NISSAN PICK-UP 2001 Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: PICK-UP, Model: NISSAN PICK-UP 2001Pages: 1306, PDF Size: 31.7 MB

Page 521 of 1306

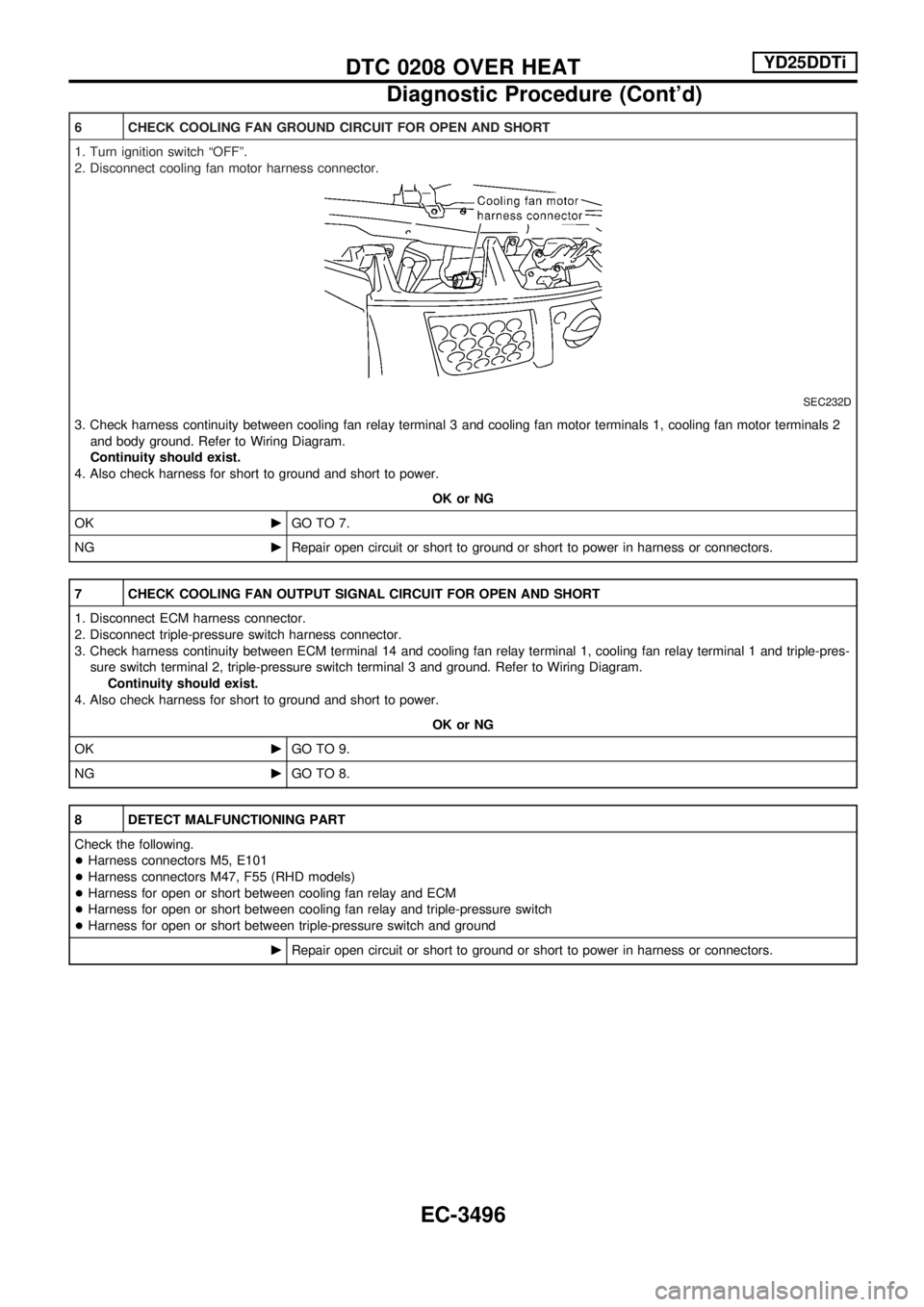

6 CHECK COOLING FAN GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect cooling fan motor harness connector.

SEC232D

3. Check harness continuity between cooling fan relay terminal 3 and cooling fan motor terminals 1, cooling fan motor terminals 2

and body ground. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 7.

NGcRepair open circuit or short to ground or short to power in harness or connectors.

7 CHECK COOLING FAN OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Disconnect triple-pressure switch harness connector.

3. Check harness continuity between ECM terminal 14 and cooling fan relay terminal 1, cooling fan relay terminal 1 and triple-pres-

sure switch terminal 2, triple-pressure switch terminal 3 and ground. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 9.

NGcGO TO 8.

8 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M5, E101

+Harness connectors M47, F55 (RHD models)

+Harness for open or short between cooling fan relay and ECM

+Harness for open or short between cooling fan relay and triple-pressure switch

+Harness for open or short between triple-pressure switch and ground

cRepair open circuit or short to ground or short to power in harness or connectors.

