NISSAN PICK-UP 2001 Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: PICK-UP, Model: NISSAN PICK-UP 2001Pages: 1306, PDF Size: 31.7 MB

Page 531 of 1306

Diagnostic Procedure

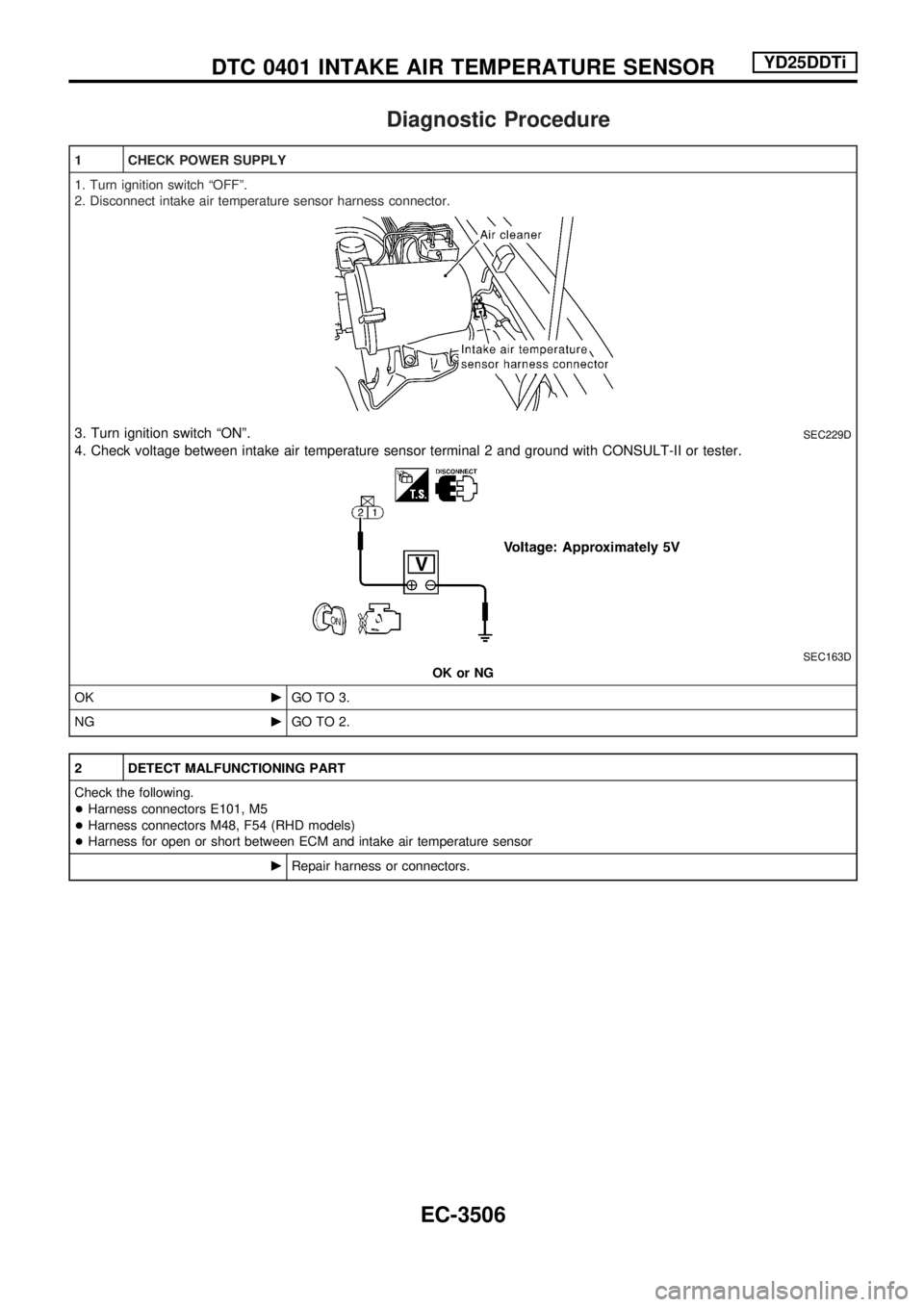

1 CHECK POWER SUPPLY

1. Turn ignition switch ªOFFº.

2. Disconnect intake air temperature sensor harness connector.

SEC229D3. Turn ignition switch ªONº.

4. Check voltage between intake air temperature sensor terminal 2 and ground with CONSULT-II or tester.

SEC163D

OK or NG

OKcGO TO 3.

NGcGO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E101, M5

+Harness connectors M48, F54 (RHD models)

+Harness for open or short between ECM and intake air temperature sensor

cRepair harness or connectors.

DTC 0401 INTAKE AIR TEMPERATURE SENSORYD25DDTi

EC-3506

Page 532 of 1306

3 CHECK GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between terminal 1 and engine ground.

Continuity should exist.

3. Also check harness for short to power.

OK or NG

OKcGO TO 5.

NGcGO TO 4.

4 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E101, M5

+Harness connectors M48, F54 (RHD models)

+Harness for open or short between ECM and intake air temperature sensor

cRepair open circuit or short to power in harness or connectors.

