control NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 2152 of 2267

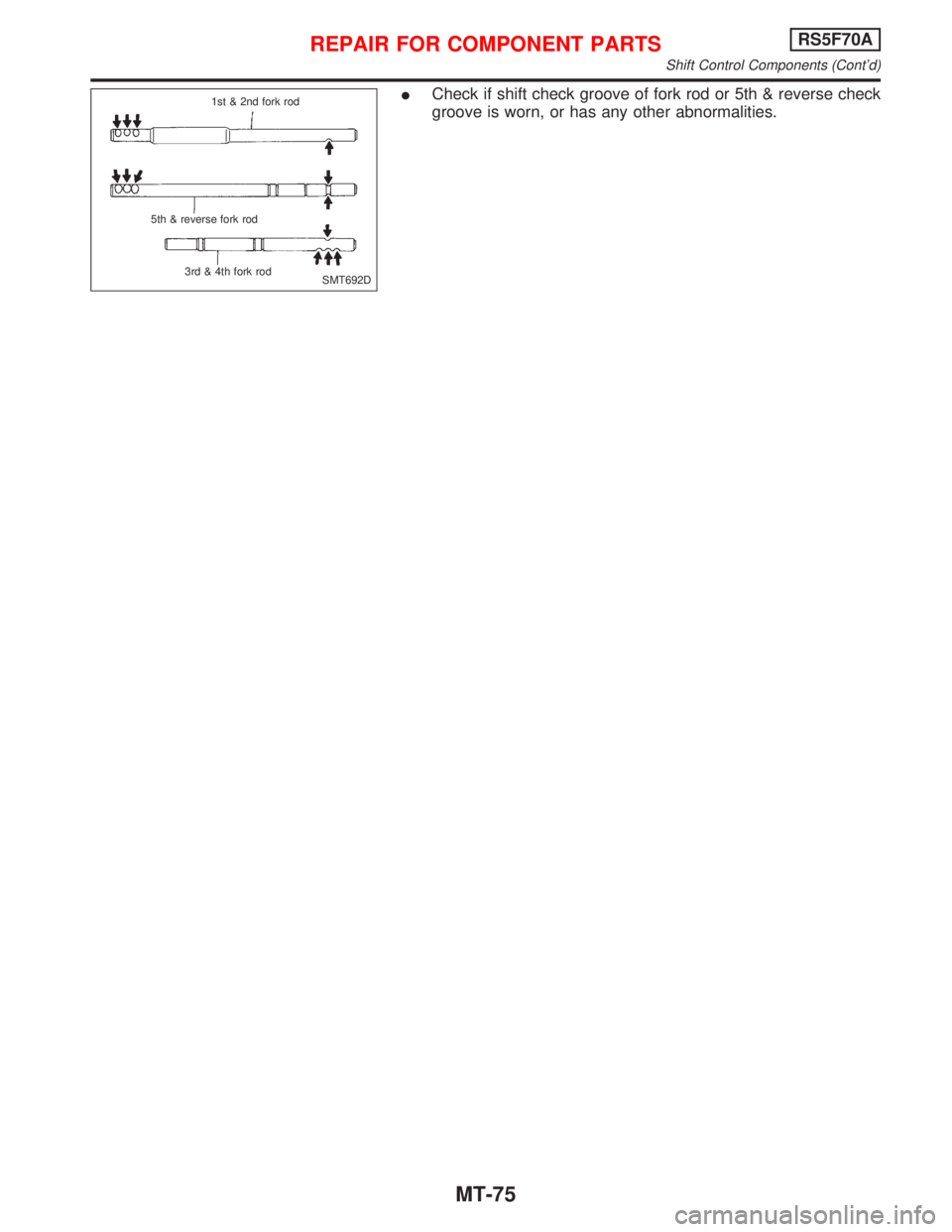

ICheck if shift check groove of fork rod or 5th & reverse check

groove is worn, or has any other abnormalities.

SMT692D 1st & 2nd fork rod

5th & reverse fork rod

3rd & 4th fork rod

REPAIR FOR COMPONENT PARTSRS5F70A

Shift Control Components (Cont'd)

