NISSAN PICK-UP 2001 Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: PICK-UP, Model: NISSAN PICK-UP 2001Pages: 1306, PDF Size: 31.7 MB

Page 441 of 1306

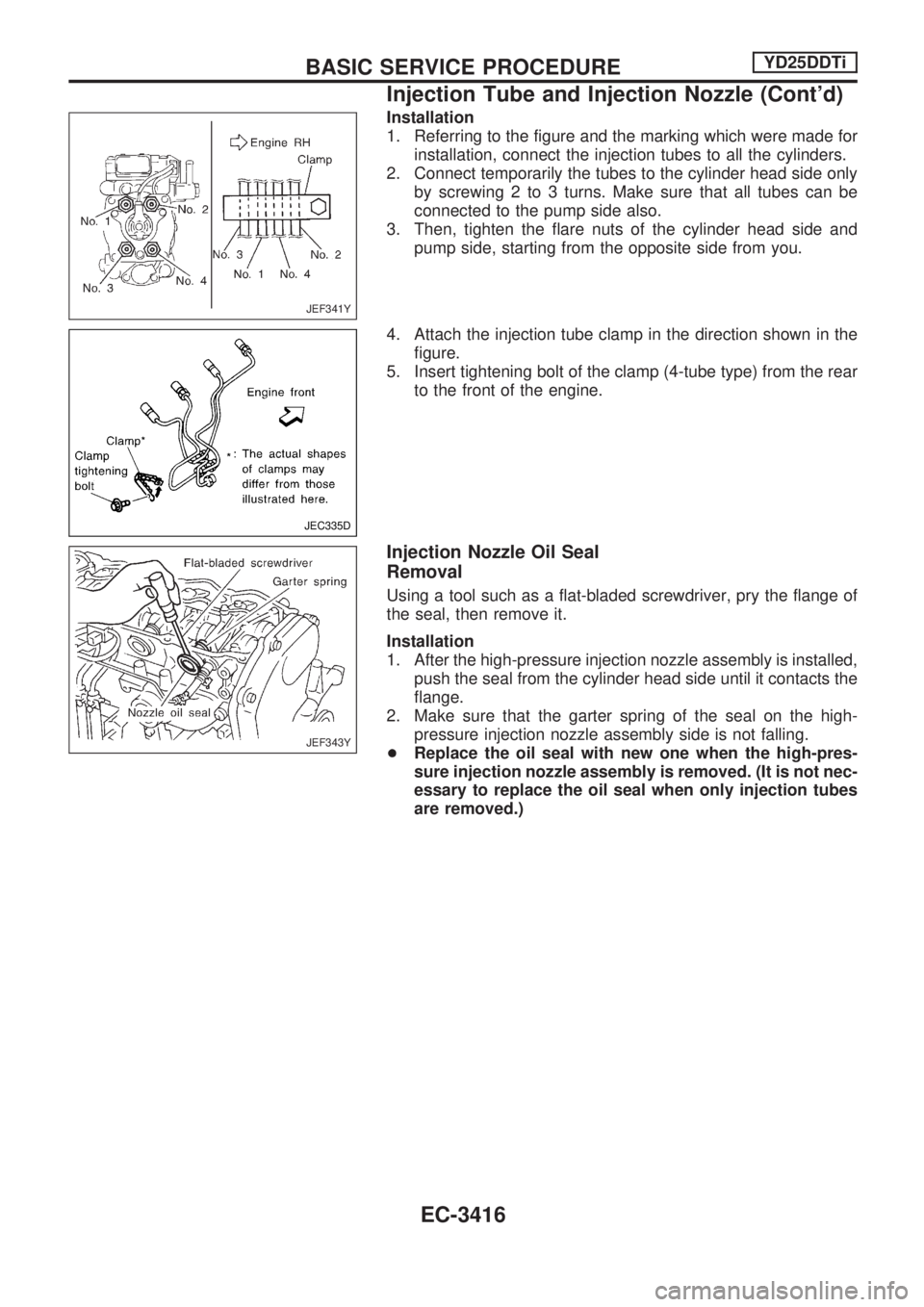

Installation

1. Referring to the figure and the marking which were made for

installation, connect the injection tubes to all the cylinders.

2. Connect temporarily the tubes to the cylinder head side only

by screwing 2 to 3 turns. Make sure that all tubes can be

connected to the pump side also.

3. Then, tighten the flare nuts of the cylinder head side and

pump side, starting from the opposite side from you.

4. Attach the injection tube clamp in the direction shown in the

figure.

5. Insert tightening bolt of the clamp (4-tube type) from the rear

to the front of the engine.

Injection Nozzle Oil Seal

Removal

Using a tool such as a flat-bladed screwdriver, pry the flange of

the seal, then remove it.

Installation

1. After the high-pressure injection nozzle assembly is installed,

push the seal from the cylinder head side until it contacts the

flange.

2. Make sure that the garter spring of the seal on the high-

pressure injection nozzle assembly side is not falling.

+Replace the oil seal with new one when the high-pres-

sure injection nozzle assembly is removed. (It is not nec-

essary to replace the oil seal when only injection tubes

are removed.)

JEF341Y

JEC335D

JEF343Y

BASIC SERVICE PROCEDUREYD25DDTi

Injection Tube and Injection Nozzle (Cont'd)