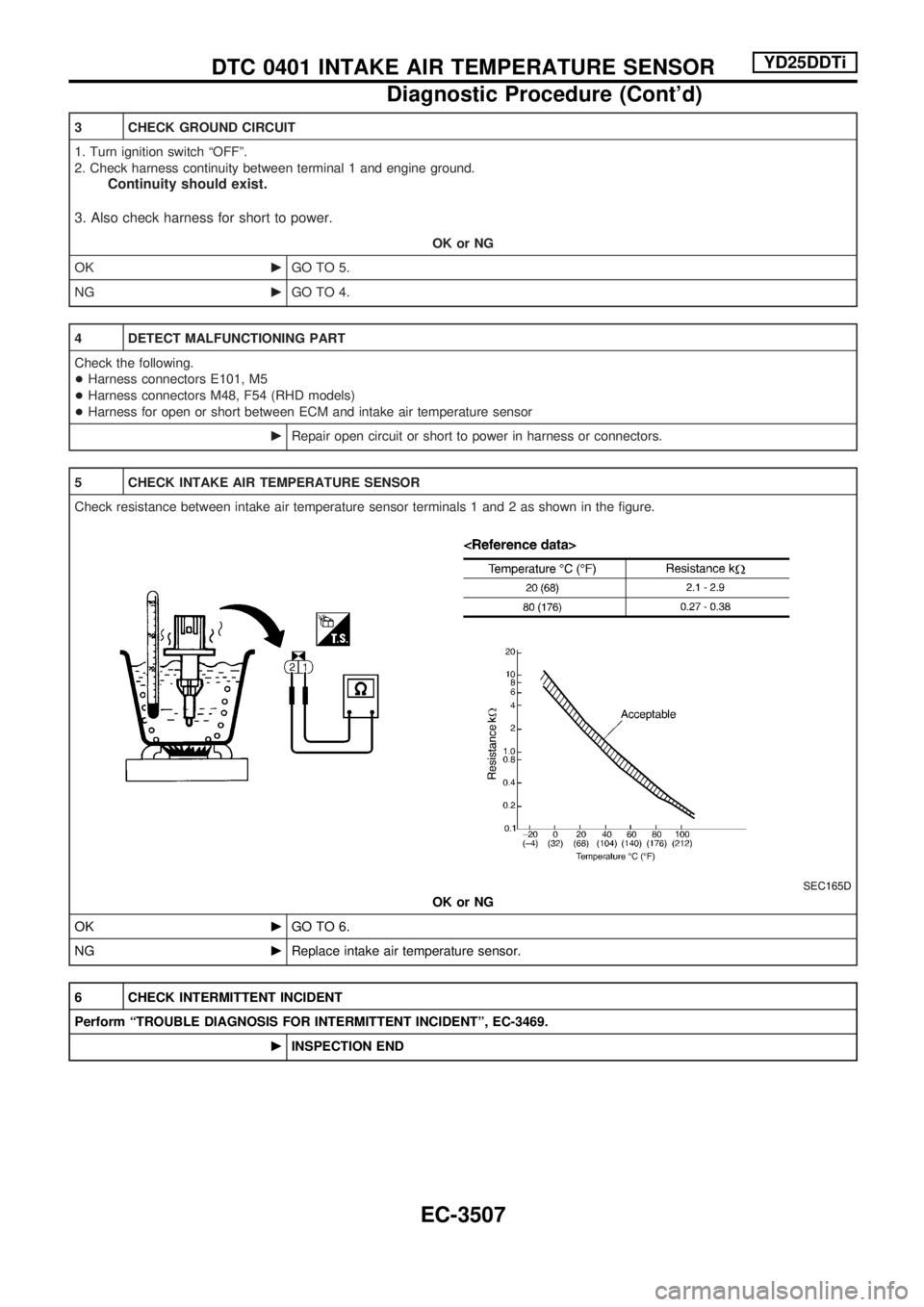

5 CHECK INTAKE AIR TEMPERATURE SENSOR

Check resistance between intake air temperature sensor terminals 1 and 2 as shown in the figure.

SEC165D

OK or NG

OKcGO TO 6.

NGcReplace intake air temperature sensor.

6 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-3469.

cINSPECTION END

DTC 0401 INTAKE AIR TEMPERATURE SENSORYD25DDTi

Diagnostic Procedure (Cont'd)