MT-75

Page 2166 of 2267

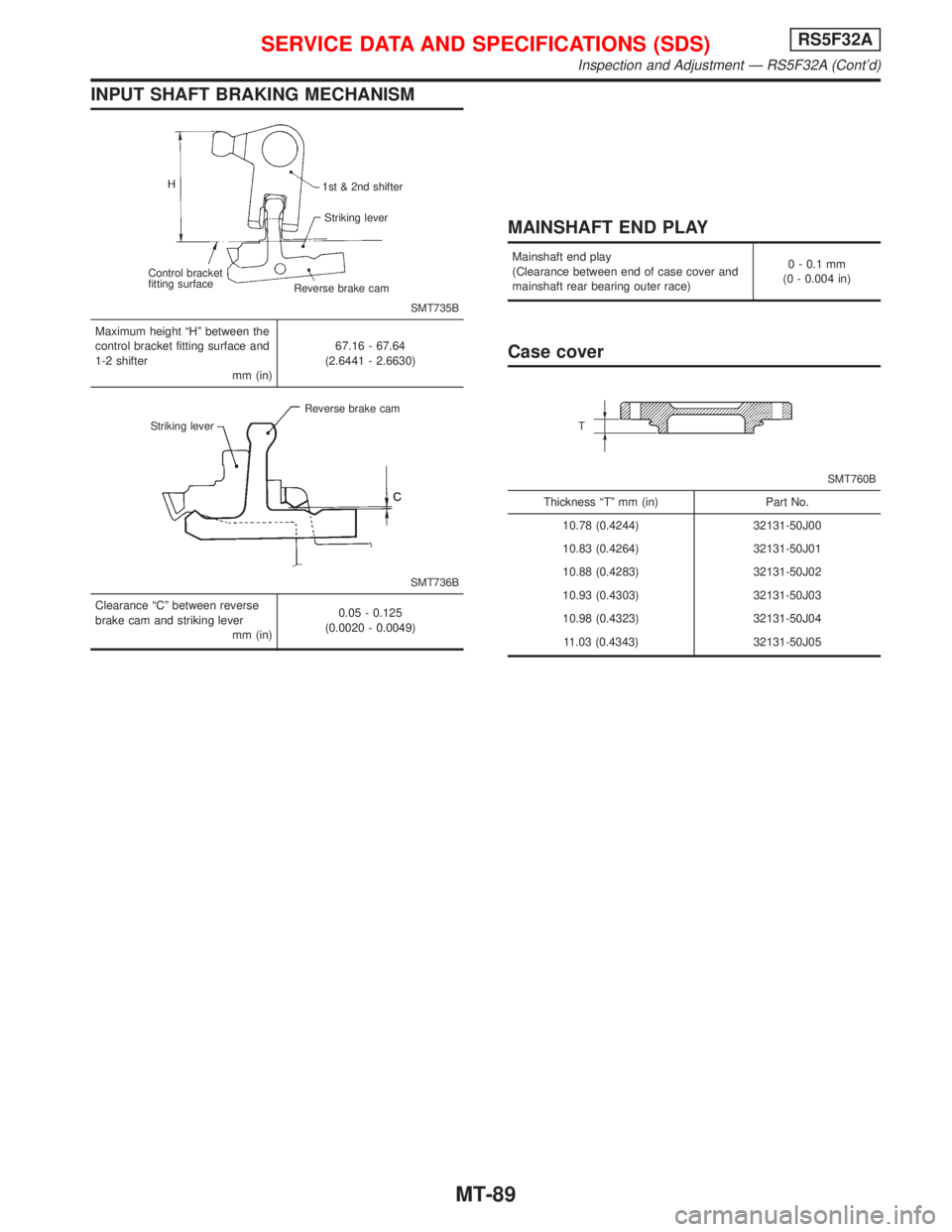

INPUT SHAFT BRAKING MECHANISM

SMT735B 1st & 2nd shifter

Striking lever

Reverse brake cam Control bracket

fitting surface

Maximum height ªHº between the

control bracket fitting surface and

1-2 shifter

mm (in)67.16 - 67.64

(2.6441 - 2.6630)

SMT736B Reverse brake cam

Striking lever

Clearance ªCº between reverse

brake cam and striking lever

mm (in)0.05 - 0.125

(0.0020 - 0.0049)

MAINSHAFT END PLAY

Mainshaft end play

(Clearance between end of case cover and

mainshaft rear bearing outer race)0 - 0.1 mm

(0 - 0.004 in)

Case cover

SMT760B T

Thickness ªTº mm (in) Part No.

10.78 (0.4244) 32131-50J00

10.83 (0.4264) 32131-50J01

10.88 (0.4283) 32131-50J02

10.93 (0.4303) 32131-50J03

10.98 (0.4323) 32131-50J04

11.03 (0.4343) 32131-50J05

SERVICE DATA AND SPECIFICATIONS (SDS)RS5F32A

Inspection and Adjustment Ð RS5F32A (Cont'd)

MT-89

Page 2170 of 2267

REAR AXLE &

REAR SUSPENSION

SECTION

RA

CONTENTS

PRECAUTIONS AND PREPARATION.......................... 2

Precautions ................................................................ 2

Special Service Tools ................................................ 2

Commercial Service Tools ......................................... 2

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING................................................... 3

NVH Troubleshooting Chart....................................... 3

REAR SUSPENSION SYSTEM..................................... 4

ON-VEHICLE SERVICE................................................ 5

Rear Axle and Rear Suspension Parts ..................... 5

Rear Wheel Bearing .................................................. 5Rear Wheel Alignment ............................................... 6

