battery NISSAN PICK-UP 2001 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: PICK-UP, Model: NISSAN PICK-UP 2001Pages: 1306, PDF Size: 31.7 MB

Page 31 of 1306

DTC 0403 ACCEL POS SENSOR...................... 3515

Description ....................................................... 3515

CONSULT-II Reference Value in Data Monitor

Mode ................................................................ 3515

ECM Terminals and Reference Value ............. 3516

On Board Diagnosis Logic ............................... 3516

DTC Confirmation Procedure .......................... 3517

Wiring Diagram ................................................ 3518

Diagnostic Procedure....................................... 3522

DTC 0406 INT AIR VOL...................................... 3531

On Board Diagnosis Logic ............................... 3531

DTC Confirmation Procedure .......................... 3531

Diagnostic Procedure....................................... 3532

DTC 0407 CRANK POS SEN (TDC).................. 3534

Description ....................................................... 3534

CONSULT-II Reference Value in Data Monitor

Mode ................................................................ 3534

ECM Terminals and Reference Value ............. 3534

On Board Diagnosis Logic ............................... 3535

DTC Confirmation Procedure .......................... 3535

Wiring Diagram ................................................ 3536

Diagnostic Procedure....................................... 3537

DTC 0502 BATTERY VOLTAGE........................ 3540

On Board Diagnosis Logic ............................... 3540

DTC Confirmation Procedure .......................... 3540

Diagnostic Procedure....................................... 3540

DTC 0701 P1zCAM POS SEN............................. 3542

Description ....................................................... 3542

CONSULT-II Reference Value in Data Monitor

Mode ................................................................ 3543

ECM Terminals and Reference Value ............. 3543

On Board Diagnosis Logic ............................... 3544

DTC Confirmation Procedure .......................... 3544

Wiring Diagram ................................................ 3545

Diagnostic Procedure....................................... 3547

DTC 0702 P2zTDC PULSE SIG........................... 3549

Description ....................................................... 3549

CONSULT-II Reference Value in Data Monitor

Mode ................................................................ 3550

ECM Terminals and Reference Value ............. 3550

On Board Diagnosis Logic ............................... 3550

DTC Confirmation Procedure .......................... 3551

Wiring Diagram ................................................ 3552

Diagnostic Procedure....................................... 3554

DTC 0703 P3zPUMP COMM LINE...................... 3556

Description ....................................................... 3556

CONSULT-II Reference Value in Data Monitor

Mode ................................................................ 3557

ECM Terminals and Reference Value ............. 3557

On Board Diagnosis Logic ............................... 3557

DTC Confirmation Procedure .......................... 3558

Wiring Diagram ................................................ 3559

Diagnostic Procedure....................................... 3561DTC 0704 P4zSPILL/V CIRC, DTC 0706

P6zSPILL VALVE................................................. 3563

Description ....................................................... 3563

CONSULT-II Reference Value in Data Monitor

Mode ................................................................ 3564

ECM Terminals and Reference Value ............. 3564

On Board Diagnosis Logic ............................... 3564

DTC Confirmation Procedure .......................... 3565

Wiring Diagram ................................................ 3566

Diagnostic Procedure....................................... 3568

DTC 0705 P5zPUMP C/MODULE........................ 3570

Description ....................................................... 3570

CONSULT-II Reference Value in Data Monitor

Mode ................................................................ 3571

ECM Terminals and Reference Value ............. 3571

On Board Diagnosis Logic ............................... 3571

DTC Confirmation Procedure .......................... 3572

Diagnostic Procedure....................................... 3572

DTC 0707 P7zF/INJ TIMG FB.............................. 3573

Description ....................................................... 3573

CONSULT-II Reference Value in Data Monitor

Mode ................................................................ 3574

ECM Terminals and Reference Value ............. 3574

On Board Diagnosis Logic ............................... 3574

DTC Confirmation Procedure .......................... 3575

Wiring Diagram ................................................ 3576

Diagnostic Procedure....................................... 3578

DTC 0802 ECM 10............................................... 3581

Description ....................................................... 3581

On Board Diagnosis Logic ............................... 3581

DTC Confirmation Procedure .......................... 3581

Diagnostic Procedure....................................... 3582

DTC 0804 ECM 11............................................... 3583

Description ....................................................... 3583

On Board Diagnosis Logic ............................... 3583

DTC Confirmation Procedure .......................... 3583

Diagnostic Procedure....................................... 3584

DTC 0807 ECM 14............................................... 3585

Description ....................................................... 3585

ECM Terminals and Reference Value ............. 3585

On Board Diagnosis Logic ............................... 3585

DTC Confirmation Procedure .......................... 3585

Wiring Diagram ................................................ 3586

Diagnostic Procedure....................................... 3587

DTC 0902 ECM RLY........................................... 3593

ECM Terminals and Reference Value ............. 3593

On Board Diagnosis Logic ............................... 3593

DTC Confirmation Procedure .......................... 3593

Wiring Diagram ................................................ 3594

Diagnostic Procedure....................................... 3596

DTC 0903 ECM 15............................................... 3598

Description ....................................................... 3598

On Board Diagnosis Logic ............................... 3598

DTC Confirmation Procedure .......................... 3598

EC-3006

Page 37 of 1306

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

NEEC0002The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger in a frontal collision.

The SRS system composition which is available to NISSAN MODEL D22 is as follows (The composition var-

ies according to the destination and optional equipment.):

Driver air bag module (located in the center of the steering wheel), front passenger air bag module (located

on the instrument panel on passenger side), seat belt pre-tensioner, a diagnosis sensor unit, warning lamp,

wiring harness and spiral cable.

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow harness connector.

Precautions for On Board Diagnostic (OBD)

System of Engine

NEEC0003The ECM has an on board diagnostic system. It will light up the malfunction indicator (MI) to warn the driver

of a malfunction causing emission deterioration.

