cooling NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 8 of 2267

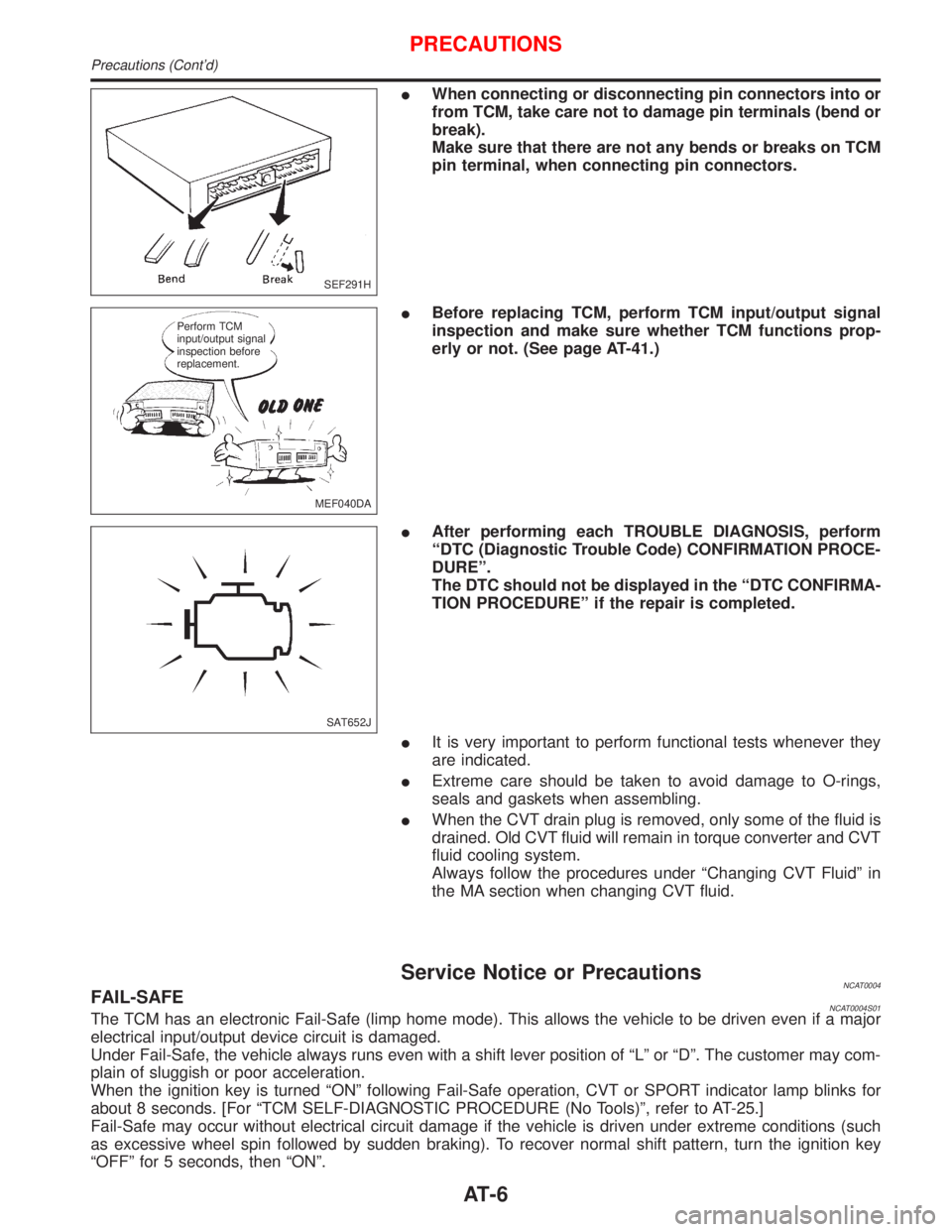

IWhen connecting or disconnecting pin connectors into or

from TCM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on TCM

pin terminal, when connecting pin connectors.

IBefore replacing TCM, perform TCM input/output signal

inspection and make sure whether TCM functions prop-

erly or not. (See page AT-41.)

IAfter performing each TROUBLE DIAGNOSIS, perform

ªDTC (Diagnostic Trouble Code) CONFIRMATION PROCE-

DUREº.

The DTC should not be displayed in the ªDTC CONFIRMA-

TION PROCEDUREº if the repair is completed.

IIt is very important to perform functional tests whenever they

are indicated.

IExtreme care should be taken to avoid damage to O-rings,

seals and gaskets when assembling.

IWhen the CVT drain plug is removed, only some of the fluid is

drained. Old CVT fluid will remain in torque converter and CVT

fluid cooling system.

Always follow the procedures under ªChanging CVT Fluidº in

the MA section when changing CVT fluid.

Service Notice or PrecautionsNCAT0004FAIL-SAFENCAT0004S01The TCM has an electronic Fail-Safe (limp home mode). This allows the vehicle to be driven even if a major

electrical input/output device circuit is damaged.

Under Fail-Safe, the vehicle always runs even with a shift lever position of ªLº or ªDº. The customer may com-

plain of sluggish or poor acceleration.

When the ignition key is turned ªONº following Fail-Safe operation, CVT or SPORT indicator lamp blinks for

about 8 seconds. [For ªTCM SELF-DIAGNOSTIC PROCEDURE (No Tools)º, refer to AT-25.]

Fail-Safe may occur without electrical circuit damage if the vehicle is driven under extreme conditions (such

as excessive wheel spin followed by sudden braking). To recover normal shift pattern, turn the ignition key

ªOFFº for 5 seconds, then ªONº.

SEF291H

MEF040DA Perform TCM

input/output signal

inspection before

replacement.