EC-3416

Page 442 of 1306

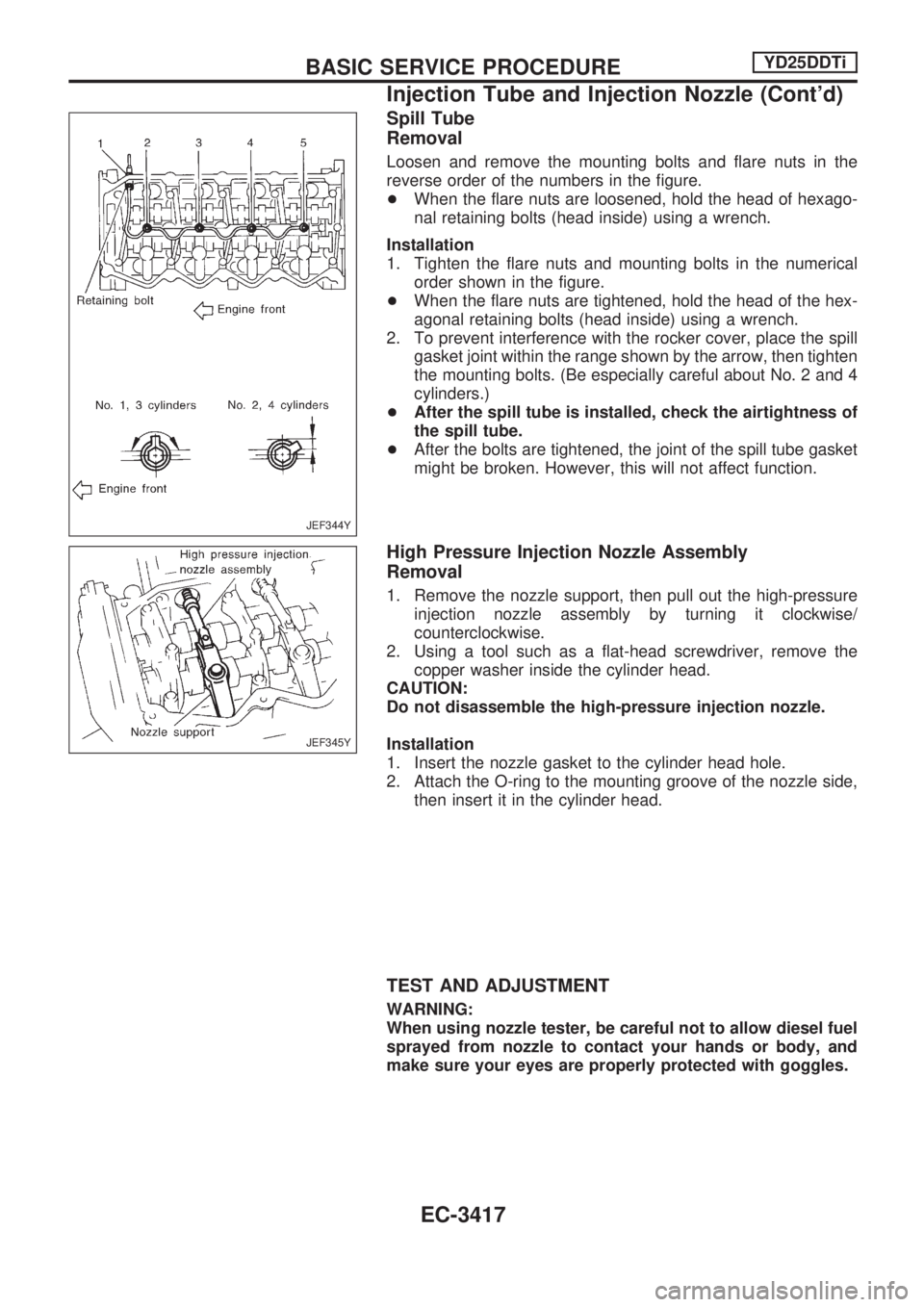

Spill Tube

Removal

Loosen and remove the mounting bolts and flare nuts in the

reverse order of the numbers in the figure.

+When the flare nuts are loosened, hold the head of hexago-

nal retaining bolts (head inside) using a wrench.

Installation

1. Tighten the flare nuts and mounting bolts in the numerical

order shown in the figure.

+When the flare nuts are tightened, hold the head of the hex-

agonal retaining bolts (head inside) using a wrench.

2. To prevent interference with the rocker cover, place the spill

gasket joint within the range shown by the arrow, then tighten

the mounting bolts. (Be especially careful about No. 2 and 4

cylinders.)

+After the spill tube is installed, check the airtightness of

the spill tube.

+After the bolts are tightened, the joint of the spill tube gasket

might be broken. However, this will not affect function.

High Pressure Injection Nozzle Assembly

Removal

1. Remove the nozzle support, then pull out the high-pressure

injection nozzle assembly by turning it clockwise/

counterclockwise.

2. Using a tool such as a flat-head screwdriver, remove the

copper washer inside the cylinder head.

CAUTION:

Do not disassemble the high-pressure injection nozzle.

Installation

1. Insert the nozzle gasket to the cylinder head hole.

2. Attach the O-ring to the mounting groove of the nozzle side,

then insert it in the cylinder head.

TEST AND ADJUSTMENT

WARNING:

When using nozzle tester, be careful not to allow diesel fuel

sprayed from nozzle to contact your hands or body, and

make sure your eyes are properly protected with goggles.

JEF344Y

JEF345Y

BASIC SERVICE PROCEDUREYD25DDTi

Injection Tube and Injection Nozzle (Cont'd)