CAUTION:

+Be sure to turn the ignition switch OFF and disconnect the negative battery terminal before any

repair or inspection work. The open/short circuit of related switches, sensors, solenoid valves, etc.

will cause the MI to light up.

+Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MI to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

+Certain systems and components, especially those related to OBD, may use a new style slide-

locking type harness connector.

For description and how to disconnect, refer to EL section, ªHARNESS CONNECTORº.

+Be sure to route and secure the harnesses properly after work. The interference of the harness with

a bracket, etc. may cause the MI to light up due to the short circuit.

+Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MI to light up due to the malfunction of the fuel injection system, etc.

+Be sure to erase the unnecessary malfunction information (repairs completed) from the ECM before

returning the vehicle to the customer.

PRECAUTIONSKA24DE (EURO OBD)

Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

EC-3012

Page 39 of 1306

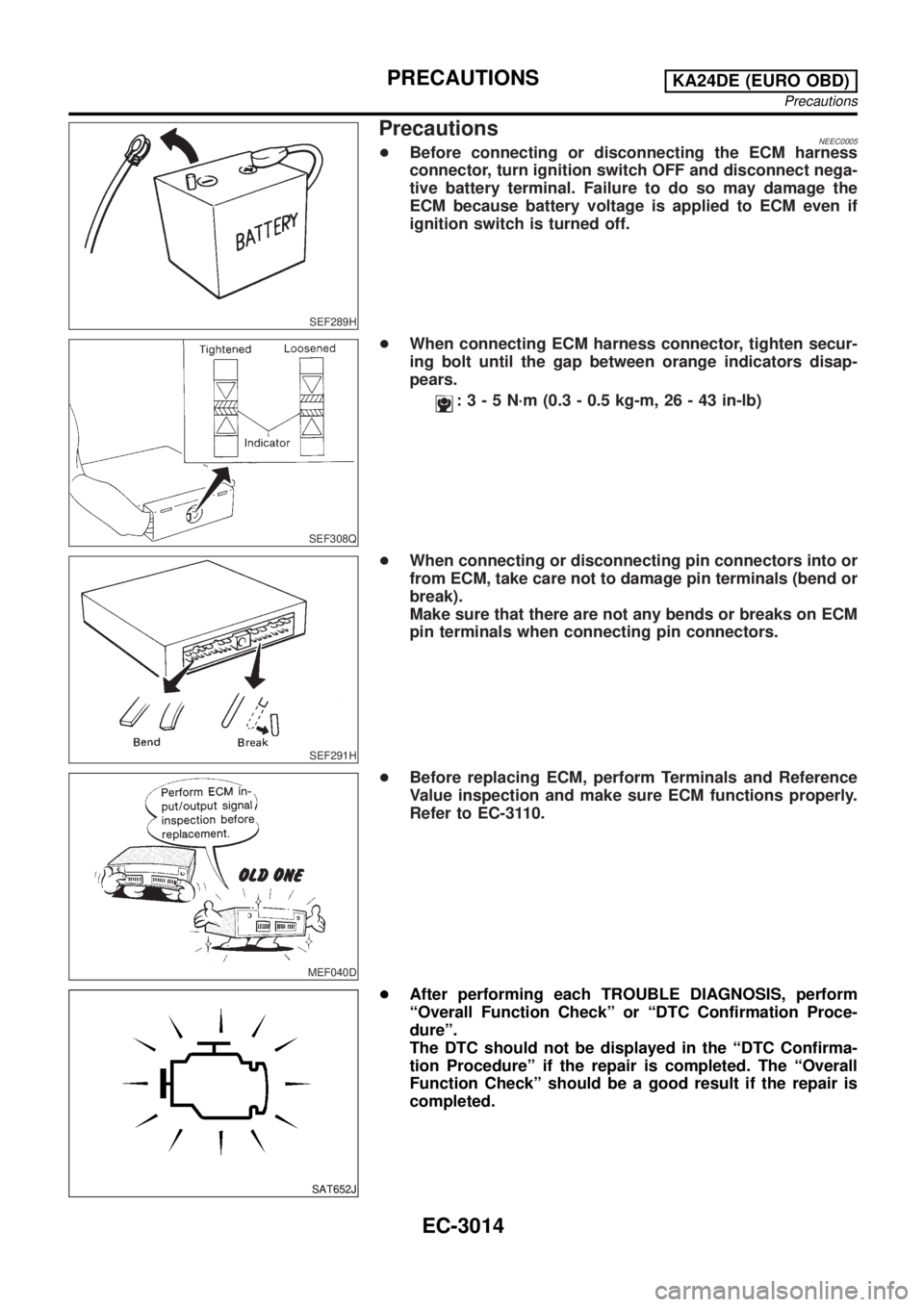

SEF289H

PrecautionsNEEC0005+Before connecting or disconnecting the ECM harness

connector, turn ignition switch OFF and disconnect nega-

tive battery terminal. Failure to do so may damage the

ECM because battery voltage is applied to ECM even if

ignition switch is turned off.

SEF308Q

+When connecting ECM harness connector, tighten secur-

ing bolt until the gap between orange indicators disap-

pears.

:3-5N´m(0.3 - 0.5 kg-m, 26 - 43 in-lb)

SEF291H

+When connecting or disconnecting pin connectors into or

from ECM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on ECM

pin terminals when connecting pin connectors.

MEF040D

+Before replacing ECM, perform Terminals and Reference

Value inspection and make sure ECM functions properly.

Refer to EC-3110.

SAT652J

+After performing each TROUBLE DIAGNOSIS, perform

ªOverall Function Checkº or ªDTC Confirmation Proce-

dureº.

The DTC should not be displayed in the ªDTC Confirma-

tion Procedureº if the repair is completed. The ªOverall

Function Checkº should be a good result if the repair is

completed.