DTC 0208 OVER HEATYD25DDTi

Diagnostic Procedure (Cont'd)

EC-3496

Page 522 of 1306

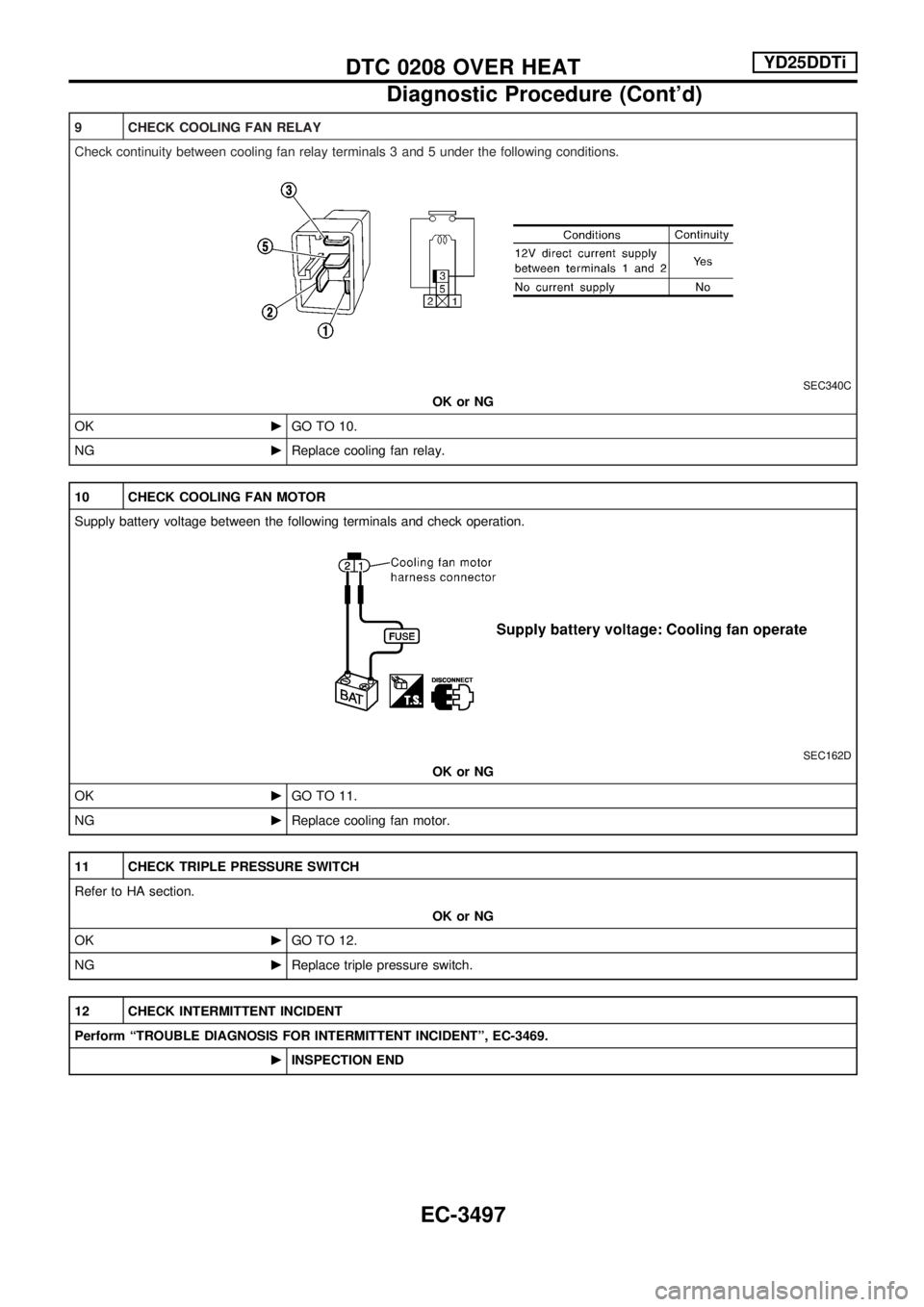

9 CHECK COOLING FAN RELAY

Check continuity between cooling fan relay terminals 3 and 5 under the following conditions.

SEC340C

OK or NG

OKcGO TO 10.

NGcReplace cooling fan relay.

10 CHECK COOLING FAN MOTOR

Supply battery voltage between the following terminals and check operation.

SEC162D

OK or NG

OKcGO TO 11.

NGcReplace cooling fan motor.

11 CHECK TRIPLE PRESSURE SWITCH

Refer to HA section.

OK or NG

OKcGO TO 12.

NGcReplace triple pressure switch.

12 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-3469.

cINSPECTION END

DTC 0208 OVER HEATYD25DDTi

Diagnostic Procedure (Cont'd)