SAT652J

PRECAUTIONS

Precautions (Cont'd)

AT-6

Page 295 of 2267

ENGINE CONTROL SYSTEM

SECTION

EC

CONTENTS

CD20T

PRECAUTIONS AND PREPARATION.......................... 3

Special Service Tools ................................................ 3

Engine Fuel & Emission Control System .................. 5

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²............. 6

Precautions for On Board Diagnostic (OBD)

System of Engine ...................................................... 6

Precautions ................................................................ 7

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM......................................................................... 9

Engine Control Module Component Parts

Location ..................................................................... 9

Circuit Diagram ......................................................... 11

System Diagram ...................................................... 12

Vacuum Hose Drawing ............................................ 13

System Chart ........................................................... 14

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION............................................. 15

Glow Control System ............................................... 15

Fuel Injection System .............................................. 15

Fuel Injection Timing System .................................. 18

Air Conditioning Cut Control .................................... 20

Cooling Fan Control................................................. 20

CRANKCASE VENTILATION SYSTEM...................... 21

Description ............................................................... 21

Blow-by Control Valve ............................................. 21

Ventilation Hose ....................................................... 21

INJECTION NOZZLE................................................... 22

Removal and Installation ......................................... 22

Test and Adjustment ................................................ 22

ELECTRONIC FUEL INJECTION PUMP.................... 24

Removal ................................................................... 24

Installation ................................................................ 25Disassembly and Assembly ..................................... 26

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION............................................................. 27

CONSULT-II ............................................................. 27

TROUBLE DIAGNOSIS - INTRODUCTION................ 33

Introduction .............................................................. 33

Diagnostic Worksheet .............................................. 34

TROUBLE DIAGNOSIS - WORK FLOW.................... 35

Work Flow ................................................................ 35

Description for Work Flow ....................................... 36

TROUBLE DIAGNOSIS - BASIC INSPECTION......... 37

Basic Inspection....................................................... 37

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION............................................................. 39

Diagnostic Trouble Chart ......................................... 39

Symptom Matrix Chart ............................................. 47

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................ 50

Major Sensor Reference Graph in Data Monitor

Mode ........................................................................ 51

ECM Terminals and Reference Value ..................... 52

TROUBLE DIAGNOSIS FOR POWER SUPPLY........ 59

Main Power Supply and Ground Circuit .................. 59

TROUBLE DIAGNOSIS 1............................................ 62

Mass Air Flow Sensor (MAFS) ................................ 62

TROUBLE DIAGNOSIS 2............................................ 66

Engine Coolant Temperature (ECT) Sensor ........... 66

TROUBLE DIAGNOSIS 3............................................ 70

Vehicle Speed Sensor (VSS) .................................. 70

TROUBLE DIAGNOSIS 4............................................ 74

Control Sleeve Position Sensor (CSPS) ................. 74

TROUBLE DIAGNOSIS 5............................................ 78

Electric Governor ..................................................... 78

TROUBLE DIAGNOSIS 6............................................ 82

EC

Page 296 of 2267

Injection Timing Control Valve ................................. 82

TROUBLE DIAGNOSIS 7............................................ 86

Engine Control Module (ECM) ................................ 86

TROUBLE DIAGNOSIS 8............................................ 87

Cooling Fan (Overheat) ........................................... 87

TROUBLE DIAGNOSIS 9............................................ 97

Needle Lift Sensor (NLS) ........................................ 97

TROUBLE DIAGNOSIS 10........................................ 100

Fuel Cut Solenoid Valve ........................................ 100

TROUBLE DIAGNOSIS 11........................................ 104

Fuel Temperature Sensor (FTS)............................ 104

TROUBLE DIAGNOSIS 12........................................ 108

Accelerator Position Sensor & Switch ................... 108

TROUBLE DIAGNOSIS 13......................................... 114

Crankshaft Position Sensor (TDC) ......................... 114

TROUBLE DIAGNOSES 14....................................... 118

Glow Control System .............................................. 118TROUBLE DIAGNOSES 15...................................... 126

Air Conditioner Cut Control ................................... 126

TROUBLE DIAGNOSES 16...................................... 129

EGRC-Solenoid Valve ........................................... 129

TROUBLE DIAGNOSES 17...................................... 136

Brake Switch .......................................................... 136

TROUBLE DIAGNOSES 18...................................... 140

ECM Relay............................................................. 140

TROUBLE DIAGNOSES 19...................................... 141

MI & Data Link Connectors ................................... 141

TROUBLE DIAGNOSES 20...................................... 145

Start Signal ............................................................ 145

SERVICE DATA AND SPECIFICATIONS (SDS)...... 147

General Specifications ........................................... 147

Injection Nozzle ..................................................... 147

Inspection and Adjustment .................................... 147

When you read wiring diagrams:

lRead GI section, ªHOW TO READ WIRING DIAGRAMSº.

lSee EL section, ªPOWER SUPPLY ROUTINGº for power distribution circuit.

lSee EL section for NATS information and wiring diagram.

When you perform trouble diagnoses, read GI section, ªHOW TO FOLLOW FLOW CHART

IN TROUBLE DIAGNOSESº and ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN

ELECTRICAL INCIDENTº.

For clarification of system component abbreviations and terminology read GI section

ªSAE J1930 TERMINOLOGY LISTº.