PRECAUTIONSKA24DE (EURO OBD)

Precautions

EC-3014

Page 48 of 1306

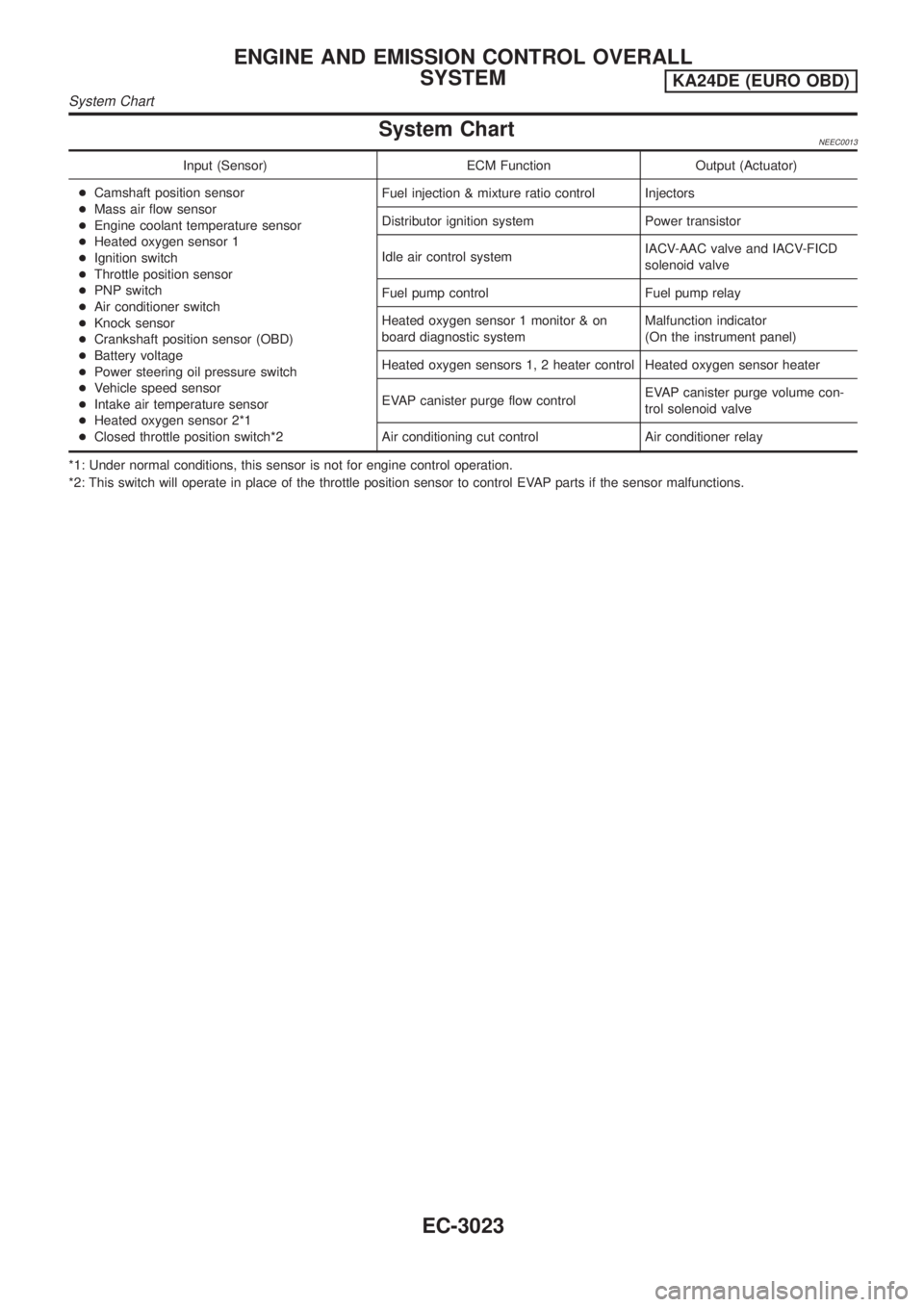

System ChartNEEC0013

Input (Sensor) ECM Function Output (Actuator)

+Camshaft position sensor

+Mass air flow sensor

+Engine coolant temperature sensor

+Heated oxygen sensor 1

+Ignition switch

+Throttle position sensor

+PNP switch

+Air conditioner switch

+Knock sensor

+Crankshaft position sensor (OBD)

+Battery voltage

+Power steering oil pressure switch

+Vehicle speed sensor

+Intake air temperature sensor

+Heated oxygen sensor 2*1

+Closed throttle position switch*2Fuel injection & mixture ratio control Injectors

Distributor ignition system Power transistor

Idle air control systemIACV-AAC valve and IACV-FICD

solenoid valve

Fuel pump control Fuel pump relay

Heated oxygen sensor 1 monitor & on

board diagnostic systemMalfunction indicator

(On the instrument panel)

Heated oxygen sensors 1, 2 heater control Heated oxygen sensor heater

EVAP canister purge flow controlEVAP canister purge volume con-

trol solenoid valve

Air conditioning cut control Air conditioner relay

*1: Under normal conditions, this sensor is not for engine control operation.

*2: This switch will operate in place of the throttle position sensor to control EVAP parts if the sensor malfunctions.