EC-3497

Page 523 of 1306

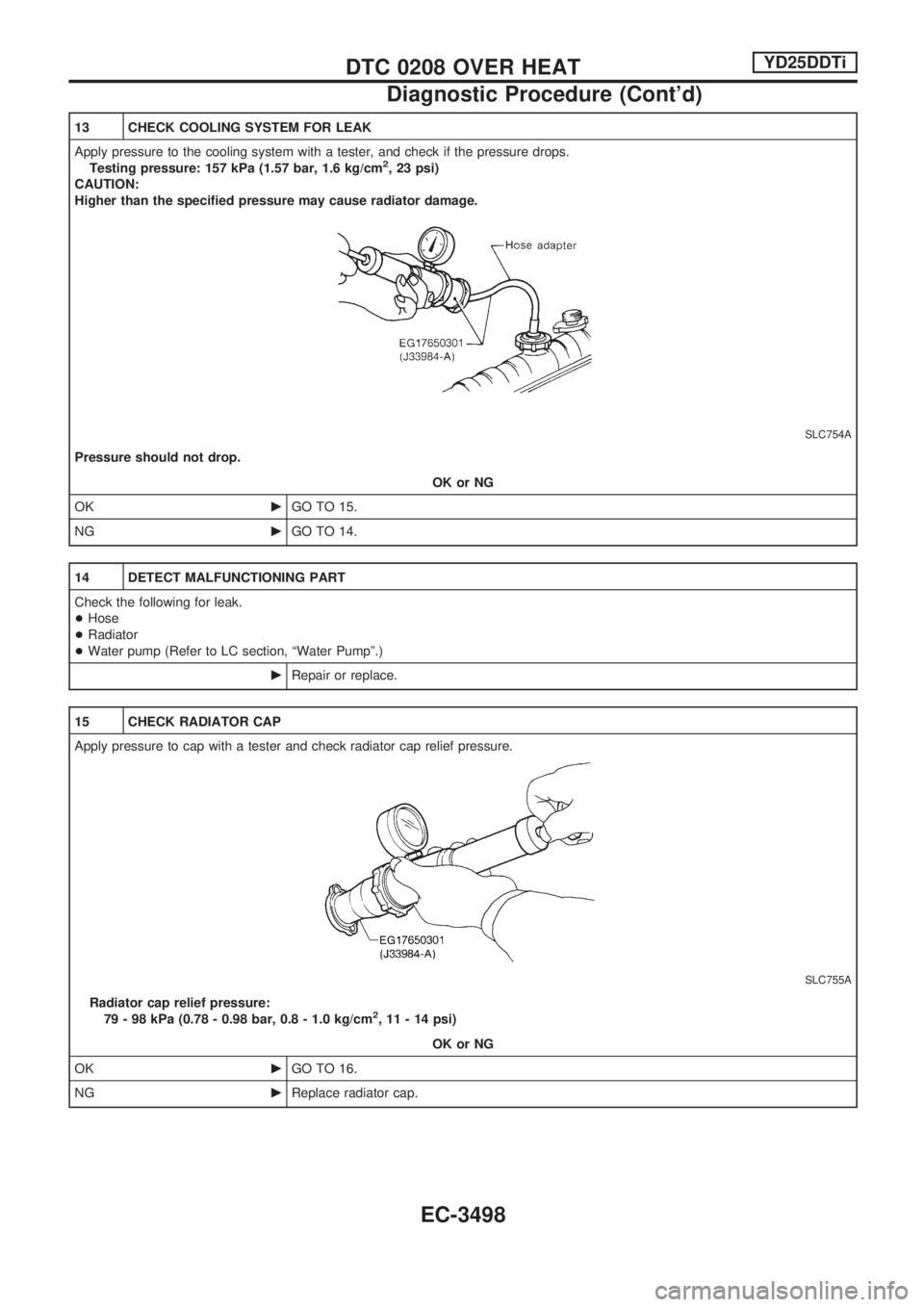

13 CHECK COOLING SYSTEM FOR LEAK

Apply pressure to the cooling system with a tester, and check if the pressure drops.

Testing pressure: 157 kPa (1.57 bar, 1.6 kg/cm

2, 23 psi)

CAUTION:

Higher than the specified pressure may cause radiator damage.

SLC754A

Pressure should not drop.

OK or NG

OKcGO TO 15.

NGcGO TO 14.

14 DETECT MALFUNCTIONING PART

Check the following for leak.

+Hose

+Radiator

+Water pump (Refer to LC section, ªWater Pumpº.)

cRepair or replace.

15 CHECK RADIATOR CAP

Apply pressure to cap with a tester and check radiator cap relief pressure.

SLC755A

Radiator cap relief pressure:

79 - 98 kPa (0.78 - 0.98 bar, 0.8 - 1.0 kg/cm2, 11 - 14 psi)

OK or NG

OKcGO TO 16.

NGcReplace radiator cap.

DTC 0208 OVER HEATYD25DDTi

Diagnostic Procedure (Cont'd)

