dimensions NISSAN PRIMERA 1999 Electronic User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 1840 of 2267

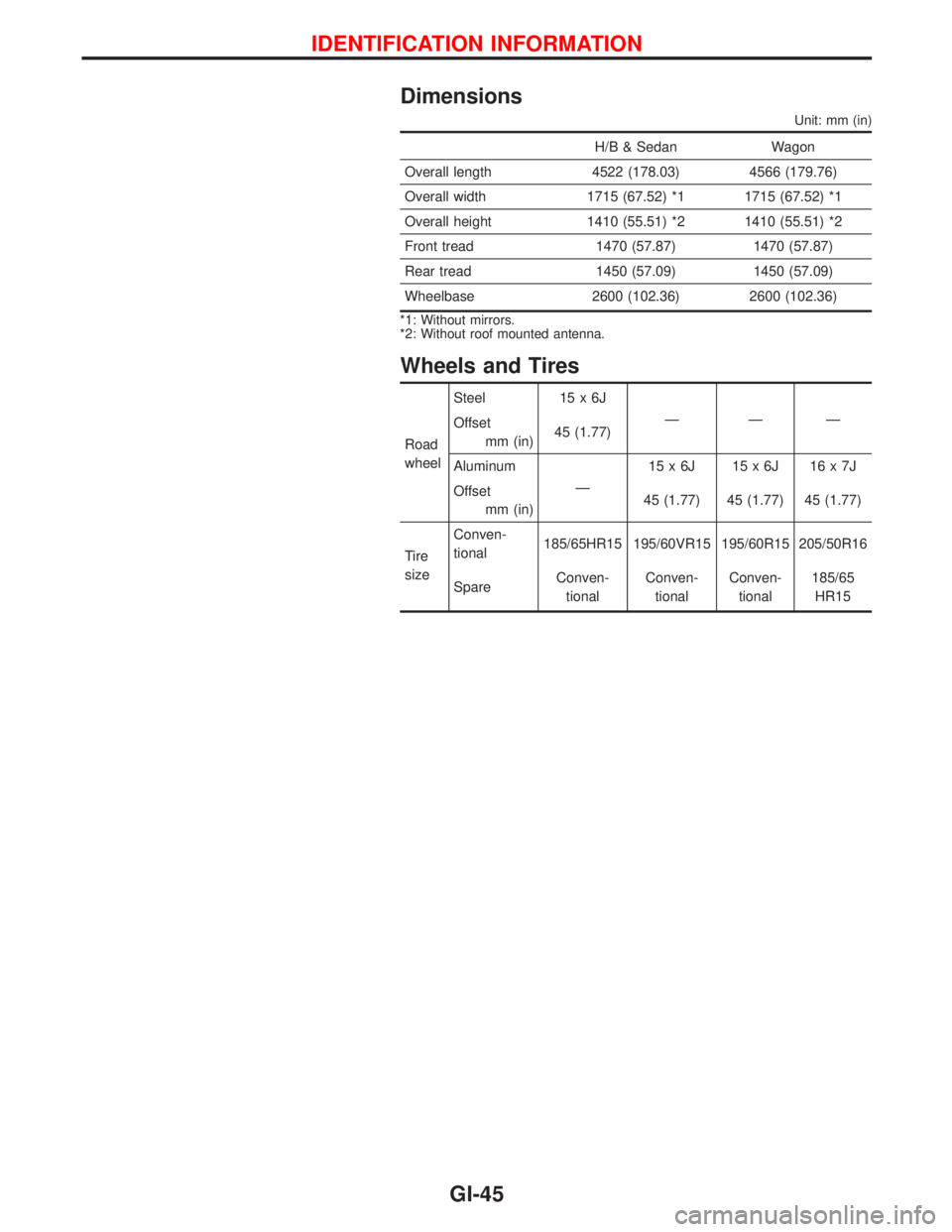

Dimensions

Unit: mm (in)

H/B & Sedan Wagon

Overall length 4522 (178.03) 4566 (179.76)

Overall width 1715 (67.52) *1 1715 (67.52) *1

Overall height 1410 (55.51) *2 1410 (55.51) *2

Front tread 1470 (57.87) 1470 (57.87)

Rear tread 1450 (57.09) 1450 (57.09)

Wheelbase 2600 (102.36) 2600 (102.36)

*1: Without mirrors.

*2: Without roof mounted antenna.