EC-2

Page 308 of 2267

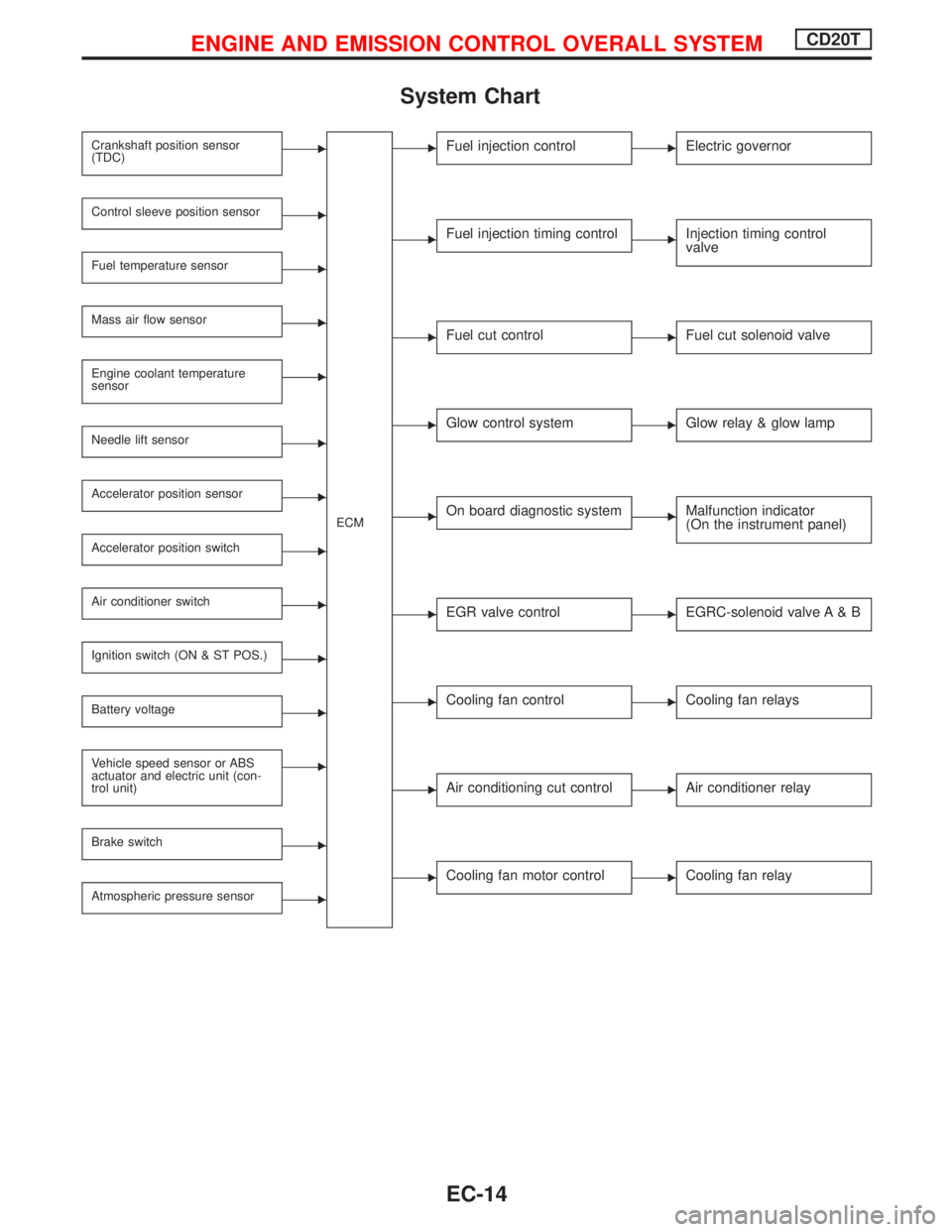

System Chart

Crankshaft position sensor

(TDC)E

ECM

Control sleeve position sensorE

Fuel temperature sensorE

Mass air flow sensorE

Engine coolant temperature

sensorE

Needle lift sensorE

Accelerator position sensorE

Accelerator position switchE

Air conditioner switchE

Ignition switch (ON & ST POS.)E

Battery voltageE

Vehicle speed sensor or ABS

actuator and electric unit (con-

trol unit)E

Brake switchE

Atmospheric pressure sensorE

EFuel injection controlEElectric governor

EFuel injection timing controlEInjection timing control

valve

EFuel cut controlEFuel cut solenoid valve

EGlow control systemEGlow relay & glow lamp

EOn board diagnostic systemEMalfunction indicator

(On the instrument panel)

