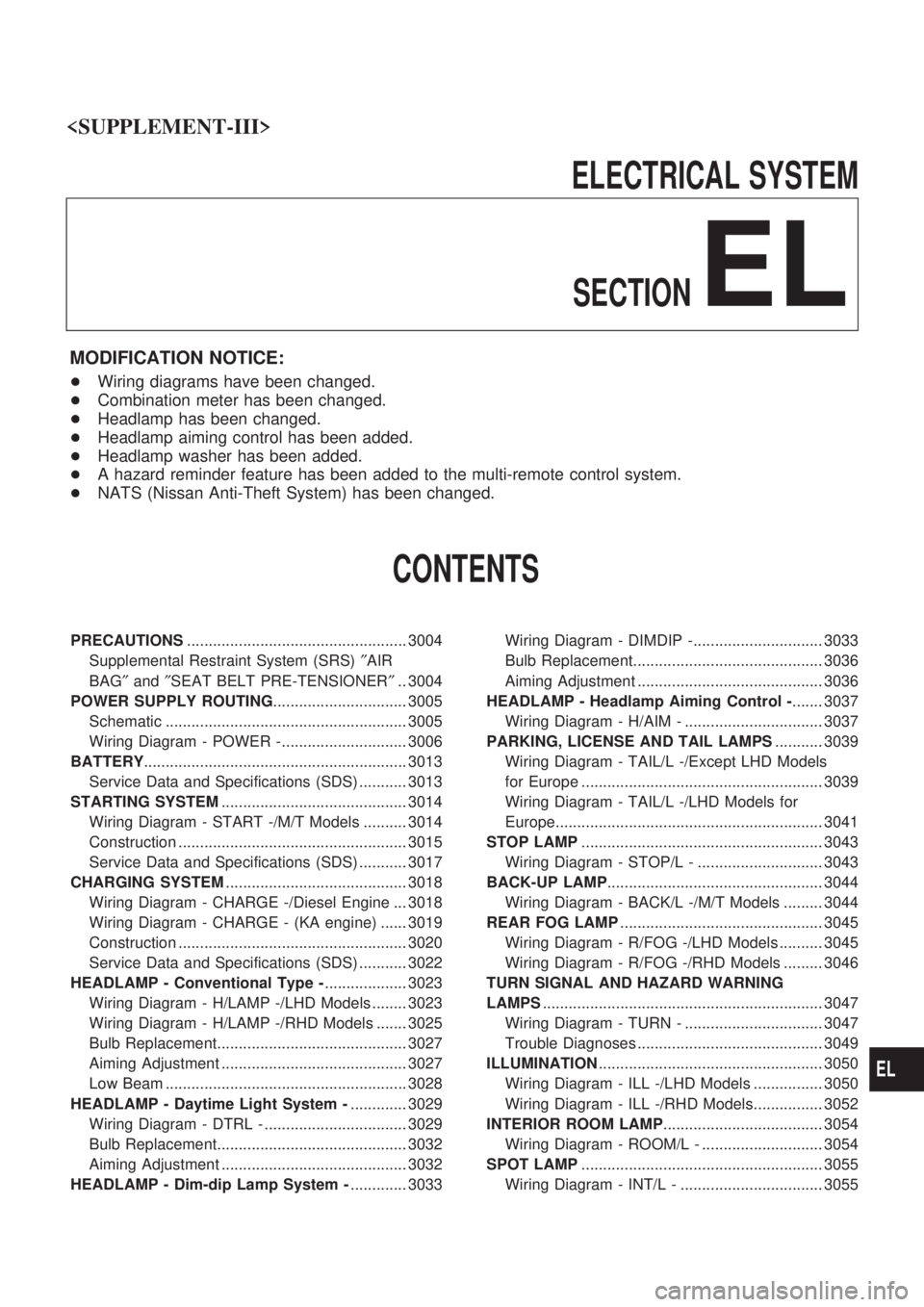

ELECTRICAL SYSTEM

SECTION

EL

MODIFICATION NOTICE:

+Wiring diagrams have been changed.

+Combination meter has been changed.

+Headlamp has been changed.

+Headlamp aiming control has been added.

+Headlamp washer has been added.

+A hazard reminder feature has been added to the multi-remote control system.

+NATS (Nissan Anti-Theft System) has been changed.