EC-3498

Page 524 of 1306

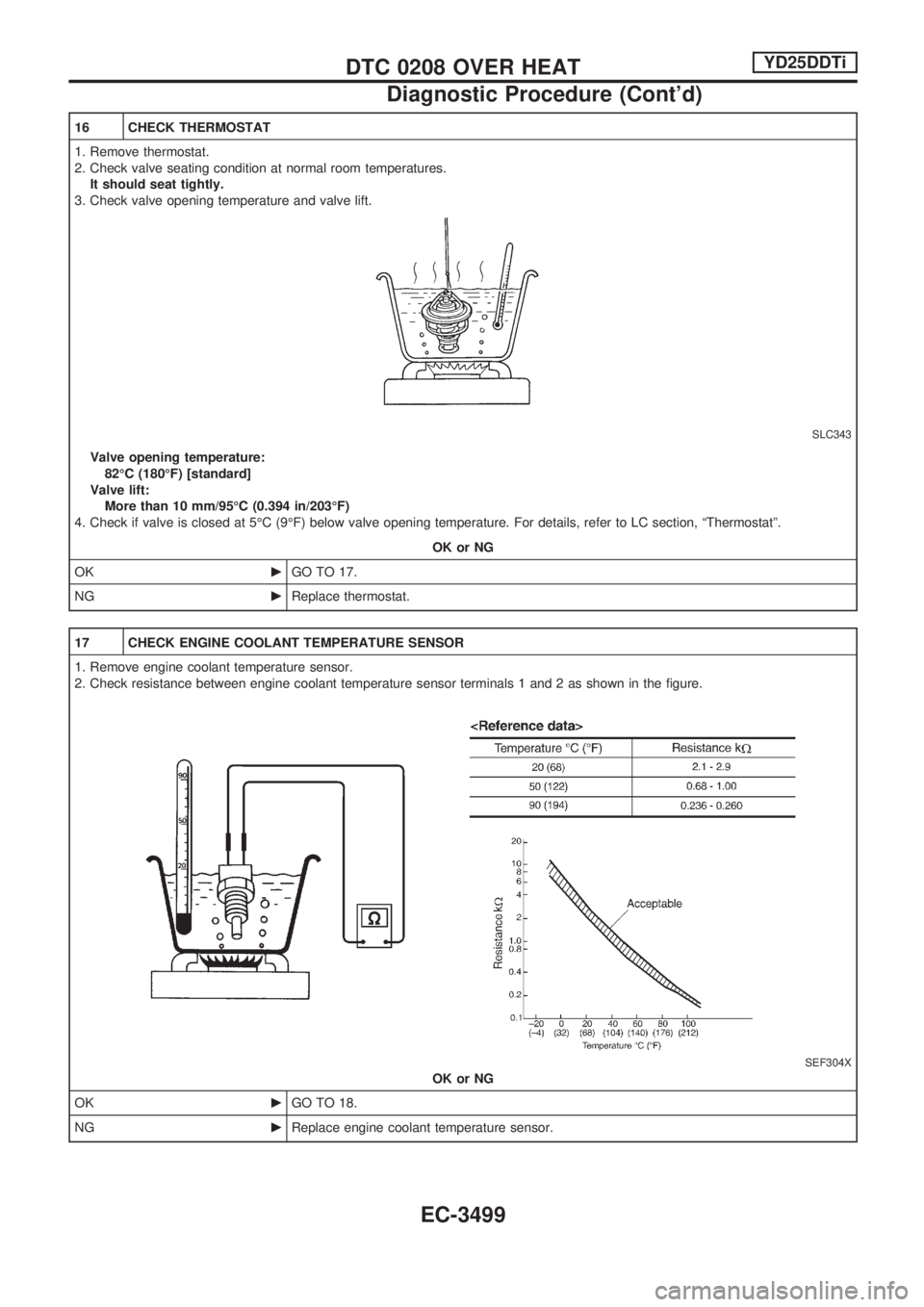

16 CHECK THERMOSTAT

1. Remove thermostat.

2. Check valve seating condition at normal room temperatures.

It should seat tightly.

3. Check valve opening temperature and valve lift.

SLC343

Valve opening temperature:

82ÉC (180ÉF) [standard]

Valve lift:

More than 10 mm/95ÉC (0.394 in/203ÉF)

4. Check if valve is closed at 5ÉC (9ÉF) below valve opening temperature. For details, refer to LC section, ªThermostatº.

OK or NG

OKcGO TO 17.

NGcReplace thermostat.

17 CHECK ENGINE COOLANT TEMPERATURE SENSOR

1. Remove engine coolant temperature sensor.

2. Check resistance between engine coolant temperature sensor terminals 1 and 2 as shown in the figure.

SEF304X

OK or NG

OKcGO TO 18.

NGcReplace engine coolant temperature sensor.

DTC 0208 OVER HEATYD25DDTi

Diagnostic Procedure (Cont'd)