EC-3507

Page 533 of 1306

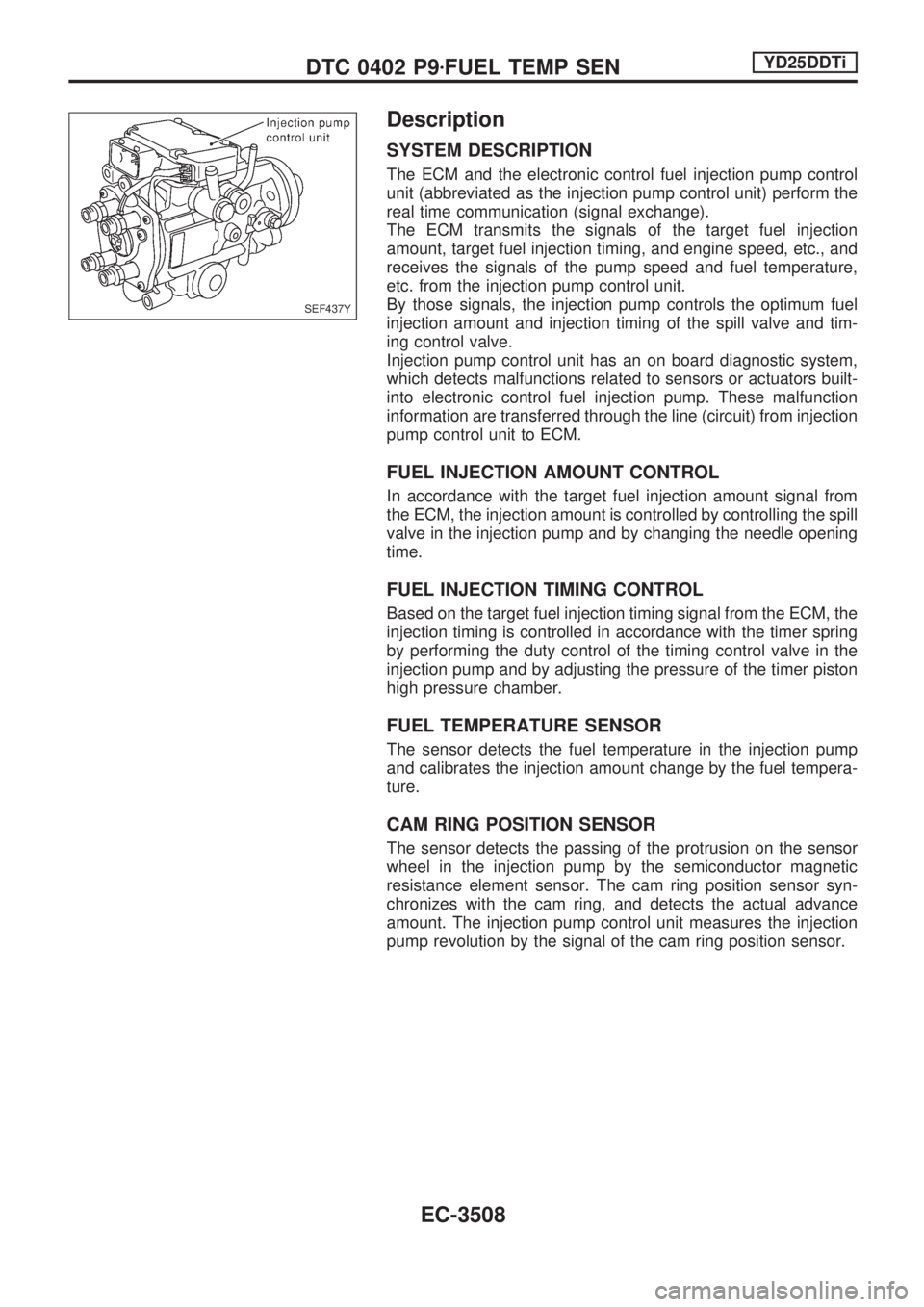

Description

SYSTEM DESCRIPTION

The ECM and the electronic control fuel injection pump control

unit (abbreviated as the injection pump control unit) perform the

real time communication (signal exchange).

The ECM transmits the signals of the target fuel injection

amount, target fuel injection timing, and engine speed, etc., and

receives the signals of the pump speed and fuel temperature,

etc. from the injection pump control unit.

By those signals, the injection pump controls the optimum fuel

injection amount and injection timing of the spill valve and tim-

ing control valve.

Injection pump control unit has an on board diagnostic system,

which detects malfunctions related to sensors or actuators built-

into electronic control fuel injection pump. These malfunction

information are transferred through the line (circuit) from injection

pump control unit to ECM.

FUEL INJECTION AMOUNT CONTROL

In accordance with the target fuel injection amount signal from

the ECM, the injection amount is controlled by controlling the spill

valve in the injection pump and by changing the needle opening

time.

FUEL INJECTION TIMING CONTROL

Based on the target fuel injection timing signal from the ECM, the

injection timing is controlled in accordance with the timer spring

by performing the duty control of the timing control valve in the

injection pump and by adjusting the pressure of the timer piston

high pressure chamber.

FUEL TEMPERATURE SENSOR

The sensor detects the fuel temperature in the injection pump

and calibrates the injection amount change by the fuel tempera-

ture.

CAM RING POSITION SENSOR

The sensor detects the passing of the protrusion on the sensor

wheel in the injection pump by the semiconductor magnetic

resistance element sensor. The cam ring position sensor syn-

chronizes with the cam ring, and detects the actual advance

amount. The injection pump control unit measures the injection

pump revolution by the signal of the cam ring position sensor.