EEGR valve controlEEGRC-solenoid valve A & B

ECooling fan controlECooling fan relays

EAir conditioning cut controlEAir conditioner relay

ECooling fan motor controlECooling fan relay

ENGINE AND EMISSION CONTROL OVERALL SYSTEMCD20T

EC-14

Page 314 of 2267

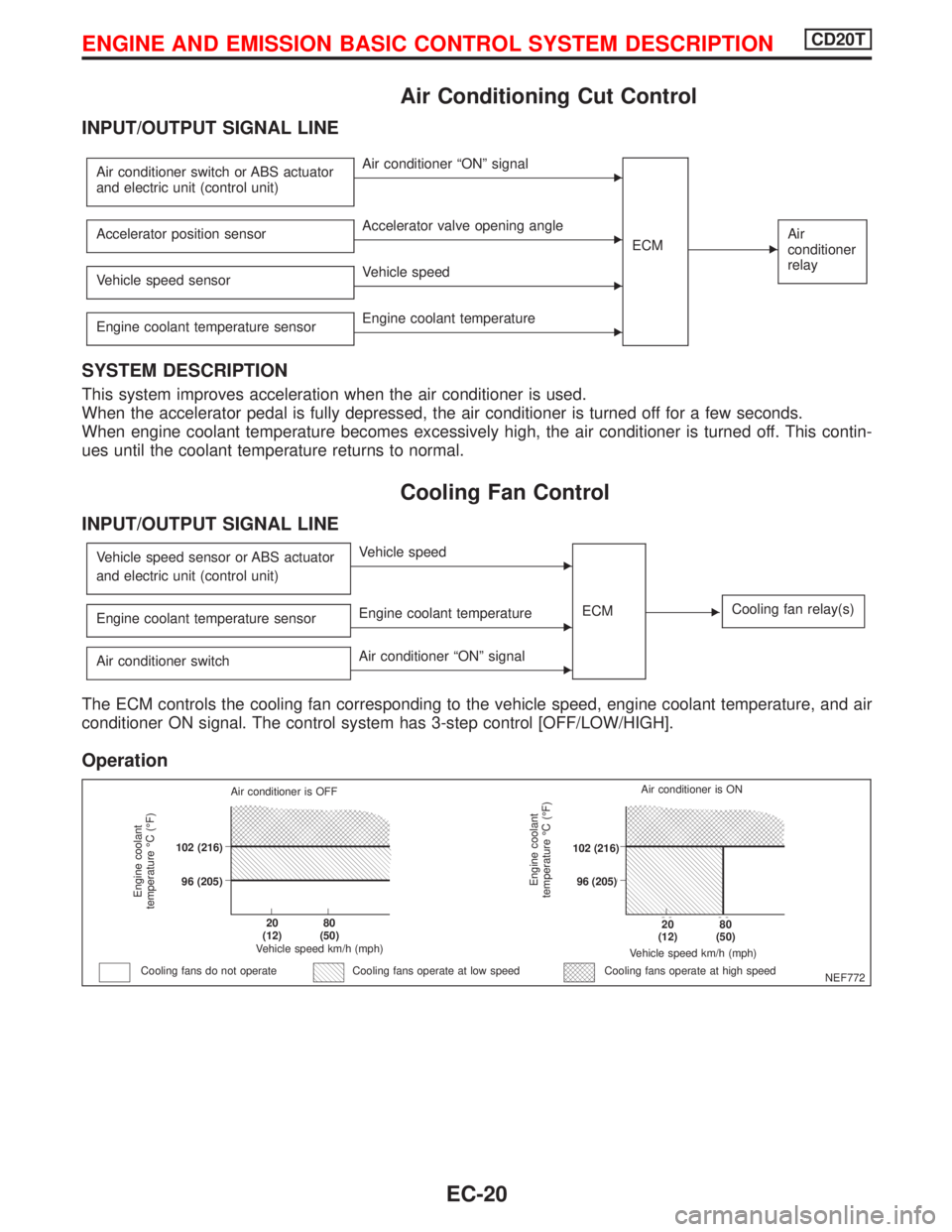

Air Conditioning Cut Control

INPUT/OUTPUT SIGNAL LINE

Air conditioner switch or ABS actuator

and electric unit (control unit)EAir conditioner ªONº signal

ECM

EAir

conditioner

relayAccelerator position sensorEAccelerator valve opening angle

Vehicle speed sensor

EVehicle speed

Engine coolant temperature sensor

EEngine coolant temperature

SYSTEM DESCRIPTION

This system improves acceleration when the air conditioner is used.

When the accelerator pedal is fully depressed, the air conditioner is turned off for a few seconds.

When engine coolant temperature becomes excessively high, the air conditioner is turned off. This contin-

ues until the coolant temperature returns to normal.

Cooling Fan Control

INPUT/OUTPUT SIGNAL LINE

Vehicle speed sensor or ABS actuator

and electric unit (control unit)EVehicle speed

ECM

ECooling fan relay(s)Engine coolant temperature sensorEEngine coolant temperature

Air conditioner switch

EAir conditioner ªONº signal

The ECM controls the cooling fan corresponding to the vehicle speed, engine coolant temperature, and air

conditioner ON signal. The control system has 3-step control [OFF/LOW/HIGH].

Operation

NEF772

Engine coolant

temperature ÉC (ÉF)

Air conditioner is OFF

.102 (216)

.96 (205)

.20

(12).80

(50)

Vehicle speed km/h (mph)

Cooling fans do not operateCooling fans operate at high speed

Engine coolant

temperature ÉC (ÉF)

Vehicle speed km/h (mph)

.20

(12).80

(50)

.102 (216)