REAR AXLE................................................................... 7

Wheel Hub ................................................................. 7

REAR SUSPENSION..................................................... 9

Removal and Installation ......................................... 10

Coil Spring and Shock Absorber .............................. 11

Torsion Beam, Lateral Link and Control Rod .......... 12

SERVICE DATA AND SPECIFICATIONS (SDS)........ 14

General Specifications ............................................. 14

Inspection and Adjustment ...................................... 14

RA

Page 2173 of 2267

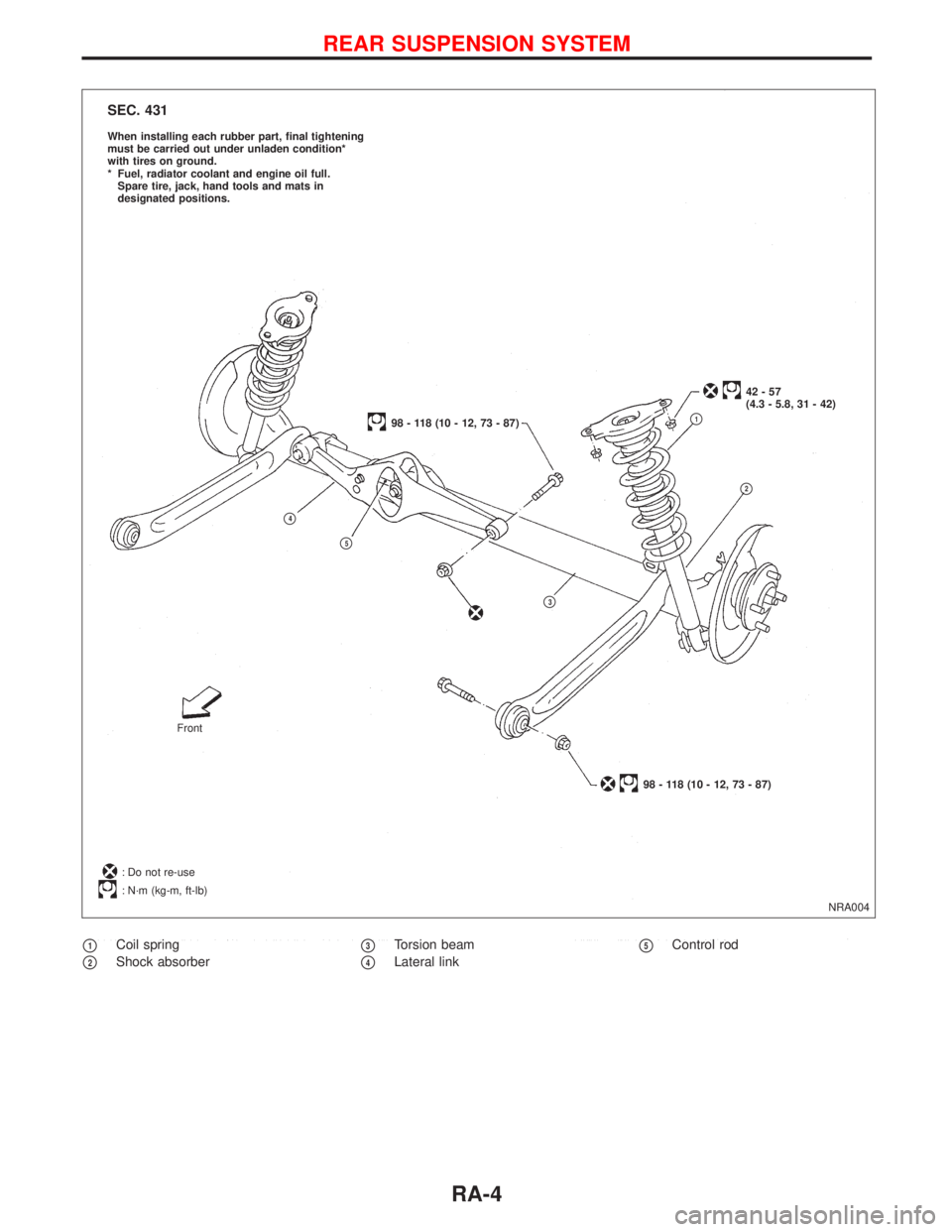

p1Coil spring

p2Shock absorberp3Torsion beam

p4Lateral linkp5Control rod

NRA004

98 - 118 (10 - 12, 73 - 87)

42-57

(4.3 - 5.8, 31 - 42)

p1

p2

p3

p4

p5

98 - 118 (10 - 12, 73 - 87) Front

: Do not re-use

: N´m (kg-m, ft-lb)

SEC. 431

When installing each rubber part, final tightening

must be carried out under unladen condition*

with tires on ground.

* Fuel, radiator coolant and engine oil full.

Spare tire, jack, hand tools and mats in

designated positions.