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM

KA24DE (EURO OBD)

System Chart

EC-3023

Page 49 of 1306

Multiport Fuel Injection (MFI) System

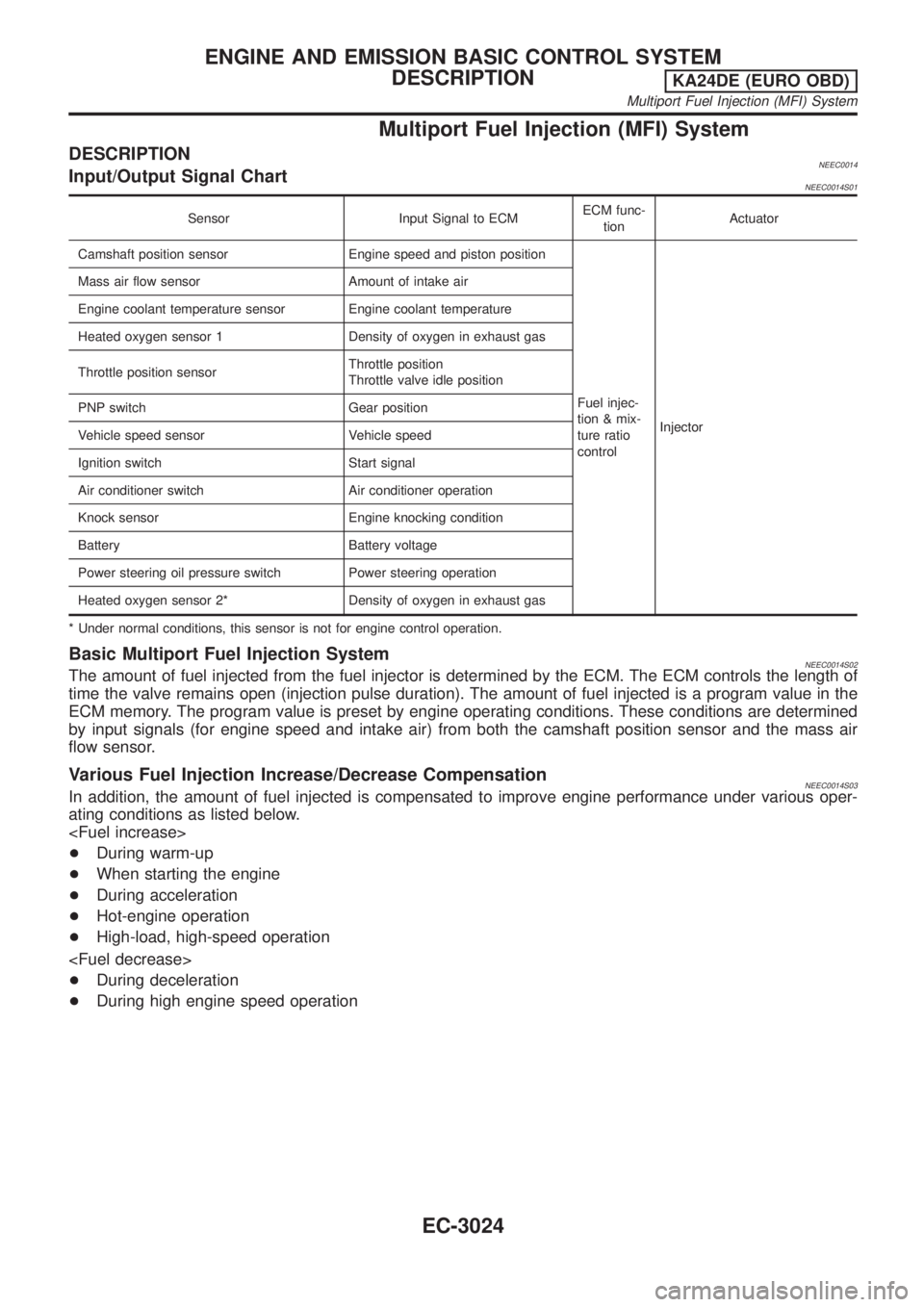

DESCRIPTIONNEEC0014Input/Output Signal ChartNEEC0014S01

Sensor Input Signal to ECMECM func-

tionActuator

Camshaft position sensor Engine speed and piston position

Fuel injec-

tion & mix-

ture ratio

controlInjector Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Heated oxygen sensor 1 Density of oxygen in exhaust gas

Throttle position sensorThrottle position

Throttle valve idle position

PNP switch Gear position

Vehicle speed sensor Vehicle speed

Ignition switch Start signal

Air conditioner switch Air conditioner operation

Knock sensor Engine knocking condition

Battery Battery voltage

Power steering oil pressure switch Power steering operation

Heated oxygen sensor 2* Density of oxygen in exhaust gas

* Under normal conditions, this sensor is not for engine control operation.

Basic Multiport Fuel Injection SystemNEEC0014S02The amount of fuel injected from the fuel injector is determined by the ECM. The ECM controls the length of

time the valve remains open (injection pulse duration). The amount of fuel injected is a program value in the

ECM memory. The program value is preset by engine operating conditions. These conditions are determined

by input signals (for engine speed and intake air) from both the camshaft position sensor and the mass air

flow sensor.

Various Fuel Injection Increase/Decrease CompensationNEEC0014S03In addition, the amount of fuel injected is compensated to improve engine performance under various oper-

ating conditions as listed below.

+During warm-up

+When starting the engine

+During acceleration

+Hot-engine operation

+High-load, high-speed operation

+During deceleration

+During high engine speed operation

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTION

KA24DE (EURO OBD)