.96 (205)Air conditioner is ON

Cooling fans operate at low speed

ENGINE AND EMISSION BASIC CONTROL SYSTEM DESCRIPTIONCD20T

EC-20

Page 322 of 2267

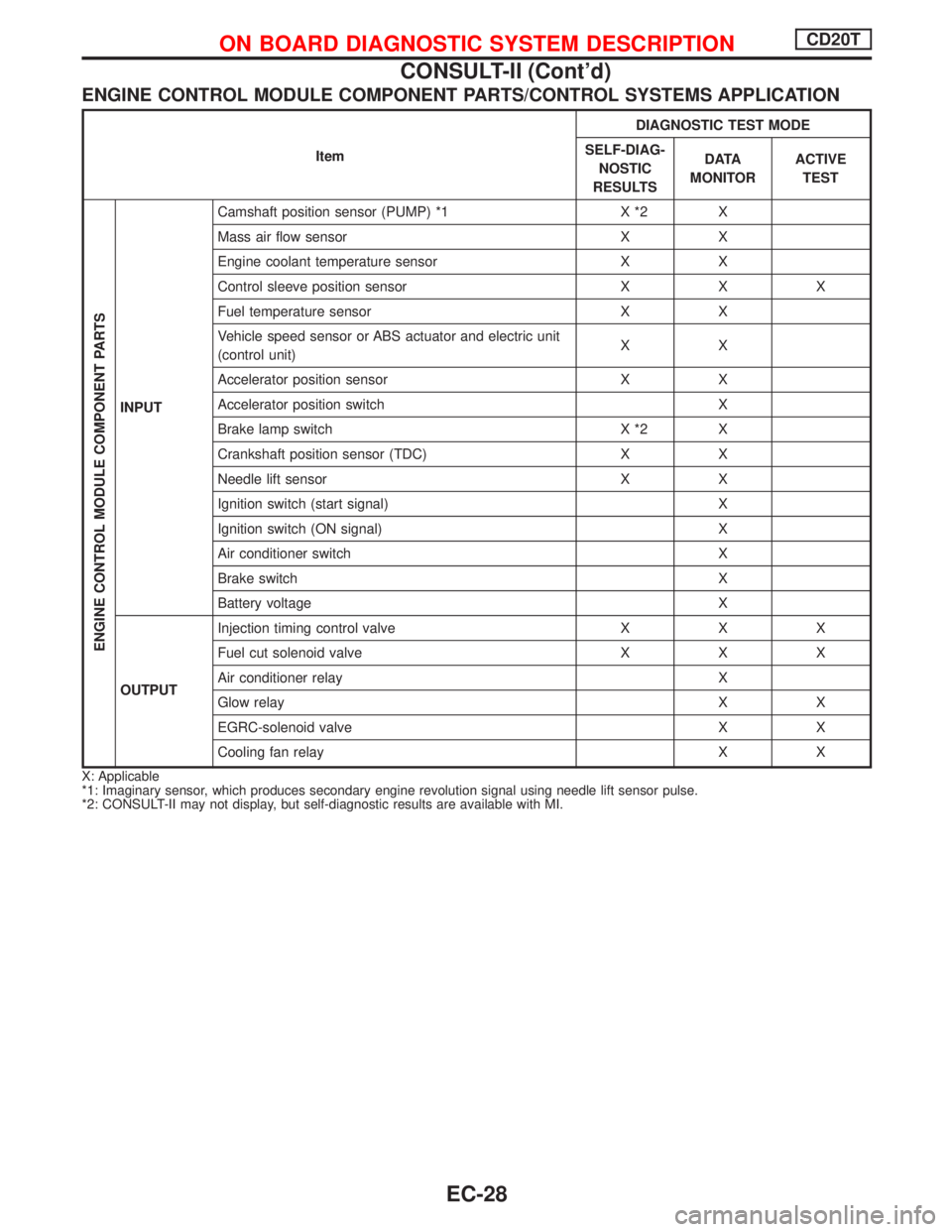

ENGINE CONTROL MODULE COMPONENT PARTS/CONTROL SYSTEMS APPLICATION

ItemDIAGNOSTIC TEST MODE

SELF-DIAG-

NOSTIC

RESULTSD ATA

MONITORACTIVE

TEST

ENGINE CONTROL MODULE COMPONENT PARTS

INPUTCamshaft position sensor (PUMP) *1 X *2 X

Mass air flow sensor X X

Engine coolant temperature sensor X X

Control sleeve position sensor X X X

Fuel temperature sensor X X

Vehicle speed sensor or ABS actuator and electric unit

(control unit)XX

Accelerator position sensor X X

Accelerator position switch X

Brake lamp switch X *2 X

Crankshaft position sensor (TDC) X X

Needle lift sensor X X

Ignition switch (start signal) X

Ignition switch (ON signal) X

Air conditioner switch X

Brake switch X

Battery voltage X

OUTPUTInjection timing control valve X X X

Fuel cut solenoid valve X X X

Air conditioner relay X

Glow relay X X

EGRC-solenoid valve X X

Cooling fan relay X X

X: Applicable

*1: Imaginary sensor, which produces secondary engine revolution signal using needle lift sensor pulse.

*2: CONSULT-II may not display, but self-diagnostic results are available with MI.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONCD20T

CONSULT-II (Cont'd)

EC-28

Page 324 of 2267

![NISSAN PRIMERA 1999 Electronic Repair Manual Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

FUEL CUT S/V

[ON/OFF]

lThe control condition of the fuel cut

solenoid valve (determined by ECM

according to the input signal) is i NISSAN PRIMERA 1999 Electronic Repair Manual Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

FUEL CUT S/V

[ON/OFF]

lThe control condition of the fuel cut

solenoid valve (determined by ECM

according to the input signal) is i](/img/5/57377/w960_57377-323.png)

Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

FUEL CUT S/V

[ON/OFF]

lThe control condition of the fuel cut

solenoid valve (determined by ECM

according to the input signal) is indi-

cated.

lOFF ... Fuel cut solenoid valve is not

operating.

ON ... Fuel cut solenoid valve is oper-

ating.

lWhen the fuel cut solenoid valve is not

operating, fuel supply is shut off.

AIR COND RLY

[ON/OFF]

q

lThe air conditioner relay control condi-

tion (determined by ECM according to

the input signal) is indicated.

GLOW RLY

[ON/OFF]

q

lThe glow relay control condition (deter-

mined by ECM according to the input

signal) is displayed.

COOLING FAN

[LOW/HI/OFF]

q

lIndicates the control condition of the

cooling fans (determined by ECM

according to the input signal).

lLOW ... Operates at low speed.

HI ... Operates at high speed.

OFF ... Stopped.

EGRC SOL/V A

[ON/OFF]

lThe control condition of the EGRC-

solenoid valve (determined by ECM

according to the input signal) is indi-

cated.

lOFF ... EGRC-solenoid valve is not

operating.