SEF437Y

DTC 0402 P9zFUEL TEMP SENYD25DDTi

EC-3508

Page 534 of 1306

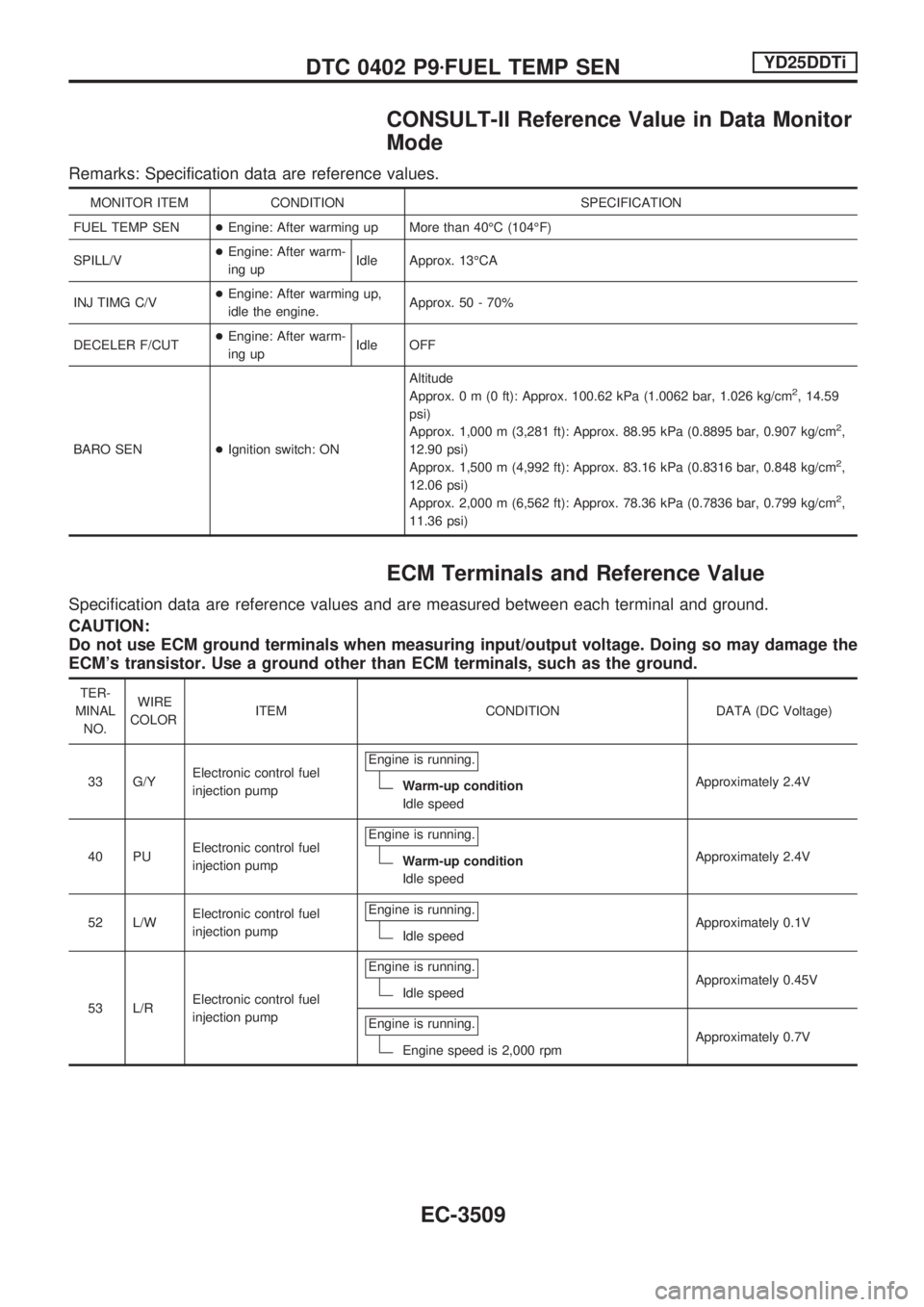

CONSULT-II Reference Value in Data Monitor

Mode

Remarks: Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

FUEL TEMP SEN+Engine: After warming up More than 40ÉC (104ÉF)

SPILL/V+Engine: After warm-

ing upIdle Approx. 13ÉCA

INJ TIMG C/V+Engine: After warming up,

idle the engine.Approx. 50 - 70%

DECELER F/CUT+Engine: After warm-

ing upIdle OFF

BARO SEN+Ignition switch: ONAltitude

Approx.0m(0ft): Approx. 100.62 kPa (1.0062 bar, 1.026 kg/cm

2, 14.59

psi)

Approx. 1,000 m (3,281 ft): Approx. 88.95 kPa (0.8895 bar, 0.907 kg/cm

2,

12.90 psi)

Approx. 1,500 m (4,992 ft): Approx. 83.16 kPa (0.8316 bar, 0.848 kg/cm

2,

12.06 psi)

Approx. 2,000 m (6,562 ft): Approx. 78.36 kPa (0.7836 bar, 0.799 kg/cm

2,

11.36 psi)

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

33 G/YElectronic control fuel

injection pumpEngine is running.

Warm-up condition

Idle speedApproximately 2.4V

40 PUElectronic control fuel

injection pumpEngine is running.

Warm-up condition

Idle speedApproximately 2.4V

52 L/WElectronic control fuel

injection pumpEngine is running.

Idle speedApproximately 0.1V

53 L/RElectronic control fuel

injection pumpEngine is running.

Idle speedApproximately 0.45V

Engine is running.

Engine speed is 2,000 rpmApproximately 0.7V

DTC 0402 P9zFUEL TEMP SENYD25DDTi

EC-3509

Page 535 of 1306

On Board Diagnosis Logic

Malfunction is detected when .... Check Items (Possible cause)

+An improper voltage signal from fuel temperature sensor

(Built-into electronic control fuel injection pump) is sent to

injection pump control unit.+Harness or connectors

(Electronic control fuel injection pump circuit is open or

shorted.)

+Electronic control fuel injection pump

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº and wait at least 2 seconds.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and run it for at least 2 seconds at idle speed.

(If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-3514.

WITHOUT CONSULT-II

1) Turn ignition switch ªONº and wait at least 2 seconds.

2) Start engine and run it for at least 2 seconds at idle speed.

(If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º

with ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-3514.