EC-3499

Page 525 of 1306

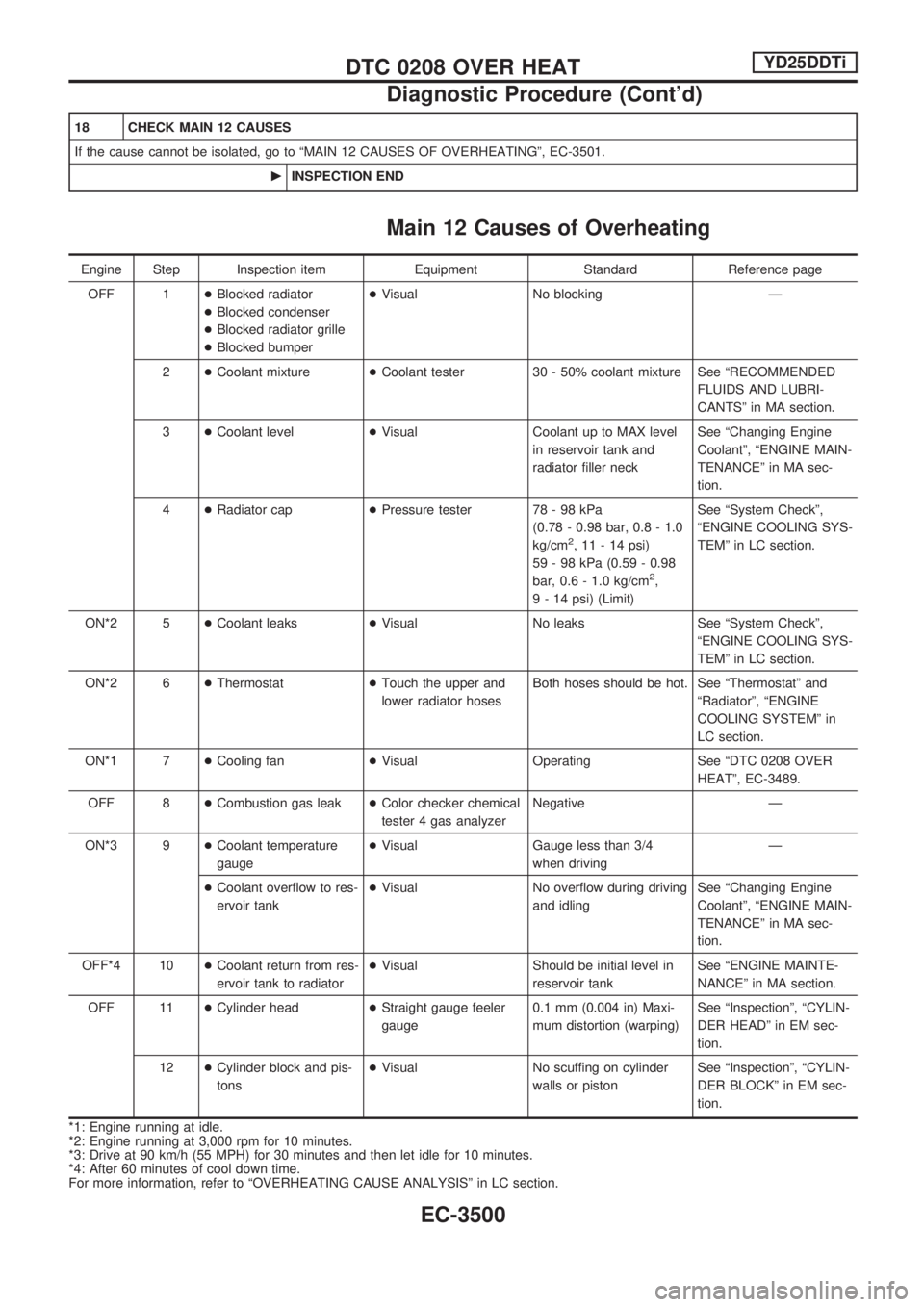

18 CHECK MAIN 12 CAUSES

If the cause cannot be isolated, go to ªMAIN 12 CAUSES OF OVERHEATINGº, EC-3501.

cINSPECTION END

Main 12 Causes of Overheating

Engine Step Inspection item Equipment Standard Reference page

OFF 1+Blocked radiator

+Blocked condenser

+Blocked radiator grille

+Blocked bumper+Visual No blocking Ð

2+Coolant mixture+Coolant tester 30 - 50% coolant mixture See ªRECOMMENDED

FLUIDS AND LUBRI-

CANTSº in MA section.

3+Coolant level+Visual Coolant up to MAX level

in reservoir tank and

radiator filler neckSee ªChanging Engine

Coolantº, ªENGINE MAIN-

TENANCEº in MA sec-

tion.

4+Radiator cap+Pressure tester 78 - 98 kPa

(0.78 - 0.98 bar, 0.8 - 1.0

kg/cm

2, 11 - 14 psi)

59 - 98 kPa (0.59 - 0.98

bar, 0.6 - 1.0 kg/cm

2,

9 - 14 psi) (Limit)See ªSystem Checkº,

ªENGINE COOLING SYS-

TEMº in LC section.

ON*2 5+Coolant leaks+Visual No leaks See ªSystem Checkº,

ªENGINE COOLING SYS-

TEMº in LC section.

ON*2 6+Thermostat+Touch the upper and

lower radiator hosesBoth hoses should be hot. See ªThermostatº and

ªRadiatorº, ªENGINE

COOLING SYSTEMº in

LC section.

ON*1 7+Cooling fan+Visual Operating See ªDTC 0208 OVER

HEATº, EC-3489.

OFF 8+Combustion gas leak+Color checker chemical

tester 4 gas analyzerNegative Ð

ON*3 9+Coolant temperature

gauge+Visual Gauge less than 3/4

when drivingÐ

+Coolant overflow to res-

ervoir tank+Visual No overflow during driving

and idlingSee ªChanging Engine

Coolantº, ªENGINE MAIN-

TENANCEº in MA sec-

tion.

OFF*4 10+Coolant return from res-

ervoir tank to radiator+Visual Should be initial level in

reservoir tankSee ªENGINE MAINTE-

NANCEº in MA section.

OFF 11+Cylinder head+Straight gauge feeler

gauge0.1 mm (0.004 in) Maxi-

mum distortion (warping)See ªInspectionº, ªCYLIN-

DER HEADº in EM sec-

tion.