Multiport Fuel Injection (MFI) System

EC-3024

Page 51 of 1306

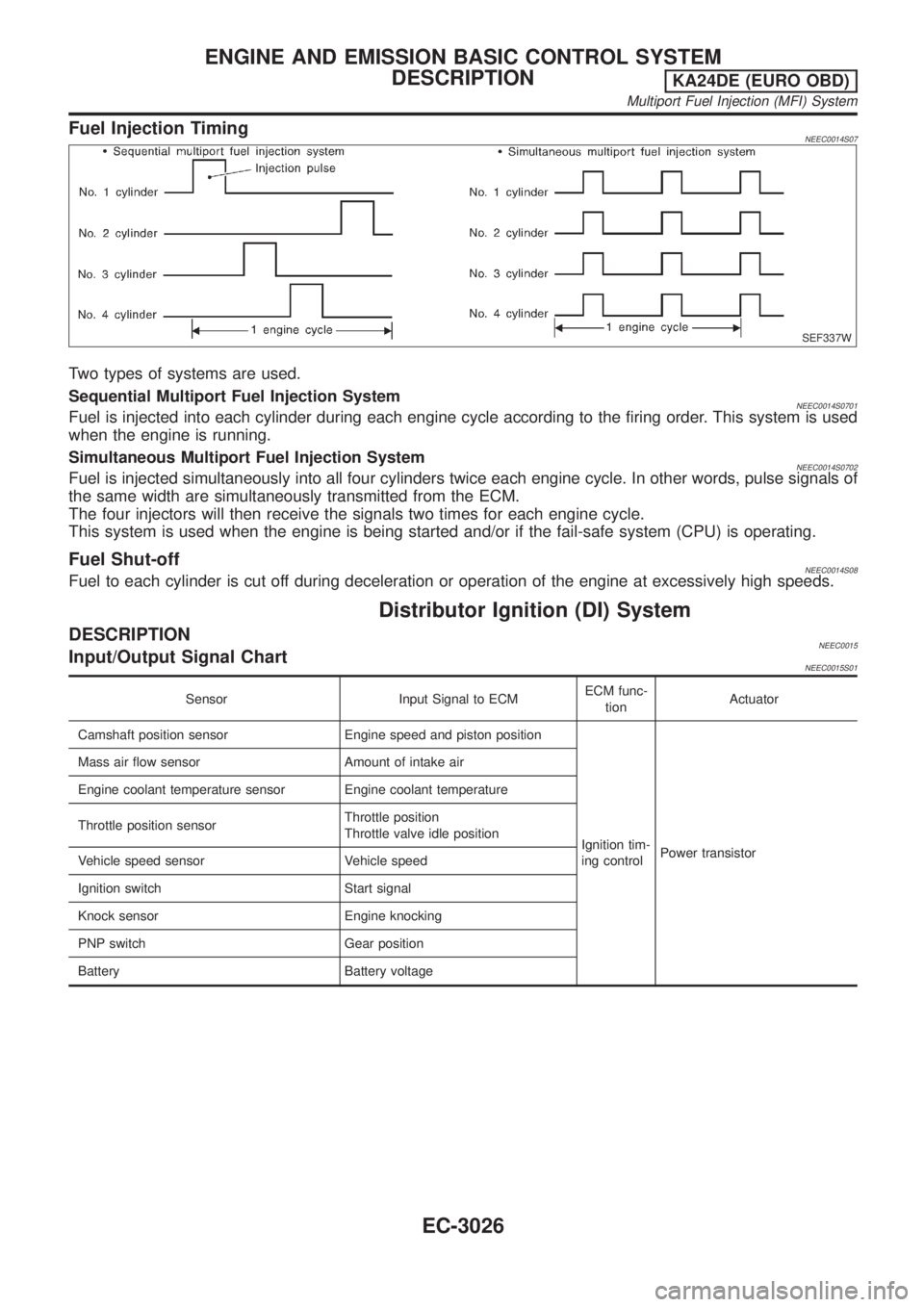

Fuel Injection TimingNEEC0014S07

SEF337W

Two types of systems are used.

Sequential Multiport Fuel Injection System

NEEC0014S0701Fuel is injected into each cylinder during each engine cycle according to the firing order. This system is used

when the engine is running.

Simultaneous Multiport Fuel Injection System

NEEC0014S0702Fuel is injected simultaneously into all four cylinders twice each engine cycle. In other words, pulse signals of

the same width are simultaneously transmitted from the ECM.

The four injectors will then receive the signals two times for each engine cycle.

This system is used when the engine is being started and/or if the fail-safe system (CPU) is operating.

Fuel Shut-offNEEC0014S08Fuel to each cylinder is cut off during deceleration or operation of the engine at excessively high speeds.

Distributor Ignition (DI) System

DESCRIPTIONNEEC0015Input/Output Signal ChartNEEC0015S01

Sensor Input Signal to ECMECM func-

tionActuator

Camshaft position sensor Engine speed and piston position

Ignition tim-

ing controlPower transistor Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Throttle position sensorThrottle position

Throttle valve idle position

Vehicle speed sensor Vehicle speed

Ignition switch Start signal

Knock sensor Engine knocking

PNP switch Gear position

Battery Battery voltage

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTION

KA24DE (EURO OBD)