SEF817Y

DTC 0402 P9zFUEL TEMP SENYD25DDTi

EC-3510

Page 536 of 1306

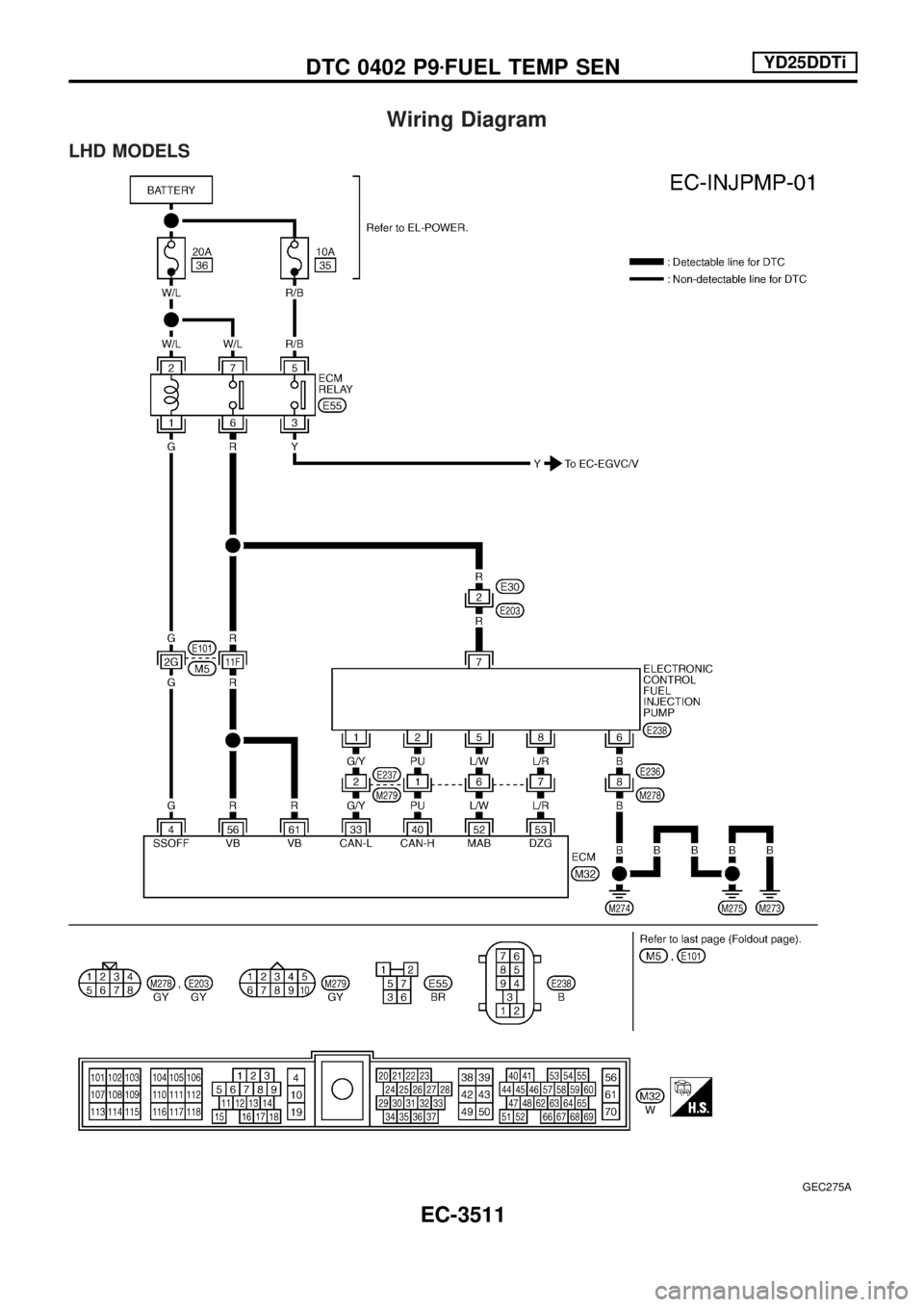

Wiring Diagram

LHD MODELS

GEC275A

DTC 0402 P9zFUEL TEMP SENYD25DDTi

EC-3511

Page 537 of 1306

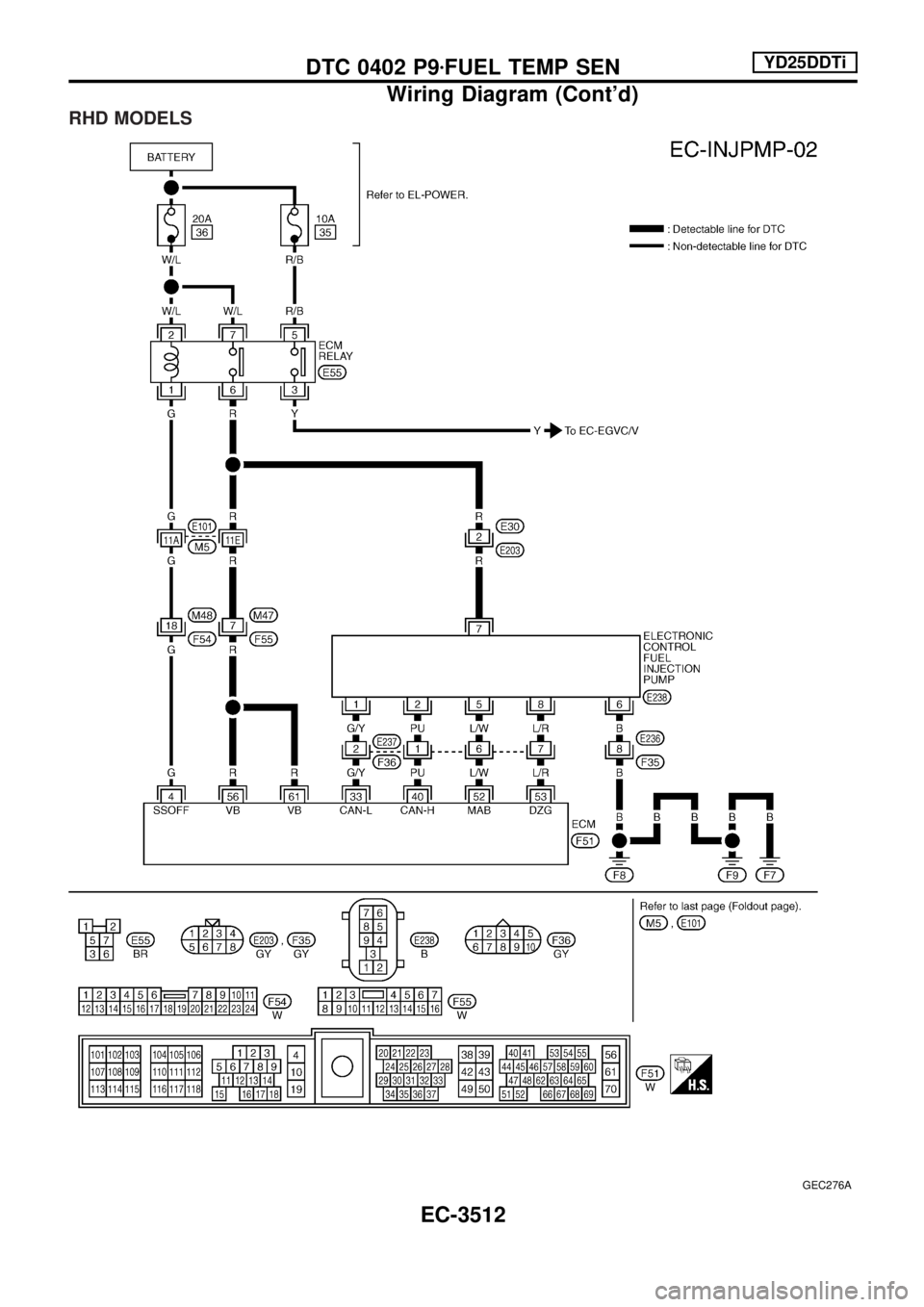

RHD MODELS

GEC276A

DTC 0402 P9zFUEL TEMP SENYD25DDTi