ON ... EGRC-solenoid valve is oper-

ating.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONCD20T

CONSULT-II (Cont'd)

EC-30

Page 325 of 2267

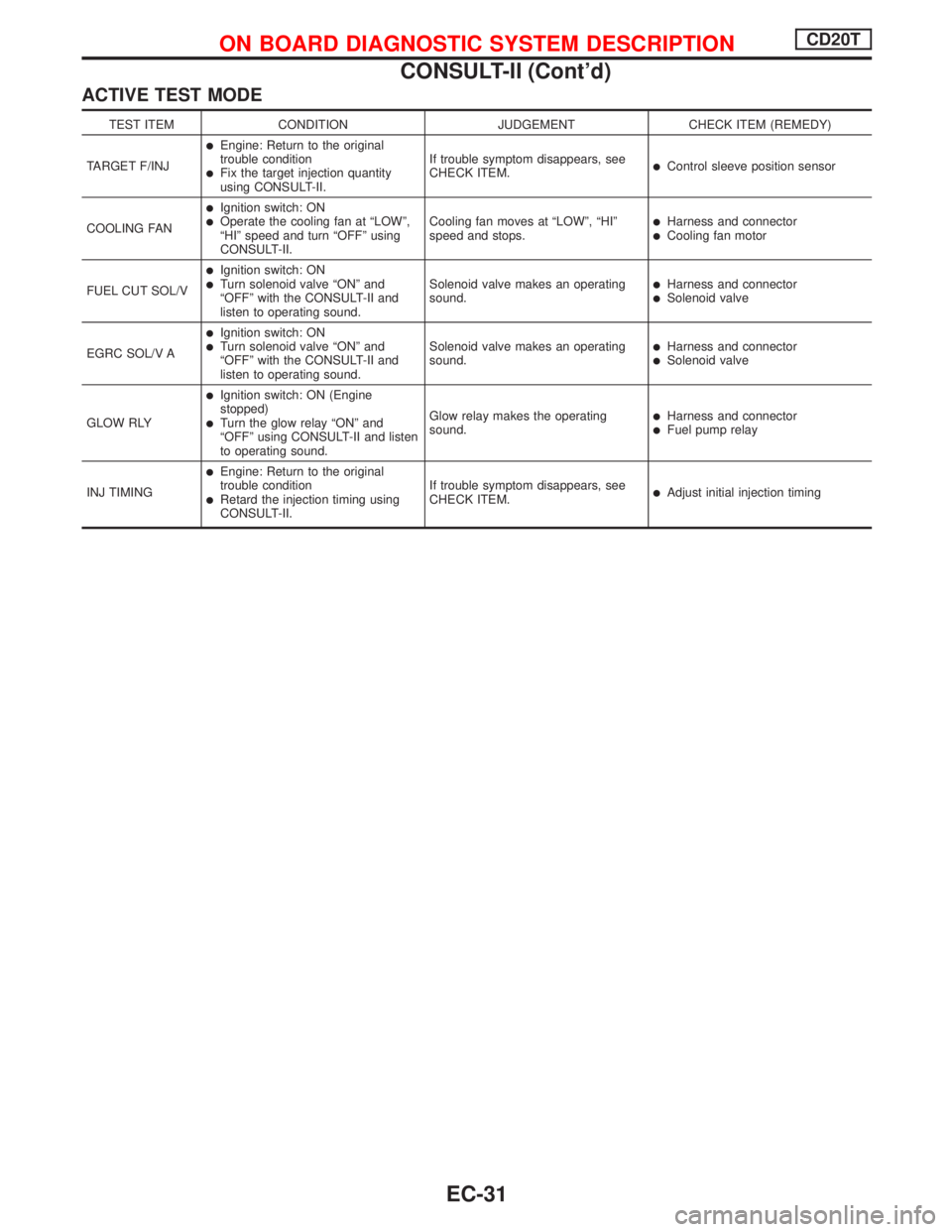

ACTIVE TEST MODE

TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

TARGET F/INJ

lEngine: Return to the original

trouble condition

lFix the target injection quantity

using CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.lControl sleeve position sensor

COOLING FAN

lIgnition switch: ONlOperate the cooling fan at ªLOWº,

ªHIº speed and turn ªOFFº using

CONSULT-II.Cooling fan moves at ªLOWº, ªHIº

speed and stops.lHarness and connectorlCooling fan motor

FUEL CUT SOL/V

lIgnition switch: ONlTurn solenoid valve ªONº and

ªOFFº with the CONSULT-II and

listen to operating sound.Solenoid valve makes an operating

sound.lHarness and connectorlSolenoid valve

EGRC SOL/V A

lIgnition switch: ONlTurn solenoid valve ªONº and

ªOFFº with the CONSULT-II and

listen to operating sound.Solenoid valve makes an operating

sound.lHarness and connectorlSolenoid valve

GLOW RLY

lIgnition switch: ON (Engine

stopped)

lTurn the glow relay ªONº and

ªOFFº using CONSULT-II and listen

to operating sound.Glow relay makes the operating

sound.lHarness and connectorlFuel pump relay

INJ TIMING

lEngine: Return to the original

trouble condition

lRetard the injection timing using

CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.lAdjust initial injection timing

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONCD20T

CONSULT-II (Cont'd)