Multiport Fuel Injection (MFI) System

EC-3026

Page 52 of 1306

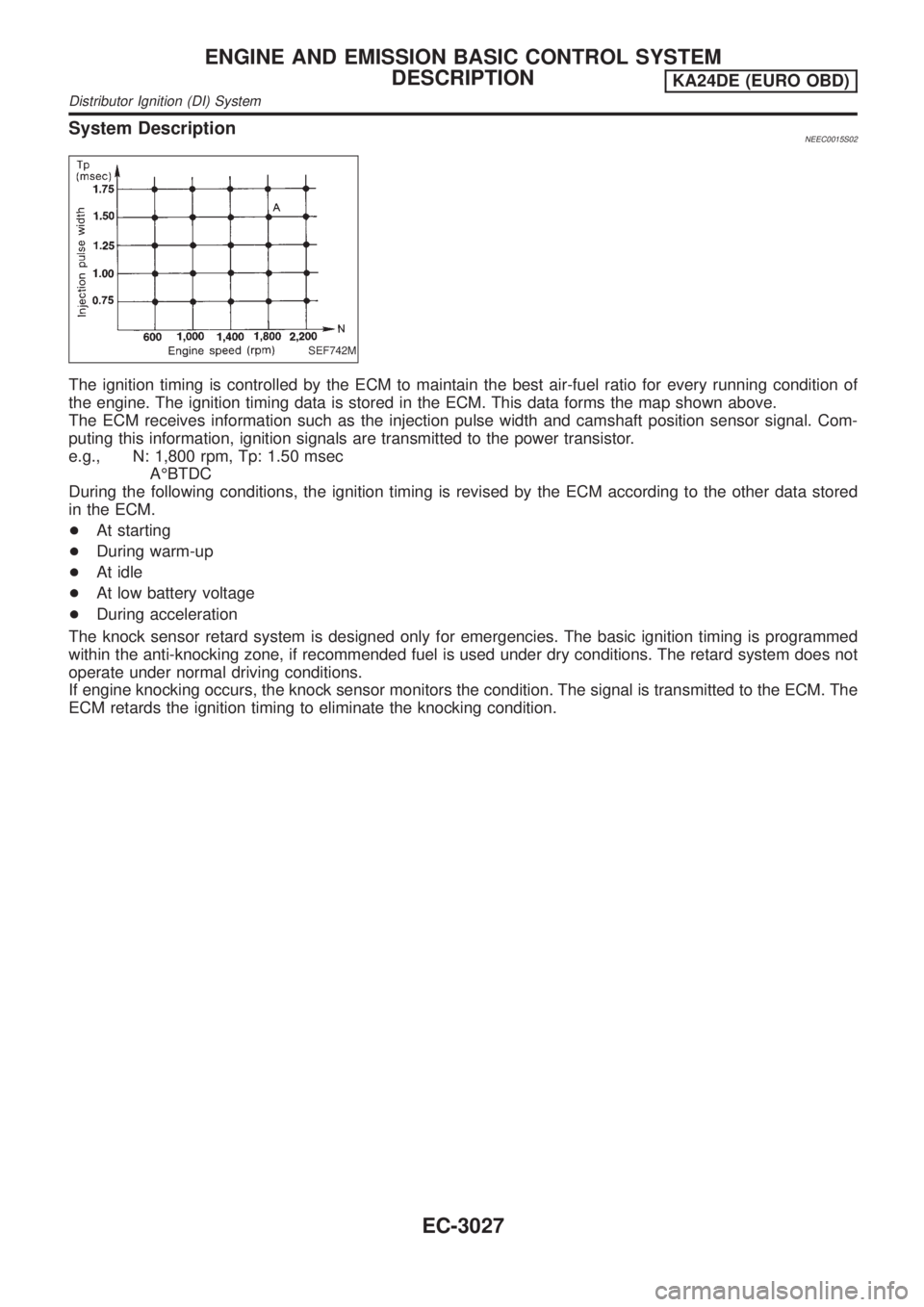

System DescriptionNEEC0015S02

SEF742M

The ignition timing is controlled by the ECM to maintain the best air-fuel ratio for every running condition of

the engine. The ignition timing data is stored in the ECM. This data forms the map shown above.

The ECM receives information such as the injection pulse width and camshaft position sensor signal. Com-

puting this information, ignition signals are transmitted to the power transistor.

e.g., N: 1,800 rpm, Tp: 1.50 msec

AÉBTDC

During the following conditions, the ignition timing is revised by the ECM according to the other data stored

in the ECM.

+At starting

+During warm-up

+At idle

+At low battery voltage

+During acceleration

The knock sensor retard system is designed only for emergencies. The basic ignition timing is programmed

within the anti-knocking zone, if recommended fuel is used under dry conditions. The retard system does not

operate under normal driving conditions.

If engine knocking occurs, the knock sensor monitors the condition. The signal is transmitted to the ECM. The

ECM retards the ignition timing to eliminate the knocking condition.

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTION

KA24DE (EURO OBD)