Wiring Diagram (Cont'd)

EC-3512

Page 538 of 1306

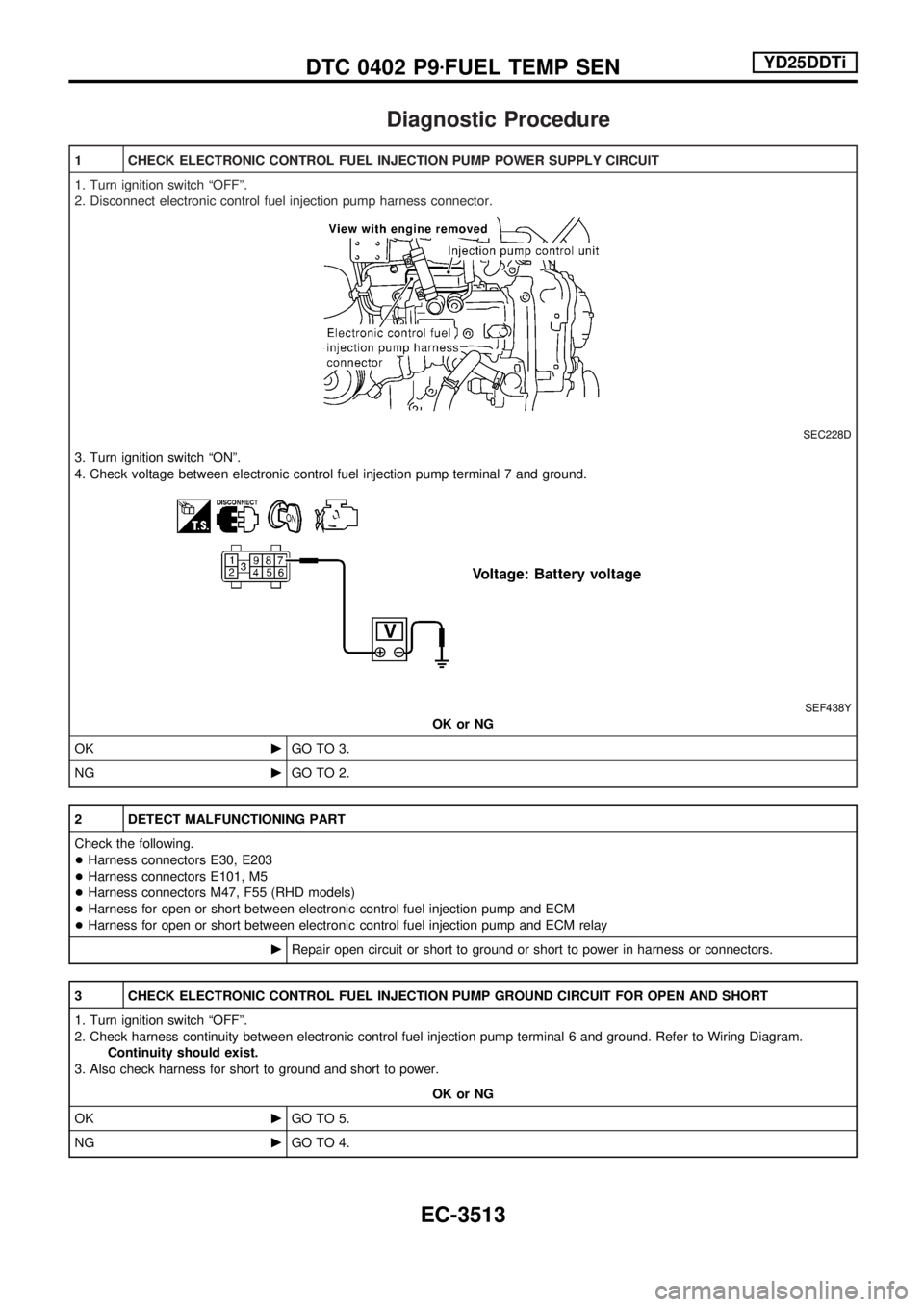

Diagnostic Procedure

1 CHECK ELECTRONIC CONTROL FUEL INJECTION PUMP POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect electronic control fuel injection pump harness connector.