12+Cylinder block and pis-

tons+Visual No scuffing on cylinder

walls or pistonSee ªInspectionº, ªCYLIN-

DER BLOCKº in EM sec-

tion.

*1: Engine running at idle.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

For more information, refer to ªOVERHEATING CAUSE ANALYSISº in LC section.

DTC 0208 OVER HEATYD25DDTi

Diagnostic Procedure (Cont'd)

EC-3500

Page 526 of 1306

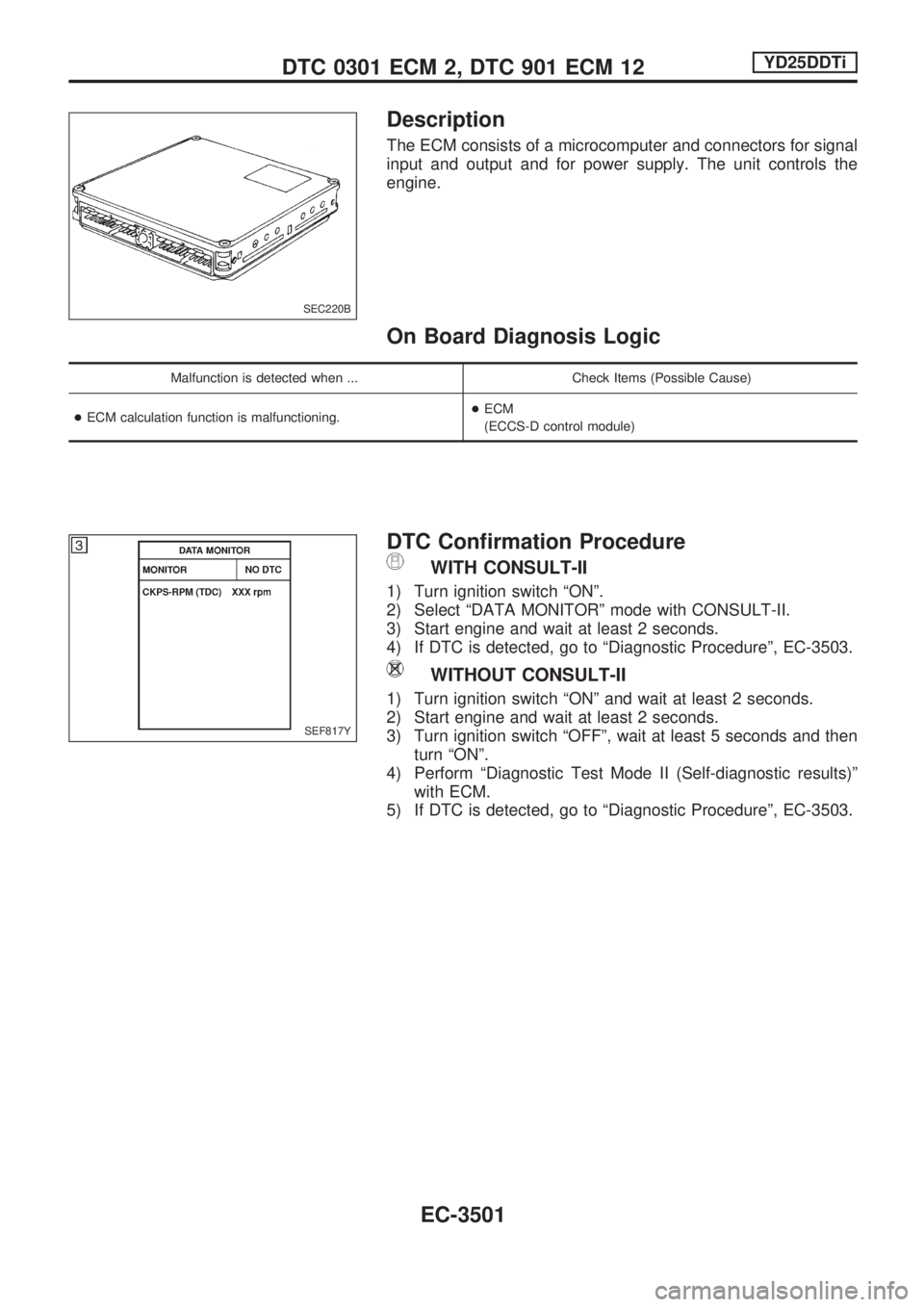

Description

The ECM consists of a microcomputer and connectors for signal

input and output and for power supply. The unit controls the

engine.

On Board Diagnosis Logic

Malfunction is detected when ... Check Items (Possible Cause)

+ECM calculation function is malfunctioning.+ECM

(ECCS-D control module)

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and wait at least 2 seconds.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-3503.

WITHOUT CONSULT-II

1) Turn ignition switch ªONº and wait at least 2 seconds.

2) Start engine and wait at least 2 seconds.

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º

with ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-3503.

SEC220B

SEF817Y

DTC 0301 ECM 2, DTC 901 ECM 12YD25DDTi

EC-3501

Page 527 of 1306

Diagnostic Procedure

1 INSPECTION START

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªSELF DIAG RESULTSº mode with CONSULT-II.