Distributor Ignition (DI) System

EC-3027

Page 60 of 1306

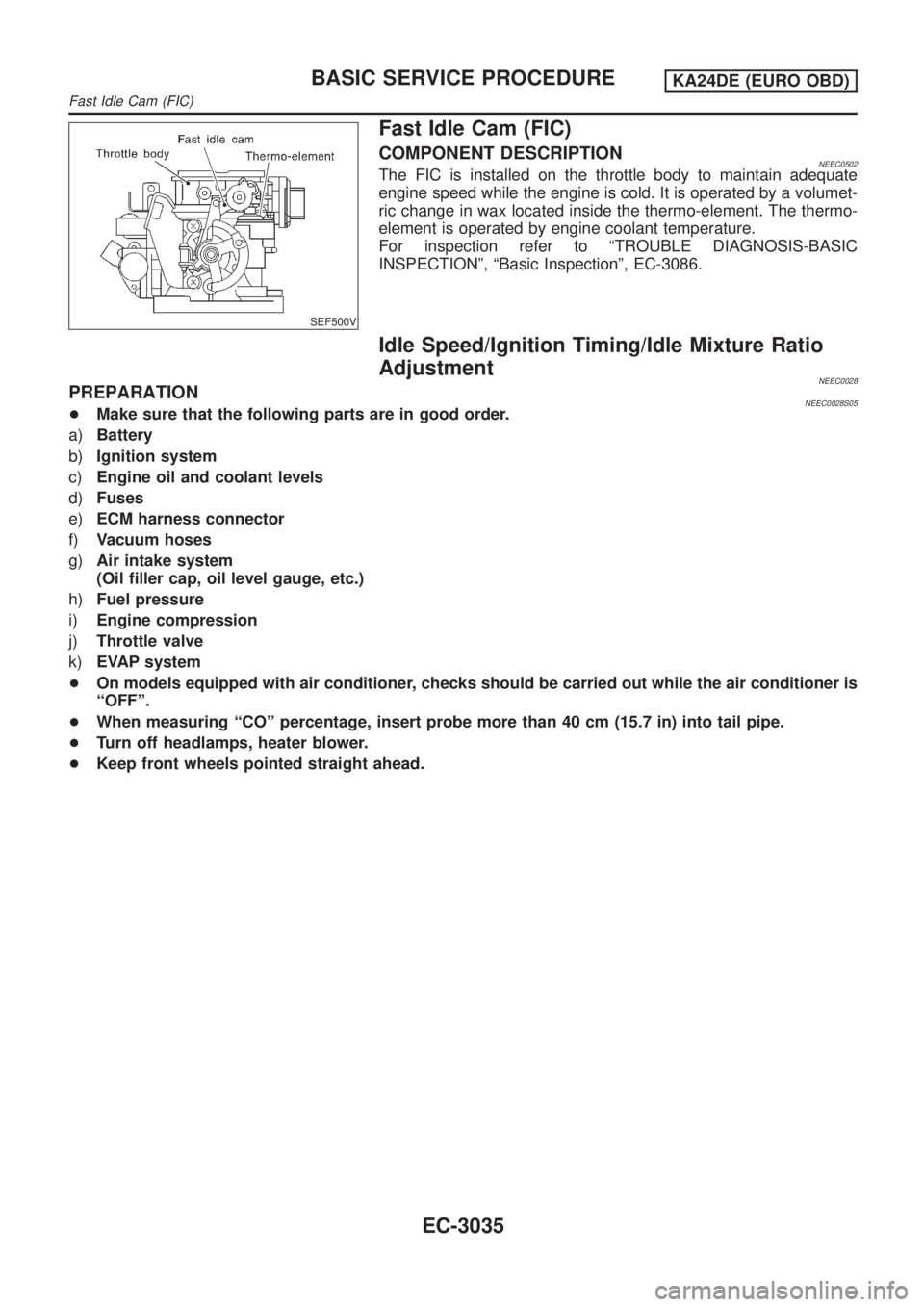

SEF500V

Fast Idle Cam (FIC)

COMPONENT DESCRIPTIONNEEC0502The FIC is installed on the throttle body to maintain adequate

engine speed while the engine is cold. It is operated by a volumet-

ric change in wax located inside the thermo-element. The thermo-

element is operated by engine coolant temperature.

For inspection refer to ªTROUBLE DIAGNOSIS-BASIC

INSPECTIONº, ªBasic Inspectionº, EC-3086.

Idle Speed/Ignition Timing/Idle Mixture Ratio

Adjustment

NEEC0028PREPARATIONNEEC0028S05+Make sure that the following parts are in good order.

a)Battery

b)Ignition system

c)Engine oil and coolant levels

d)Fuses

e)ECM harness connector

f)Vacuum hoses

g)Air intake system

(Oil filler cap, oil level gauge, etc.)

h)Fuel pressure

i)Engine compression

j)Throttle valve

k)EVAP system

+On models equipped with air conditioner, checks should be carried out while the air conditioner is

ªOFFº.

+When measuring ªCOº percentage, insert probe more than 40 cm (15.7 in) into tail pipe.

+Turn off headlamps, heater blower.

+Keep front wheels pointed straight ahead.

BASIC SERVICE PROCEDUREKA24DE (EURO OBD)

Fast Idle Cam (FIC)