SEC228D

3. Turn ignition switch ªONº.

4. Check voltage between electronic control fuel injection pump terminal 7 and ground.

SEF438Y

OK or NG

OKcGO TO 3.

NGcGO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E30, E203

+Harness connectors E101, M5

+Harness connectors M47, F55 (RHD models)

+Harness for open or short between electronic control fuel injection pump and ECM

+Harness for open or short between electronic control fuel injection pump and ECM relay

cRepair open circuit or short to ground or short to power in harness or connectors.

3 CHECK ELECTRONIC CONTROL FUEL INJECTION PUMP GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between electronic control fuel injection pump terminal 6 and ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 5.

NGcGO TO 4.

DTC 0402 P9zFUEL TEMP SENYD25DDTi

EC-3513

Page 539 of 1306

4 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E236, M278 (LHD models)

+Harness connectors E236, F35 (RHD models)

+Harness for open or short between electronic control fuel injection pump and engine ground

cRepair open circuit or short to ground or short to power in harness or connectors.

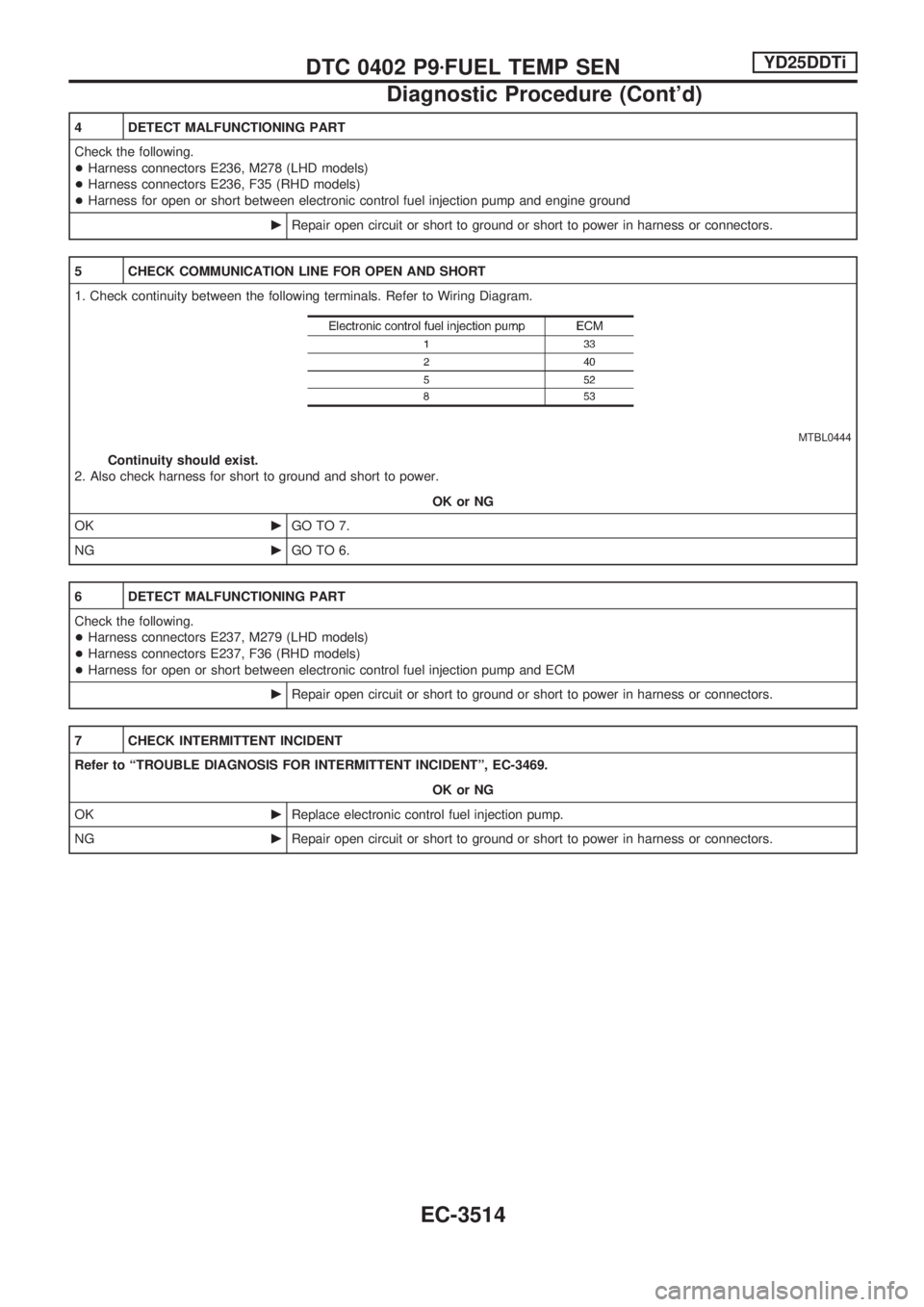

5 CHECK COMMUNICATION LINE FOR OPEN AND SHORT

1. Check continuity between the following terminals. Refer to Wiring Diagram.

MTBL0444

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 7.