EC-3417

Page 443 of 1306

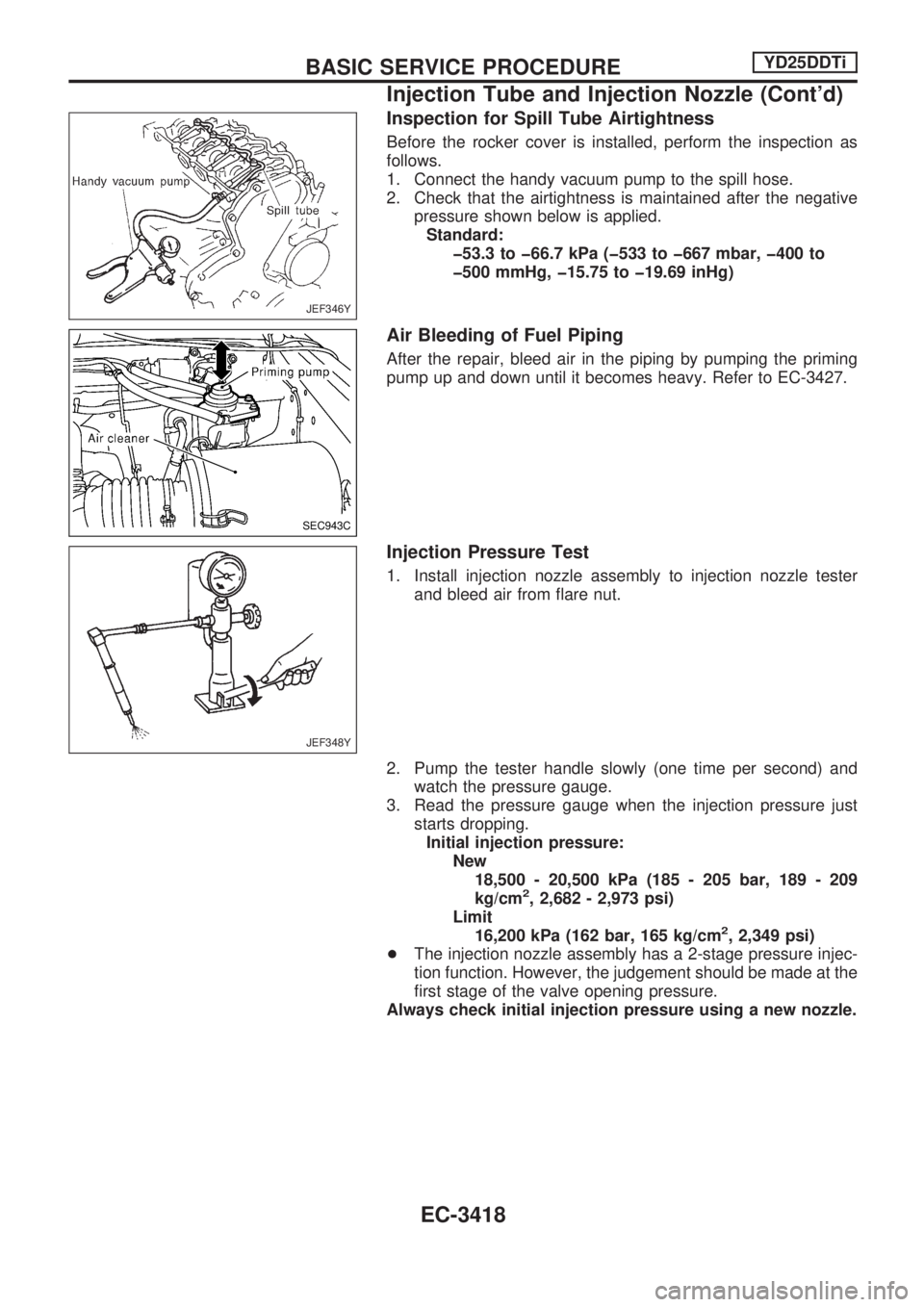

Inspection for Spill Tube Airtightness

Before the rocker cover is installed, perform the inspection as

follows.

1. Connect the handy vacuum pump to the spill hose.

2. Check that the airtightness is maintained after the negative

pressure shown below is applied.

Standard:

þ53.3 to þ66.7 kPa (þ533 to þ667 mbar, þ400 to

þ500 mmHg, þ15.75 to þ19.69 inHg)

Air Bleeding of Fuel Piping

After the repair, bleed air in the piping by pumping the priming

pump up and down until it becomes heavy. Refer to EC-3427.

Injection Pressure Test

1. Install injection nozzle assembly to injection nozzle tester

and bleed air from flare nut.

2. Pump the tester handle slowly (one time per second) and

watch the pressure gauge.

3. Read the pressure gauge when the injection pressure just

starts dropping.

Initial injection pressure:

New

18,500 - 20,500 kPa (185 - 205 bar, 189 - 209

kg/cm

2, 2,682 - 2,973 psi)

Limit

16,200 kPa (162 bar, 165 kg/cm

2, 2,349 psi)

+The injection nozzle assembly has a 2-stage pressure injec-

tion function. However, the judgement should be made at the

first stage of the valve opening pressure.

Always check initial injection pressure using a new nozzle.

JEF346Y

SEC943C

JEF348Y

BASIC SERVICE PROCEDUREYD25DDTi

Injection Tube and Injection Nozzle (Cont'd)

EC-3418

Page 444 of 1306

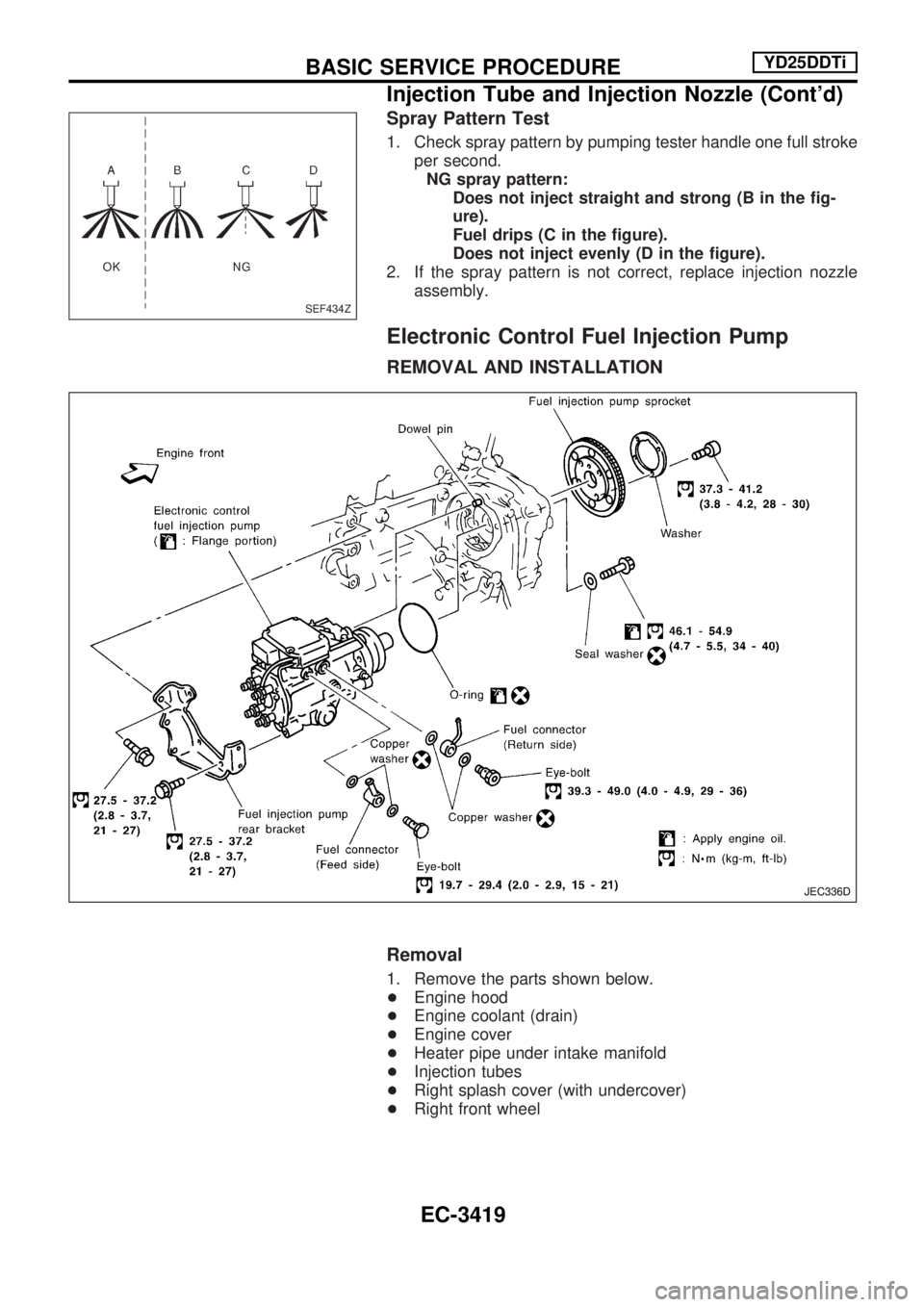

Spray Pattern Test

1. Check spray pattern by pumping tester handle one full stroke

per second.