Wheels and Tires

Road

wheelSteel 15 x 6J

ÐÐÐ

Offset

mm (in)45 (1.77)

Aluminum

Ð15x6J 15x6J 16x7J

Offset

mm (in)45 (1.77) 45 (1.77) 45 (1.77)

Tire

sizeConven-

tional185/65HR15 195/60VR15 195/60R15 205/50R16

SpareConven-

tionalConven-

tionalConven-

tional185/65

HR15

IDENTIFICATION INFORMATION

GI-45

Page 1970 of 2267

Combination meter removal and instal-

lation - See Instrument panel ......................BT-15

Combination switch .........................................EL-64

Combustion chamber replacement ..............EM-146

Component location (cool box) ......................HA-39

Compression pressure ..........EM-69, 126, 188, 196

Compressor clutch removal and

installation .................................................HA-111

Compressor mounting ..................................HA-109

Compressor precaution ....................................HA-7

Compressor special service tool ......................HA-7

Connecting rod......EM-55, 171, 176, 186, 193, 200

Connecting rod bearing

clearance....EM-58, 111, 115, 170, 187, 195, 201

Connecting rod bushing clearance ........EM-59, 116

Console box - See Instrument panel ..............BT-15

CONSULT for ABS .........................................BR-69

CONSULT for engine ...........EC-QG-55, EC-SR-68,

EC-CD-27

CONSULT-II general information .....................GI-39

Control sleeve position sensor ................EC-CD-74

Converter housing installation .......................AT-117

COOL/F - Wiring diagram ....................EC-QG-292,

EC-SR-282, EC-CD-89

Coolant replacement .........................MA-19, 29, 40

Cooling circuit (engine) ........................LC-8, 21, 31

Cooling fan control ...........EC-QG-289, EC-SR-279,

EC-CD-20, 87

Cooling fan motor .............EC-QG-299, EC-SR-289

Cooling fan relay ..............EC-QG-299, EC-SR-289,

EC-CD-96

Crank angle sensor built into distributor

- See Camshaft position sensor .......EC-QG-238,

EC-SR-239

‘‘Crankcase emission control system -

See positive crankcase

ventilation’’ .........................EC-QG-28, EC-SR-30

Crankcase ventilation system - See

Positive crankcase

ventilation ..........................EC-QG-28, EC-SR-30

Crankshaft ........EM-53, 57, 61, 110, 113, 118, 131,

138, 139, 167, 172, 175, 186, 194, 200

Crankshaft position sensor (OBD) .......EC-QG-232,

EC-SR-234, 290

Crankshaft position sensor (POS).........EC-QG-232

Crankshaft position sensor (TDC)..........EC-CD-114

CSPS - Wiring diagram ...........................EC-CD-75

Cylinder block .........................EM-52, 55, 109, 166,

173, 184, 192, 199

Cylinder head ..........EM-31, 86, 140, 178, 188, 196

D

Data link connector for

Consult ..............................EC-QG-29, EC-SR-31

Daytime light system.......................................EL-78

DEF - Wiring diagram ...................................EL-209

Detonation sensor - See Knock

sensor ............................EC-QG-228, EC-SR-230

Diagnosis sensor unit .....................................RS-13Diagnostic trouble code (DTC) for OBD