NGcGO TO 6.

6 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E237, M279 (LHD models)

+Harness connectors E237, F36 (RHD models)

+Harness for open or short between electronic control fuel injection pump and ECM

cRepair open circuit or short to ground or short to power in harness or connectors.

7 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-3469.

OK or NG

OKcReplace electronic control fuel injection pump.

NGcRepair open circuit or short to ground or short to power in harness or connectors.

DTC 0402 P9zFUEL TEMP SENYD25DDTi

Diagnostic Procedure (Cont'd)

EC-3514

Page 540 of 1306

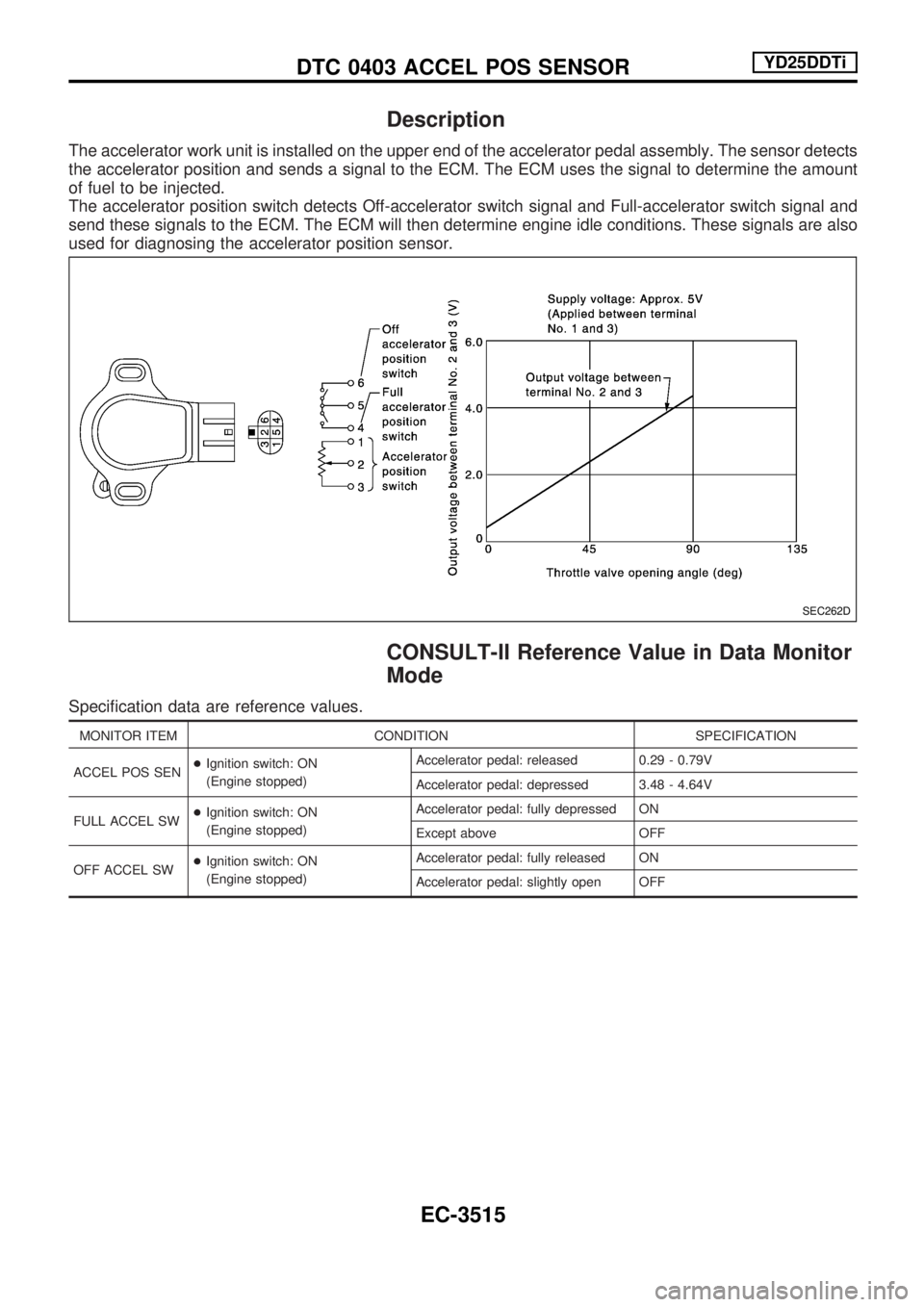

Description

The accelerator work unit is installed on the upper end of the accelerator pedal assembly. The sensor detects

the accelerator position and sends a signal to the ECM. The ECM uses the signal to determine the amount

of fuel to be injected.

The accelerator position switch detects Off-accelerator switch signal and Full-accelerator switch signal and

send these signals to the ECM. The ECM will then determine engine idle conditions. These signals are also

used for diagnosing the accelerator position sensor.

CONSULT-II Reference Value in Data Monitor

Mode

Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

ACCEL POS SEN+Ignition switch: ON

(Engine stopped)Accelerator pedal: released 0.29 - 0.79V

Accelerator pedal: depressed 3.48 - 4.64V

FULL ACCEL SW+Ignition switch: ON

(Engine stopped)Accelerator pedal: fully depressed ON

Except above OFF

OFF ACCEL SW+Ignition switch: ON

(Engine stopped)Accelerator pedal: fully released ON

Accelerator pedal: slightly open OFF

SEC262D

DTC 0403 ACCEL POS SENSORYD25DDTi

EC-3515