NG spray pattern:

Does not inject straight and strong (B in the fig-

ure).

Fuel drips (C in the figure).

Does not inject evenly (D in the figure).

2. If the spray pattern is not correct, replace injection nozzle

assembly.

Electronic Control Fuel Injection Pump

REMOVAL AND INSTALLATION

Removal

1. Remove the parts shown below.

+Engine hood

+Engine coolant (drain)

+Engine cover

+Heater pipe under intake manifold

+Injection tubes

+Right splash cover (with undercover)

+Right front wheel

SEF434Z

JEC336D

BASIC SERVICE PROCEDUREYD25DDTi

Injection Tube and Injection Nozzle (Cont'd)

EC-3419

Page 445 of 1306

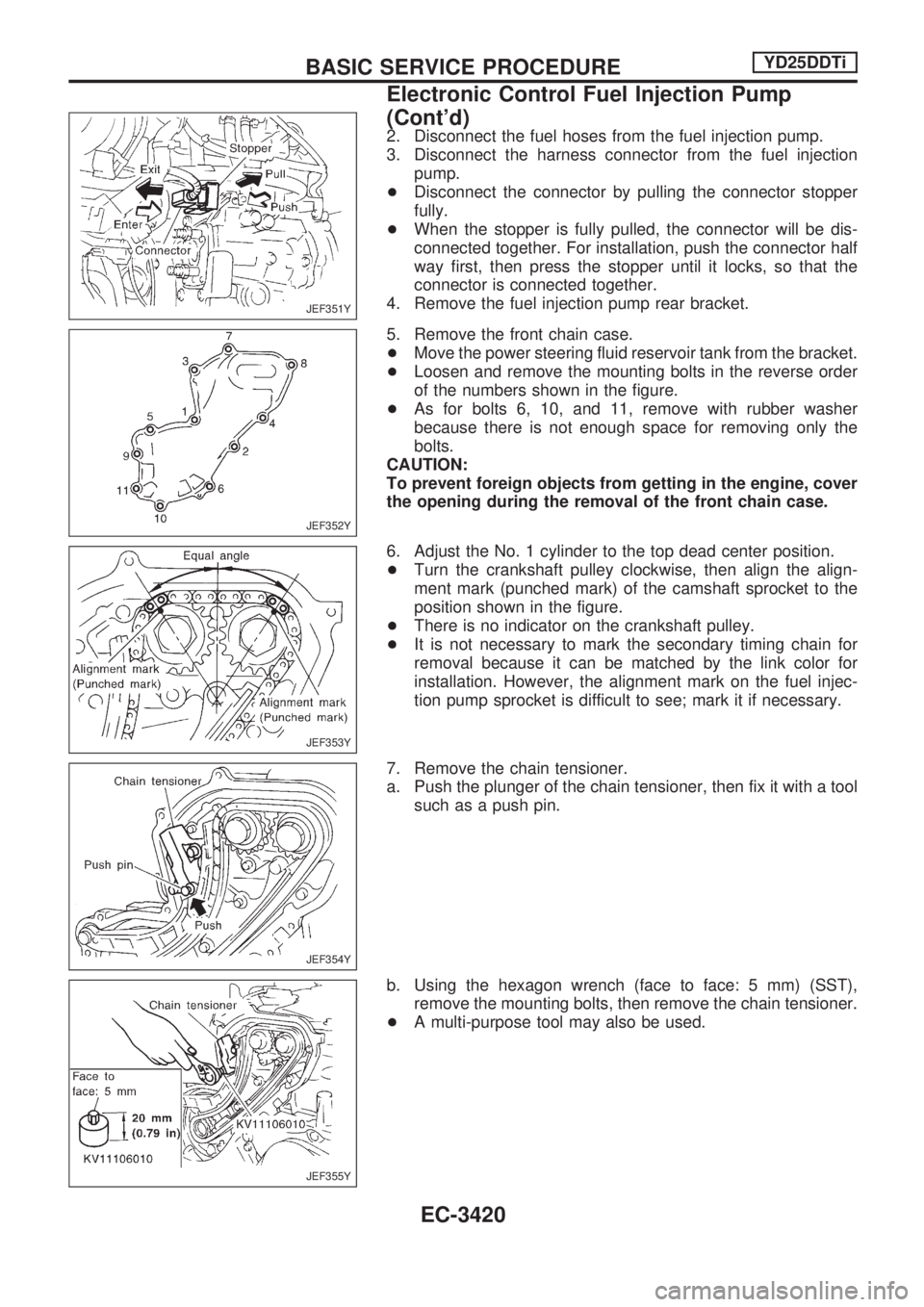

2. Disconnect the fuel hoses from the fuel injection pump.

3. Disconnect the harness connector from the fuel injection

pump.

+Disconnect the connector by pulling the connector stopper

fully.

+When the stopper is fully pulled, the connector will be dis-

connected together. For installation, push the connector half

way first, then press the stopper until it locks, so that the

connector is connected together.

4. Remove the fuel injection pump rear bracket.

5. Remove the front chain case.

+Move the power steering fluid reservoir tank from the bracket.

+Loosen and remove the mounting bolts in the reverse order

of the numbers shown in the figure.

+As for bolts 6, 10, and 11, remove with rubber washer

because there is not enough space for removing only the

bolts.

CAUTION:

To prevent foreign objects from getting in the engine, cover

the opening during the removal of the front chain case.

6. Adjust the No. 1 cylinder to the top dead center position.

+Turn the crankshaft pulley clockwise, then align the align-

ment mark (punched mark) of the camshaft sprocket to the

position shown in the figure.

+There is no indicator on the crankshaft pulley.

+It is not necessary to mark the secondary timing chain for

removal because it can be matched by the link color for

installation. However, the alignment mark on the fuel injec-

tion pump sprocket is difficult to see; mark it if necessary.

7. Remove the chain tensioner.

a. Push the plunger of the chain tensioner, then fix it with a tool

such as a push pin.

b. Using the hexagon wrench (face to face: 5 mm) (SST),

remove the mounting bolts, then remove the chain tensioner.

+A multi-purpose tool may also be used.