system ...................................EC-QG-6, EC-SR-6

Diagnostic trouble code (DTC) inspec-

tion priority chart...............EC-QG-80, EC-SR-92,

EC-CD-39

Dimensions ......................................................GI-45

Direct ignition system ..............................EC-QG-32

Door lock .........................................................BT-13

Door mirror ......................................................BT-58

Door trim .........................................................BT-24

Door, front .......................................................BT-13

Door, rear ........................................................BT-13

Drive belt inspection ..........................MA-18, 28, 39

Drive plate runout...................................EM-60, 117

Drive shaft (front) ............................................FA-15

Dropping resistor (A/T) ....................................AT-78

DTC work support .................EC-QG-63, EC-SR-76

DTRL - Wiring diagram ...................................EL-79

E

ECCS relay ............................................EC-CD-140

ECM input/output signal......EC-QG-91, EC-SR-103

ECTS - Wiring diagram ....EC-QG-122, EC-SR-134,

EC-CD-67

EGR control (EGRC) - solenoid valve ...EC-CD-129

EGR control valve..........................EC-QG-252, 311

EGR temperature sensor ......................EC-QG-300

EGR/TS - Wiring diagram .....................EC-QG-302

EGRC - Wiring diagram .........................EC-CD-131

EGRC1 - Wiring diagram ..............EC-QG-248, 309

Electric governer ......................................EC-CD-78

Electric sun roof ............................................EL-230

Electrical diagnoses.........................................GI-24

Electrical ignition system.......EC-QG-23, EC-SR-25

Electrical unit ................................................Foldout

Electronic fuel injection pump ..................EC-CD-24

Engine control circuit

diagram ...........EC-QG-17, EC-SR-19, EC-CD-11

Engine control component parts

location ..............................EC-QG-14, EC-SR-15

Engine control module

(ECM) .....EC-QG-282, EC-SR-277, EC-CD-9, 86

Engine control system diagram and

chart ................EC-QG-18, EC-SR-20, EC-CD-12

Engine coolant temperature sensor

(ECTS) ........EC-QG-120, EC-SR-132, EC-CD-66

Engine fail-safe system .........EC-QG-81, EC-SR-93

Engine oil filter replacement ....................MA-24, 45

Engine oil precautions .......................................GI-6

Engine oil replacement ......................MA-24, 34, 45

Engine removal..............................EM-48, 106, 162

Engine serial number ......................................GI-44

Engine trouble diagnoses ........................EC-CD-33

EVAP canister .......................EC-QG-26, EC-SR-28

EVAP canister purge volume control

solenoid valve ...........EC-QG-26, 262, EC-SR-28

EVAP canister purge volume control

valve ..............................EC-QG-262, EC-SR-250

EVAP vapor lines inspection....................MA-26, 37

ALPHABETICAL INDEX

IDX-3

Page 1974 of 2267

S/SIG - Wiring diagram ....EC-QG-333, EC-SR-313,

EC-CD-145

Stabilizer bar (front) ........................................FA-32

Stall test (A/T) .................................................AT-34

Standardized relay ............................................EL-8

START - Wiring diagram .................................EL-37

Start signal .................EC-QG-38, 332, EC-SR-312,

EC-CD-145

Starter .......................................................EL-37, 43

Starting system ...............................................EL-37

Steering gear and linkage inspection ............MA-53

Steering knuckle........................................FA-11, 12

Stop lamp ......................................................EL-104

STOP/L - Wiring diagram..............................EL-104

Sun roof, electric ...........................................EL-230

Sunload sensor ..............................................HA-86

Sunroof .....................................................BT-31, 46

Super lock .............................................EL-245, 265

Supplemental Restraint System .......................RS-8

Supplemental restraint system - Wiring

diagram .......................................................RS-33

Symbols and abbreviations .............................GI-38

Symptom matrix chart ...........EC-QG-82, EC-SR-94

Synchronizer (M/T) ......................MT-22, 27, 59, 65

System readiness test (SRT) code ..........EC-SR-50

T

Tachometer ...........................................EL-141, 146

Tail lamp ........................................................EL-100

TCM circuit diagram ........................................AT-10

TCM inspection table ......................................AT-41

Temperature control cable and linkage

adjustment ..................................................HA-83

THEFT - Wiring diagram ...............................EL-316

Theft warning system ....................................EL-311

Thermal protector .........................................HA-113

Thermo control amp .......................................HA-80

Thermostat ..........................................LC-11, 23, 34

Third link (front susp.) .....................................FA-29

Three way catalyst ............EC-QG-258, EC-SR-246

Three way catalyst precautions.........................GI-6

Throttle position sensor

(TPS) .............................EC-QG-125, EC-SR-137

Throttle position sensor

adjustment .........................EC-QG-72, EC-SR-84

Throttle position switch ...............EC-SR-271, AT-85

Tightening torque of standard bolts.................GI-50

Time control system ......................................EL-306

Timing belt....................................................EM-131

Timing chain.............................................EM-19, 75

Tire rotation ....................................................MA-53

Tire size ...........................................................GI-45

Torque converter installation .........................AT-117

Torque convertor clutch solenoid valve...........AT-69

Tow truck towing ..............................................GI-46

Towing point.....................................................GI-49

TP/SW - Wiring diagram ........................EC-SR-273

TPS - Wiring diagram .......EC-QG-128, EC-SR-140

Transmission case (M/T) ................................MT-39Transverse link (front) .....................................FA-32