3. Touch ªERASEº.

4. Perform ªDTC Confirmation Procedureº, EC-3501, again.

5. Is the malfunction displayed again?

Without CONSULT-II

1. Turn ignition switch ªONº.

2. Erase the Diagnostic Test Mode II (Self-diagnostic results) memory.

3. Perform ªDTC Confirmation Procedureº, EC-3501, again.

4. Perform ªDiagnostic Test Mode II (Self-diagnostic results)º.

5. Is the DTC 0301 or 0901 displayed again?

Yes or No

YescGO TO 2.

NocINSPECTION END

2 REPLACE ECM

1. Replace ECM.

2. Perform initialization of NATS system and resistration of all NATS ignition key IDs. Refer to EC-3429. (Models with NATS)

3. Perform ªAccelerator Position Sensor Idle Position Learningº of ªBASIC SERVICE PROCEDUREº. Refer to EC-3427.

cINSPECTION END

DTC 0301 ECM 2, DTC 901 ECM 12YD25DDTi

EC-3502

Page 528 of 1306

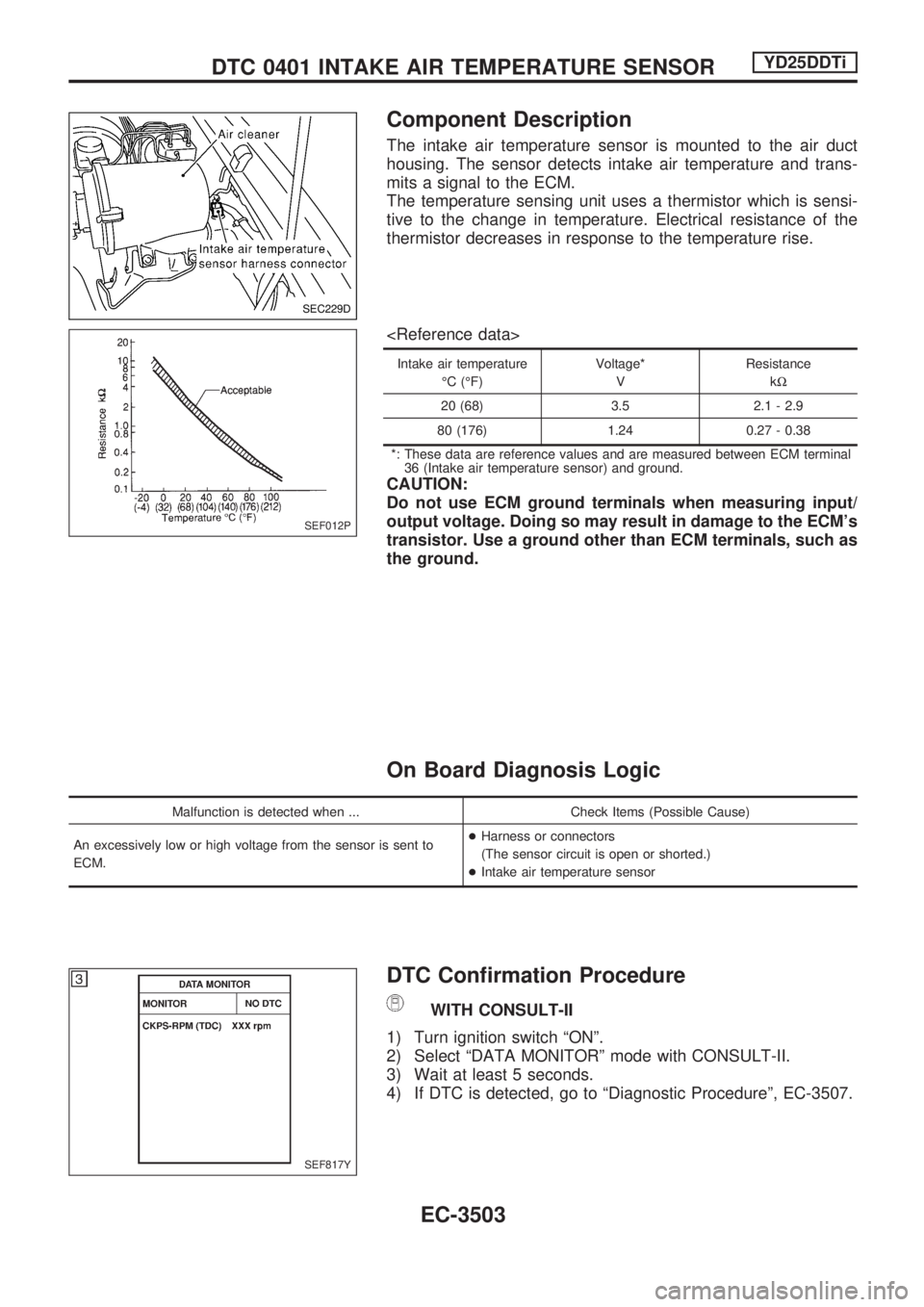

Component Description

The intake air temperature sensor is mounted to the air duct

housing. The sensor detects intake air temperature and trans-

mits a signal to the ECM.

The temperature sensing unit uses a thermistor which is sensi-

tive to the change in temperature. Electrical resistance of the

thermistor decreases in response to the temperature rise.