REAR SUSPENSION SYSTEM

RA-4

Page 2178 of 2267

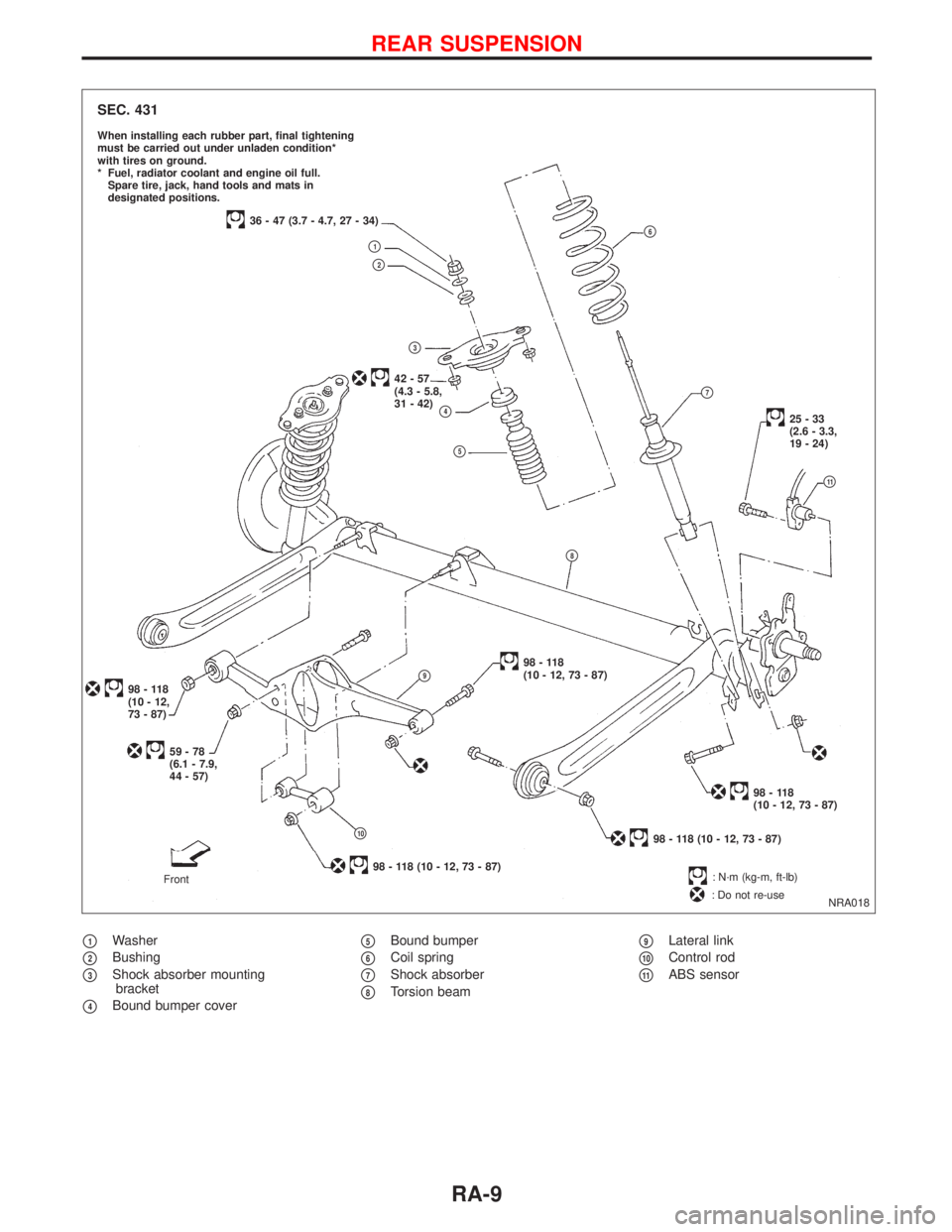

p1Washer

p2Bushing

p3Shock absorber mounting

bracket

p4Bound bumper cover

p5Bound bumper

p6Coil spring

p7Shock absorber

p8Torsion beam

p9Lateral link

p10Control rod

p11ABS sensor

NRA018

SEC. 431

When installing each rubber part, final tightening

must be carried out under unladen condition*

with tires on ground.

* Fuel, radiator coolant and engine oil full.

Spare tire, jack, hand tools and mats in

designated positions.

36 - 47 (3.7 - 4.7, 27 - 34)

p1

p2

p3

42-57

(4.3 - 5.8,

31 - 42)

p4

p5

p6

p7

25-33

(2.6 - 3.3,

19 - 24)

p8

98-118

(10 - 12, 73 - 87)p9

p10

98-118

(10 - 12,

73 - 87)

59-78

(6.1 - 7.9,

44 - 57)

Front

98 - 118 (10 - 12, 73 - 87)

p11

98-118

(10 - 12, 73 - 87)

: N´m (kg-m, ft-lb)

: Do not re-use

98 - 118 (10 - 12, 73 - 87)