EC-31

Page 328 of 2267

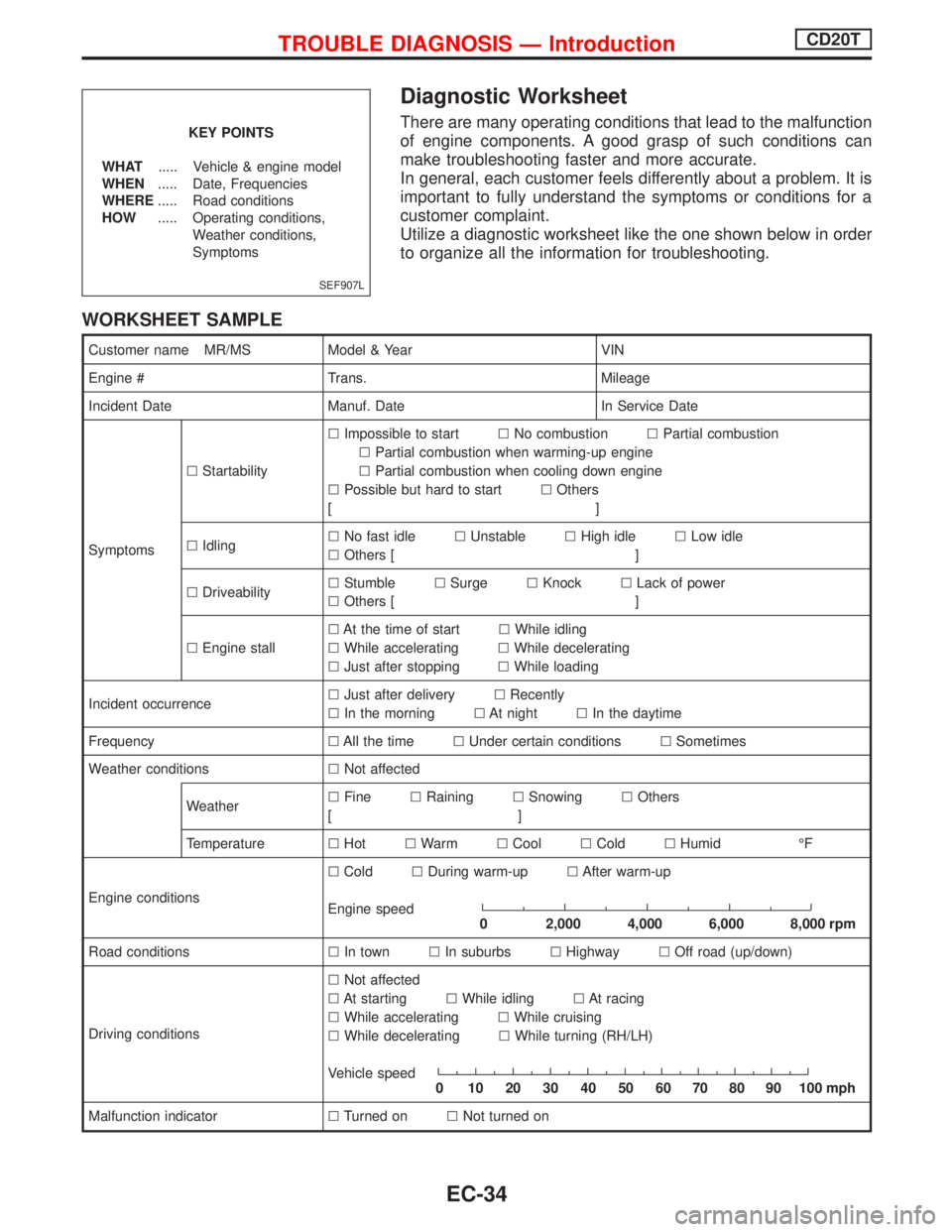

Diagnostic Worksheet

There are many operating conditions that lead to the malfunction

of engine components. A good grasp of such conditions can

make troubleshooting faster and more accurate.

In general, each customer feels differently about a problem. It is

important to fully understand the symptoms or conditions for a

customer complaint.

Utilize a diagnostic worksheet like the one shown below in order

to organize all the information for troubleshooting.

WORKSHEET SAMPLE

Customer name MR/MS Model & Year VIN

Engine # Trans. Mileage

Incident Date Manuf. Date In Service Date

SymptomslStartabilitylImpossible to startlNo combustionlPartial combustion

lPartial combustion when warming-up engine

lPartial combustion when cooling down engine

lPossible but hard to startlOthers

[]

lIdlinglNo fast idlelUnstablelHigh idlelLow idle

lOthers [ ]

lDriveabilitylStumblelSurgelKnocklLack of power

lOthers [ ]

lEngine stalllAt the time of startlWhile idling

lWhile acceleratinglWhile decelerating

lJust after stoppinglWhile loading

Incident occurrencelJust after deliverylRecently

lIn the morninglAt nightlIn the daytime

FrequencylAll the timelUnder certain conditionslSometimes

Weather conditionslNot affected

WeatherlFinelRaininglSnowinglOthers

[]

TemperaturelHotlWarmlCoollColdlHumid ÉF

Engine conditionslColdlDuring warm-uplAfter warm-up

Engine speed

0 2,000 4,000 6,000 8,000 rpm

Road conditionslIn townlIn suburbslHighwaylOff road (up/down)

Driving conditionslNot affected

lAt startinglWhile idlinglAt racing

lWhile acceleratinglWhile cruising

lWhile deceleratinglWhile turning (RH/LH)