Trim .................................................................BT-18

Triple pressure switch ....................................HA-79

Trouble diagnoses ...........................................GI-35

Trunk lid ............................................................BT-7

Trunk lid opener - See Trunk lid .......................BT-7

Trunk room lamp...................................EL-130, 131

Trunk room trim...............................................BT-28

Turbocharger........................................EM-156, 201

Turbocharger precautions..................................GI-6

TURN - Wiring diagram.................................EL-118

Turn signal lamp............................................EL-117

Two trip detection logic .........EC-QG-36, EC-SR-48

U

Upper link (front susp.) ...................................FA-29

V

Vacuum hose (brake system).........................BR-20

Vacuum hose drawing (Engine

control) ............EC-QG-19, EC-SR-21, EC-CD-13

Valve clearance .............................EM-40, 179, 191

Valve guide..............EM-36, 93, 142, 180, 189, 197

Valve lifter ..............................EM-40, 145, 179, 198

Valve seat................EM-38, 95, 143, 182, 190, 198

Valve spring.............EM-39, 96, 145, 179, 189, 197

Vehicle identification number...........................GI-43

Vehicle speed sensor

(VSS) ..........EC-QG-267, EC-SR-255, EC-CD-70

Viscosity number (SAE) .................................MA-17

VSS - Wiring

diagram .......EC-QG-269, EC-SR-257, EC-CD-71

W

WARN - Wiring diagram ...............................EL-167

Warning buzzer .............................................EL-180

Warning chime ..............................................EL-180

Warning lamps ..............................................EL-165

Washer, front .................................................EL-186

Washer, rear..................................................EL-193

Water cock control rod adjustment ................HA-82

Water pump ........................................LC-10, 22, 33

Water temperature gauge .....................EL-141, 146

Weatherstrip - See Exterior ............................BT-31

Wheel alignment (front) ..................................FA-35

Wheel alignment (rear).....................................RA-6

Wheel balance ...............................................MA-53

Wheel bearing (front axle) ....................FA-6, 12, 35

Wheel bearing (rear) ........................................RA-5

Wheel hub (front) ............................................FA-12

Wheel hub (rear) ..............................................RA-7

Wheel sensors (ABS) .....................................BR-53

Wheel size .......................................................GI-45

Wheelbase (Dimensions) ................................GI-45

ALPHABETICAL INDEX

IDX-7

Page 1975 of 2267

Wide open & closed throttle position

switch.............................EC-QG-125, EC-SR-137

Width (Dimensions) .........................................GI-45

WINDOW - Wiring diagram ..........................EL-240

Windshield.......................................................BT-53

WIP/R - Wiring diagram ................................EL-195Wiper and washer .........................................EL-188