CONTENTS

PRECAUTIONS................................................... 3004

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER².. 3004

POWER SUPPLY ROUTING............................... 3005

Schematic ........................................................ 3005

Wiring Diagram - POWER -............................. 3006

BATTERY............................................................. 3013

Service Data and Specifications (SDS) ........... 3013

STARTING SYSTEM........................................... 3014

Wiring Diagram - START -/M/T Models .......... 3014

Construction ..................................................... 3015

Service Data and Specifications (SDS) ........... 3017

CHARGING SYSTEM.......................................... 3018

Wiring Diagram - CHARGE -/Diesel Engine ... 3018

Wiring Diagram - CHARGE - (KA engine) ...... 3019

Construction ..................................................... 3020

Service Data and Specifications (SDS) ........... 3022

HEADLAMP - Conventional Type -................... 3023

Wiring Diagram - H/LAMP -/LHD Models ........ 3023

Wiring Diagram - H/LAMP -/RHD Models ....... 3025

Bulb Replacement............................................ 3027

Aiming Adjustment ........................................... 3027

Low Beam ........................................................ 3028

HEADLAMP - Daytime Light System -............. 3029

Wiring Diagram - DTRL - ................................. 3029

Bulb Replacement............................................ 3032

Aiming Adjustment ........................................... 3032

HEADLAMP - Dim-dip Lamp System -............. 3033Wiring Diagram - DIMDIP -.............................. 3033