EC-3035

Page 69 of 1306

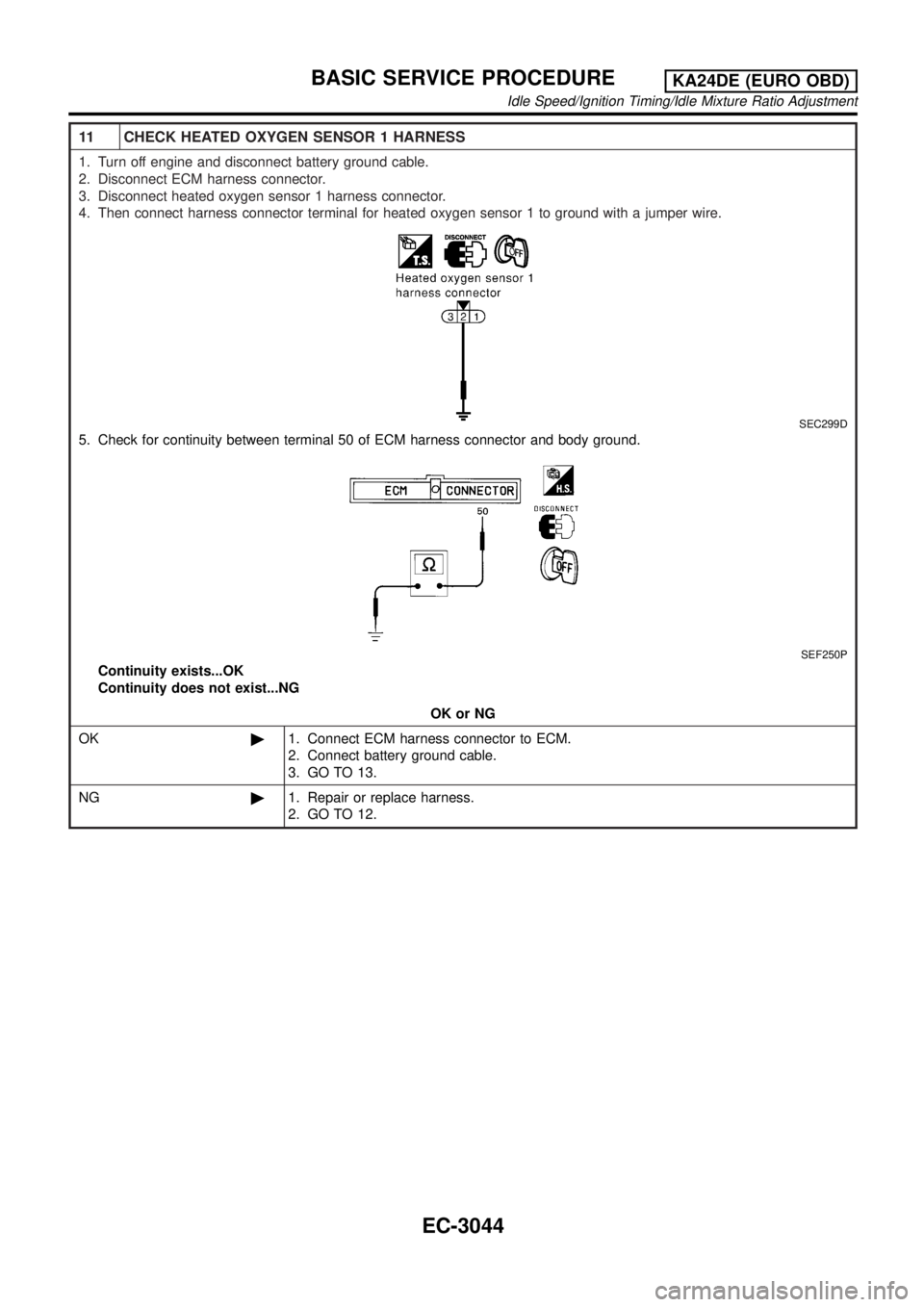

11 CHECK HEATED OXYGEN SENSOR 1 HARNESS

1. Turn off engine and disconnect battery ground cable.

2. Disconnect ECM harness connector.

3. Disconnect heated oxygen sensor 1 harness connector.

4. Then connect harness connector terminal for heated oxygen sensor 1 to ground with a jumper wire.

SEC299D

5. Check for continuity between terminal 50 of ECM harness connector and body ground.

SEF250P

Continuity exists...OK

Continuity does not exist...NG

OK or NG

OK©1. Connect ECM harness connector to ECM.

2. Connect battery ground cable.

3. GO TO 13.

NG©1. Repair or replace harness.

2. GO TO 12.

BASIC SERVICE PROCEDUREKA24DE (EURO OBD)

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment

EC-3044

Page 71 of 1306

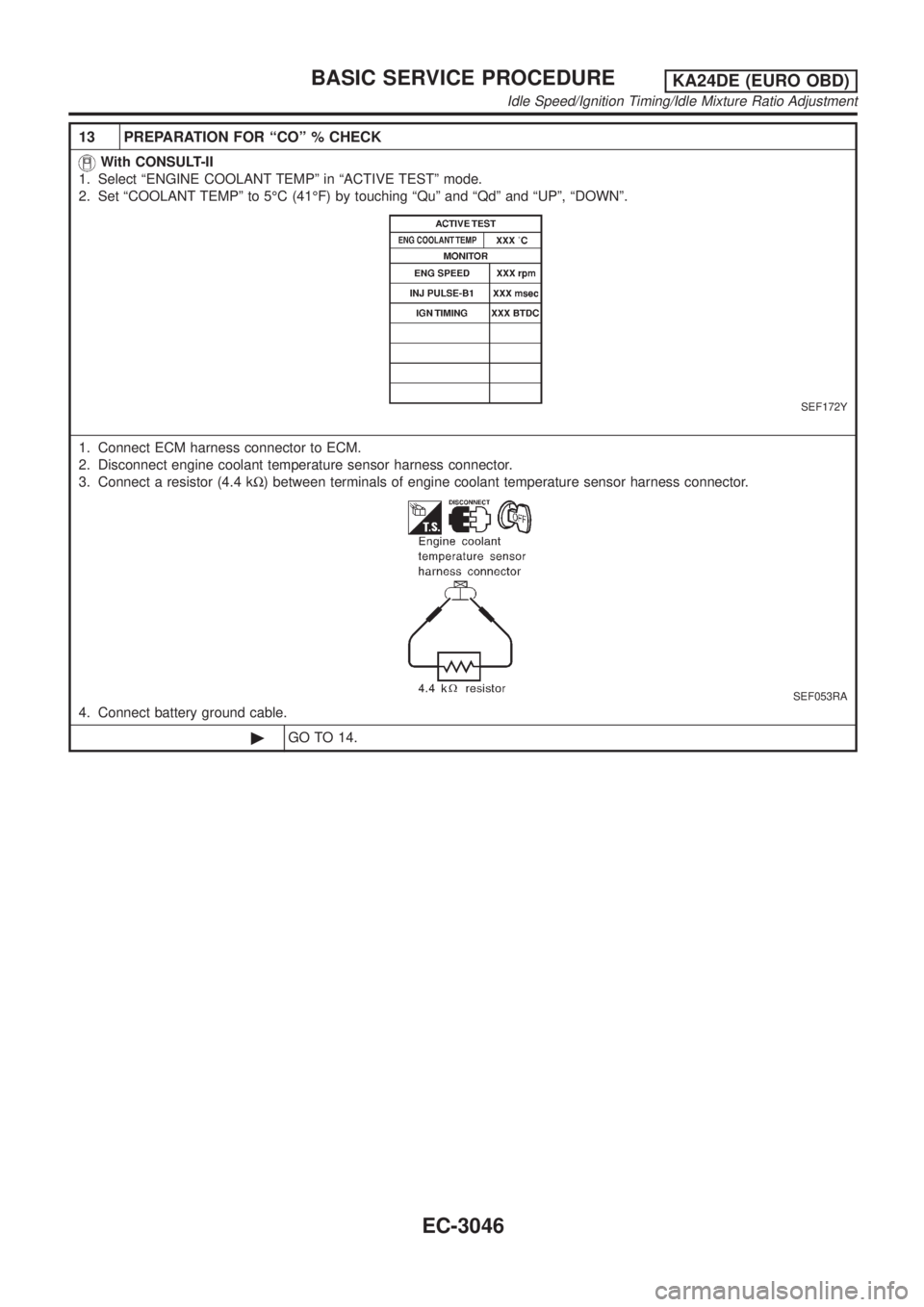

13 PREPARATION FOR ªCOº % CHECK

With CONSULT-II

1. Select ªENGINE COOLANT TEMPº in ªACTIVE TESTº mode.

2. Set ªCOOLANT TEMPº to 5ÉC (41ÉF) by touching ªQuº and ªQdº and ªUPº, ªDOWNº.

SEF172Y

1. Connect ECM harness connector to ECM.

2. Disconnect engine coolant temperature sensor harness connector.

3. Connect a resistor (4.4 kW) between terminals of engine coolant temperature sensor harness connector.

SEF053RA

4. Connect battery ground cable.

©GO TO 14.

BASIC SERVICE PROCEDUREKA24DE (EURO OBD)

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment

EC-3046