Intake air temperature

ÉC (ÉF)Voltage*

VResistance

kW

20 (68) 3.5 2.1 - 2.9

80 (176) 1.24 0.27 - 0.38

*: These data are reference values and are measured between ECM terminal

36 (Intake air temperature sensor) and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/

output voltage. Doing so may result in damage to the ECM's

transistor. Use a ground other than ECM terminals, such as

the ground.

On Board Diagnosis Logic

Malfunction is detected when ... Check Items (Possible Cause)

An excessively low or high voltage from the sensor is sent to

ECM.+Harness or connectors

(The sensor circuit is open or shorted.)

+Intake air temperature sensor

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait at least 5 seconds.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-3507.

SEC229D

SEF012P

SEF817Y

DTC 0401 INTAKE AIR TEMPERATURE SENSORYD25DDTi

EC-3503

Page 529 of 1306

WITHOUT CONSULT-II

WITHOUT CONSULT-II

1. Turn ignition switch ªONº and wait at least 5 seconds.

2. Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

3. Perform ªDiagnostic Test Mode II (Self-diagnostic results)º

with ECM.

4. If DTC is detected, go to EC-3507.

DTC 0401 INTAKE AIR TEMPERATURE SENSORYD25DDTi

DTC Confirmation Procedure (Cont'd)

EC-3504

Page 530 of 1306

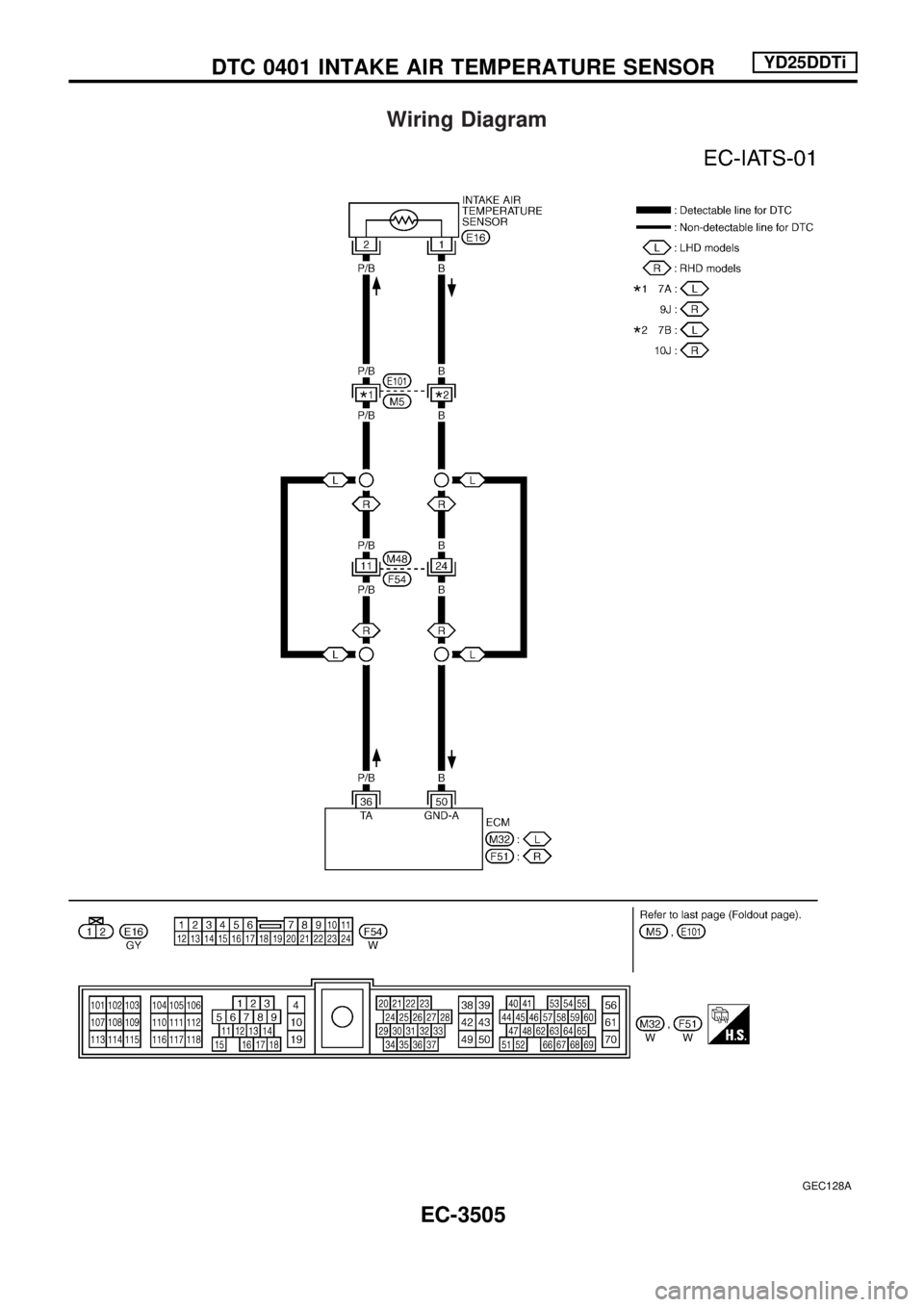

Wiring Diagram

GEC128A

DTC 0401 INTAKE AIR TEMPERATURE SENSORYD25DDTi

EC-3505