Bulb Replacement............................................ 3036

Aiming Adjustment ........................................... 3036

HEADLAMP - Headlamp Aiming Control -....... 3037

Wiring Diagram - H/AIM - ................................ 3037

PARKING, LICENSE AND TAIL LAMPS........... 3039

Wiring Diagram - TAIL/L -/Except LHD Models

for Europe ........................................................ 3039

Wiring Diagram - TAIL/L -/LHD Models for

Europe.............................................................. 3041

STOP LAMP........................................................ 3043

Wiring Diagram - STOP/L - ............................. 3043

BACK-UP LAMP.................................................. 3044

Wiring Diagram - BACK/L -/M/T Models ......... 3044

REAR FOG LAMP............................................... 3045

Wiring Diagram - R/FOG -/LHD Models .......... 3045

Wiring Diagram - R/FOG -/RHD Models ......... 3046

TURN SIGNAL AND HAZARD WARNING

LAMPS................................................................. 3047

Wiring Diagram - TURN - ................................ 3047

Trouble Diagnoses ........................................... 3049

ILLUMINATION.................................................... 3050

Wiring Diagram - ILL -/LHD Models ................ 3050

Wiring Diagram - ILL -/RHD Models................ 3052

INTERIOR ROOM LAMP..................................... 3054

Wiring Diagram - ROOM/L - ............................ 3054

SPOT LAMP........................................................ 3055

Wiring Diagram - INT/L - ................................. 3055

EL

Page 677 of 1306

METER AND GAUGES....................................... 3056

System Description .......................................... 3056

Combination Meter/With Tachometer .............. 3057

Combination Meter/Without Tachometer ......... 3058

Schematic/With Tachometer ............................ 3059

Schematic/Without Tachometer ....................... 3060

Construction ..................................................... 3061

Wiring Diagram - METER -/Gasoline Engine

with Tachometer .............................................. 3062

Wiring Diagram - METER -/Gasoline Engine

without Tachometer ......................................... 3064

Wiring Diagram - METER -/LHD Diesel Engine

Models with Tachometer.................................. 3065

Wiring Diagram - METER -/RHD Diesel

Engine Models with Tachometer ..................... 3067

Wiring Diagram - METER -/Diesel Engine

without Tachometer ......................................... 3069

Meter/Gauge Operation and Odo/Trip Meter

Segment Check in Diagnosis Mode ................ 3070

Trouble Diagnoses/With Tachometer .............. 3071

Trouble Diagnoses/Without Tachometer ......... 3076

WARNING LAMPS.............................................. 3081

Schematic/With Tachometer ............................ 3081

Schematic/Without Tachometer ....................... 3082

Wiring Diagram - WARN -/Gasoline Engine

with Tachometer .............................................. 3083

Wiring Diagram - WARN -/Gasoline Engine

without Tachometer ......................................... 3087

Wiring Diagram - WARN -/Diesel Engine with

Tachometer ...................................................... 3091

Wiring Diagram - WARN -/Diesel Engine

without Tachometer ......................................... 3095

A/T INDICATOR................................................... 3100

Wiring Diagram - AT/IND -/RHD Models ......... 3100

Wiring Diagram - CHIME -/LHD Models.......... 3101

Wiring Diagram - CHIME -/RHD Models ......... 3102

FRONT WIPER AND WASHER.......................... 3103

Wiring Diagram - WIPER -/Without Intermittent

for Floor-shift .................................................... 3103

Wiring Diagram - WIPER -/Without Intermittent

for RHD Column-shift Models .......................... 3106

HEADLAMP WASHER........................................ 3108

Wiring Diagram - HLC - ................................... 3108

HORN................................................................... 3109

Wiring Diagram - HORN -................................ 3109

CIGARETTE LIGHTER........................................ 3110

Wiring Diagram - CIGAR - ............................... 3110

CLOCK................................................................. 3111

Wiring Diagram - CLOCK - .............................. 3111

REAR WINDOW DEFOGGER AND MIRROR

DEFOGGER......................................................... 3112

Wiring Diagram - DEF - ................................... 3112

AUDIO.................................................................. 3113

Wiring Diagram - AUDIO -/LHD Models .......... 3113Wiring Diagram - AUDIO -/RHD Models ......... 3114