Wiper, front....................................................EL-186

Wiper, rear ....................................................EL-193

Wiring diagrams ...............................................GI-11

ALPHABETICAL INDEX

IDX-8

Page 2104 of 2267

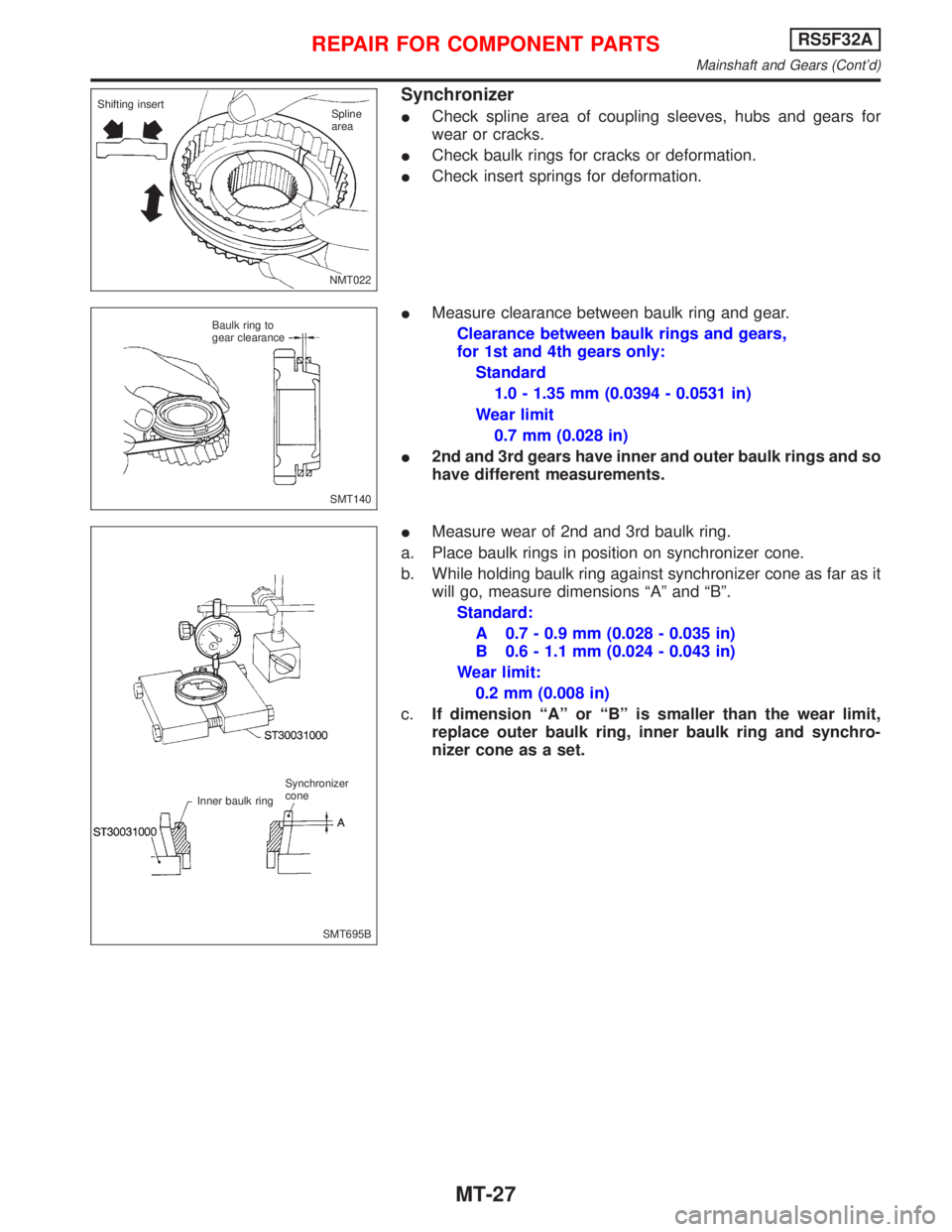

Synchronizer

ICheck spline area of coupling sleeves, hubs and gears for

wear or cracks.

ICheck baulk rings for cracks or deformation.

ICheck insert springs for deformation.

IMeasure clearance between baulk ring and gear.

Clearance between baulk rings and gears,

for 1st and 4th gears only:

Standard

1.0 - 1.35 mm (0.0394 - 0.0531 in)

Wear limit

0.7 mm (0.028 in)

I2nd and 3rd gears have inner and outer baulk rings and so

have different measurements.

IMeasure wear of 2nd and 3rd baulk ring.

a. Place baulk rings in position on synchronizer cone.

b. While holding baulk ring against synchronizer cone as far as it

will go, measure dimensions ªAº and ªBº.

Standard:

A 0.7 - 0.9 mm (0.028 - 0.035 in)

B 0.6 - 1.1 mm (0.024 - 0.043 in)

Wear limit:

0.2 mm (0.008 in)

c.If dimension ªAº or ªBº is smaller than the wear limit,

replace outer baulk ring, inner baulk ring and synchro-

nizer cone as a set.

NMT022 Shifting insert

Spline

area

SMT140 Baulk ring to

gear clearance

SMT695B Synchronizer

cone

Inner baulk ring

REPAIR FOR COMPONENT PARTSRS5F32A

Mainshaft and Gears (Cont'd)