REAR SUSPENSION

RA-9

Page 2179 of 2267

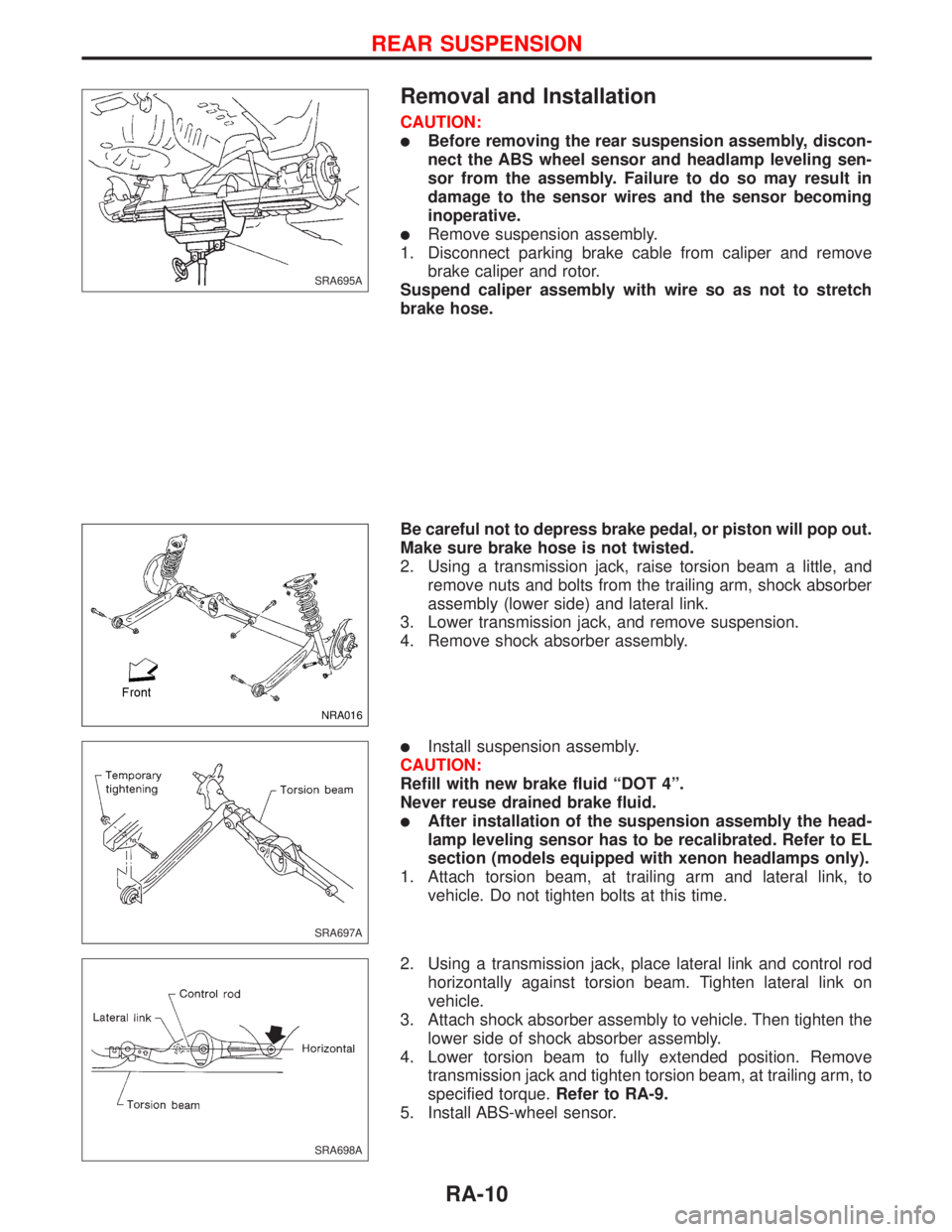

Removal and Installation

CAUTION:

lBefore removing the rear suspension assembly, discon-

nect the ABS wheel sensor and headlamp leveling sen-

sor from the assembly. Failure to do so may result in

damage to the sensor wires and the sensor becoming

inoperative.

lRemove suspension assembly.

1. Disconnect parking brake cable from caliper and remove

brake caliper and rotor.

Suspend caliper assembly with wire so as not to stretch

brake hose.

Be careful not to depress brake pedal, or piston will pop out.

Make sure brake hose is not twisted.

2. Using a transmission jack, raise torsion beam a little, and

remove nuts and bolts from the trailing arm, shock absorber

assembly (lower side) and lateral link.

3. Lower transmission jack, and remove suspension.

4. Remove shock absorber assembly.

lInstall suspension assembly.

CAUTION:

Refill with new brake fluid ªDOT 4º.

Never reuse drained brake fluid.

lAfter installation of the suspension assembly the head-

lamp leveling sensor has to be recalibrated. Refer to EL

section (models equipped with xenon headlamps only).

1. Attach torsion beam, at trailing arm and lateral link, to

vehicle. Do not tighten bolts at this time.

2. Using a transmission jack, place lateral link and control rod

horizontally against torsion beam. Tighten lateral link on

vehicle.

3. Attach shock absorber assembly to vehicle. Then tighten the

lower side of shock absorber assembly.

4. Lower torsion beam to fully extended position. Remove

transmission jack and tighten torsion beam, at trailing arm, to

specified torque.Refer to RA-9.