AUDIO ANTENNA............................................... 3115

Power Antenna/Wiring Diagram - P/ANT - ...... 3115

POWER DOOR MIRROR.................................... 3116

Wiring Diagram - MIRROR -/LHD Models....... 3116

Wiring Diagram - MIRROR -/RHD Models ...... 3117

HEATED SEAT.................................................... 3118

Wiring Diagram - H/SEAT - ............................. 3118

POWER WINDOW............................................... 3120

Schematic/Without Interruption Detection

Function ........................................................... 3120

Schematic/With Interruption Detection

Function ........................................................... 3121

Wiring Diagram - WINDOW -/Without

Interruption Detection Function........................ 3122

Wiring Diagram - WINDOW -/With Interruption

Detection Function ........................................... 3126

Trouble Diagnoses/Without Interruption

Detection Function ........................................... 3130

Trouble Diagnoses/With Interruption Detection

Function ........................................................... 3131

POWER DOOR LOCK......................................... 3133

Wiring Diagram - D/LOCK - ............................. 3133

MULTI-REMOTE CONTROL SYSTEM............... 3135

System Description .......................................... 3135

MULTI-REMOTE CONTROL SYSTEM............... 3136

Wiring Diagram - MULTI - ............................... 3136

Trouble Diagnoses ........................................... 3137

ID Code Entry Procedure ................................ 3139

Remote Controller Battery Replacement ......... 3140

THEFT WARNING SYSTEM............................... 3141

Wiring Diagram - PRWIRE - ............................ 3141

NATS (Nissan Anti-Theft System).................... 3142

Component Parts and Harness Connector

Location............................................................ 3142

System Description .......................................... 3143

System Composition ........................................ 3144

Wiring Diagram - NATS -/LHD Models............ 3145

Wiring Diagram - NATS -/RHD Diesel Engine

Models.............................................................. 3146

CONSULT-II ..................................................... 3147

Trouble Diagnoses ........................................... 3149

How to Replace NATS IMMU .......................... 3160

LOCATION OF ELECTRICAL UNITS................. 3161

Engine Compartment ....................................... 3161

Passenger Compartment ................................. 3162

HARNESS LAYOUT............................................ 3164

Main Harness ................................................... 3164

Engine Room Harness..................................... 3174

Engine Control Harness/KA engine ................. 3182

Engine Control Harness................................... 3184

Engine Harness ............................................... 3185

Alternator Harness ........................................... 3187

Instrument Harness.......................................... 3189

EL-3002

Page 703 of 1306

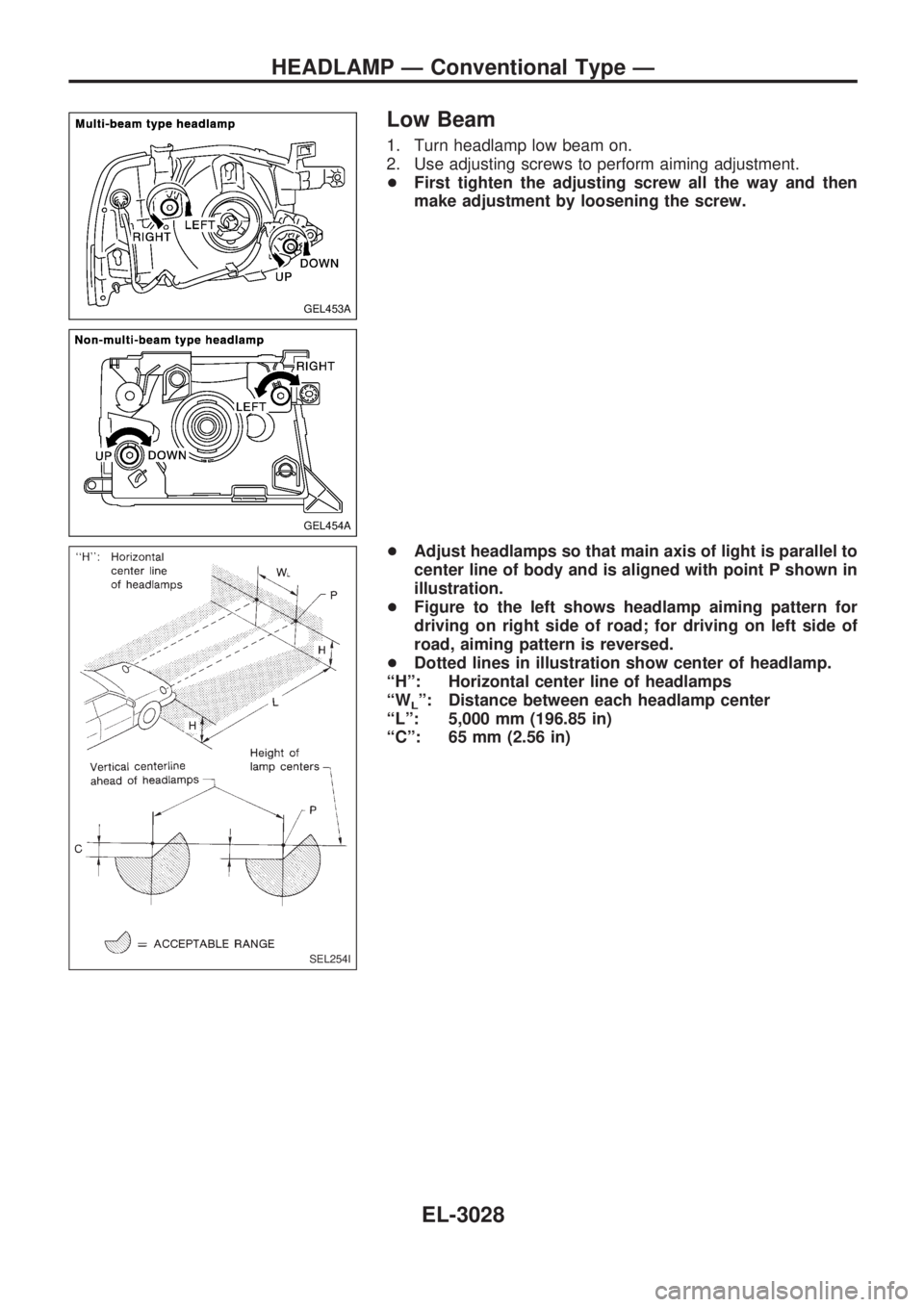

Low Beam

1. Turn headlamp low beam on.

2. Use adjusting screws to perform aiming adjustment.

+First tighten the adjusting screw all the way and then

make adjustment by loosening the screw.

+Adjust headlamps so that main axis of light is parallel to

center line of body and is aligned with point P shown in

illustration.

+Figure to the left shows headlamp aiming pattern for

driving on right side of road; for driving on left side of

road, aiming pattern is reversed.

+Dotted lines in illustration show center of headlamp.

ªHº: Horizontal center line of headlamps

ªW

Lº: Distance between each headlamp center

ªLº: 5,000 mm (196.85 in)

ªCº: 65 mm (2.56 in)

GEL453A

GEL454A

SEL254I

HEADLAMP Ð Conventional Type Ð

EL-3028