JEF351Y

JEF352Y

JEF353Y

JEF354Y

JEF355Y

BASIC SERVICE PROCEDUREYD25DDTi

Electronic Control Fuel Injection Pump

(Cont'd)

EC-3420

Page 446 of 1306

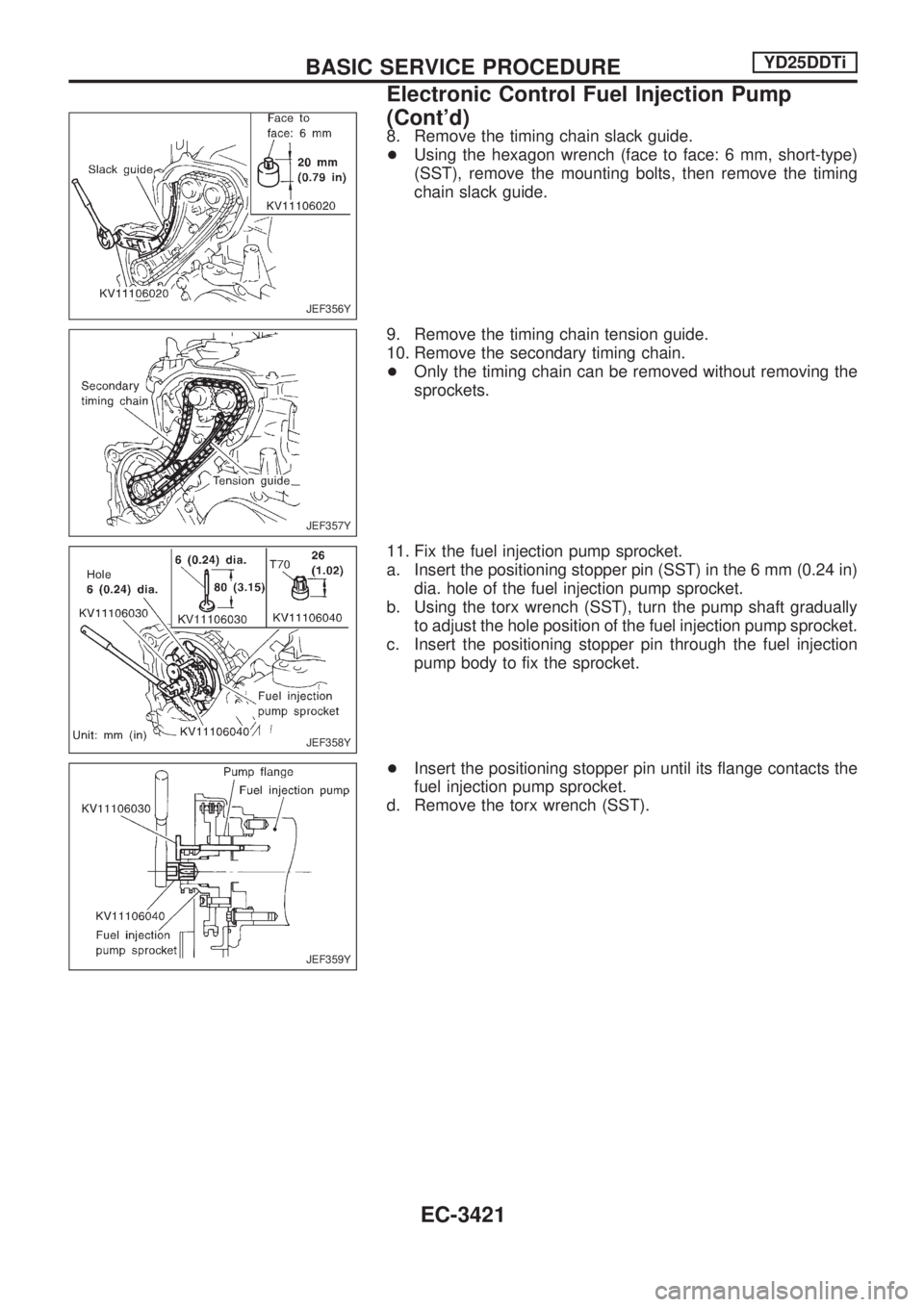

8. Remove the timing chain slack guide.

+Using the hexagon wrench (face to face: 6 mm, short-type)

(SST), remove the mounting bolts, then remove the timing

chain slack guide.

9. Remove the timing chain tension guide.

10. Remove the secondary timing chain.

+Only the timing chain can be removed without removing the

sprockets.

11. Fix the fuel injection pump sprocket.

a. Insert the positioning stopper pin (SST) in the 6 mm (0.24 in)

dia. hole of the fuel injection pump sprocket.

b. Using the torx wrench (SST), turn the pump shaft gradually

to adjust the hole position of the fuel injection pump sprocket.

c. Insert the positioning stopper pin through the fuel injection

pump body to fix the sprocket.

+Insert the positioning stopper pin until its flange contacts the

fuel injection pump sprocket.

d. Remove the torx wrench (SST).

JEF356Y

JEF357Y

JEF358Y

JEF359Y

BASIC SERVICE PROCEDUREYD25DDTi

Electronic Control Fuel Injection Pump

(Cont'd)