5. Install ABS-wheel sensor.

SRA695A

NRA016

SRA697A

SRA698A

REAR SUSPENSION

RA-10

Page 2181 of 2267

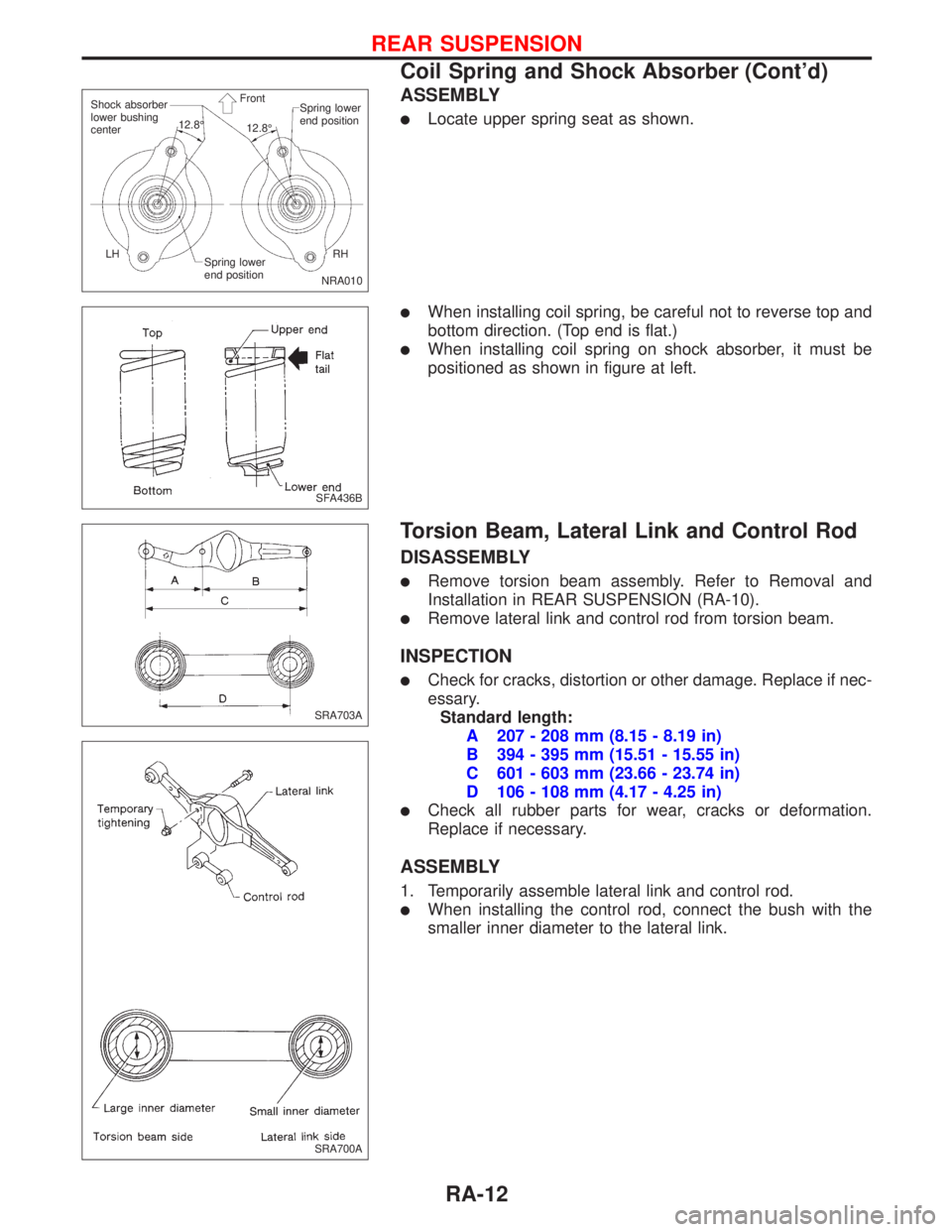

ASSEMBLY

lLocate upper spring seat as shown.

lWhen installing coil spring, be careful not to reverse top and

bottom direction. (Top end is flat.)

lWhen installing coil spring on shock absorber, it must be

positioned as shown in figure at left.

Torsion Beam, Lateral Link and Control Rod

DISASSEMBLY

lRemove torsion beam assembly. Refer to Removal and

Installation in REAR SUSPENSION (RA-10).

lRemove lateral link and control rod from torsion beam.

INSPECTION

lCheck for cracks, distortion or other damage. Replace if nec-

essary.

Standard length:

A 207 - 208 mm (8.15 - 8.19 in)

B 394 - 395 mm (15.51 - 15.55 in)

C 601 - 603 mm (23.66 - 23.74 in)

D 106 - 108 mm (4.17 - 4.25 in)

lCheck all rubber parts for wear, cracks or deformation.

Replace if necessary.

ASSEMBLY

1. Temporarily assemble lateral link and control rod.

lWhen installing the control rod, connect the bush with the

smaller inner diameter to the lateral link.