Vehicle speed

0 102030405060708090100mph

Malfunction indicatorlTurned onlNot turned on

SEF907L

KEY POINTS

WHAT..... Vehicle & engine model

WHEN..... Date, Frequencies

WHERE..... Road conditions

HOW..... Operating conditions,

Weather conditions,

Symptoms

TROUBLE DIAGNOSIS Ð IntroductionCD20T

EC-34

Page 335 of 2267

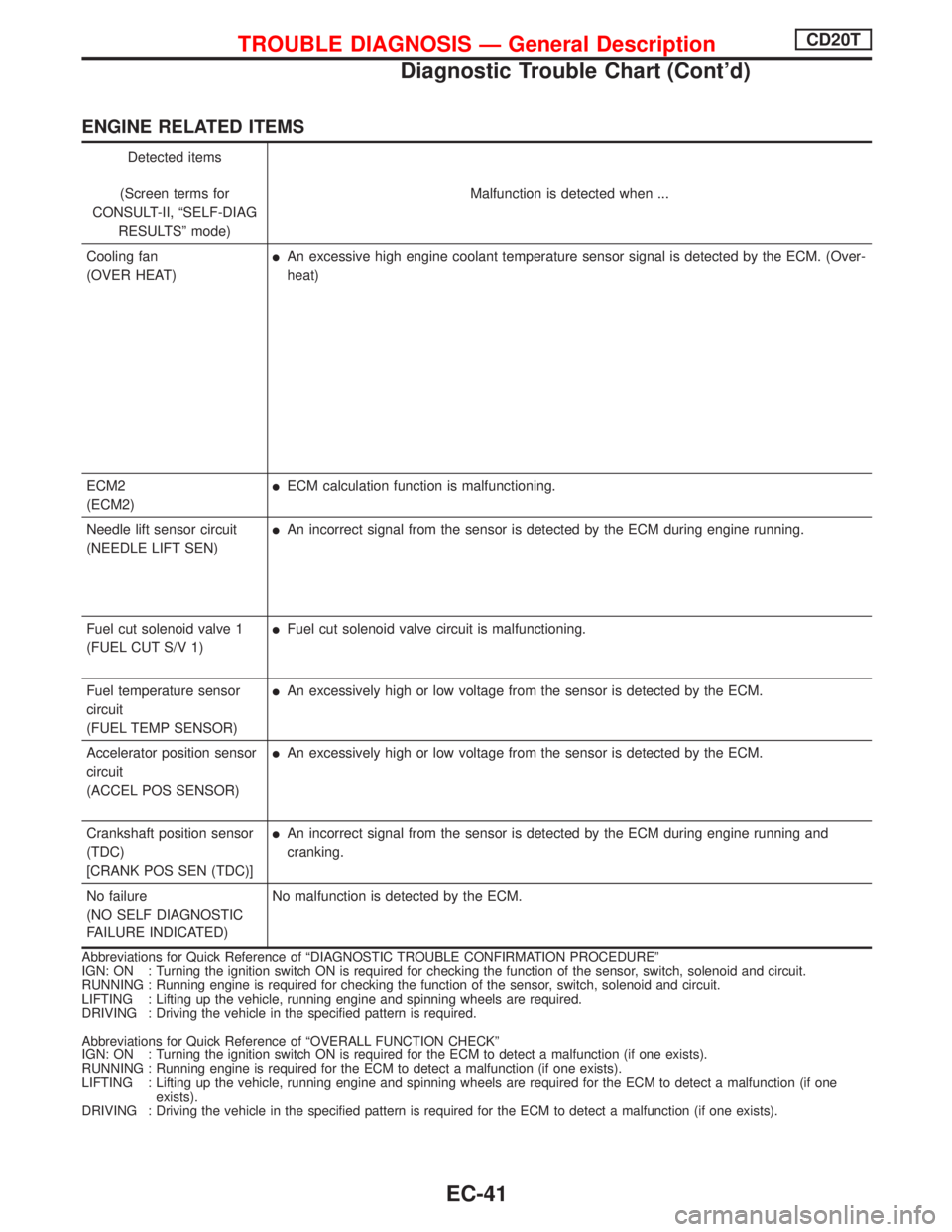

ENGINE RELATED ITEMS

Detected items

(Screen terms for

CONSULT-II, ªSELF-DIAG

RESULTSº mode)Malfunction is detected when ...

Cooling fan

(OVER HEAT)

lAn excessive high engine coolant temperature sensor signal is detected by the ECM. (Over-

heat)

ECM2

(ECM2)

lECM calculation function is malfunctioning.

Needle lift sensor circuit

(NEEDLE LIFT SEN)

lAn incorrect signal from the sensor is detected by the ECM during engine running.

Fuel cut solenoid valve 1

(FUEL CUT S/V 1)

lFuel cut solenoid valve circuit is malfunctioning.

Fuel temperature sensor

circuit

(FUEL TEMP SENSOR)

lAn excessively high or low voltage from the sensor is detected by the ECM.

Accelerator position sensor

circuit

(ACCEL POS SENSOR)

lAn excessively high or low voltage from the sensor is detected by the ECM.

Crankshaft position sensor

(TDC)

[CRANK POS SEN (TDC)]

lAn incorrect signal from the sensor is detected by the ECM during engine running and

cranking.

No failure

(NO SELF DIAGNOSTIC

FAILURE INDICATED)No malfunction is detected by the ECM.

Abbreviations for Quick Reference of ªDIAGNOSTIC TROUBLE CONFIRMATION PROCEDUREº

IGN: ON : Turning the ignition switch ON is required for checking the function of the sensor, switch, solenoid and circuit.

RUNNING : Running engine is required for checking the function of the sensor, switch, solenoid and circuit.

LIFTING : Lifting up the vehicle, running engine and spinning wheels are required.

DRIVING : Driving the vehicle in the specified pattern is required.

Abbreviations for Quick Reference of ªOVERALL FUNCTION CHECKº

IGN: ON : Turning the ignition switch ON is required for the ECM to detect a malfunction (if one exists).

RUNNING : Running engine is required for the ECM to detect a malfunction (if one exists).

LIFTING : Lifting up the vehicle, running engine and spinning wheels are required for the ECM to detect a malfunction (if one

exists).

DRIVING : Driving the vehicle in the specified pattern is required for the ECM to detect a malfunction (if one exists).

TROUBLE DIAGNOSIS Ð General DescriptionCD20T

Diagnostic Trouble Chart (Cont'd)

EC-41