EC-3421

Page 447 of 1306

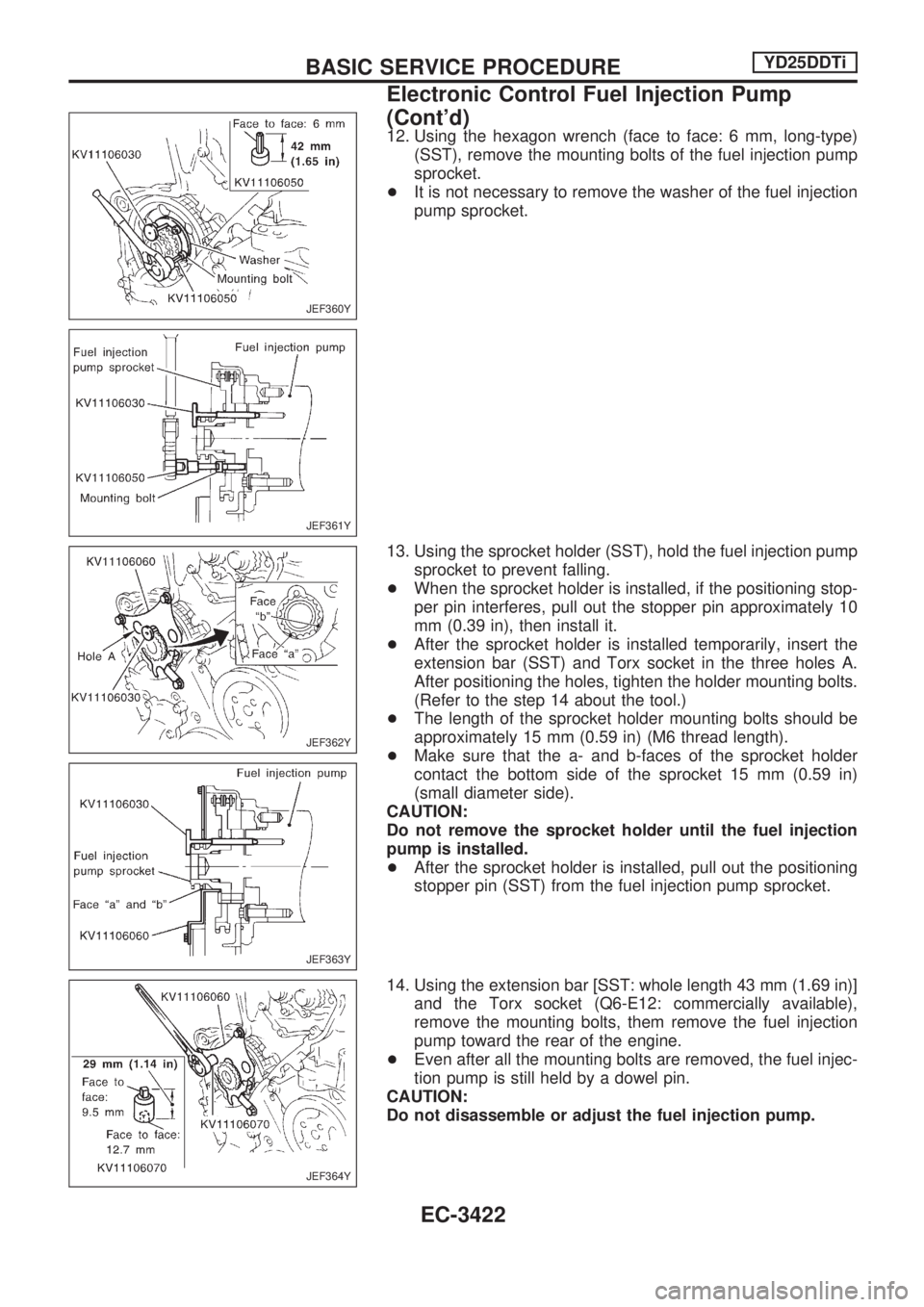

12. Using the hexagon wrench (face to face: 6 mm, long-type)

(SST), remove the mounting bolts of the fuel injection pump

sprocket.

+It is not necessary to remove the washer of the fuel injection

pump sprocket.

13. Using the sprocket holder (SST), hold the fuel injection pump

sprocket to prevent falling.

+When the sprocket holder is installed, if the positioning stop-

per pin interferes, pull out the stopper pin approximately 10

mm (0.39 in), then install it.

+After the sprocket holder is installed temporarily, insert the

extension bar (SST) and Torx socket in the three holes A.

After positioning the holes, tighten the holder mounting bolts.

(Refer to the step 14 about the tool.)

+The length of the sprocket holder mounting bolts should be

approximately 15 mm (0.59 in) (M6 thread length).

+Make sure that the a- and b-faces of the sprocket holder

contact the bottom side of the sprocket 15 mm (0.59 in)

(small diameter side).

CAUTION:

Do not remove the sprocket holder until the fuel injection

pump is installed.

+After the sprocket holder is installed, pull out the positioning

stopper pin (SST) from the fuel injection pump sprocket.

14. Using the extension bar [SST: whole length 43 mm (1.69 in)]

and the Torx socket (Q6-E12: commercially available),

remove the mounting bolts, them remove the fuel injection

pump toward the rear of the engine.

+Even after all the mounting bolts are removed, the fuel injec-

tion pump is still held by a dowel pin.

CAUTION:

Do not disassemble or adjust the fuel injection pump.

JEF360Y

JEF361Y

JEF362Y

JEF363Y

JEF364Y

BASIC SERVICE PROCEDUREYD25DDTi

Electronic Control Fuel Injection Pump

(Cont'd)