MT-27

Page 2143 of 2267

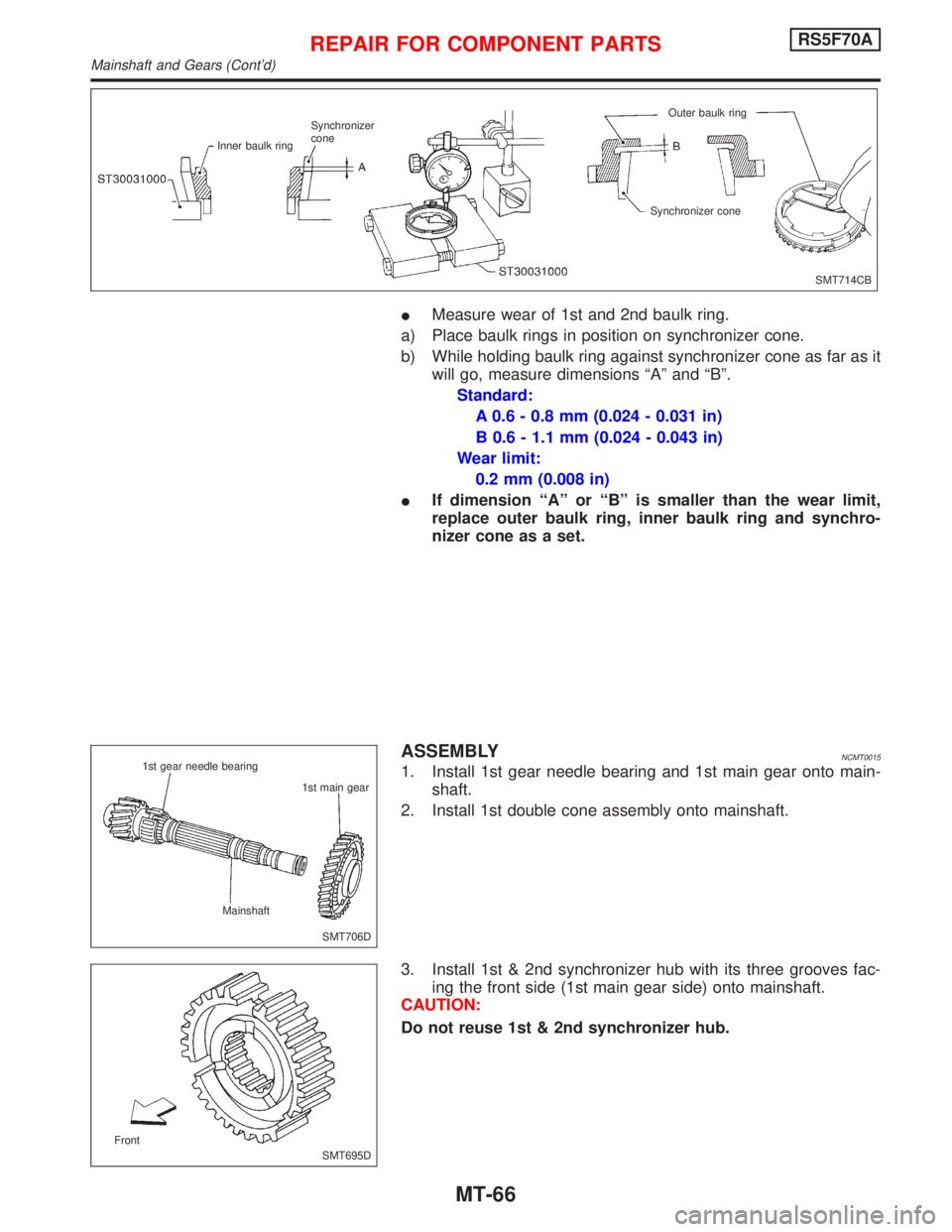

IMeasure wear of 1st and 2nd baulk ring.

a) Place baulk rings in position on synchronizer cone.

b) While holding baulk ring against synchronizer cone as far as it

will go, measure dimensions ªAº and ªBº.

Standard:

A 0.6 - 0.8 mm (0.024 - 0.031 in)

B 0.6 - 1.1 mm (0.024 - 0.043 in)

Wear limit:

0.2 mm (0.008 in)

IIf dimension ªAº or ªBº is smaller than the wear limit,

replace outer baulk ring, inner baulk ring and synchro-

nizer cone as a set.

ASSEMBLYNCMT0015

1. Install 1st gear needle bearing and 1st main gear onto main-

shaft.

2. Install 1st double cone assembly onto mainshaft.

3. Install 1st & 2nd synchronizer hub with its three grooves fac-

ing the front side (1st main gear side) onto mainshaft.

CAUTION:

Do not reuse 1st & 2nd synchronizer hub.

SMT714CB Inner baulk ringSynchronizer

coneOuter baulk ring

Synchronizer cone

SMT706D 1st gear needle bearing

1st main gear

Mainshaft

SMT695D Front

REPAIR FOR COMPONENT PARTSRS5F70A

Mainshaft and Gears (Cont'd)

MT-66