NRA010 Shock absorber

lower bushing

centerSpring lower

end position

Spring lower

end positionRH LH12.8É

12.8É Front

SFA436B

SRA703A

SRA700A

REAR SUSPENSION

Coil Spring and Shock Absorber (Cont'd)

RA-12

Page 2182 of 2267

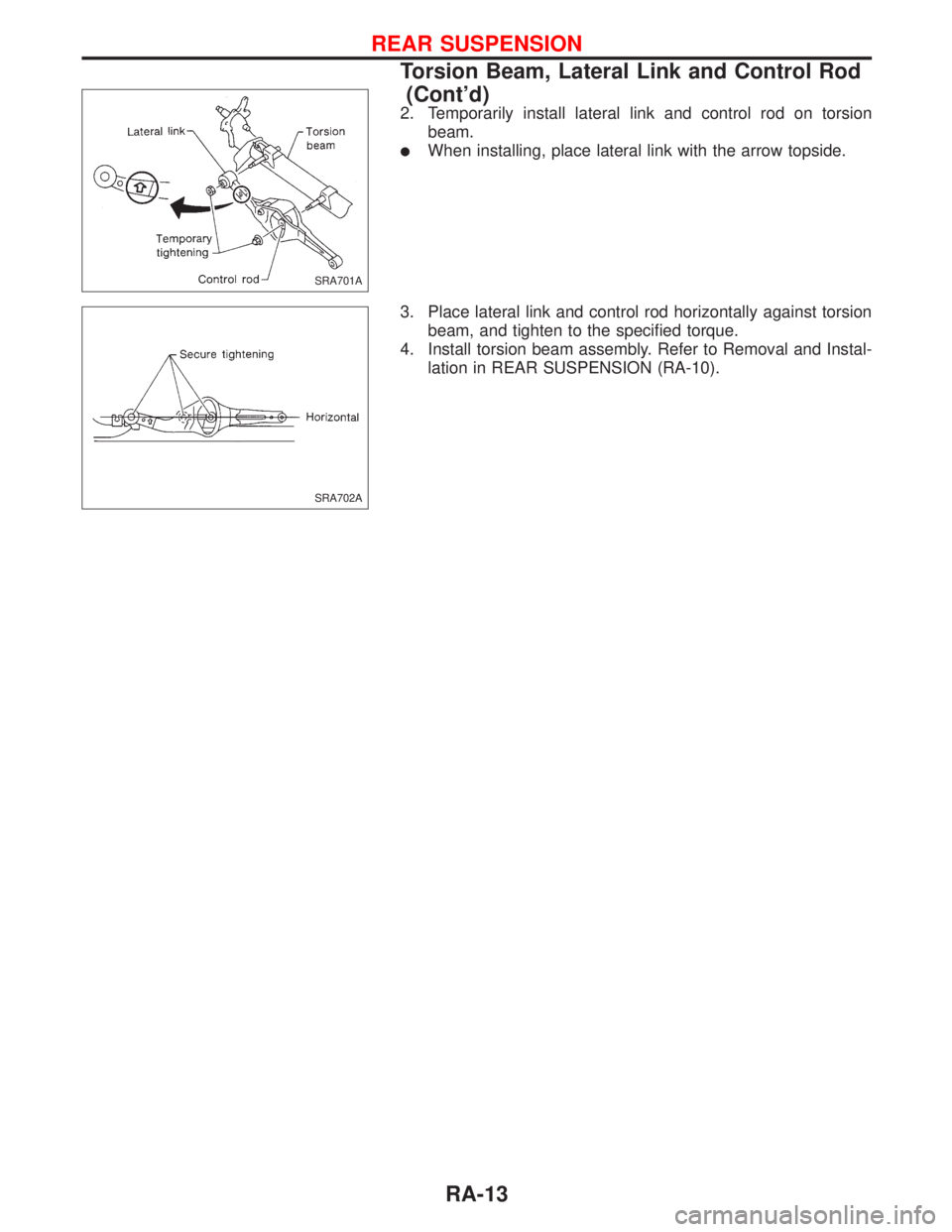

2. Temporarily install lateral link and control rod on torsion

beam.

lWhen installing, place lateral link with the arrow topside.

3. Place lateral link and control rod horizontally against torsion

beam, and tighten to the specified torque.

4. Install torsion beam assembly. Refer to Removal and Instal-

lation in REAR SUSPENSION (RA-10).

SRA701A

SRA702A

REAR SUSPENSION

Torsion Beam, Lateral Link and Control Rod

(Cont'd)

RA-13

Page 2224 of 2267

![NISSAN PRIMERA 1999 Electronic Repair Manual Diagnostic item ExplanationRepair order

Recheck SRS at each

replacement.

SATELLITE SENS RH

[UNIT FAIL]

SATELLITE SENS RH

[COMM FAIL]

lSatellite sensor (RH) 1. Visually check the wiring

harness connect NISSAN PRIMERA 1999 Electronic Repair Manual Diagnostic item ExplanationRepair order

Recheck SRS at each

replacement.

SATELLITE SENS RH

[UNIT FAIL]

SATELLITE SENS RH

[COMM FAIL]

lSatellite sensor (RH) 1. Visually check the wiring

harness connect](/img/5/57377/w960_57377-2223.png)

Diagnostic item ExplanationRepair order

Recheck SRS at each

replacement.