EC-3422

Page 448 of 1306

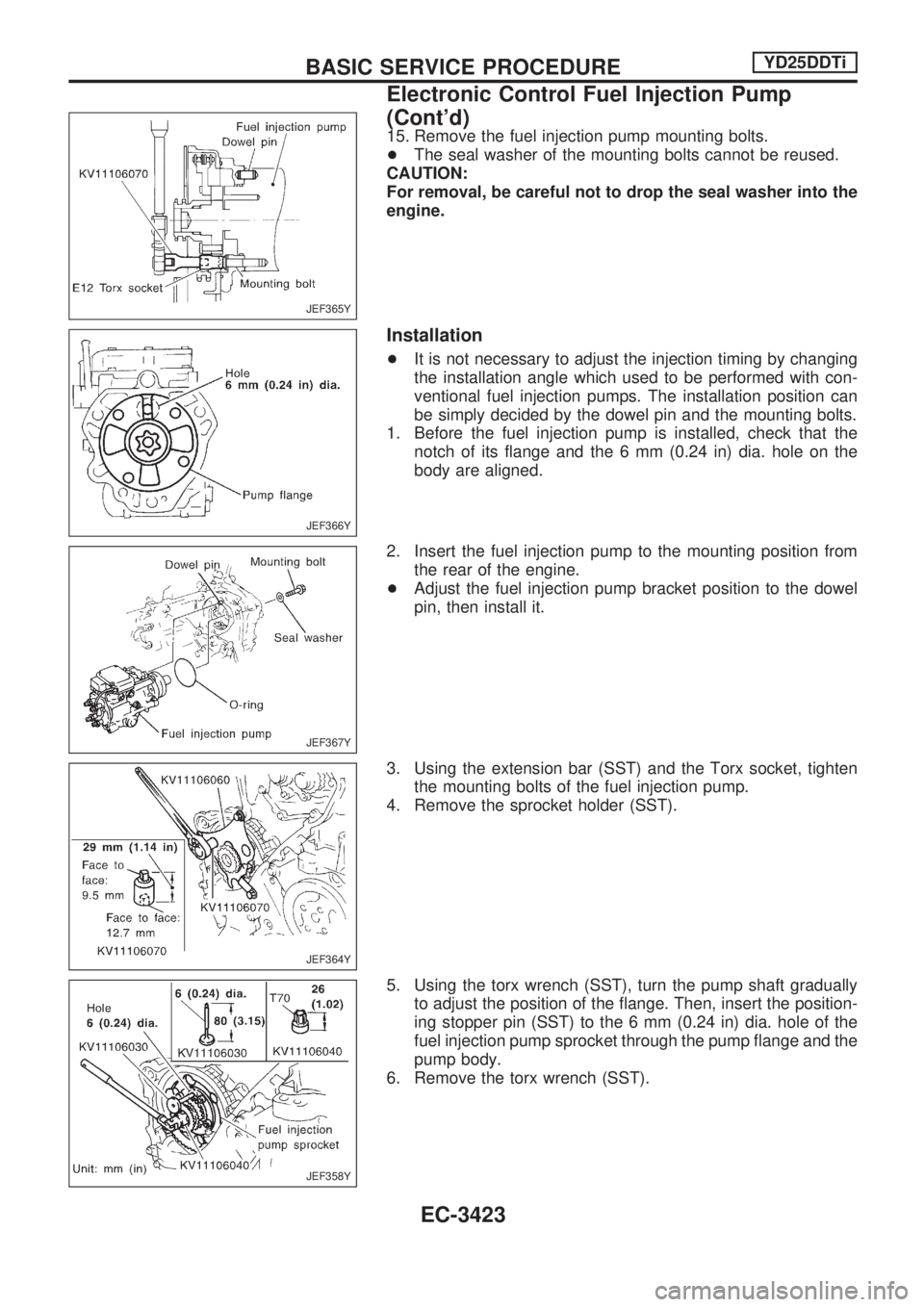

15. Remove the fuel injection pump mounting bolts.

+The seal washer of the mounting bolts cannot be reused.

CAUTION:

For removal, be careful not to drop the seal washer into the

engine.

Installation

+It is not necessary to adjust the injection timing by changing

the installation angle which used to be performed with con-

ventional fuel injection pumps. The installation position can

be simply decided by the dowel pin and the mounting bolts.

1. Before the fuel injection pump is installed, check that the

notch of its flange and the 6 mm (0.24 in) dia. hole on the

body are aligned.

2. Insert the fuel injection pump to the mounting position from

the rear of the engine.

+Adjust the fuel injection pump bracket position to the dowel

pin, then install it.

3. Using the extension bar (SST) and the Torx socket, tighten

the mounting bolts of the fuel injection pump.

4. Remove the sprocket holder (SST).

5. Using the torx wrench (SST), turn the pump shaft gradually

to adjust the position of the flange. Then, insert the position-

ing stopper pin (SST) to the 6 mm (0.24 in) dia. hole of the

fuel injection pump sprocket through the pump flange and the

pump body.

6. Remove the torx wrench (SST).

JEF365Y

JEF366Y

JEF367Y

JEF364Y

JEF358Y

BASIC SERVICE PROCEDUREYD25DDTi

Electronic Control Fuel Injection Pump

(Cont'd)

EC-3423

Page 449 of 1306

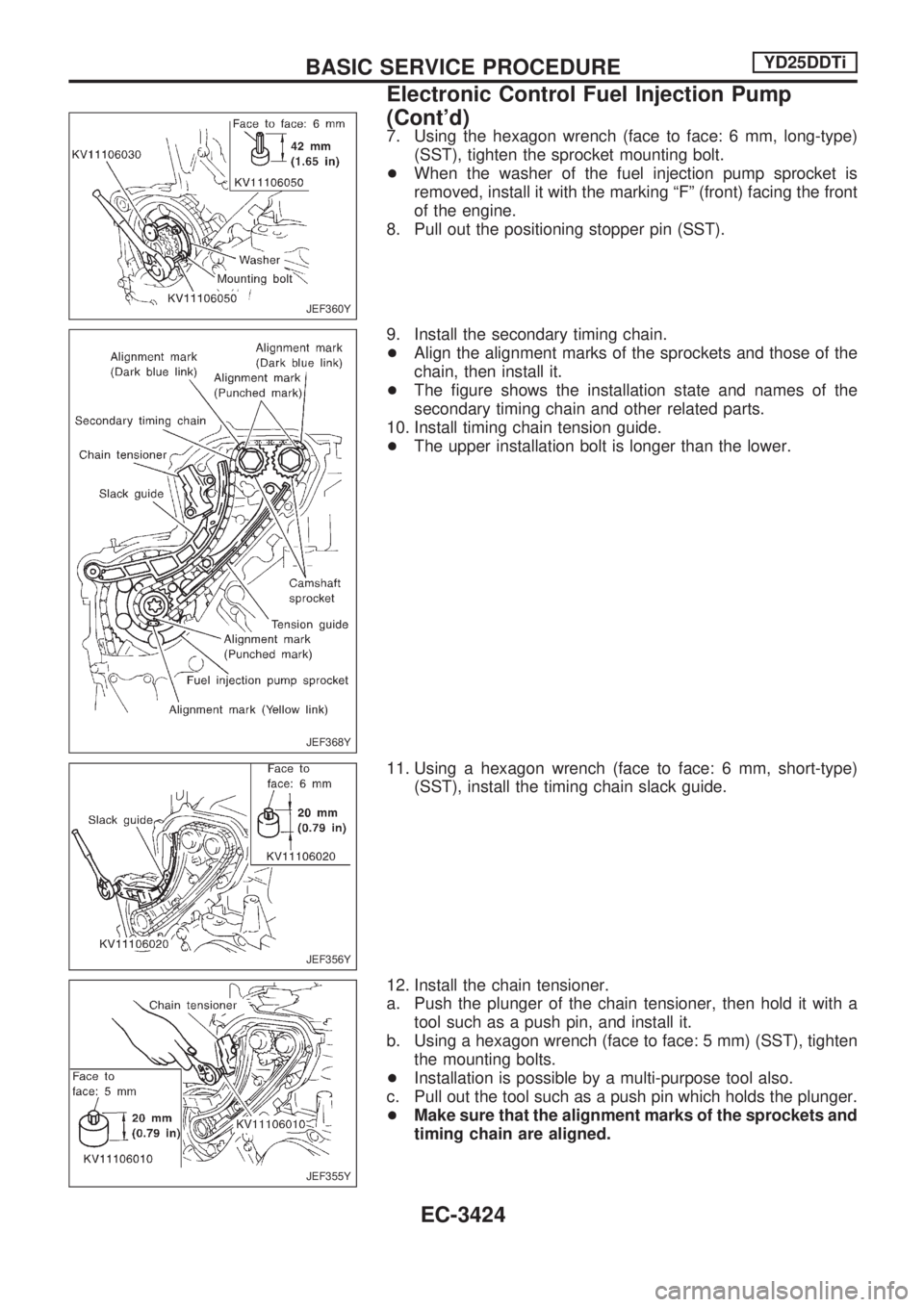

7. Using the hexagon wrench (face to face: 6 mm, long-type)

(SST), tighten the sprocket mounting bolt.

+When the washer of the fuel injection pump sprocket is

removed, install it with the marking ªFº (front) facing the front

of the engine.

8. Pull out the positioning stopper pin (SST).

9. Install the secondary timing chain.

+Align the alignment marks of the sprockets and those of the

chain, then install it.

+The figure shows the installation state and names of the

secondary timing chain and other related parts.

10. Install timing chain tension guide.

+The upper installation bolt is longer than the lower.

11. Using a hexagon wrench (face to face: 6 mm, short-type)

(SST), install the timing chain slack guide.

12. Install the chain tensioner.

a. Push the plunger of the chain tensioner, then hold it with a

tool such as a push pin, and install it.

b. Using a hexagon wrench (face to face: 5 mm) (SST), tighten

the mounting bolts.

+Installation is possible by a multi-purpose tool also.

c. Pull out the tool such as a push pin which holds the plunger.

+Make sure that the alignment marks of the sprockets and

timing chain are aligned.

JEF360Y

JEF368Y

JEF356Y

JEF355Y

BASIC SERVICE PROCEDUREYD25DDTi

Electronic Control Fuel Injection Pump

(Cont'd)

EC-3424

Page 450 of 1306

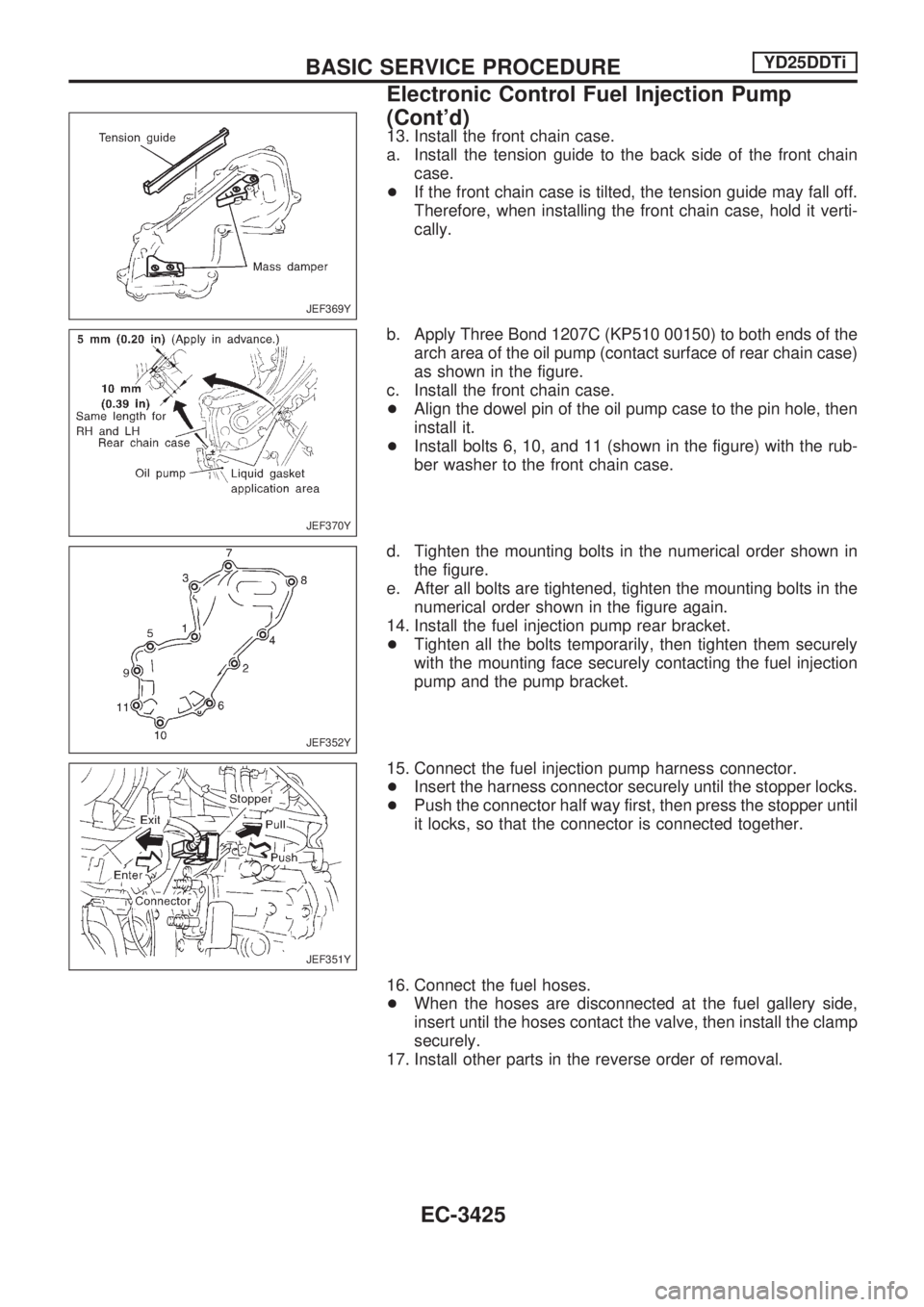

13. Install the front chain case.

a. Install the tension guide to the back side of the front chain

case.

+If the front chain case is tilted, the tension guide may fall off.

Therefore, when installing the front chain case, hold it verti-

cally.

b. Apply Three Bond 1207C (KP510 00150) to both ends of the

arch area of the oil pump (contact surface of rear chain case)

as shown in the figure.

c. Install the front chain case.

+Align the dowel pin of the oil pump case to the pin hole, then

install it.

+Install bolts 6, 10, and 11 (shown in the figure) with the rub-

ber washer to the front chain case.

d. Tighten the mounting bolts in the numerical order shown in

the figure.

e. After all bolts are tightened, tighten the mounting bolts in the

numerical order shown in the figure again.

14. Install the fuel injection pump rear bracket.

+Tighten all the bolts temporarily, then tighten them securely

with the mounting face securely contacting the fuel injection

pump and the pump bracket.

15. Connect the fuel injection pump harness connector.

+Insert the harness connector securely until the stopper locks.

+Push the connector half way first, then press the stopper until

it locks, so that the connector is connected together.

16. Connect the fuel hoses.

+When the hoses are disconnected at the fuel gallery side,

insert until the hoses contact the valve, then install the clamp

securely.

17. Install other parts in the reverse order of removal.

JEF369Y

JEF370Y

JEF352Y

JEF351Y

BASIC SERVICE PROCEDUREYD25DDTi

Electronic Control Fuel Injection Pump

(Cont'd)

EC-3425