SATELLITE SENS RH

[UNIT FAIL]

SATELLITE SENS RH

[COMM FAIL]

lSatellite sensor (RH) 1. Visually check the wiring

harness connection.

2. Replace the harness if it

has visible damage.

3. Replace the satellite sen-

sor (RH).

4. Replace the diagnosis

sensor unit.

5. Replace the related har-

ness.

PRE-TEN LH

[OPEN/VB-SHORT]

lThe circuit for LH pre-tensioner is open or shorted to some

power supply circuit.1. Visually check the wiring

harness connections.

2. Replace the harness if it

has visible damage.

3. Replace LH seat belt.

(Before disposing, it must

be deactivated.)

4. Replace the diagnosis

sensor unit

5. Replace the related har-

ness. PRE-TEN LH

[GND-SHORT]

lThe circuit for LH pre-tensioner is shorted to ground.

PRE-TEN RH

[OPEN/VB-SHORT]

lThe circuit for RH pre-tensioner is open or shorted to some

power supply circuit.1. Visually check the wiring

harness connections.

2. Replace the harness if it

has visible damage.

3. Replace RH seat belt.

(Before disposing, it must

be deactivated.)

4. Replace the diagnosis

sensor unit

5. Replace the related har-

ness. PRE-TEN RH

[GND-SHORT]

lThe circuit for RH pre-tensioner is shorted to ground.

CONTROL UNIT

lLow battery voltage or diagnosis sensor unit is out of order. 1. Charge battery.

2. Visually check wiring har-

ness connections.

3. Replace diagnosis sensor

unit.

CONTROL UNIT

lLow battery voltage (Less than 9V)lGo to DIAGNOSTIC PRO-

CEDURE 3 (RS-42) to after

charging battery.

lDiagnosis sensor unit is malfunctioning. 1. Visually check wiring har-

ness connections.

2. Replace the harness if it

has visible damage.

3. Replace diagnosis sensor

unit.

4. Replace the related har-

ness.

* Follow the procedures in numerical order when repairing malfunctioning parts. Confirm whether malfunction is eliminated

using the air bag warning lamp or CONSULT-II each time repair is finished. If malfunction is still observed, proceed to the

next step. When malfunction is eliminated, further repair work is not required.

TROUBLE DIAGNOSES Ð Supplemental Restraint System (SRS)

Trouble Diagnoses with CONSULT-II

(Cont'd)

RS-41

Page 2230 of 2267

![NISSAN PRIMERA 1999 Electronic Repair Manual Diagnostic item Explanation Repair order

SATELLITE SENS RH

[UNIT FAIL]

SATELLITE SENS RH

[COMM FAIL]

lSatellite sensor (RH) 1. Visually check the wiring

harness connection.

2. Replace the harness if i NISSAN PRIMERA 1999 Electronic Repair Manual Diagnostic item Explanation Repair order

SATELLITE SENS RH

[UNIT FAIL]

SATELLITE SENS RH

[COMM FAIL]

lSatellite sensor (RH) 1. Visually check the wiring

harness connection.

2. Replace the harness if i](/img/5/57377/w960_57377-2229.png)

Diagnostic item Explanation Repair order

SATELLITE SENS RH

[UNIT FAIL]

SATELLITE SENS RH

[COMM FAIL]

lSatellite sensor (RH) 1. Visually check the wiring

harness connection.

2. Replace the harness if it

has visible damage.

3. If the harness check is

OK, replace the diagnosis

sensor unit and satellite

sensor (RH).

PRE-TEN LH

[OPEN/VB-SHORT]

lThe circuit for LH seat belt pre-tensioner is open or shorted

to some power supply circuit.1. Visually check the wiring

harness connections.

2. Replace the harness if it

has visible damage.

3. If the harness check is

OK, replace the diagnosis

sensor unit and LH seat

belt. (Before disposing the

LH seat belt pre-tensioner,

if must be deployed.) PRE-TEN LH

[GND-SHORT]

lThe circuit for LH seat belt pre-tensioner is shorted to

ground.

PRE-TEN RH

[OPEN/VB-SHORT]

lThe circuit for RH seat belt pre-tensioner is open or shorted

to some power supply circuit.1. Visually check the wiring

harness connections.

2. Replace the harness if it

has visible damage.

3. If the harness check is

OK, replace the diagnosis

sensor unit and RH seat

belt. (Before disposing the

RH seat belt pre-tensioner,

if must be deployed.) PRE-TEN RH

[GND-SHORT]

lThe circuit for RH seat belt pre-tensioner is shorted to

ground.

CONTROL UNIT

lDiagnosis sensor unit is malfunctioning. 1. Visually check the wiring

harness connection.

2. Replace the harness if it

has visible damage.

3. If the harness check is

OK, replace the diagnosis

sensor unit.

* Follow the procedures in numerical order when repairing malfunctioning parts, then make the final system check.

TROUBLE DIAGNOSES Ð Supplemental Restraint System (SRS)

Trouble Diagnoses with CONSULT-II

(Cont'd)

RS-47